Sera PROFIBUS Technical Manual

TECHNICAL MANUAL

PROFIBUS

INTERFACE MODULE

TRANSLATION OF ORIGINAL TECHNICAL MANUAL EN

INTRODUCTION

NOTE

Keep the operating manual for future use!

ATTENTION

Subject to technical modifications!

About this instructions

Special notes in these instructions are marked with text and danger symbols.

NOTE

Notes or instructions that faciliate work and ensure a safe operation.

ATTENTION

The non-observance of these safety instructions can result in malfunctions or material damages.

WARNING

The non-observance of these safety instructions can lead to material damages and personal injuries.

Quality notes

The sera quality management and quality assurance system is certified in accordance with DIN EN ISO 9001:2015.

The sera product complies with the applicable safety requirements and accident prevention regulations.

2 www.sera-web.com

CONTENTS

SAFETY INSTRUCTIONS ............................................................................................................. 4

Personnel qualification and training .............................................................................................................................. 4

Dangers in the case of non-observance of the safety instructions ...................................................................................... 4

Safety-conscious working ............................................................................................................................................ 4

Safety instructions for owner / operator ........................................................................................................................ 4

Improper operations ................................................................................................................................................... 4

Intended use .............................................................................................................................................................. 4

TRANSPORT / STORAGE ...........................................................................................................5

Transport .................................................................................................................................................................. 5

Storage ..................................................................................................................................................................... 5

PRODUCT DESCRIPTION ............................................................................................................ 6

Type plate ................................................................................................................................................................. 6

Accessoires ............................................................................................................................................................... 6

TECHNICAL DATA ......................................................................................................................7

Electrical data ............................................................................................................................................................ 7

Ambient conditions ..................................................................................................................................................... 7

Dimensions ................................................................................................................................................................ 7

ELECTRICAL CONNECTIONS .....................................................................................................8

Installation example / bus diagram ............................................................................................................................ 10

Stub cables ............................................................................................................................................................. 11

Bus cable ................................................................................................................................................................ 11

COMMISSIONING ..................................................................................................................12

OPERATION ............................................................................................................................ 13

LED operation indicators ........................................................................................................................................... 13

Operation window ................................................................................................................................................... 13

Operating Modes .................................................................................................................................................... 14

Modules ................................................................................................................................................................. 14

Explanation of the modules ....................................................................................................................................... 14

PROFIBUS acyclic data exchange .............................................................................................................................. 14

Modules / Input ....................................................................................................................................................... 15

Modules / Output .................................................................................................................................................... 16

Settings (parameters) ................................................................................................................................................ 16

Data from module to the master ................................................................................................................................. 23

MESSAGE ...............................................................................................................................29

Diagnostics signals ................................................................................................................................................... 29

Error message.......................................................................................................................................................... 29

MAINTENANCE / DECOMMISSIONING / DISPOSAL ................................................................ 30

Maintenance and cleaning ........................................................................................................................................ 30

Decommissioning ..................................................................................................................................................... 30

Disposal .................................................................................................................................................................. 30

www.sera-web.com 3

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

WARNING

Before commissioning, installating and during operation of the sera dosing pump the respective regulations valid at the

place of installation are to be observed!

Compliance with these operating instructions and, in particular, the safety instructions, helps to:

■ Prevent danger to people, machines and the environment.

■ Increase reliability and service life of the product and the complete system.

■ Reduce repair costs and downtimes.

Personnel qualification and training

The personnel for operation, maintenance, inspection and installation must be suitably qualified for their tasks. The

owner must clearly define responsibility and supervision of the personnel.

If the personnel do not have the knowledge required, then personnel is to be trained and instructed correspondingly.

Such training can be provided by the manufacturer / supplier upon order of the owner. In addition, the owner has to

ensure that personnel have understood the operating instructions completely.

Dangers in the case of non-observance of the safety instructions

Non-observance of the safety instructions can result in hazards both for persons as well as for the environment and the product,

and can, for example, cause the following hazards:

■ Failure of important functions of the product.

