Page 1

Model 3100/3200

Standard & Heavy Duty OEM Industrial Pressure Transducers

FEATURES

Low Cost for High Volume OEM Installations

Thin Film Tech. Assures Long-Term Stability

No Oil Fill Prevents Thermal Instability &

Leakage

Wide Choice of Pressure Ranges from 50 PSI

up to 32,000 PSI

DESCRIPTION

The 3100/3200 Series high-pressure OEM transducers

feature a sputtered thin-lm sensor to provide high

levels of performance and stability for large volume OEM

installations. A wide choice of outputs as well as electrical

and pressure connections means that the unit is suitable

for most applications without modication. In addition,

the compact construction of the 3100/3200 Series makes

it ideal for installations where space is at a premium.

The Model 3200 features a thicker diaphragm and a restrictor

(optional) to handle environments where extreme positive

or negative pressure spikes are a concern. Proof pressures

on the Model 3200 are 3x full scale on 50 psi up to 10,000

psi pressure ranges.

PRINCIPLE OF OPERATION

Sputtered Thin Film Strain Gauge Pressure Sensors

Using the well proven Wheatstone Bridge principle,

molecular layers are sputtered onto a 17-4 PH stainless steel

diaphragm and the circuit is etched to provide excellent

resistor denition and uniformity. Sputtered thin lm

technology allows the design of simple, highly accurate

and compact strain gauges deposited onto the back of

the sensing diaphragm, which is in direct contact with the

media. This method virtually eliminates drift, while oering

enhanced sensitivity.

