Page 1

Model 524

Slimline Immersible Pressure Transducers

Gauge Pressure

Applications

● Ground Water Table

Levels

● Liquid Level

● Industrial and Municipal

Wells

Benefits

■ Superior Stability

Avoids Down Time

■ Small 3/4 inch Diameter

FootPrint

■ ±0.25% FS Accuracy

■ Millivolt, Voltage, or

Current Outputs

■ Less than 10ms Switch

On/Setting Period

■ Triple Sealed to ensure

Long-Term Immersibility

etra System’s Model 524 new slim-line,

fully immersible pressure transducers are

S

ideal for industrial and residential water

level applications that require exceptional longterm stability, immersibility, and high accuracy.

Immersible to 200mwg, the Model 524 is rated

for IP68 operation. Its custom hermetic header

is triple sealed and guaranteed to eliminate the

potential of water intrusion in the transducer

even if the cable sheath is damaged.

All wetted parts are constructed of corrosion

resistant 316 Stainless Steel, Polyurethane, and

Acetal, which makes the sensor resistant to the

effects of condensation caused by a high

humidity environment, assuring long-term

stability and service.

The Model 524 offers 0.25% FS accuracy,

compensated temperature range of -15°F to

+120°F (-10°C to 50°C), operating temperatures

as low as -40°F to 180°F (-40°C to 80°C), and

gauge pressure ranges from 33 ft. WG (10m WG)

up to 656 ft. WG (200m WG).

The Model 524’s modular design is offered in

a wide choice of millivolt, voltage or current,

outputs over almost any pressure range, and a

variety of pressure and electrical connections,

enabling this unit to be custom configured for

your OEM application.

Principle of Operation

Micro-Electro-Mechanical Systems (MEMS)

brings together silicon-based microelectronics

with micromachining technology. The

electronics are fabricated using integrated

circuit process sequences (e.g., CMOS, Bipolar,

or BICMOS process,) and mechanical elements,

such as strain gauge sensors are fabricated

using compatible micromachining processes

that etch away part of the silicon wafer or add

new layers to form the mechanical and

electromechanical devices, providing a

complete system-on-a chip.

■ IP68 Rated

■ Meets

Standards

When it comes to a product to

rely on - choose the Model 524 .

When it comes to a company to

trust - choose Setra.

CECE

CE Conformance

CECE

ISO

9001:

2000

Certified

✓

Visit Setra On-line:

http://www.setra.com

159 Swanson Road, Boxborough, MA 01719/Telephone: 978-263-1400/Fax: 978-264-0292

800-257-3872

Page 2

Performance Data

Accuracy RSS* (at constant temp)±0.25% Full Scale

Thermal Effects

Compensated Range °F (°C) -15 to +120(-10 to + 50)

Thermal Error

(32° to 122°F/0 to 50°C) 0.5% T ypical

Long-Term Stability 0.2% FS/Year

Proof Pressure 1.5 x FS Nominal Range

Burst Pressure 3 x FS

Response Time <10 ms

*RSS of Non-Linearity, Non-Repeatability and Hysteresis.

**Units calibrated at nominal 70°F. Maximum thermal error computed from

this datum.

**

Environmental Data

Temperature

Operating* °F (°C) -40 to +180 (-40 to +80)

Storage °F (°C) -40 to +180 (-40 to +80)

Vibration 35g Peak to Peak Sinusoidal,

5 to 2000 Hz

Shock Withstands freefall to IEC 68-2-32

Procedure 1

*Operating temperature limits of the electronics only.

Model 524 Specifications

Electrical Data (Millivolt)

Circuit 4 -Wire (+Exc. -Out, +Out, -Exc)

Excitation 10 VDC (15 VDC Max.) Regulated

*

Output

Bridge Resistance 3K5 + 20% @ 25°C

*Zero output is factory set to 1.0% of Full Scale.

*Span output is factory set 1.0% of Full Scale.

Electrical Data (Voltage)

Circuit 3 -Wire (Exc, Out,Com)

Excitation 13 to 28VDC

*

Output

Load Resistance (FS output/2) Kohms

Current Consumption Approximately 6 mA @ 8VDC

*Zero output is factory set to 1.0% of Full Scale.

*Span output is factory set 1.0% of Full Scale.

Electrical Data (Current)

Circuit 2-Wire

*

Output

Loop Supply Voltage 24 VDC, (8-28 VDC)

Maximum Loop Resistance (Vs-7) x 50 Ohms

*Zero output factory set to within ±0.16 mA.

*Span output factory set to within ±0.16 mA.

100 mV ±1 mV

0 to 10VDC

4 to 20 mA

**

Physical Description

Case 316 Stainless Steel

Ratings IP68 to 200m WG

Wetted Parts 316 Stainless Steel, Polyurethane, Acetal

Electrical Connection Polyurethane Cable

Pressure Fitting G1/4” AT Fitting, Fitted with Nose Cone

Weight 3.5oz (100g)

Pressure Media

Liquids or gases compatible with316 Stainless Steel, Polyurethane,

and Acetal

Specifications subject to change without notice.

