Page 1

Dual Output Pressure Sensor

Model DS

User’s Manual

008-0627-00

Version 1.10

Page 2

Table of Contents

Chapter 1 Introduction

Chapter 2 Command Summary

Chapter 3 Command Format

Chapter 4 System Commands

Chapter 5 Digital Output Commands

Chapter 6 Analog Output Commands

Chapter 7 Electrical Connections

Page 3

1.1 Overview

The Model DS Pressure Sensor combines high performance with the versitility of

both analog and digital outputs. The high accuracy pressure readings are fully

temperature compensated across the entire operating temperature range of the

transducer. In addition the Model DS Pressure Sensor maintains a maximum

update rate of 2500 times a second for both digital and analog outputs.

The Model DS provides a configurable analog ouput of 0 to 5 VDC. In default

operation, the fully temperatrue compensated voltage output is proportional to

the pressure applied to the pressure port. Alternately the analog output may be

configured for independent control by the user through the digital interface.

The Model DS provides a digital output of either a RS-232 full duplex interface or

a RS-485 half duplex interface which allows for multi-unit operation. Each

transducer has an universal address for setup and an user defined address for

multidrop operation. In addtion to pressure readings, all operating parameters of

the transducer are accessible through the digital interface. For example, user

adjustment of span and offset are provided for each output independently

through the digital interface.

1. INTRODUCTION

The following chapters detail the features and operating parameters of Model DS

Pressure Sensor.

1.2 SPECIFICATIONS

Power Requirements: 15 - 28 VDC

50 mA typ.

75 mA peak (during RS-485 operation)

Pressure:

Accuracy:

Digital: ± 0.05% of F.S. typ.

± 0.10% of F.S. max.

Analog: ± 0.10% of F.S. typ.

± 0.20% of F.S. max.

Resolution:

Digital: 0.05% or 5 significant digits

Analog: 1.4 mV steps

Operating Temperature Range: -40 to 180 Degree F

Page 4

Digital output: RS-485 Half Duplex, or RS-232 Full Duplex

Baud Rates: 1200, 2400, 4800, 9600, 19.2K,

38.4K, 57.6K, 115.2K

Data Framing: 1 start bit, 8 data bits, 1 stop bit

Parity: No parity

Addressing; User assigned

1 null address (address not assigned)

Bus operating mode: Response to a designated unit request

(Master/slave)