■ Failure of prescribed methods for maintenance and repair.

■ Danger to people from electrical, mechanical and chemical influences.

Safety-conscious working

The safety instructions shown in this operating manual, the existing national accident prevention regulations and any internal

working, operating and safety regulations of the owner must be observed.

Safety instructions for owner / operator

Danger caused by electrical energy is to be avoided.

Improper operations

Operating safety of the supplied product is only guaranteed if the product is used as intended, according to the

descriptions in Chapter „Intended use“ of these operating instructions.

Intended use

The sera product is only to be deployed according to the intended purpose stated in the product description and the

acceptance test certificate.

If the product is to be used for other applications, then the suitability of the product for the new operating conditions

must be discussed with sera beforehand!

Criteria for operation in accordance with the intended use:

■ Operating conditions at the place of installation.

■ Voltage supply.

4 www.sera-web.com

TRANSPORT / STORAGE

General

sera products are checked for perfect condition and function previous to shipment.

Check for transport damage immediately after arrival of goods. If damage is found, this is to be reported immediately to the

responsible carrier and the manufacturer.

Storage

An undamaged packaging protects the unit during storage and should only be opened when the product is installed.

Proper storage increases the service life of the product and includes prevention of negative influences such as heat, moisture,

dust, chemicals etc.

The following storage specifications are to be obsered:

■ Storage place: cool, dry, dustfree and slightly ventilated

■ Storage temperature and relative air humidity see Chapter „TECHNICAL DATA“.

■ The maximum storage time for the standard packaging is 12 months.

If these values are exceeded, metal products should be sealed in foil and protected from condensation water with a suitable

desiccant.

Do not store solvents, fuels, lubricants, chemicals, acids, disinfectants and similar in the storage room.

www.sera-web.com 5

PRODUCT DESCRIPTION

107

The INTERFACE MODULE must only be used as communication interface between a controllable sera dosing pump and a

PROFIBUS network.

A proprietary sera protocol is used for the internal communication between INTERFACE MODULE and dosing pump.

NOTE

The sera dosing pump PROFIBUS option is integrated in the network via the device master data (DMD) file which must be

integrated in the development environment. This file contains the characteristics of the pump and information for the communication capability.

The DMD file can be downloaded by scanning the QR code (see type plate) or directly from the sera website www.

sera-web.com.

