Page 1

SP395 SoundPro Audio Integrator Form7492 Operation Manual

SP395

SoundPro

Audio Integrator

Operation Manual

(Firmware version 1.32)

3200 Sencore Drive, Sioux Falls, SD 57107

http://www.sencore.com

mailto:sales@sencore.com 1.800.736.2673 or 1.605.339.0100

Page 2

SP395 SoundPro Audio Integrator Form7492 Operation Manual

WARNING

PLEASE OBSERVE THESE SAFETY PRECAUTIONS

There is always a danger present when using electronic test equipment.

Unexpected voltages can be present at unusual locations in defective

equipment and distribution systems. Become familiar with the equipment

with which you are working, and observe the following safety precautions.

Every precaution has been taken in the design of the SoundPro SP395 Audio

Integrator to insure that it is as safe as possible. However, safe operation

depends on you, the operator.

1. Never exceed the limits of the SoundPro SP395 as given in the specifications

section or other special warnings provided in this manual.

2. Always be sure that your equipment is in good working order. Broken or

frayed test leads or cables can be extremely dangerous and may expose you to

high voltages.

3. Remove test leads immediately following measurements to reduce the

possibility of shock.

4. Do not work alone when working under hazardous conditions. Always have

another person available in case of an accident.

5. Never assume that a cable shield is at earth ground potential. Both static

and electrical voltages can be present on a cable’s sheath.

6. Always follow standard safety procedures.

When in doubt, be careful.

Sencore reserves the right to make changes in specifications and other information contained in this publication

without prior notice, and the reader should in all cases consult Sencore to determine whether any such changes have

been made. This manual may not be reproduced, and is intended for the exclusive use of Sencore users.

ii

Page 3

SP395 SoundPro Audio Integrator Form7492 Operation Manual

SP395

SoundPro

Audio Integrator

Operation Manual

(Firmware version 1.32)

3200 Sencore Drive, Sioux Falls, SD 57107

iii

Page 4

SP395 SoundPro Audio Integrator Form7492 Operation Manual

TABLE OF CONTENTS

SAFETY PRECAUTIONS ...................................................................... inside front cover

DESCRIPTION................................................................................................................ 1

Introduction ............................................................................................................................1

SP395 Audio Integrator Features.......................................................................................... 1

Specifications......................................................................................................................... 4

Front Panel Control Descriptions ......................................................................................... 9

Right Side Panel – Input Description................................................................................... 9

Left Side Panel – Output Description ................................................................................10

SP395 Audio Integrator Accessories .................................................................................11

Firmware Add-on Test Functions ....................................................................................... 13

OPERATION................................................................................................................. 14

Power ON/OFF Switch ........................................................................................................... 14

Power Input Jack.................................................................................................................... 14

Battery.................................................................................................................................... 14

Installing/Removing Battery............................................................................................... 15

Battery Charging & Battery Life .........................................................................................15

User Interface – Control Knob................................................................................................ 16

Menu Navigation .................................................................................................................... 16

Menu Overview ......................................................................................................................17

Inputs & Outputs ....................................................................................................................18

Audio Inputs....................................................................................................................... 18

Audio Outputs....................................................................................................................19

Audio Monitoring Output.................................................................................................... 19

Input Gain Control - Preamplifiers ..................................................................................... 20

Menu Toolbars .......................................................................................................................21

Top Tool Bar......................................................................................................................21

Bottom Tool Bar................................................................................................................. 22

Headphone/Speaker Monitor Control ...........................................................................22

Memory Control ............................................................................................................23

SPL .............................................................................................................................. 24

Sound Level Meter .................................................................................................................24

LEQ ........................................................................................................................................26

Dosimeter............................................................................................................................... 27

Sound Study Graph................................................................................................................ 29

Acoustics ..................................................................................................................... 31

Real Time Analyzer................................................................................................................ 31

FFT Analyzer.......................................................................................................................... 35

Energy Time Graph................................................................................................................ 38

Reverb Decay Time................................................................................................................ 43

Multi-Band Decay................................................................................................................... 47

TDA - Time Delay Analysis......................................................................................... 50

Main Output & Generator Control ................................................................................. 23

iv

Page 5

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Noise Tools.................................................................................................................. 57

ALCONS ................................................................................................................................57

RaSTI .....................................................................................................................................60

STI-PA.................................................................................................................................... 63

Noise Curves.......................................................................................................................... 65

Transmission Loss ................................................................................................................. 67

Audio Stethoscope .................................................................................................................69

Tech Bench.................................................................................................................. 70

Level/Freq. Meter ...................................................................................................................71

Signal Generator ....................................................................................................................72

Amplitude Sweep ................................................................................................................... 74

Distortion Meter...................................................................................................................... 76

Phase Meter........................................................................................................................... 80

Crosstalk Meter ......................................................................................................................81

Speakers ...................................................................................................................... 82

Speaker Polarity..................................................................................................................... 82

Speaker Distortion.................................................................................................................. 84

Impedance Meter ................................................................................................................... 86

Impedance Sweep .................................................................................................................87

Cable Tester........................................................................................................................... 90

Tools............................................................................................................................. 92

USB Preamp Display & Controls............................................................................................ 92

USB Preamp Operation..................................................................................................... 93

USB Output Operation....................................................................................................... 94

Utility Function ............................................................................................................ 95

Audio Scope........................................................................................................................... 95

Save Settings .........................................................................................................................97

Setup & Calibration ................................................................................................................98

Setup – Unlock Firmware .................................................................................................. 98

Setup – General ................................................................................................................99

SPL Calibration................................................................................................................ 100

PC Interface/About............................................................................................................... 101

Computer Interface ................................................................................................... 102

Uploading Memories to the Computer.................................................................................. 102

Upgrading Firmware in SP395 ............................................................................................. 103

TerraLink Software: Real-Time Computer Interface............................................................. 104

APPENDIX A

dB SPL Scale .......................................................................................................................105

APPENDIX B

ANSI Weighting Curves........................................................................................................ 106

APPENDIX C

ANSI Balanced Noise Criterion Curves................................................................................ 107

APPENDIX D

Serial Protocol for Accessing SP395 Memories................................................................... 108

WARRANTY AND SERVICE

INFORMATION......................................................................................inside back cover

v

Page 6

SP395 SoundPro Audio Integrator Form7492 Operation Manual

DESCRIPTION

Introduction

The Sencore SP395 SoundPro Audio Integrator is a quality, high-end audio and acoustic

analyzer designed for audio professionals, commercial audio installers, and audio system

engineers. Its audio analyzing functions make it attractive for virtually anyone involved with

audio acoustics or audio systems testing.

The Audio Integrator employs a powerful DSP

engine. All functions, filters, and processing

are implemented in DSP firmware algorithms.

As each function is selected, loaded into

internal memory and executed, the analyzer

takes on a completely new personality. Over

25 different test functions become possible in

one instrument.

The SP395 is especially good at multi-tasking.

It employs independent input, DSP processing,

output, monitor, and USB circuit sections. For

example, you can run the Sound Study Graph

to record SPL over time, while monitoring the

input in headphones, and simultaneously

feeding the input signals to a PC through the

USB audio interface.

The Integrator uses precision 24-bit A/D and

D/A converters, and internal 64-bit processing.

The input and output amplifier stages are fully

balanced, low noise, high-resolution gain

stages. The result is precision measurements

for accurate audio/acoustic analysis.

SP395 Audio Integrator Features

The SP395 provides multiple audio analyzing features including:

• Sound Level Meter or (SPL) Sound Pressure Level: Measures loudness of ambient

sound according to ANSI Type 1 A and C weighting networks and ANSI Class 1 octave

and 1/3 octave band filters. Selectable slow, fast, impulse, or peak sound level

measurement averaging modes.

• Leq: Measures linear averaged Sound Pressure Level over a specified period of time to

determine if noise standards are being met.

• Dosimeter: Measures noise dosage level according to ANSI S1.25-1991 and ASA 98-1991

specifications for noise studies, machinery noise evaluations, and occupational noise

analysis.

• Sound Study Graph: Analyzes and records SPL noise levels over a specified time period

from 1 minute to 24 hours, and graphs the results. Automatically runs multiple sound

studies storing up to 40 sound study tests.

• Real Time Analyzer (RTA): An audio spectrum analyzer which graphs the dB level of

each audio octave or 1/3 octave band. Fast DSP audio analyzing can be used for live music

or sound analysis. An ANSI X curve weighting network for motion picture theater setup is

included. RTA graphs can be stored to memory or compared with the “difference” mode

for before and after analysis.

