Page 1

Model 267 & 267MR

Operating Instructions

Setra Systems, Inc.

159 Swanson Road, Boxborough, MA 01719

800.257.3872 • www.setra.com

Page 2

1.0 General information

Every Model 267 and Model 267MR (multi-range) has been tested and calibrated before

shipment. Specic performance specications are listed on page 9 of this guide.

The Model 267 is single range only. The Model 267MR has eld selectable range capability.

The 267MR is factory calibrated for the highest pressure range. The range label on the cover

of the unit indicates the factory-calibrated range. Should the 267MR be re-ranged in the eld,

other multi-range labels are included.

Setra Systems 267 and 267MR pressure transducers sense differential or gauge (static)

pressure and convert this pressure difference to a proportional high level analog output for both

unidirectional and bidirectional pressure ranges. Two output versions are offered: A congurable

voltage output of 0 to 5 VDC or 0 to 10 VDC, and a current output of 4 to 20 mA.

Sections 1 through 4 and 7 through 9 of this guide apply to both models 267 and 267MR.

Section 5 refers to the model 267 only. Section 6 refers to the model 267MR only.

2.0 Mechanical installation

2.1 Media compatibility

Model 267 and 267MR transducers are designed to be used with air or nonconducting gases.

Use with liquids or corrosive gases will damage the unit.

2.2 Environment

The operating temperature limits of the 267 and 267MR are as follows:

Operating temperature 0°F to +150°F (-18°C to +65°C)

Compensated temperature range +40°F to +150°F (+5°C to +65°C)

2.3 Pressure ttings

The Model 267 and 267MR can be supplied with three different pressure tting congurations:

A. 3/16” O.D. Barbed brass pressure ttings – Typically installed with 1/4” push-on tubing

B. 1/4”NPT Brass pressure ttings – Typically installed with mating NPT male tting.

C. Static pressure probe – Installed on the duct by drilling a 7/16” hole in the duct at the

desired mounting location, inserting the pressure probe into the duct, and mounting the

267 onto the duct with the mounting tabs.

For the 3/16” O.D. and 1/4” NPTF pressure ttings, both the positive (high) pressure port and

the reference (low) pressure port are located on the bottom of the unit, labeled “high” and “low”

respectively. For the best results (shortest response times), 3/16” I.D. for tubing is suggested

for tubing lengths up to 100 feet long, 1/4” I.D. for tubing lengths up to 300 feet, and 3/8” I.D.

for tubing lengths up to 900 feet.

The static pressure probe is positive (high) pressure port located on the back of the unit. The

reference (low) pressure port is located on the bottom of the unit and can be used for differential

pressure measurements.

Page 3

3.0 Electrical installation

Wiring is through a 1/2” conduit opening or factory installed PG-9, PG-13.5 or 9 pin D-sub

connector. (See section 3.2 for instructions on wiring the 9 pin D-sub connector). Both current

and voltage output units are reverse wiring protected.