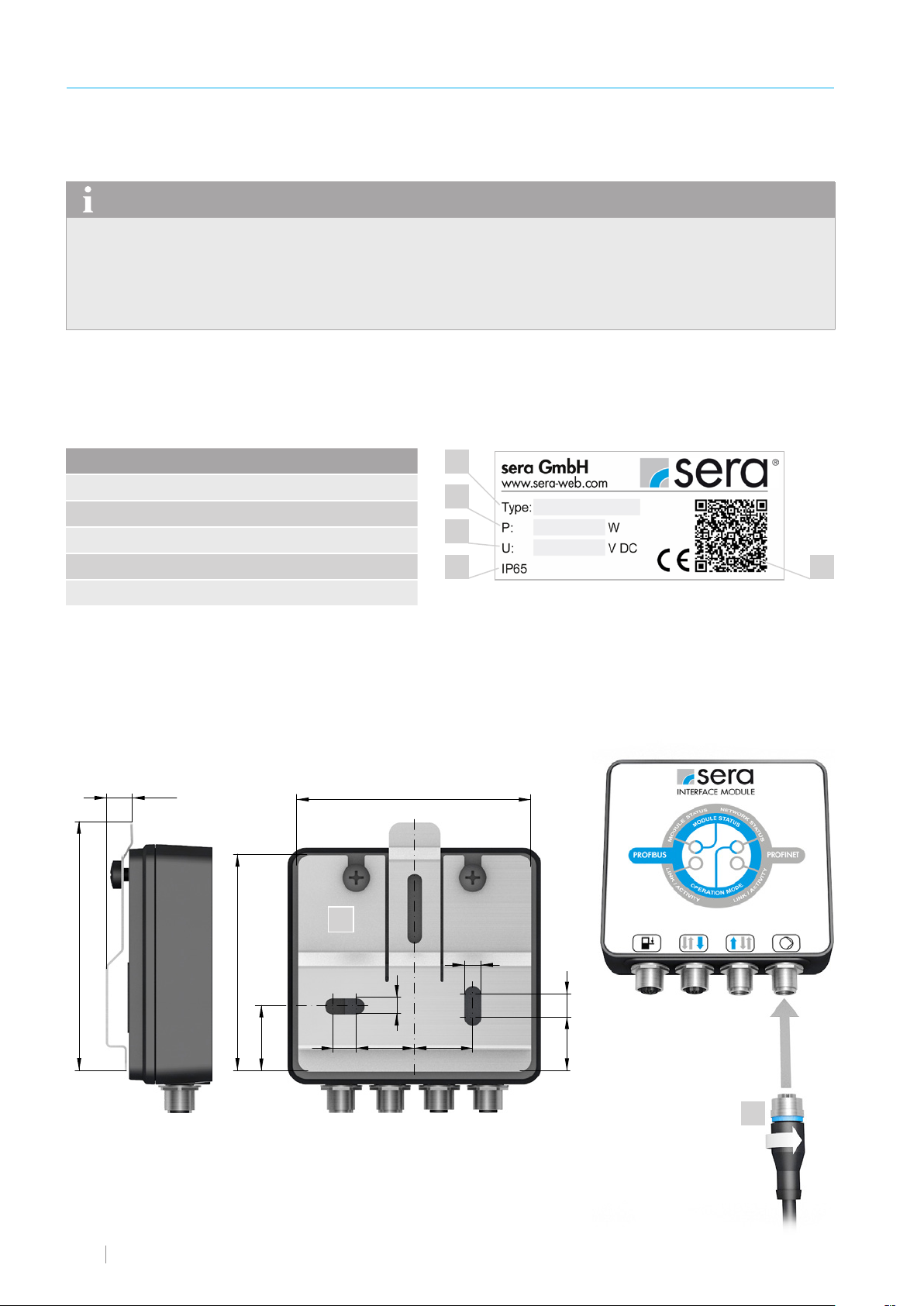

Type plate

The INTERFACE MODULE is provided with a type plate at the factory.

The information on the type plate is explained below.

No. Designation

1 Type

2 Max. power consumption

3 Supply voltage

4 Protection rating

5 QR code (for the DMD file)

Accessoires

The supply includes the following accessories:

■ Wall mount (1)

■ Sensor cable (2)

~12

100

1

2

3

4

5

6 www.sera-web.com

93

28

1

7

7

252510

23 10

2

TECHNICAL DATA

Electrical data

109

113

50

M12 x 1

102

M12 x 1

~ 43

35

TECHNICAL DATA

PROFIBUS interface

Transmission rate

Supply voltage

Max. power consumption

PROFIBUS DP-V1 (slave)

