Page 1

TC28

"

THE HYBRIDER

SERVICE

"

MANUAL

Page 2

SAFETY REMINDERS

When testing electronic equipment, there is always a danger present.

Unexpected high voltages can be present at unusual locations in defective

equipment. The technician should become familiar with the device that

he is working on and observe the following precautions.

2.

3.

4.

5.

1.

When making test lead connections to high voltage points, remove

the power. If this cannot be done, be sure to avoid contact with

other equipment or metal objects. Place one hand in your pocket

as a safety precaution and stand on an insulated floor to reduce

the possibility of shock.

Discharge filter capacitors before connecting test leads to them.

Capacitors can store a charge that could be dangerous to the tech-

nician.

Be sure your equipment is in good order. Broken or frayed test

leads can be extremely dangerous and can expose the technician

to dangerous potentials.

Remove the test leads immediately after the test has been completed

to reduce the possibility of shock.

Do not work alone when working on hazardous circuits. Always

have another person close by in case of accident. Remember, even

a minor shock can be the cause of a more serious accident,

falling against the equipment, or coming in contact with

voltages.

such as

high

1

Page 3

TABLE OF CONTENTS

SAFETY REMINDERS

INTRODUCTION

DESCRIPTION

FEATURES

SPECIFICATIONS

CONTROLS

GENERAL OPERATIONS

OPERATION

TUBE TEST SET UP

SHORTS TEST

EMISSION TEST

GRID - LEAKAGE TEST

LIFE TEST

FILAMENT WARM UP TIME

FILAMENT VOLTAGE SENSITIVITY

REJUVENATION

SET UP FOR NEW TUBES .

"A" PIN ELIMINATION

"B" FILAMENT .

"C" LOAD

"D" SET UP

SOCKET SET UP

EXAMPLE OF SETTING UP THE TC28 FOR NEW TUBES

TRANSISTOR TESTS

GAIN TEST

LEAKAGE TEST

DETERMINING BASING

LOCATING LEAKAGE

CHECKING DIODES .

CIRCUIT DESCRIPTION

THEORY OF OPERATION - TUBE TEST'

EMISSION TEST

GRID - LEAKAGE TEST

SHORTS TEST

THEORY OF OPERATION - TRANSISTOR TEST

GAIN TEST

POWER SUPPLY

2KHz OSCILLATOR AND SIGNAL AMPLIFIERS

LOGIC CIRCUIT AND INDICATOR DRIVE

LEAKAGE TEST

SERVICING

DISSASSEMBLY INSTRUCTIONS

CALIBRATION

TROUBLE CHARTS . .

SERVICE AND WARRANTY

..........................................................................................

THE

.

.

.

.................................................................

.

.

. .

. . .

............................................................

................................................................................

.............................................................................

. .

. .

........................................................................

......................................

.................................................................................

.....................................................................................

..................................................................................

.................................

.

TC28 . .

..............................

.......................

.......................

.

.

.

.

17

18

18

19

20

20

21

21

22

22

22

24

25

25

26

29

32

1

3

3

3

3

4

4

6

6

6

7

7

7

8

8

8

9

9

9

10

10

10

11

12

12

13

13

14

2

Page 4

INTRODUCTION

DESCRIPTION

Numerous solid-state devices are finding increasing application in tele-

vision and other home entertainment equipment. These devices are also

being used in conjunction with a multitude of tube types to produce the

hybrid sets.

To be effective in the field service of these units, the service technician is

faced with transporting a rather cumbersome and costly array of test

equipment. The Sencore engineering staff is aware of the problems and

needs encountered in the service industry. In response to these needs, the

ever popular Mighty Mite Tube tester has been expanded to incorporate

the features of Sencore's latest solid state device tester, the

TONE CRICKET. Now, in one compact, rugged, easy-to-use unit, exists

the ability to completely and reliably test the tubes, transistors, FET's

and diode devices found in modern home entertainment equipment.

FEATURES

TOUCH

*

A single instrument for fast, accurate testing of tubes, transistors and

FET's without complicated set ups.

*

Pin elimination switches for greater capability in tube tests as

types are announced.

*

Full cathode current emission test of tubes.

Sensitive 100 megohm grid leakage test in addition to regular shorts

*

test, all on a large easy-to-read meter.

Complete test for transistors and FET's including in-circuit gain

*

out-of-circuit gain and leakage with NO set-up or basing data required.

Rugged construction throughout, including protection against overload

*

for sensitive meter and circuitry.

SPECIFICATIONS

DEVICES TESTED

new

and

Devices tested

TUBE TESTS:

Emission

Tubes, transistors, diodes, single-gate FET's

Load currents to 120mA and maximum applied

voltage of 40 VAC RMS

3

Page 5

Grid-Leakage

100 Megohm or less reads BAD. 100 Megohms to

200 Megohms reads in questionable area.

Shorts 200,000 ohms or less (40 VAC RMS applied voltage)

indicates short on meter.

TRANSISTOR TESTS:

Gain (IN or

OUT of

Circuit)

VCE = 5 volts; VBE = 3 volts peak-to-peak, zero

reference, 2KHz frequency.

indication

plus audible "chirp" for good test

GOOD/BAD meter

indication.

Leakage (OUT

of circuit only)

5VDC applied voltage, meter indicates 0 - 3000

microamps leakage current.