• FFT Analyzer: Digital signal processing with three FFTs that graph the dB sound level

with 1/6 or 1/12 octave band resolution to 20 kHz. RTA graphs can be stored to memory or

compared with the “difference” mode for before and after analysis.

• Energy Time Graph: Graphs the arrival of sound energy to the microphone input and/or

shows the decay of sound energy in dB over time. Starts with sound initiated from the

1

Page 7

SP395 SoundPro Audio Integrator Form7492 Operation Manual

SP295 generator or an external sound pickup such as a handclap. Valuable in setting time

delays from speaker to listening positions and analyzing sound decay for reflections or

decay time.

• Reverb Decay Time (RT60): Measures and computes reverb decay time or the time it

takes the sound in a room to decrease 60 dB. The measurement computes wideband RT60

(20Hz-20 kHz) or the RT60 of any octave band.

• Multi-Band Decay: Measures, computes and displays the reverb decay time RT60 for

seven audio octave bands simultaneously to identify differences in room sound absorption

characteristics in each band.

• Time Delay Analysis: Times a swept audio generator (20-20,000Hz) and tracking audio

1/12 octave band level meter, with a variable filter Q of 6 to 150, graphing the detected

level. Measurement eliminates room reverberations or echoes for accurate frequency

response testing of speakers or microphones.

• Speech Intelligibility: Measures speech intelligibility using the most popular industry

standards including ALCONS, RaSTI and STI-PA. A CD with the proper test signal for

these tests is provided.

• Noise Curve: Measures noise in a room and characterizes it to a numeric value taking into

account how the human ear hears. Performs standard NC or NCB (balanced noise curves),

RC (Room Criteria), and PNC (preferred noise curve) ANSI tests.

• Transmission Loss: Measures sound transmission loss through a partition. Computes

STC, RW and OITC standard transmission loss measurements by comparing 1/3 octave

RTAs from the source and received sound.

• Audio Stethoscope: Combines the microphone input and sensitive audio preamplifier with

the audio monitoring headphones to form an audio stethoscope. Weighted filters and

octave or 1/3 octave band filters may be selected.

• Level/Freq. Meter: Measures two channel left and right audio input levels from -120 dBu

to +40 dBu and sine wave frequency from 10 Hz to 32 kHz. Measures dBu, dBV, Vave,

Vrms, Vp-p and dBr.

• Signal Generator: Generates audio test signals including sine wave to 22 kHz, square

wave, pink noise and white noise with variable output level. Also outputs octave or 1/3

octave band limited pink noise.

• Amplitude Sweep: Plots the frequency response of audio equipment by sweeping the

generator through its frequency range and graphing the amplitude input level of each 1/12

octave.

• Distortion Meter THD: Measures THD+N (Total Harmonic Distortion plus Noise) of an

incoming signal by comparing the level of the incoming signal with the level of harmonics

and noise.

• Distortion Meter IMD: Measures IMD (Inter-modulation Distortion) of an incoming

signal by outputting a multi-frequency output test tone and measuring the distortion

components. Performs SMPTE IMD and DIN IMD tests.

• Phase Meter: Measures the phase difference between left and right input sine waves of the

same frequency.

• Crosstalk Meter: Measures the amount of dB isolation between the left and right input

audio sources or the signal bleeding from one channel into the other.

• Speaker Polarity: Determines the polarity of the speakers to determine proper wiring.

• Speaker Distortion: Tests speaker distortion, using the THD+N test function, to identify

speaker defects or performance problems.

• Impedance Meter: Measures the impedance of an audio device or component such as a

speaker. The frequency of the test is variable. Also indicates watts or amplification

required at a particular voltage.

2

Page 8

SP395 SoundPro Audio Integrator Form7492 Operation Manual

• Impedance Sweep: Plots the impedance of a load by sweeping the generator through its

frequency range and graphing the impedance at each 1/12 octave step.

• Cable Tester: Provides a cable attenuation test at 1 kHz and 20 kHz, and a polarity test to

identify defective or improperly wired cables.

• USB Preamp Control: Serves as a calibrated USB microphone preamp. Use as a sound

card for a PC based analysis program or to route audio from a PC to the Audio Integrator

main outputs.

• Audio Scope: Provides a voltage vs. time graph of the audio waveform to look for

distortion or clipping.

3

Page 9

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Specifications

SoundCore™ Module

Sound Level Meter (SLM): Measures ambient sound energy levels at microphone input

Displays true RMS SPL

Averaging: Meets ANSI S1.4

Slow

Fast

Impulse

Peak

Avg – Equal time-averaged SPL

Sound Study Graph (SSG): 1 minute to 24 hour continuous recorded SPL measurement

“Strip Chart Recorder”

Peak or Avg mode

Auto-Saves to internal memory

SPL/SSG Measurements

Weighting networks: ANSI Type 1 A, C, Flat, octave, or 1/3-octave band filtered

Level Range: 25-140 dBA with MIC-TP2 mic

Level Accuracy: ±0.1 dB at 1 kHz with MIC-TP2 mic

Level Resolution: 0.1 dB

Frequency Range: 20 Hz to 22 kHz

Real-Time Analyzer (RTA): Plots sound energy levels vs. octave band filtered spectrum

ANSI-compliant 1/3 octave digital filter-based

FIR Filters: Full octave, 1/3 octave frequency resolution.

Weighting networks: Flat, A, C, X-curve, difference mode.

FFT Analyzer (FFT): Plots sound energy levels vs. octave band filtered spectrum

ANSI-compliant 1/12 octave resolution

Three 1024-point cascaded FFTs

Weighting networks: Flat, A, C, difference mode.

RTA, FFT Analyzer

Display range: 30 dB or 15 dB window within 0 dB to 165 dB range, adjustable in

5 dB steps

Level range: 25-140 dBA with MIC-TP2 mic

Level accuracy: ±0.1 dB at 1 kHz with MIC-TP2 mic

Level resolution: ±0.1 dB

Frequency range: 20 Hz – 22 kHz

Frequency accuracy: ±0.5 dB 10 Hz to 22 kHz, ±0.2 dB 100 Hz to 16 kHz

Averaging: 1 sec, 3, sec, 6 sec, 10 sec, 30 sec, 60 sec, equal time-weighted,

peak hold

4

Page 10

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Energy-Time Graph (ETG): Graphs impulse sound decay energy vs. time or distance

Identifies arrival time of direct sound and audio reflections

Displayed in mS (milliseconds), ft (feet), m (meters)

Decay time ranges: From 0-15 mS to 0-7680 mS

Calculates RT10-RT60 from cursor points on decay curve

Accuracy: Better than ±1% of full scale

Reverb Decay Time: Calculates time for residual pink noise test signal to decay 60 dB in

room

Also RT10, RT20

Range: 0-15 sec

Accuracy: ±2% of full signal

Resolution: 1 mSec

Weighting networks: A, C, Flat, octave, or 1/3-octave band filtered.

Ambient Noise: Ambient noise level must be at least 26 dB lower than test signal

RT60 Time: Extrapolated from Decay Time measurement.

Impedance Meter:

Accuracy: 1 ohm to 50 ohms, ±2%, 50 Hz – 12.5 kHz

1 ohm to 8 kohms, ±10%, 20 Hz – 20 kHz

Speaker Polarity: Tests absolute speaker phase (polarity) by analyzing a proprietary

waveform

Shows polarity of mid-frequency wavefront

Range: 0-100 ft, speaker to SoundPro

Cable Tester: Tests XLR, 1/4”, and RCA audio cables, balanced and unbalanced

Performs analog transmission test to test transmission loss at 1 kHz and 20 kHz

Resolution: 0.1 dB

Performs polarity test

Signal Generator:

Signals: Sine, square, gaussian white noise, pseudo-random pink noise,

band-filtered pink noise

Frequency Range:

Sine: 1 Hz to 22 kHz; fine, 1/3 octave, or one octave steps

Square: 1 Hz to 6 kHz; fine, 1/3 octave, or one octave steps

Noise bandwidth: Full (20 Hz to 20 kHz), octave, or 1/3-octave band filtered

Frequency Accuracy: 50 ppm; 0.005%

Level range: -35 dBu to 17 dBu

Maximum Sine Output Level: Balanced: +16 dBu

Unbalanced: +10 dBu

Level Accuracy: ±0.1 dBu at 1 kHz, ±0.2 dBu, 16 Hz to 20 kHz

Typical: ±0.05 dBu at 1 kHz, ±0.1 dBu, 16 Hz to 20 kHz

Sine distortion: < 0.01% THD at full-scale output

Audio Monitor: Source independent channel for monitoring

Software volume control

Headphone or built-in internal speaker output

5

Page 11

SP395 SoundPro Audio Integrator Form7492 Operation Manual

TechBench™ Module

Level Meter: Stereo level meter reads in dBu, dBv, Vp-p, Vrms, or dBr

(reference)

Frequency Range: 10 Hz to 22 kHz

Auto-level ranging.