GSD File sera sera0FA2.gsd

9.6/19.2/45.45/93.75/187.5/500 kbit/s

1.5/3/6/12 Mbit/s

Automatic baud rate detection

24 V DC

1 W

Ambient conditions

Max. height above sea level 1000 m

Max. relative humidity 90%

Protection rating IP65

Electrical protection class III

Ambient temperature 0 °C to 40 °C

Dimensions

M12 x 1

35

~ 43

102

113

50

109

M12 x 1

M12 x 1

www.sera-web.com 7

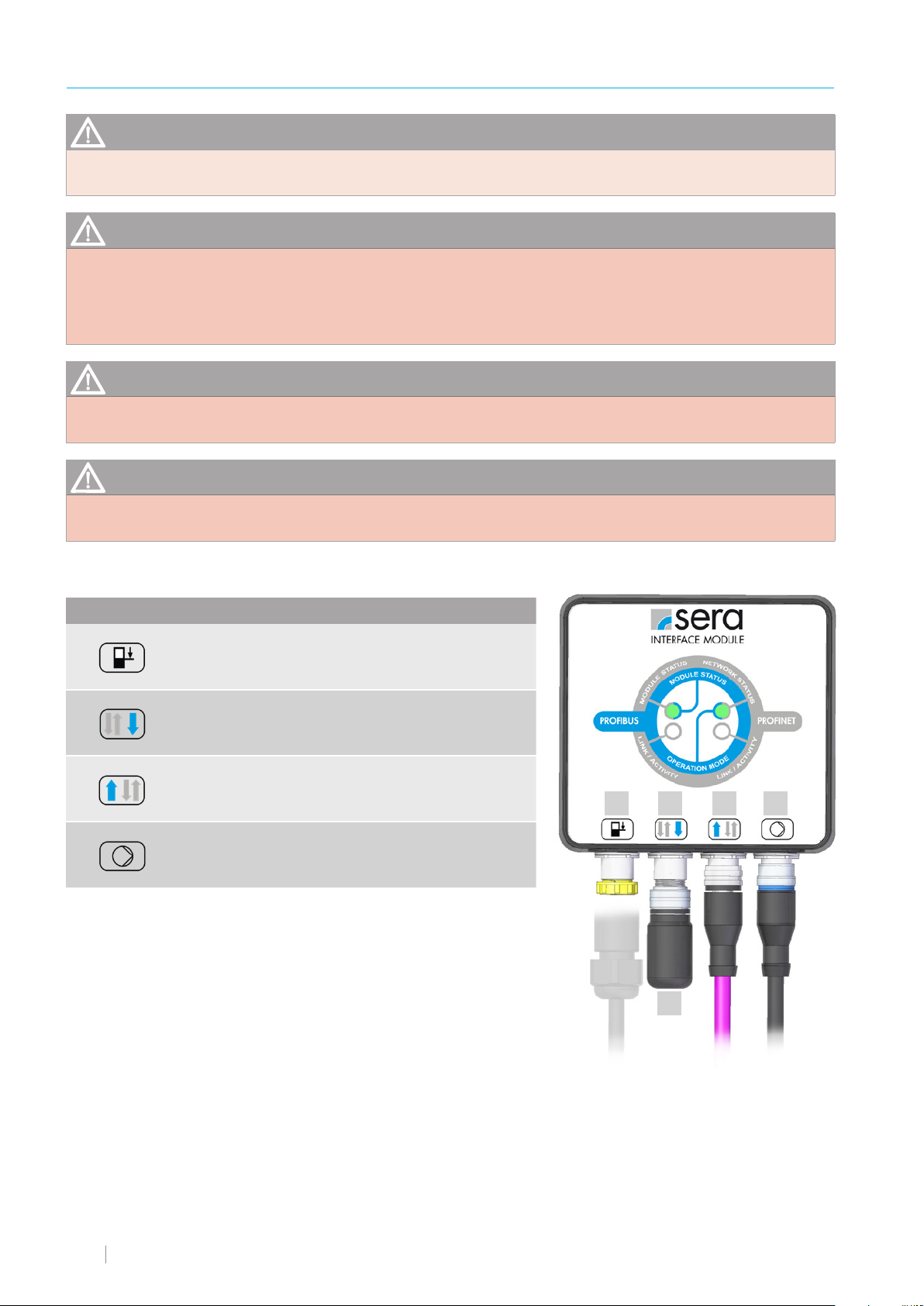

ELECTRICAL CONNECTIONS

ATTENTION

The electrical connection must be made by qualified personnel in compliance with the local regulations.

WARNING

Ensure absence of voltage of all cables and devices for the installation of electrical components!

Contact with stripped wires or live components can result in serious injuries or even death.

Any short-circuit can cause severe and expensive damage to the assemblies.

WARNING

Damaged cables should always be replaced!

