Page 1

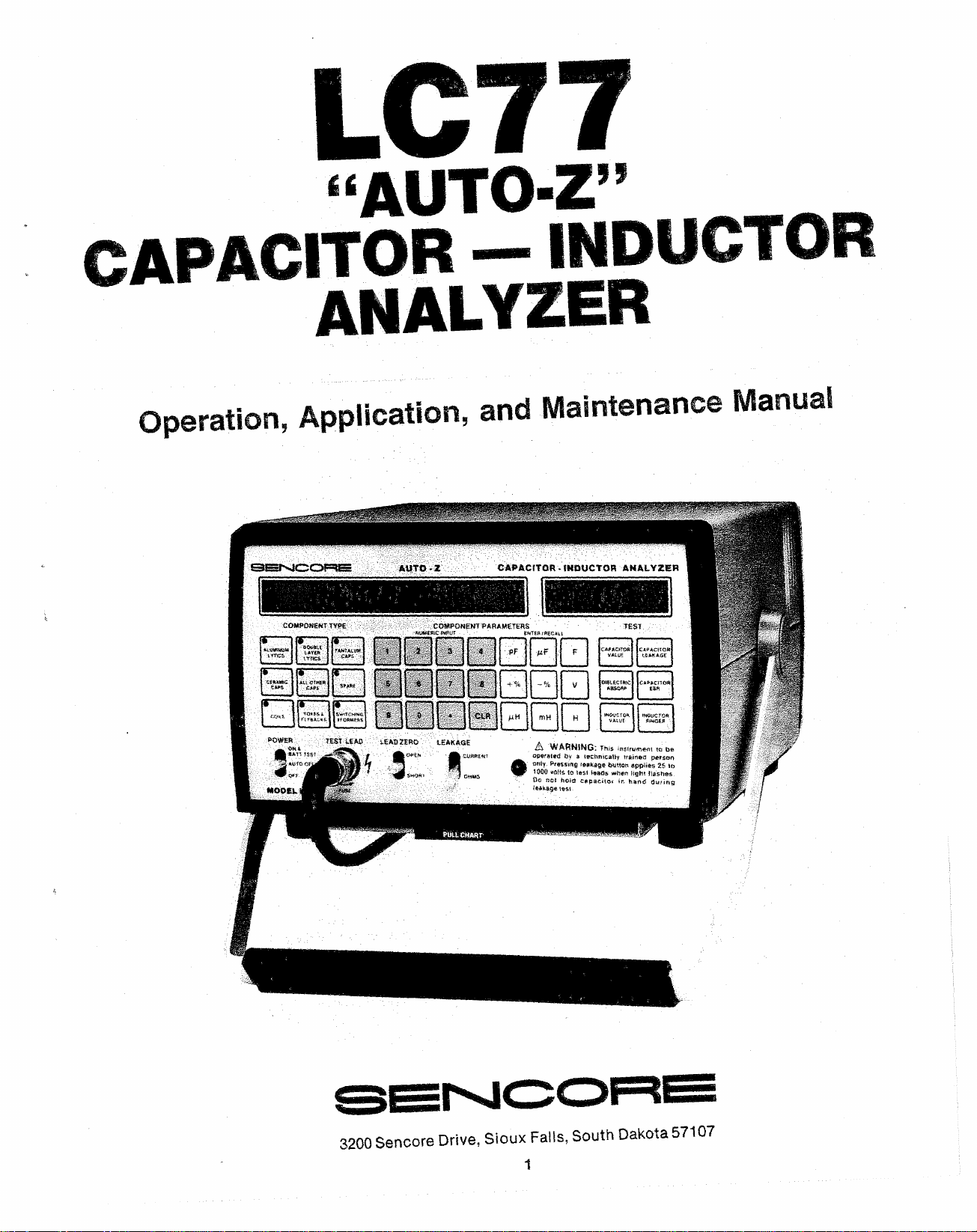

LC77

“AUTO-Z”

CAPACITOR — INDUCTOR

ANALYZER

Operation, Application, and Maintenance Manual

SENCORE

3200 Sencore Drive, Sioux Fails, South Dakota 57107

1

Page 2

TAB LE O F CO NTEN TS

SAFETY PRECAUTIONS

SIMPLIFIED OPERATIONS

DESCRIPTION

Introduction

Features ...

Specifications

Controls

Rear Panel Features ................................. 10

Supplied Accessories .................................

Optional Accessories

OPERATION

Introduction . ...................................... 12

AC Power Operation ............................................ 12

Battery Operation .............................12

Battery Test .. ............................................... 13

Recharging the Battery

Auto O f f.............................................................

Test L e a d s

Test Lead Mounting Clip .................. 15

Test Lead Adapter.................. . .... 15

Test Lead Fuse ......................... 15

Lead Zeroing ................................... 16

Entering Component Data ................. .. 16

Error Codes ........... ......... : ...i. . • 18

Capacitor Testing ..... ..... .,.............. 19

Capacitance Measurement Accuracy ........ 19

Measuring Small Capacitance Values in

Noisy Environments ..................... 20

Capacitor Parameter Testing

Measuring Capacitor Value ................ 20

Measuring Capacitor Dielectric Absorption .... 20

Measuring Capacitor Leakage (Microamps) .. . 21

Paper, Mica and Film Capacitor

Aluminum Electrolytics :...

Tantalum Electrolytics . ...

Non-polarized Electrolytics ........... ... 22

Leakage Charts............................ . .... 22

Aluminum Electrolytics . .................................

Tantalum Electronics......................................24

Measuring Capacitor Leakge (ohms)

Measuring Capacitor ESR ....................................25

Capacitor Automatic Good/Bad Testing

Inductor Testin g

Balancing Out Lead Inductance

Inductor Value Testing ........................ .... 30

Inductor Automatic Good/Bad Testing .......... 30

Checking Inductors with the Ringer Test

Good/Bad Inductor Value Testing ........... 31

...............................

.....................................................................

.................................................... 6

............................................... 8

................................................................14

Ceramic Capacitors ..........................

........................................................

.............

....................................... 10b

Inside Front Cover

............... ......................

............

............................ 14

................... 20

.. 6

.............

......... 22

....

...........

..............................

.................................22

...............

...........

........................

.........

4

6

10a

.. 14

22

22

23

24

26

29

29

30

IEEE 488 BUSS OPERATION

Connecting the LC77 for IEEE Operation

Sending Data to the LC77 .......

Component Type Commands ...................... 33

Value Multipliers . ...

Test Function Commands

General Commands ............................................35

Reading Data from the LC77 ...................................

Data Format............................................................36

Separating Data Fields .......................................36

Advanced Programming Ideas

Error Testing ....................................................... • 37

Good/Bad Results ..............................................

Shorted Capacitors ..............................................

Open Inductors ,........................ 38

Making Leakage Tests with IEEE ......................

Making ESR Tests with IE E E ....................

Programming Examples ...

Sending Listener Codes .....................................39

Sending Talker C odes.........................................39

Sample Programs ................................................

APPLICATIONS ....

Introduction .................................................................44

Indentifying Capacitor Types

Aluminum Electrolytics ...

Tantalum Electrolytics .....................................

Double Layer Electrolytics .. . .

Ceramic Capacitors................... ..........................46

: Ail Other Capacitors

Identifying Inductors Types ......................................47

Yokes and Flybacks ....... .............................47

Switching Transformers . ......................................47

Coils.";.... .. .. .. .. . ..........................................48

Identify Unknown Components . ...........................t 48

Capacitor Testing Applications ...............................

Interpreting Capacitor Value Readings

Dielectric Stress ... .. . .

Checking Leakage in Multi-Section Lytics .... 49

Intermittent Capacitors ........................................50

Checking Ceramic Temperature

Characteristics...................................................... 50

Checking Capacitance of Silicon Diodes

and Transistors

Testing High Voltage Diodes .. .

Reforming Electrolytics

Inductor Testing Applications ...

Testing Inductors In-Circuit..................................

■v - Mutual inductance . . . . . . . ...............................

Ringing Peaking C oils

Ringing Metal Shielded Coils

Ringing Flyback Transformers

Ringing Deflection Yokes ...

Note on Solid State Yokes & Flybacks

...................................31

.............

................................ 32

........................

.........................................39

.............

...................................,44

.....................................45

.........

..................................47

..................................................50

...........

.........................................

....

.................

.............

..............................

............................44

.................

................................

................................

.. 34

..........................

.............

........................

............................

............................

..........................

.............

31

33

35

37

. 37

38

38

........

38

40

.. 45

46

49

49

.. 49

51

51

52

52

52

52

53

53

54

55

2

Page 3

Notes

Page 4

Introduction

DESCR I PTION

Capacitor and inductor usage is extensive, encompas

sing all facets of industrial and consumer electronics.

Very few circuits lack either of these components. Be

cause the transistor gave way to the IC, and the IC

gave way to the LSIC, capacitor and inductor usage

continues to increase rapidly since neither of these com

ponents can be physically incorporated into ICs on a

broad basis.. Though they have changed some in phys

ical size, capacitors still perform the same basic func

tions. But in today's circuits, more than ever before,

the tolerances and parameters of capacitors and induc

tors are critical to proper circuit operation.

Capacitor value and tight tolerance is just one impor

tant parameter. In today’s high performance circuits,

leakage, dielectric absorption, and ESR are necessary

indicators of a capacitor’s ability to perform properly

in circuit. Inductors too, require tight tolerances and

quality checks. Unless all of these parameters can be

thoroughly analyzed, troubleshooting becomes a gues

sing game.

The Sencore LC77 “AUTO-Z” takes the guess work out

of capacitor and inductor testing. It provides automatic

tests of capacitor value, leakage, ESR, and a patented

dielectric absorption test. Inductors are automatically

analyzed for value and quality with patented tests. The

LC77 is a complete, automatic, microprocessor-control-

led capacitor and inductor analyzer. Its features make

it ideally suited for both single component analyzing

in service or maintenance work, or for large volume

batch testing in a lab or incoming inspection.

Features

The Sencore LC77 “AUTO-Z” is a dynamic, portable,

automatic capacitor and inductor tester. It is designed

to quickly identify defective components by simply con

necting the capacitor or inductor to the test leads and

pushing a test button. The test result is readily dis

played on an LCD readout in common terms. All

capacitor and inductor test results may also be dis

played as good/bad compared to standards adopted by

the Electronic Industries Association (ElA). User de

fined limits may also be programmed into the LC77 for

the good/bad comparison.

In addition to testing capacitors for value up to 20

Farads, the LC77 checks capacitors for leakage at their

rated working voltage, up to 1000 volts. ESR is checked

with a patent-pending test, and an automatic, patented

test checks capacitor dielectric absorption. A patented

inductance value test provides a fast, accurate test of

true inductance. A patented ringing test checks coils,

deflection yoke, switching power supply transformers,

and other non-iron core inductors with a fast, reliable

good/bad quality test.

Automatic lead zeroing balances out test lead capaci

tance, resistance, and inductance for accurate readings

on small capacitors and inductors. The LC77 is pro

tected from external voltages applied to the test leads

by a fuse in the TEST LEAD JACK and special circuitry

which locks out all test buttons when voltage is sensed

on the test leads.

Battery operation makes the LC77 completely portable

for on-location troubleshooting in all types of servicing

from industrial equipment to avionics to cable fault

locating. An optional SCR & Triac tester extends the

LC77 test .capabilities to provide a fast, accurate test

of these components. The LC77 may be interfaced into

any IEEE 488 Bus system for fully automatic, computer

controlled testing in a laboratory or incoming inspec

tion area.

Specifications

DIGITAL READOUT

TYPE: .45”, 6 digit, 7 segment LCD

READINGS: Fully autoranged with auto decimal place

ment. One or two place holding zeros added as needed

to provide standard value readouts of pF, uF, F, uH

or mH.

ANNUNCIATORS: pF, uF, F, uH, mH, H, uA, mA, %,

V, kft, MA, OHMS, RINGS, SHORT, OPEN, WAIT,

GOOD, BAD.

CAPACITORS (Out of circuit)

Dynamic test of capacity value is determined by

measuring one RC time constant as capacitor is charged

to 4-5 V through:

1.5 Megohms for 0 - .002 uF

15 Kilohms for .002 uF - 2 uF

Values above 2 uF are charged with a constant current

of:

60 mA for 2uF - 2000uF

416 mA for 2000 uF - 19.99 F

Maximum voltage across capacitors larger than 2000

uF limited to 1.75 V.

ACCURACY: + / — 1% + /- lp F 4- /- 1 digit for values

to 1990 uF. 4-/ —5% 4 - / - .1% of range full scale for

values 2000 uF to 19.99 F.

RESOLUTION AND RANGES: 1.0 pF to 19.99 F, fully

autoranged:

.1 pF —

IpF —

.00001 uF —

.0001 uF —

.001 uF —

.01 uF —

1.0 pF to

200 pF to

0.00200 uF to

0.0200 uF to

0.200 uF to

2.00 uF to

199.9 pF

1999 pF

0.01999 uF

0.1999 uF

1.999 uF

19.99 uF

6

Page 5

.luF —

luF — 200 uF

10 uF —

100 uF —

.001F —

.01F — 2.00 F

20.0 uF

2,000 uF to

20,000 uF

0.200 F

to

to

to

to

to

199.9uF

1,999 uF

19,990 uF

199,900 uF

1.999 F

19.99 F

CAPACITOR LEAKAGE

READOUT: User selectable between leakage current

and resistance.

ACCURACY: + / - 5% + / -1 digit.

APPLIED VOLTAGE: Keyboard entry; 1.0 to 999.9

volts in . 1 volt steps; accuracy +0 -5%. Short circuit

current limited to 900mA, power limited to 6 watts.

RESOLUTION AND RANGES: .OluA to 20 mA, fully

autoranged:

.O luA —. 0.01 uA to 19.99 uA

.l uA — 20.0 uA to 199.9 uA

1 uA — 200uA to 1999uA

.01mA— 2.00 mA to 19.99 mA

CAPACITOR ESR (Test patent pending)

ACCURACY: +/ -5% + /- 1 digit.

CAPACITOR RANGE: 1 uF to 19.99 F.

RESOLUTION AND RANGES: .10 ohm to 2000 ohms,

fully autoranged:

.01 ohm — 0:10 ohms to '1.99 ohms

.lohm — 2.0ohms to 19.9ohms

1 ohm — 20 ohms to 199 ohms

10 ohm — 200 ohms to 1990 ohms

CAPACITOR D/A (U.S. Patent #4,267,503)

ACCURACY: + /- 5 counts.

RANGE: 1 to 100%.

CAPACITOR RANGE: .01 uF to 19.99 F.

RINGING TEST

A dynamic test of inductor quality determ ined by apply

ing an exciting pulse to the inductor and counting the

number of cycles the inductor rings before reaching a

preset damping point. (U.S. Patent # 3,990,002)

INDUCTOR RANGE: 10 uH and larger ,-non-iron core

ACCURACY: -i- / — 1 count on readings between 8 and

13.

RESOLUTION: + /-1 count.

EXCITING PULSE: 5 volts peak; 60 Hz rate.

GENERAL

TEMPERATURE: Operating range: 32c to 104°F (0°

to 40°C) Range for specified accuracy (after 10

minute warmup): 50° to 86°F (10° to 30°C)

POWER: 105-130V AC, 60Hz, 24 watts max. with

supplied PA251 power adapter. Battery operation

with optional BY234 rechargeable battery. 210-230V

AC operation with optional PA252 Power Adapter.

AUTO OFF: Removes power during battery operation

if unit sits idle longer than 15-20 minutes.

BATTERY LIFE: 8 hours typical inductor testing; 7

hours typical capacitor testing.

SIZE: 6” x 9” x 11.5” (15.2cm x 22.9cm. x 29.1cm) HWD

WEIGHT: 6 lbs. (2.7kg) without battery, 7.6 lbs (3.4kg)

GOOD/BAD INDICATION: Functions on all tests. Re

quires user input of component type and value, or

input of desired limits.

IEEE: Requires the use of Sencore IB72 Bus Interface

Accessory..

The following interface codes apply: SHI, AH1, T8,

L4, SRO, RLO, PPO, DCO, DTC, CO. All readings

are test accuracy 4-/-.1 count.

