Page 1

Very Low Differential Pressure Transducer

Air or Non-Conducting Gas

the diaphragm away from the electrode,

decreasing the capacitance. The change in

capacitance is detected and

converted to a

electronic circuit.

The tensioned sensor allows up to 2 PSI over-

to the unit. In addition, the parts that make up

the sensor have matched thermal coeffi cients,

which promote improved temperature per-

formance and excellent long-term stability.

etra Systems Model 269 pressure

transducers sense differential

and convert this pressure difference

to a proportional electrical output for either

20 mA analog output.

applications

, these transducers are capable

of

The 269 Series transducers are available for

air pressure ranges as low as 0.1 in. W.C. full

scale. Static standard

accuracy is ±0.25% full

scale (terminal-based) in normal ambient

temperature environments. The units can

temperature compensated to 0.01% FS/

o

thermal error over the temperature range of

20

o

o

The Model 269 utilizes an improved all

stainless steel micro-tig welded sensor. The

tensioned stainless steel diaphragm and in-

sulated stainless steel electrode, positioned

close to the diaphragm, form a variable

capacitor. Positive pressure moves the dia-

capacitance. A decrease in pressure moves

CRITICAL

HIGHER

ACCURACY

&

PEFORMANCE

Model 269

Applications

● Critical Environments

● Clean Rooms

● Isolation Rooms

● Room Pressure Monitoring

● Environmental Pollution

Control

Features

■ Installation Time Minimized

with Din Rail Mounting

and Easy-to- Access Pressure Ports and Electrical

Connections

■ Removable Process Heads

Eliminates the Need to Cut

Tubes for Easier Installation

■ Detachable Terminal Block

so Field Wiring Can Remain

In-Situ During Calibration

S

■ Calibration Secure - Calibra-

tion Key for Making Zero

and Span Adjustments

■ 2-Wire 4 to 20 mA Analog

Output Compatible with Energy Management Systems

■ Reverse Wiring Protection

■ Internal Regulation Permits

Use with Unregulated DC

Power Supplies

■ Fire Retardent Case

(UL 94 V-0 Approved)

■ Calibration Certs Available

■ 2:1 Turndown Ratio

Available

■ Meets CE Conformance

Standards

Visit Setra Online:

http://www.setra.com

800-257-3872

Page 2

Accuracy Class (FS) Code V E G

±0.25% ±0.50% ±1.00%

±0.15% ±0.35% ±0.75%

±0.10%

±0.25% ±0.55%

0.05%

±0.05%

±0.10%

±

0.05%

±0.05%

±0.05%

Zero Setting Tolerance

±

.04mA

±

.08mA

±

.12mA

Span Setting Tolerance

.04mA

.08mA

.12mA

Thermal Effects

*

Compensated Range °F 20 to +140

Zero/Span Shift %FS/°F 0.01% 0.02% 0.02%

Overpressure Up to 2 psi i(Range Dependent)

Circuit 2-Wire

Output

4 to 20mA

**Calibrated at factory with a 24 VDC loop supply voltage and a 250 ohm load.

T

ypically air or similar non-conducti

Specifi cations subject to change without notice.

Toll Free: 800-257-3872; Fax: 978-264-0292; email: sales@setra.com

Code all blocks in table.

Model

2691 = 269

Calibration Certifi cates are standard for all units.

ordering for calibration key accessory.

