Page 1

Model 550

Low Pressure Transducer

General Service and Submersible

Applications

● Tank Level

● Reservoir Level

● River Level

● Hydro-Power

● Open Channel Flow

● Flood Warning

● Process

● Waste Water

● Clean Room

Benefits

■ Superior Stability

Avoids Down Time

■ ±0.25% FS High Accuracy

■ NEMA 4/ IP65and NEMA

6/IP68 Rated

etra’s Model 550 low pressure transducer

features 3:1 range turndown for field

S

adjustment from 110% to 32% of the

nominal pressure range, making this unit well

suited to applications that are subject to

overpressure. Adjustment is made via the switch

and potentiometer conveniently located on the

top of the transducer housing.

Utilizing capacitance technology, the Model 550

is designed to measure pressures as low as

10 in. W.C up to 400 in. W.C. (1 psi up to 15 psi)

and features a wide selection of current or

voltage outputs with 0.25% full scale accuracy.

The Model 550 is packaged in a rugged 316

stainless steel housing for use in general

purpose and submersible applications. A male

or female threaded pressure fitting is offered for

general purpose applications, and an open face

style with a KF25 flange is offered for

submersible applications. This open face

architecture keeps the internal bore of the

transmitter as large as possible, making this unit

well-suited to waste water and viscous fluid

applications. A triple sealed cable assembly

assures that water cannot penetrate the sensor

or electronic enclosure, even if the sheath

sustains damage during use.

159 Swanson Road, Boxborough, MA 01719/Telephone: 978-263-1400/Fax: 978-264-0292

Principle of Operation

The capacitive sensor is constructed of an

electrically isolated stainless steel electrode

and a ceramic diaphragm, mounted closely

and in parallel to each other. The diaphragm is

capable of slight flexing under applied

pressure. A minute change in applied pressure

alters the gap between the electrode and

diaphragm. This change is detected by a

custom designed ASIC, amplified, and

converted to high-level linear output signal

that is proportional to applied pressure.

The Model 550 circuit is RFI/lightning

protected, virtually eliminating costly field

replacement.

This unit offers high performance, exceptional

long-term service and stable operation, yet is

a cost-effective choice for the most

demanding applications.

Pressure Ranges

Pressure Proof Burst

Range Pressure Pressure

≤85 in. W.C. 803 in. W.C. 1219 in. W.C.

86 in.W.C. to 140 in. W.C. 1607 in. W.C. 2410 in. W.C.

141 in. W.C. to 400 in. W.C. 2025 in. w.C. 4017 in. W.C.

≤3 psi 29 psi 44 psi

3.1 to 5 psi 58 Psi 87 psi

5.1 to 15 psi 102 psi 145 psi

■ 3:1 Range Turndown

■ Fast 5ms Response

■ Long-Term Service

Exceeding 10 Million

Cycles.

■ Meets

Standards

When it comes to a product to

rely on - choose the Model 550 .

When it comes to a company to

trust - choose Setra.

CECE

CE Conformance

CECE

ISO

9001:

2000

Certified

✓

Visit Setra On-line:

http://www.setra.com

800-257-3872

Page 2

Model 550 Specifications

Performance Data

Accuracy RSS

Thermal Effects

Compensated Range °F (°C) -5 to +140 (-20 to +60)

Zero Shift %FS/100°F (100°C) 1.0 (2.0)

Span Shift %FS/100°F (100°C) 1.0 (2.0)

Long-Term Stability 0.25% FS/1 year

Response Time 5 ms

Zero Adjustment ±10% (by Potentiometer)

Span Adjustment ±10% (by Potentiometer)

Mounting Effects 25% Span Max.

*RSS of Non-Linearity, Non-R epeatability and Hysteresis.

**Units calibrated at nominal 70°F. Maximum thermal error computed from

this datum.

*

(at constant temp) ±0.25% FS

**

Pressure Media

Water or Viscous Fluids Compatible with 316 SS,

Ceramic and Nitrile

Specifications subject to change without notice.

