Sencore TC28 Service Manual

TC28

" THE HYBRIDER "

SERVICE MANUAL

SAFETY REMINDERS

When testing electronic equipment, there is always a danger present. Unexpected high voltages can be present at unusual locations in defective equipment. The technician should become familiar with the device that he is working on and observe the following precautions.

1.When making test lead connections to high voltage points, remove the power. If this cannot be done, be sure to avoid contact with other equipment or metal objects. Place one hand in your pocket

as a safety precaution and stand on an insulated floor to reduce the possibility of shock.

2.Discharge filter capacitors before connecting test leads to them.

Capacitors can store a charge that could be dangerous to the technician.

3.Be sure your equipment is in good order. Broken or frayed test leads can be extremely dangerous and can expose the technician to dangerous potentials.

4.Remove the test leads immediately after the test has been completed to reduce the possibility of shock.

5.Do not work alone when working on hazardous circuits. Always have another person close by in case of accident. Remember, even

a minor shock can be the cause of a more serious accident, such as falling against the equipment, or coming in contact with high voltages.

1

TABLE OF CONTENTS

SAFETY REMINDERS |

|

1 |

|

INTRODUCTION . |

|

3 |

|

DESCRIPTION |

|

|

3 |

FEATURES |

. |

|

3 |

SPECIFICATIONS |

|

3 |

|

CONTROLS |

. |

|

4 |

GENERAL OPERATIONS................................................................. |

. |

4 |

|

OPERATION |

. |

|

6 |

TUBE TEST SET UP |

|

6 |

|

SHORTS TEST . |

|

6 |

|

EMISSION TEST . . |

|

7 |

|

GRID - LEAKAGE TEST |

|

7 |

|

LIFE TEST |

. . . |

|

7 |

FILAMENT WARM UP TIME............................................................ |

. |

8 |

|

FILAMENT VOLTAGE SENSITIVITY |

|

8 |

|

REJUVENATION |

................................................................................ |

. |

8 |

SET UP FOR NEW TUBES . |

|

9 |

|

"A" PIN ELIMINATION |

|

9 |

|

"B" FILAMENT . |

|

. |

9 |

"C" LOAD |

|

|

10 |

"D" SET UP |

|

|

10 |

SOCKET SET UP |

|

|

10 |

EXAMPLE OF SETTING UP THE TC28 FOR NEW TUBES |

|

11 |

|

TRANSISTOR TESTS ............................................................................. |

|

12 |

|

GAIN TEST . . |

|

|

12 |

LEAKAGE TEST . . |

|

13 |

|

DETERMINING BASING |

|

13 |

|

LOCATING LEAKAGE |

|

14 |

|

CHECKING DIODES . |

|

17 |

|

CIRCUIT DESCRIPTION........................................................................ |

|

18 |

|

THEORY OF OPERATION - TUBE TEST' ...................................... |

|

18 |

|

EMISSION TEST................................................................................. |

|

|

19 |

GRID - LEAKAGE TEST |

|

20 |

|

SHORTS TEST..................................................................................... |

|

|

20 |

THEORY OF OPERATION - TRANSISTOR TEST....................... |

|

21 |

|

GAIN TEST.......................................................................................... |

|

21 |

|

POWER SUPPLY.................................................................................. |

|

22 |

|

2KHz OSCILLATOR AND SIGNAL AMPLIFIERS....................... |

22 |

||

LOGIC CIRCUIT AND INDICATOR DRIVE ................................. |

22 |

||

LEAKAGE TEST . |

24 |

||

SERVICING THE TC28 . . |

25 |

||

DISSASSEMBLY INSTRUCTIONS |

25 |

||

CALIBRATION.............................. |

|

26 |

|

TROUBLE CHARTS . . |

29 |

||

SERVICE AND WARRANTY |

32 |

||

2

INTRODUCTION

DESCRIPTION

Numerous solid-state devices are finding increasing application in television and other home entertainment equipment. These devices are also being used in conjunction with a multitude of tube types to produce the hybrid sets.