INDUCTORS (In or out of circuit)

A dynamic test of value determined by measuring the

EMF produced when a changing current is applied to

the coil under test. (U.S. Patent # 4,258,315)

CURRENT- RATES: automatically selected

50 mA/uSec —

5 mA/uSec —

.5 mA/uSec —

50 m A/mSec —

5mA/mSec —

.5 m A/mSec —

.05 mA/mSec — 1.8H

ACCURACY: +/- 2% +/ - I digit

RESOLUTION AND RANGES: .10 uH to 20 H, ful

autoranged

.01 uH — 0.10 uH

.1 uH —

1 uH —

.001 mH —

.01 mH —

.ImH —

1 mH —

.001H —

.01H —

OuH to 18 uH

18 uH

180 uH to 1.8 mH

1.8 mH :

18 mH to 180 mH

180 mH

20.0 uH

200 uH

1.000 mH

2.00 mH

20.0 mH

200 mH

1.000 H

2.00H

to 180 uH

to

to

to 19.99 H

to

to

to

to

to

to

to

to

to

19.99 uH

199.9 uH

999 uH

1.999 m il

19.99 mH

199.9 mH

999 mH

1.999H

19.99 H

18 mH

1.8 H

Specifications subject to change without notice

ACCESSORIES

SUPPLIED:

39G143 Test Leads

39G144 Test Lead Adapter

39G201 Test Button Hold Down Rod

64G37 Test Lead Mounting Clip

PA251 AC Power Adapter/Recharger

OPTIONAL:

39G85 Touch Test Probe

FC221 Field Calibrator

BY234 Rechargeable Lead Acid Battery

SCR250 SCR/Triac Tester

CC254 Carrying Case

CH255 Component Holder

CH256 Chip Component Test Lead

IB 72 Bus Interface Accessory

PA252 220V AC Power Adapter/Recharger

7

Page 6

Controls

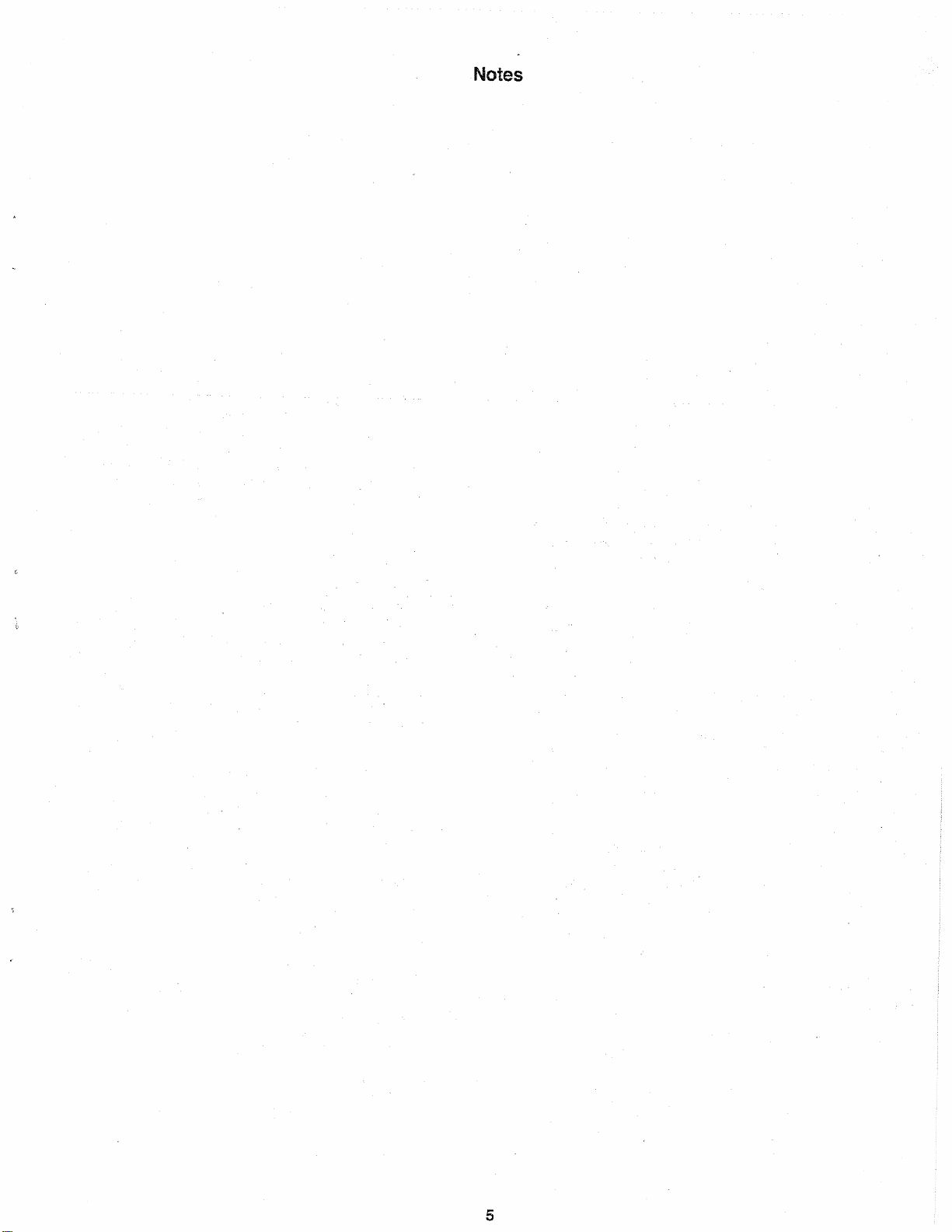

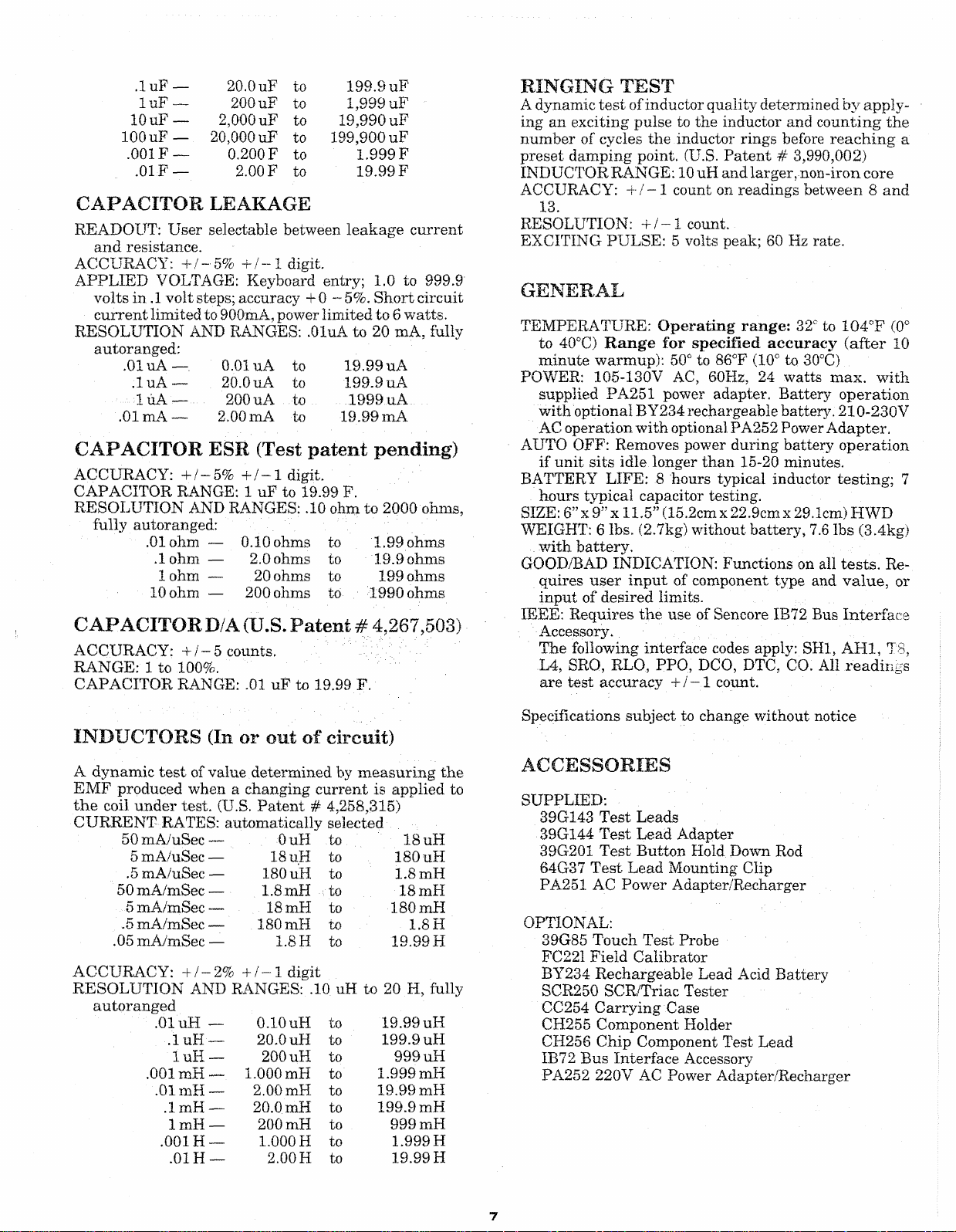

1. COMPONENT TYPE select buttons. Use with

TEST buttons (4), and COMPONENT PARAMETERS

buttons (6) for component limit testing.

a. - e. capacitor type buttons - Use with other beige

color coded capacitor buttons (4a - d) and (6m - o).

f. SPARE - Provides a spare button to allow for

future component types and internal memory up

dates.

g. - i. Inductor type buttons - Use with other blue

color coded inductor buttons (4e - f) and (6s - u).

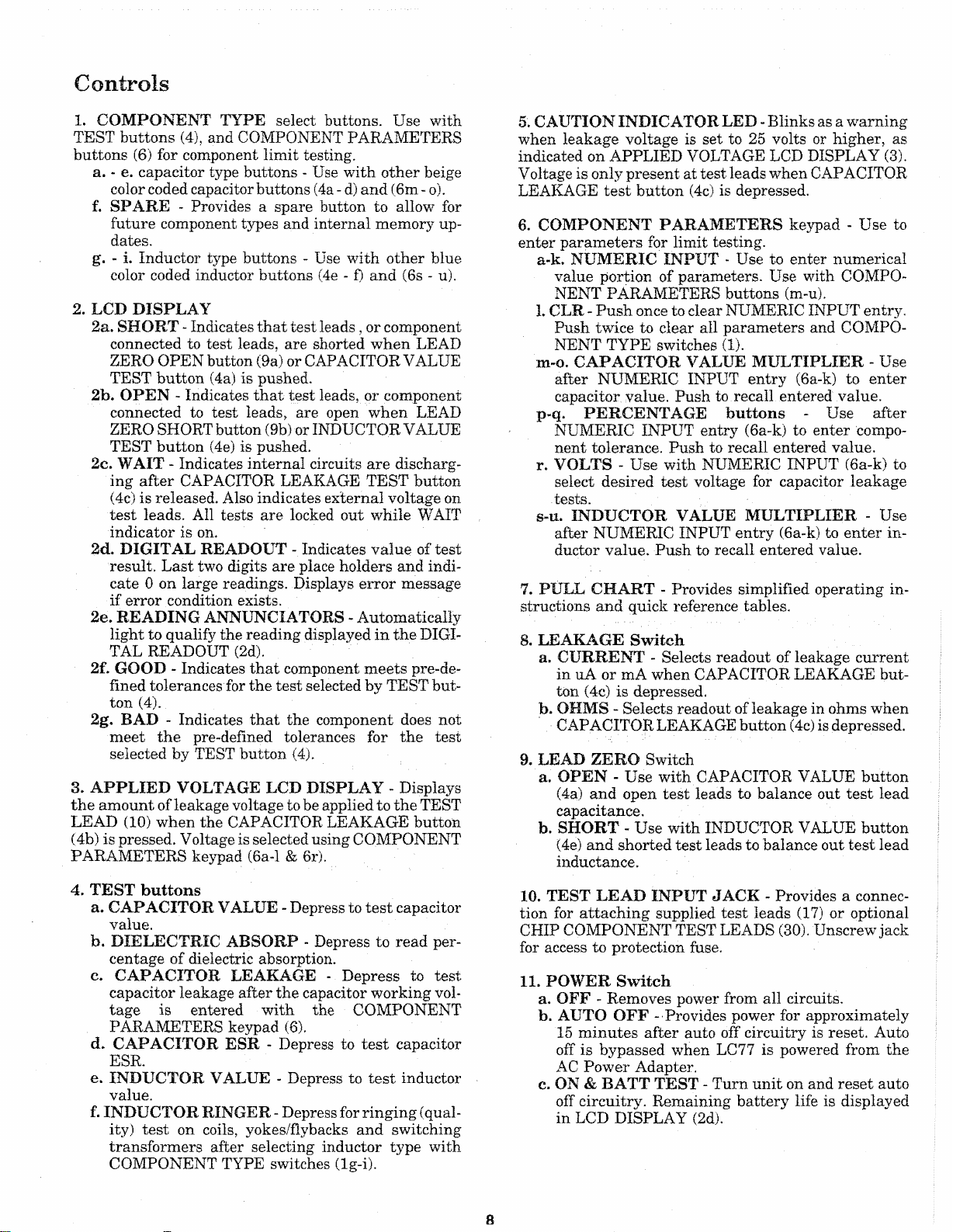

2. LCD DISPLAY

2a. SHORT - Indicates that test leads, or component

connected to test leads, are shorted when LEAD

ZERO OPEN button (9a) or CAPACITOR VALUE

TEST button (4a) is pushed.

2b. OPEN - Indicates that test leads, or component

connected to test leads, are open when LEAD

ZERO SHORT button (9b) or INDUCTOR VALUE

TEST button (4e) is pushed.

2c. WAIT - Indicates internal circuits are discharg

ing after CAPACITOR LEAKAGE TEST button

(4c) is released. Also indicates external voltage on

test leads. All tests are locked out while WAIT

indicator is on.

2d. DIGITAL READOUT - Indicates value of test

result. Last two digits are place holders and indi

cate 0 on large readings. Displays error message

if error condition exists.

2e. READING ANNUNCIATORS - Automatically

light to qualify the reading displayed in the DIGI

TAL READOUT (2d).

2f. GOOD - Indicates that component meets pre-de-

fined tolerances for the test selected by TEST but

ton (4).

2g. BAD - Indicates that the component does not

meet the pre-defined tolerances for the test

selected by TEST button (4).

3. A PPLIED VOLTAGE LCD DISPLAY - Displays

the amount of leakage voltage to be applied to the TEST

LEAD (10) when the CAPACITOR LEAKAGE button

(4b) is pressed. Voltage is selected using COMPONENT

PARAMETERS keypad (6a-l & 6r).

5. CAUTION INDICATOR LED - Blinks as a warning

when leakage voltage is set to 25 volts or higher, as

indicated on APPLIED VOLTAGE LCD DISPLAY (3).

Voltage is only present at test leads when CAPACITOR

LEAKAGE test button (4c) is depressed.

6. COMPONENT PARAMETERS keypad - Use to

enter parameters for limit testing.

a-k. NUM ERIC INPUT - Use to enter numerical

value portion of parameters. Use with COMPO

NENT PARAMETERS buttons (m-u).

1. CLR - Push once to clear NUMERIC INPUT entry.

Push twice to clear all parameters and COMPO

NENT TYPE switches (1).

m-G. CAPACITOR VALUE MULTIPLIER - Use

after NUMERIC INPUT entry (6a-k) to enter

capacitor value. Push to recall entered value.

p-q. PERCENTAGE buttons - Use after

NUMERIC INPUT entry (6a-k) to enter compo

nent tolerance. Push to recall entered value.

r. VOLTS - Use with NUMERIC INPUT (6a-k) to

select desired test voltage for capacitor leakage

tests.

s-u. INDUCTOR VALUE MULTIPLIER - Use

after NUMERIC INPUT entry (6a-k) to enter in

ductor value. Push to recall entered value.

7. PULL CHART - Provides simplified operating in

structions and quick reference tables.

8. LEAKAGE Switch

a. CURRENT - Selects readout of leakage current

in uA or mA when CAPACITOR LEAKAGE but

ton (4c) is depressed.

b. OHMS - Selects readout of leakage in ohms when

CAPACITOR LEAKAGE button (4c) is depressed.

9. LEAD ZERO Switch

a. OPEN - Use with CAPACITOR VALUE button

(4a) and open test leads to balance out test lead

capacitance.

b. SHORT - Use with INDUCTOR VALUE button

(4e) and shorted test leads to balance out test lead

inductance.

4. TEST buttons

a. CAPACITOR VALUE - Depress to test capacitor

value.

b. DIELECTRIC ABSORP - Depress to read per

centage of dielectric absorption.

c. CAPACITOR LEAKAGE - Depress to test

capacitor leakage after the capacitor working vol

tage is entered with the COMPONENT

PARAMETERS keypad (6).

d. CAPACITOR ESR - Depress to test capacitor

ESR.

e. INDUCTOR VALUE - Depress to test inductor

value.

f. INDUCTOR RINGER - Depress for ringing (qual

ity) test on coils, yokes/flybacks and switching

transformers after selecting inductor type with

COMPONENT TYPE switches (lg-i).