Long-Term Stability Better Than ±0.1% FS/Yr

0.25% Full Scale Accuracy

Dual Temperature and Pressure Output on

Voltage Units

Small Footprint -Less than 1 inch Diameter

Choice of Current, Voltage, or Ratiometric

Outputs

Reverse Wiring Protected

Accuracy Specied Over Full Temperature

Range

All Welded Stainless Steel Construction

No Internal Elastomers or O-Rings, no RTV’s

or Epoxies

CE, RoHS Compliant & UL Approved

APPLICATIONS

Refrigeration

HVAC/R Compressors

Medical

Hydraulic Pressure

Variable Speed Pumps

Industrial/OEM

Pumps

GENERAL PURPOSE/OEM

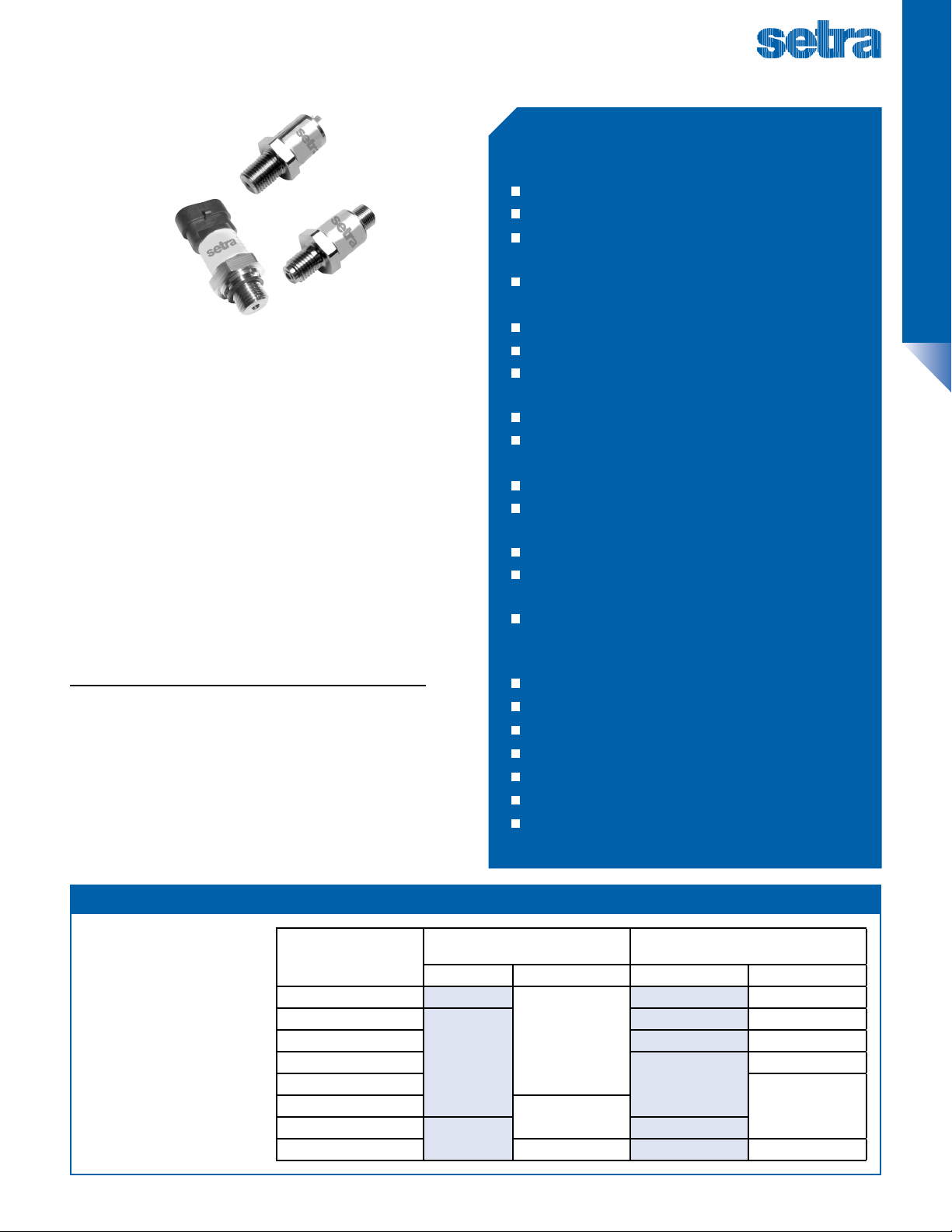

PRESSURE CAPABILITY

Application pressure should be

restricted to the rated-range of

the transducer. The maximum

overpressure is the pressure limit

at which the transducer will not

show signicant oset shift. The

minimum burst pressure is the

test-rating for uid containment.

The data in the tables is “times

rate ranges” (xRR).

©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com

Pressure Range

PSI (BAR)

50-300 (3.5-25) 3.00 x FS

500-1,500 (35-100)

2,000-6,000 (160-400) 8 x FS 10 x FS

7,500-9,000 (600)

10,000 (700)

15,000 (1,000)

25,000 (1,600)

30,000 (2,200) — 1.8 x FS —

Proof Pressure

(x Full Scale)

3100 3200 3100 3200

3.00 x FS

2.00 x FS

2.50 x FS

1.40 x FS

Burst Pressure

(x Full Scale)

40 x FS 40 x FS

20 x FS 20 x FS

4 x FS

>60,000 PSI

(4,000 Bar)