To be effective in the field service of these units, the service technician is faced with transporting a rather cumbersome and costly array of test equipment. The Sencore engineering staff is aware of the problems and needs encountered in the service industry. In response to these needs, the ever popular Mighty Mite Tube tester has been expanded to incorporate the features of Sencore's latest solid state device tester, the TOUCH TONE CRICKET. Now, in one compact, rugged, easy-to-use unit, exists the ability to completely and reliably test the tubes, transistors, FET's and diode devices found in modern home entertainment equipment.

FEATURES

*A single instrument for fast, accurate testing of tubes, transistors and FET's without complicated set ups.

*Pin elimination switches for greater capability in tube tests as new types are announced.

*Full cathode current emission test of tubes.

*Sensitive 100 megohm grid leakage test in addition to regular shorts test, all on a large easy-to-read meter.

*Complete test for transistors and FET's including in-circuit gain and out-of-circuit gain and leakage with NO set-up or basing data required.

*Rugged construction throughout, including protection against overload for sensitive meter and circuitry.

SPECIFICATIONS

DEVICES TESTED

Devices tested

TUBE TESTS:

Emission

Tubes, transistors, diodes, single-gate FET 's

Load currents to 120mA and maximum applied voltage of 40 VAC RMS

3

Grid-Leakage |

100 Megohm or less reads BAD. 100 Megohms to |

|

200 Megohms reads in questionable area. |

Shorts |

200,000 ohms or less (40 VAC RMS applied voltage) |

|

indicates short on meter. |

TRANSISTOR TESTS: |

|

Gain (IN or |

VCE = 5 volts; VBE = 3 volts peak-to-peak, zero |

OUT of |

reference, 2KHz frequency. GOOD/BAD meter |

Circuit) |

indication plus audible "chirp" for good test |

|

indication. |

Leakage (OUT |

5VDC applied voltage, meter indicates 0 - 3000 |

of circuit only) |

microamps leakage current. |

CONTROLS

GENERAL OPERATION

TUBES/TRANSISTORS FUNCTION SWITCH: This rotary switch applies power to the TC28, selects tube or transistor tests and the type test to be made.

METER ZERO: This control is used to set meter to zero previous to making any test.

CONTROLS RELATED TO TUBE TEST:

"A " SWITCHES: These slide switches switched to the down position serve to isolate extra connections to the tube which would falsely indicate a shorted condition. The slide switch labeled RESET instantly clears all pin elimination switches.

FILAMENT or "B" SWITCH: This rotary switch sets the proper filament voltage for the tube being tested.

LOAD or "C" SWITCH: This rotary switch determines the range of load current to be carried by the tube during the emission test.

4

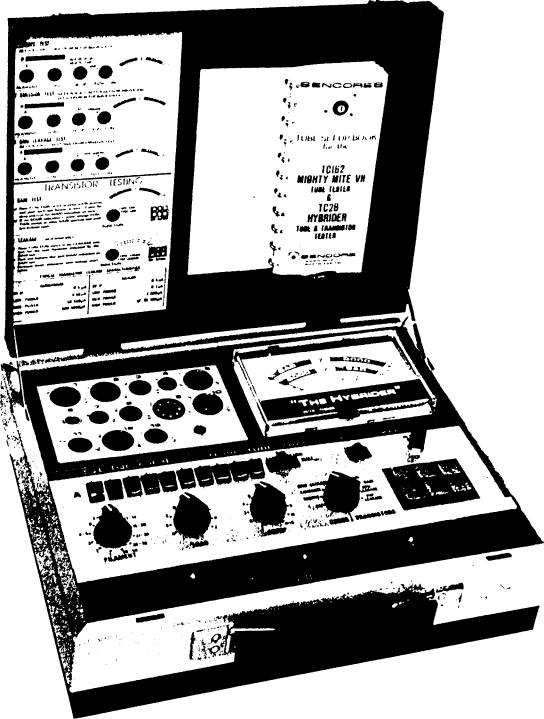

Fig. 1 TC28 "The Hybrider"

5

SETUP or "D" SWITCH: This rotary switch selects the control grid pin for the emission test. It also serves as the shorts test switch, for any interelectrode shorts, by rotating the switch through its positions.

