Page 1

Installation Guide

Setra Systems Model 269 High Performance

Very Low Differential Pressure Transducer

1.0 GENERAL INFORMATION

Every Model 269 has been tested and calibrated before shipment. Specific

performance specifications are shown on page 3 of this Guide.

Setra Systems 269 pressure transducers sense differential or gauge (static)

pressure and convert this pressure difference to a proportional high level

analog output for both unidirectional and bidirectional pressure ranges. A

current output of 4 to 20 mA is offered.

2.0 MECHANICAL INSTALLATION

2.1 Media Compatibility

Model 269 transducers are designed to be used with air or nonconducting

gases. Use with liquids or corrosive gases will damage the unit.

2.2 Environment

The operating temperature limits of the 269 are -20°F to +160°F

The compensated temperature range is 20°F to +140°F

2.3 Pressure Fittings

The Model 269 is designed to be used with 3/16” I.D. push-on tubing on a

removable process head. Both the positive (high) pressure port and the

reference (low) pressure port are located on the top of the unit, labeled “+”

(HIGH) and “-” (LOW) respectively. For best results (shortest response times),

3/16” I.D. tubing is suggested for tubing lengths up to100 feet long, 1/4” I.D. for

tubing lengths up to 300 feet, and 3/8” I.D. for tubing lengths up to 900 feet

(See Diagram 1).

3.0 ELECTRICAL INSTALLATION

3.1 Current Output Units

The Model 269 is a two-wire loop-powered 4 to 20mA current output unit and

delivers rated current into any external load of 0 to 800 ohms. These terminals

have the designation of + and - (See Diagram 1).

Page 2

The current flows into the + terminal and returns back to the power supply

through the - terminal (See Diagram 2). The power supply must be a DC

voltage source with a voltage range between 13.5 and 30 measured between

the + and - terminals. The unit is calibrated at the factory with a 24 VDC loop

supply voltage and a 250 ohm load.