2.2 x FS

10 x FS

Page 2

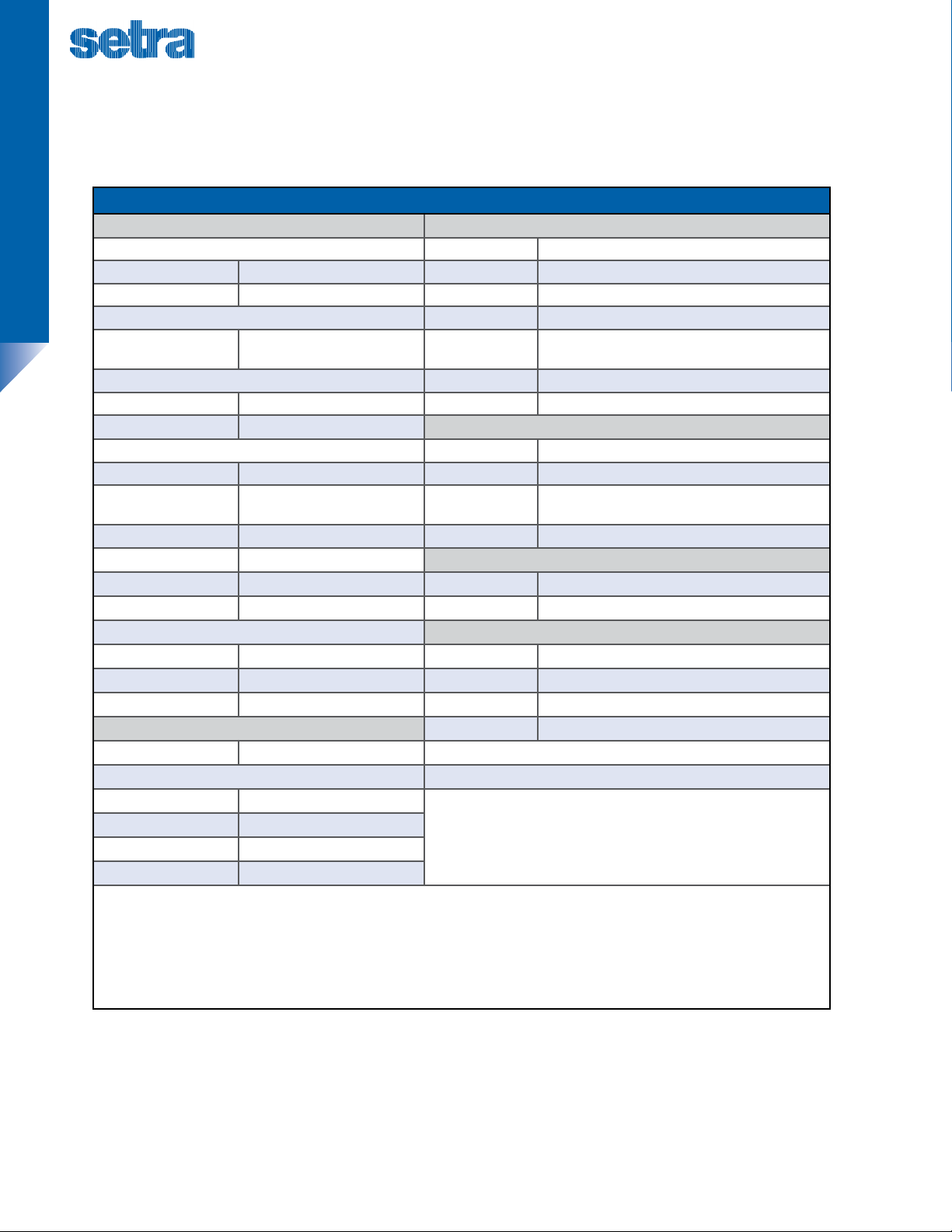

SPECIFICATIONS

Performance Data Physical Description

Accuracy1 Data Pressure Port See Ordering Instructions on page 4

Model 3100 ±0.25% FS Wetted Parts 17-4 PH Stainless Steel (Diaphragm) 304 Stainless Steel (Fittings)

GENERAL PURPOSE/OEM

Model 3200 ±0.5% FS Electrical Connections See Ordering Instructions on page 4

Thermal Eects

Compensated Range

2

o

F (oC) -40 to +221 (-40 to +105) Vibration 40G Peak to Peak Sinusoidal to 2000 Hz (Random Vibration: 20 to

Zero/Span Shift %FS/100

Model 3100 0.83 (1.5) Weight 35 grams

Model 3200 0.94 (2.0) for <1000 PSI (60 BAR)

Zero/Span Tolerance Circuit 3-Wire (Exc, Out, Com)

