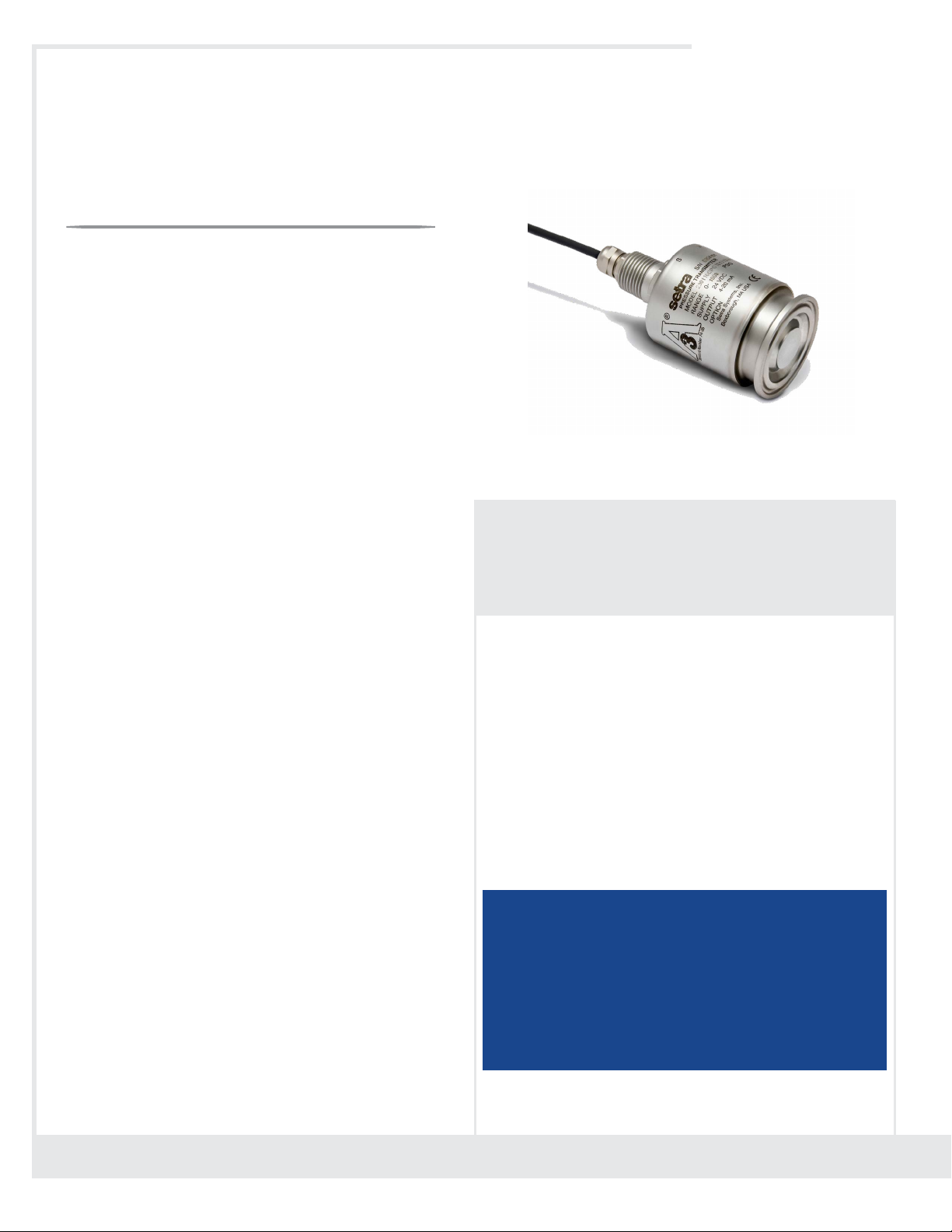

Model 290

Sanitary Pressure Transducer

The Model 290 is Setra’s highest accuracy solution for measuring gauge and compound pressure ranges in sanitary processing applications. Unlike competitive transducers which

use an oil lled design, the 316L stainless steel sensor is designed to operate without the need for an intermediary liquid within the sensor. The design of the 290 negates clamp

eect making installation and service faster and easier than

the competition. Its small footprint and accuracy (±0.2% FS)

covers a wide range of pressure ranges that meet both 3A

certication and withstand CIP/SIP environmental conditions, making it ideal for a variety of applications.

Robust Non-Liquid Filled Sensor

The Model 290 sanitary pressure transducer uses an air

variable capacitance sensor. This sensor design eliminates

chance of “product” contamination, position eect and thermal transients when compared to liquid lled sensors. The

diaphragm is able to withstand pressure down to full vacuum for worry free operation during tank and piping evacuation cycles.

n Eliminates Process Contamination Risk

n 316L SS For Harsh Environments

n Meets 3A Sanitary Standards

Model 290 Features:

Negligible Clamping Effect

The process interface of the 290 negates the eect of clamping pressure on the output signal of the sensor. This design

allows the sensor to be delivered in a small footprint with the

diaphragm closely mounted to the process media which ensures the most accurate measurements.

