Page 1

Installation Instructions for

Cold Carbonation Retrofit (CCR) Kits

Read all of the instructions carefully before beginning installation.

1) Disconnect power to the dispenser, icemaker and carbonator.

If your CCR Kit does not contain a pre-chill coil basket, go to step 18.

2) Remove ice from the dispenser bin. NOTE: Save some ice if possible to fill the bin after installation of

the coil basket.

3) Move the top-mounted icemaker to gain access to the dispenser bin. NOTE: On most installations, the

icemaker will not have to be removed.

4) Remove strip lid(s), if present.

5) Remove paddlewheel pin, agitator bar, paddlewheel, bin liner and paddlewheel area (shroud) from the ice

bin.

6) Remove any remaining ice from the bin.

7) Place coil basket into the ice bin.

8) Trim the bin top gasket to allow the tubes passing over the bin wall to lay flat against the top of the bin wall.

9) Clean the bin wall behind the corner cover with the supplied alcohol wipes.

10) Fasten the corner cover in place with the double-sided tape on the cover. The cover should be even with the

top of the bin gasket.

11) Use the silicone provided to seal the tubes to the top of the bin wall.

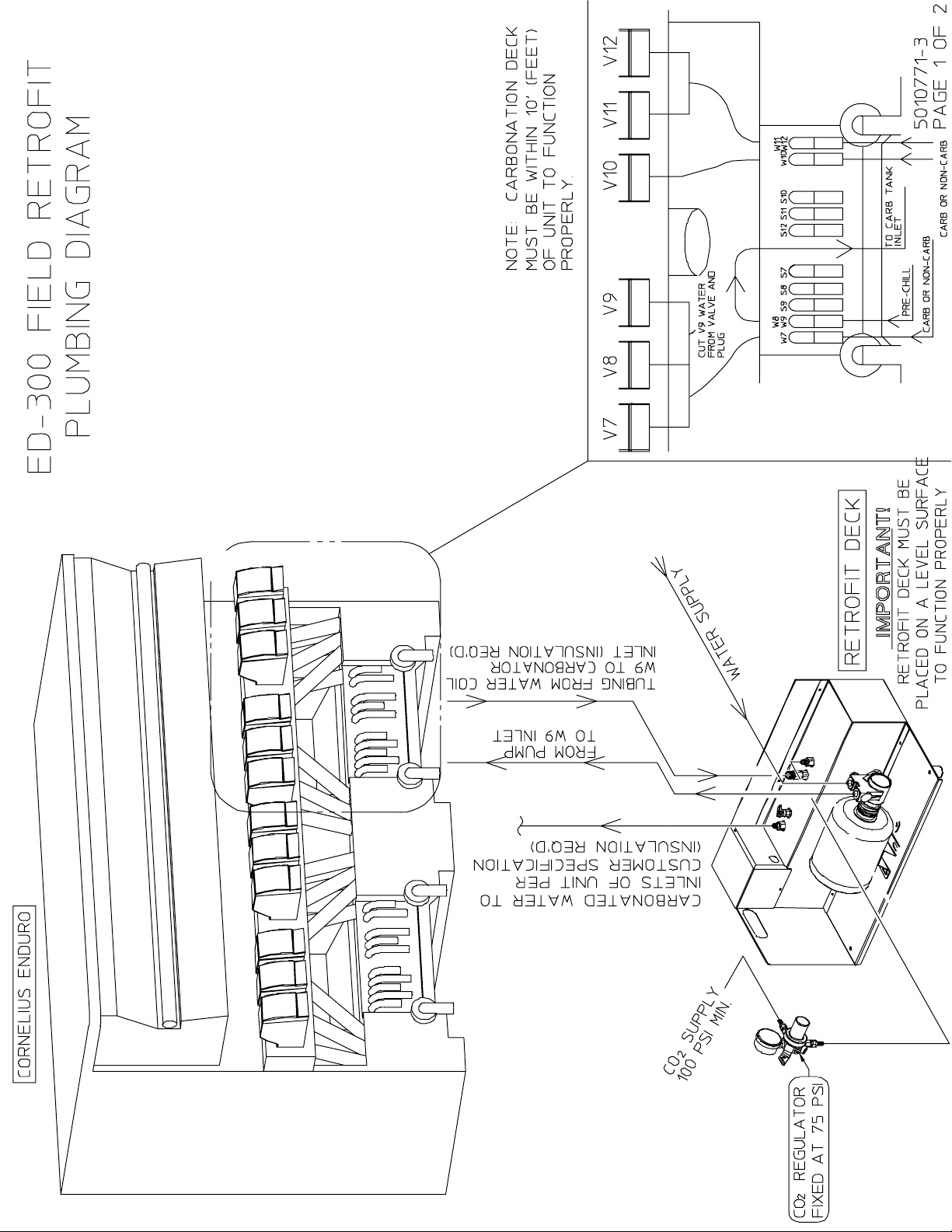

12) Re-install the paddlewheel area and bin liner. NOTE: The corner cov er bracket must be installed under

the left side of the bin liner. The bin liner screws hold the bracket and the liner in place.