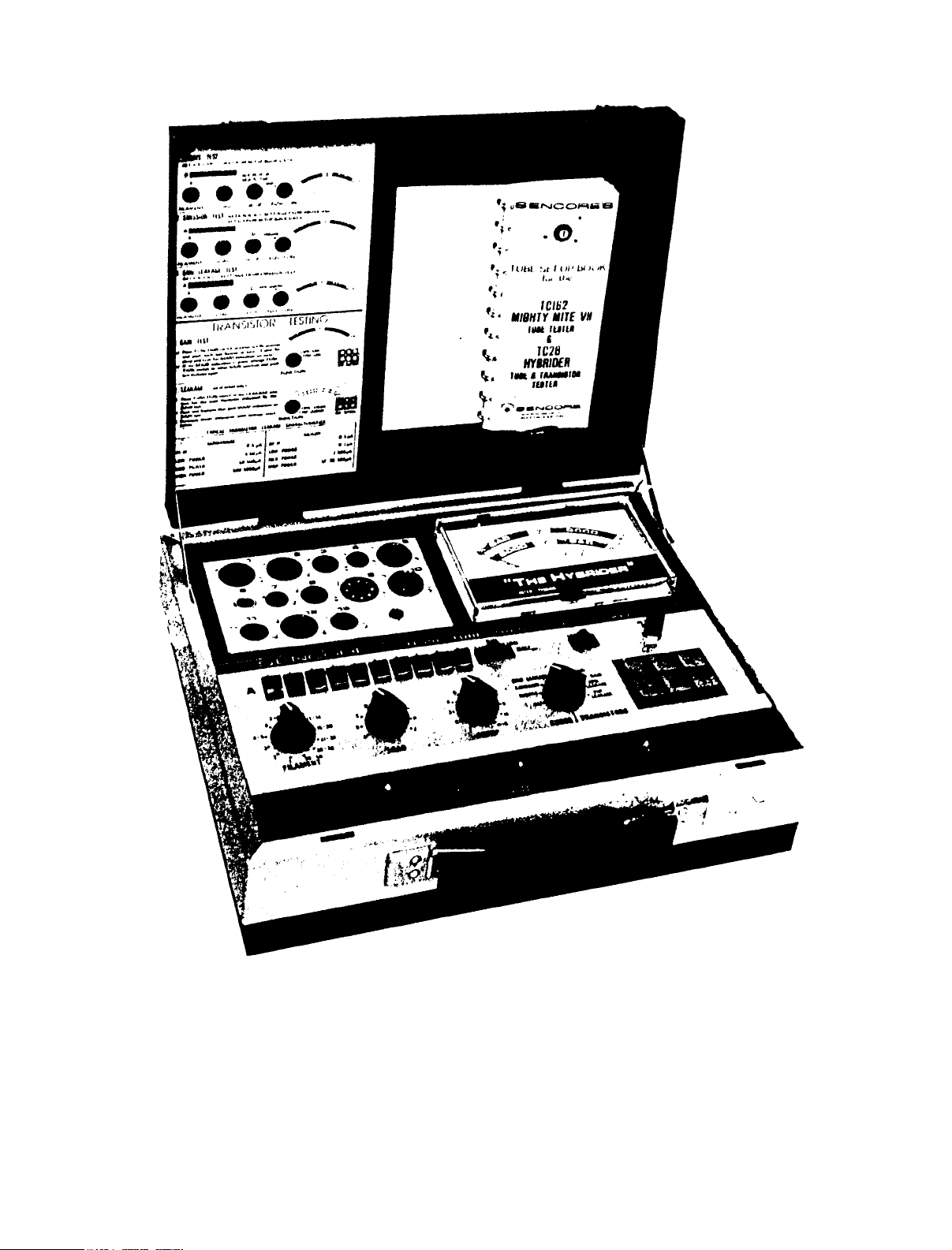

CONTROLS

GENERAL OPERATION

TUBES/TRANSISTORS FUNCTION SWITCH:

applies power to the TC28, selects tube or transistor tests and the type

test to be made.

This rotary switch

METER ZERO: This control is used to set meter to zero previous to

making any test.

CONTROLS RELATED TO TUBE TEST:

"

"A

SWITCHES: These slide switches switched to the down position

serve to isolate extra connections to the tube which would falsely indicate

a shorted condition. The slide switch labeled RESET instantly clears all

pin elimination switches.

FILAMENT or "B" SWITCH: This rotary switch sets the proper fila-

ment voltage for the tube being tested.

LOAD or "C" SWITCH: This rotary switch determines the range of

load current to be carried by the tube during the emission test.

4

Page 6

Fig. 1

TC28 "The Hybrider"

5

Page 7

SETUP or "D" SWITCH: This rotary switch selects the control grid pin

for the emission test. It also serves as the shorts test switch, for any inter-

electrode shorts, by rotating the switch through its positions.

LIFE TEST: This slide switch provides a test of the useable life of a

tube by measuring how well the tube performs with a reduced filament

voltage.

CONTROLS RELATED TO TRANSISTOR TEST:

TEST SWITCHES: These six pushbutton switches apply the test voltage

to the elements of the device under test, and mechanically rotate lead

connection to all possible basing configurations, thus eliminating

requirements for basing or circuit information.

CONNECTIONS: A socket panel provides a total of 13 tube sockets

plus 1 transistor socket for all test conditions. A test lead cable terminat-

ed in

3

EZ Hook connectors facilitates in-circuit transistor or FET gain

and leakage tests.

OPERATION

TUBE TEST SET UP

Operation of the TC28 Hybrider has been designed for simplicity, speed

and accuracy.

follow the basic test procedure outlined below.

Connect the TC28 Hybrider to a grounded source of 105 to 125

1.

volts, 50 to 60 Hz, AC power.

2.

Locate the tube type to be tested in the setup chart. Looking to the

right of the tube number, observe the setup information for the

controls labeled A,B,C,D and socket. Some tubes have more than

one listing indicating that the tube has more than one section to be

tested.

3.

Push the PIN ELIMINATION switches listed under A down

inate those pins. If none are listed, leave all switches in the up

position.

4.

Set the B,C, and D switches to the positions indicated and insert the

tube into the socket listed.

make the emission and grid leakage test on each section. The shorts

test need be made only once.

All that is necessary to completely check a tube is to

Each section of the multiple tube is tested separately.

Where more than one setting is listed,

to elim-

;

SHORTS TEST

Set the TUBES/TRANSISTOR Function Switch to SHORTS and check

the front panel METER ZERO adjust to ensure a "0" indication on the

meter.

rotate the "D

Allow a period of time for the tube filament to warm up, then

"

switch slowly through all of its positions while observing

6

Page 8

the meter. If no short exists or the resistance of the short is greater than

200,000 ohms, the meter will remain in the GOOD area of the GOOD/

BAD SHORTS scale. Shorts of 200,000 ohms or less will be indicated to

a relative degree on the SHORTS scale. Tubes having a directly heated

cathode (those in which the filament serves as the cathode) will show a

direct short between heater and cathode on the H-K position of the "D"

Switch.

setup book by an asterisk (*) .

This is a normal condition and these tubes are indicated in the

EMISSION TEST

If the tube passes the SHORTS test, rotate the Function switch to the

EMISSION position and read the emission quality of the tube on the top

scale of the meter. A tube indicating in the questionable area (?), has

an emission level much lower than normal. It's replacement would be

determined by you and your customer, based on the nature of the circuit

in which the tube is to operate.

GRID-LEAKAGE TEST

If the tube reads in the GOOD area of the meter and passes the EMISSION

test, switch to GRID LEAKAGE and read the grid leakage of the tube on

the GRID LEAKAGE scale of the meter. This is a very important check

and will pinpoint troublesome tubes that may otherwise check good. If

the meter is indicating in the GOOD area of the scale but slowly rising,

wait a minute or so to allow the meter to stabilize before judging test

results.

make a grid leakage check after an extended emission check. If the tube

is left in the emission check position for several minutes, the grid will

heat up and, when switched to grid leakage, will read higher than normal.

