Sennheiser HME 46-3PTT-LA, HME 46-3PTT-6, HME 46-ATC, HME 46-3PTT-M, HME 46-31 Service Manual

...

Service manual

Product variants

500857 HME 46-3

500467 HME 46-3-6

500874 HME 46-3PTT-M

500468 HME 46-3PTT-6

500469 HME 46-3PTT-L

502172 HME 46-3PTT-LA

500851 HME 46-ATC

502484 HME 46-31

500849 HMD 46-3

500466 HMD 46-3-6

500873 HMD 46-3PTT-M

502483 HMD 46-31

502594 HMD 46-3(5)

Cable variants

500836 -6

502360 -7

502365 -L

500844 -PTT-6

502418 -PTT-6-1

500845 -PTT-L

502187 -PTT-LA

500930 -D-3PTT-M

500931 -E-3PTT-M

Revision

02/2008

Air Traffic Control

HME 46-3

HMD 46-3

SA 070401

Short description

This headset features dynamic, open headphones. The noise-compensating

microphone ensures excellent speech transmission even in noisy

environments. Designed for air traffic control, intercom systems and other

communication purposes.

Features

• ActiveGard™ (not HME 46-31 and HMD 46-31)

• “Flip-away“ earcup

• Automatic two-piece headband

• Flexible microphone boom can be worn on either left or right-hand side

• Single-sided cable

• Comfortable wearing earpads

• PTT button integrated in the cable (HME/HMD 46-3PTT-x only)

Subject to alterations

Sennheiser electronic GmbH & Co. KG • 30900 Wedemark, Germany

Phone: +49 (5130) 600 0 • Fax: +49 (5130) 600 300 1/25

Safety requirements

Observe safety regulations.

Observe ESD instructions while handling electrostatically endangered components.

Only skilled perso

approved components according to the current spare parts list are allowed.

For safety and certification reasons it is forbidden to alt

authorization. Otherwise, the person who has

consequential damage.

repairs/exchanges The following instructions for overhaul and testing must

In case of unusual problems please contact yo

ns are allowed to alter and repa

ir. For repairs and exchanges only

altered the product is liable for any

ur Sennheiser distributor.

er the product without

be followed.

HME 46-3, HMD 46-3

2/25 02/2008

Contents

1 Outline dimension ..........................................................................................5

2 Technical Data.................................................................................................6

2.1 Headphones........................................................................................................... 6

2.2 Microphone of HMD 46-3.................................................................................... 6

2.3 Microphone of HMD 46-3(5) .............................................................................. 6

2.4 Microphone of HME 46-3 (with preamplifier) ................................................ 6

2.5 General data .......................................................................................................... 6

3 Disassembly ....................................................................................................7

3.1 Removal of the cable ........................................................................................... 7

3.2 Disassembly of the cap........................................................................................ 7

3.3 Disassembly of the cable .................................................................................... 7

3.4 Disassembly of the microphone arm ................................................................ 8

4 Assembly .........................................................................................................9

4.1 Assembly of the cap............................................................................................. 9

4.2 Assembly of the -PTT-x cable............................................................................. 9

4.3 Assembly of the cable to the headset............................................................10

4.4 Assembly of the microphone arm ...................................................................10

5 Testing and fault isolation......................................................................... 11

5.1 Tools and test equipment .................................................................................11

5.2 Operational test of the audio system............................................................. 11

5.2.1 Audio testing the headset with cable ............................................................11

5.2.2 Operational testing of the pre-polarized m

at the headset with cable (HME 46-3-x only) .............................................. 11

5.2.3 Testing of the dynamic microphone

a

t the headset with cable (HMD 46-3-x only)..............................................12

5.2.4 Operational testing of the headset cables .................................................... 12

Audio testing of the headset without cable .................................................12

5.2.5

5.2.6 Testing of the ActiveGard™ of the PCB (not HMD/E 46-31)...................... 13

icrophone

6 Wiring diagrams .......................................................................................... 15

6.1 Wiring diagram for cable -E-3PTT-M, -D-3PTT-M.........................................15

6.2 Wiring diagram for cable -PTT-L...................................................................... 16

6.3 Wiring diagram for cable -PTT-6..................................................................... 17

6.4 Wiring diagram for cable -PTT-LA................................................................... 18

6.5 Printed circuit boards ........................................................................................ 19

6.6 Block diagram......................................................................................................20

7 Exploded views with spare part lists........................................................ 21

7.1 Exploded view HME 46-3 / HMD 46-3 ............................................................ 21

7.2 Spare part list for HME 46................................................................................. 22

7.3 Spare part list for HMD 46 ................................................................................ 22

7.4 Exploded view of the system module ............................................................ 23

7.5 Spare part list of the system module

not microphone side (525764) .......................................................................23