Model 3100 ±0.5% of Span Output 1 to 6 VDC, 1 to 5 VDC, 0.5 to 4.5 VDC, 0 to 5 VDC, 0 to 10 VDC

Model 3200 1% FS for <1000 PSI (60 BAR) Excitation 2 Volts above Full Scale to max 30 Volts @ 4.5 mA (6.5mA Dual

Response Time 1 ms Source and Sinks 2 mA

Long Term Stability ±0.2% FS/YR Non-Cumulative

Proof/Burst Pressure See Table on Page 1 Output 0.5 to 4.5 VDC @ 4 mA (6.5 mA on Dual Output Version)

Fatigue Life Designed for more than 100 M cycles Excitation 5 VDC ± 10%

Temperature Output Range

Series 3101/2301 -40 to +221 (-40 to +105) Circuit 2-Wire

Series 3201/3202 +32 to +212 (0 to +100) Output 4 to 20 mA

Series 3103/3203 +32 to +176 (0 to +80) Excitation 8 to 30 VDC (24 VDC max. above 110

Performance Data

Operating/Storage Temp.

Approvals Miswire Protection (Option 1)

CE Conforms to European Pressure Directive Full miswire protection between all signal and power lines (any combination)

EMC Radiated Immunity is 100V/m

RoHS Fully Compliant

UL E312651

1

RSS of Non-Linearity, Hysteresis, and Non-Repeatability .

2

Note: Hydrogen not recommended for use with 17-4 PH Stainless Steel.

3

Temperature outputs are for voltage output pressure sensors only and limited to connections that have 4 pins (Electrical Codes -D, -E, -8).

4

Requires additional 2 mA of power.

5

For use with pull-down resistors, contact factory before ordering.

6

Reverse Wiring Protected.

7

Not available for pressure ranges lower than 100 PSI (7 BAR)

Model 3100/3200

Standard & Heavy Duty OEM Industrial Pressure Transducers

Enclosure IP67 (IP65 for Electrical Code A)

1000 Hz @ approx. 40G Peak per MIL-STD-810E

o

F )%FS/100oC) Shock Withstands free fall to IEC 68-2-32 procedure 1

Electrical Data (Voltage)

Electrical Data (Ratiometric)

oFo

3,4,5

(C)

oFo

(C) -40 to +221 (-40 to +105) Options

Electrical Data (Current)

Max. Loop Resistance (Supply Voltage -8) x 50 ohms

Full short-circuit protection for Vout1 to 0V or Vout1 connected to supply, indenitely.

Ratiometric output not available

Supply Voltage must be 4V above the maximum Vout1 output. This also accounts for worsecase customer output leads.

Output Version)

6

7

o

C applications)

7

Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com ©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 3

Model 3100/3200

Standard & Heavy Duty OEM Industrial Pressure Transducers

ELECTRICAL FITTINGS

Din 9.4 mm M12 x 1P Amp Superseal 1.5 Deutsch DT4-4P Packard Metri Pack 3-Pin Deutsch

3

1

2

4

0.28 (7)

0.87 (21.8)

0.75 (19)

Code B Code E Code 6 Code 8 Code 9 Code C

Pin #Voltage

Mode

V

1

(pressure)

2 V

V

3

(temp)

4 Ground Return

out

supply

out

Current

Mode

1

Connect

V

2

Connect

No

supply

No

3

4

2

2

1

0.38 (10)

0.38 (9.7)

0.71 (18)

0.72 (18)

0.75 (19)

0.75 (19

Voltage

Mode

V

V

(pressure)

supply

out

Current

Mode

V

supply

1

No

Connect

Ground Return V

V

out

(temp)

2

No

Connect

Voltage

(pressure)

Ground Return V

1 2 3

1.02 (26)

1.46 (37)

Mode

V

1

out

No Connect Ground Return

supply

— —

Current

Mode

V

supply

1.50 (38)

0.75 (19)

Voltage

Mode

supply

V

2

out

(temp)