Level Range: -120 dBu to +40 dBu

Level Accuracy (–85 dBu to +40 dBu): ±0.2 dB, 10 Hz to 22 kHz

Typical: ±0.01 dB, 100 Hz to 16 kHz; ±0.05 dB, 10 Hz to 22 kHz

Level Resolution: 0.01 dBu

Frequency Counter:

Frequency Range: 16 Hz to 40 kHz

Accuracy: ±5%

Resolution: 1 Hz

Amplitude Sweep: Graphical display of 1/3 and 1/12 frequency response

User adjustable frequency range

Impedance Sweep: Graphical display of 1/3 and 1/12 octave impedance values

User adjustable frequency range

Distortion Meter: THD+N – Computes Total Harmonic Distortion plus Noise

Compares level of output harmonics and noise to single test frequency

Test Frequencies: 63 Hz, 125 Hz, 250 Hz, 500 Hz, 1 kHz, 2 kHz, 4 kHz

IMD – Computes Inter-modulation Distortion

Compares levels of output sum and difference frequencies to dual test frequencies

Test Types: SMPTE 60/7kHz, DIN 250/8kHz.

Inputs: Speaker, microphone, line level.

Range: 0.02% to 50% THD+N

Accuracy: ±5% of reading

Phase Meter: Shows the phase difference in degrees between 2 sine waves

Crosstalk Meter: Displays the amount of isolation that exists between two audio

sources

Displayed in dB

Audio Scope: Shows audio signal on an oscilloscope-like screen

Dual-trace, auto-triggering

AC-only input coupling (down to approx. 3 Hz)

X-Y mode for phase display

Sample rate: Hz

Accuracy: ±1 display pixel

6

Page 12

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Speech Intelligibility Module: (RaSTI and STI-PA test waveforms included on CD)

ALCONS: Computes Percent Apparent Loss of Consonants

RaSTI: Calculates Rapid Speech Transmission Index

STI-PA: Computes Speech Transmission Index using STI-PA method

(STI for Public Address)

Time-Delay Analysis Module:

Time-Delay Analysis: Measures frequency response using log-swept sine wave.

(TerraLink software included)

Noise Curves Module

NC Curves: Displays Noise Criteria data, based on ANSI standard S12.2-1995

(ASA 115-1995)

Displays limiting band, SPL by octave band

RC Curves: Displays Room Criteria rating

PNC Curves: Displays Preferred Noise Criteria rating

STC/NIC Measurement: 1/24th octave Sound Transmission Class/Noise Isolation Class

measurement

Multi-Band Decay Module

Multi-Band Decay: Displays seven octave-band filtered RT60 measurements

simultaneously

Audio Stethoscope Module

Audio Stethoscope: Filters incoming left input audio through to the headphone or

speaker

Filters: Flat (no filter), A or C ANSI Weighted, octave, 1/3 octave filters

Audio Hardware

Sample Rate: 48 kHz

Input Gain Ranges: -50 dB to +50 dB

Maximum Rated Input: +40 dBu

Preamplifier

Distortion: -90 dB THD+N

Phantom Power output: 48 VDC ± 1 VDC

ADC/DAC

Cirrus Logic: CS4224 48 kHz 24-bit 105 dB Audio CODEC

USB Preamplifier

Burr-Brown Texas Instruments® USB Audio CODEC

USB 1.1 full-speed

USB isochronous data format

7

Page 13

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Standards

Sound Level Meter: ANSI S1.4-1983 (ASA 47-1983)

Leq: ANSI S1.43-1997

Dosimeter: ANSI S1.25-99 (ASA 98-1991) Class 2

Digital Filters: ANSI S1.11-1986 1/1, 1/3 octave digital filters

All filters, weighting networks, response rates, and algorithms meet or exceed ANSI

Type 1 specifications

General/Environmental

Input Impedances

XLR and balanced inputs: 40 kohms nominal

RCA unbalanced inputs: 20 kohms nominal

Output Impedances

XLR and balanced outputs: 300 ohms nominal

RCA unbalanced outputs: 150 ohms nominal

Non-Volatile Memory: 40 graph data storage locations

Display: 64x128 pixel blue LCD with backlight

Size: 9 1/2" x 5 1/2" x 2 1/4" (HWD)

Weight: 2 lbs. 5 oz.

Temperature Range: 5°C to 45°C, non-condensing

Power

Battery: Li-Ion pack provides over 5 hours of service, depending on usage

AC adapter/charger: 120/130/230/240 VAC, 9-12VDC, 800 mA (Nominal 9V)

8

Page 14

SP395 SoundPro Audio Integrator Form7492 Operation Manual

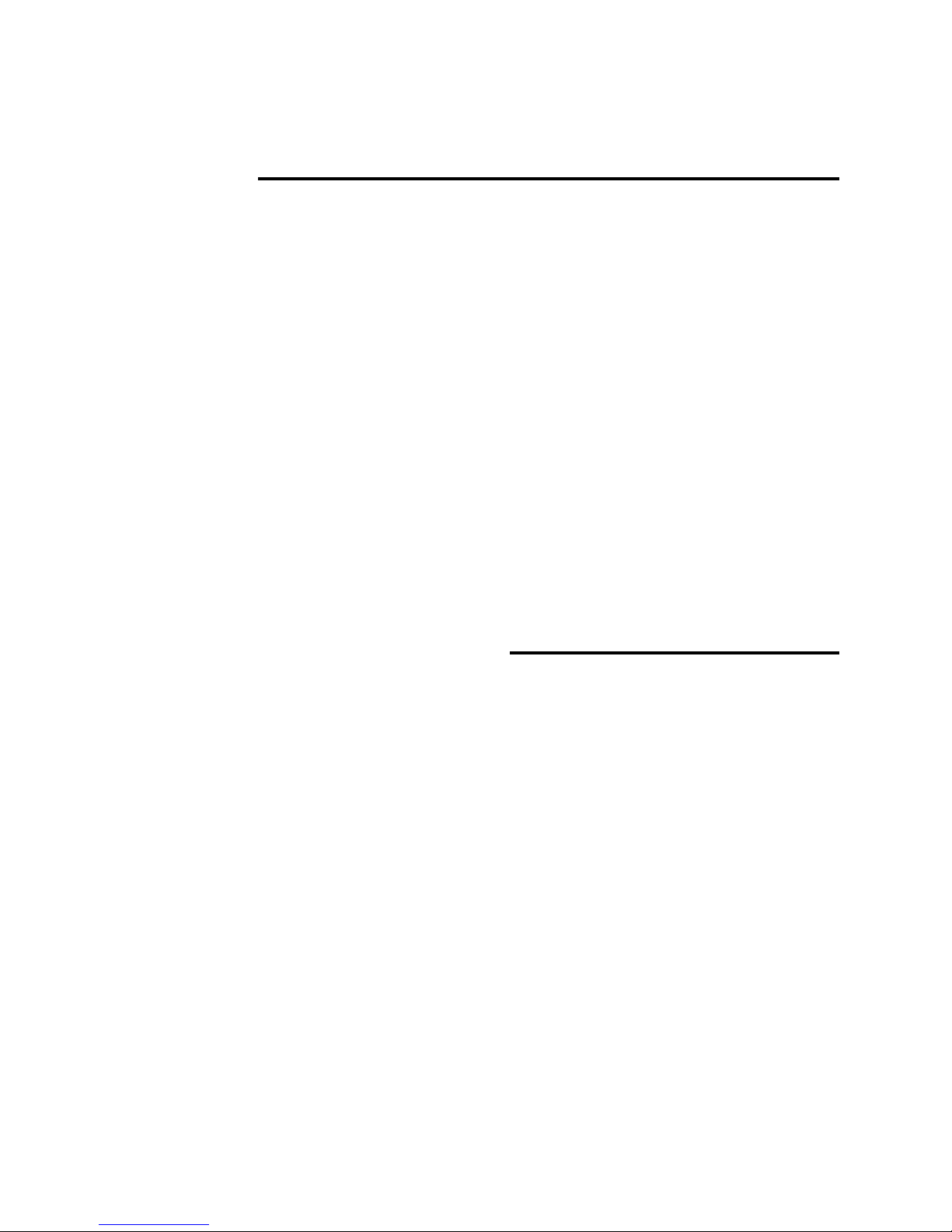

Front Panel Description

1. Display Screen: Provides a visual

interface to the user of all instrument

functions and test results.