10. TEST LEAD INPUT JACK - Provides a connec

tion for attaching supplied test leads (17) or optional

CHIP COMPONENT TEST LEADS (30). Unscrew jack

for access to protection fuse.

11. POWER Switch

a. OFF - Removes power from all circuits.

b. AUTO OFF - Provides power for approximately

15 minutes after auto off circuitry is reset. Auto

off is bypassed when LC77 is powered from the

AC Power Adapter.

c. ON & BATT TEST - Turn unit on and reset auto

off circuitry. Remaining battery life is displayed

in LCD DISPLAY (2d).

8

Page 7

2 c v

WAIT

2b— OPEN

2a

-SHORT

Fig. 1 — Location of front panel controls and features.

O O O O O O S F m H m A K Q G ° 6 D

U . U . U . U . U . U .

Fig. 2 — LCD annuncia tors.

r in g s % n BAD

-------

29

Page 8

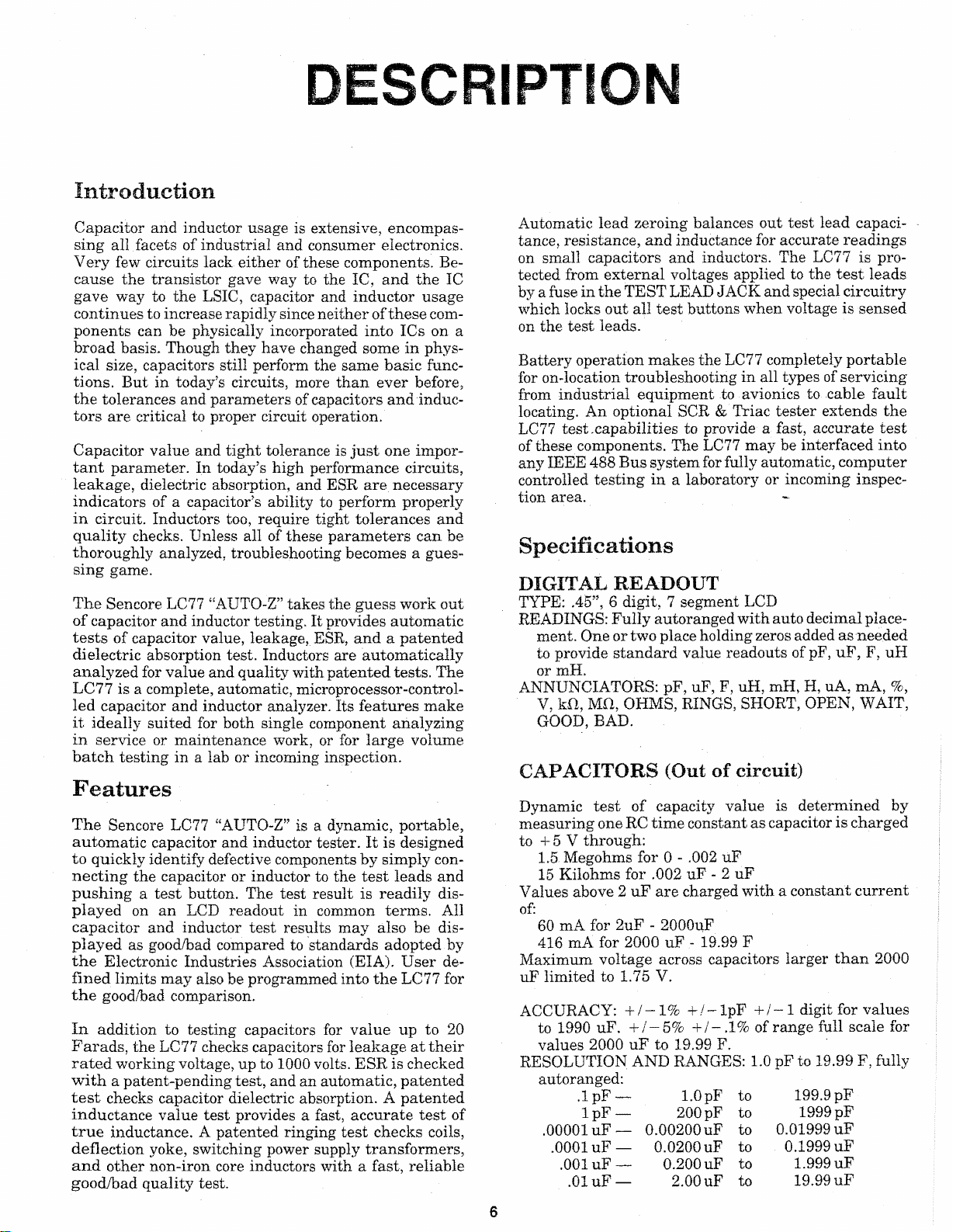

Supplied Accessories

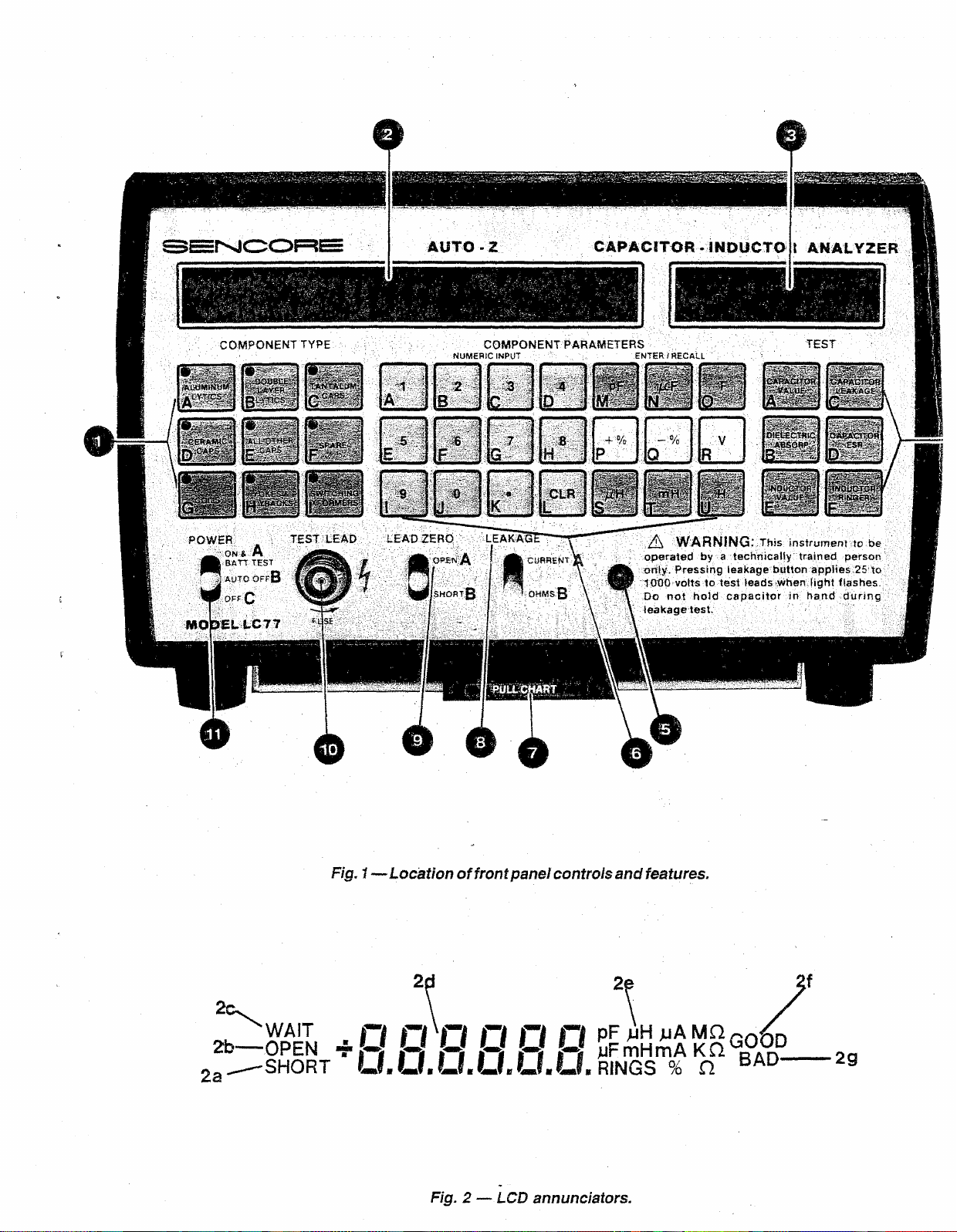

17. TEST LEADS (39G145) - Special low capacity

cable with E-Z Hook® clips. Connect to TEST LEAD

INPUT (10).

18. 39G144 TEST LEAD ADAPTER (39G144) - Use

to adapt TEST LEADS (17) to large, screw terminal

capacitors,

19. TEST BUTTON HOLD DOWN ROD (39G201) -

Use to hold CAPACITOR LEAKAGE button (4c) depre

ssed when reforming capacitors.

20. TEST LEAD MOUNTING CLIP (64G37) - Use

to hold Test Lead when not in use.

21. POWER ADAPTER (PA251) - Plugs into POWER

INPUT (16) to power unit from 105-130 VAC line. Also

recharges the (optional) BY234 Battery when installed

inside the LC77.

Fig. 4 — Supplied Accessories.

Page 9

OPERATIO N

Introduction

Before you begin to use your LC77 “Auto-Z”, take a

few minutes to read through the Operations and Appli

cations sections of this manual and acquaint yourself

with the features and capabilities of your instrument.

After you have familiarized yourself with the general

operation of the LC77, most tests can be performed with

the information on the front panel.

AC Power Operation

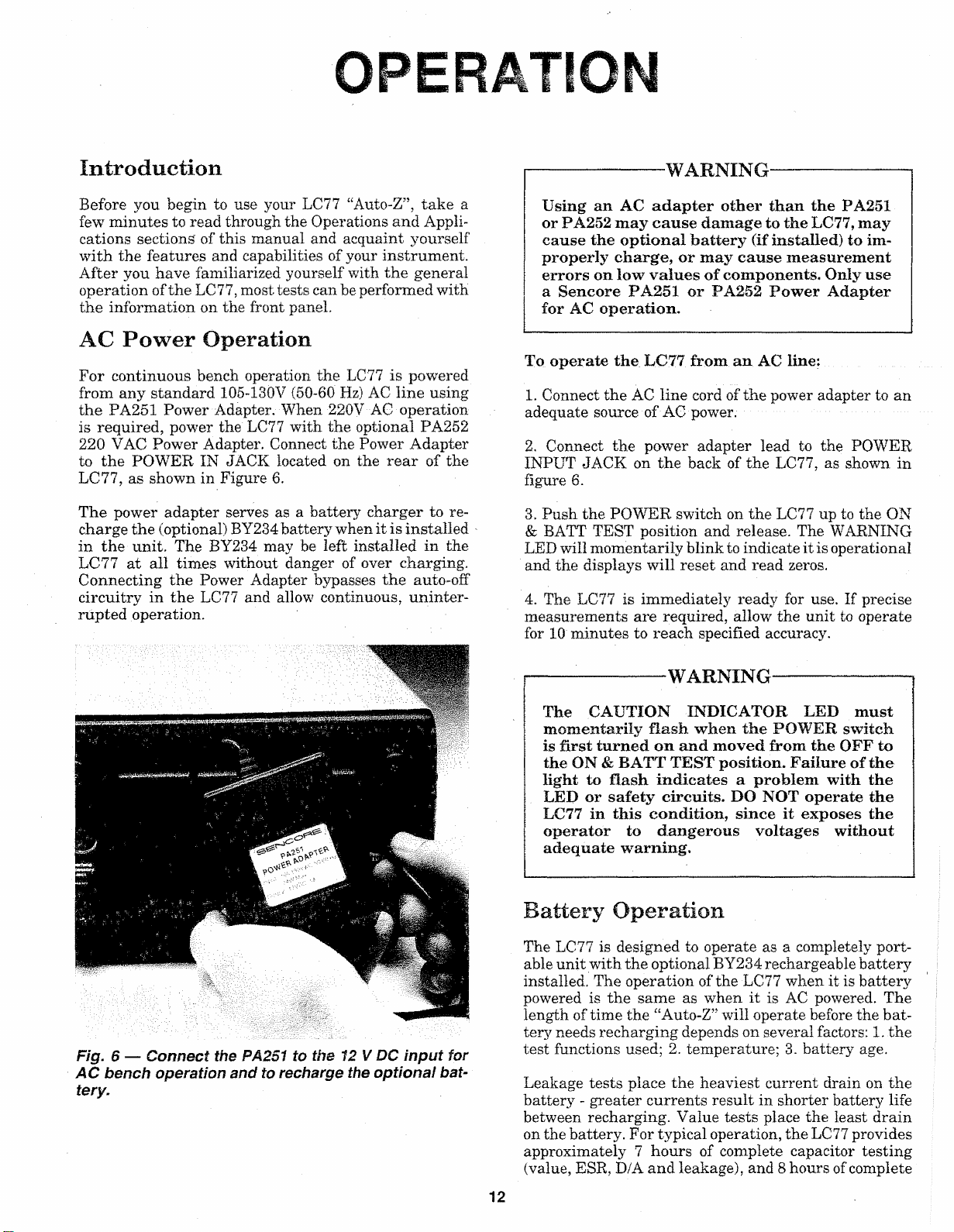

For continuous bench operation the LC77 is powered

from any standard 105-130V (50-60 Hz) AC line using

the PA251 Power Adapter. When 220V AC operation

is required, power the LC77 with the optional PA252

220 VAC Power Adapter. Connect the Power Adapter

to the POWER IN JACK located on the rear of the

LC77, as shown in Figure 6.

The power adapter serves as a battery charger to re

charge the (optional) BY234 battery when it is installed

in the unit. The BY234 may be left installed in the

LC77 at all times without danger of over charging.

Connecting the Power Adapter bypasses the auto-off

circuitry in the LC77 and allow continuous, uninter

rupted operation.

------------------

Using an AC a dapter other than the PA251

or PA252 may cause damage to the LC77, may

cause the optional b attery (if installed) to im

properly charge, or may cause measurement

errors on low values of components. Only use

a Sencore PA251 or PA252 Pow er A dapter

for AC operation.

To operate the LC77. from an AC line:

1. Connect the AC line cord of the power adapter to an

adequate source of AC power.

2. Connect the power adapter lead to the POWER

INPUT JACK on the back of the LC77, as shown in

figure 6.

3. Push the POWER switch on the LC77 up to the ON

& BATT TEST position and release. The WARNING

LED will momentarily blink to indicate it is operational

and the displays will reset and read zeros.

4. The LC77 is immediately ready for use. If precise

measurements are required, allow the unit to operate

for 10 minutes to reach specified accuracy.

WARNING

------------------

Fig. 6 — Connect the PA251 to the 12 V DC input for

AC bench operation and to rechar ge the optional bat

tery.

-------:-------------

The CAUTION INDICATOR LED m ust

momentarily flash when the POWER switch

is first turned on and moved from the OFF to

the ON & BATT TEST position. Failure of the

light to flash indicates a problem with the

LED or safety circuits. DO NOT operate the

LC77 in this condition, since it exposes the

operator to dangerous voltages without

adequate warning.

WARNING— :

............

..........