V

1

out

(pressure)

4

1

3

2

Current

Mode

V

supply

No Connect V

No Connect — — — — —

1.53 (39)

0.75 (19)

Voltage

Mode

V

1

out

(pressure)

C

A

B

Current

Mode

No

Connect

C V

C

Current

Mode

supply

1.02 (25.86)

A

B

1.63 (41.38)

Voltage

Mode

V

supply

Ground Return A Ground Ground B

supply

V

supply

No

B

Connect

V

1

out

(pressure)

GENERAL PURPOSE/OEM

A

C

WIRING

PRESSURE FITTINGS

SAE

Dimensions

in Inches

Fitting Code OL = M12 x 1.5 01 = G1/4 Ext. 1G = 1/4-SAE Female 7/16 UNF

Torque 28-30 NM 30-35 NM 18-20 NM 18-20 NM 18-20 NM

Fitting Code 2T = M12 x 1.5 04 = 7/16-20 Ext. (SAE #4, J514

Torque 30-35 NM 15-16 NM 2-3 TFFT* 2-3 TFFT*

7

.28

0.28 (7)

0.35 (9)

0.28 (7)

0.49 (13)

0.28 (7)

0.67 (17)

0.28 (7)

0.44 (11)

1J = 7/16-20Ext.(SAE#4, J1926-

w/Schraeder

16.5

.65

0.28 (7)

0.55 (14)

0.28 (7)

0.57 (14)

2)w/O-Ring

0.28 (7)

0.38 (10)

4C = 1/4NPTF Dryseal EXT. 4D = 1/8NPTF Dryseal EXT. 05 = G 1/4 Ext. Face Seal

w/37°Flare

0.28 (7)

0.47 (12)

1P = SAE6

(9/16-18UNF 2A)

0.28 (7)

0.43 (11)

0.28 (7)

0.57 (14)

0.28 (7)

0.63 (16)

0.28 (7)

0.38 (10)

0.37 (10)

0.55 (11)

Fitting Code 02 = 1/4-18 PT Ext. OE = Female 1/4-18NPT 08 = 1/8-27 NPT Ext. OK = M14 x 1.5 Straight

Torque 2-3 TFFT* 2-3 TFFT* 2-3 TFFT* 2-3 TFFT*

Dimensions: in. (mm)

©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com

Page 4

Model 3100/3200

Standard & Heavy Duty OEM Industrial Pressure Transducers

ORDERING INFORMATION

Model Output Range Code Pressure Type Pressure Fittings Electrical Conn. Restrictor (3200 only) Option

See Table 1 B 4-20 mA See Table 2 C Compound See Table 3 See Table 4 O No Restrictor 1

C 1-6 VDC G Gauge R Restrictor

H 1-5 VDC S Sealed

GENERAL PURPOSE/OEM

N 0.5-4.5 VDC

R 0-5 VDC

S 0-10 VDC

T 0.5-4.5 V

Ratiometric

Gauge

2

Miswire Protection

None

7

Table 1. Model Specication

CODE DESCRIPTION

3100

3200

Std. 3100

Std. 3200

Voltage Units w/Temp. Ouput

31011Temp. Output

Range: -40°C to +105°C

1

3102

3103

3201

3202

3203

Temp. Output

Range: -0°C to +100°C

1

Temp. Output

Range: -0°C to +80°C

1

Temp. Output

Range: -40°C to +105°C

1

Temp. Output

Range: -0°C to +100°C

1

Temp. Output

Range: -0°C to +80°C

Table 4. Fitting Specication

CODE DESCRIPTION

B Industrial DIN

C 3-Pin Deutsch (Sealed Only)

E M12xP,4-Pin

6 AMP Superseal 1.5 Series

8 Deutsch DT04-4P

9 Packard Metri Pack

Table 2. Range Specication

RANGE

CODE

2,6

050P

2

075P

2

100P

2

150P

2

230P

250P

2

300P

2

500P

2

10CP

2

15CP

23CP

36CP

60CP

10KP

3

15KP

3

25KP

3,5

32KP

PSI

50

75

100

150

230

250

300

500

1000

1500

2300

3600

6000

10000

15000

25000

32000

RANGE

CODE

0004

Table 3. Fitting Specication

CODE DESCRIPTION

08 1/8-27 NPT Ext.