3.1 Voltage output units

1/2” conduit opening, PG9 or PG-13.5 electrical termination

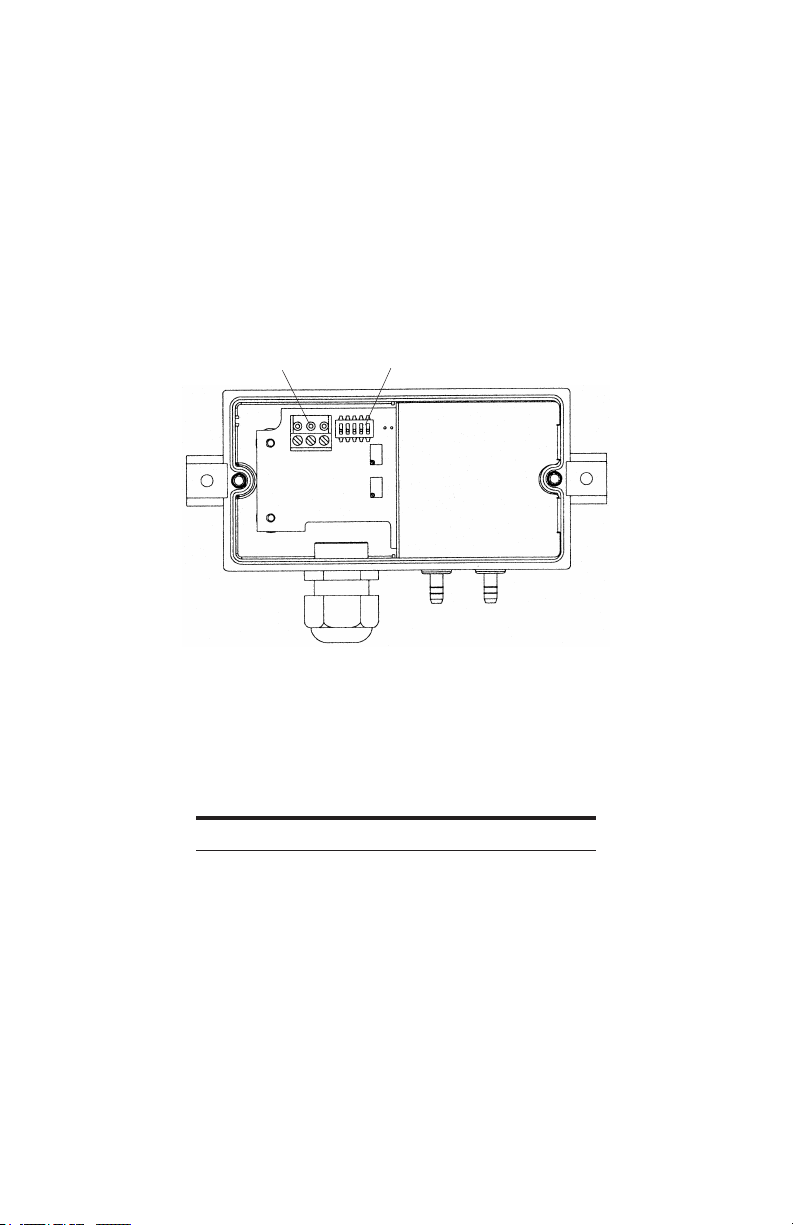

Wiring terminations are identied on the circuit board below the terminal strip (see section 3.1

for voltage output units or Section 3.3 for current units). To access the terminal strip, turn the

screws on top of the case counter clockwise until the cover can be removed. The screws are

captured and will be secured in the top of the case.

Electrical

connections

+EXC GND +SIG

Range select switches

(267MR version only)

Span

Zero

Diagram 1

The Model 267and 267MR voltage output is a 3-wire circuit, with three terminals available for

winning (see diagram 1).The -excitation and -output are common on the circuit (see diagram

2). The excitation/output specications are:

Excitation Output

9 to 30 VAC/ 11.5 to 42 VDC 0 to 5 VDC

12 to 30 VAC/ 13 to 42 VDC 0 to 10 VDC

The 267MR has a eld selectable 0-5 or 0-10 VDC output. (See section 6.0 for switch settings

to determine whether the voltage output is set to 0-5 or 0-10 VDC). The 267 has either a 0-5

or 0-10 output, calibrated at the factory.

