Page 1

Food Server

Supreme

MODEL:

FSPW-SS

81195 COMPLETE

81150 WARMER BASE

Thank You

...for purchasing our topping warmer.

Its temperature sensing thermostat helps reduce

food costs while the pump delivers consistent portions.

SERVE BETTER WITH PRECISE, WARM TOPPINGS

Page 2

SAFETY

WARNING-

ELECTRICAL SHOCK COULD OCCUR

This unit must be earthed or grounded.

This requires all three prongs (terminals) on cord

plug to be plugged into power source.

PARTS

According to food and safety regulations, most

foods must be stored and/or served at certain

temperatures or they could become hazardous.

Check with local food and safety regulators for

specific guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

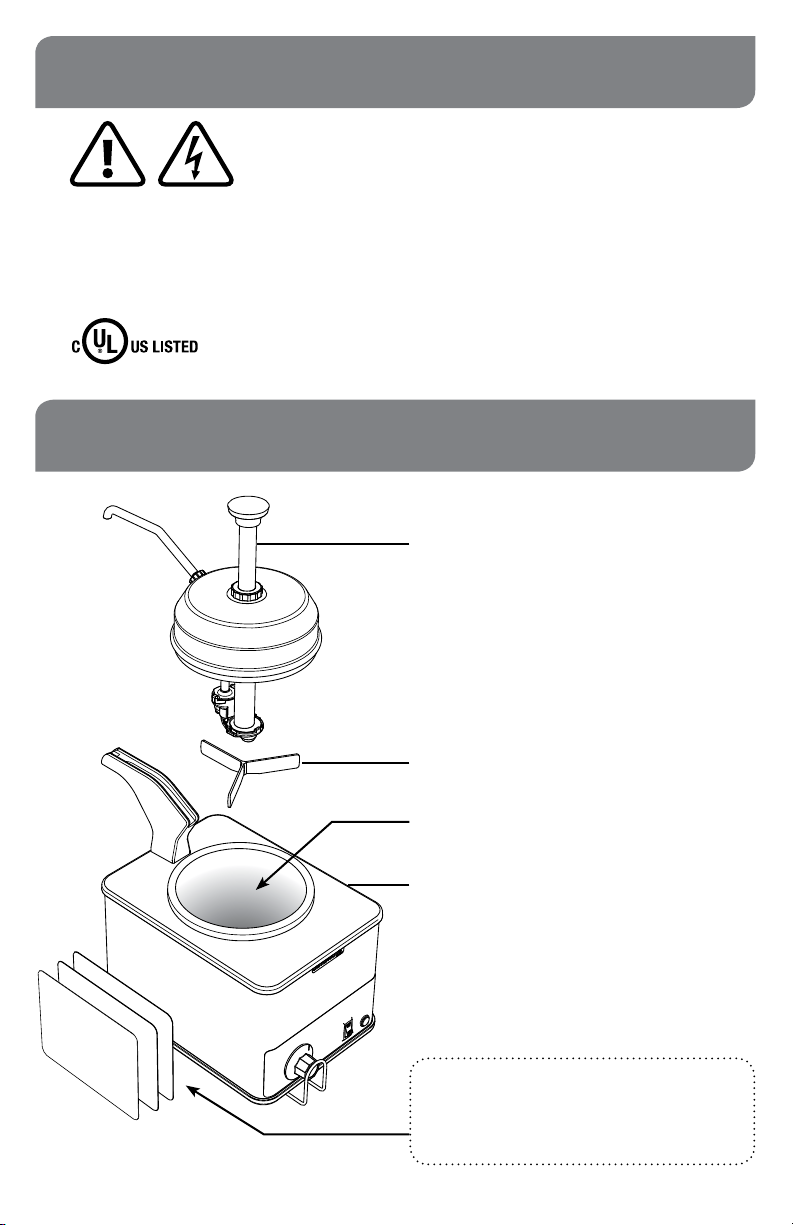

PUMP

81196

Page 2

SPACER

82063

WATER

VESSEL

BASIN

BASE

81150

MAGNETIC

DECALS

86787 CHEESE GRAPHIC

86788 FUDGE GRAPHIC

86789 CARAMEL GRAPHIC

Page 3

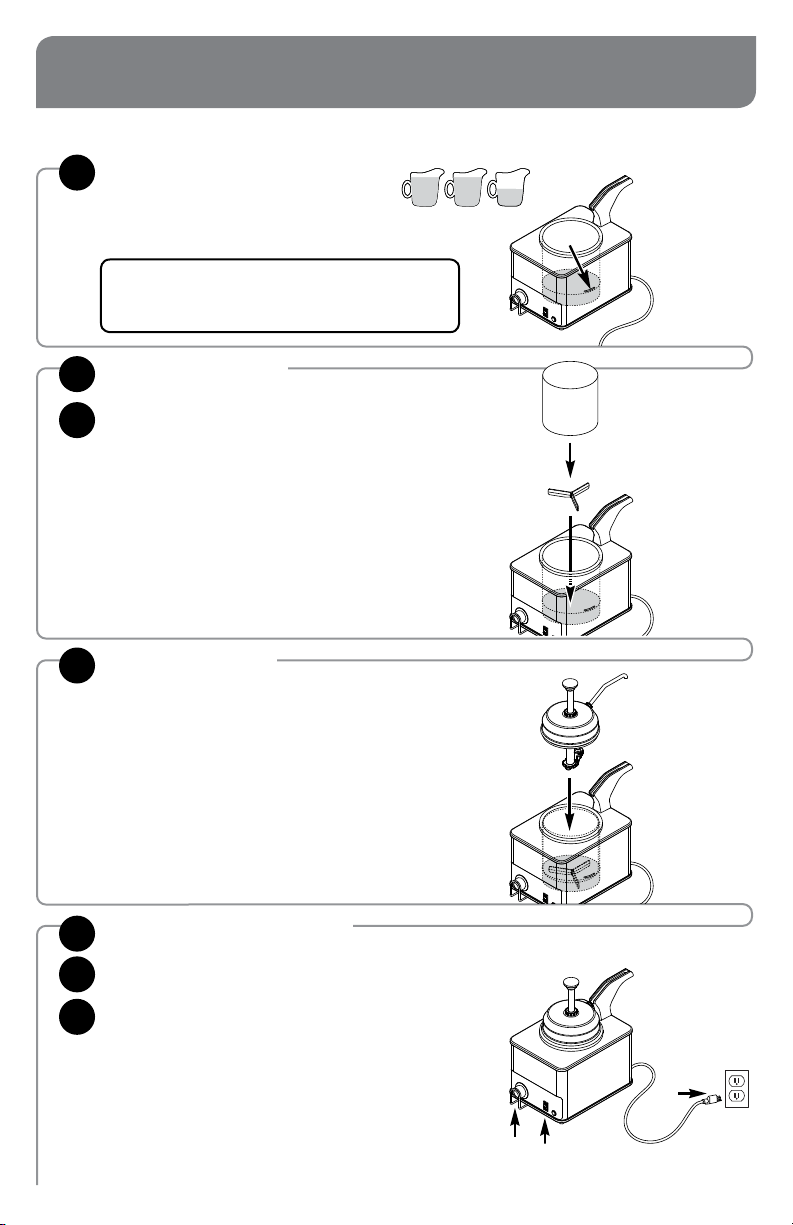

WASH ALL PARTS PROPERLY

UNIT SET-UP

BEFORE EVERY USE.

SEE SEPARATE PUMP MANUAL FOR PUMP INSTRUCTIONS.

FILL WATER VESSEL BASIN

1

• Fill 2.5 cups (20 oz/0.59 liter) of water up to

water level line inside basin.

• Do not overfill.

TIP: Check water levels throughout the holding period

to ensure even heating.

Filtered water is recommended to deter corrosion.

INSERT SPACER

2

PUT FOOD CONTAINER INTO

3

WATER VESSEL BASIN

• Product being served must be

inside #10 can or stainless steel jar.

Never place food directly into water

vessel basin of unit.

See page 6.

INSTALL PUMP

4

PLUG CORD into power source.

5