LIFE TEST: This slide switch provides a test of the useable life of a tube by measuring how well the tube performs with a reduced filament voltage.

CONTROLS RELATED TO TRANSISTOR TEST:

TEST SWITCHES: These six pushbutton switches apply the test voltage to the elements of the device under test, and mechanically rotate lead connection to all possible basing configurations, thus eliminating requirements for basing or circuit information.

CONNECTIONS: A socket panel provides a total of 13 tube sockets plus 1 transistor socket for all test conditions. A test lead cable terminated in 3 EZ Hook connectors facilitates in-circuit transistor or FET gain and leakage tests.

OPERATION

TUBE TEST SET UP

Operation of the TC28 Hybrider has been designed for simplicity, speed and accuracy. All that is necessary to completely check a tube is to follow the basic test procedure outlined below.

1.Connect the TC28 Hybrider to a grounded source of 105 to 125 volts, 50 to 60 Hz, AC power.

2.Locate the tube type to be tested in the setup chart. Looking to the right of the tube number, observe the setup information for the controls labeled A,B,C,D and socket. Some tubes have more than one listing indicating that the tube has more than one section to be tested. Each section of the multiple tube is tested separately.

3.Push the PIN ELIMINATION switches listed under A down ; to eliminate those pins. If none are listed, leave all switches in the up position.

4.Set the B,C, and D switches to the positions indicated and insert the tube into the socket listed. Where more than one setting is listed, make the emission and grid leakage test on each section. The shorts test need be made only once.

SHORTS TEST

Set the TUBES/TRANSISTOR Function Switch to SHORTS and check the front panel METER ZERO adjust to ensure a "0" indication on the

meter. Allow a period of time for the tube filament to warm up, then rotate the "D" switch slowly through all of its positions while observing

6

the meter. If no short exists or the resistance of the short is greater than 200,000 ohms, the meter will remain in the GOOD area of the GOOD/ BAD SHORTS scale. Shorts of 200,000 ohms or less will be indicated to a relative degree on the SHORTS scale. Tubes having a directly heated cathode (those in which the filament serves as the cathode) will show a direct short between heater and cathode on the H-K position of the "D" Switch. This is a normal condition and these tubes are indicated in the setup book by an asterisk (*) .

EMISSION TEST

If the tube passes the SHORTS test, rotate the Function switch to the EMISSION position and read the emission quality of the tube on the top scale of the meter. A tube indicating in the questionable area (?), has an emission level much lower than normal. It's replacement would be determined by you and your customer, based on the nature of the circuit in which the tube is to operate.

GRID-LEAKAGE TEST

If the tube reads in the GOOD area of the meter and passes the EMISSION test, switch to GRID LEAKAGE and read the grid leakage of the tube on the GRID LEAKAGE scale of the meter. This is a very important check and will pinpoint troublesome tubes that may otherwise check good. If the meter is indicating in the GOOD area of the scale but slowly rising, wait a minute or so to allow the meter to stabilize before judging test results. On large power tubes, such as a horizontal output tube, do not make a grid leakage check after an extended emission check. If the tube is left in the emission check position for several minutes, the grid will heat up and, when switched to grid leakage, will read higher than normal. Allow the tube to cool slightly before the grid leakage check. You can expedite the grid leakage check by raising the filament voltage for a few seconds. This is not the same overheating as was caused in the emission check, but will show up grid leakage. If the grid leakage indication climbs into the BAD area on the meter, reduce the filament voltage and see if the meter remains in the bad area. If it does so, then the tube will give trouble in the circuit and should be replaced. If the meter drops off rapidly back into the GOOD area, then the tube is good.