Battery Operation

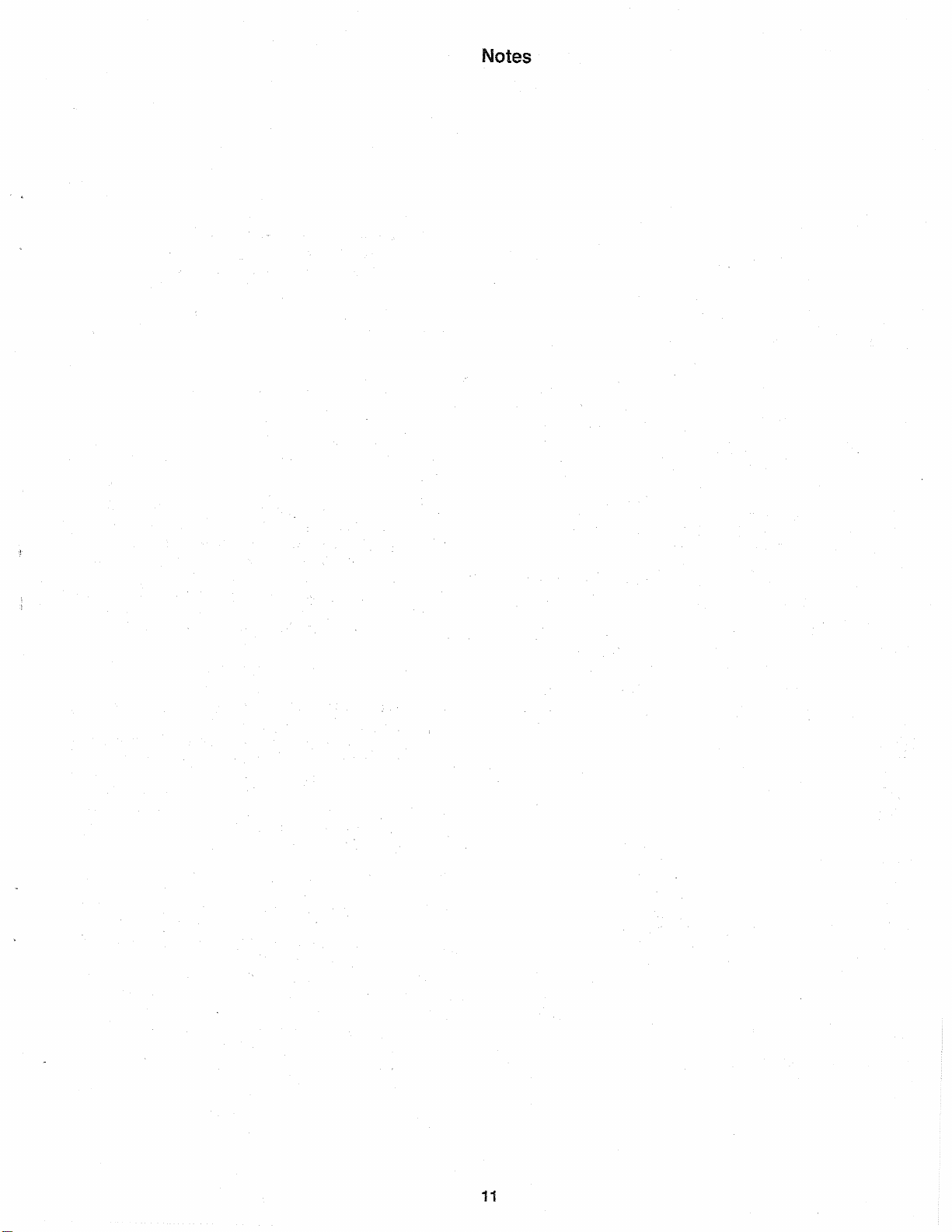

The LC77 is designed to operate as a completely port

able unit with the optional BY234 rechargeable battery

installed. The operation of the LC77 when it is battery

powered is the same as when it is AC powered. The

length of time the “Auto-Z” will operate before the bat

tery needs recharging depends on several factors: 1. the

test functions used; 2. temperature; 3. battery age.

Leakage tests place the heaviest current drain on the

battery - greater currents result in shorter battery life

between recharging. Value tests place the least drain

on the battery. For typical operation, the LC77 provides

approximately 7 hours of complete capacitor testing

(value, ESR, D/A and leakage), and 8 hours of complete

12

Page 10

Notes

11

Page 11

inductor testing (value and ringing). These times, of

course, will vary with temperature and battery age.

As the temperature of the battery decreases, its capac

ity also decreases. The operating time between recharg

ings decreases at the rate of approximately 1 hour for

every 20 degrees F drop in temperature below 70°F.

The BY234 battery is a sealed, lead-acid type which

requires no maintenance other than recharging. As a

battery ages, it will require more frequent rechargings.

If used properly, the BY234 will provide several years

of service before needing replacement.

You can maximize the lifetime of the BY234 several

ways: 1. Never allow the battery to deeply discharge.

The LC77 has a built-in battery test and low battery

shut off circuitry. Check the remaining charge period

ically and recharge the battery before the low battery

circuit shuts the unit off. 2. Keep the battery fully

charged. The BY234 will not be harmed if it is left

installed in the LC77 during AC operation. Instead,

this will keep the battery fresh and ready for use and

will actually lengthen its useful lifetime, 3. Recharge

the battery before using it if it has sat idle for more

than a couple of weeks. Lead-acid batteries normally

lose some of their charge if they sit idle for a period of

time.

Fig. 7 — The optional BY234 is installed in the LC77

for por table ope ration.

To install the optional BY234 Battery:

----------------

Observe these precautions when using lead-

acid batteries:

X. Do not dispose of old lead-acid batteries in

fire. This may cause them to burst, spraying acid

through the air.

2. Do not short the “ 4-” and “ — ” term inals

to geth er. This will burn open internal connec

tions, making the battery useless.

3. Do not charge 12 volt lead-acid batteries

with a voltage greater than 13.8 VDC. High

charging voltage may damage the battery or cause

it to explode.

4. Do not drop the battery. While lead-acid bat

teries are well sealed, they may break if dropped

or subjected to a strong mechanical shock. If the

battery does break and the jelled electrolyte leaks

out, neutralize the acid with baking soda and

water.

5. Do not charge the battery below 0° C or

above +40° C.

—WARNING.

---------

— ------

1. Open the BATTERY COMPARTMENT COVER lo

cated on the rear of the unit by unscrewing the

thumbscrew. Fold the cover down on its hinge.

2. Slide the battery end that does not have the connector

attached into the battery compartment. (The wire

should be facing out after the battery is in place.)

3. Connect the plug from the battery to the jack inside

the battery compartment.

4. Close the battery compartment cover and tighten the

thumbscrew to hold the door and batteries in place.

Not e: Rec harge th e BY234 overnight before usi ng it f or

the first time.

Battery Test

The LC77 has a built-in battery test feature which

shows the remaining battery recharge. A reading of

100% indicates that the battery is fully charged. As the

battery charge is used up, the reading will drop in 10%

intervals. The low battery circuits will turn the unit

off shortly after the battery test reading drops to 0%,

and before the battery level drops too low for reliable

operation. The LC77 never fully discharges the battery

which helps extend the life of the BY234.

13

Page 12

To perform the battery test:

A u to O ff

1. With a BY234 installed, move the POWER switch

to the ON & BATT TEST position.

2. Read the percentage of remaining battery charge in

the LCD DISPLAY, as shown in figure 8.

3. If the reading shows 0%, the unit may not operate,

or operate for just a short time since the low battery

circuit turns the LC77 off at this battery level.

To conserve battery charge, the LC77 contains an auto

off circuit. This circuit keeps the batteries from running

down if you should forget to turn the unit off, but keeps

the “Auto-Z” powered up during use. The auto off circuit

will shut the LC77 off after approximately 15 minutes

if none of the front panel buttons have been pushed.

Pushing any COMPONENT TYPE button, COMPO

NENT PARAMETERS button, TEST button, or

momentarily moving the POWER button to the ON &

BATT TEST position will reset the auto off circuits.

The auto off circuits are bypassed when the LC77 is

operated from the PA251 AC Adapter/Charger.

To operate the LC77 using the optional BY234 bat

tery:

1. Install the BY234 battery into the LC77 battery com

partment.

NOTE: If you are using the BY234 for the first time,

be sure to charge the battery before using the LC77.

Though factory tested, the BY234 may not be charged

when you receive it.

2. Push the POWER switch to the ON & BATT TEST

position and release. The WARNING LED will momen

tarily blink to indicate it is operational and the displays

will reset and read zeros.

Fig, 8 — Push the Power switch to "On & Batt Test”

to r ead the remaining battery charge.

Recharging the Battery

The BY234 battery should never be allowed to remain

discharged for more than a few hours, since this will

shorten its lifetime. The battery must be recharged

whenever the battery test reads 0%. However, you

should recharge the battery more often than this to

lengthen the battery’s lifetime and keep the LC77 ready

for portable use at all times.

To recharge the battery, simply leave it installed inside

the LC77 while the unit in connected to the PA251 AC

Adapter/Charger and the Power Adapter is connected

to a source of AC power. The charging time required

to return the battery to 100% depends on how far it is

discharged. The battery will trickle charge while the

LC77 is in use and powered from the AC adapter, but

it will recharge the quickest if the POWER switch is

in the “OFF” position. Normally, a battery will com

pletely recharge in about 8 hours with the POWER

switch “OFF”.

3. The LC77 is immediately ready for use. If precise

measurements are required, allow the unit to operate

for 10 minutes to reach specified accuracy.

-----:---------

The CAUTION' INDICATOR LED must

mom entarily flash when the POWER switch

is m oved from the OFF to the ON & BATT

TEST position. Failure of the light to flash

indicates a problem w ith the LED or safety

circuits. DO NOT operate the LC77 in this con

dition, since it exposes the operator to dang er

ous voltages w ithout adequate warning.

------

WARNING

---------

■■■■■

..........

Test Leads

The test leads supplied with the LC77 (39G143) are

made of special, low capacity coaxial cable. Using any

other cable will add extra capacity to the meter circuits,

which may not be within the range of the lead zeroing

circuits. Attempting to zero the leads with another,

higher capacitance cable connected will cause the LCD

DISPLAY to show the message error. This indicates

that the value is beyond the zeroing limits of the LC77.

If the test leads ever require replacement, new leads

(part # 39G143) may be ordered directly from the: SEN

CORE SERVICE DEPARTMENT at 3200 Sencore

Drive, Sioux Falls, SD 57107.

14

Page 13

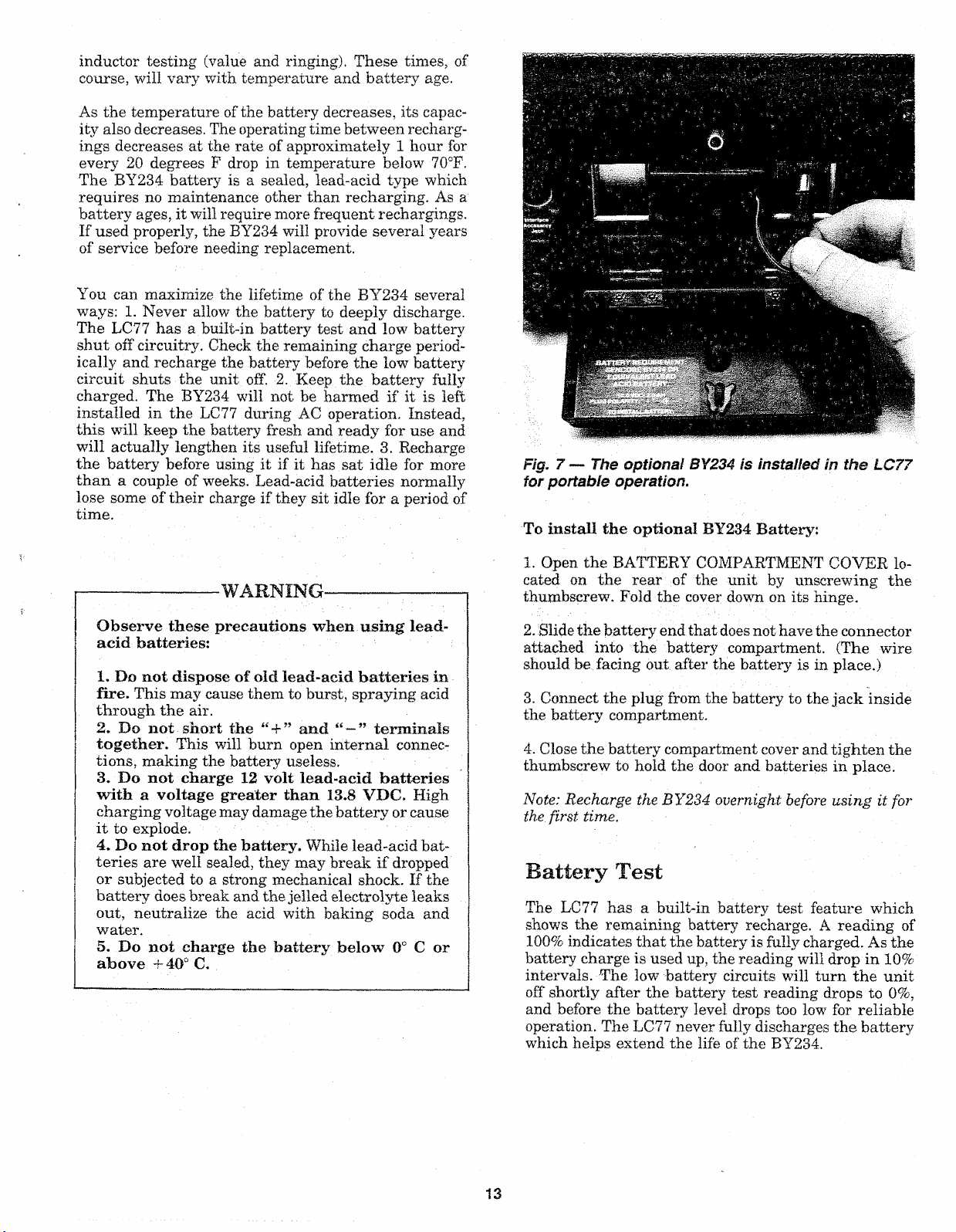

Test Lead Mounting Clip

A TEST LEAD MOUNTING CLIP (64G37) is supplied

with the LC77. This clip is useful to hold the test leads

out of the way when not in use, but keeps them ready

and within reach at any time. The mounting clip may

be attached on the top of the LC77, on the side of the

handle, or wherever it is most convenient. To mount

the clip, peel off the backing, place the clip in the desired

location and press it firmly in place.

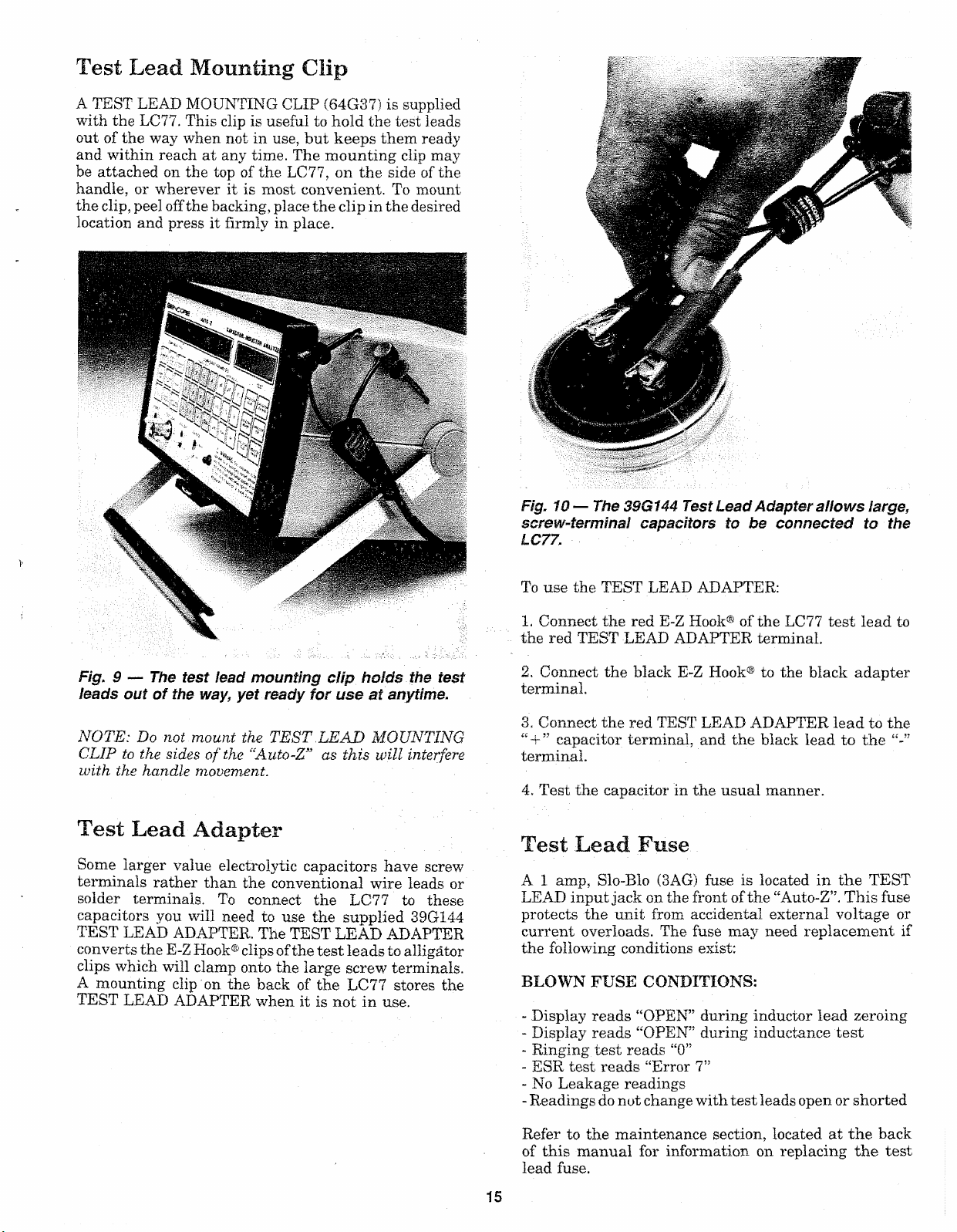

Fig. 10 — The 39G144 Test Lead Adapter allows large,

screw-ter minal capacitors to be con nected to the

LC77.