7.6 S

7.7 E

7.8 Spare part list of the cap, microphone side...................................................24

7.9 Exploded view cable -PTT-x .............................................................................. 25

7.10 Spare part list for cable -PTT-x ........................................................................ 25

pare part list of the system module

microphone side (525763)............................................................................... 23

xploded view of the cap, microphone side ..................................................24

HME 46-3, HMD 46-3

02/2008 3/25

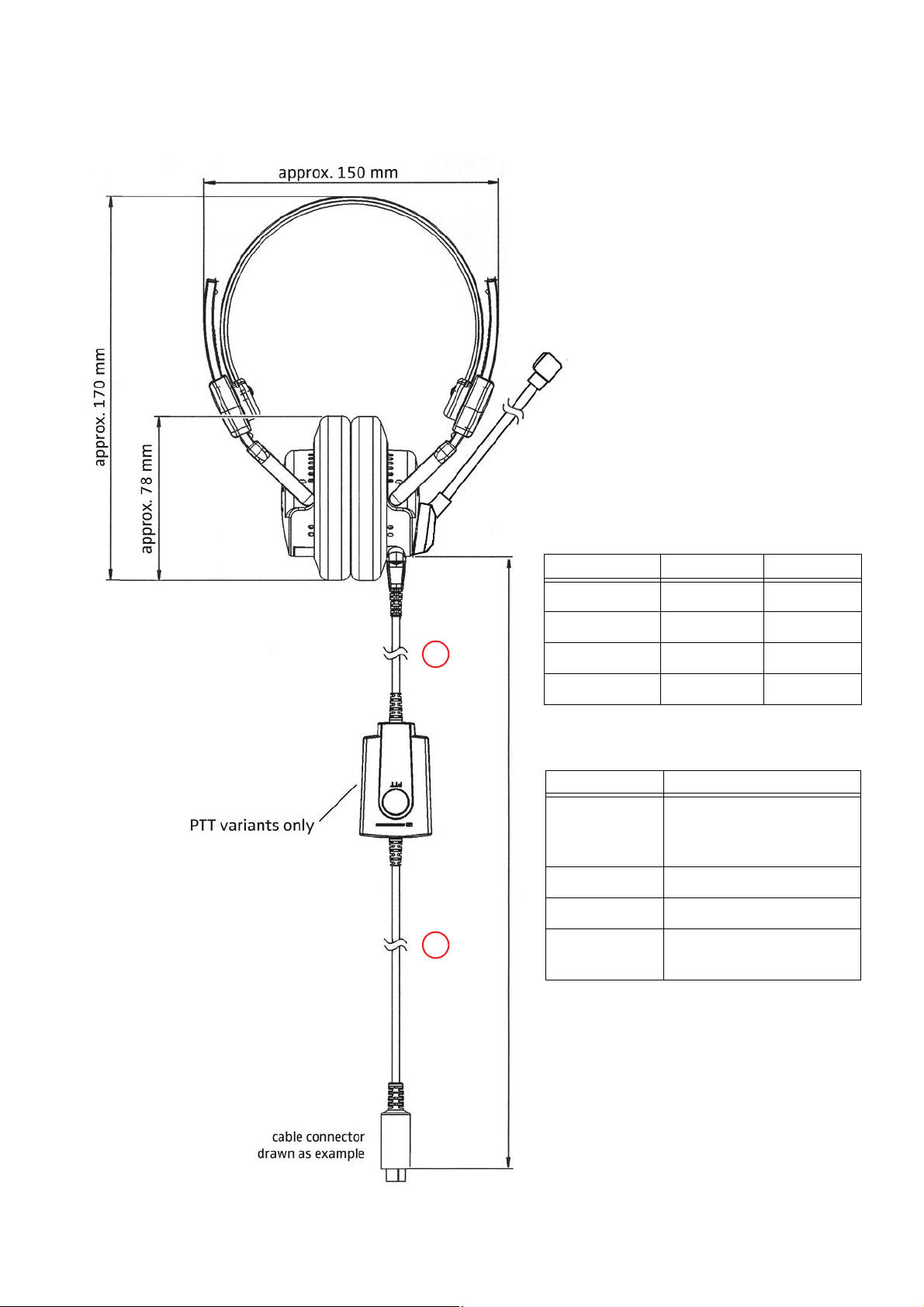

1 Outline dimension

1

2

Cable type Complete cable length

-PTT-6,

-PTT-6-1,

-PTT-L

1.85 m

-PTT-LA

2.30 m

-E/D-3PTT-M

2.45 m

-7,

-ATC / -L

2.00 m

Cable type

Length of

Length of

-E/D-3PTT-M 0.80 m

1.60 m

-PTT-LA 0.50 m

1.75 m

-PTT-L, -PTT-6 1.50 m

0.30 m

-PTT-6-1 0.80 m

1.00 m

HME 46-3, HMD 46-3

02/2008 5/25

2 Technical Data

2.1 Headphones

Transducer principle_______________________ dynamic, open

Ear coupling_____________________________ supra-aural

Frequency response _______________________ 20 to 14.000 Hz

Impedance _____________________________300 ohms per system

Sensitivity

HMD/E 46-3 _______________________ 95 dB/SPL at 1 kHz, 1 mW mono

83 dB/SPL at 1 kHz, 1 V

HMD/E 46-31 ______________________ 95 dB/SPL at 1 kHz, 1 mW mono

103 dB/SPL at 1 kHz, 1 V

THD

HMD/E 46-3 _______________________ < 1 % at 95 dB SPL (350 to 3.000 Hz)

HMD/E 46-31

Contact pressure _________________________aprx. 3.0 N

2.2 Microphone of HMD 46-3

Type _______________________________ MD 46-413

Transducer principle

Frequency response

Output voltage

Impedance

____________________________ 200 ohms

______________________< 1 % at 110 dB SPL (350 to 3.000 Hz)

_____________________ dynamic, noise compensating

______________________ 100 to 12.000 Hz

_________________________ 0.5 mV/Pa

2.3 Microphone of HMD 46-3(5)

Type _______________________________ MD 46-413_5 ohms

Transducer principle

Frequency response

Output voltage

Impedance

____________________________ 5 ohms

_____________________ dynamic, noise compensating

______________________ 100 to 12.000 Hz

_________________________ 0.125 mV/Pa

2.4 Microphone of HME 46-3 (with preamplifier)