If the tube passes all of the above tests, it can be considered good and need not be replaced. If the tube is in the questionable area on any test, it becomes a value judgement based upon circumstances as to whether or not it should be replaced.

LIFE TEST

If the meter needle climbs very slowly into the GOOD area or Questionable area of the meter on the Emission test, the life expectancy of the tube can be considered much less than if the meter indicated GOOD in a

7

shorter period of time. Also, if the needle should climb into the GOOD area and then "fall off," life expectancy can be considered much less. A general measure of the usable life remaining in a tube can be obtained by using the "Life test" position of the TC28 "Hybrider." Simply slide the LIFE TEST switch to the right and hold it for a few moments. Observe the emission level of the tube during this time. If the emission remains the same or drops only slightly the tube can be considered good. If the emission falls off quickly into the questionable or bad areas, it may be wise to replace the tube. (The rapid drop in emission generally indicates a short life expectancy).

FILAMENT WARM UP TIME

When replacing a costly horizontal output tube in a television receiver, it is a good idea to not only check the horizontal oscillator for emission and other standard tests, but to also check the length of time it takes to warm up. If the horizontal oscillator tube is slower in warming up than the output tube, the output tube will draw heavy current and its life will be shortened considerably. Checking the warm up time of the oscillator tube and making sure that it is as fast or faster than the output tube can reduce the chance of a call back later for the same trouble and keep your customer's confidence high in your service ability.

FILAMENT VOLTAGE SENSITIVITY

Some tubes may check good on the emission test and pass the other tests in the Hybrider, but still not operate properly in the receiver. These tubes may have a filament sensitive cathode. This means that the emission from the tube will change with a change in the applied filament voltage to the tube. This is caused from a low power line or defective power transformer in the receiver. This type of tube can be most troublesome in series string receivers. To test for this trouble, simply push the LIFE TEST switch while monitoring the emission of the tube on the meter. A good tube will not change its reading at all while a filament sensitive tube will drop in emission. If the tube falls into the questionable area (?) on the meter, it will give trouble in the circuit and should be replaced.

REJUVENATION

If you wish to rejuvenate a small tube, merely increase the filament voltage by setting switch "B" one setting higher for ten to fifteen

seconds. This will super heat the cathode and boil out more emitting material from under the oxide coating. This is only a temporary

measure as rejuvenation of a receiving tube will not last very long.

8

SET UP FOR NEW TUBES

New tubes can sometimes be a problem as they may not be listed in the set-up chart. This can be especially true on new receivers just introduced by the set manufacturers. Though new tubes are seldom being added at the present time, new tubes will undoubtedly appear in the future. With an understanding of the setup controls and what each does, you can set the Hybrider from a tube manual or even the schematic of the receiver itself.

"A" PIN ELIMINATION

The "A" PIN ELIMINATION switch is used to isolate internal connections of two pins to the same element of the tube so that a test may be made. For example, the tube basing shown in Figure 2 is a 9QL basing. The con- trol grid is tied to pins 2 and 6, the screen grid to pins 1 and 7 and pin 9 is an internal connection that could be connected to any pin inside of the tube. To eliminate any shorts indication other than that which are true shorts in the tube, the PIN ELIMINATION switches 6, 7, and 9 would be

set in the down position to open these pins before the test is made. All the numbers correspond to the tube base pin number except for socket number 10, the compactron, where pin 11 is connected to PIN ELIMINATION switch number 1. If no isolation is needed, all switches should be in the uppermost position. After each tube is tested, push the RESET switch to the right to place all switches in the up position. Each can be moved independently of each other, either up or down or set with RESET switch.

"B" FILAMENT

This switch selects the filament voltage applied to the tube under test from 1 volt to over 50 volts. The twelve position switch selects a voltage range and, with the unique design of the filament transformer,

9

the tube under test will load the transformer to obtain the correct voltage for testing. When setting up a new tube, simply set the "B" FILAMENT switch to the correct voltage or voltage range.