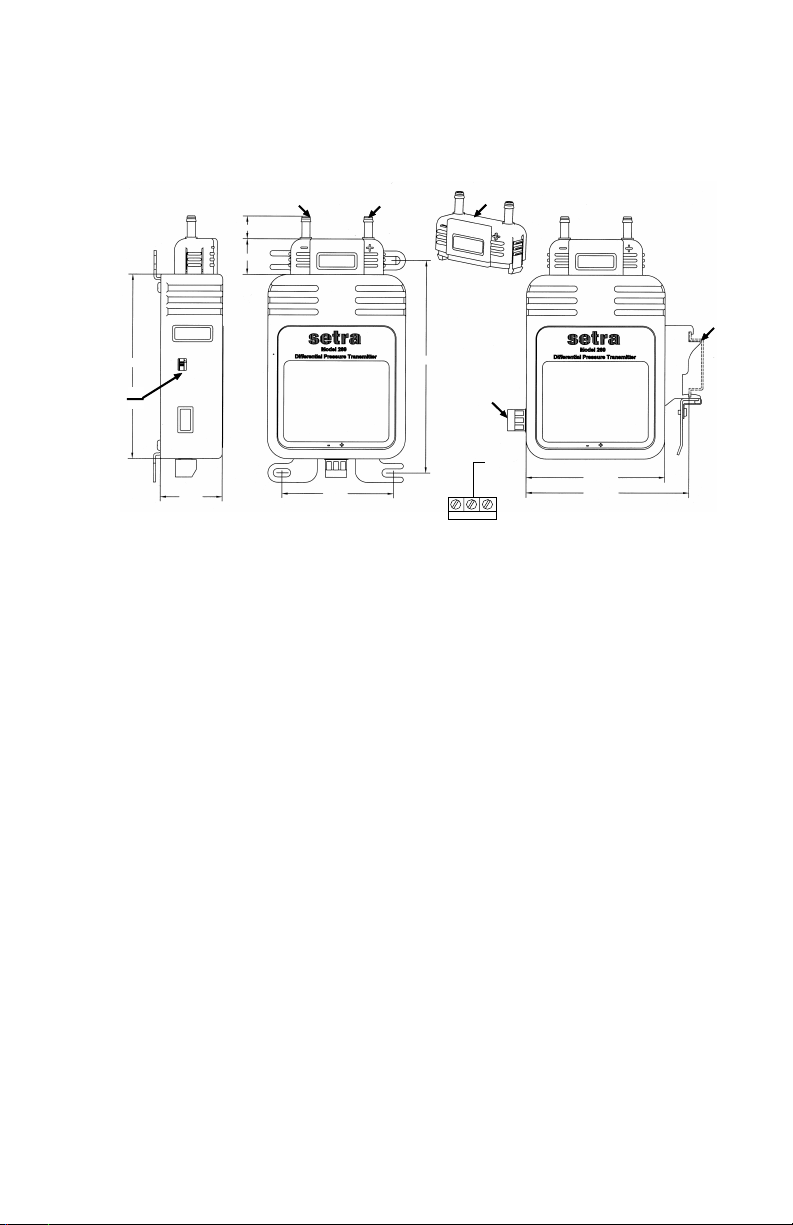

Low Pressure Port

.48”

High Pressure Port

Detachable Process

Head

Din

Rail

4.50”

Detachable

Electrical

Connector

Shield

to

Ground

- +

2.90”

3.70”

Turn-Down

Switch

3.90”

1.30”

2.35”

4.0. CALIBRATION

The 269 transducer is factory calibrated and should require no field adjustment

if mounted in a vertical position. Whenever possible, any zero and/or span

offsets should be corrected by software adjustment in the user’s control system.

However, fine zero and span adjustments can be made thru a calibration secure

access key. The Model 269 transducer zero offset is trimmed in the vertical

position (pressure ports pointing upward) prior to shipping from factory.

4.1 Zero/Span Adjustments with Security Key

To make secure zero and span adjustments, remove detachable process head by

pressing and pulling on side tabs. Install calibration security key in-place of

process head. (See Diagram 3).

4.2 Zero Adjustment (Current Output)

While applying zero differential pressure, zero may be adjusted by pressing the

cal button to tare zero. If fine adjustment is needed on analog output, depress

cal button while turning the encoder.

4.3 Span Adjustment (Current Output)

Span or full scale output adjustments should only be performed by using an

accurate pressure standard (electronic manometer, digital pressure gauge, etc.)

with at least comparable accuracy to the 269 transducer. With full range

pressure applied to the high pressure port (reference port open to atmosphere),

the span may be adjusted by pressing the cal button to set span. If fine

adjustment is needed on span, and control pressure is applied at least 75% of

full range, turn encoder until target output is achieved.

Diagram 1

4.4 Turn Down Adjustment (Option)

For units with optional turn-down gain, turn down is easily adjusted through

use of slider switch located on side of unit. (See Diagram 1)

2

Page 3

Current Circuit Diagram

269

13.5 to 30 VDC+_

Current

Monitoring

Device

Security Cal Key

Cal Button

Cal Encoder

Diagram 3

Diagram 2

4.5 Restoring Factory Calibration

To restore factory set calibration, turn unit off power and press cal button. Turn

on the power while cal button is depressed and release cal button.

5.0 MODEL 269 PERFORMANCE SPECIFICATIONS

Performance Codes V E G

Accuracy Class (FS) ±0.25% FS ± 0.50% FS ±1.0% FS

Non-Linearity

Terminal Point ±0.15% FS ± 0.35% FS ±0.75% FS

BFSL ±0.10% FS ± 0.25% FS ±0.55% FS

Hysteresis (Typical) ±0.05% FS ± 0.05% FS ±0.10% FS

Non-Repeatability ±0.05% FS ± 0.05% FS ±0.10% FS

Thermal Effects

Compensated Range °F 20 to +140

Zero Shift %FS/°F 0.01% 0.02% 0.03%

Span Shift %FS/°F 0.01% 0.02% 0.03%

Maximum Line Pressure 2 psi

Overpressure 2 psi in positive or negative direction

Long-term Stability 0.5% FS/1 Yr

Position Effect Range Zero Offset (%FS/G)

