Page 1

Operating Instructions

Model 270 Pressure Transducer

General Information

Your Setra transducer has been carefully calibrated before shipment to you, and it should be handled with

the same care given any precision instrument. Pressure range and dimensions are reported on the

specifications bulletin for the transducer.

Ambient Conditions

Do not use in ambient conditions corrosive to anodized aluminum, or submerge in liquids, subject to spray

or vibration environment.

Electrical Connections:

Standard

“Belden” Cable Lead Optional

Function (#8723 Grey Cable) “Tensolite” Cable Lead

Positive Excitation Red White

Positive Output Green Yellow

Negative Output White Brown

Negative Excitation Black Black

Case Shield Shield

Electrical

The electrical circuit is equivalent to a 4-terminal network which can be grounded at only one point, either

at the negative excitation or the negative signal output lead, but must not be commoned or grounded at

more than one point.

The pressure transducer must be operated with the case connected either to the negative excitation

terminal or to the negative output terminal. Failure to do this may result in damage to, or unsatisfactory

operation of the unit. This connection may be made by connecting shield and black (negative excitation)

leads or alternatively by connecting the shield and negative output signal leads together. Best shielding

against noise will be obtained by connecting the shield and negative excitation leads. Circuit is reversed

voltage protected for at least 5 minutes. Internal transient suppression network is provided for short

duration transients to 150 volts.

In some instances, use of long cables (several hundred feet long) , may introduce enough cable capacitance into the output circuit to cause output oscillation. If encountered, this oscillation may be eliminated

by connecting a 100 ohm resistor (1/8 watt or larger) in series in each of the output leads at the end of the

2 foot transducer cable. These series resistors of course add to the output resistance.

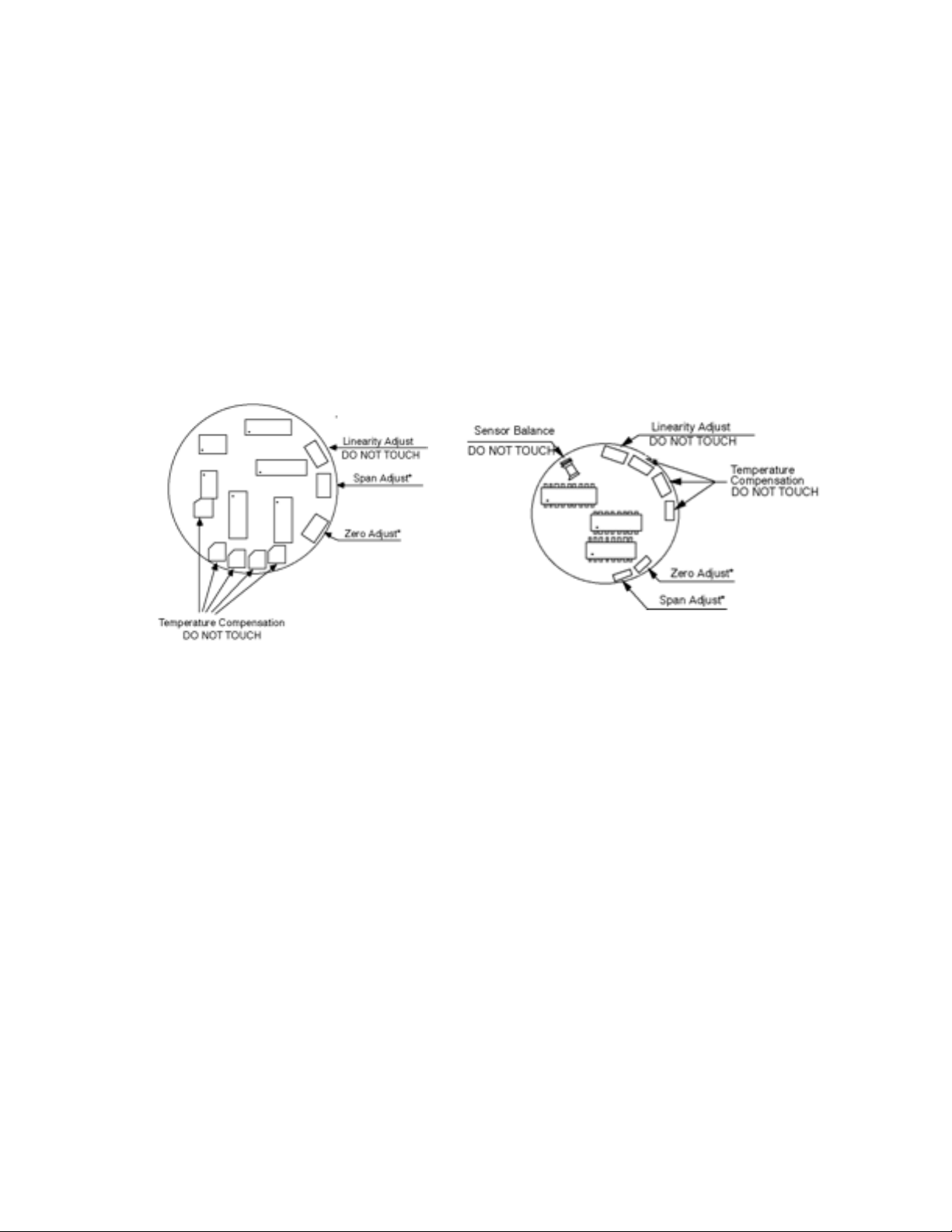

Adjustments (with cover removed)

CAUTIONS: 1. Before making any adjustments, determine which circuit board diagram on

Page 2 matches the circuit board in your transducer.