PRESS SWITCH to the “ON” position.

6

SET THERMOSTAT KNOB

7

to recommended serving temperature.

• Dial indicator uses increments of 10º F.

• Thermostat maximum is 230º F/110º C.

• To heat unit faster, thermostat may

TEMPORARILY be rotated to maximum.

Page 3

Page 4

RETHERMALIZATION HOT FOOD HOLDING

Rethermalization of food products is achieved by

this appliance when it elevates the food product

temperature from a refrigerated 40°F (4°C) to a

safe serving temperature of 165°F (74°C) within a

period of 2 hours.

PRE-HEAT UNIT

1 1

for at least 5 minutes

• Correct amount of water in basin.

• Lid closed.

• Thermostat knob set at maximum setting.

ADD FOOD PRODUCT

2 2

• Put food container into the water

vessel basin.

• Maximum capacity of food product is

3 quarts (96 oz./12 cups). Do not overfill.

MAINTAIN SAFE

3

HOT FOOD HOLDING

•

After food reaches safe serving temperature

of 165°F (74°C), maintain product

temperature at or above 150°F (66°C).

• Adjust controller if needed to avoid

overheating food.

with:

NSF International and ANSI (American National Standards Institute) list this unit as a

“Rethermalization and Hot Food Holding unit (Standard 4).”

Hot Food Holding is achieved with this appliance

when it maintains a food product temperature at or

above 150°F (66°C), in all locations throughout the

product, for a minimum of 2 hours, even if any lid,

cover, or pump is removed. The lid, cover, or pump is

recommended to help maintain product temperature.

PRE-HEAT UNIT

for at least 5 minutes

• Correct amount of water in basin.

• Lid closed.