02 1/4-18 NPT Ext.

4C 1/4 NPTF Dryseal Ext.

4D 1/8 NPTF Dryseal Ext.

04 7/16-20 Ext. (SAE #4, J514) w/37° Flare

1J 7/16-20 Ext.(SAE #4, J1926-2) w/O-Ring

5

1G

1/4 -SAE Female 7/16 UNF w/ Schraeder

Deater/European Threads

1P SAE6 (9/16-18UNF 2A

01 G 1/4 Ext.

05 G 1/4 Ext. Face Seal

0L M12 x 1.5 (<1000 bar, <15,000 psi)

3

2T

M12 x 1.5 (6g) (≥1000 bar, ≥15,000 psi)

OK M14 x 1.5 Straight

OE Female 1/4-18NPT

0005

0007

0010

0016

0020

0035

0070

0100

0160

0250

0400

0700

1000

1800

1600

BAR

2,6

2

2

2

2

2

2

2

2

3

3

3

4

5

7

10

16

20

35

70

100

160

250

400

700

1000

1800

1600

NOTES

1 Temperature outputs are for voltage output pressure sensors only (applies temperature span. Requires

additional 2mA of power.

2 Sealed gauge not available on ranges ≤1500 psi (≤100 bar).

3 Ranges 1000 bar (15,000 psi) and above available with 2T pressure port only.

4 For use with pull-up or pull-down resistors, contact factory.

5 Pressure ports OE and 1G are NOT available with the Restrictor option.

6 0 to 50 PSI (4 bar) - Not available with 4 to 20 mA or 0 to 10 VDC outputs.

7 Temperature outputs not available with Option 1 Miswire Protection PCB

Ratiometric output not available

ACCESSORIES - Mating Connectors

Part No. Description For Code Par t No. Description For Code

557230

557703-01M0

557703-03M0

557703-04M0

557703-05M0

557701 210729

Mini Din Connector, Strain Relief

M12 Cord Set - 1 Meter (Red 1, Green 2, Blue 3, Yellow 4)

M12 Cord Set - 3 Meters (Red 1, Green 2, Blue 3, Yellow 4)

M12 Cord Set - 4 Meters (Red 1, Green 2, Blue 3, Yellow 4)

M12 Cord Set - 5 Meters (Red 1, Green 2, Blue 3, Yellow 4)

Recommended Mating Parts (AMP p/n: Housing 282087-1;

Contacts 3X 183025-1; Seal 281934-1; Boot 880811-2)

AMP Superseal Mate Kit

AMP 3.5’ Cable Cord Set - Clear Pos 1, Black Pos 2, Red Pos 3

B

E

E

210730

E

E

224153

6

6

577

6

581

582

Recommended Mating Parts (AMP p/n: Socket Conn. 1-967325-1,

Consult AMP for Contacts, Wire Seal and Strain Relief options)

AMP 12” Flying Leads Cord Set

Recommended Mating Parts (Deutsch p/n: Housing

Plug DT064S-P012; Wedge W4S-P012; Sockets 4X 0462-201-1631)

Deutsch Cord Set 3’ Long (18 AWG PVC Cable - Black 1, Red 2, Green 3, White, 4

Recommended Mating Parts (Delphi Packard MetriPack p/n: Body 12065268; Seal

12052893; Consult Delphi for Contacts)

Packard Mate Kit

Packard Cord Set 3’ Long

Packard Cord Set 6’ Long

Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com ©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

6

6

8

8

9

9

9

9

SSP3100 RevC 4/2014

Loading...

Loading...