Allow the tube to cool slightly before the grid leakage check. You can

expedite the grid leakage check by raising the filament voltage for a few

seconds.

check, but will show up grid leakage. If the grid leakage indication climbs

into the BAD area on the meter, reduce the filament voltage and see if the

meter remains in the bad area. If it does so, then the tube will give

trouble in the circuit and should be replaced. If the meter drops off

rapidly back into the GOOD area, then the tube is good.

On large power tubes, such as a horizontal output tube, do not

This is not the same overheating as was caused in the emission

If the tube passes all of the above tests, it can be considered good and

need not be replaced. If the tube is in the questionable area on any test,

it becomes a value judgement based upon circumstances as to whether or

not it should be replaced.

LIFE TEST

If the meter needle climbs very slowly into the GOOD area or Questionable

area of the meter on the Emission test, the life expectancy of the tube

can be considered much less than if the meter indicated

7

GOOD

in

a

Page 9

shorter period of time. Also, if the needle should climb into the GOOD

area and then "fall off," life expectancy can be considered much less.

A general measure of the usable life remaining in a tube can be obtained

by using the "Life test" position of the TC28 "Hybrider." Simply slide

the LIFE TEST switch to the right and hold it for a few moments. Observe

the emission level of the tube during this time. If the emission remains

the same or drops only slightly the tube can be considered good. If the

emission falls off quickly into the questionable or bad areas, it may be

wise to replace the tube. (The rapid drop in emission generally indicates a

short life expectancy).

FILAMENT WARM UP TIME

When replacing a costly horizontal output tube in a television receiver, it

is

a good idea to not only check the horizontal oscillator for emission

and other standard tests, but to also check the length of time it takes to

warm up. If the horizontal oscillator tube is slower in warming up than

the output tube, the output tube will draw heavy current and its life will

be shortened considerably. Checking the warm up time of the oscillator

tube and making sure that it is as fast or faster than the output tube can

reduce the chance of a call back later for the same trouble and keep your

customer's confidence high in your service ability.

FILAMENT VOLTAGE SENSITIVITY

Some tubes may check good on the emission test and pass the other tests

in the Hybrider, but still not operate properly in the receiver. These tubes

may have a filament sensitive cathode.

from the tube will change with a change in the applied filament voltage to

the tube.

transformer in the receiver. This type of tube can be most troublesome

in series string receivers.

TEST switch while monitoring the emission of the tube on the meter. A

good tube will not change its reading at all while a filament sensitive tube

will drop in emission. If the tube falls into the questionable area (?) on

the meter, it will give trouble in the circuit and should be replaced.

This is caused from a low power line or defective power

To test for this trouble, simply push the LIFE

This means that the emission

REJUVENATION

If you wish to rejuvenate a small tube, merely increase the filament

voltage by setting switch "B" one setting higher for ten to fifteen

seconds.

material from under the oxide coating.

measure as rejuvenation of a receiving tube will not last very long.

This will super heat the cathode and boil out more emitting

This is only a temporary

8

Page 10

SET UP FOR NEW TUBES

New tubes can sometimes be a problem as they

set-up chart. This can be especially true on new receivers just introduced

by the set manufacturers. Though new tubes are seldom

the present time, new tubes will undoubtedly

an

understanding of the setup controls and what

the Hybrider from a tube manual or even the schematic

itself.

"A"

The "A" PIN ELIMINATION switch is used to isolate internal connections

of two pins to the same element of the tube so that a test

For example, the tube basing shown in Figure 2 is a

trol grid is tied to pins 2 and 6, the screen grid to pins 1 and 7 and pin 9 is

an internal connection that could be

tube.

shorts in the tube, the PIN ELIMINATION switches 6, 7, and

set in the down position to open these pins before the test is made. All the

numbers correspond to the tube base pin number except for socket

number 10, the compactron, where pin 11 is connected to PIN

ELIMINATION switch number 1. If no isolation is

should be in the uppermost position. After

RESET switch to the right to place all switches in the

can be moved independently of each other, either up

RESET switch.

PIN ELIMINATION

connected to any pin inside of the

To eliminate any shorts indication other than that which

may not be listed in the

being added at

appear in the future. With

each does, you can set

of the receiver

may be made.

9QL basing. The con-

are true

9 would be

needed, all switches

each

tube

is tested, push the

up position. Each

or down or set with

"B"

This switch selects the filament voltage applied to the

from 1 volt to over 50 volts. The twelve position switch selects

voltage range and, with the unique design of the

FILAMENT

filament transformer,

9

tube under test

a

Page 11

the tube under test will load the transformer to obtain the correct voltage for testing.

FILAMENT switch to the correct voltage or voltage range.

When setting up a new tube, simply set the "B"

"C"

This switch selects the proper AC voltage to be applied to the plate of the

tube as well as the correct load resistor so that the tube's designed current

can be set and the tube checked under full load. The current ranges for

the settings of the "C" LOAD switch are as follows:

LOAD switch

A

B

C

D

E

The current that the "C" LOAD switch is set to is the normal cathode

current under normal bias conditions as listed in the tube manual. If a

tube manual is not handy, compute the cathode current by the voltage

drop

schematic by using Ohm's Law.

LOAD

Cathode Current

50mA plus

20 - 50mA

15 - 30mA

10 -16mA

6 - 12mA

across the cathode or plate load resistor in the circuit or from the

LOAD switch

F 2 - 7mA

G

H

J

Cathode Current

.7 - 2mA

.5 - .8m A

.5mA or less

"D"

The "D" switch is used to pick up the control grid for the test on the

tube. It was discovered many years ago that approximately 97% of the

electrons would go to the control grid when checking cathode emission.

This is now used as the pick-up element. In the example of Figure 2, the

"D" switch would be set to one of the control grids that is not isolated.

If pin 6 were to be isolated, the "D" switch would be set to pick up pin

2.

The only exception to the above is on socket number 10 where pin 11 on

the tube base is picked up with the first position of the "D" switch.

Sockets number 3 and 8 are wired identically except that socket number

8 has three pins not connected. This socket is used to isolate extra

connections where more than two base pins are connected to the same

element such as in the 1X2 high voltage rectifier. The seven-pin sockets

4 and 7 are alike except that the filament pins on socket 4 are 3 and 4

while on socket 7 they are 1 and 7.