2. Left Side Panel: Contains

Computer, USB and analog audio

jacks and speaker. See Left Side

Panel Description section for details.

3. Right Side Panel: Contains power

input jack, audio input jacks, on/off

switch and contrast control. See

Right Side Panel Description section

for details.

4. Control Knob: Provides navigation

through instrument menus. All test

operations and user selections are

performed using this control. This

control is both rotated and pressed.

Rotate the control to move the

screen cursor or increment through menu selections. Momentarily pressing inward

(clicking the control knob) makes a selection or change.

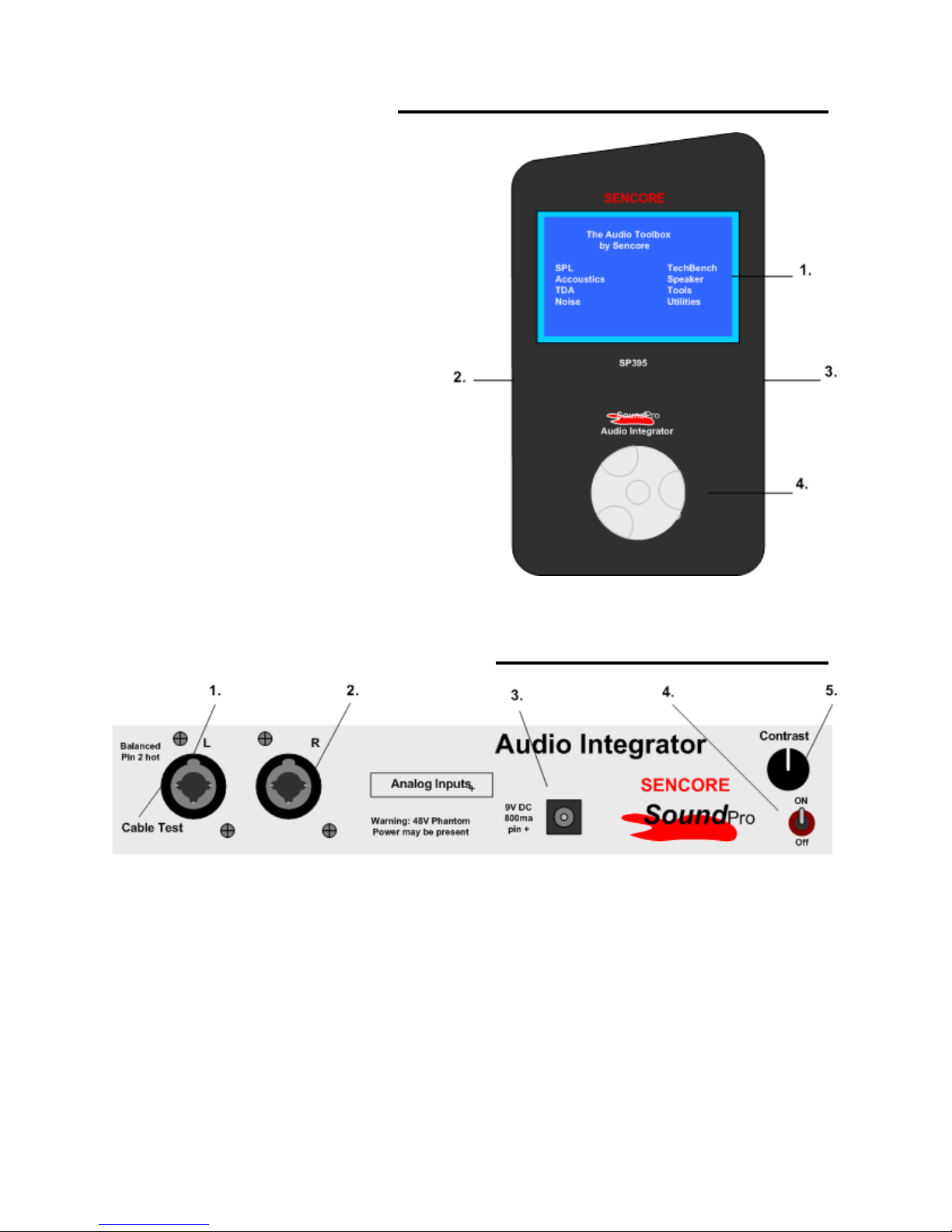

Right Side Panel – Input Description

1. Left Analog Input: Combination XLR and ¼ inch Balanced Microphone /Line input.

Used as main input for most tests. May have 48 Volt Phantom Power switched to jack by

instrument. Used as Cable Test Input.

2. Right Analog Input: Combination XLR and ¼ inch Balanced Microphone /Line input.

May have 48 Volt Phantom Power switched to jack by instrument.

3. Power Adapter Input: Powers the instrument and charges the internal rechargeable

battery. Use a Sencore approved adapter nominal 9V @ min 800 mA. (Center pin

positive)

4. Power Switch: Turns the instrument power on or off. Down is Off.

5. Contrast Control: Sets the contrast of the display screen for best viewing.

9

Page 15

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Left Side Panel – Output Description

1. RS232 Computer Interface Connector: Serial DE-9 connector. Interfaces instrument to

computer for use with automation software and for the purpose of updating unit firmware

to factory changes.

2. USB Audio Connector: Provides USB connection for digital audio signals.

3. Stereo Headphone (Hdpn) Output Jack: ¼ inch headphone jack. Provides stereo audio

monitoring with headphone.

4. RCA Phono Audio Output Jack: Provides unbalanced audio output through female

RCA phono jack.

5. Balanced mono Audio Output Jack: Provides balanced audio output through a ¼ inch

headphone jack (TRS).

6. Balanced XLR Audio output: XLR jack male, Provides a balanced mono audio output.

Jack also used for Cable Test output.

7. Internal Speaker: Provides audio output to monitor input audio to instrument or audio

generated and output by instrument.

10

Page 16

SP395 SoundPro Audio Integrator Form7492 Operation Manual

SP395 Audio Integrator Accessories

Sencore

Part #s

133G527

13G122

13G123

Description Photo

TerraLink Viewer Software /Speech

Intelligibility Audio CD provides

TerraLink – viewer only capability – along

with the audio CD files needed for the

STIPA and RASTI speech intelligibility

tests.

supplied

XLR Audio Cable – a microphone cable

for interfacing balanced audio inputs and

outputs to the SP395.

supplied

USB Cable – a 6’ connection cable (type

A to type B), connects the unit’s USB

connector to a USB port on a computer

PC USB port.

supplied

Serial Interface Adapter Cable – a 6’

computer serial interface adapter cable

13G124

17G65

39G1156

(straight through), connects between the

unit’s RS232 jack and a computer serial

port.

supplied

Lithium Ion Battery – install battery to

power the instrument. The battery is

removable, supplies up to 5 hours of

continuous power per charge, depending

on use.

supplied

Standard Measurement Microphone

meets or exceeds ANSI Type 2

specifications. Microphone Holder Clip

mounts on a standard microphone stand

and holds the test microphone.

Both are supplied.

11

Page 17

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Impedance Test Cable 1/4 inch mono

plug to clip connections – provides a test

39G1171

60G80

lead connection when using the

Impedance Meter and Impedance Sweep

test functions.

supplied

AC Power Adapter/ Charger plugs into

the SP395 to charge the battery or to

provide AC operation.

supplied

Soft Carry Case padded carrying case to

CC309

SPPMIC1

optional

SPSW-TL

optional

transport unit; includes extra storage

capacity for supplied accessories.

supplied

Precision Low Noise Microphone –

meets or exceeds ANSI Type 1

specifications

optional

Software – provides a real-time PC

connection/interface with the instrument.

Plots memories and displays FFT, RTA,

SSG and SLM Meter results in real-time.

(Requires purchase and authorization of

an UNLOCK code from Sencore) Included

as part of the Time Delay Analysis (TDA)

Firmware Add-on Module. optional

Terra Link Software Unlock

Code

http://www.sencore.com mailto:sales@sencore.com 1.800.736.2673

12

Page 18

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Firmware Add-on Test Functions

The Audio Integrator comes standard with a solid core of audio analyzing tests. These tests are

fundamental to most audio and acoustic analysis work. The core tests are referred to as the

SP395’s “SoundCore” measurements.