Type _______________________________ MKE 46

Transducer principle

Frequency response

Output voltage

HME 46-3, -3-6, -3PTT-M,

-3PTT-6, -3PTT-L, HME 46-31

HME 46-3PTT-LA, -ATC adjustable from 17 to 215 mV/Pa,

Terminating impedance

Supply voltage

_____________________ pre-polarized condenser microphone, noise compensating

______________________ 350 to 6.000 Hz

__________ adjustable from 17 to 100 mV/Pa,

80 mV/Pa (factory pre-set) ≅ 800 mV at

152 mV/Pa (factory pre-set) ≅ 1520

___________________ 150 to 2.200 ohms

_________________________ 8 to 16 V DC

114 dB SPL

mV at

114 dB SPL

2.5 General data

Ambient temperature

operating mode ___________________ -15°C to 55°C

stocking

Weight, without cable

6/25 02/2008

_________________________ -55°C to 70°C

____________________ aprx. 150 g

HME 46-3, HMD 46-3

3 Disassembly

3.1 Removal of the cable

Reference:

• see “Exploded view HME 46-3 / HMD 46-3”, page 21.

1. Loosen the screws of the cable.

2. Remove the cable from the cable holder (110).

3.2 Disassembly of the cap

Reference: see “Exploded view HME 46-3 / HMD 46-3”, page 21.

1. Remove the earpad (90) from the relevant cap (20 or -25).

2. Lift the sides of the discs (80), now the screws (70) are visible

caps (20 or -25) completely if necessary.

3. Remove the screws (70).

4. Pull out the the resonator (60) with capsule.

5. Remove the center (50).

6. Remove the felt plate (40).

7. Unsolder the leads of the cable (TP1 to TP4) of t

see “Printed circuit boards”, page 19.

8. Unsolder the leads from the capsules (TP8, TP9), see “Printed circuit boards”, page 19 or see “Exploded view of the system module”, page 23.

9. Unsolder the cable from the microphone arm (100 or -105) (TP5 to TP7)*.

10.

Remove the cable holder (110) from the cap (20)*.

11. Remove the cap (20 or -25) from the split headband (10).

he split headband (10) from the PCB,

or remove the discs (80) from the

3.3 Disassembly of the cable

Reference: see “Exploded view cable -PTT-x”, page 25.

1. Remove the four screws (40) of the housing (10).

2. Open the housing (10, 30).

3. Remove the inserts (50).

4. Take out the PCB (60) and the cables (90, 100) of the

5. Desolder the cables (90, 100) from the PCB (60).

housing (10).

* Only microphone side.