Pressure Units: Shipped as PSI, field selectable

Update Rate: 2500 updates per second, maximum

Mechanical Shock: TBD

Thermal Shock: TBD

Vibration: TBD

Long term stability: TBD

Media Compatibility: Exposed surfaces are 316L stainless steel

Page 5

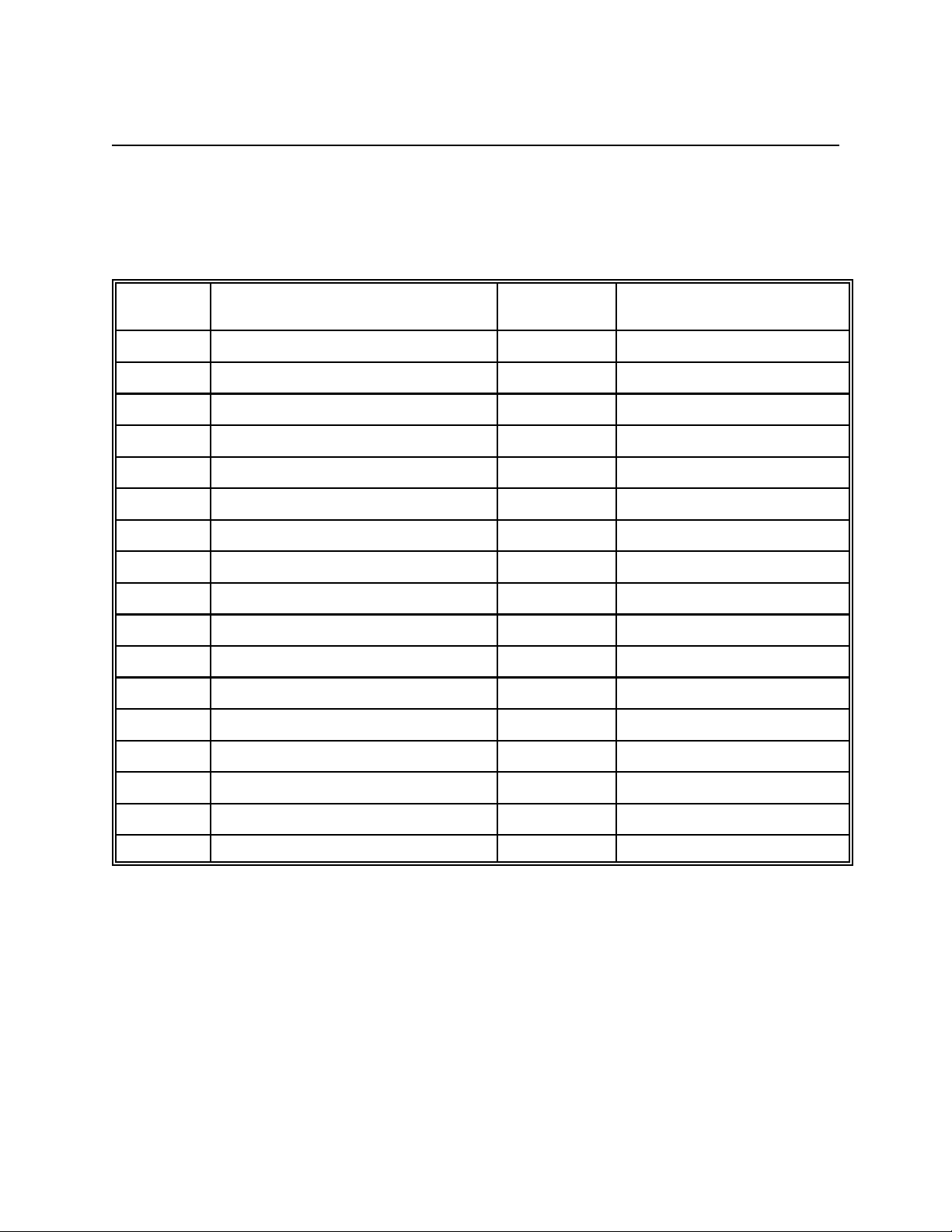

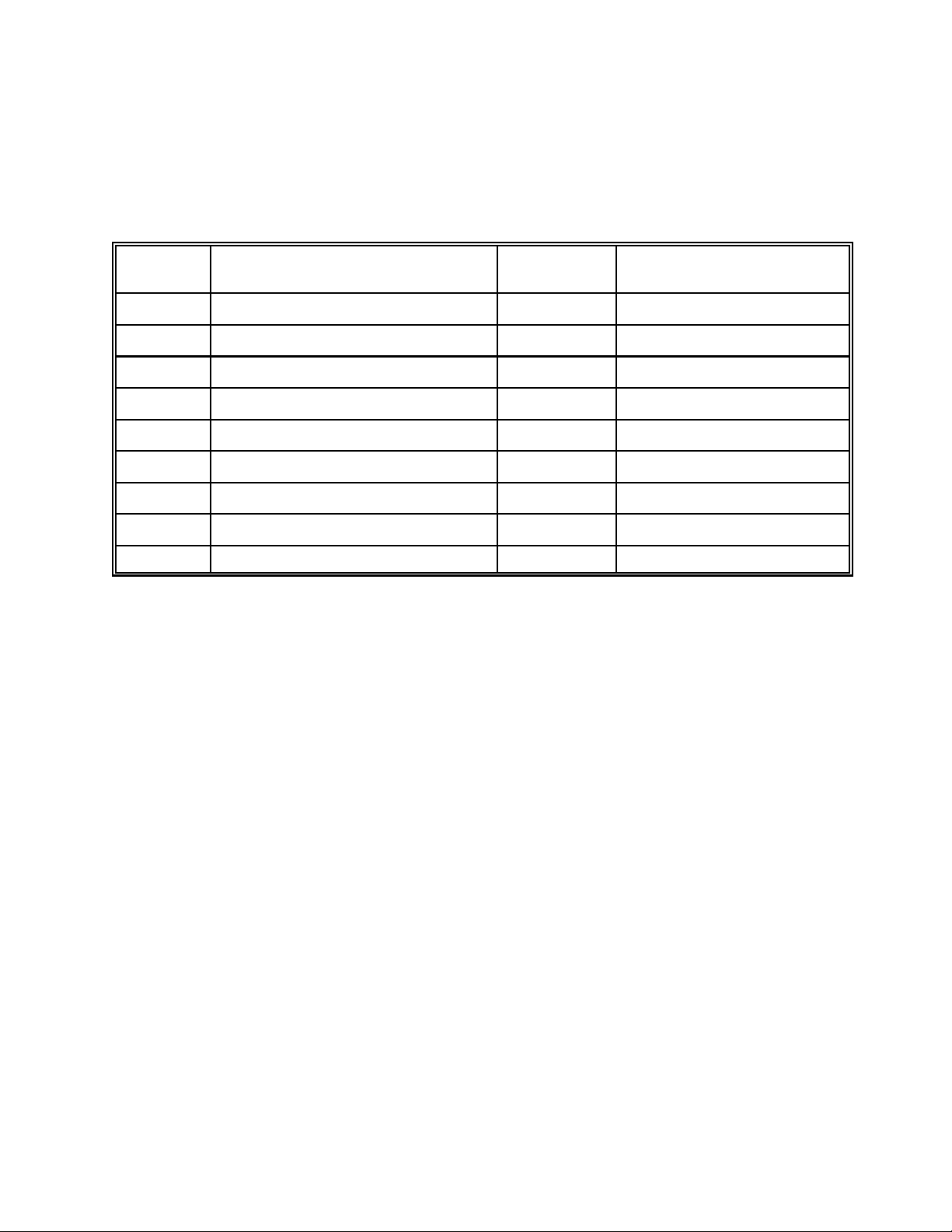

2. Command Summary

2.1 System Commands

Detailed descriptions of each system command is given in alaphabetical order in

Chapter 4.