(Unit is factory calibrated at 0g effect To 0.1 in. WC 2.50

in the vertical position, pressure To 0.5 in. WC 1.00

ports pointing upward.) To 1.0 in. WC 0.50

To 2.5 in. WC 0.22

To 5 in. WC 0.14

Electrical

Calibrated at factory with a 24 VDC loop supply and a 250 ohm load.

Zero output factory set to 4±.04 mA for unidirectional pressure ranges and 12±.04 mA for

bidirectional ranges in vertical position.

Span factory set to 16±.04 mA.

3

Page 4

6.0 EMC CERTIFICATION

This product complies with EN61326 Electrical Equipment for Measurement, Control and Laboratory use - EMC

Requirements for Minimum Requirements and Industrial Locations. Special caution should be taken to meet

Standard EN61000-4.5: 1995 Surge Immunity if any of the following conditions apply to the installation: The

product is installed outside; all or any part of the cable is exposed to the outside; the cable is greater than 30

meters in length. In order to meet the Surge Immunity Requirements, the following conditions must be

followed during installation:

1. Shielded cable must be used, and the shield must be tied to earth ground (not power supply

ground) on at least one end of the cable shield/drain wire. The shield must be maintained all the

way from sensor to the power supply.

2. If unshielded cable is used, an earth grounded metal conduit fitting can be used to replace the

shielded cable.

3. For a sensor with a metal body or enclosure, the body/enclosure must be ground to earth. If a

protective metal housing is used, the metal housing should be grounded to earth.

4. If a protective plastic housing is used, the housing must be able to withstand at least 2 KV from

the housing to earth ground, without damaging the circuit.

7.0 RETURNING PRODUCTS FOR REPAIR

Please contact a Setra application engineer (800-257-3872, 978-263-1400) before returning unit for repair to

review information relative to your application. Many times only minor field adjustments may be necessary.

When returning a product to Setra, the material should be carefully packaged and shipped prepaid to:

To assure prompt handling, please supply the following information and include it inside the package or

returned material:

1. Name and phone number of person to contact.

2. Shipping and billing instructions.

3. Full description of the malfunction.

4. Identify any hazardous material used with product.

Notes: Please remove any pressure fittings and plumbing that you have installed and enclose any required

mating electrical connectors and wiring diagrams.

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase order to cover repair

charges.

Setra maintains a complete calibration facility that is traceable to the National Institute of Standards &

Technology (NIST). If you would like to recalibrate or recertify your Setra pressure transducers or transmitters,

please call our Repair Department at 800-257-3872 (978-263-1400) for scheduling.

8.0 WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its Model 269 products to the original consumer purchaser against defects for a period of one

year from the date of sale by SETRA, as shown in its shipping documents. Without charge, SETRA will repair or

replace products found to have manufacturing defects within the warranty period.

The serial number or date code must not have been removed, defaced or otherwise changed.

SETRA must be notified in advance of any returns; any products returned to SETRA must be transportation

prepaid.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not limited to, any

implied warranty of merchantability for a particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be repaired or

replaced, to a refund of the purchase price. SETRA’s liability for all other breaches is limited to a refund of the

purchase price. In no instance shall SETRA be liable for incidental or consequential damages arising from a

breach of warranty, or from the use or installation of its products.

No representative or person is authorized to give any warranty other than as set out above or to assume for

SETRA any other liability in connection with the sale of its products.

159 Swanson Road, Boxborough, MA 01719-1304

SS2135 Rev. D 7/19/07

Tel: 800-257-3872/978-263-1400

Calibration Services

ISO

9001:

2000

Certified

✓

4

Loading...

Loading...