Page 1

Model 31CS/32CS

Standard & Heavy Duty Intrinsically Safe CSA Rated Pressure Transducers

FEATURES

CSA Certied Intrinsically Safe for use in:

Class I, Division 1, Groups C & D

Class I, Zone 0 Ex ia IIB T4 Ga

Class I, Zone 0 AEx ia IIB T4 Ga

When Used in Conjunction with a Zener Safety Barrier

GENERAL PURPOSE/OEM

DESCRIPTION

For applications in hazardous areas that need intrinsically

safe pressure sensors with consistent high levels of

performance, reliability and stability. The 31CS/32CS Series

sputtered thin lm units oer an unbeatable price-toperformance ratio in a small package size. They feature all

stainless steel wetted parts, a broad selection of electrical

and pressure connections, and a wide choice of electrical

outputs ready for installation.

For heavy duty applications, the 32CS Series feature a thicker

diaphragm and a pressure resistor to withstand the rigors

of cavitation or extreme pressure spikes, delivering years or

reliable and stable performance in pulsating applications.

For ATEX & IECEx intrinsically safe pressure transducers,

refer to Setra’s 31IS/32IS.

PRINCIPLE OF OPERATION

Sputtered Thin Film Strain Gauge Pressure Sensors

Using the well proven Wheatstone Bridge principle,

molecular layers are sputtered onto a 17-4 PH stainless steel

diaphragm and the circuit is etched to provide excellent

resistor denition and uniformity. Sputtered thin lm

technology allows the design of simple, highly accurate

and compact strain gauges deposited onto the back of

the sensing diaphragm, which is in direct contact with the

media. This method virtually eliminates drift, while oering

enhanced sensitivity.

Low Cost for High Volume OEM Installations

Thin Film Tech. Assures Long-Term Stability

No Oil Fill Prevents Thermal Instability &

Leakage

Pressure Ranges from 75 PSI up to 32,000 PSI

Long-Term Stability Better Than ±0.1% FS/Yr

0.25% Full Scale Accuracy

Small Footprint -Less than 1 inch Diameter

Reverse Wiring Protected

Accuracy Specied Over Full Temperature

Range

All Welded Stainless Steel Construction

No Internal Elastomers, no RTV’s or Epoxies

CE, RoHS Compliant

APPLICATIONS

Industrial Processes

Chemical

HVAC/R Equipment

Water Management

Intrinsically Safe Control Panels

Other Hazardous Areas

PRESSURE CAPABILITY

Application pressure should be

restricted to the rated-range of

the transducer. The maximum

overpressure is the pressure limit

at which the transducer will not

show signicant oset shift. The

minimum burst pressure is the

test-rating for uid containment.

The data in the tables is “times

rate ranges” (xRR).

©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com

Pressure Range

PSI (BAR)

100-300 (7-20) 3.00 x FS

500-1,500 (40-100)

2,000-6,000 (140-400) 10 x FS

10,000 (700)

15,000 (1,000) 2.50 x FS

25,000 (1,800)

30,000 (2,200) —

Proof Pressure

(x Full Scale)

31CS 32CS 31CS 32CS

3.00 x FS

2.00 x FS

1.40 x FS

1.70 x FS

Burst Pressure

(x Full Scale)

40 x FS

20 x FS

>60,000 PSI

(4,000 Bar)

Page 2

Model 31CS/32CS

Standard & Heavy Duty Intrinsically Safe CSA Rated Pressure Transducers

SPECIFICATIONS

Performance Electrical Data

Accuracy1 RSS ±0.25% FS Voltage

Long Term Drift 0.2% FS/YR (non-cumulative) Output (3-Wire) OV min to 10V max.

Thermal Error

31CS ±1.5% max, ±1% typical/212ºF (100ºC)