Command

Code

DC Display Temperature (Centigrade) No sddd<CR>

DP Display User Defined String No xxxxxxxxxxxxxxxx<CR>

DR Display Errors No Err_x<CR>

DT Display Temperature (Fahrenheit) No sddd<CR>

FC Read Calibration Date No dd/dd/dd<CR>

FE Read Serial Number No dddddd<CR>

FR Restore Factory Default Settings Yes OK<CR>

FT Test Data Storage Checksum No OK<CR>

II Set Update Rate Yes OK<CR>

R4 Read Unit Address No dd<CR>

R5 Read Full Scale Range No sd.dddddEsdd<CR>

RM Read Mfg. Part Number No xxxxxxxxxxxx<CR>

RR Read Software Revision No ddd-dddd-dd d.dd<CR>

Description Write Enable

Required

Typical Response

SP Set User Defined String Yes OK<CR>

W1 Write Baud Rate Yes OK<CR>

W4 Write New Address Yes OK<CR>

WE Write Enable No OK<CR>

Typical Response Key: d - decimal digit s - sign indicator: “+” or “-”

x - any valid ASCII character <CR> - Carriage Return

All other characters and punctuation appear as is.

Page 6

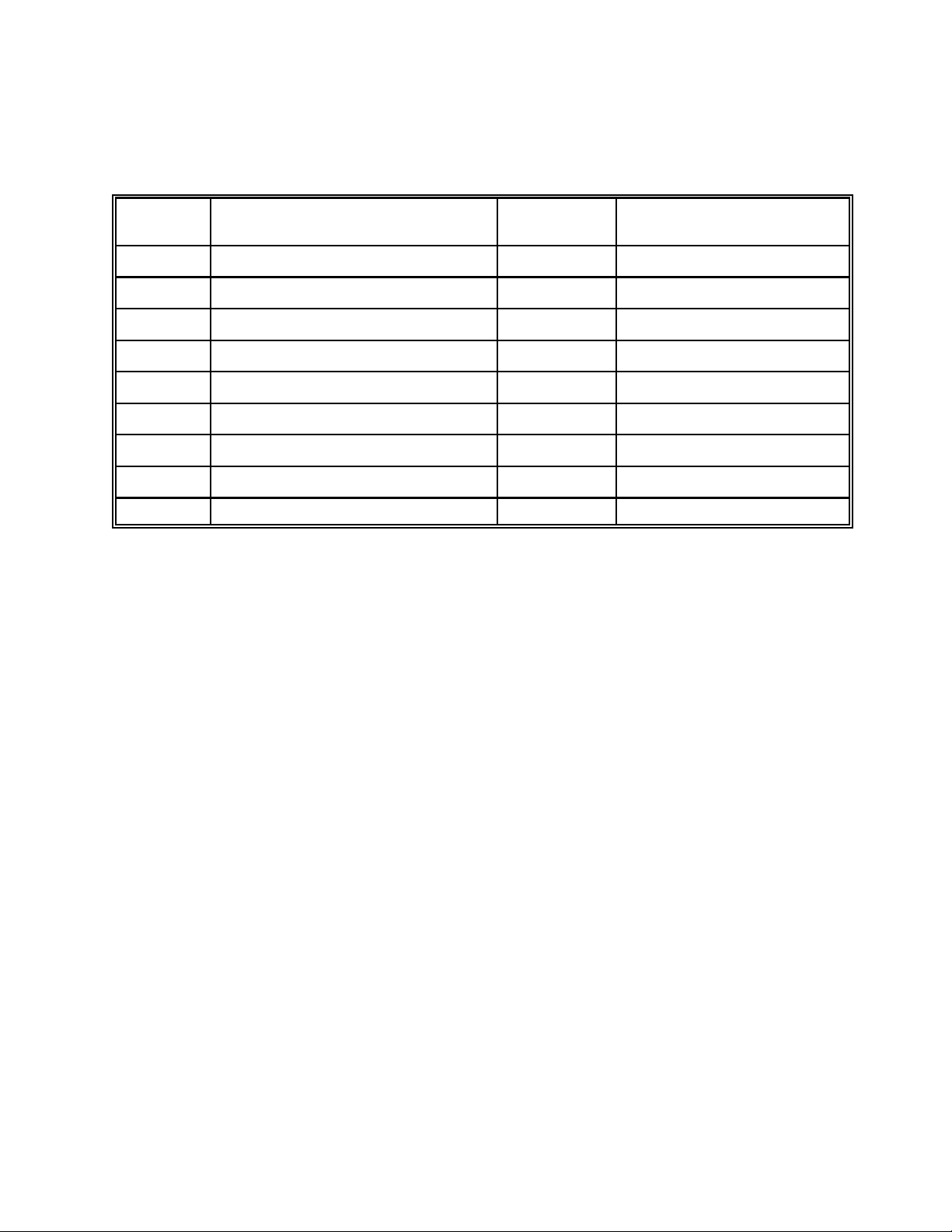

2.2 Digital Output Commands

Detailed descriptions of each digital output command is given in alaphabetical order in

Chapter 5.

Command

Code

D0 Display Digital Pressure Reading No sd.dddddEsdd<CR>

DB Display Digital Zero Adjustment No sd.dddddEsdd<CR>

DE Display Eng. Units Conversion Factor No sd.dddddEsdd<CR>

DM Display Digital Span Adjustment No sd.dddddEsdd<CR>

R6 Read Engineering Units Label No xxxx<CR>

SB Set Digital Zero Adjustment Yes OK<CR>

SE Set Eng. Units Conversion Factor Yes OK<CR>

SM Set Digital Span Adjustment Yes OK<CR>

W6 Write Engineering Units Label Yes OK<CR>

Typical Response Key: d - decimal digit s - sign indicator: “+” or “-”

Description Write Enable

Required

x - any valid ASCII character <CR> - Carriage Return

All other characters and punctuation appear as is.

Typical Response

2.3 Analog Output Commands

Page 7

Detailed descriptions of each analog output command is given in alaphabetical order in

Chapter 6.