The Audio Integrator contains, in its internal operating software or firmware, instructions for

performing many more audio and acoustic tests than provided by the standard “SoundCore”

measurements. These additional tests may be purchased based upon individual user and company

requirements. The additional available tests are divided into packages or “Firmware Modules”

for easy implementation or purchase.

Firmware Module Function Menu

TechBench Amplitude Sweep TechBench

TechBench Distortion Meter TechBench

TechBench Phase Meter TechBench

TechBench Crosstalk TechBench

TechBench Audio Scope Utilities

TechBench Impedance Sweep Speaker

Noise Curves NCB, RC, PNC Noise Tools

Noise Curves Transmission Loss

(RW, STC, OITC)

Speech Intelligibility ALCONS, RASTI,STI-PA Noise Tools

Time Delay Analysis TDA TDA

Audio Stethoscope Audio Stethoscope Noise Tools

Multi-Band Decay RT60 Multi-Band Decay Acoustics

The optional functions are available for use upon purchasing the firmware module and entering

the supplied unlock code. The functions contained within a single firmware module may appear

on more than one menu. The table lists the firmware modules and the functions they contain,

along with the Audio Integrator menu that the function appears in.

To purchase an unlock code for a firmware module, contact Sencore. For instructions on how to

unlock a firmware module, see the Setup & Calibration section of this manual.

Specifications, accessories and software add-on test functions are subject to change without

notice.

Noise Tools

13

Page 19

SP395 SoundPro Audio Integrator Form7492 Operation Manual

OPERATION

Power On/Off Switch

The power switch is mounted at the top of the right side panel. The power switch turns the Audio

Integrator on or off, whether the unit is powered by the internal battery or the AC adapter.

When you turn on the power switch, the unit begins initialization. During this time software is

loaded from memory locations within the Audio Integrator including updates. The unit is ready

to use as soon as the main menu screen appears, no warm-up time is needed. The Audio

Integrator can be powered off at any time – there is no required shutdown procedure.

Power Input Jack

The Power Input Jack is located in the center of the right side panel. The DC Input Jack requires

the input of a DC voltage to power the instrument and charge the internal battery. The SP395

requires a 9-12v DC power adapter, regulated or unregulated, rated at a minimum of 800ma. The

input connector is a 2.1mm coaxial power connector with the positive polarity voltage on the

center pin of the connector.

An AC power adapter/charger is supplied to power the Audio Integrator and charge the internal

battery. Use only the Sencore-supplied power adapter, if possible. Using an improper AC adapter

can damage the unit and/or improperly charge the battery. Using an improper AC power

adapter/charger voids the unit warranty.

The AC plug symbol in the display screen beside the < (back) field indicates the

unit is powered form the AC power adapter/charger.

When the AC power adapter is plugged in, the battery level indicator

shows an AC power plug symbol. When the AC power adapter is

removed, the indicator shows a battery symbol with a relative battery

charge level.

Battery

A lithium-ion rechargeable battery is supplied with the Audio Integrator. The battery is charged

whenever the AC adapter is plugged in, or can be charged using an

external charger.

Battery operation is indicated with a battery symbol near the < (back) field. The

symbol indicates the approximate charge level of the battery.

Battery operation is indicated in the Audio Integrator screens with a

battery symbol located in the upper left of the screen adjacent to the <

(back field). The symbol also indicates the relative charge of the

battery. It the battery symbol is filled to the top, the battery is at or near

full charge. A battery symbol that shows little or no fill indicates that

the battery is nearing a discharge level in which it must be recharged.

14

Page 20

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Installing / Removing Battery

The battery can be removed for replacement. The battery is installed in a small compartment in

the bottom rear of the Audio Integrator. To remove the battery you must open the battery door or

cover plate. Unscrew the thumb screw holding

the plate to the instrument case. The door

contains a cutout so if you push the door away

from the screw the door can be hinged open. Use

the nylon strap that surrounds the battery to lift

it up and out of the compartment. The battery

terminals plug into the small circuit board lining

the top side of the battery. Gently pull the circuit

board away from the battery to disconnect the

battery from the circuit board.

To install a battery, reverse the removal process.

The battery is polarized and needs to be installed

correctly. Line up the flat side of the battery

with the flat side of the circuit board. Push the

board male connector pins gently and straight

into the battery terminals. Seat the battery into

the instrument, close the battery door and secure

it by tightening the retainer screw.

The battery may be removed from the rear battery compartment.

Warning: Observe proper polarity. Do not plug the battery into the connector board the

wrong way, or the battery may be damaged.

Battery Charging & Battery Life

The battery is charged anytime that the AC adapter is

plugged into the Integrator. It charges at the same

Charger Charge Time

Charge in Integrator 6.0 hours

rate, whether the unit is turned on or not. You can

also charge the battery in an external lithium-ion battery charger. You cannot overcharge the

battery, as long as you charge it in the instrument or use an approved external charger. The

battery requires about 6 hours to fully charge.

The Audio Integrator uses different amounts of

battery power, depending on what functions are

being used. The phantom power uses a significant

amount of power. Also, the headphone monitor

Battery Life

Maximum run time 5.5 hours

Phantom power on 4.5 hours

amplifier consumes power when it is enabled. Expect 4-5 hours of run time on a full charge.

Warning: Storing the unit with the battery in a state of discharge for long periods of time can

shorten the life of the battery, or possibly destroy it. We recommend that the battery be kept

charged at all times. The battery cannot be overcharged, so it is fine to leave the instrument

plugged in, or to leave the battery plugged into an external charger when not in use.

15

Page 21

SP395 SoundPro Audio Integrator Form7492 Operation Manual

User Interface – Control Knob

All the Audio Integrator operations and user selections are performed using the front panel

control knob. This control is either rotated or momentarily pressed (clicking) the control knob.

Turning the control knob moves a display highlight (white box with dark text) between menu

options and fields on the screen. Clicking a highlighted choice selects it. To exit from a function

and return to the previous menu or screen, highlight and click on the “<” symbol located in the

upper left corner of the display.

To change the value of a selected field, click the control knob. The highlighted field will either

toggle to a new value (fields with only a few possible values) or will change to an underlined

“control lock” (data with many possible values).

To change the value of a “control-lock” field, click the control knob to “lock” (underline) the

field and then turn the knob to change the value. When the desired value is shown, click the

control knob again to unlock the control highlight. Turning the knob then moves you to the next

field

All user selections are made using the control knob either by rotating it to select a menu field or

by momentarily pressing or “clicking” the knob to increment values or lock to a field.

Menu Navigation

The main menu with eight main function categories appears shortly after the Audio Integrator is

turned on. By default the first item or category is highlighted. Turn the control knob to highlight

the different menu items and click the control knob to select the item or category. A sub-menu

appears with fields that list test functions that can be selected for that category. To select a

function in the sub-menu, turn the control knob to highlight the desired field or function and

click the control knob (press down momentarily). To exit from a sub-menu back to the main

menu move the highlight to the upper left “<” field and click the control knob.

Click the < field located in the upper left corner of every display to

return to the previous menu.

16

Page 22

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Menu Overview

All user selections to configure the Audio Integrator are performed with indications in the

display screen. The Audio Integrator includes a main menu with eight categories of tests in

which to choose from. Choosing a category in the main screen results in a submenu. The

submenu lists all the tests available in that category.

Note: Some of the tests shown in the submenu screens may not be included in your Audio

Integrator. These test features may be purchased as Software Additions to your

instrument.

1. Main Menu: Opening menu screen listing eight categories of Audio Integrator tests.

2. SPL Submenu: Appears when the SPL selection is made in the main menu. This

submenu lists the sound level measurements available for selection using the Audio

Integrator.

3. Acoustics Submenu: Appears when the Acoustics selection is made in the main menu.

This submenu lists the acoustic analyzing tests available for selection using the Audio

Integrator. Note: The Multi-Band Decay tests is available as a firmware option. It

appears in submenu but cannot be implemented without purchasing an unlock code.

17

Page 23

SP395 SoundPro Audio Integrator Form7492 Operation Manual

4. TDA Submenu: Appears when the TDA selection is made in the main menu. This

submenu shows the TDA test functions available on the Audio Integrator.

Note: The TDA tests are optional firmware add-on test functions.