Flexibility in Application

The Model 290 is the most versatile sanitary pressure transducer on the market. Its design allows full scale tank level

measurements as low as 27.7” WC with an accuracy of 0.027”

and up to 1000 PSI for process lines. The 316L wetted components meet 3A requirements for food and beverage industry applications; its optional 20Ra nish make it the ideal

solution for use in Biotech applications.

• High Accuracy: ±0.2% FS

• Robust Non-Liquid Filled Capacitive Sensor

• Negligible Clamping Eect for Easy Installation

• Designed for Clean-In-Place (CIP) and Sterilize-In-Place

(SIP) Installations

• 1.5” and 2” Tri-Clover Fittings

• High Overpressure Protection

• Not Sensitive to Thermal Shock

Applications:

• Food Processing

• Dairy and Beverage Processing

• Pharmaceutical Processing

• Liquid Level Control

• Sanitary Pipelines

Model 290

Sanitary Pressure Transducer

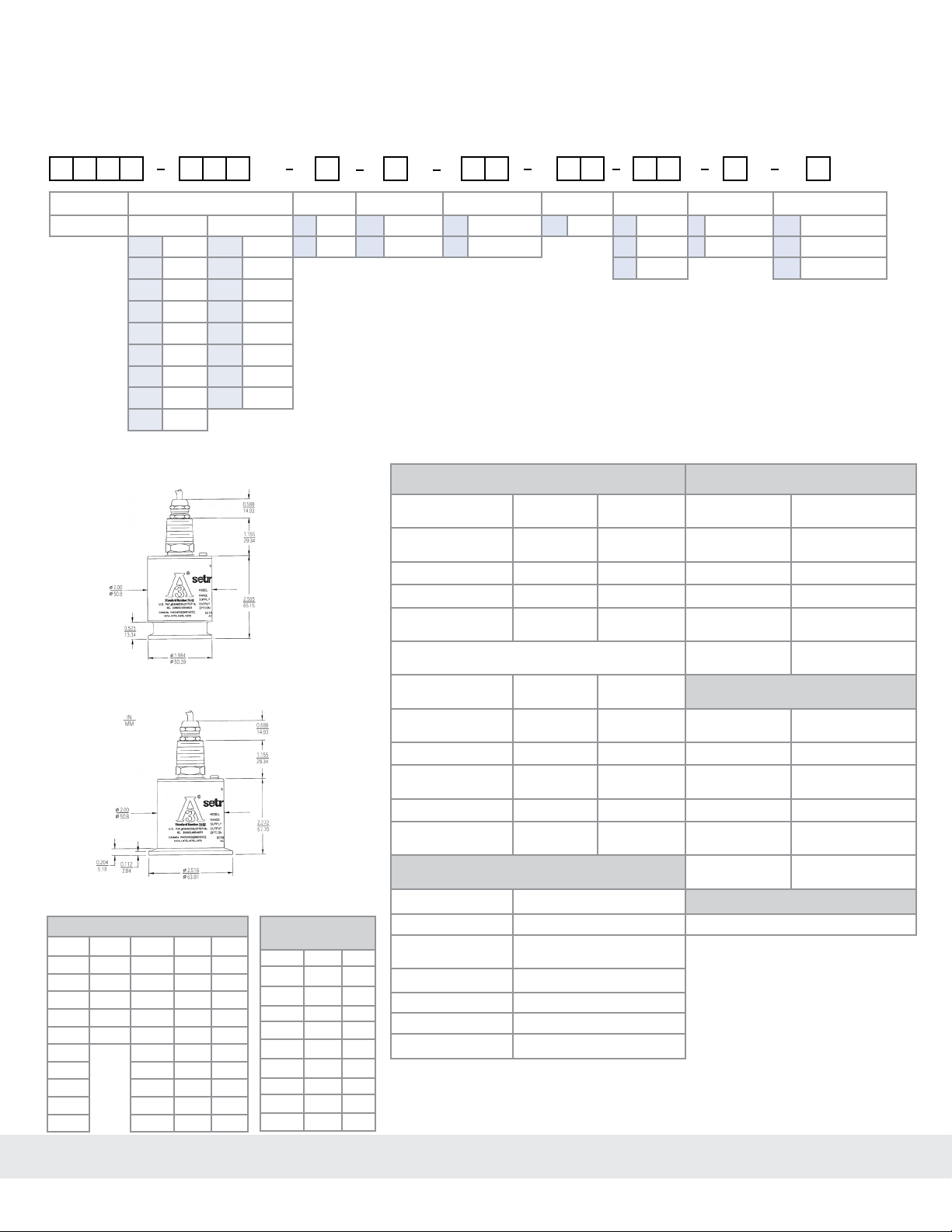

ORDERING INFORMATION

2 9 0 1 1 1

None

N

Etched SS Tags

L

20 Ra Sensor Finish

R

2

Model Range Units Pressure Type Fitting Output Termination Accuracy Options

2901 = 290 2” Tri-Clover (PSI) 1 1/2” Tri-Clover(PSI)

001

002

005

010

015

030

060

100

150

0-1

0-2

0-5

0-10

0-15

0-30

0-60

0-100

0-150

030

045*

060

100

150

300

500

10C

0-30

0-45

0-60

0-100

0-150

0-300

0-500

0-1000

PSI

P

mBAR

M

Example: Part No. 2901001PGT811153N = Model 290, 2” Tri-Clover 0 to 1 PSI, Gauge Pressure, 2” Tri-Clover Fitting, 4 to 20 mA Output, 15’ Cable Termination, ± 0.2% FS Accuracy.