Command

Code

DA Display Analog Output Voltage No sd.ddd<CR>

RN Read Analog Output Offset No sd.dddddEsdd<CR>

RO Read Analog Output Scaling Factor No sd.dddddEsdd<CR>

SA Set Analog Output No OK<CR>

SS Select Analog Output Source Yes OK<CR>

SV Set Analog Output Default Value Yes OK<CR>

SY Read Analog Output Default Value No sd.dddddEsdd<CR>

WN Write Analog Output Offset Yes OK<CR>

WO Write Analog Output Scaling Factor Yes OK<CR>

Typical Response Key: d - decimal digit s - sign indicator: “+” or “-”

Description Write Enable

Required

x - any valid ASCII character <CR> - Carriage Return

All other characters and punctuation appear as is.

Typical Response

Page 8

3.1 Serial Protocol

The Model DS pressure transducer uses either a half duplex RS-485 or a full

duplex RS-232 hardware interface for serial communications. All serial

communication is in ASCII format using 8 data bits, one start bit, one stop bit and

no parity bits. Baud rates of 1200, 2400, 4800, 9600, 19.2K, 38.4K, 57.6K and

115.2K are available. As shipped from the factory, the baud rate is set to 9600

baud, the default baud rate.

3.2 Command Format

Each command is a string of ASCII characters. The following represents the

general format of the transducer commands:

#aaccxx...xx<cr>

# The pound sign is the start of command character.

3. COMMAND FORMAT

aa This two byte field is the unit address.

cc This two byte field is the command.

xx...xx The data field is an optional field of up to 18 characters.

<cr> The carriage return is the end of command character.

3.2.1 Start of Command

The pound sign, ‘#’, ASCII code 35 decimal, indicates the start of a command.

The transducer continually monitors the serial communication bus, ignoring all

characters until the pound sign is detected. Once the pound sign is detected the

transducer enters receive mode and begins looking for a valid address.

3.2.2 Unit Address

The unit address is a two character field of ASCII alphanumeric characters. The

address may be any combination of numerals or letters and is case sensitive.

Each transducer supports two addresses. The first is an universal address to

which all transducers respond. The address of ‘ff', (ASCII codes 102 decimal,

102 decimal) is reserved as the universal address. This universal address should

not be used when multiple transducers are setup as a RS-485 network. All

Page 9

transducers on the network will respond to this address at the same time

resulting in corrupted responses.

The second address is an unique, user defined address to which only the

specific transducer will respond. The user must define this unique address using

the W4 command. As shipped from the factory, the default value for this address

is ‘00" (ASCII codes 48 decimal, 48 decimal).

After the transducer detects the start of command character and enters receive

mode, it monitors the serial communications port for a valid address. If the

address found is the universal address or the transducer’s unique address, the

transducer will continue to process the serial communications for a command.

If the address found is not the universal address or the transducer’s unique

address, the transducer will exit receive mode and will return to monitor the serial

communication for a start of command character. If characters received after the

start of command character are not ASCII alphanumeric characters, the

transducer also exits receive mode.

3.2.3 Command

A command is comprised of two ASCII alphanumeric characters. Commands are

not case sensitive; either upper or lower case letters may be used. The following

chapters offer a detailed explanation of each command.

3.2.4 Data Field

The data field is an optional field of up to 16 ASCII characters. This field contains

the data for commands which write data to the transducer. Valid characters for

the data field include all alphanumerics, decimal point, plus sign, and minus sign.

3.2.5 End of Command

The carriage return, ASCII code 13 decimal, indicates the end of a command. If

a command requires no additional data, the end of command character follows

the two character command. If a command requires additional data, the end of

command character follows the data field.

The transducer does not process a command until it receives an end of

command character. If the transducer does not receive a end of command

character within approximately 5 seconds after receiving a start of command

character, the command is aborted.

3.3 Command Response

Page 10

The digital transducer transmits only in response to a command which uses its

unique address (or the universal address of ‘ff'). The transducer itself never

initiates a transmission.

There are two basic types of responses. The transducer will transmit an ASCII

string in response to commands which request data. This ASCII string is

terminated by a carriage return. For commands which do not request data, the

transducer acknowledges the command with ‘OK’ followed by a carriage return.

Examples of the typical response for each command are included in the

following chapters.

NOTE: Commands which change the operating parameters of the transducer are

implemented immediately. Changes are written to nonvolatile memory with each

command issued. Nonvolatile memory is guaranteed for 20,000 writes. A

checksum command is available to test the integrity of the nonvolatile memory.

The transducer indicates the following error conditions:

Response Description

Err_NaC Not a Command: The command was not recognized as a

valid command by the transducer.

Err_AcD Access Denied: The required Write Enable command did

not preceed the present command.

Err_NaN Not a Number: The data accompanying the command do not

represent a valid number.

Err_InF Invalid Format: The data accompanying the command do

not represent a valid option for the command.

Err_CsF Checksum Error:This response to the FT command

indicates a checksum error in data storage.

Err_OvR Over Range: This response to the D0 command indicates

the input pressure is approximate 6 % above the full scale

range of the transducer.

Err_UnR Under Range: This response to the D0 command indicates

the input pressure is approximately 3 % below the range of

the transducer.

4. SYSTEM COMMANDS

Page 11

4.1 DC Display Temperature (Centigrade)

DESCRIPTION

The DC command reads the temperature at the transducer’s sensing element.