HME 46-3, HMD 46-3

02/2008 7/25

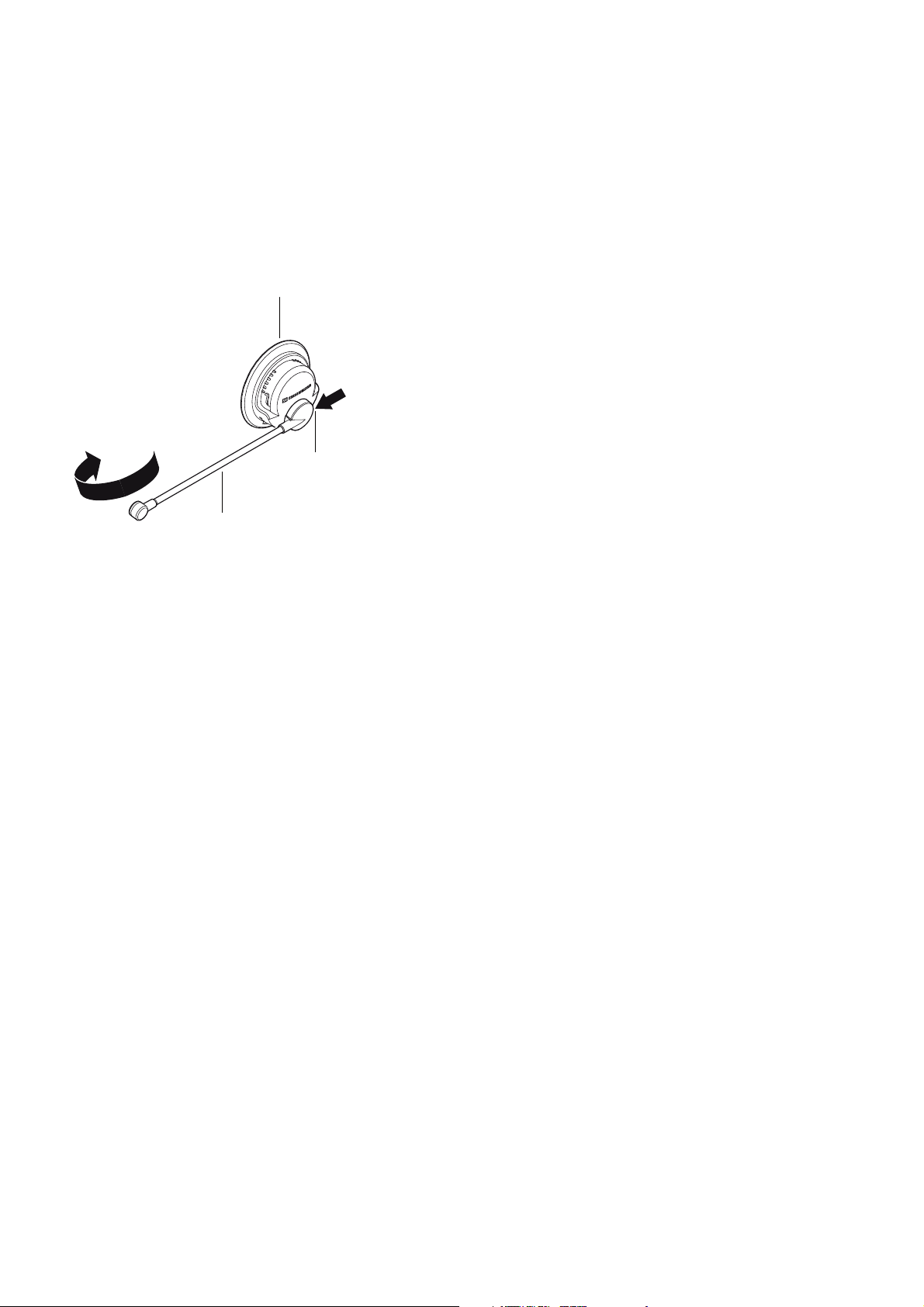

3.4 Disassembly of the microphone arm

100

20

10 (of the cap module)

Reference: see “Exploded view HME 46-3 / HMD 46-3”, page 21 or see “Exploded view of the cap, microphone

side”, page 24.

1. Rotate the microphone arm (100 or

-105) to the side position if necessary

(see figure below).

2. Screw the threaded pin (10 of the cap module) completely into the microphone arm fixing

3. Disassemble the microphone arm (100 or -105) from the cap (20) by

moving the microphone down

towards to the other cap (-25) of the headset .

.

HME 46-3, HMD 46-3

8/25 02/2008

4 Assembly

4.1 Assembly of the cap

Reference:

• see “Exploded view HME 46-3 / HMD 46-3”, page 21.

1. Attach the relevant cap (20 or -25) to the headband (10).

2. Solder the relevant leads of the split headband cable to the PCBs (TP1 to TP4), see “Printed circuit boards”, page 19 and see “Block diagram”, page 20.

3. Solder the microphone cable (TP5 to TP7) at the microp

and see “Block diagram”, page 20.

4. Put the center (50) over the resonator (60) and solder

(TP8 and TP9) to the PCB , see “Printed circuit boards”, page 19 and see “Block diagram”, page 20.