Page 4

Voltage circuit diagram

Power

supply

Readout

or

DAS

+EXC

GND

+SIG

Model

267MR

Diagram 2

+EXC Connected to positive terminal of DC or AC power supply

GND Connect as the reference for power supply and output signal

+SIG Connect to positive terminal of control or pressure monitor

3.2 Voltage output units:

9 pin D-sub connector electrical termination

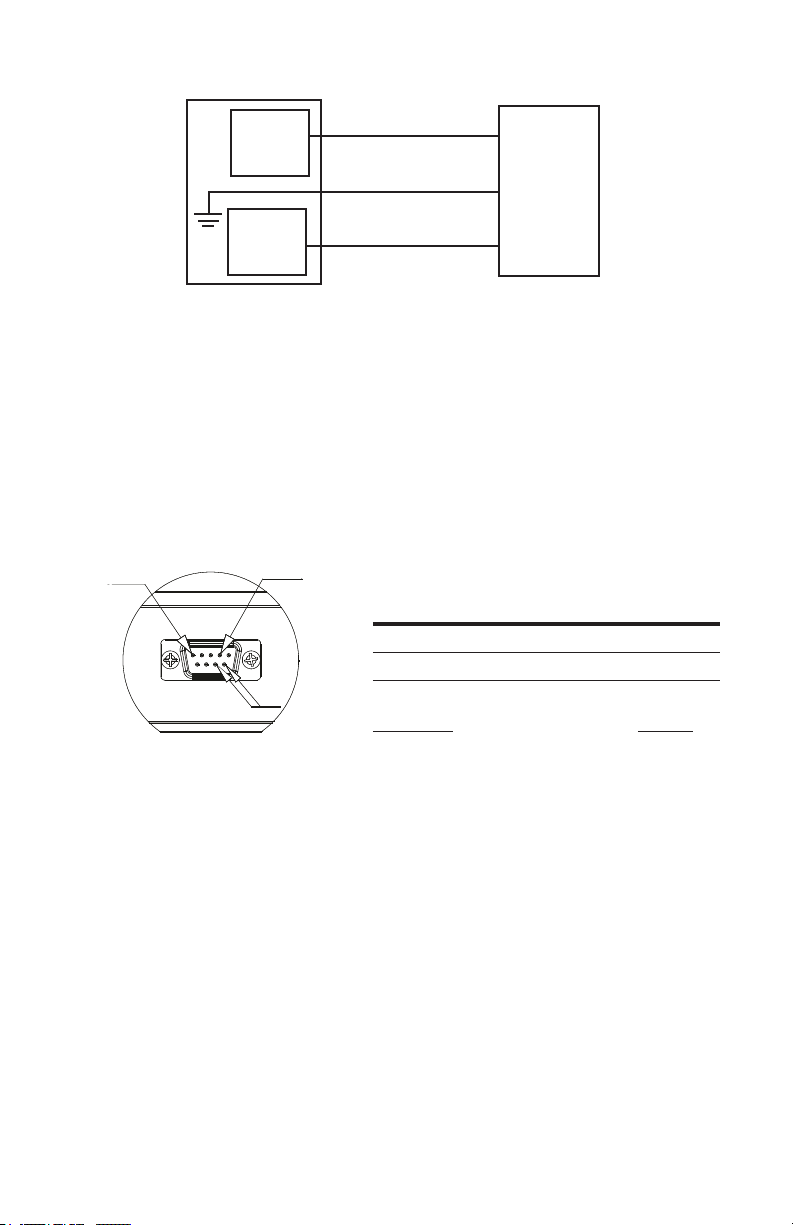

The Model 267 and 267MR voltage output is a 3-wire circuit, with three pins available

for wiring (see diagram 3). The voltage output pin designations are shown in diagram 4:

PIN 1

+ output

Diagram 3

PIN 4

+ EXC

PINS 8,9*

common

9 pin D-sub connector

Connection

+Excitation 4

+Output 1

Common 9

electric termination

Excitation Output

9 to 30 VAC / 11.5 to 42 VDC 0 to 5 VDC

12 to 30 VAC / 13 to 42 VDC 0 to 10 VDC

Diagram 4

* Pins 8 and 9 are internally commoned together, user can connect to either pin.

3.3 Current output units:

1/2’’ conduit opening, PG9 or PG-13.5 electrical termination

The Model 267 and 267MR is a two-wire loop-powered 4 to 20mA current output unit (see

diagram 5). The current flows into +EXC terminal and returns back to the power supply through

the -EXC terminal (see diagram 6). The power supply must be a DC voltage source with a voltage

range between 9 and 30 measured between terminal +EXC and -EXC. The unit is calibrated

with a 24VDCC loop supply voltage and a 250 ohm load.

Page 5

Span

Zero

Range select switches

(267MR version only)

9 to 30 VDC

Current

Monitor

Devce

+

267MR

_

Electrical connections

+EXC -

Diagram 5 Diagram 6

3.4 Current output units:

9 pin D-sub connector electrical termination

The Model 267 and 267MR is a two-wired loop-powered 4 to 20mA current output unit (see

diagram 6). The current flows into +EXC. Pin 4 (+EXC) and return to the power supply through

pin 9 (-EXC) (see diagram 7). The power supply must be a DC voltage source with a voltage

range between 9 and 30 measured between pin 4 and pin 9 (-EXC). The unit is calibrated with

a 24VDC loop supply voltage and a 250 ohm load. The current output9 pin D-sub connector

pin designations are shown in diagram 8.