SET

UP

SOCKET SET UP

The sockets on the TC28 have the filament pins prewired to eliminate the

extra setup that is involved. The actual pin connections can be seen on

10

Page 12

the schematic diagram of the unit. Note that the two octal sockets

different filament connections. Socket number 1 is for filaments on pins

2 and 7 while socket number 2 is for filaments on pins 7 and 8. Sockets

3 and 8 have filaments on pins 4 and 5 while socket number 13 is for

special Hi-Fi tubes with filaments on pins 1 and 2.

have

There are two novar sockets that are wired identically. Socket number

5

is for the standard novar based tubes while socket number 12 is for the

magnoval based tubes. The pins on the magnoval based tubes are larger in

diameter than the standard novar base and can damage the novar socket.

All magnoval tubes are checked in socket number 12 to prevent damage to

the regular novar socket number 5. When selecting the socket for

a

new

,

tube, select the socket for the filament wiring as well as the socket the

tube should fit into.

4

EXAMPLE

OF

SETTING

UP THE TC28

FOR NEW TUBES

Let's use for our example, the 6JE6 shown in Figure 2. This tube is a

standard novar based tube with the control grid tied to two pins on the

tube base.

FIRST: Determine the socket to use. In this case, the tube is a standard

novar base tube so that socket number 5 will be used.

SECOND: All the pins that must be isolated for testing must be noted.

In this example, we have the control grid on pins 2 and 6 and the screen

grid on pins 1 and 7 with pin 9 possibly connected to some pin internally.

With the "A" PIN ELIMINATION switch,we will isolate the extra pins.

For our example, we will push switches 6 and 7 down to the isolation

position along with switch 9 to eliminate any possibility of this pin caus-

ing a false indication.

THIRD: Determine the filament voltage. In this case, it is the 6JE6 so

that the filament switch "B" will be set to 6. The first set of numbers on

the tube generally indicate the filament voltage of the tube. On foreign

tubes, consult a substitution guide to find the filament voltage and

characteristics that can be used to check the tube.

FOURTH: Select the current range that the tube is to be checked at

using the information under "C" LOAD switch section of "SETUP FOR

NEW TUBES. For our example, the A position would be used as the

6JE6 draws a very heavy plate current under normal use. Then perform

the tests as previously described.

11

Page 13

TRANSISTOR TESTS

GAIN TEST

The gain test on a transistor or FET with the TC28 is actually simpler

than testing a tube.

polarity, or even if it is a transistor or an FET. Merely connect the leads in

any combination and press the test buttons. Follow the procedure below

to make a gain test on a transistor or FET.

There is no need to know the transistor basing,

1.

tested and discharge all power supply filter capacitors.

2.

power.

3.

the test leads to the leads of the device to be tested. If the device to he

tested is a plug-in type and can be removed easily, you may use the transistor socket located on the socket panel in place of the test cable. It is

not necessary to determine basing of the device, the automatic test circuit

will accomplish this.

4.

and meter does not indicate in the GOOD area of GAIN / EMISSION

meter scale, select the opposite polarity on the TUBES/TRANSISTORS

Function switch and press the six test buttons again. If audible chirp is

still

circuit it should be removed from the circuit and retested before a replacement is installed.

a GOOD indication on two of the test buttons. If the exact basing of the

device under test is desired, refer to the section of this manual on

"Determining transistor basing." Some special devices such as Darlington

amplifiers or diode protected transistors will test good on only one test

button.

devices.

Remove power from the equipment

Connect the TC28 to a source of 105 - 125 volts, 50 to 60Hz, AC

The test cable is located in the lead storage compartment. Connect

Press each of the six test buttons in turn. If no audible chirp is heard

not heard, the device being tested is bad. If the device tests bad in

A good FET and most good transistors will give

Refer to the table in Figure 3 to determine the basing of these

containing

the device to be

There are some rare cases where a good transistor may test BAD by the

Hybrider when testing in-circuit. This will occur for a circuit whose base

to collector resistance is less than 100 ohms, or when large electrolytic

capacitors of 50uf or more are connected directly between the base or

collector leads of the transistor and ground.

usually found in typical circuit applications.

Therefore, it is recommended that if the in-circuit test of a transistor

indicates BAD, it should be removed and retested for gain before a

l2

These situations are not

Page 14

replacement is installed. This retest should also include the out-of-circuit

leakage test.

If a transistor tests BAD in-circuit and GOOD out-of-circuit, this may

indicate other problems in the circuit.

resistors of less than 100 ohms between base and collector or electrolytic

capacitors of 50uf or more connected to the transistor base or collector.

If these are not found, check the circuit board for the possibilities of:

1.

Shorted foils on the board.

2.

Large resistors, connected to the transistor, which may have changed

value or become shorted.

First check the schematic for

LEAKAGE TEST

It is possible for a transistor or FET to have good gain, and still

in the circuit because the leakage upsets the DC circuit values. The leakage test on a transistor is nearly the same as the grid

tube. To make the leakage test, proceed as follows:

1.

socket on the test panel or connect the test leads to the

device.

good indication.

2.

good gain test. This test checks the ICBO and ICEO leakage values of

transistors and the IGDO and IGSO leakage of FET's. These leakages

should measure zero for FET's and small silicon transistors. High power

silicon and small germanium transistors may indicate up to 100uA

leakage, while germanium power transistors may indicate up to

and

3.

scale leakage reading and the other two may or may not

depending on the transistor.

all four remaining buttons, while a MOS FET should

only two buttons. If you desire to determine the

a particular transistor, refer to the

manual.

Remove the transistor from the circuit and plug it into the transistor

Make the gain test and note which two test buttons result in a

Switch to the LEAKAGE test, and press the two buttons that

still be acceptable.

Press the remaining four buttons. Two of these will result in

A junction FET will indicate full scale on

exact type leakage for

Locating Leakage section of this

leakage test of

indicate leakage

indicate leakage on

not work

leads of the

3000uA

gave

a

full

a

a

DETERMINING BASING

If the device being tested checks good on two of the test buttons, it is

either a standard transistor or an FET. To determine if the device is a

transistor or FET, and the basing diagram, if it is a transistor, it is

necessary to insert a resistor in series with the base/gate

13

lead. The value

Page 15

of this resistor will depend on the transistor being tested, but the

minimum value to use is 10K. If the device still tests good on two

buttons, the value of the resistor will have to be increased in 10% steps

(10K, 12K, 15K, etc.) until it tests good on only one button. If the device

is still testing good on two buttons with a 100K resistor in series with the

base, it is an FET. Since the source and drain are interchangeable on an

FET, it is not possible to determine the exact basing. To determine the

basing on a transistor,

proceed as follows:

1.

which two test buttons produce a good indication.

2.

connect a 10K resistor in series with it.

3.

indication. Increase the value of the base resistor as necessary until the

transistor tests good on only one button. Note the button that produces

a good indication.

4.

transistor.