This value is provided as a diagnostic tool. The accuracy of this value is not

guaranteed but is typically within ±2 degrees Centigrade.

The response to this command is a varible length string representing the

temperature in degrees Centigrade.

EXAMPLE

#00DC

This command, followed by a carriage return, returns the temperature in

Centigrade of the transducer with the address of ‘00'.

Typical responses to this command illustrating the varible length of the response

include:

43

8

-5

-14

4.2 DP Display User Defined String

DESCRIPTION

The DP command displays the character string set by the SP command. This

character string is 16 characters in length. The default value for this character

string is 16 blank spaces (ASCII code 32 decimal).

EXAMPLE

#00DP

This command, followed by a carriage return, reads the character string set by

the SP command from a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

Page 12

Part # 456-1003P

For this example the transducer transmits the character string set by the SP

command example below.

4.3 DR Display Errors

DESCRIPTION

At power up the Model DS performs a complete checksum test of all stored data.

During operation the checksum test is repeated periodically. Also during

operation the transducer continually monitors the pressure and temperature

signals for out of range conditions. The DR commands displays the results of

these test.

When an error occurs, the transducer sets the appropiate bit of a status byte to 1

to indicate the presence of an error. Bits set to 0 indicate the absense of an

error. This status byte is available as the last character of the response to this

command.

The following is the bit assignment of this status byte:

bit 0 Temperature over range error

bit 1 Temperature under range error

bit 2 Pressure over range error

bit 3 Pressure under range error

bit 4 1

bit 5 1

bit 6 Checksum error

bit 7 0

(Bit 0 is the least significant bit of the status byte. Note that three of the bits are

constants; this ensures that the status byte is an ASCII printable character.)

Error bits set in the status byte are nonvolatile: bits indicating errors will remain

set after the error condition ceases to exist. Using the DR command to read the

error status will clear all error indications. Removing power from the transducer

will also clear all error indications.

EXAMPLE

Page 13

#00DR

This command, followed by a carriage return, returns the error status of the

transducer with the address of ‘00'.

In response to this command, the transducer transmits the following:

Err_0

In this case, the last character of the response is the ASCII character for zero, 30

hexadecimal. The binary value of this character is 0011 0000 indicating that no

errors have been detected since the last time the error status was read.

As another example, the response to this command could be

Err_4

In this case the last character of the response is the ASCII character for the

numeral 4, 34 hexadecimal. The binary value of this character is 0011 0100. Bit

2 is set to a one indicating a pressure over range error was detected since the

last time the error status was read.

4.4 DT Display Temperature (Fahrenheit)

DESCRIPTION

The DT command reads the temperature at the transducer’s sensing element.

This value is provided as a diagnostic tool. The accuracy of this value is not

guaranteed but is typically within ±4 degrees Fahrenheit.

The response to this command is a varible length string representing the

temperature in degrees Fahrenheit.

EXAMPLE

#00DT

This command, followed by a carriage return, returns the temperature in

Fahrenheit of the transducer with the address of ‘00'.

Typical responses to this command illustrating the varible length of the response

include:

145

Page 14

67

5

-2

-23

4.5 FC Read Calibration Date

DESCRIPTION

The FC command reads the transducer’s date of calibration. This date is set at

the factory and can not be changed by the user.

EXAMPLE

#00FC

This command, followed by a carriage return, requests the date of calibration

from a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

06/14/01

The format of the response is month/day/year. For this example, the date of

calibration is June 14, 2001.

4.6 FE Read Serial Number

DESCRIPTION

The FE command reads the transducer’s serial number. The serial number is set

at the factory and can not be changed by the user.

EXAMPLE

#00FE

This command, followed by a carriage return, requests the serial number from a

transducer with the address of ‘00'.

The transducer produces a response to this command similar to:

123456

Page 15

For this example, the transducer’s serial number is ‘123456'.

4.7 FR Restore Factory Default Settings

DESCRIPTION

The FR command restores all factory default settings to the transducer. The

transducer reinitializes all operating parameters with the default settings. All

changes made by the user are lost. This command must be preceded by the WE

command.

EXAMPLE

#00FR

This command , followed by a carriage return, restores all default settings to a

transducer with an address of ‘00'.

In response to this command, the transducer transmits the following:

OK

4.8 FT Test Data Storage Checksum

DESCRIPTION

The FT command performs a checksum test on all stored data within the

transducer. The reponse to this command returns the result of this test.

The transducer performs a checksum test at power up and periodically during

operation. This command allows the user to perform a checksum test on

demand. If this command detects a checksum error, the appropiate bit of the

status byte reported by the DR command is set also.

EXAMPLE

#00FT

This command, followed by a carriage return, instructs the transducer with the

address of ‘00' to perform a checksum test.

In response to this command, the transducer transmits

Page 16

OK

to indicate no checksum errors, or

Err_CsF

to indicate a checksum failure.

4.9 II Set Update Rate

DESCRIPTION

The II command controls the update rate of the transducer. The transducer

calculates primary updates to the digital reading and the analog output voltage at

a maximum rate of 2500 times per second. These primary updates may be

averaged together to implement a simple averaging filter. This command controls

the number of primary updates averaged together to generate the digital reading

and the analog output voltage. As the number of primary updates averaged

increases, the update rate of the digital reading and of the analog output voltage

decreases. The default value for the command is no averaging enabled which

provides the maximum update rate for the transducer.

