Sensotec WP9000 User Manual

Model WP9000

WeldProbe Force Gage

2080 Arlingate Lane, Columbus, Ohio 43228 USA • (614)850-5000

Sensotec, Inc.

2080 Arlingate Lane Columbus, Ohio 43228 USA

Copyright © 1999 by Sensotec, Inc. all rights reserved Telephone: (614)850-5000

FAX: (614)850-1111

Toll Free: 1-800-848-6564 E-mail: sales@sensotec.com WWW: http://www.sensotec.com

Model WP9000 WeldProbe Force Gage

Sensotec Part Number: 008-0548-00

Rev. D: March, 2003

IMPORTANT! IT IS RECOMMENDED THAT YOU READ THIS DOCUMENT THOROUGHLY BEFORE APPLYING

POWER TO THIS UNIT. THIS DOCUMENT CONTAINS

INFORMATION ON WIRING, CALIBRATION, AND USE OF FEATURES.

Sensotec continually improves its products, and thus the information herein is subject to change without notice.

TABLE OF CONTENTS

Chapter 1

INTRODUCTION

1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Quick Operation Guide . . . . . . . . . . . . . . . . . . . . . 6

1.3 Instrument Layout. . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 Low Battery Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.3 Decimal Point Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.4 Incremental Display Step . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.5 Load Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Maximum Safe Overload . . . . . . . . . . . . . . . . . . . 9

1.5 Front and Side Views . . . . . . . . . . . . . . . . . . . . . 10

1.6 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

OPERATION

2.1 Battery Replacement . . . . . . . . . . . . . . . . . . . . . 13

2.2 Turning the Instrument On and Off. . . . . . . . . . . 14

2.3 Zeroing the Display. . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Restoring the Calibrated Zero . . . . . . . . . . . . . . 15

2.5 Reading the High/Low Values . . . . . . . . . . . . . . 15

2.6 Clearing the High/Low Values . . . . . . . . . . . . . . 16

Chapter 3

FIELD SELECTABLE FEATURES

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Setup Menu Operation. . . . . . . . . . . . . . . . . . . . 17 3.3 Enable Options (“( ”) Description . . . . . . . . . . . 19

3.3.1 Auto-off Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 3.3.2 Always-On Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 3.3.3 [Zero] Button Disable Feature . . . . . . . . . . . . . . . . . . . . . .20 3.3.4 [Hi/Lo] Button Disable Feature . . . . . . . . . . . . . . . . . . . . .20 3.3.5 [Clear] Button Disable Feature . . . . . . . . . . . . . . . . . . . . .20

3.4 Enable Options (“( ”) Menu Item . . . . . . . . . . . . 21 3.5 Engineering Units (“81,W”) Menu Item . . . . . . . . . 22 3.6 Auto-off time (“$R))”) Menu Item . . . . . . . . . . . . 23 3.7 Update Rate (“U$W(”) Menu Item . . . . . . . . . . . . 23 3.8 Internal Software Version (“Y(U”) Menu Item . . . 24

Chapter 4

CALIBRATION

4.1 Calibration Considerations. . . . . . . . . . . . . . . . . 25

4.2 Required Forces . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Calibration Procedure . . . . . . . . . . . . . . . . . . . . 27

4.3.1 Enter Forces to be Applied . . . . . . . . . . . . . . . . . . . . . . . .27

4.3.2 Apply Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.4 Rear View of Front Face Panel . . . . . . . . . . . . . 31

4.5 Calibration Error Messages . . . . . . . . . . . . . . . . 32

Chapter 5

TROUBLESHOOTING

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 Help Message Codes. . . . . . . . . . . . . . . . . . . . . 33

5.3 Troubleshooting Hints . . . . . . . . . . . . . . . . . . . . 34

Chapter 1

INTRODUCTION

1.1 Overview

The WeldProbe is a rugged, hand-held instrument for accurately calibrating weld electrode force on resistance welding machines. This device helps ensure compliance with ISO 9000 or QS 9000 quality requirements by taking the guesswork out of setup. Measuring accurate force levels at the electrode tips helps eliminate inaccuracies of the line-pressure readings, air cylinder friction, and mechanical wear.

The WeldProbe is designed for long life in the harsh welding environment by using Sensotec’s standard fullywelded load cell construction and NEMA 4 electronics packaging. The easy-to-use design includes a simple push-button format and a large LCD display that provides both continuous and peak (maximum) force values in key- pad-selectable engineering units.

High-speed digital electronics sample readings during the squeeze-weld-hold sequence and capture the peak force for display. A simple, one-button CLEAR prepares the instrument for the next reading. Two standard 9-volt alkaline batteries provide 80 hours of continuous use. Battery life is maximized with a programmable power-off feature.

Model WP9000 WeldProbe Force Gage page 5

1.2 Quick Operation Guide

1.Depress the [On/Off] button to power up the instrument. Wait about 5 seconds for the instrument to warm up.

2.If a non-zero value appears on the display, press and hold the [Zero] button until the display reads “ ” (this takes about three seconds).

3.Insert probe, initiate welder, and take reading.

4.Press and hold the [Hi/Lo] button until the display reads “+, ” to read the maximum (or peak) force value.

5.Press [Clear] to clear the maximum value in preparation for the next reading.

6.As shipped from the factory, the instrument will automatically shut itself off if no buttons have been pressed in four minutes.

Note: The WP9000 is a force calibration device designed to measure the force between electrodes on resistance welders. It can withstand passing current through the force transducer.