5. Noise Tools Submenu: Appears when the Noise selection is made in the main menu.

Provides noise related measurements using the Audio Integrator. Note: The ALCONS,

RaSTI, and STI-PA are speak intelligibility tests available as part of the Speech

Intelligibility firmware option. The Audio Stethoscope is available as a Stethoscope

firmware option.

6. TechBench Submenu: Appears when the TechBench selection is made in the main

menu. Provides selection of audio bench testing functions. Note: The Amplitude Sweep,

Impedance Sweep, Distortion Meter,, Phase Meter, and Crosstalk Meter are part of the

TechBench firmware option.

7. Speakers Submenu: Appears when the Speaker selection is made in the main menu. The

submenu provides selection of speaker related tests.

8. Tools Submenu: Appears when the Tools selection is made in the main menu. This

submenu provides a selection for USB Preamp Control.

9. Utilities Submenu: Appears when the Utilities selection is made in the main menu. The

Utilities Functions submenu provides user options to save settings, calibrate and interface

the Audio Integrator. Note: The Audio Scope function is part of the TechBench firmware

add-on option.

All test functions available for the Audio Integrator are listed in the submenus. This includes all

functions which are part of the standard or “Sound core” tests and test functions which can be

added with firmware add-on purchases. If you select a test in the submenu that has not been

added with a firmware purchase, the instruments indicates an “unlock required” message.

Inputs & Outputs

Audio Inputs

The Audio Integrator receives audio signal inputs from a microphone or line input

The input signal jacks are located on the right side of the instrument. There are two input jacks

which are labeled left (L) and right (R). The input jacks are a combination connector which

accepts a balanced XLR connector male input and a ¼ inch stereo mono headphone male

connector. This provides compatibility with most audio microphone cables and line input cables.

Left side input signal connectors are a combination XLR and ¼ inch mono headphone jack

18

Page 24

SP395 SoundPro Audio Integrator Form7492 Operation Manual

The left (L) input should be considered as the main channel input when using the Audio

Integrator. Some test functions, such as the cable test and audio stethoscope, only use one input.

In these cases you always use the left (L) input connector when performing the test.

Be aware that the different test functions of the Audio Integrator are setup for a mic. Level input

and others for a line level input. In each case, the input signal is taken from the left and right

input jacks. For the acoustics test functions, a microphone is normally connected, and for the

TechBench tests, a line level (or lower) electrical audio signal is anticipated by the SP395.

The acoustics functions, which expect input from a microphone, use the microphone SPL

calibration that is stored in the Utilities Calibration section. Electrical functions, which expect

their input from a line level source, use the dBu calibration. Keep this in mind to prevent

potential confusion over measurement results. For example, if a 0 dBu electrical signal is

plugged into the Sound Level Meter, you may see results like +150 dB SPL, depending on the

sensitivity calibration that is stored. Conversely, if you are using a microphone with the

Amplitude Sweep function, you will see very low results, perhaps in the –70 to –60 dBu range.

Audio Outputs

The Audio Integrator provides 3 output jacks for connecting analog audio output to sound

systems. You may use either the XLR, 1/4” TRS, or RCA phono jack. These jacks are located on

the left hand side of the instrument. All carry the same signal. The output range of the Audio

Integrator is approximately -72 dBu to +17 dBu.

The left side panel contains three analog audio outputs including an XLR, ¼ TRS headphone mono, and

unbalanced RCA phono jack.

Use the XLR male output jack when a balanced XLR audio output is needed. The ¼ inch TRS

headphone jack output is available when this connection is desired. This connector is wired in

parallel with the XLR output jack. It provides a TRS (tip, ring, sleeve) balanced audio output.

One side of the balanced output is routed to the RCA phono to form an unbalanced output. Use

this jack when you desire connection to an RCA connection cable.

Audio Monitoring Output

The Audio Integrator provides a headphone output jack for monitoring output audio. It is a stereo

output headphone jack with the purpose of simultaneously monitoring both a right and left audio

channel. The stereo headphone jack powers 32 ohm or grater headphones. The headphone jack

can also serve as a line level output if needed.

A speaker is built into the Audio Integrator for the purpose of monitoring the output audio. The

speaker is located on the left side panel of the instrument. The internal speaker outputs the mixed

left and right outputs taken from the headphone output.

19

Page 25

SP395 SoundPro Audio Integrator Form7492 Operation Manual

The audio output from the headphone jack and speaker is routed through separate output

monitoring circuits within the Integrator. Audio to the headphone or speaker is independently

switched on or off in the monitor part of the menu screen. The audio level output to the

headphone and speaker is controlled in the monitor part of the menu screen. Internal generated

audio or audio to the input jacks of the Audio Integrator may be routed to the monitor circuits.

Right, left, stereo, mixed (mono) audio may be selected. See the Bottom Toolbar section of this

manual.

Input Gain Control - Preamplifiers

The left and right audio inputs of the Audio Integrator feed into separate audio preamplifiers and

gain control circuits. These circuits provide audio measurement over a wide range of audio levels

and provide great sensitivity. There are thirteen gain ranges that are available to set the level of

both the left and right input audio signal. The gain ranges of the left and right inputs are

controlled independently in the top toolbar section of the test menu. See the Top Tool Bar

Section of this manual.

The selected input level or gain control setting establishes an overall amplification of the input

signal and best signal-to-noise ratio. The gain setting must be properly chosen for proper testing

results. You should select the range which provides the most amplification without overdriving

the sensitive input pre-amplifiers. The table below defines the clip points of each gain setting,

both in dBu and related for available standard microphones.

Clip Points Table

Gain Setting

Line Input

( dBu)

MIC-TP2

( dB SPL)

MIC-TP1

( dB SPL)

58 -45

52 -39

46 -34

40 -29 110 80

34 -23

28 -16

20 -9 130 100

10 1 140 110

-10 15 160* 130

-20 25 170* 140

-30 35 180* 150*

-40 45 190* 160*

* Beyond microphone maximum level

Note: To get the lowest SPL or noise levels you should use the maximum input gain setting

possible without clipping. In many cases this will be 42-58. At this setting you will have the most

sensitivity, but the input may clip at normal room SPL levels, depending on the sensitivity of the

microphone.

The Audio Integrator provides both manual and automatic range selection for the left and right

audio channels. The auto-gain function selects an input range for best measurement. If the input

level gets within 2dB of clipping, the gain is set to the next least sensitive gain (if possible). If

the input level is below that level at which the most accurate measurements can be made, the

gain is increased in steps until the maximum input gain is reached.

20

Page 26

SP395 SoundPro Audio Integrator Form7492 Operation Manual

The Audio Integrator provides an indication when the input level is approaching or overdriving

the input preamplifier. The range number in the top tool bar of the menu blinks. When you see

this select a higher gain setting in the top toolbar for that channel.

Menu Toolbars

The Audio Integrator uses “toolbars” to provide access to often-used features and controls.

Toolbars along the top edge and bottom edge of the screen provide user selections which are

common to many of the test functions. For example, you can adjust input gain, turn phantom

power on and off, and control the generator output and the headphone monitor from any screen

using the top SP395. It is important that you understand the use of the toolbars to properly

operate the SP395. Individual items which can be selected and changed are referred to as fields

in this manual.

Toolbars along the top edge and bottom edge

of the screen provide user selections which are

common to many of the test functions

.

Top Tool Bar

The top toolbar provides a function identification field and is used to control the SP395 inputs.

You can manually select input gain, turn on phantom power, or invert the phase of either channel

independently. You can also enable auto-gain scaling for both inputs.

The Top Tool Bar provides function

identification and selections for the L & R

inputs.

Top Toolbar Icons

1. Back Arrow. Clicking on this icon exits the currently running function and returns to the

function menu.

2. Battery Indicator. When operated on the internal battery, this field shows the relative

battery level, or remaining charge, in the battery. When operated in AC mode, this field

shows the AC power symbol.

3. Screen Title. This is the abbreviated name of the function that is currently running.

4. Function related selection – Not on all menus

5. Left Input Polarity The N/R icon changes the left input from normal (N) polarity to

reverse (R) polarity.

6. Left Input Phantom Power Click to select the icon, then turn clockwise to enable

phantom power (48v), or counter-clockwise to disable phantom power (0v).

21

Page 27

SP395 SoundPro Audio Integrator Form7492 Operation Manual

7. Left Input Gain There are 12 selectable input gain settings. Click and turn to select the

gain for this channel. A blinking value or digits indicate clipping and the need to reduce

the gain selection number.