This command requires a data field of one character. The table below lists the

valid values and the resulting approximate update rates .

Data Field Value Updates / Second

0 (zero) 2500 (averaging disabled)

1 1250

2 625

3 312

4 156

5 78

6 39

7 19

8 9

This command must be preceded by the WE command.

EXAMPLE

Page 17

#00II2

This command, followed by a carriage return, instructs the transducer with the

address of ‘00' to average output results at a rate of 625 updates / second.

In response to this command, the transducer transmits the following:

OK

4.10 R4 Read Unit Address

DESCRIPTION

The R4 command displays the unique two character user defined address

assigned to the transducer by the W4 command.

EXAMPLE

#ffR4

This command, followed by a carriage return, requests the user defined address

of the transducer using the universal address of ‘ff'.

The transducer transmits a response to this command similar to:

33

For this example, the user defined address is 33.

4.11 R5 Read Full Scale Range

DESCRIPTION

The R5 command reads the transducer’s full scale pressure range in units of

PSI. This value is set at the factory and can not be changed by the user. The

response to this command is presented in scientific notation.

EXAMPLE

#00R5

This command, followed by a carriage return, reads the full scale pressure range

of a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

Page 18

+1.00000E+02

For this example the full scale pressure range is 100 PSI.

4.12 RM Read Manufacturer’s Part Number

DESCRIPTION

The RM command reads the Sensotec Part Number of the transducer. This

value is set at the factory and can not be changed by the user. The response is

an 11 character ASCII string representing the part number.

EXAMPLE

#00RM

This command, followed by a carriage return, reads the Sensotec part number of

the transducer with the address of ‘00'.

The transducer transmits a response to this command similar to::

060-G769-01

For this example the Sensotec part number is 060-G769-01.

4.13 RR Read Software Revision

DESCRIPTION

The RR command reads the transducer’s software part number and software

revision level.

EXAMPLE

#00RR

This command, followed by a carriage return, requests the software revision level

from a transducer with the address of ‘00'.

The transducer produces a response to this command similar to:

084-1406-03 1.00

The software part number is ‘084-1406-03'. The software revision level is ‘1.00'.

Page 19

4.14 SP Set User Defined String

DESCRIPTION

The SP command writes an user defined ASCII character string to the

transducer. This command requires a data field of up to 16 characters. The user

may use this command to store custom information in the transducer. The

default value for this command is 16 spaces (ASCII code 32 decimal).

Information stored in the transducer with this command is maintained when

power is removed from the transducer. Information stored in the transducer with

this command may be read by the DP command. This command must be

preceded by the WE command.

EXAMPLE

#00SPPart # 456-1003P

This command, followed by a carriage return, writes “Part # 456-1003P” to a

transducer with the address of ‘00'.

In response to this command, the transducer transmits the following:

OK

4.15 W1 Write Baud Rate

DESCRIPTION

The W1 command changes the transducer’s baud rate for serial communication.

This command requires a data field of one numeric value to indicate the new

baud rate. A list of the available baud rates and the corresponding value to be

placed in the data field follows.

Baud Rate Data Field Value

1200 1

2400 2

4800 3

Page 20

9600 4

19.2 K 5

38.4 K 6

57.6 K 7

115.2 K 8

The change to the new baud rate takes place immediately after the transducer

acknowledges the command. This command must be preceded by the WE

command. The default baud rate is 9600.

EXAMPLE

#00W15

This command, followed by a carriage return, changes the baud rate of the

transducer with the address of ‘00' to a baud rate of 19.2K for subsequent serial

communication.

Before changing to the new baud rate, the transducer transmits the following:

OK

4.16 W4 Write New Address

DESCRIPTION

The W4 command writes a user defined address to the transducer. This

command requires a data field of two characters representing the new address.

The address may be any two alphanumeric characters and is case sensitive.

This command must be preceded by the WE command. The default value of this

address is ‘00'.

EXAMPLE

#00W4EE

This command, followed by a carriage return, writes a new user defined address

of ‘EE’ to the transducer addressed with the default address of ‘00'.

In response to this command, the transducer transmits the following:

OK

4.17 WE Write Enable

Page 21

DESCRIPTION

All commands which write data to the transducer or which change the operating

parameters of the transducer must be preceded by the Write Enable command.

The Write Enable command is valid for the next single command only. Each

command which writes data to the transducer must be preceded by a separate

Write Enable command.

EXAMPLE

#00WE

This command, followed by a carriage return, enables a transducer with the

address of ‘00' to process the next command which writes data to the

transducer.

In response to this command, the transducer transmits the following:

OK

5. DIGITAL OUTPUT COMMANDS

5.1 D0 Display Digital Pressure Reading

DESCRIPTION

Page 22

The D0 (D, numeral 0) command displays the most recently computed

temperature compensated pressure reading. The pressure reading is presented

in scientific notation as a string of ASCII characters. If the most recent pressure

reading is out of range or a checksum error has been detected, the transducer

will respond to this command with an error indication. See Section 3.3.

EXAMPLE

#00D0

This command, followed by a carriage return, reads the pressure reading of a

transducer with the address of ‘00’.

The transducer transmits a response to this command similar to:

+6.24250E+01

For this example, the pressure reading is 62.4250.

5.2 DB Display Digital Zero Adjustment

DESCRIPTION

The DB command displays the value of the digital zero adjustment in scientific

notation.

EXAMPLE

#00DB

This command, followed by a carriage return, reads the digital zero adjustment of

a transducer with an address of ‘00'.

