Page 1

Model 526

General Purpose/Submersible Pressure Transducer

Gauge, Absolute, and Compound Pressure

Applications

● Off-Highway

● Natural Gas Equipment

● Power Plants

● HVAC-Compressors

● Refrigeration

● Robotics

Benefits

■ Superior Stability

Avoids Down Time

■ ±0.25% FS Accuracy

Optional ±0.15%

Accuracy

■ IP30, IP65, and IP68 Rated

■ High Shock and

Vibration Resistance

etra System’s Model 526 General

Purpose pressure transducer is

S

designed with a thicker diaphragm

for robust industrial and submersible

applications that require exceptional stability

and high accuracy.

The Model 526’s CVD strain gauge design is

resistant to aging and virtually insensitive

to thermal transients and pressure cycling.

The stability of this technology assures the

user of high reliability with less than 0.2% drift

per year.

Depending upon the electrical connection

selected, when coupled with the Model 526

enclosure, which is fabricated in 316 SS/17-4

PH SS, this unit is rated for IP30, IP65, or IP68

operation.

The Model 526 offers 0.25% FS accuracy

(optional 0.15% FS), compensated temperature range of -5°F to +180°F (-20°C to 80°C),

and gauge, absolute, or compound pressure

ranges from -14.7 psi up to 6000 psi.

The Model 526’s modular design is offered in

a wide choice of millivolt, voltage or current

outputs over almost any pressure range, and a

variety of pressure and electrical connections,

enabling this unit to be custom configured for

your OEM application.

Principle of Operation

Using the well proven Wheatstone Bridge

principle, a chemical vapor is deposited in thin

layers of silicon and silicon dioxide onto a

stainless steel sensor to form a very sensitive

and accurate polysilicon strain gauge. The

elements of the strain gauge are fused

together at the atomic level, assuring the

strength and integrity of the bond, which

exceeds the adhesives used in common

bonded strain gauge pressure sensors. A

custom designed ASIC performs signal

amplification and temperature compensation.

This technology offers the user the option of

configurable output and pressure ranges, sets

the zero and span tolerance, and ensures

interchangeability from unit to unit.

■ Meets

Standards

When it comes to a product to

rely on - choose the Model 526 .

When it comes to a company to

trust - choose Setra.

CECE

CE Conformance

CECE

ISO

9001:

2000

Certified

✓

Visit Setra On-line:

http://www.setra.com

159 Swanson Road, Boxborough, MA 01719/Telephone: 978-263-1400/Fax: 978-264-0292

800-257-3872

Page 2

Model 526 Specifications

Performance Data

Accuracy RSS* (at constant temp) ±0.25% Full Scale

±0.15% Full Scale, Optional

Thermal Effects

**

Compensated Range °F (°C) -5 to +180 (-20 to + 80)

Accuracy 0.25% Full Scale

Zero Shift %FS/100°F (100°C) 0.8 (1.5)

Span Shift %FS/100°F (100°C) 0.8 (1.5)

Accuracy ±0.15% Full Scale

Zero Shift %FS/100°F (100°C) 0.5 (1.0)

Span Shift %FS/100°F (100°C) 0.5 (1.0)

Long-Term Stability 0.2% FS/year

Response Time 0.5 ms

Proof Pressure 2 x FS (1.5 x FS for 400 Bar,

>=5000 PSI)

Burst Pressure >35 x FS <= 100 Psi (6 Bar)

>20 X FS <=1000 Psi (60 Bar)

>5 X FS <= 6000 Psi (400 Bar)

*RSS of Non-Linearity, Non-Repeatability and Hysteresis.

**Units calibrated at nominal 70°F. Maximum thermal error computed from

this datum.

Pressure Media

Liquids or gases compatible with 17-4 PH Stainless Steel*

*Note: Hydrogen not recommended for use with 17-4 PH Stainless Steel

Specifications subject to change without notice.

Physical Description

Case 316, 17-4 PH Stainless Steel

Ratings IP65 for Elec Codes B3, B1, E2

IP68 for Elec Code UA (Max. Depth

200 Meters H2O)

IP30 for Elec Code A2 w/Flying Leads

Wetted Parts 17-4 PH Stainless Steel

Electrical Connection See Ordering Information Below

Pressure Fitting See Ordering Information Below

Weight 3.5oz (100g)

Environmental Data

Temperature

Operating

for Elec. Code B1, B3 -40 to +260 (-40 to +125)

for Elec Code A2. E2 -5 to +180 (-20 to +80)

for Elec Code UA -5 to +125 (-20 to +50)

Storage °F (°C)

for Elec. Code B1, B3 -40 to +260 (-40 to +125)

for Elec Code A2, E2 -5 to +180 (-20 to +80)

for Elec Code UA -5 to +125 (-20 to +50)

Vibration 70g Peak to Peak Sinusoidal,

Acceleration 100g Steady Acceleration in any

Shock 20g, 11 ms, per MIL-STD-810E

*Operating/Storage temperature limits of the connector only.