32CS ±2% max Source & Sinks 2 mA

GENERAL PURPOSE/OEM

Compensated Range -4 to +176ºF (-20 to +80ºC) Current

Operating Temp -40 to +176ºF (-40 to +80ºC) Output (2-Wire) 4-20 mA

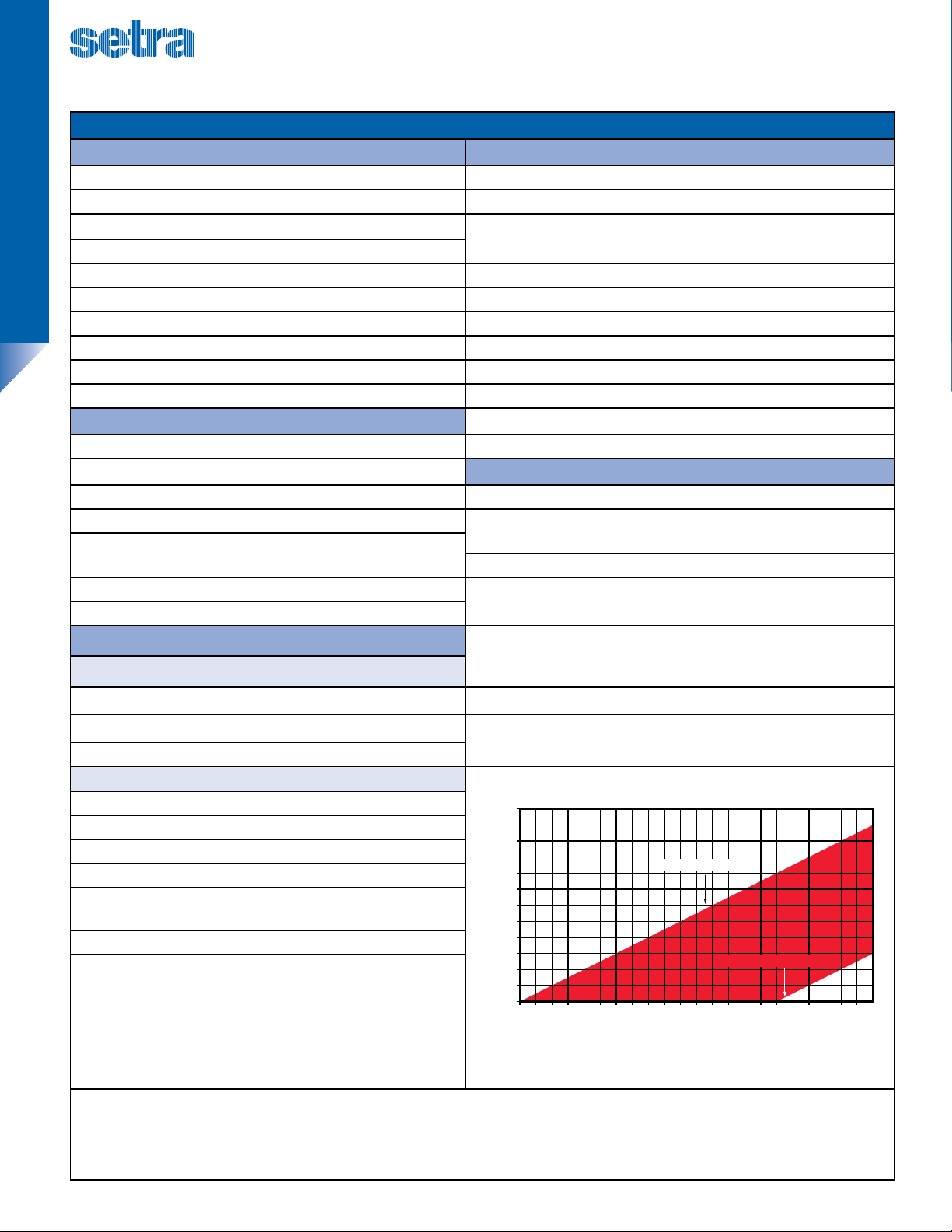

Zero Tolerance Max. 0.5% of Span Supply Voltage 8-24 Volts measured at the input to the transducer terminals

Span Tolerance Max. 0.5% of Span Max Loop Resistance (Supply Voltage - 8) x 50 ohms. See Graph Below

Fatigue Life Designed for more than 100M cycles Ratiometric Output

Physcial Description

Output 0.5 to 4.5V (Source & Sink 2 mA)

Pressure Port See Ordering Information Supply Voltage 5 VDC ±10% at 4.5 mA

Wetted Parts

2

17-4 PH Stainless Steel (Diaphgram)

EMC Specications

Electrical Connection See Ordering Information Emission Tests: EN61326-1:2006 and EN61326-2-3:2006

Enclosure IP67 (IP65 for Electrical Code A) EN55011:2007 Radiated Emissions 30-230MHz 30dB µV/M @10M

Vibration BSEN 60068-2-6 (FC) Sine (20G)

BSEN 60068-2-64 (FH) Random (14.1 Grms)

Immunity Tests: EN61326-1:2006 and EN61326-2-3:2006

Shock BSEN 60068-2-27 (Ea) (50G, 11ms) EN61000-4-2:2009 Electrostatic

Weight (Conguration dependant.) 1.8 to 5.3 oz (50-150 grams).