WARNING

In order to guarantee the IP65 protection rating, all unused connections should be provided with a blanking plug.

Interface Assignment Function

1

2

3

4

no Y-connector necessary

*

Level

connection

PROFIBUS

Output *

PROFIBUS

Input *

Pump

connection

8-pole

5-pole

5-pole

8-pole

Pre-alarm and dry running protection

Connection to the

PROFIBUS network or

terminating resistor (5)

Connection to the

PROFIBUS network

Data transfer between

pump and INTERFACE

MODULE

1 2 3 4

5

8 www.sera-web.com

The field bus box modules are connected via the supplied connection cable.

The INTERFACE MODULE has a socket and a plug, whereby no Y-connector is necessary.

The supply voltage (+5 V DC) for the terminating resistor is only applied on the socket.

The terminating resistor is only available as plug connector.

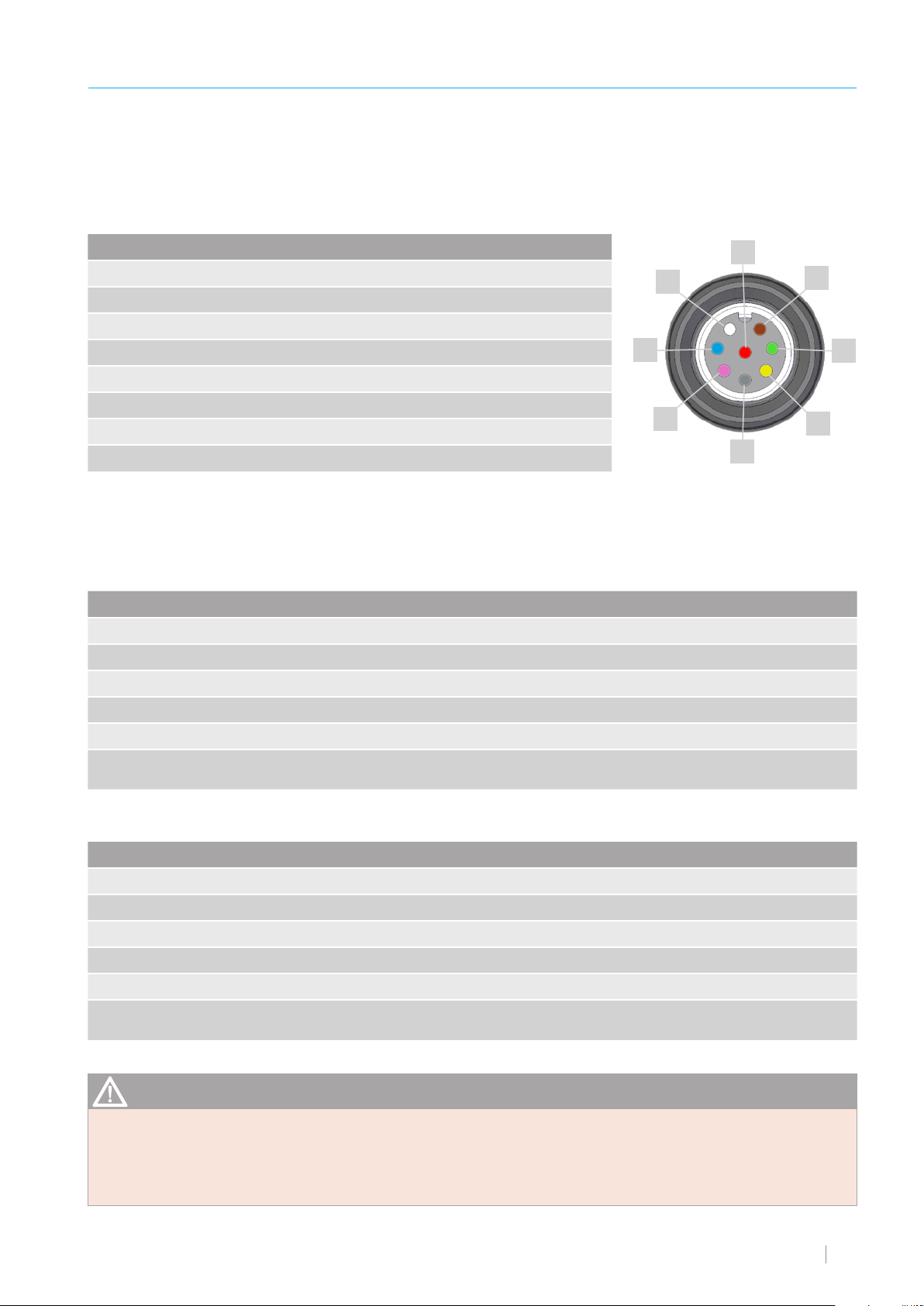

Level connection (1)

ELECTRICAL CONNECTIONS

Pin Wire colour Function (factory setting)

Pin 1 WH (white) not assigned

Pin 2 BN (brown) not assigned

Pin 3 GN (green) not assigned

Pin 4 YE (yellow) not assigned

Pin 5 GY (grey) not assigned

Pin 6 PK (pink) Pre-alarm level

Pin 7 BU (blue) Dry run

Pin 8 RD (red) GND

The inputs can be switched using a floating contact signal.

Pre-alarm and dry running are set to normally open floating contacts at the factory.