8. Auto-Gain. Select manual (M) or auto (A). In auto-gain, the gain setting for the channel

is automatically adjusted to prevent clipping and to have enough gain for accurate

measurements. Note that in some functions, such as Leq, you may want to hold the gain at

a fixed level. In this case, choose manual (M).

9. Right Input Gain There are 12 selectable input gain settings. Click and turn to select the

gain for this channel. A blinking value or digits indicate clipping and the need to reduce

the gain selection number.

10. Right Phantom power Click to select the icon, then turn clockwise to enable phantom

power (48v), or counter-clockwise to disable phantom power (0v).

11. Right channel polarity reverse The N/R icon changes the left input from normal (N)

polarity to reverse (R) polarity.

Bottom Tool Bar

The bottom toolbar contains three functional control sections. The sections include:

1. Headphone/Speaker Monitor

2. Memory

3. Output Generator

All or part of the bottom tool bar sections or

selections within each section may be

present in the various test functions of the

Audio Integrator.

The Bottom Tool Bar provides

headphone/speaker, memory, and internal

generator control.

Headphone/Speaker Monitor Control

The five icons at the left end of the bottom toolbar control the monitor output.

1. Monitor Output On/Off The 1/0 icon turns the analog monitor output on and off. This

controls both the headphone jack and the built-in speaker.

2. Level The bar level gauge icon controls the analog output level. Every turning step of the

control knob changes the output level by approximately 1 dB.

3. Speaker On/Off. This icon turns the speaker on and off. The speaker can be turned off,

even when the headphone output is enabled. To hear the speaker output, both the Monitor

On/Off and the Speaker On/Off must be turned on.

4. Source The I/O source icon determines the source for the monitor output. The I selects

the Input for monitoring, the O selects the Output signal (usually the internal digital

generator) for monitoring. Therefore, in Input mode you will hear exactly what is being

received, as selected by the input select field on the top toolbar, and in Output mode, an

exact copy of the digital output signal will be routed to the headphone jack.

5. Mode. The monitor mode field changes between stereo (S), left mono (L), right mono

(R), and the mixed left and right channels (M).

Headphone Warning: Be careful when wearing headphones and changing input connections,

input gain, and phantom power. Although the analog output is usually muted in situations that may

cause high output, unexpected loud volume may occasionally occur at the headphone output. We

recommend turning off the output before changing functions, and in other situations that may cause

loud volume.

22

Page 28

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Memory Control

Some test functions support saving measurement data to internal, non-volatile memory. The

SP395 provides memory storage of RTA, FFT, ETG, Dosimeter, Sound Study Graphs,

Amplitude Sweep and Impedance Sweep functions. These functions use the four memory control

icons, in the center of the bottom toolbar. Note that a memory must be empty (cleared) before

measurement data can be stored into it. The Clear (C) icon can be used to erase the contents of a

memory.

6. Memory Number The memory number icon selects a memory location for storing,

recalling, or clearing. There are memory numbers 0 through 39 or 40 locations. When the

memory number field is selected, the type of data stored in that location (or “---” if

empty) appears on the bottom of the graph.

7. Store Click the S (Store) icon to store the results of the current function. The memory

location must be available (empty) before storing results. If the function does not support

memories, the icon does nothing.

8. Recall Click the R (Recall) icon to retrieve the results stored in the current memory

location and to display them on the screen. If the current function does not support

memories, the icon does nothing.

9. Clear Click the C (Clear) icons to erase the contents of the current memory location.

Main Output and Generator Control

The five icons that control the main output and signal generator are located on right end of the

bottom toolbar. Some fields control only the generator, while others control features of the main

output section.

10. On/Off The 1/0 icon turns the generator on and off. This field also controls functions that

use special output signals, such as the transparency test.

11. Level The bar level gauge controls the digital generator output level. Every turning step

of the control knob changes the output level by exactly 1 dB.

12. Waveform This icon selects the generator waveform. It can also select the USB input as

a signal source. The available waveforms are sine, square, white noise, and pink noise.

The USB selection sets up the USB input as a source for the main output.

13. Select Frequency This field changes the frequency of the generator output, as

determined by the Step Size field.

14. Step Size This field selects how the frequency field changes the generator frequency.

Choices are octave steps (Oct), one-third octave steps (1/3), or fine mode (Full). In full

mode the generator frequency is selectable in 1 Hz steps to 10 kHz and 2 Hz steps above

10 kHz.

In some functions the output generator is required to be in set conditions to perform the test

function. Examples include the Impedance Meter, the Cable Tester, and the Sweep tests. In these

functions, some icons on the bottom toolbar will not appear. However, even if generator settings,

levels, and other items are changed, the settings that were in effect most recently will re-appear

when a function is selected that uses the normal toolbars.

23

Page 29

SP395 SoundPro Audio Integrator Form7492 Operation Manual

SPL

The SPL main menu selection provides several functions that are used in measuring Sound

Pressure Level (SPL). SPL typically uses a microphone as an input. The standard input for the

SPL tests in the left (L) input.

The SPL tests that are available on the SP395 include:

Sound Level Meter: Measures sound pressure level in dB.

Leq: Measures linear averaged sound pressure level over

time.

Dosimeter: Measures sound dosage according to ANSI or

ASA specifications.

Sound Study Graph: Graphs sound level changes over

time.

Sound Level Meter

A sound pressure level meter measures the

changes in air pressure created by sound

waves and displays this pressure as a dB level,

relative to the threshold of hearing sound

pressure. Weighting curves are added to SPL

measurements to make SPL readings

correspond to perceived loudness. The

SP395’s Sound Pressure Level function

measures the loudness of the ambient sound

level in standard dB SPL measurement units,

auto ranged from 30 to 130 dB (A-weighted).

Use the SLM function when you need to know

objective sound volume, such as when

checking for sound level uniformity, balancing

speaker output levels, or adjusting room sound

levels.

The SPL level is a true-RMS measurement,

using ANSI Type 1 standard display time

averages, ANSI Type 1 standard A and C

weighting networks, ANSI Class 1 octave and

1/3 octave band filters, and ANSI Slow, Fast,

and Impulse averaging. SPL measurements are

made using the supplied microphone

connected to the Microphone Input. The large,

digital display shows the ambient sound level

in standard units of dB SPL and the level is

also shown on an analog bar graph meter (one

pixel equals one dB).

The SLM measurement screen.

24

Page 30

SP395 SoundPro Audio Integrator Form7492 Operation Manual

The following fields and parameters are displayed in the SLM function:

1. Averaging - Three ANSI-standard averaging modes are available. These modes use

exponential decay averaging, in which the more recent sounds have more bearing in the

average.

Slow – 1000 mS exponential decay, time-averaged RMS SPL.

Fast – 125mS exponential decay, time-averaged SPL.

Impulse – 35 mS exponential decay, time-averaged SPL

Peak – Peak, rather than RMS SPL.

Highlight the Averaging field and press the control knob to toggle between these four

modes.

2. Weighting - Standard unweighted (flat), A-weighted, and C-weighted filters are

available. These weighting filters make SPL readings correspond more closely to what

our ears hear. Ten ANSI Class 1 octave-band filters – 31, 63, 125, 250, 500, 1k, 2k, 4k,

8k, 16 kHz; and 30 ANSI Class 1 1/3 octave-band filters are also available. Highlight the

field and press the control knob. Rotate the knob to the desired filter and click to select it.

3. Test Function: Identifies the current test selected.

4. R - Relative (Seat to Seat SPL) Clicking on the “R” (relative) field sets the currently

displayed SPL reading as the relative SPL reference. Then, the numeric dB field will

show the difference between the current reading and the stored reference. This is useful

to show relative seat-to-seat SPL readings.

5. Max – Max Hold Clear The maximum SPL reading is constantly updated and displayed.

To reset the displayed value, highlight and click on the "Max" field.

6. Bar Graph SPL: Indicates SPL measurement in bar graph presentation.

7. Digital Readout: Indicates SPL measurement with a digital numeric value.

SLM Operation

1. Connect a test signal to the audio system input. SPL tests require a constant-level

signal, such as a single-frequency test tone or wide-band pink noise. To use the SP395 as

the signal source, connect a cable from an output connector to the desired audio system

input.

Caution: Preset the amplifier gain to minimum to prevent speaker damage

when the SPL test is turned on. There will be no output until the signal generator is

turned on in the bottom Toolbar.

2. Position the microphone. Position the microphone for SPL testing. For example, when

setting speaker level balance, position the microphone in the center of the listening

position.