With the transistor out of circuit, connect the TC28, and determine

Refer to the table in Figure 3, to determine the base lead, and

Retest the transistor and note which test button produces a good

Refer to the table in Figure 3, to determine the basing of the

t

LOCATING LEAKAGE

In some cases it may be desirable to determine the exact nature of leakage

in a transistor.

With the test switches on the TC28 there is no need to

14

Page 16

connect to the transistor four different ways, the test switches do it for

you. To locate the exact nature of the leakage, proceed as follows:

1.

Determine the basing of the transistor or FET. Connect the green

test lead to the emitter, the yellow test lead to the base and the red lead

to the collector. If the device is an FET, connect the yellow test lead to

the gate and the red lead to either the source or the drain. Connect the

green lead to the remaining element of the FET.

2.

desired leakage test.

Refer to Figure 4, and press the test button corresponding to the

Note that for regular transistors, buttons number 2

and 6 will produce a full scale leakage indication, corresponding to the

conduction of the forward biased base-emitter and base-collector

junctions respectively, junction FET's will produce a full scale reading on

buttons 2 and 6 corresponding to the forward conduction of the gate

diode: and on buttons 3 and 5 corresponding to the current flow through

the low resistance source-drain channel.

MOS or IG FET's should only

produce a full scale reading on buttons 3 and 5; corresponding to the

current flow through the channel.

1,

3.

each

The following is an explanation of which

test button, and its importance to the operation of the transistor

leakage is measured with

or FET. This information is summarized in Figure 5.

ICBO

Button 1:

ICBO is the leakage current that flows in a transistor

voltage is applied between the collector and base, with the emitter open

and the collector-base junction reverse biased. (Collector positive with

respect to base for NPN transistor). Its effect

in

a tube in that even a small amount will upset the DC bias in the circuit.

is similar to grid leakage

In an FET, this leakage is called IGDO, and its effect on the DC

15

when

bias of

a

Page 17

the circuit is even greater than for transistor ICBO.

leakage measurement, press the button carefully and note any up scale

deflection of the meter. Even a very small up scale deflection should be

cause to reject a small silicon transistor or FET. Larger silicon and small

germanium transistors may safely indicate up to 50uA leakage, while

some special high power germanium transistors may indicate up to

3,000uA and still be within manufacturers specifications.

IBEO

Button 2: IBEO in transistors is the current that flows through the

forward biased base-emitter junction. (Base positive with respect to the

emitter for an NPN transistor). This button should produce a full scale

indication for transistors.

and indicate full scale for junction FET's and zero for MOS or IG

FET's.

IECO

For FET's this leakage would be called ISGO

When making this

Button 3:

voltage is applied between emitter and collector with the base open.

(Emitter positive with respect to collector for an NPN transistor). IECO

is a measurement of the transistors ability to block reverse voltages, such

would be encountered in circuits with an inductive load in the

as

collector.

dicate full scale because of the normal conduction of the low resistance

drain source channel.

IEBO

Button 4:

voltage is applied between emitter and base, with the collector open and

the emitter-base junction reverse biased. (Emitter positive with respect

to base for NPN transistor). IEBO is most important in pulse circuits,

where the base is driven deep into reverse bias and the leakage current

could influence the pulse shaping circuits. In an FET, this leakage is

called IGSO, and is a measurement of leakage current that flows from

gate to source, with the gate source junction reverse biased for junction

FET's. Even a small up scale deflection should be cause to reject a small

silicon transistor or any FET. Larger silicon and small germanium transistors may safely indicate up to 50uA of leakage, while some special high

power germanium transistors may indicate up to 3,000uA and still be

within manufacturers specifications.

IECO is the leakage current that flows in a transistor when a

In FET's, this current would be called 1DSO and should in-

IEBO is the leakage current that flows in transistors when a

ICEO

Button 5:

voltage is applied between the collector and the emitter, with the base

ICEO is the leakage current that flows in a transistor when a

16

Page 18

open. (Collector positive with respect to emitter for an NPN transistor).

Excessive ICEO will cause a transistor to operate unreliably

however, the transistors most prone to this type leakage are high power

types such as those used in audio output circuits and power supply

regulators.

indicate full scale because of the normal conduction of the low resistance

source-drain channel.

IBCO

In FET's this current would be called ISDO and should

in any

circuit,

Button 6:

collector for an NPN transistor) is the current that flows through the

forward biased base-collector junction. This button should produce a full

scale indication for transistors.

IDGO, and indicate full scale for junction FET's and zero for MOS or

IG FET's.

IBCO in transistors (Base positive with respect to the

For FET's this leakage would be called

CHECKING DIODES

The leakage test on the TC28 provides a simple, accurate method of

determining the front to back ratio of a diode or rectifier. The test

switches allow measurement of both forward and reverse currents with

no need to reconnect the diode.

1.

LEAKAGE position.

Set the TUBES/TRANSISTORS Function Switch to the NPN

17

Page 19

2.

lead to the cathode.

3.

ward current should indicate at or near full scale.

Connect the red test lead to the anode of the diode and the yellow

Press button number 1 to measure the forward current. The for-

4.

current should indicate at or near zero on the leakage scale.

Press button number 6 to measure the reverse current. The leakage

CIRCUIT DESCRIPTION

THEORY OF OPERATION - TUBE TEST

The basic circuit of the tube-test section of the TC28 Hybrider, shown in

Figure 6, is a balanced bridge meter amplifier circuit consisting of FET

TR103 and the combination of R136 and R10. These resistors represent

an adjustable voltage that takes the place of the second FET normally

needed for the bridge circuit. The METER ZERO control, R10, on the

front panel is just like the zero controls of a VTVM and balances the

circuit so that with no signal input, the meter reads zero. When a voltage

is impressed on the gate of the FET TR103, the bridge is unbalanced and

the meter will read in proportion to the applied signal.

18

Page 20

The cathode emission test puts AC voltage between the control grid of

the tube under test and the cathode, with a load resistor in series with the

cathode to develop a pulsating DC voltage. The "C" LOAD switch selects

the different size load resistors and applied voltage so that a full range of

current is available from less than .5mA to 120mA. The tube under test

rectifies the applied AC voltage and develops a voltage drop across the

load resistors R3 through R9.

through the filter network of R103 and C110 to smooth it to a pure

DC voltage.

additional isolation and filtering network of R127, R128, R131, and

C112, shown in Figure 6. The resultant DC voltage is coupled through

SW4D and upsets the balance of the circuit causing the meter to read up-

scale in proportion to the emission quality of the tube.