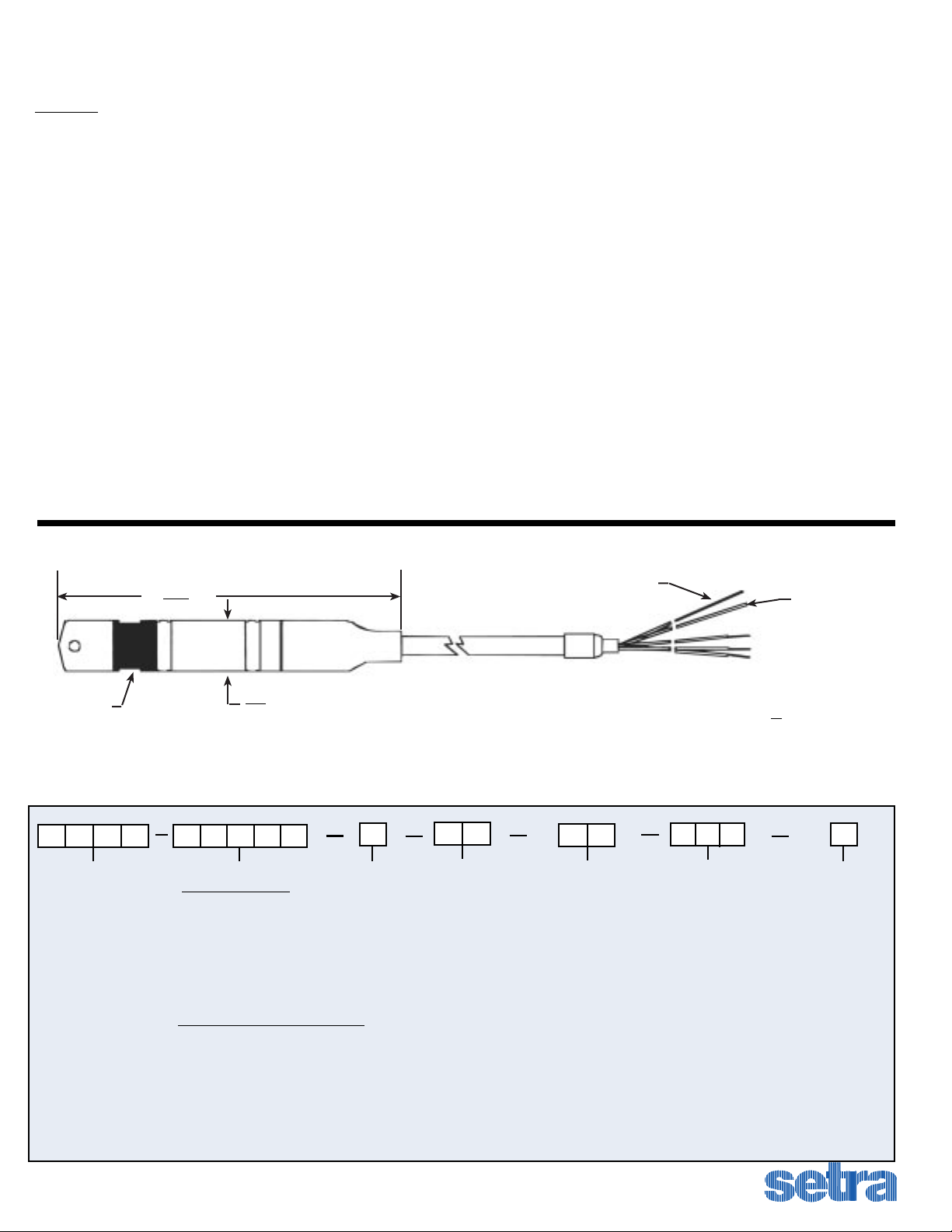

Outline Drawings

Vent Tube

0.67/17

Spanner flats

5.90

150

0.75

19

dia.

Shown w/Immersible Cable and Plastic Nose Cone

ORDERING INFORMATION

Code all blocks in table.

.Example: Part No 5241010WDG1M1120F - For a Model 524 Pressure Transducer, 10mWG )33 ft. WG, Gauge Pressure, Platic Nose Cone, 4-20 mA Output, 20 ft. Submersible Cable, 0.25% Accuracy

5 2 4 1

Model

5241 = 524

Code

Range

100 mV Output Range

010WD = 10mWG (33 ft. WG)

020WD = 20mWG (66 ft. WG)

050WD = 50mWG (164 ft. WG)

100WD = 100m WG (328 ft.WG)

200WD = 200m WG (656 ft. WG)

GF

Pressure

G = Gauge

W 1

Pressure Fitting

W1 = Plastic Nose Cone

Output

BP = 100 mV

(Not Rangeable)

11 = 4-20 mA*

*Specify in 1 psi

increments the full scale

calibration required.

Elec. Termination

xxx = Immersible Cable **

** Order from 1 meter (3.28 ft.) to 18.3

meters (60 ft.)(Additonal charges apply

over standard 1m (3.28 ft) length.)

Ex. Order 1 meter i.e., 010 - 1 meter

in

mm

Drain Wire

Accuracy

F = 0.25% FS

SSP524 Rev. C 05/23/07

4 to 20 mA & 0 to 10 VDC Output Range

ZZZWD = 4m WG (13 ft. Wg) up to 200m WG (656 ft. WG)*

*Range in 1 meter (3.28 ft.) increments from 004 (13 ft) to 200 meters (656 ft.)

While we provide application assistance on all Setra products, both

personally and through our literature, it is the customer’s responsibility

to determine the suitability of the product in the application.

Please contact factory for

configurations not shown.

159 Swanson Road, Boxborough, MA 01719/Tel: 978-263-1400;

Toll Free: 800-257-3872; Fax: 978-264-0292; email: sales@setra.com

Loading...

Loading...