Fig. 9 — The test lead mounting clip holds the test

leads out of the way, yet ready for use at anytime.

NOTE: Do not mount the TEST . LEAD MOUNT ING

CLIP to the sides of th e “Auto- Z” as this will interfere

with the handle mov ement.

Test Lead Adapter

Some larger value electrolytic capacitors have screw

terminals rather than the conventional wire leads or

solder terminals. To connect the LC77 to these

capacitors you will need to use the supplied 39G144

TEST LEAD ADAPTER. The TEST LEAD ADAPTER

converts the E-Z Hook® clips of the test leads to alligator

clips which will clamp onto the large screw terminals.

A mounting clip on the back of the LC77 stores the

TEST LEAD ADAPTER when it is not in use.

To use the TEST LEAD ADAPTER:

1. Connect the red E-Z Hook® of the LC77 test lead to

the red TEST LEAD ADAPTER terminal.

2. Connect the black E-Z Hook® to the black adapter

terminal.

3. Connect the red TEST LEAD ADAPTER lead to the

“ + ” capacitor terminal, and the black lead to the

terminal.

4. Test the capacitor in the usual manner.

Test Lead Fuse

A 1 amp, Slo-Blo (3AG) fuse is located in the TEST

LEAD input jack on the front of the “Auto-Z”. This fuse

protects the unit from accidental external voltage or

current overloads. The fuse may need replacement if

the following conditions exist:

BLOWN FUSE CONDITIONS:

- Display reads “OPEN” during inductor lead zeroing

- Display reads “OPEN” during inductance test

- Ringing test reads “0”

- ESR test reads “Error 7”

- No Leakage readings

- Readings do not change with test leads open or shorted

Refer to the maintenance section, located at the back

of this manual for information on replacing the test

lead fuse.

15

Page 14

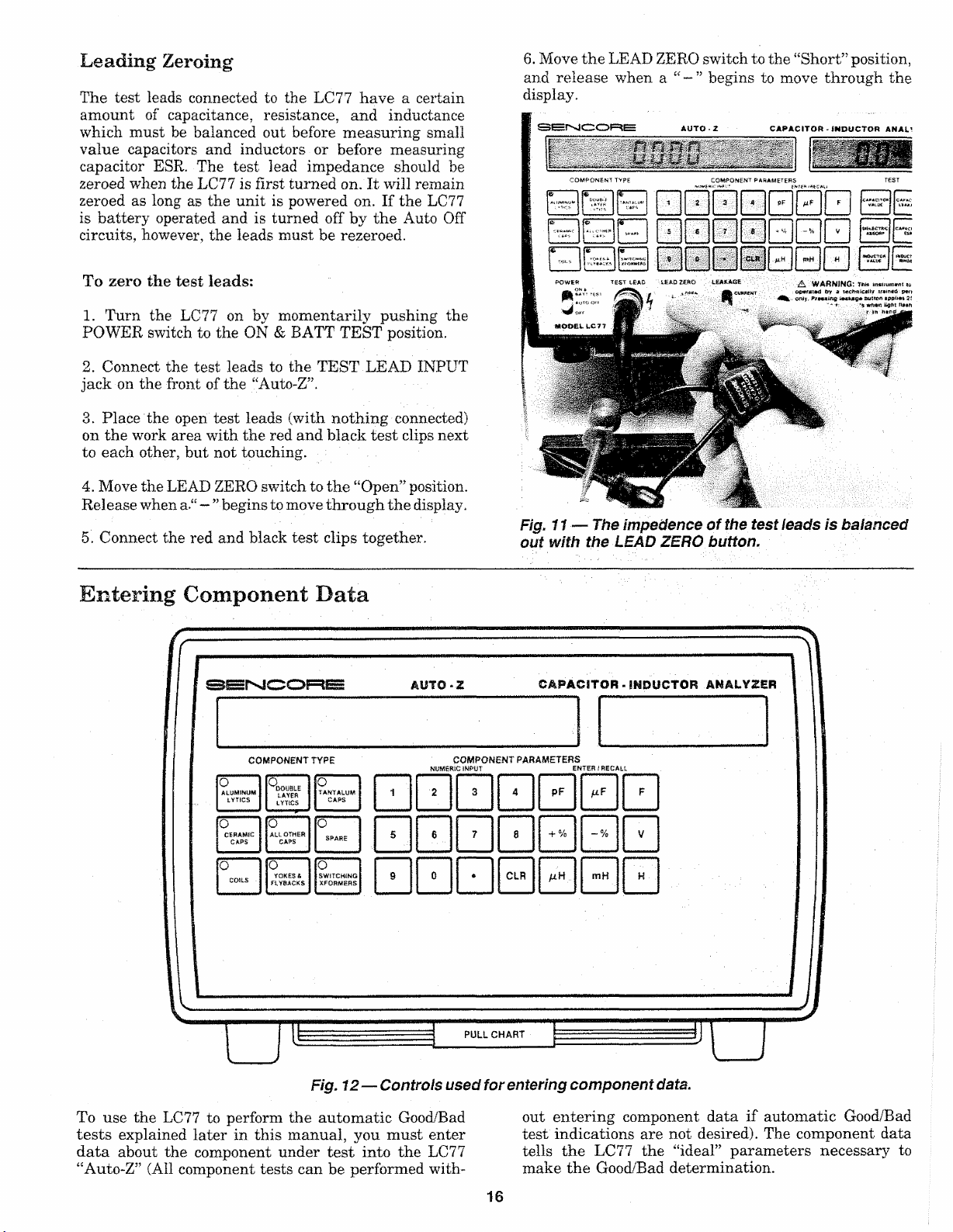

Leading Zeroing

The test leads connected to the LC77 have a certain

amount of capacitance, resistance, and inductance

which must be balanced out before measuring small

value capacitors and inductors or before measuring

capacitor ESR. The test lead impedance should be

zeroed when the LC77 is first turned on. It will remain

zeroed as long as the unit is powered on. If the LC77

is battery operated and is turned off by the Auto Off

circuits, however, the leads must be rezeroed.

6. Move the LEAD ZERO switch to the “Short” position,

arid release when a “ — ” begins to move through the

display.

CAPACITOR-INDUCTOR ANAL’

COMPONENT TYPE

COMPONENT PARAMETERS

—IIr™

0000000

i B Q 0 0 0 0 0 0 0

To zero the test leads:

1. Turn the LC77 on by momentarily pushing the

POWER switch to the ON & BATT TEST position.

2. Connect the test leads to the TEST LEAD INPUT

jack on the front of the “Auto-Z”.

3. Place the open test leads (with nothing connected)

on the work area with the red and black test clips next

to each other, but not touching.

4. Move the LEAD ZERO switch to the “Open” position.

Release when a “ — "begins to move through the display,

5. Connect the red and black test clips together.

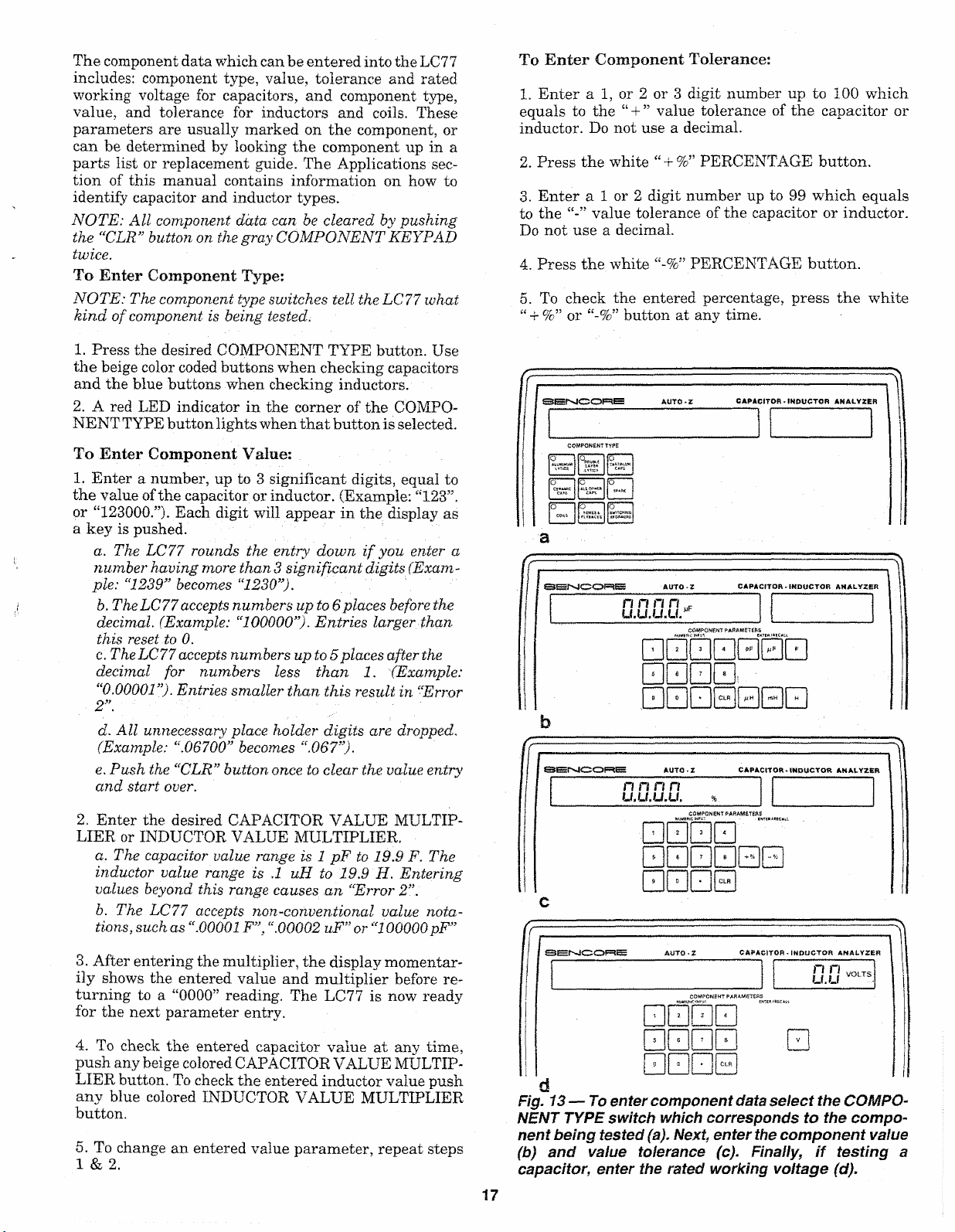

Entering Component Data

S E N C O R E

AUTO - Z

TEST ICAO L£AD2£BO LEAKAGE

I CUKfltNT .

A WARNING: T** ic

optfra tf td by d v «n ia p«ri

oMy. i M U g * B utton 2!

• - *-• Ught

Fig. 11 — Th e impedence of the test feads is balanced

out with the L EAD ZERO button.

CAPACI TOR - INDUCTOR ANALYZER

COMPONENT PARAMETERS

nu m e r i c i n p u t en t er / rec a l l

o

ALUMINUM

IYTICS

0

CEHAtffC

CAPS

0

COILS

OMPONENT TYPE

o

DOUBLE

TANTALUM

LAYER

LYTICS

YOKES &

FLYBACKS

5

0

SWITCHING

XFQRME8S

[O

I ALL OTHER

I CAPS

0

CAPS

SPARE

Fig. 12— Controls used for enter ing c ompo nent data.

To use the LC77 to perform the automatic Good/Bad

tests explained later in this manual, you must enter

data about the component under test into the LC77

“Auto-Z” (All component tests can be performed with

pF PL?

CLR

mh

PULL CHART F—

out entering component data if automatic Good/Bad

test indications are not desired). The component data

tells the LC77 the “ideal” parameters necessary to

make the Good/Bad determination.

16

..........

mH

_______

Page 15

The component data which can be entered into the LC77

includes: component type, value, tolerance and rated

working voltage for capacitors, and component type,

value, and tolerance for inductors and coils. These

parameters are usually marked on the component, or

can be determined by looking the component up in a

parts list or replacement guide. The Applications sec

tion of this manual contains information on how to

identify capacitor and inductor types.

NOTE: All component d ata can be cleare d by pushing

the “CLR” button on the gray COMPONENT KEYPAD

twice.

To Enter Component Type:

NOTE: The compo nent type swit ches t ell th e LC77 wha t

kind of component is b eing t este d.

1. Press the desired COMPONENT TYPE button. Use

the beige color coded buttons when checking capacitors

and the blue buttons when checking inductors.

2. A red LED indicator in the corner of the COMPO

NENT TYPE button lights when that button is selected.

To Enter Component Value:

1. Enter a number, up to 3 significant digits, equal to

the value of the capacitor or inductor. (Example: “123”.

or “123000.”). Each digit will appear in the display as

a key is pushed.

a. The LC77 rounds the entry down if yo u enter a

number having more tha n 3 si gnificant d igi ts (Exam

ple : “1239” bec ome s “1230”).

b. TheLC77accepts numbers up to 6places before the

decimal. (Example: “10 000 0”). E ntries larger th an

this reset to 0.

c. TheLC77 accepts numbers up to 5 pla ces aft er t h e

de cim al for numbers le ss than 1. (Exam ple:

“0.00001”). Entries smaller than this re sult in “Erro r

2” . '

d. All unneces sary place holder dig its a re drop ped,

(Examp le: “.06 700” becomes “.067 ”).

e. Pu sh the “CLR” b utton once to clea r the va lue entry

a nd st art over.

To Enter Component Tolerance:

1. Enter a 1, or 2 or 3 digit number up to 100 which

equals to the “ + ” value tolerance of the capacitor or

inductor. Do not use a decimal.

2. Press the white “ + %” PERCENTAGE button.

3. Enter a 1 or 2 digit number up to 99 which equals

to the value tolerance of the capacitor or inductor.

Do not use a decimal.

4. Press the white PERCENTAGE button.

5. To check the entered percentage, press the white

“ -r %” or “ -%” button at any time.

SENCORE

COMPONENT TYPE

o

G

G-O

G

2-

O

CAPAC ITO R- IND UC TO R ANALYZER

a

©ENCORE

COMPONENT PARAMETERS

H H Q E D ' '

□ □ □ 0 0 0 H

b

CAPACITOR • INDUCTOR ANALYZER

2. Enter the desired CAPACITOR VALUE MULTIP

LIER or INDUCTOR VALUE MULTIPLIER.

a. The c apacitor value range is 1 pF to 19.9 F. The

inductor value range is .1 uH to 19.9 H. Ente ring

values beyond this ra nge causes an “E rror 2”.

b. The LC77 accepts non-convention al value n ota

tions, such as “.00001F”, 00002 uF” or “100000pF”

3. After entering the multiplier, the display momentar

ily shows the entered value and multiplier before re

turning to a “0000” reading. The LC77 is now ready

for the next parameter entry.

4. To check the entered capacitor value at any time,

push any beige colored CAPACITOR VALUE MULTIP

LIER button. To check the entered inductor value push

any blue colored INDUCTOR VALUE MULTIPLIER

button.

5. To change an entered value parameter, repeat steps

1 & 2.

CAPACITOR - INDUCTOR ANALYZES

n n

COMPQUH

MT P AR AWTjERS

L UJ

0000

0000

□ □ □ 0

d

Fig. 13 — To enter compon ent data select the COMPO

NENT TYPE switch which corresponds to the compo

nent being tested (a). Next, enter the component value

(b) and value tolerance (c). Finally, if te sting a

capacitor, enter the rated working voltage (d).

17

Page 16

To Enter Leakage Voltage:

1. Enter the desired voltage from 1 to 999.9 using the

gray keys on the NUMERIC INPUT keypad, A decimal,

followed by one digit may be entered, but is not neces

sary.

2. Push the white “V” key to enter the voltage. The

voltage will appear in the APPLIED VOLTAGE LCD

DISPLAY. For values greater than 25 volts the red

CAUTION INDICATOR LED will blink.

NOTE: The voltage is appl ied to the component Test

Leads when the CAPACITOR LE A K AG E test butt on is

pus hed.