This voltage is applied to the gate of TR103 through an

The pulsating DC voltage is coupled

19

Page 21

GRID-LEAKAGE TEST

In the grid leakage test, the control grid of the tube under test is made

negative to all other elements in the tube by connecting the grid to

ground through the 30 megohm gate resistor consisting of R127 and

R128 of Figure 6, and applying +8 volts to all other tube elements.

If the tube has any grid leakage or contamination causing the grid to emit

electrons, the flow of electrons will be through the gate resistor. Any

current flow through the resistor will cause a voltage drop across the

resistor resulting in an unbalance in the bridge circuit. The meter will

read upscale in proportion to the amount of grid current in the tube

under test. A leakage of 100 megohms or less will cause the meter to read

into the BAD area. A leakage of 100 to 200 megohms will cause a

meter reading in the questionable area and a leakage of 200 megohms or

more will read in the GOOD area on the meter. A leakage of 100

megohms represents a grid current in the tube under test of .5 microamps.

SHORTS TEST

20

Page 22

The shorts test utilizes the Sencore stethoscopic approach

every element in the tube is checked against all other elements.

divider consisting of C105 and R102 in figure 8 is placed

volt secondary of the transformer. The 40 volts AC RMS is divided down

to approximately 34 volts RMS. The

arc over and breakdown in nuvistors and frame-grid tubes. C106

coupling capacitor which prevents any DC action of the tube from upsetting the shorts test. Any shorting resistance present between the tube

elements will upset the action of the voltage divider which will in turn

increase the AC voltage at the input of the peak-to-peak detector

comprised of CR102 and CR103. The output of the peak-to-peak

detector is filtered by C108 and C109 and presented across CR111 and

R105.

sent at the tube elements by blocking DC voltages of

The output of the detector greater than 0.6 volts DC is applied to the

of TR103 through SW4D. The increased DC

causes the meter to indicate up scale in proportion to the

short. R105 at the detector output is a calibration control that establishes

the sensitivity of the test such that a shorting resistance of less than

200,000 ohms will indicate BAD on the meter.

CR111 prevents an upscale meter indication with no short pre-

lower voltage is necessary to prevent

level at the source of TR103

where each and

A voltage

across the 40

less than 0.6 volts.

severity of the

is a

gate

THEORY OF OPERATION - TRANSISTOR TEST

GAIN TEST

The operation of the TC28 transistor gain test represents

approach to the testing of transistors and FET's. The test depends on a

good transistor or FET providing a signal polarity reversal from input to

output when operating with the emitter or source common. Refer to the

TC28 Schematic and Parts List insert for this brief description of overall

test circuit operation.

A 2KHz square wave is generated by IC1B, and through an emitter follower TR101 and TR104, is coupled to the base or gate of the device under

test by the test switches. The test switches ground the emitter or source

and also connect a positive 5 volts from the power supply to the

collector or drain. If the device under test is good, the collector signal

voltage developed at the junction of R111 and R112 will be 180

out of phase with the base signal.

The base signal from the 2KHz oscillator is amplified by

collector signal is amplified by IC1D. The outputs of IC1C

IC1D are

coupled to the logic circuit of IC2, that provides an output to the

and speaker only when the two input signals are 180 degrees out of

This provides both audio and visual indication of a good transistor.

a

unique

degrees

IC1C,and the

and

phase.

meter

21

Page 23

The 14VAC from the transformer is rectified by CR107 and CR109,

shown in Figure 9, and filtered by C116 and C117 to produce 16 volts DC.

This voltage is regulated by R137 and CR106 to produce 8.2 volts DC for

the bridge circuit. Positive and negative 5 volts DC for transistor test voltages are obtained from CR110, CR108, and R138. The plus 5 volt supply

is filtered by C113, and the minus 5 volt supply is filtered by C114.

2KHz OSCILLATOR AND SIGNAL AMPLIFIERS

IC1B is connected as a square wave oscillator operating at approximately

2KHz as shown in figure 10. The frequency of operation is determined

by R108 and C101. The amplitude of the output signal is set by the ratio

of R106 and R107. TR101 and TR104 operate as dual emitter followers

providing a low impedance source for the 2KHz signal. TR101 and

TR104 are both biased off and have a common emitter load resistor

R118. TR101 passes the positive portion of the square wave and TR104

passes the negative portion. The total square wave signal then appears

across R118.

The 2KHz signal is coupled by R119, SW4H, and the test switches to the

base of the transistor under test. It is also coupled to the non-inverting

input of IC1C by C104 and R120.

22

Page 24

IC1C amplifies the signal applied to the base of the transistor under test.

The amplified signal from the output of IC1C is coupled by R123 to

input 2 of IC2. IC1D amplifies the signal from the collector of the

transistor under test.

coupled by R125 to input 4 of IC2.

The amplified signal from the output of IC1D is

LOGIC CIRCUIT

The logic circuitry of IC2 is the heart of the TC28. It is here that the

base and collector signals from the transistor under test are compared,

and the differentiation made between a good and a bad transistor. IC2 is

actually a quad, two-input "NAND" gate.

"NAND" gate shows that the only time that the output of the gate is

zero is when both inputs are positive. The input and output signals in

Figure 11 show operation of the circuit for a good transistor.

With a good transistor connected to the TC28, the base

into pin 2 of IC2A will be out of phase with the collector signal coupled

into pin 4 of IC2B. IC2A is simply connected as an inverter so that it's

output from pin 3 is in phase with the collector signal. IC2B is then used

as a NAND gate, that is it will produce a zero output only when the two

AND

INDICATOR DRIVE

The truth table for the

signal

23

coupled

Page 25

inputs are positive. Finally, IC2C is used as an inverter so that it's output

is

positive only when the input pin 12 is zero. This pulsating positive

output from IC2C is used to drive the meter and the speaker transistor

TR102.

A bad transistor will not yield an out-of-phase collector signal for pin 4

input of IC2B. IC1D is biased such that it's output is zero when there is

no input signal from the collector of the transistor under test. This zero

level is coupled to pin 4 of IC2B and makes the output at pin 6 positive.

The output of IC2C is then zero which indicates BAD on the meter.

LEAKAGE TEST

The collector lead of the transistor under test is connected through R111

and R112 to plus or minus 5 volts by one section of SW4B, as shown in

Figure 12.

ground through Ml by SW4F or SW4G and indicates the leakage

current through the transistor. CR101 provides meter compression and

R101 is a calibration adjustment to set the full scale leakage sensitivity at

3000uA. The emitter lead is disconnected from the circuit by one section

of SW4J.