Environmental Data

Temperature

Operating* °F (°C)

w/Elec Codes E2 +15 to +185 (+25 to +85)

w/Elec. Codes UA -5 to +120 (-20 to +50)

w/Process Media -40 to +212 (-40 to +100)

Storage °F (°C)

w/Elec Codes E2 +15 to +185 (+25 to +85)

w/Elec code UA -5 to 120 (-20 to +50)

w/Process Media -40 to +212 (-40 to +100)

*Operating/Storage temperature limits of the cable or process media.

Physical Description

Case 318 Stainless Steel

Rating IP68 (NEMA 6) Submersible

G IP65

Wetted Parts Inconel, Ceramic & Nitrile

Electrical Connection See Order Chart Below

Pressure Fitting 318 SS See Order Chart Below

Weight 11.6oz (330g)

Diameter 38.1 mm w/o K2 flange

40.0 mm w K2 flange

Electrical Data (Voltage)

Circuit 3 -Wire

Excitation 7.5 to 35 VDC (8-35 VDC,

1-6 VDC Output)

Output 0.5 to 5.5 VDC, 1 to 6 VDC,

0 to 5 VDC, 0.1 to 5.1 VDC,

1 to 5 VDC

*Zero output is factory set to 1.0% of Full Scale

*Span output is factory set 1.0% of Full Scale

Electrical Data (Current)

Circuit 2 -Wire

Excitation 9 to 35 VDC

*

Output

4 to 20 mA

Maximum Loop Resistance (Vs-9) x 50 Ohms

*Zero output factory set to within ±0.16 mA.

*Span output factory set to within ±0.16 mA.