3. To enter a different voltage, repeat steps 1 & 2.

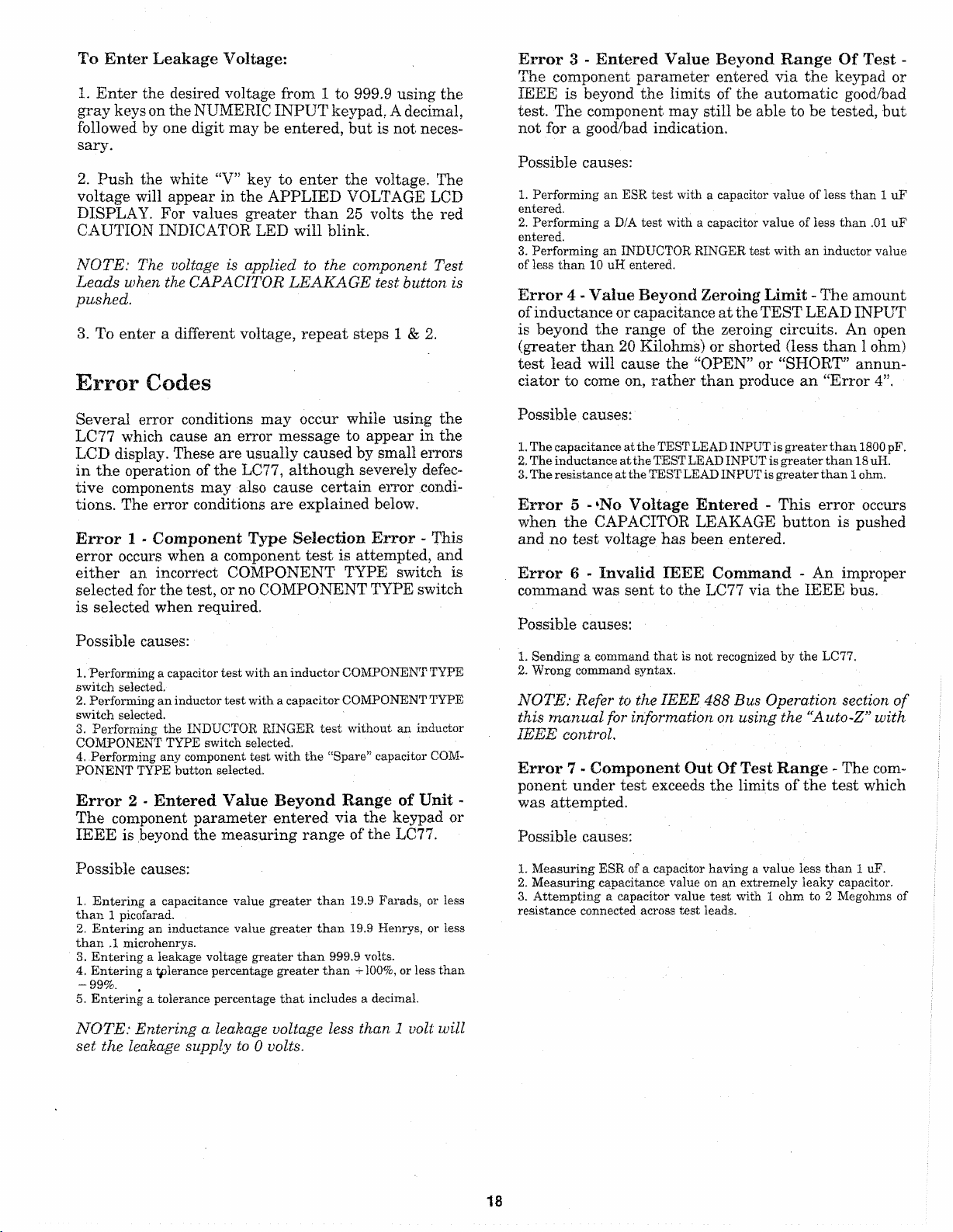

Error Codes

Error 3 - Entered Value Beyond Range Of Test -

The component parameter entered via the keypad or

IEEE is beyond the limits of the automatic good/bad

test. The component may still be able to be tested, but

not for a good/bad indication.

Possible causes:

1. Performing an ESR test with a capacitor value of less than 1 uF

entered.

2. Performing a D/A test with a capacitor value of less than .01 uF

entered.

3. Performing an INDUCTOR RINGER test with an inductor value

of less than 10 uH entered.

E rror 4 - Value Beyond Zeroing Limit - The amount

of inductance or capacitance at the TEST LEAD INPUT

is beyond the range of the zeroing circuits. An open

(greater than 20 Kilohms) or shorted (less than 1 ohm)

test lead will cause the “OPEN” or “SHORT” annun

ciator to come on, rather than produce an “Error 4”.

Several error conditions may occur while using the

LC77 which cause an error message to appear in the

LCD display. These are usually caused by small errors

in the operation of the LC77, although severely defec

tive components may also cause certain error condi

tions. The error conditions are explained below.

E rror 1 - Component Type Selection E rro r - This

error occurs when a component test is attempted, and

either an incorrect COMPONENT TYPE switch is

selected for the test, or no COMPONENT TYPE switch

is selected when required.

Possible causes:

1. Performing a capacitor test with an inductor COMPONENT TYPE

switch selected.

2. Performing an inductor test with a capacitor COMPONENT TYPE

switch selected.

3. Performing the INDUCTOR RINGER test without an inductor

COMPONENT TYPE switch selected.

4. Performing any component test with the “Spare” capacitor COM

PONENT TYPE button selected.

Error 2 - Entered Value Beyond Range of Unit -

The component parameter entered via the keypad or

IEEE is beyond the measuring range of the LC77.

Possible causes:

1. The capacitance at the TEST LEAD INPUT is greater than 1800 pF.

2. The inductance at the TEST LEAD INPUT is greater than 18 uH.

8. The resistance at the TEST LEAD INPUT is greater than 1 ohm.

Error 5 - ‘No Voltage E ntered - This error occurs

when the CAPACITOR LEAKAGE button is pushed

and no test voltage has been entered.

Error 6 - Invalid IEEE Command - An improper

command was sent to the LC77 via the IEEE bus.

Possible causes:

1. Sending a command that is not recognized by the LC77.

2. Wrong command syntax.

NOTE: Ref er to the IEEE 488 Bu s Ope ration sec t i on of

this manu al for infor mation on usi ng the “Auto-Z” with

IEEE contr ol.

E rror 7 - Component Out Of Test R ange - The com

ponent under test exceeds the limits of the test which

was attempted.

Possible causes:

Possible causes:

1. Entering a capacitance value greater than 19.9 Farads, or less

th an 1 picofarad.

2. Entering an inductance value greater than 19,9 Henrys, or less

th an .1 microhenrys.

3. Entering a leakage voltage greater than 999.9 volts.

4. Entering a tolerance percentage greater than 4-100%, or less than

- 99%. ,

5. Entering a tolerance percentage that includes a decimal.

NOTE: E ntering a leakag e voltage les s t han 1 volt wi ll

set th e leakag e supply to 0 volts.

1. Measuring ESR of a capacitor having a value less than 1 uF.

2. Measuring capacitance value on an extremely leaky capacitor.

3. Attempting a capacitor value test with 1 ohm to 2 Megohms of

resistance connected across test leads.

18

Page 17

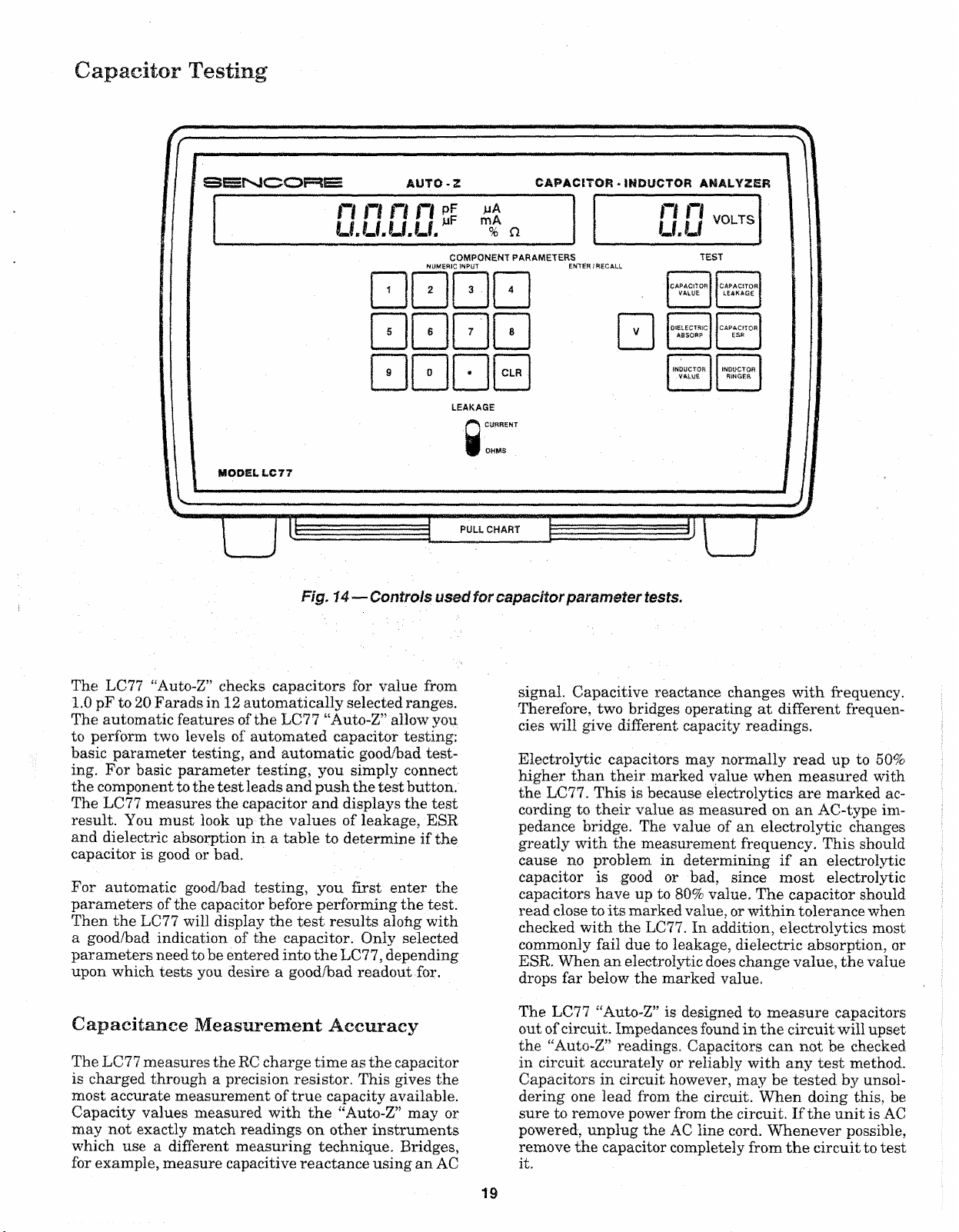

Capacitor Testing

S E N C O R E AU TO -Z

n n n n

U.U.U.U. m% n

NUMERIC INPUT ENTER / RECALL

(MODEL LC 77

Fig. 14— Controls used for capacitor p arameter tests.

CAPACIT OR - INDUCTOR ANALYZER

COMPONENT PARAMETERS

CLR

LEAKAGE

CURRENT

OHMS

PULL CHART

TEST

The LC77 “Auto-Z” checks capacitors for value from

1.0 pF to 20 Farads in 12 automatically selected ranges.

The automatic features of the LC77 “Auto-Z” allow you

to perform two levels of automated capacitor testing:

basic parameter testing, and automatic good/bad test

ing. For basic parameter testing, you simply connect

the component to the test leads and push the test button.

The LC77 measures the capacitor and displays the test

result. You must look up the values of leakage, ESR

and dielectric absorption in a table to determine if the

capacitor is good or bad.

For automatic good/bad testing, you first enter the

parameters of the capacitor before performing the test.

Then the LC77 will display the test results alofig with

a good/bad indication of the capacitor. Only selected

parameters need to be entered into the LC77, depending

upon which tests you desire a good/bad readout for.

Capacitance M easurement Accuracy

The LC77 measures the RC charge time as the capacitor

is charged through a precision resistor. This gives the

most accurate measurement of true capacity available.

Capacity values measured with the “Auto-Z” may or

may not exactly match readings on other instruments

which use a different measuring technique. Bridges,

for example, measure capacitive reactance using an AC

signal. Capacitive reactance changes with frequency.

Therefore, two bridges operating at different frequen

cies will give different capacity readings.

Electrolytic capacitors may normally read up to 50%

higher than their marked value when measured with

the LC77. This is because electrolytics are marked ac

cording to their value as measured on an AC-type im

pedance bridge. The value of an electrolytic changes

greatly with the measurement frequency. This should

cause no problem in determining if an electrolytic

capacitor is good or bad, since most electrolytic

capacitors have up to 80% value. The capacitor should

read close to its marked value, or within tolerance when

checked with the LC77. In addition, electrolytics most

commonly fail due to leakage, dielectric absorption, or

ESR. When an electrolytic does change value, the value

drops far below the marked value.

The LC77 “Auto-Z” is designed to measure capacitors

out of circuit. Impedances found in the circuit will upset

the “Auto-Z” readings. Capacitors can not be checked

in circuit accurately or reliably with any test method.

Capacitors in circuit however, may be tested by unsol

dering one lead from the circuit. When doing this, be

sure to remove power from the circuit. If the unit is AC

powered, unplug the AC line cord. Whenever possible,

remove the capacitor completely from the circuit to test

it.

19

Page 18

WARNING

Measuring Capacitor Value

When checking capacitors, remove the

capacitor from circuit if possible. Otherwise,

make sure the power is removed from the cir

cuit and the AC line cord to the unit contain

ing the capacitor is unplugged. Always con

nect the capacitor to the LC77 test leads be

fore depressing the CAPACITANCE VALUE

test button.

_______

___

_____

Measuring Small Capacitance

Values In Noisy Environments

The sensitive “Auto-Z” measuring circuits may be af

fected by large, outside signals (such as the AC fields

radiated by some lights and power transformers) when

small capacitance values are being measured. Special

circuits in the LC77 help minimize noise pickup and

stabilize the readings.

Measurements of small value capacitors in noisy envi

ronments may be further improved by grounding the

LC77 case to earth ground. When possible, power the

LC77 with the PA251 AC Adapter/Charger connected

to a properly grounded AC outlet. The PA251 Adapter/

Charger maintains the third wire ground shield and

keeps the noise away from the measuring circuits inside

the “Auto-Z”.

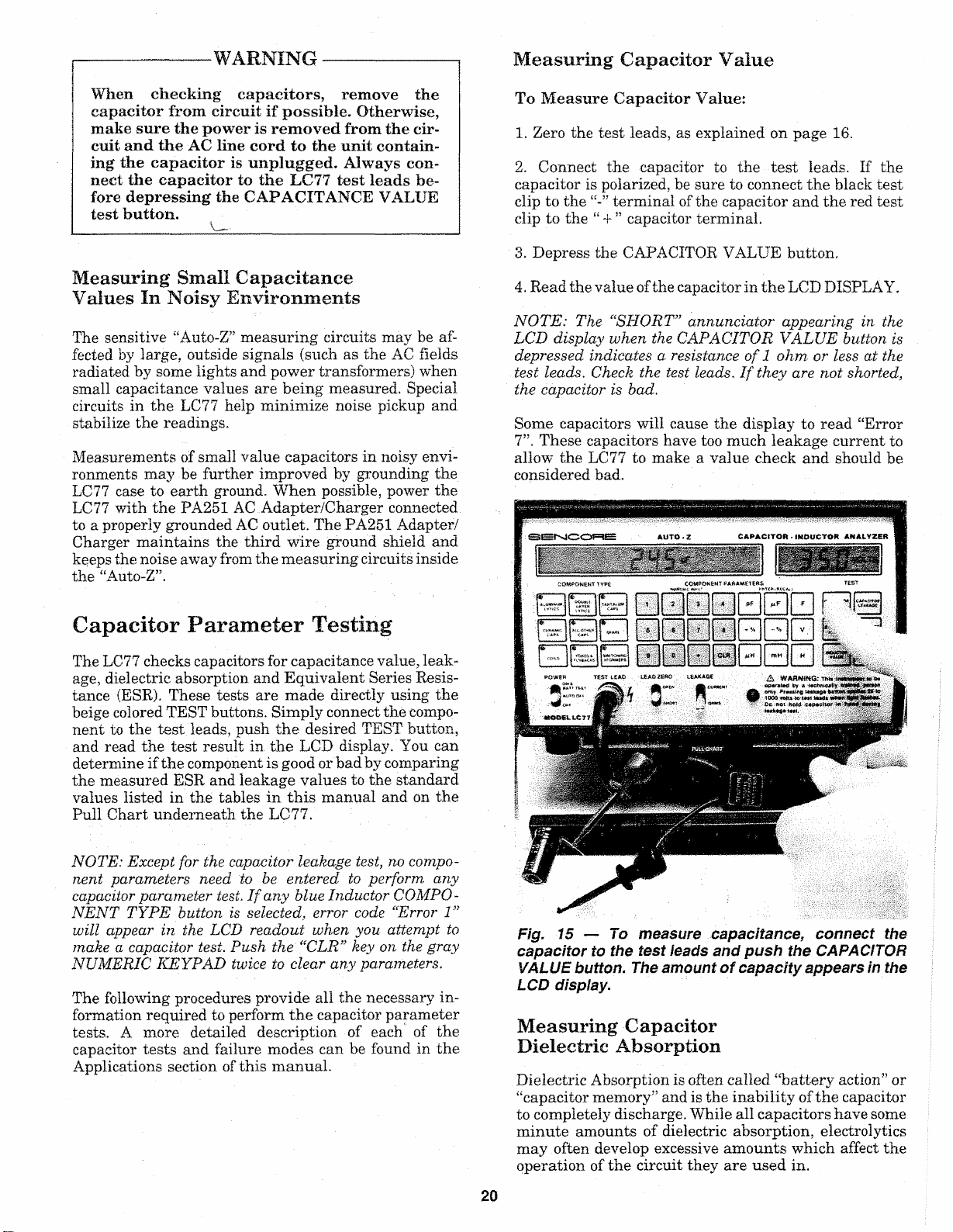

To Measure Capacitor Value:

1. Zero the test leads, as explained on page 16.

2. Connect the capacitor to the test leads. If the

capacitor is polarized, be sure to connect the black test

clip to the terminal of the capacitor and the red test

clip to the “ + ” capacitor terminal.