5. Install the felt plate (40) on the PCBs

6. Turn the center (50) into the cap (20 or -25).

7. Set the capsule with resonator (60)

8. Install the screws (70) with a torque of 25 Ncm

9. Install the label (120) on the cap (-25), if applicable.

10. Install the disc (80) on the resonator (60) if necessary.

11. Install the earpad (90) over the disc (80) on the cap (20 or -25).

(20 of the system module).

into the cap (20 or -25).

±3 Ncm.

4.2 Assembly of the -PTT-x cable

hone arm PCB, see “Printed circuit boards”, page 19

the orange and brown leads at the relevant pins

Reference: see “Exploded view cable -PTT-x”, page 25

1. Solder the cables (90, 100) at the PCB (60), see “Wiring diagrams”, page 15 et sqq.

2. Install the PCB (60) with the cables (90, 100) into the housing (10).

3. Close the housing (10) with the cover (30).

4. Install the inserts (50) at the top of the housing (10).

5. Fasten the screws (40) of the housing (10) with a torque of 25

Ncm ±3 Ncm.

* Only for microphone side.

HME 46-3, HMD 46-3

02/2008 9/25

4.3 Assembly of the cable to the headset

PCB

PCB cable (inside)

20

100

10 (of the cap module)

Reference:

• see “Exploded view HME 46-3 / HMD 46-3”, page 21.

1. Set the connector of the system cable into the cable

2. Fasten the screws of the system cable with a torque of 25 Ncm

holder (110)*.

±3 Ncm.

4.4 Assembly of the microphone arm

Reference: see “Exploded view HME 46-3 / HMD 46-3”, page 21.

1. At the inside of the microphone arm fixing is a latch . Fi

position of the cap (20).

2. Hook

3. Fix the

the microphone arm (100 or -105) into the cap (20).

microphone arm (100 or -105) with the threaded pin (10 of the cap module) to outside.

threaded pin (10 of the cap module) out to exceed in the assembled condition 0.1 to 0.3 mm over the

surface of the microphone arm fixing.

rstly set this latch at the right socket

Turn the

* Only for microphone side.

HME 46-3, HMD 46-3

10/25 02/2008

5 Testing and fault isolation

5.1 Tools and test equipment

Description Specification / Type Source

Power supply U: 0-30V DC adjustable

I: ≥500 mA

Hum: <1%

Sine wave generator AF Level adjustable Commercial

Multimeter U: 0-30V DC

I: ≥50

Resolution ≤ 0.1 V

Oscilloscope - Commercial

Intercom

Audio amplifier

-

Any audio amplifier with

hi

impedance micro

gh

input

0 mA

eff

eff

5.2 Operational test of the audio system

References

• see “Cable connector´s pin alignment”, page 14.

• see “Wiring diagrams”, page 15 et sqq.

• see “Printed circuit boards”, page 19.

Commercial

Commercial

Commercial

Commercial

5.2.1 Audio testing the headset with cable

1. Connect the sine wave generator with the negative and the positive line at the relevant pins of the connector, see “Cable connector´s pin alignment”, page 14 or see “Wiring diagrams”, page 15 et sqq.

2. Set the sine wave generator to 300 mV eff ± 5 mV with a signal of 1

3. A clear signal without any distortion must

be audible in both capsules.

kHz and switch the generator on.

5.2.2 Operational testing of the pre-polarized microphone at the headset with cable (HME 46-3-x only)

A. Audio testing, see “Cable connector´s pin alignment”, page 14 and see “Wiring diagrams”, page 15 et sqq.

1. Connect the headset with the cable

2. Put on the headset, adjust the microphone to the correct position and talk into the microphone.

3. Listen to the audio output signal. No distortion should be

B. Visual testing

1. For detailed visual testing please use the ossiloscope, see “Microphone test setup according to RTCA/DO214”, page 14.

connectors into the intercom.

audible.

HME 46-3, HMD 46-3

02/2008 11/25

5.2.3 Testing of the dynamic microphone at the headset with cable (HMD 46-3-x only)

Reference: See fig. 1 “Operational test of the dynamic microphone” page 13

A. Operational testing

1. Connect the microphone connector of the headset wi

audio amplifier input, see “Cable connector´s pin alignment”, page 14 or see “Wiring diagrams”, page 15

et sqq.

2. Connect the headphone connector of the headset with th

fier output, see “Cable connector´s pin alignment”, page 14 or see “Wiring diagrams”, page 15 et sqq.

3. Connect the oscilloscope into a free amplifier output, see “Operational test of the dynamic m

page 13

4. Speak into the microphone of the headset:

- The speaker´s voice will be audible without any distortion in both

- The amplified audio signal of the speaker´s voic

B. Testing of the capsule via resistor measurement

1. Set the multimeter into resistor measurement mode.

2. Connect the multimeter at the relevant pins of the cable connector, see “Cable connector´s pin alignment”,

page 14 or see “Wiring diagrams”, page 15 et sqq. Result: The multimeter displays 20

correct connection of the cable and the capsule. There is no failure

th the negative and positve line into the

e negative and positve line into the audio ampli-

icrophone”,

capsules of the headset.

e will be displayed via oscilloscope.