The base lead of the transistor under test is connected to

24

Page 26

SERVICING THE TC28

DISSASSEMBLY INSTRUCTIONS

To remove the TC28 from its case for adjustment of the internal calibration controls, or to facilitate service, merely remove the four screws

from the back of the instrument case. The front panel may now be lifted

from the case, exposing all circuitry for calibration or service. All of the

circuitry, except for the point-to-point wired switches and

been contained on the one printed circuit board. The board

easily removed by simply unplugging the keyed molex connectors and

removing the two screws that hold the board in place. To re-assemble the

TC28 merely reverse the above procedure.

25

sockets, has

may be

Page 27

The TC28 Hybrider should seldom need calibration. However, should

you desire to periodically check the TC28 calibration accuracy, thereby

insuring its top performance, the calibration module described above in

Figure 13, is recommended. The module can be constructed on an octal

plug or discarded octal tube base and is to be inserted into the socket 1

on the TC28 socket panel.

Some of the calibration adjustments for the TC28 interact and for this

reason the following adjustment procedure must be followed:

There are six calibration controls located on the printed-circuit board

the TC28. Refer to Figure 14 for the

location of

these

controls.

first three adjustments have to do only with the tube test functions

the TC28. The remaining three adjustments pertain to the transistor

test portion of the TC28.

1.

To begin the calibration procedure, remove the TC28 from its

cabinet and, with the unit in its normal operating position, adjust the

mechanical-zero adjust on the meter of the TC28 for a "0" indication.

2.

Apply 105 - 125 VAC power to the unit and turn the TUBES/

TRANSISTORS Function Switch to the NPN LEAKAGE position.

Connect the positive terminal of a DC milliameter to the red test lead.

Connect a 2000 ohm variable resistor between the negative terminal of

the meter and the yellow test lead. Press TEST button No. 1 and adjust

the external resistor until the external meter indicates 3.0mA. Adjust

R101, the Leakage Cal. Control, for a full scale indication on the TC28

meter.

Insert the calibration module into socket 1 and make the following

3.

setup on the front panel selectors:

in

The

of

A

ALL UP

B C

1

D

26

D

SKT

4

1

Page 28

4.

adjust the meter to zero with the front panel METER ZERO control.

5.

and adjust R132, the Grid Leakage Cal. Control until the meter reads

between the "?" and BAD on the GRID LEAKAGE scale on the meter.

Set the TUBES/TRANSISTORS Function Switch to SHORTS and

Switch to the GRID—LEAKAGE position on the Function switch

6.

panel METER ZERO control if necessary.

7.

8.

position 3.

9.

adjust R103, the Emission Cal. Control until the meter indicates "?"on

the EMISSION/GAIN scale of the meter.

Switch back to SHORTS and recheck the meter zero. Adjust front

Repeat steps 4 and 5 as required to achieve continuity.

Change the setting of the SETUP or "D" switch from position 4 to

Set the TUBES/TRANSISTORS Function Switch to EMISSION and

27

Page 29

10.

Adjust front panel METER ZERO control if necessary.

Switch back to the SHORTS position and recheck the meter zero.

11.

12.

position 5.

13.

position, adjust R105, the Short Cal. Control, so that the meter indicates

on

scale of the meter.

14.

position 7 and observe that the meter indicates zero. Adjust the front

panel METER ZERO if required.

15.

Repeat steps 9 and 10 as required.

Change the setting of the SETUP or "D" switch from position 3 to

With the TUBES/TRANSISTORS Function Switch in the SHORTS

the line between GOOD and "?"on the GRID LEAKAGE - SHORTS

Change the setting of the SETUP or "D" switch from position 5 to

Repeat steps 11 through 13 as required.

28

Page 30

29

Page 31

30

Page 32

Page 33

SERVICE AND WARRANTY

You have just purchased the finest amplifier tester on the market today.

The Sencore TC28 has been inspected and tested twice at the factory and

has passed a rugged use test by our Quality Assurance Department to

insure the best quality instrument to you. If something should happen,

the TC28 is covered by a standard 90 day warranty as explained on the

warranty policy enclosed with your instrument.

Sencore has six regional offices to serve you. Instruments to be serviced

should be returned to the nearest regional office by UPS if possible.

Parcel post should only be used as a last resort. Instruments should be

packed with the original packing materials or equivalent, and double

boxed to insure safe arrival at the regional office. The display carton IS

NOT an acceptable shipping container.

for service, be sure to state the nature of the problem to insure faster

service.

If you wish to repair your own TC28 Hybrider, we have included a

schematic, trouble charts, and parts list.

ordered directly from the regional office nearest you.

When returning an instrument

Any of these parts may be

We reserve the right to examine defective components before an in

warranty replacement is issued.

SENCORE REGIONAL OFFICES:

East Central Sales & Service

4105 Duke Street

Alexandria, VA 22304

A/C

TWX

Western Sales & Service

833 Mahler Rd.

Burlingame,

A/C 415-697-5854

TWX 910-375-3307

Southeastern Sales & Service

2459 Roosevelt

College Park, GA 30337

A/C 404-768-0606

TWX 810-751-3546

703-751-3556

710-832-0618

CA 94010

Hwy., Suite B9

Central Sales & Service

2711 B. Curtis Street

Downers Grove, IL 60515

A/C 312-852-6800

TWX 910-695-3226

Central West Sales & Service

3200 Sencore Drive

Sioux Falls, SD 57107

A/C 605-339-0100

TWX 910-660-0300

Northeastern Sales Office

1593 H Central Avenue

Albany, NY 12205

A/C 518-869-0996

TWX 710-444-4969

32

Page 34

Page 32: "Sencore Regional Offices"

The Northeastern Sales Office address has been changed to:

1237 Central Avenue

Albany, New York 12205

(518) 459-6040

The Southeastern Sales Office address has been changed to:

2459 Roosevelt Hwy., Suite B3

College Park, Georgia 30337

(404) 768-0606

ADDITIONAL APPLICATION NOTES

IN-CIRCUIT TESTING

There are some rare cases where a good transistor may test BAD by

the Hybrider when testing in-circuit.

where the base to collector resistance is less than 100 ohms, or when

large electrolytic capacitors of 50mF or more are connected directly

between the base or collector leads of the transistor and ground.

This will occur for a circuit

Therefore, it is recommended that if the in-circuit test of a transistor

indicates BAD, it should be removed and retested for gain before a

replacement is installed.

circuit leakage test.

If a transistor tests BAD in-circuit and GOOD out-of-circuit, this

may indicate other problems in the circuit. First, check the schematic

for resistors of less than 100 ohms or electrolytic capacitors of 50mF

or more, connected between the transistor base and collector. If

these are not found, check the circuit board for the possibilities of:

Shorted foils on the board, or resistors or capacitors connected to

the transistor which may have changed value or become shorted.