13) Re-install the paddlewheel, agitator bar and paddlewheel pin.

14) Place supplied foam gasket around the bin top to seal icemaker to dispenser.

15) Re-install strip lid(s), if present.

16) Fill ice bin.

17) Move icemaker to correct position on dispenser bin.

18) Shut off water supply to dispenser and carbonator.

19) Depressurize system.

20) Connect new cold carbonation pump deck to dispenser according to the diagram for the dispenser in the

instruction packet. NOTE: Pump deck must be located within 10 feet of the dispenser. Al l chilled

water lines must be insulated.

21) Restore water to dispenser and carbonator.

22) Restore CO2 to carbonator. CO2 supply to fixed regulator on pump deck should be set to 100 psi.

23) Restore electricity to dispenser carbonator and icemaker.

24) Operate carbonated beverage valve on dispenser until a steady stream of carbonated water flows out.

Repeat for each carbonated beverage valve. NOTE: Do NOT bleed more than two (2) beverage valves

at a time.

NOTE: The incoming water pressure must not exceed 55 psi. If static water pressure is above 55 psi, it must

be regulated to 50 – 55 psi. Incoming water pressure below 45 psi and available water flow of less than 2.5

gpm may require a water booster and regulator system. To test available water flow, open supply line and fill

a one-gallon container. The container should be filled in less than 25 seconds.

NOTE: The motor cord is equipped with a 3-prong electrical plug. To ensure both the safety and proper

operation of this equipment, be certain that the electrical receptacle is a proper design so as to accept this

plug assuring that the carbonator is properly grounded.

NOTE: If the carbonator is to be installed in an area or community whose local codes require permanent

wiring, the following procedure should be followed:

1) Remove electrical box cover. Disconnect green ground wire from the metal shroud, black and white

wires from the terminal block. Remove flexible cord restraint from hole in electrical box by

compressing sides of restraint and pulling outward. Replace it with a U.L. Listed conduit connector

that should be firmly screwed into the electrical box. The three wires (white, black, and green) should

be fed through the conduit connector, brought into the electrical box and connected to the te rminal

block. WANRING: NO. 14 AWG WIRE MUST BE USED FOR FIELD WIRING. The conduit may now be

inserted into the connector and secured.

2) The green wire from the conduit should be connected to the metal shroud.

3) The white and black wires from the conduit must connect to the corresponding white and black wires

on the terminal block.

Part number 5011411

Revised 5/14/02

Page 2

CCR (Cold Carbonation Retrofit) Kit Cleaning and Sanitizing Instructions

1. Disconnect power to the pump deck

2. Disconnect the water supply to the pump deck.

3. Place the water inlet fitting into a 5-gallon bucket filled with a warm water and mild, non-foaming, antibacterial detergent solution. Use a low foaming detergent to avoid excess foam in the carbonator

tank. Foam causes liquid level probes to see a false full condition in the tank.

4. Secure the water inlet fitting and hose to the bucket. The fitting must not lose contact with the water or

the pump will be damaged.

5. Reconnect power to the pump deck.

6. Activate the beverage valve to pull the 5 gallons of detergent solution through the system.

7. Secure the water inlet fitting and hose to a 5-gallon bucket filled with clean tap water.

8. Activate the beverage valve to pull 5 gallons of tap water through the system.

9. Prepare a 5-gallon bucket of sanitizing solution consisting of 4 gallons tap water and 2 oz. Liquid,

unscented laundry bleach (5.25% CL Na O concentration). This solution will provide 200 PPM

available chlorine.

10. Secure the water inlet fitting to the 5-gallon bucket of sanitizing solution.

11. Activate the beverage valve to pull 2 gallons of sanitizing solution through the system.

12. Deactivate the beverage valve and allow the sanitizing solution to remain in the system for a minimum

of 15 minutes.

13. Activate the beverage valve and draw the remaining 2 gallons of sanitizing solution through the

system.

14. Fill a 5-gallon bucket with clean tap water.

15. Secure the water inlet fitting and hose to a 5-gallon bucket filled with clean tap water.

16. Activate the beverage valve and pull clean tap water through the system.

17. Repeat steps 3 through 16 on all beverage valves.

NOTE: These instructions are intended to sanitize the CCR Kit only. Please follow manufacturer’s

instructions to sanitize the remainder of the beverage dispenser.

Part number 5011411

Revised 5/14/02

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Loading...

Loading...