2. Turn off excitation power during cover removal or replacement.

3. Touching any adjustments other than zero or span may necessitate

recalibration and voids the warranty.

Page 2

ZERO OUTPUT

Output can be adjusted to zero by potentiometer as shown in diagram. Unit factory adjusted to

0.00 VDC output (±5mV).

SPAN

Can be adjusted by potentiometer as shown in diagram. Unit factory adjusted to 5.00 VDC full

scale output (±5mV).

LINEARITY - DO NOT TOUCH

Factory adjusted for best linearity.

Circuit Board 1 Circuit Board 2

NOTE: When circuit cover is removed, a zero shift can be noticed. The zero will return by the same

amount when the cover is replaced. This displacement of the output should be taken into account when

making adjustments or during recalibration

*Adjustments: Due to the high accuracy of this transducer, adjustments to zero and span should only be

made with the use of primary pressure standards of known accuracy higher than that of the Model 270.

Page 3

INSTALLATION INSTRUCTIONS FOR MULTIPLE HOOK-UP

OF 4-WIRE SETRA PRESSURE TRANSDUCERS

OPTION #1

Uses a single, ground referenced power supply for excitation and separate, isolated (not ground referenced) readout or “differential input” to a data acquisition system for each pressure transducer output.

OPTION #2

Uses a separate, isolated power supply for each pressure transducer’s excitation and a single, ground

referenced readout or “single ended input” to a data acquisition system for all of the outputs.

Power Supply (Nominal 24 VDC)

PT - Pressure Transducer (4 Wire Circuit)

DVM/DAS - Digital Volt Meter or Data Acquisition System

Page 4

OPTION #3

Uses a single, ground referenced power supply for excitation and either a single, isolated readout with a

bipolar switch that “breaks before makes” both the + output and - output of each pressure transducer, or a

single data acquisition system with a multiplexer (MUX).

NOTE: The shield is internally commoned to the case and pressure port of the transducer. When the

shield is connected to ground the case and pressure port of the transducer will also be commoned to that

ground.

RETURNING PRODUCTS FOR REPAIR

Please contact Setra (1-800-257-3872, 978-263-1400) before returning unit for repair to review information relative to your application. When returning a product to Setra, the material should be carefully

packaged and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719

Attn: Repair Department

To assure prompt handling, please supply the following information and include it inside the package of

returned material:

1. Name and phone number of person to contact.

2. Shipping and billing instructions.

3. Full description of the malfunction.

4. Identify any hazardous material used with product.

Notes: Please remove any pressure fittings and plumbing that you have installed and enclose any

required mating electrical connectors and wiring diagrams.

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase order to cover repair

charges.

Calibration Services

Setra maintains a complete calibration facility that is traceable to the National Institute of Standards &

Technology (NIST). If you would like to recalibrate or recertify your Setra pressure transducers or transmitters, please call our Repair Department at 1-800-257-3872 (978-263-1400) for scheduling, cost and

turnaround estimates.

Page 5

LIMITED WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its products to be free from defects in materials and workmanship, subject to the following terms and conditions:

Without charge, SETRA will repair or replace products found to be defective in materials or workmanship

within the warranty period; provided that:

a) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our

own, improper installation or servicing, or use in violation of instructions furnished by

SETRA;

b) the product has not been repaired or altered by anyone except SETRA for its authorized

service agencies;

c) the serial number or date code has not been removed, defaced, or otherwise changed;

and

d) examination discloses, in the judgment of SETRA, the defect in materials or

workmanship developed under normal installation, use and service;

e) SETRA is notified in advance of and the product is returned to SETRA transportation

prepaid.

Unless otherwise specified in a manual or warranty card, or agreed to in a writing signed by a SETRA

officer, SETRA pressure and acceleration products shall be warranted for one year from date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not limited

to, any implied warranty of merchantability for a particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be

repaired or replaced, to a refund of the purchase price. SETRA’s liability for all other breaches is limited

to a refund of the purchase price. In no instance shall SETRA be liable for incidental or consequential

damages arising from a breach of warranty, or from the use or installation of its products.

No representative or person is authorized to give any warranty other than as set out above or to assume

for SETRA any other liability in connection with the sale of its products.

159 Swanson Road, Boxborough, MA 01719-1304; 800-257-3872;

(978) 263-1400; Fax. 978-264-0292; WEB; www.setra.com;

E-mail: transducer.sales@setra.com

Rev. D 6/98

Loading...

Loading...