0 ohms ± 10 % for

or breaking in the cables.

5.2.4 Operational testing of the headset cables

References

• see “Cable connector´s pin alignment”, page 14.

• see “Wiring diagrams”, page 15 et sqq.

A. Conductivity test:

Set the multimeter into the conductivity mode and check each cable

connector for conductivity.

B. Operational test of the PTT-button:

The contactivity is available when the PTT-button is pressed.

For the following testing procedures disassemblin

g of the headset is necessary.

from the connector to the system

5.2.5 Audio testing of the headset without cable

A. Testing audio via PCB at the PCB socket P1, see “Printed circuit boards”, page 19.

1. Supply 1 kHz signal at the PCB socket P1.

2. In the headphones, the 1 kHz tone must be audible.

B. Testing of the acoustic transducer.

1. Set the sine wave generator to 100 mVeff ± 5 mV with a signal of 1 kH

and TP9 (-), see “Printed circuit boards”, page 19.

2. In the headphones, the 1 kHz tone must be audible.

z to the PCB. Set a signal to TP8 (+)

HME 46-3, HMD 46-3

12/25 02/2008

5.2.6 Testing of the ActiveGard™ of the PCB (not HMD/E 46-31)

Speaker´s voice

Audio amplifier

output

Headphone

connector

input

Microphone

connector

output

Oscilloscope

1. Connect the sine wave generator with the negative and the positive line at TP3 (+) and TP4 (-), see “Printed circuit boards”, page 19.

2. Measure the output signal at TP8 (+) and TP9 (-), see “Printed circuit boards”, page 19.

3. The following table show you the input levels of the signal generator and the c

measurement results:

orresponding

Input signal of 1 kHz

at TP3 (+) and TP4 (-)

Output level at TP8 (+) and TP9 (-):

Audible via loudspeaker

of the PCB

300 mV

±5 mV Output level is reduced about

eff

min. 8 dBV. The PCB with

1 V

±5 mV 30 to 40 mV

eff

loudspeaker works correctly.

Output level at TP8 (+) and TP9 (-):

Damaged loudspeaker or open

cable connection

290 to 310 mV

eff

eff

HME 46-3, HMD 46-3

02/2008 13/25

Figure 1

Operational test of the dynamic microphone

Oscilloscope

Multimeter

Power supply

8-16V DC

Sine wave

generator

Artificial

mouth

Microphone Hi

Microphone Lo

Nearfield sensitivity

25 µF

220 ohms

470 ohms

SPL = 94 dB

6 mm (0.24 inch)

Connector cable -L (also cable HME 46-ATC)

149

8

5

10

6

7

2

3

bridge

orange

blue

redbrown

greenn. c.

white

screen

Solder side

Connector system cable

Audio Hi right

Audio Lo right

not connected

Screen

Audio Hi left

Audio Lo left

Microphone Hi

Microphone Lo

Bridge to pin 10

Bridge to pin 9

1

2

3

4

5

6

7

8

9

10

orange

brown

green

yellow

red

blue

screen

Audio Hi left

Audio Hi right

Audio Lo left

Audio Lo right

not connected

Microphone Hi

Microphone Lo

Screen

white

Cable -6

orange

brown

green

yellow

red

blue

screen

Audio Hi left

Audio Hi right

Audio Lo left

Audio Lo right

not connected

Microphone Hi

Microphone Lo

Screen

white

Figure 2

Microphone test setup according to RTCA/DO-214

14/25 02/2008

Figure 3

ble connector´s pin alignment

Ca

HME 46-3, HMD 46-3

6 Wiring diagrams

System cable

white / orange

not connected

brown / green

not connected

yellow

screen

red

blue

white

not connected

brown

green

not connected

not connected

screen

E-3PTT-M: red or

D-3PTT-M: orange

blue

white

orange

green

screen

blue

red

brown

soldering side

System cable

white / orange

not connected

brown / green

not connected

yellow

screen

red

blue

white

not connected

brown

not connected

green

screen

bridge

blue

E-3PTT-M: red or

D-3PTT-M: orange

515760

515761

bridge

Audio Hi

Audio Lo

Dyn. Mic Hi

not connected

Pre-polarized Mic Hi

PTT

PTT / Screen

Mic Lo

1234567

8

6.1 Wiring diagram for cable -E-3PTT-M, -D-3PTT-M

HME 46-3, HMD 46-3

02/2008 15/25

6.2 Wiring diagram for cable -PTT-L

System cable

white

orange

brown

green

yellow

screen

red

blue

white

orange

brown

yellow

green

black

screen

red

blue

brown

screen

white

blue

red

orange

green

black

yellow

soldering side

Audio Hi left

Audio Lo left

PTT

PTT (bridge to pin 10)