Accessories

Part No. Description

GA9 Large Din, 4365-A, Strain Relief

GA10 Large Din, 4365-A, 1/2” Conduit

GA11 6-Pin Bendix to 125°C

GA25 Plastic Noe Cone w/G 1/4 Port

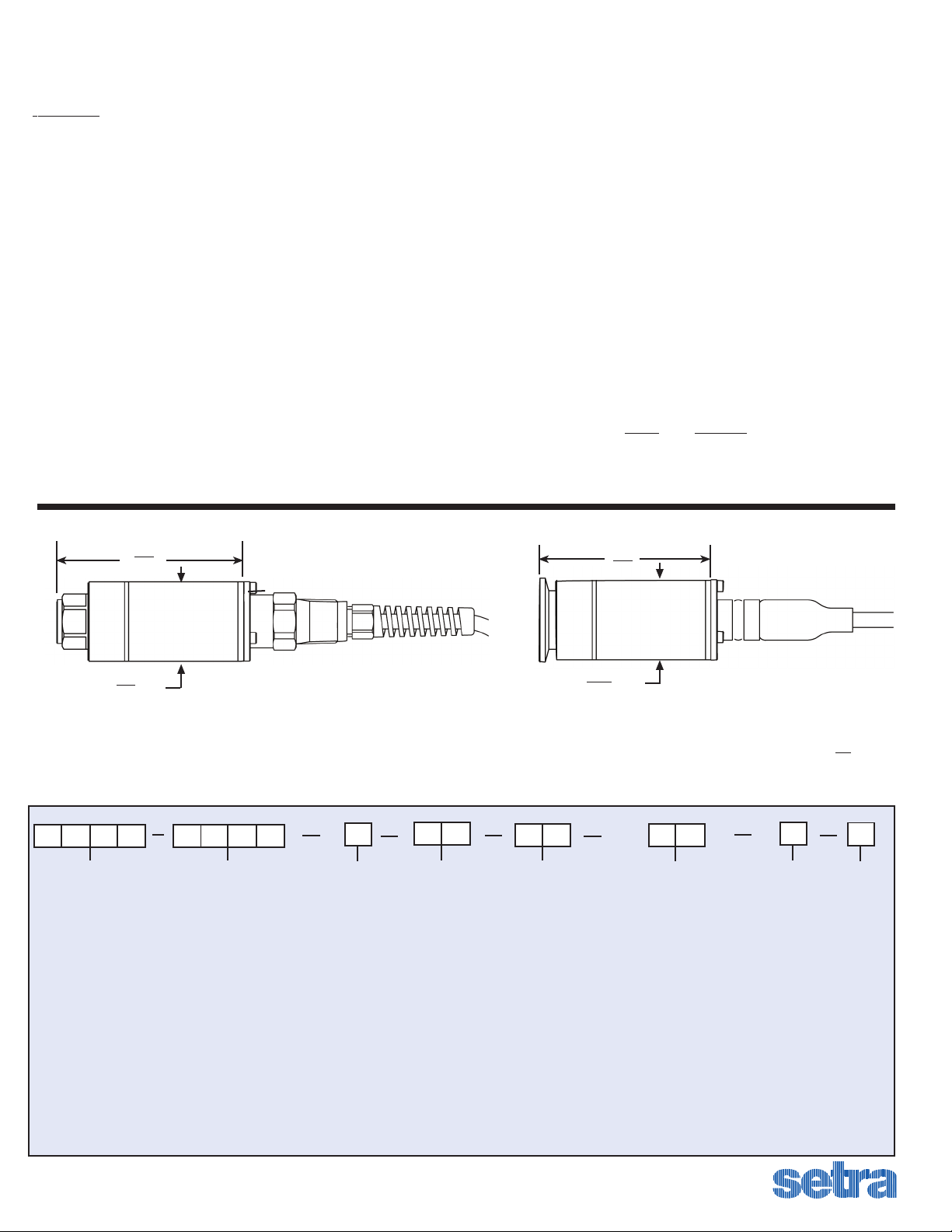

Outline Drawings

3.2

81

1.5

dia.

38

Shown w/1/2-14 NPT Conduit

2.9

74

1.57

dia.

40

Shown w/KF25 Flange and

Submersible Cable Assembly

ORDERING INFORMATION

Code all blocks in table.

Example: Part No 5501002PG211UAF- For a Model 550 Pressure Transducer, 2 PSIG, G 1/4” Male Pressure Fitting, 4-20 mA Output, Molded Submersible Cable, and 0.25% Accuracy

G

Model

5501 = 550

Range

001P = 1 psi 010W = 10 in W.C.

002P = 2 psi 015W = 15 in W.C.

003P = 3 psi 025W = 25 in W.C.

004P = 4 psi 050W = 50 in W.C.

005P = 5 psi 100W = 100 in w.C.

007P = 7 psi 150W = 150 in W.C.

010P = 10 psi 200W = 200 in W.C.

012P = 12 psi 250W = 250 in W.C.

015P = 15 psi 300W = 300 in W.C.

350W = 350 in W.C.

400W = 400 in W.C.

Pressure

G = Gauge

Pressure Fitting

G3 = G1/4 Female

2M =1/4-18 NPT Male

4M =1/2-14 NPT Male

G2 = G1/4 Male

N2 = KF25 Flange

Output

11 = 4-20mA, 2 wire

28 = 1-6VDC, 3 wire

2B = 0-5VDC, 3 wire

24 = 0.5-5.5VDC, 3 wire

27 = 1-5VDC, 3 wire

22 = 0.1-5.1VDC, 3 wire

Elec. Termination

UA = Molded Submersible

Cable* (Submersible up to

200 Meters [656 ft.])

E2 = Large DIN 43650 Connector

w/Mating Plug

* Cable has a polyurethane sheath and is not

recommended for use with Hydrocarbons, please

contact factory and specify Hytrel cable. when ordering

F

Accuracy

F = 0.25% FS

in.

mm

Approval

(Option)

G = Galvanic

Intrinsic Safe

SSP550 Rev. C 12/27/06

While we provide application assistance on all Setra products, both

personally and through our literature, it is the customer’s responsibility

to determine the suitability of the product in the application.

Please contact factory for

configurations not shown.

159 Swanson Road, Boxborough, MA 01719/Tel: 978-263-1400;

Toll Free: 800-257-3872; Fax: 978-264-0292; email: sales@setra.com

Loading...

Loading...