*

°F (°C)

5 to 2000 Hz (Random)

Direction 0.32% F

Method 516.4 Procedure

Electrical Data (Millivolt)

Circuit 4 -Wire (+Exc. -Out, +Out, -Exc)

Excitation 10 VDC (15 VDC Max.) Regulated

*

Output

100 mV (10mV/V)

Bridge Resistance 2600-6000 Ohms

*Zero output is factory set to 1.0% of Full Scale

*Span output is factory set to 1.0% of Full Scale

Electrical Data (Voltage)

Circuit 3 -Wire (Exc, Out, Com)

Excitation 1.5 VDC Above Span to 35 VDC

@ 6mA **

0 to 5VDC, 0 to 10VDC, 0.5 to 5.5 VDC,

Output

*

1 to 5 VDC, 1 to 6 VDC, 1 to 11 VDC,

0.1 to 5.1 VDC, 0.2 to 10.2 VDC

Current Consumption*** Approx. 6 mA @ 7.5 VDC output

*Zero output is factory set to <1.0% of Full Scale.

*Span output is factory set to <1.0% of Full Scale.

**Temperatures>100°C/212°F supply is limited to 24 VDC.

***Minimum Load Resistance: (FS output/2) Kohms

Electrical Data (Current)

Circuit 2-Wire

*

Output

Loop Supply Voltage 24 VDC, (7-35 VDC)

Maximum Loop Resistance (Vs-7) x 50 Ohms

*Zero output factory set to within ±0.16 mA.

*Span output factory set to within ±0.16 mA.