Audio Lo right

Audio Hi right

Microphone Hi

Microphone Lo

Screen

PTT (bridge to pin 4)

123456789

10

System cable

white

orange

brown

green

yellow

screen

red

blue

white

orange

brown

green

yellow

black

screen

red

blue

515760

515761

HME 46-3, HMD 46-3

16/25 02/2008

6.3 Wiring diagram for cable -PTT-6

System cable

white

orange

brown

green

yellow

screen

red

blue

white

orange

brown

yellow

green

black

screen

red

blue

System cable

white

orange

brown

green

yellow

screen

red

blue

white

orange

brown

green

yellow

black

screen

red

blue

515760

white

orange

brown

green

yellow

black

red

blue

screen

Audio Hi left

Audio Hi right

Audio Lo left

Audio Lo right

PTT

PTT

Mic Hi

Mic Lo

Screen

515761

HME 46-3, HMD 46-3

02/2008 17/25

6.4 Wiring diagram for cable -PTT-LA

System cable

white

orange

brown

green

yellow

screen

red

blue

white

orange

brown

yellow

green

screen

not connected

red

blue

yellow

screen

white

brown

red

blue

soldering side

System cable

white

orange

brown

green

yellow

screen

red

blue

white

orange

brown

green

yellow

screen

not connected

red

blue

515760

123

4

56789

10

Audio Hi right

Audio Lo right

PTT

PTT / screen, bridge to pin 9,

resistor 75R between pin 4

and pin 10

Audio Hi left

Audio Lo left

Mic Hi

Mic Lo

bridge to pin 4, PTT / screen

resistor 75R between pin 4

and pin 10 / screen

515761

10

9

18/25 02/2008

HME 46-3, HMD 46-3

6.5 Printed circuit boards

L

P1

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8 TP9

Audio signal

Left

Hi

Right

Hi

Left

Lo

Right

Lo

300 mV/1 kHz 300 mV/1 kHz

510721

(see rear side of the PCB)

L

P1

TP1

TP2

TP3

TP4

TP6

TP5

TP7

TP8 TP9

Audio signal

Left

Hi

Right

Hi

Left

Lo

Right

Lo

300 mV/1 kHz 300 mV/1 kHz

510722

(see rear side of the PCB)

PCB headphone, solder side, PCB-no. 510721

PCB headphone, solder side, PCB-no. 510722

The PCB layout

is simular on

both sides

The PCB layout

is simular on

both sides

The capsule´s impedance has

been customized. Therefore

the PCB assembling has been

changed.

For PCB no. 510721 order the

• spare part module 527565

(not microphone side) or

• spare part module 525763

(microphone side)

For PCB no. 510722 several

spare parts are available.

HME 46-3, HMD 46-3

02/2008 19/25

6.6 Block diagram

HME 46-3, HMD 46-3

20/25 02/2008

7 Exploded views with spare part lists

7.1 Exploded view HME 46-3 / HMD 46-3

120

20

threaded pin

100

Microphone side

10

90

80

70

60

50

transducer

110

PCB

40

Note:

The system module consists of

- the resonator (60)