"C" LOAD

This switch selects the proper AC voltage to be applied to the plate of the tube as well as the correct load resistor so that the tube's designed current can be set and the tube checked under full load. The current ranges for the settings of the "C" LOAD switch are as follows:

LOAD switch |

Cathode Current |

LOAD switch |

Cathode Current |

|

A |

50mA plus |

F |

2 - 7mA |

|

B |

20 |

- 50mA |

G |

.7 - 2mA |

C |

15 |

- 30mA |

H |

.5 - .8m A |

D |

10 |

-16mA |

J |

.5mA or less |

E |

6 - 12mA |

|

|

|

The current that the "C" LOAD switch is set to is the normal cathode current under normal bias conditions as listed in the tube manual. If a tube manual is not handy, compute the cathode current by the voltage drop across the cathode or plate load resistor in the circuit or from the schematic by using Ohm's Law.

"D" SET UP

The "D" switch is used to pick up the control grid for the test on the tube. It was discovered many years ago that approximately 97% of the electrons would go to the control grid when checking cathode emission. This is now used as the pick-up element. In the example of Figure 2, the "D" switch would be set to one of the control grids that is not isolated. If pin 6 were to be isolated, the "D" switch would be set to pick up pin 2.

The only exception to the above is on socket number 10 where pin 11 on the tube base is picked up with the first position of the "D" switch.

Sockets number 3 and 8 are wired identically except that socket number 8 has three pins not connected. This socket is used to isolate extra connections where more than two base pins are connected to the same element such as in the 1X2 high voltage rectifier. The seven-pin sockets 4 and 7 are alike except that the filament pins on socket 4 are 3 and 4 while on socket 7 they are 1 and 7.

SOCKET SET UP

The sockets on the TC28 have the filament pins prewired to eliminate the extra setup that is involved. The actual pin connections can be seen on

10

the schematic diagram of the unit. Note that the two octal sockets have different filament connections. Socket number 1 is for filaments on pins

2 and 7 while socket number 2 is for filaments on pins 7 and 8. Sockets 3 and 8 have filaments on pins 4 and 5 while socket number 13 is for special Hi-Fi tubes with filaments on pins 1 and 2.

There are two novar sockets that are wired identically. Socket number 5 is for the standard novar based tubes while socket number 12 is for the magnoval based tubes. The pins on the magnoval based tubes are larger in diameter than the standard novar base and can damage the novar socket. All magnoval tubes are checked in socket number 12 to prevent damage to the regular novar socket number 5. When selecting the socket for a new , tube, select the socket for the filament wiring as well as the socket the tube should fit into.

4

EXAMPLE OF SETTING UP THE TC28 FOR NEW TUBES

Let's use for our example, the 6JE6 shown in Figure 2. This tube is a standard novar based tube with the control grid tied to two pins on the tube base.

FIRST: Determine the socket to use. In this case, the tube is a standard novar base tube so that socket number 5 will be used.

SECOND: All the pins that must be isolated for testing must be noted. In this example, we have the control grid on pins 2 and 6 and the screen grid on pins 1 and 7 with pin 9 possibly connected to some pin internally. With the "A" PIN ELIMINATION switch,we will isolate the extra pins. For our example, we will push switches 6 and 7 down to the isolation position along with switch 9 to eliminate any possibility of this pin causing a false indication.

THIRD: Determine the filament voltage. In this case, it is the 6JE6 so that the filament switch "B" will be set to 6. The first set of numbers on the tube generally indicate the filament voltage of the tube. On foreign tubes, consult a substitution guide to find the filament voltage and characteristics that can be used to check the tube.

FOURTH: Select the current range that the tube is to be checked at using the information under "C" LOAD switch section of "SETUP FOR NEW TUBES. For our example, the A position would be used as the 6JE6 draws a very heavy plate current under normal use. Then perform the tests as previously described.

11

Loading...

Loading...