3. Depress the CAPACITOR VALUE button.

4. Read the value of the capacitor in the LCD DISPLAY.

NOTE : Th e “SHORT” annunciator appearing in t he

LCD di splay when the CAPACIT OR VALUE butt on is

depressed indicates a res istance of 1 ohm. or less at the

test leads. Check t he test leads. If they are no t s horted,

the capacitor is bad.

Some capacitors will cause the display to read “Error

7”. These capacitors have too much leakage current to

allow the LC77 to make a value check and should be

considered bad.

Capacitor Parameter Testing

The LC77 checks capacitors for capacitance value, leak

age, dielectric absorption and Equivalent Series Resis

tance (ESR). These tests are made directly using the

beige colored TEST buttons. Simply connect the compo

nent to the test leads, push the desired TEST button,

and read the test result in the LCD display. You can

determine if the component is good or bad by comparing

the measured ESR and leakage values to the standard

values listed in the tables in this manual and on the

Pull Chart underneath the LC77.

NOTE: Except for the cap acitor lea kage te st, no compo

nent parameters need to be enter ed to perf orm any

capa citor para meter test. I f any blue Inductor COMPO

NENT TYPE butto n is select ed, error code “Error 1”

w ill appear in the LCD readout when you atte mp t to

make a capacitor test . Push the “CLR" key on the gray

NU MERIC KEYPAD twice to clear any p arameter s.

The following procedures provide all the necessary in

formation required to perform the capacitor parameter

tests. A more detailed description of each of the

capacitor tests and failure modes can be found in the

Applications section of this manual.

Fig. 15 — To measure capacita nce, connect the

capacit or to the te st ieads and push the CAPACITOR

VALUE button. The amount of capacity appears in the

LCD display.

Measuring Capacitor

Dielectric Absorption

Dielectric Absorption is often called “battery action” or

“capacitor memory” and is the inability of the capacitor

to completely discharge. While all capacitors have some

minute amounts of dielectric absorption, electrolytics

may often develop excessive amounts which affect the

operation of the circuit they are used in.

20

Page 19

To check a capacitor for dielectric absorption, press the

DIELECTRIC ABSORPTION button and compare the

value to the chart. A fully automatic good/bad test may

also be used to test for dielectric absorption. This test

is explained in a later section.

charts. The capacitor is good if the measured leakage

is be low the amount shown in the chart. A fully automa

tic good/bad test may also be used to check capacitors

for leakage. This test is explained in a later section.

To measure capacitor dielectric absorption:

1. Connect the capacitor to the test leads. If the

capacitor is polarized, connect the red test clip to the

“ + ” capacitor terminal and the black test clip to the

terminal.

2. Depress the DIELECTRIC ABSORPTION button. A

will appear and slowly move through the display

indicating that the test is in progress.

3. Read the percentage of dielectric absorption on the

display.

4. Compare the measured D/A to the amount listed in

Table 1 for the capacitor type you are testing to deter

mine if the capacitor is good or bad.

NO TE: Depending on the capacitor’s value, type and

actual D/A, the LC 77 may, in a few cases, take up to 10

seco nds to displa y a reading.

Maximum Allowable Percent Of D/A

Capacitor type Maximum % of D/A

Double Layer Lytic Meaningless. D/A may normally

be very high.

Aluminum Lytic

Tantalum Lytic 15%

15%

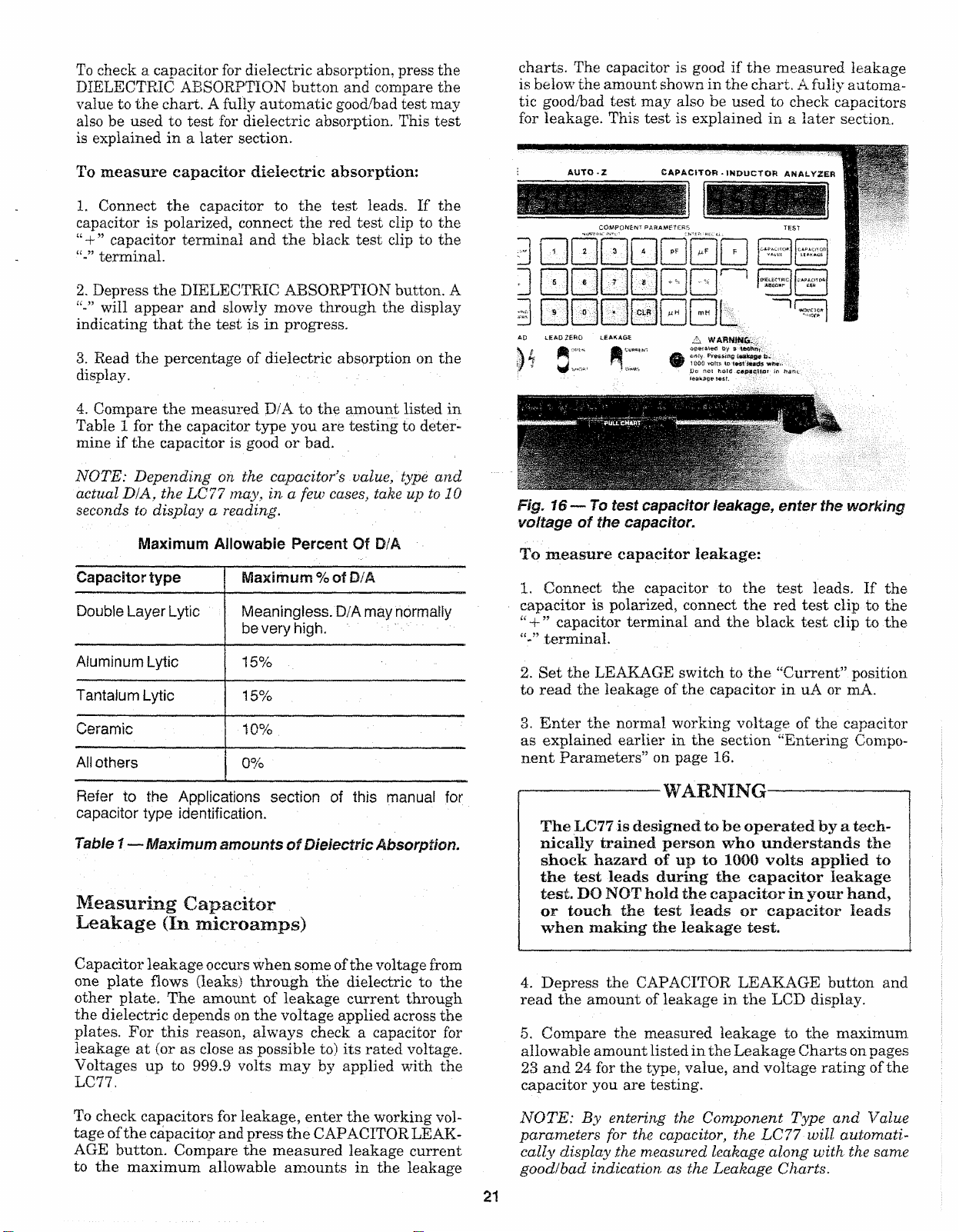

CAPA CIT OR- IND UCT OR ANALYZER

COMPONENT PARAMETERS

“ i

1

5

9 0

2

=5'l

7 j

6

" I

H M I f I ”

— . — —

i.. H *>; \ loicu-ci’wc

j[ | I

1! li Trr —

MH mw fl

CLR I

A WARNING. .

op ei a tv d b y s * e ef tn f

1000 vofts id imnJs wftev.

Bo not capaeiim ut

i&a kage t«st.

tAPAC-iTO*

Pr&ssmg leakage to-

rj

D

1

Fig. 16— To test capacitor leakage, enter the working

voltage of the capacitor.

To measure capacitor leakage:

1. Connect the capacitor to the test leads. If the

capacitor is polarized, connect the red test clip to the

“ + ’’ capacitor terminal and the black test clip to the

terminal.

2. Set the LEAKAGE switch to the “Current” position

to read the leakage of the capacitor in uA or mA.

i

Ceramic

All others

Refer to the Applications section of this manual for

capacitor type identification.

Table 1— Maximum amounts of Dielectric Absorption.

10%

0%

Measuring Capacitor

Leakage (In microamps)

Capacitor leakage occurs when some of the voltage from

one plate flows (leaks) through the dielectric to the

other plate. The amount of leakage current through

the dielectric depends on the voltage applied across the

plates. For this reason, always check a capacitor for

leakage at (or as close as possible to) its rated voltage.

Voltages up to 999.9 volts may by applied with the

LC77.

To check capacitors for leakage, enter the working vol

tage of the capacitor and press the CAPACITOR LEAK

AGE button. Compare the measured leakage current

to the maximum allowable amounts in the leakage

3. Enter the normal working voltage of the capacitor

as explained earlier in the section “Entering Compo

nent Parameters” on page 16.

-----------

-------

WARNING

-------------------

The LC77 is designed to be operated by a tech

nically trained person who understands the

shock hazard of up to 1000 volts applied to

the test leads during the capacitor leakage

test. DO NOT hold the capacitor in your hand,

or touch the test leads or capacitor leads

when making the leakage test.

4. Depress the CAPACITOR LEAKAGE button and

read the amount of leakage in the LCD display.

5. Compare the measured leakage to the maximum

allowable amount listed in the Leakage Charts on pages

23 and 24 for the type, value, and voltage rating of the

capacitor you are testing.

NOTE: By enter ing the Com ponent Type and Value

p aramet ers for th e capac itor, the LC77 will a utomati

call y display the measured leakage along wi th the same

good!h ad indic atio n as the L eakage Charts.

21

Page 20

Voltage will be applied to the capacitor as long as the

CAPACITOR LEAKAGE button remains depressed,

and the leakage readings will decrease as the capacitor

continues to charge. Some capacitors may take a few

seconds to charge up to the applied voltage and may

cause the display to overrange with a flashing “88.88

mA” display. Continue to depress the CAPACITOR

LEAKAGE button until the leakage reading drops

below the maximum allowable amount listed in the

Leakage Chart.

When the CAPACITOR LEAKAGE button is released,

the LC77 discharges the capacitor through a low value,

high wattage resistor. The LC77 contains safety circuits

which sense the voltage across the test leads. Therefore,

when you release the CAPACITOR LEAKAGE button

after checking a large value capacitor, or after applying

a high leakage voltage, the display may show “Wait -

- - until the voltage is gone from the test leads. All

data input and test buttons will be locked out until the

display returns to “0000”.

LEAKAGE IN PAPER, MICA AND

FILM CAPACITORS

Paper, mica and film capacitors should have extremely

small amounts of leakage. Measuring any leakage

when checking these types of capacitors indicates a bad

component. The leakage reading may take 1-2 seconds

to show an accurate display while the capacitor charges,

LEAKAGE IN CERAMIC CAPACITORS

Leakage in ceramic capacitors is generally very low.

Ceramic disc capacitors, however, may have small

amounts of normal leakage. Ceramic disc capacitors

with voltage ratings above 50 WVDC should have less

than 1 uA of leakage. Some discs with working voltages

less than 50 WVDC may have a lower insulation resis

tance, and therefore may show somewhat more leakage,

depending upon manufacturer. In general, a 10 WVDC

ceramic disc capacitor may show as much as 16 uA of

leakage, and 25 WVDC ceramic disc may read up to

2.5 uA of leakage and still be considered good.

LEAKAGE IN ALUMINUM ELECTROLYTICS

Because of their larger value and higher leakage

characteristics, aluminum electrolytic capacitors may

take several seconds to charge. The LC77 display may

overrange (flashing 88.88 mA display) indicating the

charging current is greater than 20 mA while the

capacitor is charging. Table 2 shows the approximate

time that you can expect the LC77 to overrange for a

given capacitor value and applied voltage. After the

LC77 stops overranging, the current will drop in prog

ressively smaller steps as the capacitor charges. When

the cap is fully charged, the leakage readings will

change just a few digits up or down. You do not need

to wait until an electrolytic capacitor is fully charged

to determine if it is good. Simply keep the CAPACITOR

LEAKAGE button depressed until the leakage reading

falls below the maximum amount shown in the Leakage

Charts.

Capacity (uF)

Table 2 — Meter Overrange time versus capacitor

valu e and applied voltage.

LEAKAGE IN TANTALUM ELECTROLYTICS

Tantalum electrolytic capacitors have much lower leak

age than aluminum electrolytics of the same size and

voltage rating. Therefore, tantalum lytics will give a

leakage reading in a much shorter time than an

aluminum lytic - typically within 2 to 5 seconds. Com

pare the measured leakage with the amounts shown in

the leakage charts to determine if the capacitor is good

or bad.

LEAKAGE IN NON POLARIZED

ELECTROLYTICS

Electrolytic capacitors which are non-pol arized should

be checked for leakage in both directions. This requires

that you measure leakage twice, reversing the LC77

test lead connections for the second test. The maximum

allowable leakage for a non-polarized electrolytic in

either direction is twice that of a similar polarized elec

trolytic of similar capacitance value and voltage rating.

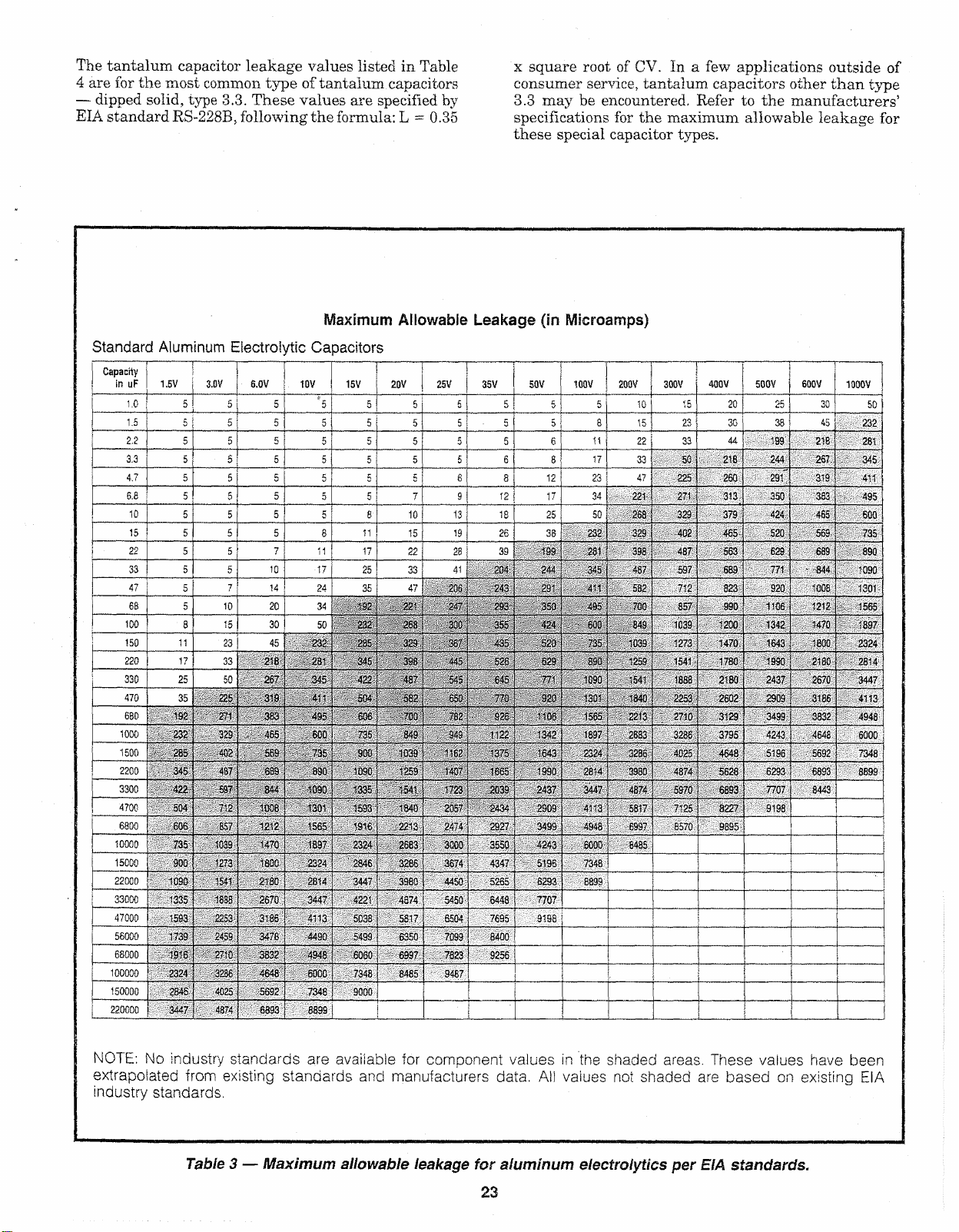

Leakage charts

The following leakage charts list the maximum amount

of allowable leakage for the most common aluminum

electrolytics and dipped soiled tantalum capacitors.