Zener Barrier & Entity Parameters

EN61000-4-3:2006 Radiated

Zener Barrier Parameters

Voltage Ui = 30VDC EN61000-4-4:2004 Fast Transients:

Current Li = 100mA

EN61000-4-6:2007 Conducted

Power Pi = 0.7W

Entity Parameters RL Load Limitations for Current Output Mode:

Signal Current In = 4 to 20mA

Eective Internal Capacitance Ci = 323n

Eective Internal Inductance Li = 9µh

Values to be added when supplied with integrated cable:

Cable Capacitance Ci = 300pF / m (max) Wire-to-Wire

or Wire-to-Shield

Cable Capacitance Li = 2µH / m (max) Wire-to-Wire

1

RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

2

Note: Hydrogen not recommended for use with 17-4 PH Stainless Steel.

3

Reverse Wiring Protected

3

Supply Voltage 1 Volt above full scale with min supply of 8V;

max 30V at 4.5mA

3

230-1000MHz 37dB µV/M @10M

±4Kv contact

Discharge:

±8Kv air

10V/M 80-1000MHz

Immunity:

3V/M 1400-2000MHz

1V/M 2000-2700MHz

±0.25, 0.5, 1Kv

3V 0.15 to 80MHz 80% 1KHz

Immunity:

1200

1100

1000

900

800

700

600

500

400

300

200

CUSTOMER LOAD RESISTOR (OHMS)

100

0

8

9 10 11 12 13 14 15 16 17 18

Min Resistor (RL) = 50 * (Vdd-24): for Vdd>24V

Max Resistor (RL) = 50 * (Vdd-8): for Vdd>8V

MAXIMUM RESISTOR (RL)

CUSTOMER SUPPLY VOLTAGE (V)

modulation

MINIMUM RESISTOR (RL)

19 20 21 22 23 24 25 26 27 28 29 30

Specications subject to change without notice.

Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com ©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 3

Model 31CS/32CS

Standard & Heavy Duty Intrinsically Safe CSA Rated Pressure Transducers

ELECTRICAL FITTINGS

M12 Deutsch DT01-4P

2

KEY

3

1

4

2

1

Industry Standard

3

4

POLARIZING

WIDE CONTACT

Form C

2 3

4 1

Code E Code 8 Code R Code G Code 6 Code 9

Voltage Current Voltage Current Voltage Current Voltage Current Pin # Voltage Current Pin # Voltage Current

Pin #

1 +IN +IN 0V 0V +IN +IN +IN +IN 1 +OP DNC A 0V 0V

2 +OP DNC +IN +IN 0V 0V 0V 0V 2 0V 0V B +IN +IN

3 0V 0V NC NC +OP DNC +OP DNC 3 +IN +IN C +OP DNC

4 NC NC +OP DNC NC NC NC NC

Recommended Mating Connector:

To IEC 61076-2-101 Hirschmann, Brad Harrison,

Lumberg

Integrated Cable

Color Voltage Current

Red +IN +IN

Black 0V 0V

White +OP

Recommended Mating Connector:

DT064S-P012 as connector plug,

W4S-P012 as wedge, 0462-2011631 as gold socket (x4)

NOTES:

DNC: Do Not Connect (Leave Floating). NC: Not Connected at Transducer End

Alternative pin-outs are not available.

Recommended Mating Connector:

Hirschmann GDS 307 Part Number

933 024-100 or equivalent

The integrated cable is shielded. For compliance with EN 61000-4-5, shielded cable should be used on all transducers.

Substitution of Components May Impair Suitability For Intrinsic Safety

EN175301-803

(DIN 43650 A)

3

2 1

E

Recommended Mating Connector:

Molex/Brad/mPm Series 121201

(C28300N0S) or equivalent

WARNING

AMP Superseal 1,5 Series METRIPACK T (150 SERIES)

A

C

2 3 1

Recommended Mating Connector:

282087-1 as housing, 183025-1 as contact (x3),

281934-3 as wire seal (x3), 880811-2 as protective

boot (strain relief)

Recommended Mating Connector:

12065286 as connector body. 12052893 as

connector seal. Consult Delphi Packard for

appropriate contacts and wire seals.