"GOOD"

All good FET's and most good transistors will show a

reading when either of two buttons is depressed. However, there are

a few transistors, such as Darlington pairs, or devices with protective

diodes between emitter and collector, that will read good on only

one button.

If an in-circuit transistor shows GOOD gain on only one button, it

may indicate a leakage condition. Therefore, it is recommended that

such a transistor be removed from the circuit and tested again, both

for gain and leakage. If the transistor gives a

one button and does not show excessive leakage when tested out of

circuit, the transistor is good and is probably one of these special

types.

READING ON

This retest should also include the out-of-

ONLY

ONE

BUTTON

GOOD

GOOD

reading on only

gain

Form 1281

Page 35

TC28 MANUAL ADDENDUM

Please note these changes to the TC28 Hybrider manual (Form 959).

Mark the following sections in the manual "Revised — Refer to

Addendum," and use these instructions.

Page 13: "Determining Basing"

If the device being tested checks good on two of the test buttons, it

is either a standard transistor or an FET. To determine if the device

is

a transistor or FET, and the basing diagram, it is necessary to

insert a 100K ohm variable resistor in series with the base/gate lead.

Perform the Gain Test with the control at zero ohms and increase

the resistance in 10% steps. Retest both buttons at each step until

the device tests good on only one button. This indicates the device

is a transistor. If the device still tests good on two buttons with the

total 100K resistance in series with the base/gate lead, it is an FET.

Since the source and drain are interchangeable on an FET, it is not

possible to determine the exact basing. To determine the basing on a

transistor, proceed as follows:

With the transistor out of circuit, connect the TC28, and determine

1.

which two test buttons produce a good indication.

Refer to the table in Figure 3 to determine the base lead, and

2.

connect a 100K ohm control in series with it.

3.

Retest the transistor and note which test button produces a good

indication.

until the transistor tests good on only one button.

button that produces the good indication.

Refer to the table in Figure 3 to determine the basing of the

4.

transistor.

Increase the resistance of the control as necessary

Note the

Page 36

Page 37

Page 38

TC28 PARTS LIST

P.C. BOARD MOUNTED COMPONENTS

IC101

IC102

TR101, 102

TR103

TR104

CR101, 104, 105

111—114

CR102,

CR106

CR107, 109

CR108, 110

R101

R103

R105

R132

R138, 139

C101-104,

110, 112, 115

C106, 108, 111

C109

C113, 114

C116, 117

103

69G9

69G10

19A28

19C11-1

19A16-1

5005-2

50C3-1

50C4.2

16S10

50C4-13

15C7-2

15C7-8

15C7-6

15C7-2

14B49-9

24G126

24G293

24G289

24G118

24G181

IC, Quad Op Amp, LM3900

IC,Quad Nand Gate, SN7400

Transistor, NPN, 2N5172

FET, N-channel, 2N5457

Transistor, PNP, 2N5227

Diode, 1N4148

Diode, 1N34A

Diode, Zener, 8.2V

Rectifier, 0.5A, 400 PIV

Diode, Zener, 5.1V

Control, 10K, Leakage Cal

Control, 1.2M, Emission Cal

Control, 500K, Shorts Cal

Control, 10K, Grid Leak Cal

Resistor, 150 Ohm, 5W, 10%

Capacitor, 0.01 mF

Capacitor, 0.lmF, Mylar

Capacitor, 0.47 mF, Mylar

Capacitor, 100mF, Lytic

Capacitor, 200mF, Lytic

2.50

1.25

.50

1.75

.75

.25

.25

.75

.50

1.00

.75

.75

.75

.75

.25

.50

.50

.75

.50

1.00

CHASSIS MOUNTED COMPONENTS

R10

R2, 3

Cl

C2

C3

T1

SW1

SW2

SW3

SW4

SW5

SW6—15

SW16

SW17, 18, 19

20, 21, 22

Ml

15C1-38

14B49-9

24G120

24G140

24G25

28B58D

25G197

25A154

25A157

25A196

25A158

25A155

25A156

25A186

23C51

Control, 200 Ohm, Meter Zero

Resistor, 150 Ohm, 5W, 10%

Capacitor, 10mF, Lytic

Capacitor, .002mF

Capacitor, 220pF, Disc

Transformer, Power & Filament

Switch, Slide, LIFE TEST

Switch, Rotary, FILAMENT

Switch, Rotary, LOAD

Switch, Rotary, FUNCTION

Switch, Rotary, SELECTOR

Switch, Slide, PIN ELIMINATION

Switch, Slide, RESET

Switch, PUSH Push

Meter, 6", 100uA

1.25

.25

.25

.25

.25

15.25

1.00

4.50

3.25

7.25

3.50

2.75

.75

3.50

22.75

Page 39

SCHEMATIC

REFERENCE

PART

NUMBER

DESCRIPTION PRICE

I1

LS1

ASSEMBLIES

MISCELLANEOUS

21A58

37A16

37A26

8B109B

20G12

48A2-2

Neon Bulb, No. NE-2

Speaker, 2", 8 ohm

108B107 Socket Panel Assembly

143A65

143A58-.1

Printed Circuit Assembly

Push Switch Assembly

143A58-2 Push Switch Assembly

168G12 Hook and Cable Assembly

110C311

110C313

26G4

Case Assembly

Cover Assembly

Socket, Octal, 1&2

26G65 Socket, 10 Pin min., 3

26G63

26G56

26G23

26G2

26G3

26G15

26G21

26G54

26G183

26G105

21A32

Socket, 7 Pin min., 4

Socket, Novar, 5&12

Socket, Nuvistor, 6

Socket, 7 Pin min., 7

Socket, 9 Pin min., 8&13

Socket, Loctal, 9

Socket, Compactron, 10

Socket, 10 Pin min., 11

Socket, Transistor

Clip, Plate Cap

Knob, Bar Pointer

21A33 Knob, Meter Zero

21A44B Glamour Cap, Black

21A44R

21A59R

Glamour Cap, Red

Glamour Cap, Large, Red

Pushbutton

27G14

Line Cord

Rubber Foot, Bottom

Rubber Foot, Back

Escutcheon

.25

2.75

24.50

42.25

7.25

7.25

10.00

25.00

15.25

.50

.50

.25

.50

.50

.25

.25

3.25

.50

.50

1.25

.75

.75

.75

.25

.25

.25

.25

2.25

.25

.25

3.25

Components not listed are standard replacement parts and may be purchased locally. When

ordering parts, please specify instrument model number, schematic reference, part number

and description. Please include remittance (check or money order) with your order, otherwise

invoices will be shipped C.O.D.Minimum billing is $3.00. Prices and specifications in effect

at date of printing and are subject to change without notice.

Page 40

Loading...

Loading...