The sockets of the connections are A-coded and the assignations of the functions are symbolically labelled.

WH

BU

PK

PROFIBUS output (2)

Pin No. Signal Description

Pin 1 VP +5 V supply for terminating resistor

Pin 2 A-line Negative RxD/TxD

Pin 3 GND bus Data ground

RD

BN

GN

YE

GY

Pin 4 B-line Positive RXD/TxD

Pin 5 Shield Not connected internally, connected internally with PROFIBUS cable with shield

Thread Cable shield Must be connected externally with PE via cable filter according to PROFIBUS

standard

PROFIBUS input (3)

Pin No. Signal Description

Pin 1 NC NC

Pin 2 A-line Negative RxD/TxD

Pin 3 GND bus Data ground.

Pin 4 B-line Positive RXD/TxD

Pin 5 Shield Not connected internally, connected internally with PROFIBUS cable with shield

Thread Cable shield Must be connected externally with PE via cable filter according to PROFIBUS

standard

ATTENTION

The M12 socket is inversely coded and has 5 pins. Pin 1 is 5 V DC and Pin 3 is GND for the active terminating resistor.

These must never be used for any other functions as this can result in destruction of the device.

Pin 2 and Pin 4 carry the data of the PROFIBUS communication. These must never be reversed otherwise the communication is disrupted. Pin 5 is the shield that is not internally connected to the module.

www.sera-web.com 9

ELECTRICAL CONNECTIONS

Anschluss Pumpe (4)