• Thermostat knob set at maximum setting.

with:

ADD FOOD PRODUCT

• Put food which has already been

preheated to 150°F (66°C) into

container in water vessel basin.

• Maximum capacity of food product is

3 quarts (96 oz./12 cups). Do not overfill.

MONITOR FOOD CLOSELY FOR FOOD SAFETY.

The United States Public Health Service

recommends that hot food be held at a minimum

of 140°F (60°C) to help prevent bacteria growth.

COLD FOOD IS NOT TO BE ADDED TO THE

UNIT FOR RETHERMALIZATION WHILE HOT

FOOD IS BEING HELD.

SMART TIP

ALWAYS USE SPACER

BENEATH FOOD

CONTAINER

Page 4

WITH SPACER

WITHOUT SPACER

Food may overheat from resting

on the bottom.

Water may overflow into food

container.

Excess product may be left in

food container.

Page 5

UNIT TAKE-DOWN

SEE SEPARATE PUMP MANUAL FOR PUMP INSTRUCTIONS.

PRESS SWITCH to the “OFF” position.

1

UNPLUG CORD

2

CAUTION- HOT

Allow unit to cool before continuing.

REMOVE PUMP

3

REMOVE FOOD CONTAINER

4

& SPACER

EMPTY WATER FROM

5

WATER VESSEL BASIN

after each use.

TIP: Remember to empty the

water each day rather than add—

This will greatly extend the life

of your warmer.

DRY

6

thoroughly with a soft dry cloth.

Proper drying after each use helps

maintain the stainless steel.

Page 5

Page 6

CLEANING

SEE SEPARATE PUMP MANUAL

FOR PUMP INSTRUCTIONS.

WARNING-

ELECTRICAL SHOCK COULD OCCUR

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

• Ensure unit is “OFF” and unplugged.

CAUTION- HOT

Allow unit to cool before cleaning.

WASH REMOVABLE PARTS

1

• Before first use and after use daily,

disassemble and clean unit.

• Ensure unit is “OFF” and unplugged.

• Wash with dishwashing soap and hot water.

RINSE fully with clear water.

2

SANITIZE all parts according to local

3

sanitization requirements. All parts in contact

with food must be sanitized.

DRY all parts fully with a clean soft cloth.

4

CLEAN EXTERNAL SURFACES

5

• Wipe daily with a clean damp cloth.

• Dry with a clean soft cloth.

• Glass and surface cleaners approved for use

in food contact areas may be used.

CARE OF STAINLESS STEEL

This warmer and accessories are

constructed of stainless steel—

one of the best materials for food

serving and storage.

If you notice corrosion beginning on any stainless

steel surface, you may need to change the

cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

Page 6

• A mildly abrasive nylon or brass brush may

be used to remove any stubborn food or

mineral deposits on interior surfaces of unit.

• Fully rinsing and drying all parts can help

prevent corrosion. Elements and minerals in

tap water can accumulate on stainless steel

parts and create corrosion.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use products containing acids,

alkalines, chlorine, or salt. These agents can

corrode stainless steel.

• Do not use metal scrapers or cleaning pads

that could scratch surfaces.

Page 7

WIRING

UNITS 81150 | 120V | USA

Cord Assembly

1

Rocker Switch

2

Thermal Cut-Out

3

Terminal Block

4

8" Wire Assembly

5

8" Wire Assembly

6

Heater Block

7

2

10

6

1 2

3

5

11

1

98

13

BLACK

WHITE

GREEN

12

4

SHROUD WATER

VESSEL

7

Thermostat

8

Heating Element

9

Indicator Light

10

14" Wire Assembly

11

10" Wire Assembly

12

Bushing/Strain Relief

13

Page 7

Page 8

TROUBLESHOOTING

UNIT DOES NOT HEAT?

• Ensure cord is securely plugged in.

• Ensure power is available from source.

• Ensure unit is on.

• Ensure thermostat knob is set correctly.

that the correct amount of water is in basin.

• Ensure

SERVER PRODUCTS

LIMITED WARRANTY

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

PREVENT PITTING ON INSIDE

SURFACE OF VESSEL

• Empty water from water vessel basin each day.

• Thoroughly dry basin each day.

• If possible, use filtered water to fill vessel basin.

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number. Service is extremely prompt. Typically, units

are repaired and ship out within 48 hours of receipt.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days

old and will be subject to a 20% restocking charge.

Electrical parts (thermostats, heating elements, etc.)

are not returnable.

Servicing Cord: Specific tools are required for safe

and proper power supply cord removal and installation.

If cord must be replaced, only a representative of the

OEM (original equipment manufacturer) or a qualified

technician may replace cord. Cord must meet code

designation H05 RN-F requirements.

HELP or ORDERING REPLACEMENT PARTS

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600 | 800.558.8722

SPSALES@SERVER-PRODUCTS.COM

Page 8

Please be prepared with your Model, Part and

Series Numbers. This information and other

important data is located on the lid and/or base

of the unit.

Manual #01929-RevA 051016

Loading...

Loading...