B

GENERAL PURPOSE/OEM

PRESSURE FITTINGS

SAE

Dimensions

in Inches

Fitting Code 08 4D 02 0E 4C

Torque 2-3 TFFT* 2-3 TFFT* 2-3 TFFT* 2-3 TFFT* 2-3 TFFT*

Dimensions

in Inches

Fitting Code 4N 1J 04 1G 1P

Torque 18-20 NM 18-20 NM 15-16 NM 18-20 NM 18-20 NM

BSP & Metric

Dimensions

in Inches

1/8”- 27 NPT* 1/8”- 27 NPTF Dryseal 1/4” - 18 NPT 1/4” - 18 NPT Internal 1/4” - 18 NPTF Dryseal

0.28

0.57

SAE J1926/2:3/8-24 w/o

O-Ring*

0.28

0.44

G1/4” - 19 External w/

O-Ring*

0.28

0.57

0.47

0.37

0.47

0.28

0.37

7/16” - 20 UNF w/ O-Ring* 7/16”-20 UNF w/37º Flare

0.28

0.5

G1/4”-19 A Integral Face

Seal*

0.28

0.57

0.47

0.28

0.28

M12 x 1.5 w/ O-Ring*

0.28

0.57

0.55

0.37

0.47

0.28

SAE 4 Female 7/16”

Schraeder

0.28

M12 x 1.5 HP Metal

Washer Seal*

0.28

0.57

0.28

0.37

9/16”-18 “Heavy Duty” w/

0.28

0.43

0.57

M14 x 1.5 w/ O-Ring*

0.28

0.47

0.57

0.37

O-Ring

0.47

0.47

Fitting Code 01 05 0L 2T 0K

Torque 30-35 NM 30-35 NM 28-30 NM 30-35 NM 2-3 TFFT*

*O-Rings are not supplied with pressure ttings.

NOTE: Not all available pressure connectors are shown. Please consult the factory for additional congurations.

©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com

Page 4

Model 31CS/32CS

Standard & Heavy Duty Intrinsically Safe CSA Rated Pressure Transducers

ORDERING INFORMATION

Model Pressure Range Pressure Port Connector Output Cable Length

31CS Standard Duty See Table 1 See Table 2 See Table 3 See Table 4 See Table 5

32CS Heavy Duty

GENERAL PURPOSE/OEM

Table 1. Pressure Range

CODE BAR CODE PSI

GAUGE

0004G 4 075PG 75

0006G 6 100PG 100

0010G 10 150PG 150

0016G 16 200PG 200

0025G 25 300PG 300

0040G 40 500PG 500

0060G 60 10CPG 1,000

SEALED

0100S 100 15CPS 1,500

0160S 160 20CPS 2,000

0250S 250 35CPS 3,500

0400S 400 50CPS 5,000

0600S 600 10KPS 10,000

1000S 1,000 15KPS 15,000

1600S 1,600 20KPS 20,000

2200S 2,200 25KPS 25,000

Table 2. Pressure Port

CODE DESCRIPTION CODE DESCRIPTION

0H 1/2” NPT 1J 7/16” - 20 UNF 2A SA1926/2 O’RING

02 1/4” - 18 NPT 1P 9/16” - 18UNF 22 A/F

0E 1/4” - 18 NPT Female 4P G1/2” A 27A/F

4C 1/4” - 18 NPT Dryseal 05 G1/4” A Integral Face Seal

0A 1/4” - 19 PT (JIS) or 1/4” - 19 BSPT 01 G1/4” A Stud (BS 5380 Port

4B 1/4” Female (7/16UN with Shraeder Deator) 0S G1/8” A Stud (BS 5380 Port)

08 1/8” 27 NPT 2T M12x1.5 (6g) High Pressure (Washer Seal)

4D 1/8” 27 NPTF Dryseal 0L M12x1.5P (6g) O’R ing to ISO 6149-2

4N 3/8” - 24 UNF Union 1G Schraeder 7-16” - 20 UN 2B Female

04 7/16” 20 (37FLARE SAE J514 SIZE 4)

30KPS 30,000

32KPS 32,000

Table 3. Connector

CODE DESCRIPTION

6 Amp Superseal 1.5 Series

8 Deutsch DT04-4P

9 Metripack T (150 Series)

E M12

G EN175301-803 (DIN 43650 A)

R Industry Standard Form C

F Integrated Cable

Table 4. Output

CODE Output TYPE

B 4-20 mA Current

C 1-6 V Absolute

F 0.1-5.1 V Absolute

G 0.2-10.2V Absolute

H 1-5 V Absolute

N 0.5-4.5 V Non Ratio-metric Absolute

P 1-10 V Absolute

R 0-5 V Absolute

S 0-10 V Absolute

T 0.5-4.5 V Ratio-metric R atio-metric

V 0.5-4 V Absolute

Table 5. Cable Length

CODE DESCRIPTION

00 Not Fitted

01 1 meter

02 2 meter

03 3 meter

05 5 meter

10 10 meter

NOTE:

Cable lengths longer than 10 meters are not available

Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com ©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

3xCS Data Sheet (CSA) 06/2013

Loading...

Loading...