G

1

C

Gauge

Compound

1 1/2” Tri-Clover 11 4-20 mA

T6

2” Tri-Clover

T8

15’ Cable

15

25’ Cable

25

30’ Cable

30

± 0.2% FS

3

± 0.1% FS

T

1

-14.7 to X psi, -1000 to XmBAR

2

Both boxes must be lled in alphabetical order:

- If No options: N + N

- If 1 option: Option Code + N

- If 2 options: Option Code + Option Code

Proof Pressure: The maximum pressure that may be applied without

changing performance beyond specications (<±0.5% FS zero shift).

Burst Pressure: The maximum pressure that may be applied to the

positive pressure port without rupturing the sensing element.

DIMENSIONS GENERAL SPECIFICATIONS

1 1/2” Tri-Clover Sanitary Fitting

Diaphragm Material: 316SS

2” Tri-Clover Sanitary Fitting

Diaphragm Material: 316LSS

PROOF PRESSURE

Pressure Ranges 2” Tri-Clover

PSIG Range mb in. H20 Proof PSIG Burst PSIG

1 100 27.7 50 100

2 160 55.4 75 150

5 400 138.4 150 200

10 600 276.8 150 200

15 1000 415.2 150 200

30 830.4 150 300

60 1660.8 180 400

100 2768 200 400

150 4152 225 400

-14.7 to 15 -407 to 415 150 300

Pressure Ranges 1 1/2”

Tri-Clover

Ramge PSIG Proof PSIG Burst PSIG

30 1000 1200

60 1000 1200

100 1000 1200

150 1000 1200

300 1000 1200

500 1000 1500

1000 1250 2400

-14.7 to 15 1000 1200

-14.7 to 45 1000 1200

Performance Data Electrical Data

2” Tri-Clover Sanitary

Fitting

1

(at constant

Accuracy RSS

temp)

±0.20% FS ±0.20% FS

Non-Linearity (BFSL) ±0.17% FS ±015% FS

Hysteresis 0.10% FS 0.12% FS

Non-Repeatability 0.025% FS 0.10% FS

Thermal Eect

Compensated Range F

Zero/Span Shift %FS/100°F

(%FS/50°C)

2

)

+20 to +180 (-7

to +82)

o(Co

2.0 (1.8) 2.0 (1.8)

Response Time 10 milliseconds 10 milliseconds

EMI/RFI Eect

< 1.0% output shift;

10V/M, 10-300 MHz

Clamping Eect, Zero/Span Shift ±0.15% FS ±0.25% FS

Maximum Vacuum (without

aecting specications)

Half on ranges

≤15 PSI

Physical Description

Zero/Span Adjustments Top Access Through Seal Screws

Case Stainless Steel CE

Electrical Connection

Pressure Fitting 2” or 1 1/2” Tri-Clover Sanitary Fitting

Sanitary Meets 3-A Sanitary Standard (74-02)

Vent Through Cable

Weight (Approx.) 8 Ounces

1/2 NPT” Conduit Fitting & Strain Relief w/ 15’

Shielded Cable

1.5” Tri-Clover

Sanitary Fitting

+20 to +180 (-7

to +82)

< 1.0% output shift;

10V/M, 10-300 MHz

Full on ranges

≥ 30 PSI

Circuit 2-Wire

3

Output

Zero/Span, Adjustment ± 0.5 mA

External Load 0 to 800 ohms

Min. Supply Voltage (VDC) 12 + 0.02 x resistance of receiver

Max. Supply Voltage (VDC) 30 + .004 x resistance of receiver

Environmental Data

Operating Temperature°F

5

(°C)

Storage Temperature°F (°C) -65 to +260 (-55 to +125)

Vibration 10g, 50-1000Hz

6

Acceleration

Shock 50g operating

Thermal Shock°F (°C) 0 to +257 (0 to +125) negligible

Approvals

Note: Setra quality standards are based on ANSI-Z540-1.

The calibration of this product is NIST traceable.

1

RSS of Non-Linearity, Non-Repeatability and Hysteresis.

2

Units calibrated at nominal 70°F. Maximum thermal error is computed from this datum.

Variations in the power supply voltage cause less than 0.005 mA change in the transmitter’s

current output, per volt change in the power supply. Reverse excitation will not damage circuit.

3

Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

4

Zero output factory set to within ±0.08mA.

4

Span (Full Scale) output factory set to within ±0.16mA.

5

Operating temperature limits of the electronics only. Pressure media temperatures may be

considerably higher or lower.

6

shift in output reading at <0.05% FS/g; pressure port axis only.

4

4 to 20 mA

plus line

plus line

-40 to +260 (-40 to +125)

10g maximum

shift

SS290 REV. H 02/15

Loading...

Loading...