The transducer transmits a response to this command similar to:

-2.50000E-01

For this example, the digital zero adjustment is -0.25%, which reduces the digital

zero reading by -0.25%.

5.3 DE Display Engineering Units Conversion Factor

DESCRIPTION

The DE command displays the transducer’s engineering units conversion factor.

Page 23

EXAMPLE

#00DE

This command, followed by a carriage return, reads the engineering units

conversion factor from a transducer with an address of ‘00'.

The transducer transmits a response to this command similar to:

+2.76790E+01

For this example, the engineering units conversion factor is ‘27.679'.

5.4 DM Display Digital Span Adjustment

DESCRIPTION

The DM command displays the value of the digital span adjustment in scientific

notation.

EXAMPLE

#00DM

This command, followed by a carriage return, reads the digital span adjustment

of a transducer with an address of ’00'.

The transducer transmits a response to this command similar to:

+9.98000E+01

For this example, the digital span adjustment is 99.8% of the unadjusted span.

5.5 R6 Read Engineering Units Label

DESCRIPTION

The R6 command reads the four character engineering units label.

EXAMPLE

#00R6

Page 24

This command, followed by a carriage return, reads the engineering units label of

a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

PSIG

For this example, the engineering units label is ‘PSIG’, (Pounds per Square Inch

Gage).

5.6 SB Set Digital Zero Adjustment

DESCRIPTION

The SB command is used to adjust the zero of the digital output only. The

command requires a data field of up to 16 characters. Data field values may be

positive or negative and are entered as an integer, a decimal number, or in

scientific notation. This command must be preceded by the WE command.

The units for the SB command is percentage. A data field value of 0.00000 is the

default value for this parameter and represents no zero adjustment.

EXAMPLE

#00SB-0.25

This command, followed by a carriage return, sets the digital zero adjustment of

a transducer with an address of ‘00' to -0.25%. This would result in a 0.25

percent reduction in the zero reading of the transducer.

In response to this command, the transducer transmits the following:

OK

5.7 SE Set Engineering Units Conversion Factor

DESCRIPTION

The SE command is used to set the engineering units conversion factor. This

conversion factor is used in the calculation of the digital output only and

determines the engineering units of the digital output. This command requires a

data field of up to 16 characters. Data field values may be entered as integers,

Page 25

decimal numbers, or scientific notation. Data field values for common conversion

factors are listed below with their corresponding engineering units. This

command must be preceded by the WE command.

NOTE: It is the user’s responsibility to ensure that the engineering units

label written with the W6 command correctly corresponds to the

appropriate engineering units conversion factor.

Engineering Units Data Field Value

CMWC centimeters of water column 70.304

INHG inches of mercury 2.0360

INWC inches of water column 27.679

KPA kilopascal 6.8948

MBAR millibar 68.948

MPA megapascal 0.0068948

PSI pounds per square inch 1.0000

EXAMPLE

#00SE27.679

This command, followed by a carriage return, writes the engineering units

conversion factor of ‘27.679' to a transducer with the address of ‘00'. The

engineering units of the transducer’s digital output will be INWC (inches of water

column) after the transducer acknowledges the command. (The W6 command

should be used to set the engineering units label to ‘INWC’.)

In response to this command, the transducer transmits the following:

OK

5.8 SM Set Digital Span Adjustment

DESCRIPTION

The SM command is used to adjust the span of the digital output only. The

command requires a data field of up to 16 characters. Data field values may be

entered as integers, decimal numbers, or scientific notation. This command must

be preceded by the WE command.

Page 26

The units for the SM command is percentage. A data field value of 100.0 is the

default value for this parameter and represents no span adjustment.

EXAMPLE

#00SM99.80

This command, followed by a carriage return, reduces the digital output span of

a transducer with the address of ‘00' by 0.2 %.

In response to this command, the transducer transmits the following:

OK

5.9 W6 Write Engineering Units Label

DESCRIPTION

The W6 command changes the four character engineering units label associated

with the digital output of the transducer. The command requires a four character

data field to specify the new engineering units label. This command does not

change anything mathematically. The SE command changes the actual

engineering units conversion factor. The label may be read by the R6 command.

This command must be preceded by the WE command.

EXAMPLE

#00W6PSIG

This command, followed by a carriage return, changes the engineering units

label of the transducer with the address of ‘00' to ‘PSIG’'.

In response to this command, the transducer transmits the following:

OK

Page 27

6. ANALOG OUTPUT COMMANDS

6.1 DA Display Analog Output Voltage

DESCRIPTION

The DA command reads the actual voltage present at the transducer’s analog

output pin. This value is provided as a diagnostic tool. The accuracy of this value

is not guaranteed but is typically within ±0.5 percent of the output voltage.

The response to this command is a fixed length string beginning with a plus or

minus sign. The voltage value is presented with three decimal places.

EXAMPLE

#00DA

This command, followed by a carriage return, reads the voltage at the analog

output pin of a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

+3.425

For this example, the analog output voltage is approximately +3.425 volts.

6.2 RN Read Voltage Output Offset

DESCRIPTION

The RN command reads the value of the analog voltage output’s offset

adjustment. The response to this command is presented in scientific notation.

The units are percentage.

EXAMPLE

#00RN

This command, followed by a carriage return, reads the voltage output’s offset

adjustment for a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

Page 28

+1.00000E-01

For this example, the voltage output zero adjustment is set to +0.1 percent.