PIN 4

+ EXC

Connection 9 pin D-sub connector

+Excitation 4

PIN 9

- EXC

-Excitation 9

Diagram 7 Diagram 8

3.5 4-20 mA circuit diagram

Minimum supply voltage (VDC)=9+0.02x (resistance of receiver plus line) maximum supply

voltage (VDC)=30+0.004x (resistance of receiver plus line). If the current loop has a current

limiter, the threshold should be adjusted to 35 mA minimum (see diagram 9).

Loop power supply vs. Loop resistance for

4 to 20 mA current transducers

Diagram 9

Operating

range

Loop resistance (Ohms)

0

9

Loop supply voltage (Vdc)

30

Page 6

3.6 EMC compliance

This product complies with EN61326-1:2006 in accordance with EN61326-2-3:2006 to be

used in controlled EM immunity and class B emission environment. Special cautions much

be taken to fully meet EU EMC compliance:

1. Shielded cable must be used, and the shield must be tied to earth ground (not

power supply ground) on at least one end of the cable shield/drain wire. The

shield must be maintained all the way from sensor to the power supply

2. If unshielded cable is used, an earth grounded metal conduit tting can be used

to replace the shielded cable.

3. For a sensor with a metal body or enclosure, the body/enclosure must be

grounded to earth.

4. If a protective plastic housing is used, the housing must be able to withstand

at least 2 KV from the housing to earth ground, without damaging the circuit.

5. The unit shall be installed or operated in a controlled electromagnetic

environment.

4.0 Calibration

The 267 and 267MR transducer is factory calibrated and should require no eld adjustment.

Generally, the mounting position will have a zero shift effect on ranges below 1” WC.

Whenever possible, any zero and/or span offsets should be corrected by software

adjustment in the user’s control system. However, both zero and span adjustments are

accessible under the cover of the unit, below and to the right of the terminal strip. The

267 and 267MR transducer is calibrated in the vertical position at the factory (mounting

tabs vertical).

4.1 Voltage output units zero adjustment

While monitoring the voltage between the positive output (+SIG) and common (GND), and

with both pressure ports open to atmosphere, the zero may be adjusted by turning the zero

adjustment screw. (See diagram 1 for location of zero adjustment.)

Factory settings are:

Unidirectional pressure ranges Bidirectional pressure ranges

Zero adjustment Output Zero adjustment Output

0.05 VDC (±25 mV) 0-5 VDC 2.5 VDC (±25 mV) 0-5 VDC

0.05 VDC (±50 mV) 0-10 VDC 5 VDC (±50 mV) 0-10 VDC

Page 7

4.2 Voltage output span adjustment

(Complete the zero adjustment before setting span.)

Span or full scale output adjustments should only be performed by using an accurate pressure

standard (electronic manometer, digital pressure gauge, etc.), with at least comparable accuracy

to the 267 or 267MR transducer (<±1% FS).

With full range pressure applied to the high pressure port (reference port open to atmosphere),

the span may be adjusted by turning the SPAN adjustment screw. (See diagram 1 for location

of SPAN adjustment). Factory settings are:

Unidirectional pressure ranges Bidirectional pressure ranges

Span adjustment Output Span adjustment Output

5.0 VDC (±25 mV) 0-5 VDC 2.5 VDC (±25 mV) 0-5 VDC

10 VDC (±50 mV) 0-10 VDC 5 VDC (±50 mV) 0-10 VDC

Example 1: Unidirectional pressure range of 0 to 1” W.C. with 0 to 5 VDC output

Apply 1.00” W.C., adjust span to 5 VDC (±25 mv)

Example 2: Bidirectional pressure range of ±5” W.C. with 0 to 5VDC output

Apply 5.00” W.C., adjust span to 5 VDC (±25 mV)

4.3 Current output zero adjustment

While monitoring the current output, and with both pressure ports open to atmosphere, the

zero may be adjusted by turning the zero adjustment screw. (See diagram 3 for location of zero

adjustment) Factory settings are:

Unidirectional pressure ranges Bidirectional pressure ranges

Zero adjustment Output Zero adjustment Output

4mA (0.08 mA) 4-20 mA 12 mA (0.08 mA) 4-20 mA

4.4 Current output span adjustment

Span or full scale output adjustments should only be performed by using an accurate pressure

standard (electronic manometer, digital pressure gauge, ect.) with at least comparable accuracy

to the 267 or 267MR transducer (<±1% FS). With full range pressure applied to the high pressure

port (reference port open to atmosphere), the span maybe adjusted by turning the SPAN

adjustment screw. (See diagram 1 for location of SPAN adjustment). Factory settings are:

Unidirectional pressure ranges Bidirectional pressure ranges

Span Adjustment Output Span Adjustment Output

20mA (0.08 mA) 4-20 mA 20 mA (0.08 mA) 4-20 mA

Example 1: Unidirectional pressure range of 0 to 1” W.C. with 4 to 20 mA output

Apply 1.00” W.C., adjust span to 20 mA (±0.08mA)

Example 2: Bidirectional pressure range of 5” W.C. with 4 to 20 mA output

Apply 5.00” W.C., adjust span to 20 mA (±0.08 mA)

Page 8

5.0 Model 267 optional LCD display

The Model 267 is available with an optional 3 1/2 digit LCD display. The LCD display is adjusted

at the factory prior to shipment. The LDC is connected to the zero and span adjustment

potentiometers. Therefore, adjustment of the zero and span according to section 4 adjusts

the LCD display.

6.0 Multi-range operation - model 267MR only

The 267MR is re-rangeable by accessing the switches located internal to the transducer

housing. To access the “Dip” switches, remove the screws on the top of the case and lift off

the cover. The “Dip” switches are located on the electronics board as shown in diagrams 1 and

5. The voltage output version has 5 switches. The current version has 4. The location of these

switches, “on” (up position) or “off” (down position), determine what range has been selected.

See table 1 or 2 below for switch positions for in WC or Pascals.

Multi-range units are factory set to the highest range. As an example, an MR2 range is factory

set to 0 to 1” W.C.

NOTE: Black square in diagram indicates switch position.

If it is a 0-5 VDC output,

the switches are set:

ON

1

2 345

If the 267MR range is re-congured from the factory calibration, place the correct range label

(enclosed) on the cover label, over the area indicating the factory default range.

To change the range to

0 to .25”W.C. with a 0-10

VDC output, change the

switches to:

ON

1 2 3 4 5

NOTES: Voltage output is set based upon ordering code. See switch settings below to conrm

voltage output. The 4-20 mA current version has only 4 switches.

Page 9

Table 1: Range switching instructions for inches of water column

NOTE: Black square in diagram indicates switch position.

MR1

range

MR2

range

Factory default setting

MR3

range

MR4

range

Switch settings

0-5V output

ON

Switch settings

0-10V output

ON

0-0.1” 0-1” 0-5” 0-30”

1

2 3 4 5

ON

ON

0-.5” 0-2.5” 0-15”

1 234 5

ON

ON

0-.25” 0-1.25” 0-7.5”

1 2 3 4 5

ON

ON

±0.05” ±.5” ±2.5” ±15”

123 4 5

ON

ON

±.25” ±1.25” ±7.5”

1 2 3 4 5

ON

ON

±1.25” ±.625” ±3.75”

123 4 5

Table 2: Range switching instructions for pascal ranges

NOTE: Black square in diagram indicates switch position

MR5

range

MR6

range

MR7

range

MR8

range

MR9

range

Switch settings

0-5V output

1 2

3 4 5

123 4 5

1 2 3 4 5

1 234 5

1 2 3 4 5

123 4 5

Switch settings

0-10V output

Switch settings

4-20MA output

ON

1 2 3 4 5

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

123 4

Switch settings

4-20mA output

Factory default setting

0-25 PA 0-200 Pa 0-1000 Pa 0-2500 Pa 0-7500 Pa

0-100 Pa 0-500 Pa 0-1250 Pa 0-3750 Pa

0-50 Pa 0-250 Pa 0-625 Pa 0-1875 Pa

±12.5 Pa ±100 Pa ±500 Pa ±1250 Pa ±3750 Pa

±50 Pa ±250 Pa ±625 Pa ±1875 Pa

±25 Pa ±125 Pa ±312 Pa ±937 Pa

ON

1 2 3 4 5

ON

1 234 5

ON

1 2 3 4 5

ON

1 2 345

ON

1 2

ON

1 2 3 4 5

3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

2 3 4 5

1

ON

1 234

ON

1 2 3 4 5

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3

4

ON

1 2 3 4

5

ON

1 2 3

4

Page 10

7.0 Model 267 & 267MR performance specications

General specications

Accuracy RSS* (at constant temperature) ±1.0% FS

Non-linearity, BFSL ±0.98 FS

Hysteresis ±0.2% FS

Non-repeatability ±0.1% FS

Compensated temperature range 40° to 150°F (5° to 65° C)