- the capsule and

- the PCB

cable

with screws

HME 46-3, HMD 46-3

02/2008 21/25

7.2 Spare part list for HME 46

FIG. ITEM PART NUMBER NOMENCLATURE UNITS PER ASSY

10 515489 SPLIT HEADBAND 1

20 525765 CAP, MICROPHONE SIDE 1

-25 515007 CAP HME 46 ATC, NOT MICROPHONE SIDE 1

-30 525763 MODULE MICROPHONE SIDE: CAPSULE WITH RESONATOR, PCB AND LEADS

NOTE: FOR SEVERAL RESONATOR, PCB OR LEAD ORDERING SEE ALSO EXPLODED VIEW

OF THE SYSTEM MODULE

-35 525764 MODULE NOT MICROPHONE SIDE: CAPSULE WITH

NOTE: FOR SEVERAL RESONATOR, PCB OR LEAD ORDERING SEE ALSO EXPLODED VIEW

OF THE SYSTEM MODULE

40 093680 FELT PLATE 1

50 600777 CENTER 1

60 094429 RESONATOR 1

70 522096 LENS SCREW 2

80 523399 DISCS, 1 PAIR 2

90 515295 EARPADS, 1 PAIR 2

-95 515296 EARPADS, 100 PAIRS 200

100 515645 MICROPHONE ARM MKE 46 STANDARD 1

-105 528136 MICROPHONE ARM MKE 46_152MV/PA 1

110 093675 CABLE HOLDER 1

120 528106 LABEL 1

- ITEM NOT ILLUSTRATED

RESONATOR, PCB AND LEADS

1

1

7.3 Spare part list for HMD 46

FIG. ITEM PART NUMBER NOMENCLATURE UNITS PER ASSY

10 515489 SPLIT HEADBAND 1

20 525765 CAP, MICROPHONE SIDE 1

-25 515432 CAP HMD 46 ATC, NOT MICROPHONE SIDE 1

-30 525763 MODULE MICROPHONE SIDE: CAPSULE WITH RESONA

5 525764 MODULE NOT MICROPHONE SIDE: CAPSULE WITH RESONATOR, PCB AND LEADS

-3

40 0936

50 600777 CENTER 1

60 094429 RESONATOR 1

70 522096 LENS SCREW

80 523399 DISCS, 1 PAIR 2

90 515295 EARPADS, 1 PAIR 2

-95 515296 EARPADS, 100 PAIRS 200

100 528135 MICROPHONE ARM MD 46-413 STANDARD 1

-105 528154 MICROPHONE ARM MD 46-413_5 OHMS 1

110 093675 CABLE HOLDER 1

120 528106 LABEL 1

- ITEM NOT ILLUSTRATED

80 FELT PLATE 1

NOTE: FOR SEVERAL RESONATOR, PCB OR LEAD ORDERING SEE ALSO EXPLODED

VIEW OF THE SYSTEM MODULE

NOTE: FOR SEVERAL RESONATOR, PCB OR LEAD ORDERING SEE ALSO EXPLODED

VIEW OF THE SYSTEM MODULE

TOR, PCB AND LEADS

1

1

2

HME 46-3, HMD 46-3

22/25 02/2008

7.4 Exploded view of the system module

10

20

40

(orange)

30

(brown)

capsule

7.5 Spare part list of the system module not microphone side (525764)

FIG. ITEM PART NUMBER NOMENCLATURE UNITS PER ASSY

10 515642 CAPSULE WITH RESONATOR AND LEADS 1

20 515644 PCB ASSEMBLY NOT MICROPHONE SIDE FOR HME/D 46-3 1

-20A 528155 PCB ASSEMBLY NOT MICROPHONE SIDE FOR HME/D 46-31

(WITHOUT ACTIVEGARD)

30 515002 LEAD BROWN 1

40 515003 LEAD ORANGE 1

- ITEM NOT ILLUSTRATED

1

7.6 Spare part list of the system module microphone side (525763)

FIG. ITEM PART NUMBER NOMENCLATURE UNITS PER ASSY

10 515642 CAPSULE WITH RESONATOR AND LEADS 1

20 515643 PCB ASSEMBLY MICROPHONE SIDE FOR HME/D 46-3 1

-20A 528156 PCB ASSEMBLY MICROPHONE SIDE FOR HME/D 46-31

(WITHOUT ACTIVEGARD)

30 515002 LEAD BROWN 1

40 515003 LEAD ORANGE 1

- ITEM NOT ILLUSTRATED

1

HME 46-3, HMD 46-3

02/2008 23/25

7.7 Exploded view of the cap, microphone side

10

cap of

microphone side

microphone arm

7.8 Spare part list of the cap, microphone side

FIG. ITEM PART NUMBER NOMENCLATURE UNITS PER ASSY

10 087509 THREADED PIN 1

- ITEM NOT ILLUSTRATED

HME 46-3, HMD 46-3

24/25 02/2008

7.9 Exploded view cable -PTT-x

30

60

40

40

40

40

PCB drawn as example

50

10

50

90

100

20

25

7.10 Spare part list for cable -PTT-x

FIG. ITEM PART NUMBER NOMENCLATURE UNITS PER ASSY

10 515048 HOUSING 1

20 514188 KNOB PTT 1

30 600698 COVER 1

40 087996 LENS SCREW TORX -6IP-EJOT, 1.8X8 4

50 039538 INSERT RD7.2X4 2

60 515649 PCB ASSY 1

-70 528106 LABEL 1

90 515058 CABLE -PTT-6, 0.3 M 1

90 600730 CABLE -PTT-6-1, 1.0 M 1

90 515060 CABLE -PTT-L, 0.3 M 1

90 600642 CABLE -PTT-LA, 1.75 M 1

90 600667 CABLE -E/D-3PTT-M, 1.6 M 1

100 515486 CABLE -PTT-6, 1.5 M 1

100 515479 CABLE -PTT-6-1, 0.8 M 1

100 515486 CABLE -PTT-L, 1.5 M 1

100 515470 CABLE -PTT-LA, 0.5 M 1

100 515479 CABLE -E/D-3PTT-M, 0.8 M 1

- ITEM NOT ILLUSTRATED

HME 46-3, HMD 46-3

02/2008 25/25

Loading...

Loading...