Pin No. Function

Pin 1 +24 V supply voltage

Pin 2 Communication IM1

Pin 3 Communication IM2

Pin 4 not assigned

Pin 5 Communication IM3

Pin 6 Pre-alarm level

Pin 7 Dry run -

Pin 8 GND

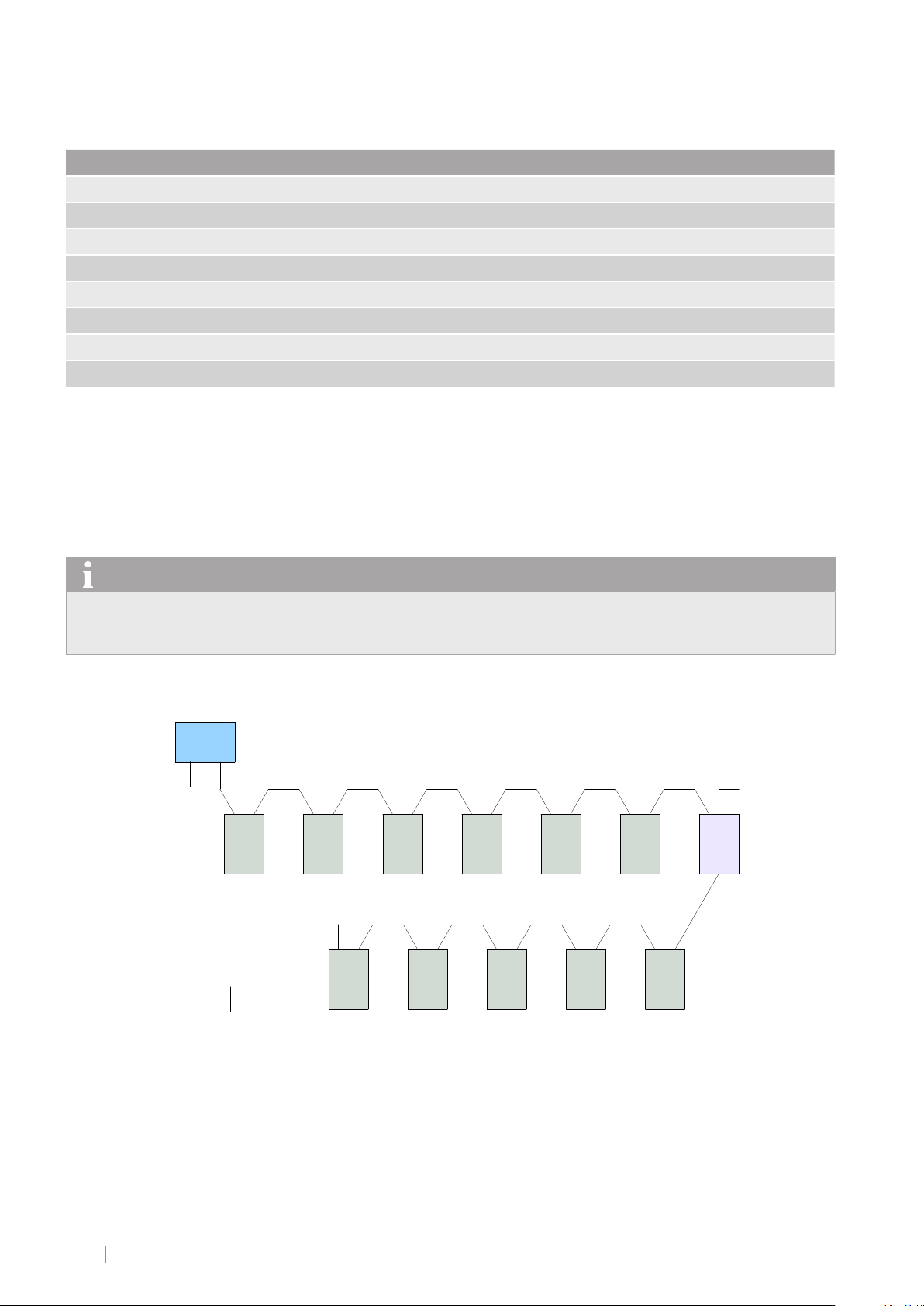

Installation example / bus diagram

All devices are connected in a bus structure (line).

Up to 32 nodes (master or slaves) can be networked within one segment.

The first and the last device must be provided with a terminating resistor. The bus segments are connected to the overall network

with repeaters (amplifiers), but remain electrically isolated. Up to maximum 126 nodes (including repeaters) can be connected

within the overall network.

The bus nodes are identified by the bus address. Each address must be unique and may only be assigned once.

NOTE

The minimum cable length between the individual nodes must be at least 1 m for transmission rates of more than 1.5 Mbit/s.

It must be ensured for the cable installation that the PROFIBUS cable does not run parallel with other live cables.

Master

Terminating resistor

Slave

Slave

Slave

Slave

Slave Slave Slave Slave

Slave Slave Slave

Repeater

10 www.sera-web.com

Loading...

Loading...