2 6 9 1

0R1WD = 0 to 0.1 in. WC R05WB = ±0.05 in. WC

R25WD = 0 to 0.25 in. WC 0R1WB = ±0.1 in. WC

0R5WD = 0 to 0.5 in. WC R25WB = ±0.25 in. WC

001WD = 0 to 1 in. WC 0R5WB = ±0.5 in. WC

1R5WD = 0 to 1.5 in. WC 001WB = ±1 in. WC

2R5WD = 0 to 2.5 in. WC 1R5WD = ±1.5 in. WC

003WD = 0 to 3 in. WC 2R5WB = ±2.5 in. WC

005WD = 0 to 5 in. WC 005WB = ±5 in. WC

010WD = 0 to 10 in. WC 015LB = ±15 Pa

025LD = 0 to 25 Pa 025LB = ±25 Pa

050LD = 0 to 50 Pa 050LB = ±50 Pa

100LD = 0 to 100 Pa 100LB = ±100 Pa

250LD = 0 to 250 Pa 250LB = ±250 Pa

500LD = 0 to 500 Pa 500LB = ±500 Pa

001KD = 0 to 1 kPa 001KB = ±1kPa

2R5KD = 0 to 2.5 kPa

Mounting

Confi guration

D = Din Rail Mount

Output

Confi guration

Confi guration

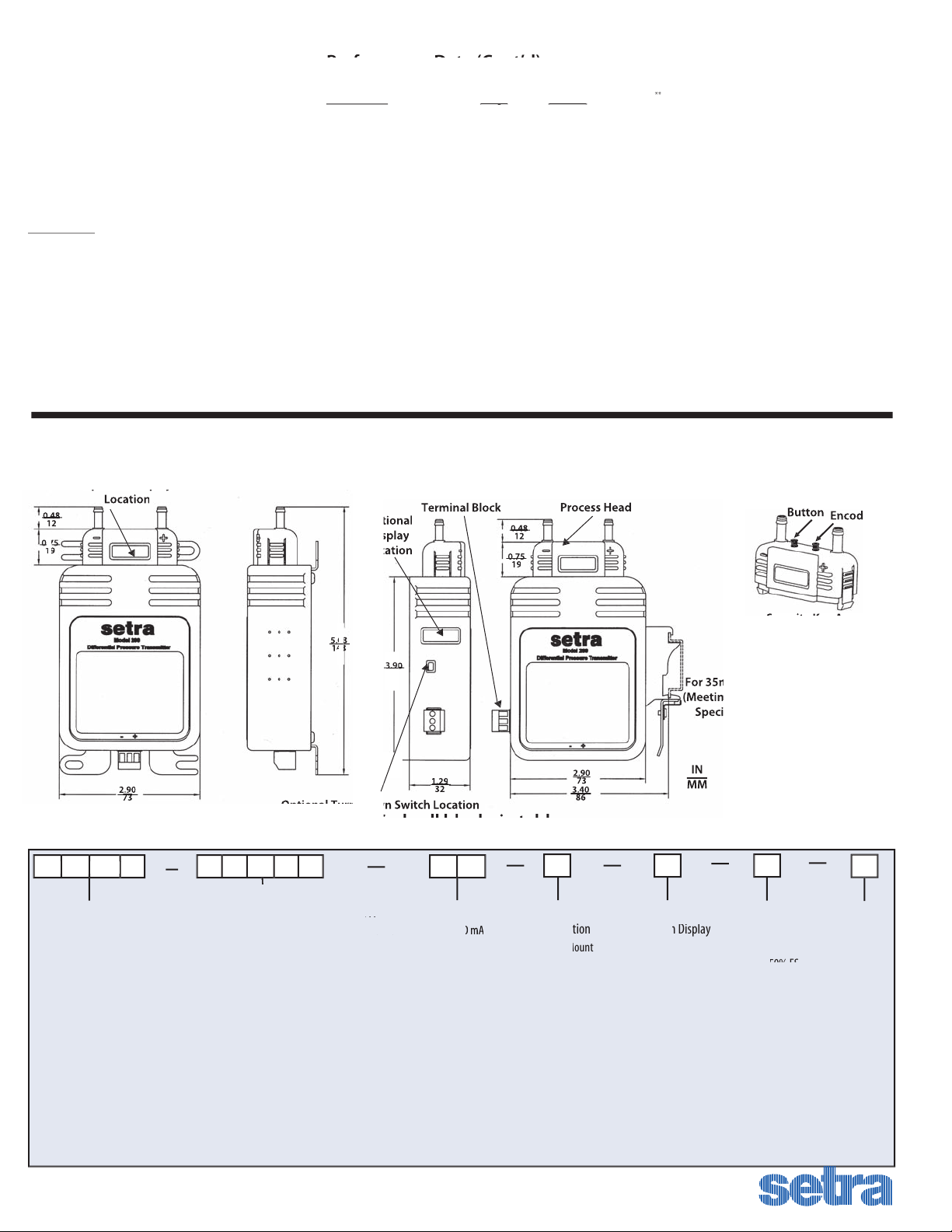

Outline Drawings

While we provide application assistance on all Setra products, both personally and

through our literature, it is the customer’s responsibility to determine the suitability

of the product in the application.

Zero Offset

effect in the vertical position.) To 0.5 in. WC 1.00

To 1.0 in. WC 0.50

To 2.5 in. WC 0.22

To 5.0 in. WC 0.14

Temperature

Operating °F -20 to +160

Storage °F -40 to +185

C

ase Fire-Retardant ABS

Connector

on Removable Process Head

Zero and Span Adjustments External Security Key

*Units calibrated at nominal 70˚F. Maximum thermal error computed from

this datum.

D = With Display

N = No Display

Version

Version

Accuracy

V = ±0.25% FS

E = ±0.50% FS

G = ±1.0% FS

Optional Display

Optional

Optional Turn-Down Switch Location

Security

Cal Key

Cal

Cal

Security Key Accessory

Transducer

Turndown

A = 2 x 1

N = None

3.90

3.90

99

Model 269 Specifi cations

Loading...

Loading...