These charts are also duplicated on the pull chart below

the LC77. Good capacitors (as far as leakage is con

cerned) will measure lower than the amounts shown

in the Leakage Charts. When measuring leakage, you

do not need to wait for the readings to drop to zero or

to its lowest point. The capacitor is good for any leakage

reading which is lower than the amount shown in the

chart.

Leakage values shown in Table 3 for aluminum elec

trolytic capacitors are the worst-case conditions, as

specified by the Electronic Industries Association (EIA)

standard RS-395. The values are determined by the

formulas: L = 0.05 x CV (for CV products less than

1000) or L= 6 x square root of CV (for CV products

greater than 1000. (The CV product is equal to the

capacitance value multiplied by the voltage rating).

Page 21

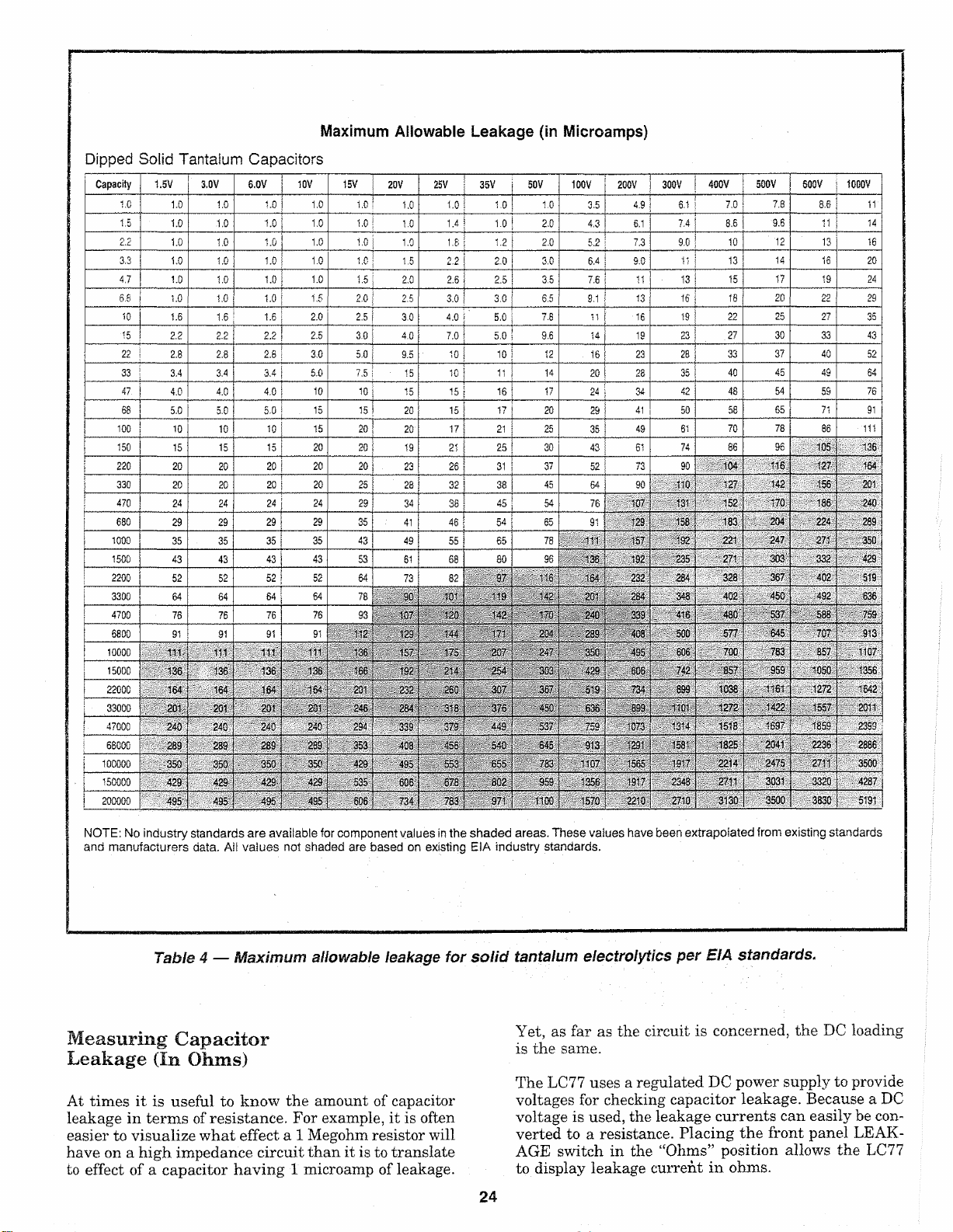

The tantalum capacitor leakage values listed in Table

4 are for the most common type of tantalum capacitors

— dipped solid, type 3.3. These values are specified by

EIA standard RS-228B, following the formula: L = 0.35

Maximu m Allowable Leakage (in Micro amps)

Standard Aluminum Electroiytic Capacitors

Capacity

in uF

1.5 V 3.GV 6.0V | 10V

1.0

1.5

2.2

3.3

4.7

6.8

10

15 5 5

22

33

47

68

100

150

220

330

470

680 192 271 383

1000

1500

2200

3300

4700 5Q 4

6800

10000

15000

22000

33000

47000

560C -:' 1739

68000

1000C0 1 2324

15000. 23-3

220 0CC ! 3 ^ 7

5

5 j 5

5 5 [ 5

5

5 5

5 5

5 5

5 5

5

5

5 10 I 20

8 15

11

17 33

25

35

V

232

285 *02

•345

422 697

606

735 1039

900

1C30 • 1541

1335

1593

|

1916'

5 5 5 5 5

5 ; 5

5

7

23

50

: 225

329 . :465 600 735 849 345

487 689

V2 1008

£57 12 >2 1565

■c?3

18 33 2570

2253

2459, 3*76 4490 5499 6350

2'< 0

3256 4648

£C25

437-

5 | 5

5 5

5

5 I 5 fi

5 | 8

7

10

14

J

30

45

218 281

267

319

569

:• : 844

1470

1300

2

j 30

3185

3B32

5592

6333

\#

5

5

5

11

•17 25 33 41

24

34

50 232

232 205 329

345 422

411

495

735

890 10 9C 1259

'.090

1301 ' '1593 1840

189“

2324

2814

3447

4:13

494 S 6060 6997 7823 9256

eooc

7346 9000

3899

20V

15 V

5

5

5

5

5

5

5 5

5 7 9

10 13

ll

15 19

17

22 28

35 47 235

22'

192

268 330

345 398 44 5

457

504 552 65 3

606 703 782

S3C 1039

'335 1541

2212

1916

2324

2583

2S46

3286

3447

3980

4574

422 1

5C 33

5617 6504 . 7695 ,L 9198

8485 .9487

7345

25 V 35V

247

357

545

’ ■63

1407

1723 2039 2437

2057 2434

24-4

3000

3674

4450

5450

7039

x square root of CV. In a few applications outside of

consumer service, tantalum capacitors other than type

3.3 may be encountered. Refer to the manufacturers’

specifications for the maximum allowable leakage for

these special capacitor types.

50V 100 V

5 5

5 5 5 j 8

5 5 e l 11 | 22

5 6

e

8 12

12

18 25

26 38

39 199

234 244

243 231 4-1

?S3 350

355 424

435

526 529

645

770 920

925

<122

1375 ■643 2324

1665 1990

2927

3550

4347

5255 S293

6448

.. 8400

5

8 j 17 33

17

520

7 7"!

■.*06

1342

2903 41-3

3499

4243

5195

7707

i

j

1

\

|

200V 300V

5

23

34 22* . 271

50

2G8

232 32 3 402

281 338

.157

345

582 712

495

70Q

600

849 . :. 1039; • 1200

735

1033 ■ 1273

aso

1259 .1541 1780

^030 154 1 1888

1 34-3

isc:

155 5

2213 2710 3129

1357

2683

3236 4025

2814

398-3

4874

3447

5517

R937

4943

S G3C

643 5

7348

B899

j .

10

15

47

400V

20 25

15

23 30 38

44

33

5C .. 213 244

225

329

437

: 597

857.

2253

3236 3795

4374

5S7 0 6S93

7125

■'8570.

260

■ 313.

■ ■ 379 ■

465

• 563

689

823

, 990 1106 ■ 1212

1470

t

2180

2602

4648

5628

8227

■ 9895

500V 600V

.....

19 9

291 ■ 319: 411

350 ■383.

424

' 520 563

629

' 771 ■ -844

• 920

■ 13 42

1643

'

1990

~ 2437

2909

3499

4243;

519 6 .. 5692

6293- 6893

7707

9198

I

...

1000V

30 50

45

232

218

- . 281

267.

345

• 495

465

600

689

890

1090

-cos

1301

• .. 1565

1470 1897

1800

2324

2180

2814

2670 3447

3186 4113

3332

4948

4648

. 6000

. . 7348

■ 8899

.8443

i

735

:

NOTE: No industry stand ards are available for component va lues in the shaded areas. These values have been

extrapolated from existing st anda rds and manufactur er s data. Ail vaiues not sh ade d are based on existing EIA

industry stand ar ds.

Table 3 — Maximum allowable leakage for aluminum e lectrolytics per EIA standards.

23

Page 22

Dippe d Solid Tantalum Capacitors

Capacity 1,5V

1.0

1.5

2.2

3.3

4,7

6.8

10

15

22

33

47

68

100

150

220

330

470

680

1000

1 SCO

2200

3300

4700

6800

1.0

1.0 1.0 1.0 1.0 1.0

1.0 1.0 1.0

1.0 1.0 1.0 1.0 1.0

1.0 1,0 1.0

1.0 1.0 1.0 1.5 2.0

1.6

2.2 2.2 2.2 2.5 3,0

2.8 2.8

3.4 3.4 3.4 5.0 7.5

4.0

5.0 5.0 5.0

10 10 10

15 15 15

20 20 20

20

24 24

29 29

35 35 35

43 43 43 43 53

52 52 52 52 64

64

76 76 76

91

1000 0 111- 111

15000

. 136

22000

33000

47000 240

g

o

100000

150000

200000

164

201 201 201

289

350

■V: .V 429

■ 495 495

3,0V 6.0V

1.0 1.0

1.6

4.0

20

64

91

.V-' 111

136

• 164

240 ' 240

239

'. 350

■ 429

10V

1.6 2.0 2.5

2.6 3.0 5.0

4.0 10 10

. 15

20 20 25

24 24

29 29 35

64

91 91

r i

136

136

164 134 201

20 1 246

240

289

350

259 353

350 429

429 425 535 606 573 5 G2

495 495

Maximum Allowable Leakage (in Microamps)

15V

1,0

1.0

1.0

1,0

1.0

1,5 2.0 2.6 2.5

15

15 20

20

20

20 20

29

.' 41

35

43

64

78

76

93

' M

-36

166 192 214 254 303

294

605

25V 35V 50V

20V

1,0 1.0 1.0

1.4

1.0

1.0 1,8 1.2 2.0 5.2 7.3

1.5 2.2 2.0 3,0

2.5

3.0

3.0 4.0

7.0 5.0

4.0

9.5 10 10 12

■ 15 10 11

15 15 16

20 15 17 20

20-

19 21

23 26 31

28 32 38

34

46

49 55 65

61 68

73 82

90

W

’.G7

120 1- 12 170

144 171 204

129

157 175

1.0 2.0

3.0 6.5

5.0

17 21 25

25 30

45 54

38

54

80 96

97

■ 19 142

2C 7

100 V 20 0V 300V

1.0 3.5 4.9 6.1

4,3

6.4

3.5

7.6 11 13

9. 1 13

7.8

9.6

65

78

11 | -16

14 19 23

. 16 23

14

20 28

17

24 34

29

35 49

43 61

37

52

45

54 90 1 1C 127

76

91

111

133 192

154 23 2

r e

2C1 28 4

24 C 339

239

247

35 C

42S

■73

307 367

449

537

763 1107

959

11 CO

513

635

753 1073

1356

157C

252 25C

31S 375 450

284

339

455 540 645 913 1291

408

553 655

495

734 78 3 S71

■- 734

; ^ 1565

400V

7.4

6.1

9.0 10

9.0

11 13

16 18

19 22 25

28 33

35 40

42 48

41 50 58

61 70

74 86

73 90

500 V

7.0 7.8

'9.6 11 14

8.6

' 12 13 16

15 17

.27

104

;: i16

14

20

30

37

45

54

65

78

96

-,-;■ 127

600V 1000V

8.6

16 20

19 24

22

27

33 43

40 52

49 64

59 76

71 91

86 111

105 136

■v. 164

142 156 201

107 131 152 170. 1 8 6 24 0

;;V - 224

■29 158 183

'57

' 19 2 221

' '235

284

.348

416 480

500

408

606-

435

742

605

£99

839 11C1

:2'4 ' 1518

15 S"

19-7

234 3

1917

271 0 3130

2210

271

328

402

577

700 • 783

857 •. 959

1038

1272 1422

1825

2214 2475

J27--1 3031 3320

204

V 247

: r- ” ; 303

367

271 350

332 429

402 519

• .450 •4 92

■ 537

■•645

583 75S

- 707

• 913

. 357 1107

1050. . . 1356

. . :1161' 1272 1642

1557

. ' 2011

1697

' 1859

' 23S 3

.•'2041. 2236

2711

■ 3500

3500

3830

; 51 91

11

29

35

289

636

2886

4287

NOTE: No i n du s t ry standa r ds a re availab l e for com p onen t val u es in th e shad ed ar eas . These valu e s h a v e b een extra pola t ed from existing standards

an d ma nufa c t urer s da t a . All values not sh aded ar e based on existing EIA ind u st r y st anda r ds.

Table 4 — Maximum allowable leakage for solid tantalum electrolytics per EIA sta ndards.

Measuring Capacitor

Leakage (In Ohms)

Yet, as far as the circuit is concerned, the DC loading

is the same.

The LC77 uses a regulated DC power supply to provide

At times it is useful to know the amount of capacitor

leakage in terms of resistance. For example, it is often

easier to visualize what effect a 1 Megohm resistor will

have on a high impedance circuit than it is to translate

to effect of a capacitor having 1 microamp of leakage.

voltages for checking capacitor leakage. Because a DC

voltage is used, the leakage currents can easily be con

verted to a resistance. Placing the front panel LEAK

AGE switch in the “Ohms” position allows the LC77

to display leakage current in ohms.

24

Page 23

To measure capacitor leakage in ohms:

1. Connect the capacitor to the test leads. If the

capacitor is polarized, connect the red test clip to the

“ + ” capacitor terminal and the black test clip to the

terminal.

2. Set the LEAKAGE switch to the “Ohms” position to

read the leakage current in ohms.

3. Enter the normal working voltage of the capacitor

as explained earlier in the section “Entering Compo

nent Parameters” on page 16.

•WARNING-

The LC77 is designed to be operated by a tech

nically trained person who understands the

shock hazard of up to 1000 volts applied to

the test leads during the capacitor leakage

test. DO NOT hold the capacitor in your hand,

or touch the test leads or capacitor leads

when making the capacitor leakage test.

4. Depress the CAPACITOR LEAKAGE button and

read the amount of leakage resistance in the LCD dis

play.

8 ■

PF

+ %/

MH

‘J u

■-%

mH

COM P O N E N T T YPE

*

in i£S :

_

| vOuts 8

©

«

f*

1

2

S

6

0

. 9

•1

'1

' I

4

CLft

•

m

CfflAWlC

CAPS