6.3 RO Read Voltage Output Scaling Factor

DESCRIPTION

The RO (R, letter O) command reads the value of the analog voltage output

span adjustment. The response to this command is in scientific notation.

EXAMPLE

#00RO

This command, followed by a carriage return, reads the voltage output span

adjustment for a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

+9.85000E+01

For this example, the voltage output span adjustment is 98.5 %.

6.4 SA Set Analog Output

DESCRIPTION

The SA command provides the value for the analog output when the transducer

is configured to use the digital interface to control the analog output. (See the SS

command.) This value is in units of percentage of full scale.

This command requires a data field of up to six characters. Data field values may

be entered as integers or decimal numbers and range from 0.00 to 100.00.

NOTE: The analog output scaling factor and offset values set by the WO and

WN commands respectively apply to the value set by this command.

EXAMPLE

#00SA50.0

This command, followed by a carriage return, sets the analog output voltage of a

Page 29

transducer with the address of ‘00' to 50 percent of full scale, i.e. 2.5 Vdc.

In response to this command, the transducer transmits the following:

OK

6.5 SS Select Analog Output Source

DESCRIPTION

The SS command selects the source from which the analog output is generated.

The analog output may be derived from either of two sources. The default source

for the analog output is the sensor at the pressure port of the transducer. The

alternate source is a discrete value provided by the user through the digital

interface.

This command requires a one character data field.Valid values for the data field

are:

Analog Output Source Data Field Value

Pressure Port 0

Digital Interface 1

This command must be preceded by the WE command.

When switching from the pressure port to the digital interface as the source for

the analog output, the initial value for the analog output is set by the SV

command. All subsequent values are provided by the SA command.

EXAMPLE

#00SS1

This command, followed by a carriage return, configures the analog output of a

transducer with the address of ‘00' to use values provided through the digital

interface. The transducer immediately uses the value set by the SV command to

set the analog output voltage.

In response to this command, the transducer transmits the following:

OK

6.6 SV Set Analog Output Default Value

Page 30

DESCRIPTION

The primary use of the SV command is to provide the default value for the

analog output when the transducer is first configured to use the digital interface

to control the analog output. (See the SS command.) It is also the value used at

power up when the transducer’s analog output is controlled by the digital

interface.

The secondary use of the SV command is to provide a default value for the

analog output to indicate a checksum error. When the analog out is under control

of the pressure port and a checksum error is detected, the value set by this

command is used to set the analog output.

This command requires a data field of up to six character. Data field values may

be entered as integers or decimal numbers and range from 0.00 to 100.00. This

value is in units of percentage of full scale. This command must be preceded by

the WE command.

NOTE: The analog output scaling factor and offset values set by the WO and

WN commands respectively apply to the value set by this command.

EXAMPLE

#00SV0.0

This command, followed by a carriage return, sets the default analog output

voltage of a transducer with the address of ‘00' to 0 percent of full scale, i.e. 0.0

Vdc.

In response to this command, the transducer transmits the following:

OK

6.7 SY Display Analog Output Default Value

DESCRIPTION

The SY command reads the default value for the analog output set by the SV

command.

EXAMPLE

#00SY

Page 31

This command, followed by a carriage return, reads the default analog output

value of a transducer with the address of ‘00'.

The transducer transmits a response to this command similar to:

+5.0000E+01

For this example, the default analog output value is 50 %, or 2.5 Vdc.

6.8 WN Write Voltage Output Offset

DESCRIPTION

The WN command is used to adjust the offset of the analog voltage output only.

The command requires a data field indicating the amount of zero offset desired.

The data field represents the percentage of full scale reading by which the zero

offset should be changed and may be entered as integers, decimal numbers, or

scientific notation. This command must be preceded by the WE command.

The zero of the analog voltage output is inversely related to this command’s data

field value. Increasing this value will lower the analog output voltage; decreasing

this value will raise the output voltage. Any zero adjustment of the voltage output

should be made before adjusting the span. The default value for this parameter

is 0.0 and represents no offset adjustment.

EXAMPLE

#00WN-0.2

This command, followed by a carriage return, adjust the offset of the analog

voltage output by -0.2 % of full scale for a transducer with the address of ‘00'. In

effect this inceases the analog output voltage by 0.2 %.

In response to this command, the transducer transmits the following:

OK

6.9 WO Write Voltage Output Scaling Factor

DESCRIPTION

The WO (W, letter O) command is used to adjust the span of the analog voltage

Page 32

output only. The command requires a data field indicating the amount of span

adjustment desired. The data field represents the percentage of full scale

reading by which the span should be changed and may be entered as integers,

decimal numbers, or scientific notation. The command must be preceded by the

WE command.

The span of the analog voltage output is inversely related to this command’s

data field value. Increasing this value will decrease the analog output span;

decreasing this value will increase the analog output span. The default value of

this parameter is 100.0 representing no analog output span adjustment.

EXAMPLE

#00WO98.5

This command, followed by a carriage return, adjusts the span of the analog

output by +1.5 % of full scale for a transducer with the address of ‘00'.

In response to this command, the transducer transmits the following:

OK

Page 33

7. ELECTRICAL CONNECTIONS

Figure 7.1 Electrical Connector Pin Assignments

Figure 7.2 - Typical Transducer Connections, RS-485 Interface

Page 34

Figure 7.3 - Typical Transducer Connections, RS-232 Interface

Loading...

Loading...