Zero/span shift, %FS/°F(°C) 0.033 (0.06)

Maximum line pressure 10 PSI

Overpressure Up to 10 PSI (range dependent)

Warm-up shift ±0.1% FS total

Position effects (unit is factory calibrated at 0g effect in the vertical position

Range Zero offset (%FS/G)

0 to 0.1” W.C. 2.1

0 to 1” W.C. 0.22

0 to 5” W.C. 0.14

*RSS of non-linearity, non-repeatability and hysteresis.

8.0 Model 267 desiccant cover

The desiccant can be easily regenerated or replaced. When the desiccant has absorbed all

the moisture it can hold, the user is alerted through the clearly visible status window, which

changes from blue (dry) to pink (saturated).

(Note: Life expectancy of the desiccant is approximately six months)

8.1 Regenerate the desiccant

The desiccant can be regenerated by removing the cover from the base and baking it in a

conventional oven at 200°F for 3-4hours or until it returns to its dry status (blue).

8.2 Replacing the desiccating cover

To ensure the uninterrupted system operation, replacement covers with desiccant are available

(refer to P/N 299201). Contact your local representative or Setra System’s customer service

department at (800) 257-3872 to order.

Page 11

9.0 Returning products for repair

Please contact a Setra application engineer (800-257-3872, 978-263-1400) before returning

unit for repair to review information relative to your application. Many times only minor eld

adjustments may be necessary. When returning a product to Setra, the material should be

carefully packaged and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

To ensure prompt handling, please supply the following information and include it inside the

package or returned material:

• Name and phone number of person to contact.

• Shipping and billing instructions.

• Full description of the malfunctions.

• Identify any hazardous material used with the product.

NOTES:

Please remove any pressure ttings and plumbing that you have installed and enclose any

required mating electrical connectors and wiring diagrams.

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit. Nonwarranty repairs will not be made without customer approval and a purchase order to cover

repair chargers.

Calibration services

Setra maintains a complete calibrations facility that is traceable to the National Institute of

Standards and Technology (NIST). If you would like to recalibrate or re-certify your Setra

pressure transducers or transmitters, please call our Repair Department at 800-257-3872

(978-263-1400) for scheduling.

Page 12

10.0 Limited warranty & limitation of repair

Setra warrants its products to be free from defects in materials and workmanship, subject to

the following terms and conditions. Without charge, Setra will repair or replace products found

to be defective in materials or workmanship within the warranty period; provided that:

A) The product has not been subjected to abuse, neglect, accident, incorrect wiring

not our own, improper installation or servicing, or use in violation of instructions

furnished by Setra

B) The product has not been repaired or altered by anyone except Setra or its

authorized service agencies

C) The serial number or date code has not been removed, defaced, or otherwise

changed

D) Examination discloses, in the judgment of Setra, the defect in materials or

workmanship developed under normal installation, use, and service

E) Setra is notied in advance of and the product is returned to Setra transportation

prepaid

Unless otherwise specied in a manual or warranty card, or agreed to in a writing signed by a

Setra ofcer, Setra pressure, and acceleration products shall be warranted for one year from

date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but

not limited to, any implied warranty of merchantability for a particular purpose.

Setra’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot

be repaired or replaced, to a refund of the purchase price.

Setra’s liability for all other breaches is limited to a refund of the purchase price. In no instance

shall Setra be liable for incidental or consequential damages arising from a breach of warranty,

or from the use or installation of its products.

No representative or person is authorized to give any warranty other than as set out above or

to assume for Setra any other liability in connection with the sale of its products.

Setra Systems, Inc.

159 Swanson Road, Boxborough, MA 01719

800.257.3872 • www.setra.com

SS2039 Rev. K 6/2019

Loading...

Loading...