**Temperatures>100°C/212°F supply is limited to 24 VDC.

4 to 20 mA

**

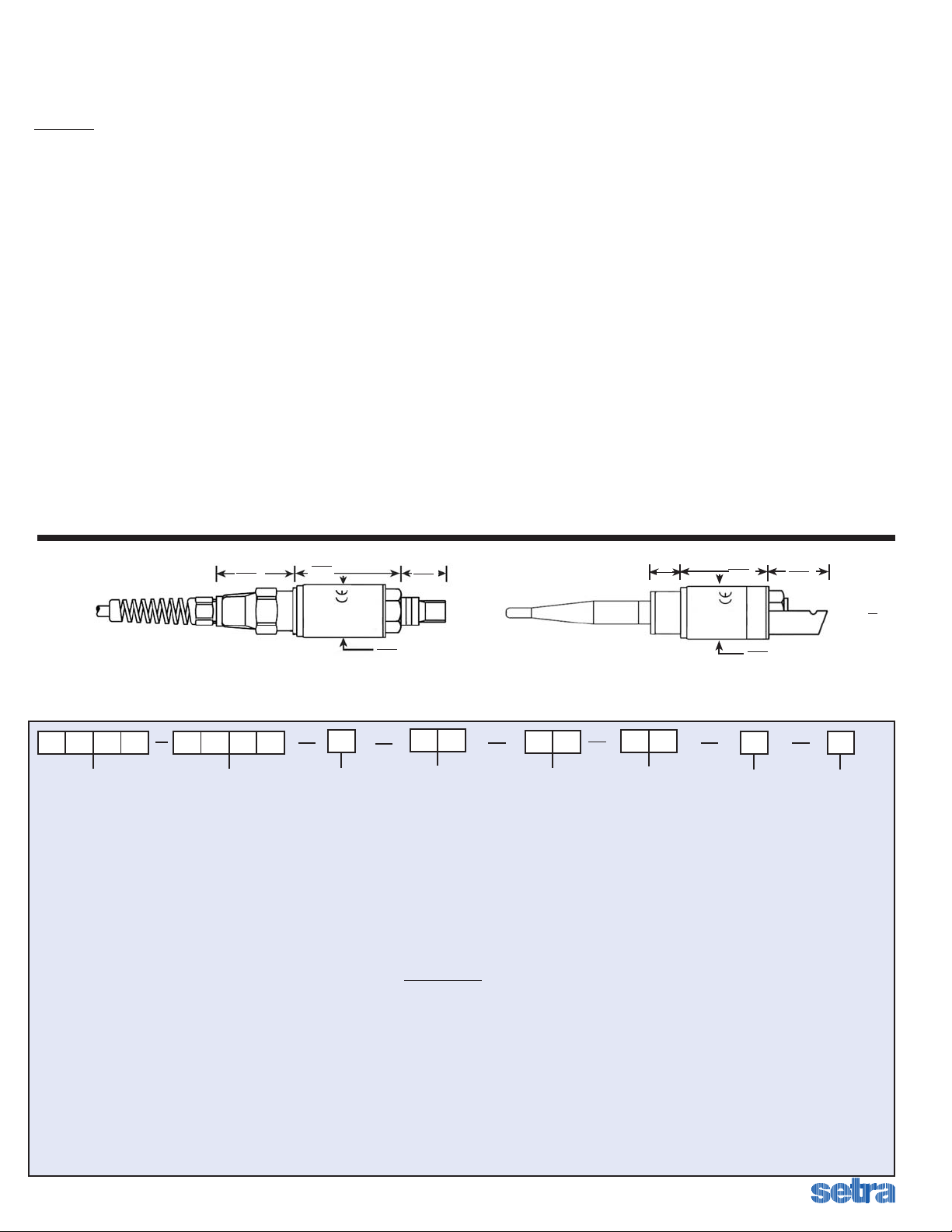

Outline Drawings

1.70

43

Shown w/Conduit Connector with Cable

& 1/8-27 NPT Pressure Fitting

2.09

53

0.59

15

1.07

27

ORDERING INFORMATION

Code all blocks in table.

0.91

23

Shown w/Molded Immersible Cable

& Plastic Nose Cone

2.09

53

0.75

19

1.07

27

mm

.Example: Part No 5261030PG1M11E2F - For a Model 522 Pressure Transducer, 30 PSI, Gauge Pressure, 1 /8-27 NPT Male Pressure Fitting, 4-20 mA Output, Large Din Plug w/Mate, 0.25% Accuracy

5 2 6 1

Model

5261 = 526

015P = 15 PSI 001B = 1 BAR

Range

030P = 30 PSI 0R6B = 1.6 BAR

060P = 60 PSI 2R5B = 2.5 BAR

100P=100 PSI 004B = 4 BAR

150P = 150 PSI 006B = 6 BAR

200P = 200 PSI 010B = 10 BAR

300P = 300 PSI 016B = 16 BAR

500P = 500 PSI 025B = 25 BAR

600P = 600 PSI 040B = 40 BAR

10CP = 1000 PSI 060B = 60 BAR

15CP = 1500 PSI 100B = 100 BAR

20CP = 2000 PSI 160B = 160 BAR

30CP = 3000 PSI 250B = 250 BAR

40CP = 4000 PSI 400B = 400 BAR

50CP = 5000 PSI 600B = 600 BAR

60CP = 6000 PSI

000P = -14.7 to 0 PSI

015P = -14.7 to 15 PSI

045P = -14.7 to 45 PSI

085P = -14.7 to 85 PSI

135P = -14.7 to 135 PSI

185P = -14.7 to 185 PSI

285P = -14.7 to 285 PSI

While we provide application assistance on all Setra products, both personally and through our literature, it is the

customer’s responsibility to determine the suitability of the product in the application.

Pressure

G = Gauge

A = Absolute*

C = Compound*

*Compound and

absolute ranges

available through

300psi only.

Pressure Fitting

1M = 1/8-27 NPT Male

1F = 1/8-27 NPT Female

2M = 1/4-18 NPT Male

J7 = 7/16 -20 UNF Male

SAE #4 (J1926-2)

G2 = G 1/4 Male

G3 = G 1/4 Female

Output

BP

= 100 mV

11 = 4-20 mA

28 = 1-6 VDC

2R = 1-11 VDC

27 = 1-5 VDC

24 = 0.5-5.5 VDC

2B = 0-5 VDC

2C = 0-10 VDC

29 = 0.2-10.2 VDC

22 = 0.1-5.1 VDC

Submersible Units

W1 = Plastic Nose Cone

W2 = Stainles Steel Sink Weight Nose Cone

159 Swanson Road, Boxborough, MA 01719/Tel: 978-263-1400;

Toll Free: 800-257-3872; Fax: 978-264-0292; email: sales@setra.com

Elec. Termination

B3 = 10-6 Bayonet

Connector

UA = Molded Immersible Cable

(up to 200 Meters [656 ft.])

B1 = 8-4 Bayonet Connector

Accuracy

F = 0.25% FS

S = 0.15% FS,

Optional

Option

A = Intrinsic Safe

(ETL approved for

Class 1, Div. 1,

Groups C & D,

hazardous areas.)

A2= 1/2” Conduit Connector

w/1 Meter (3.28 ft.) Flying

Leads

E2 = Large DIN 43650 Connector

w/Mating Plug

Please contact factory for configurations not shown.

in

SSP526 Rev.A 4/16/03

Loading...

Loading...