3. Select one of the four available ANSI-standard averaging modes:

• Use Slow (1000 mS exponential decay time, time-averaged RMS) for most SPL

measurements. This averages transients and provides the best indication of the sound

level that our ears hear.

• Use Fast (125 mS exponential decay time, time-averaged RMS) to follow fast audio

changes.

• Use Impulse mode, (35 mS exponential decay time, time-averaged RMS) to measure

noise spikes.

• Use Peak mode to show peak SPL, rather than RMS.

4. Select the weighting filter. Select one of 38 filtering modes:

• C-weighting for louder SPL levels, including most system measurements.

• A-weighting for low SPL levels, or for measurements that need to correlate to noise-

induced hearing damage.

• Flat (un-weighted).

25

Page 31

SP395 SoundPro Audio Integrator Form7492 Operation Manual

• Any of nine ANSI Class 1 octave-band filters – 31, 63, 125, 250, 500, 1000, 2000,

4000, and 8000Hz.

• Any of 25 ANSI Class 1 1/3 octave-band filters.

5. If you are using the Audio Integrator as the signal source for the audio system:

• Turn the generator on by clicking the "on/off" field.

• Adjust the generator output level.

6. Read the SPL level.

Leq

Leq is defined as the linear average of the sound pressure level over a period of time. You can

use this to determine if noise standards are being met. The LEQ function computes and displays

the time-averaged sound level. When an A-weighting filter is used to measure the time-averaged

effects of noise, this measurement is often called LAeq.

Leq measurement screen.

The following fields and parameters are displayed in the Leq Screen:

1. Weighting - Standard unweighted (flat), A-weighted, and C-weighted filters are

available. These weighting networks make SPL readings correspond more closely to what

our ears hear. Ten ANSI Class 1 octave-band filters – 31, 63, 125, 250, 500, 1k, 2k, 4k,

8k, 16 kHz; and 30 ANSI Class 1 1/3 octave-band filters are also available. Highlight the

field and press the control knob. Rotate the knob to the desired filter and click to select it.

2. Max SPL - The SPL reading in the upper right is a peak-hold SPL reading. Highlight the

"Max" field and click the control knob to reset this reading.

3. Linear Averaged Sound Level dB – Leq measurement value.

4. Time Duration of Test - Select time interval of test including 10 sec, 1, 5, 10, or 15 min.

or 1, 8, or 24 hrs. Can be set to Manual for manual starting and stopping of the test

interval.

5. Elapsed Time - This field shows the time that the input sound level has been averaged,

in hours, minutes, and seconds since the start of the test.

6. Start/Reset - This field starts the time or interval for the test measurement. This field

also resets the time interval to start a new test during or after a previous Leq test interval.

26

Page 32

SP395 SoundPro Audio Integrator Form7492 Operation Manual

Leq Operation:

1. Connect a microphone to the L input. Apply phantom power and set the gain range.

2. Select the desired filter: Choose from A or C -weighting, an octave or one-third octave

band, or flat (unweighted). A-weighting is often desired when noise is being measured.

3. Select the time. Choose from 10seconds, 1, 5, 10, or 15minutes, or 1, 8, or 24 hours. Or,

select Manual and start and stop the LEQ test yourself.

4. Click Start. After a 2 second delay, the SP395 starts averaging the incoming sound. It

stops automatically at the end of the selected time, or, if you are in Manual mode,

continues to run until you click Reset.

Note: To avoid the possibility of incorrect averages, do not use Auto-gain in the Leq function. Pick a

range that will handle the highest expected SPL without clipping through the length of the LEQ test.

Dosimeter

The SP395 can be used as a Noise Dosimeter for noise surveys, hearing conservation programs,

community noise studies, machinery noise evaluations, and occupational noise analysis. The

Noise Dosimeter meets ANSI S1.25-1991 and ASA 98-1991 specifications.

The Dosimeter test screen.

The following fields and parameters are displayed in the Dosimeter test screen.

Control Fields

1. Criterion - Criterion Level The Criterion Level is the 8 hour dB exposure level that is

considered a 100% Dose. For most regulating agencies, a 100% dose occurs with an

average sound level of 90dB over an 8-hour period.

2. Threshold Level –

3. Test Function: Identifies current test function as Dosimeter

4. Exchange Rate - Three Exchange Rates are available: 3 dB ISO, 4 dB DOD, and 5 dB

OSHA. The Exchange Rate affects how sound energy is averaged over time. The ISO 3

dB standard, used by most users, causes the reported Dose to double for every 3 dB

increase in the time-weighted average sound energy. The DOD 4 dB standard, used by

27

Page 33

SP395 SoundPro Audio Integrator Form7492 Operation Manual

the U.S. military, causes the reported Dose to double for every 4 dB increase in the time-

weighted average sound energy. The OSHA (and MSHA) 5 dB standard causes the

reported Dose to double for every 5 dB increase in the time-weighted average sound

energy.

5. Speed – Averaging Speed. Slow (1000 mS time constant) and Fast (125 mS time

constant) averaging speeds are available. Highlight the field and press the control knob to

select the desired averaging speed.

6. Time - Criterion Time. Sets the Criterion Time from 0.1 hour to 24.0 hours, in 0.1 hour

steps. Highlight the field and press the control knob. Rotate the knob to select the desired

time.

7. Weighting– Standard A-weighted, and C-weighted filters are available. Highlight the

field and press the control knob to select the desired filter.

Display Fields -

As the test is running, the elapsed time is shown on the screen. The fields displayed are:

8. SPL – Current Sound Pressure Level, using selected weighting and averaging speed.

9. Leq – Equal-weighted average SPL from start of test. Also referred to as the time-

averaged sound pressure level.

10. Max – Maximum SPL since beginning of test, using selected weighting and averaging

speed.

11. Dose – Noise Dose accumulated since start of test. For example, running at the Criterion

Level for 1/2 of the Test Length would equal a 50% dose.

12. Proj – Projected Dose. This is defined as the dose that would be reported at the end of

the Criterion Time Length, if no more sound above the Threshold was measured.

13. TWA – Time-Weighted-Average. The average sound level for the measured time

period, spread out over the selected workday period (Time), which is normally set to 8

hours.

14. Pause/Resume – Permits test to be paused and then to be resumed.

15. Elapsed Time – Time that has lapsed since the start of the test period.

16. Start/Reset – Starts or resets the test.

Dosimeter Operation

1. Set the Criterion Level. This is the level that will result in a 100% dose reading if

maintained for the entire test. The criterion level is normally 90dB, but may be overridden

if desired.

2. Set the Threshold Level. Any sound below this level does not contribute to the measured

dose. Normally, this is set to 80dB. You can override this setting if desired. It may not be

set higher than the Criterion Level.

3. Set the Averaging Speed. Normally, Slow (1 second time constant) is used, but may be

changed to Fast if desired.

4. Set the Criterion Time. This time is normally set to 8 hours to match the typical work

day. Dosimeter standards are all written around 8 hour work days. All Dose calculations

are referenced to this time.

5. Set the Exchange Rate. This is defined as the number of dB equaling a doubling (or

halving) of the Dose. For example, if a 90 dB dose for 8 hours equals 100%, with a 5dB

exchange rate, an 85 dB dose for 8 hours would equal a 50% dose. 95dB for 8 hours

would equal a 200% dose. This field also displays OHSA, DOD (US Department of

Defense), and ISO, when the Exchange Rate specified by those agencies is selected.

28

Page 34

SP395 SoundPro Audio Integrator Form7492 Operation Manual

6. Start the test. Click on “Start” to begin the test.

7. Pause / Resume. You can use this field to pause the test whenever desired, for example to

not include an event or time period in the Dosimeter test period.

The Dosimeter results may be stored in a memory, or recalled to examine a previous test.

Sound Study Graph

The Sound Study Graph function graphically displays the SPL level over a period of time. Use

this function to analyze noise levels over time, or to record concert or PA sound levels. It can run

in peak or average mode, and any of the A, C, octave-band or 1/3 octave-band filters may be

selected. The time can range from 1 minute to 24 hours. When the function runs, it divides the

time period into 120 equal divisions, sampling the sound level at each period. The SP395

computes either the average or peak SPL for that period, and draws a bar on the graph. This

continues until the total time for the test has expired.

As the function is running, the LEQ is computed and displayed. After the graph is complete, the

full LEQ is displayed, and stored with the graph. The graph can then be stored in one of the

memories, if desired.

The Sound Study Graph function graphically displays the SPL level over a period of time

The following fields and parameters are displayed in the Sound Study Graph test screen.

1. Test Function – Shows the selected test function.