It is recommended for the saftey of the operator and the WP9000 to disable current before operation. Many repeated current firings may damage the weld force indicator.

page 6 Introduction

1.3 Instrument Layout

1.3.1 LCD Display

The 4½-digit liquid crystal display (LCD) readout displays the load applied to the instrument, interacts with the user when the instrument is being set up or calibrated, and indicates if there is a problem with the instrument.

When a WP9000 instrument is turned on, it illuminates all LCD segments. Then, the engineering units the gauge will be using appears on the display. Most WP9000 instruments are calibrated in pounds (“/E6”) and the instrument has conversion factors for many standard engineering units built in. However, if the instrument displays 63&/

(special) it has been specially calibrated to another engineering unit at the factory. In that case, the serial number tag on the top of the instrument will indicate the engineering units being used and the capability to select other engineering units should not be used.

After the display of the engineering units, the force applied to the load cell is shown on the display. If the load applied to the load cell is above the instrument's ability to measure, the display will indicate this overrange condition by showing a " " on the far left hand side of the display.

The display will read " " if the instrument is underranged.

1.3.2 Low Battery Indicator

On the left side of the display, just above the minus sign, is the low battery indicator (in the shape of an arrow).

When the battery voltage is less than 5 volts, the display will be blanked and the low battery indicator will illuminate to indicate that the batteries should be replaced. The low battery indicator can be seen when the instrument is turned on and all segments of the display are momentarily lighted.

Model WP9000 WeldProbe Force Gage page 7

When the low battery indicator is illuminated, change the batteries as soon as possible. The instrument will not function if the battery voltage falls below approximately 4 volts.

1.3.3 Decimal Point Position

The decimal point position automatically changes depending upon:

•the user selected engineering units

•the load range of the instrument

The decimal point position cannot be changed manually.

1.3.4 Incremental Display Step

The incremental display step is the value by which the last digit of the display will change. This value will be either 1, 2, or 5 display counts. It automatically changes depending upon:

•the user selected engineering units

•the load range of the instrument

The incremental display step cannot be changed manually.

1.3.5 Load Cell

The WP9000 instrument can be ordered with one of two types of load cells: those with a load sensing button, and those with a load sensing indentation. The load sensing button is useful when the WeldProbe is used with projection welders. The load sensing indentation is useful for most spot welding applications.

page 8 Introduction

1.4 Maximum Safe Overload

Maximum safe overload is the force which the instrument can experience occasionally without loss of accuracy or permanent damage.

Table 1: Maximum Safe Overload

Force Range (lbs.) |

Maximum Safe Overload |

||

(lbs.) |

|||

|

|

||

|

|

||

|

|

||

0 - 500 = 500 |

750 |

||

|

|

|

|

0 - 1000 |

= 1K |

1500 |

|

|

|

|

|

0 - 2000 |

= 2K |

3000 |

|

|

|

|

|

0 - 5000 |

= 5K |

7500 |

|

|

|

|

|

0 - 10000 |

= 10K |

15000 |

|

|

|

|

|

Model WP9000 WeldProbe Force Gage page 9

1.5 Front and Side Views

Figure 1-1: Model WP9000 Front View

Figure 1-2: Model WP9000 Display Side View

page 10 Introduction

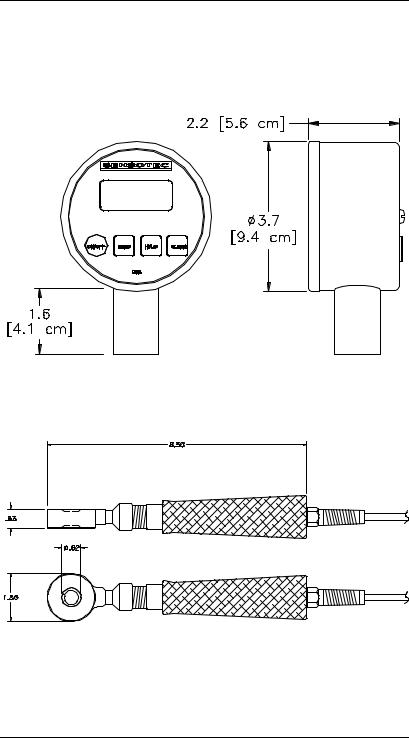

1.6 Dimensions

Figure 1-3: Model WP9000 Display Dimensions

Figure 1-4: Model WP9000 Load Cell Dimensions (2000 lbs. Range with Sensing Indentation)

Model WP9000 WeldProbe Force Gage page 11

1.7 Specifications

Sensotec continually improves its products, and thus these specifications are subject to change without notice.

Display Diameter: |

3.7 inches |

Accuracy: |

0.5% |

Operating Temperature: |

30 to 180 ºF |

Force Ranges 0 to: |

1000, 2000, 5000, 10000 lbs. |

Overload Capability: |

150% of full-scale range |

Calibration Engineering |

lbs |

Units: |

|

Built-in Engineering Unit |

lbs, Kg, kN, N, g (field selectable) |

Conversion: |

|

Sampling Rate: |

19.2kHz internal; 24Hz display update |

Power Requirements: |

two 9 Volt alkaline batteries provide |

|

approximately 80 hrs continous life |

Load Cell Material: |

BeCu |

Housing Material: |

Stainless steel |

High and Low Capture: |

Standard, same update rate as dis- |

|

play |

Zero and Span Adjust- |

Standard |

ment: |

|

Front Panel Membrane |

Tactile feedback, raised buttons |

Calibration Data: |

Stored on non-volatile memory chip |

Package: |

All-welded load cell; NEMA 4 rated |

|

display unit |

Weld Current: |

Survives accidental current discharge |

page 12 Introduction

Loading...

Loading...