Page 1

LC53

“Z M ET ER "

C A P A CIT O R — IN DUCT OR

ANALYZER

Operation, Application, and Maintenance Ma nu a l

" '• 4 .

S E N C O R E

.. . th e e lectr onic inst ru m en t “analyzer peop l e ”

3200 S E N CO R E DRIVE . SIOUX FAL LS . SO UT H DA K O T A 57107 -(6 0 5 ) 339-010 0

1

Page 2

T A B L E OF CONTENTS

SAFETY PRECA UT ION S

SIMPLIFIED OPERATIONS

DESCRIPTION

Int r oduc t i on........................................................... 6

Feat ur es... .

Speci f i cati ons ..................................................... 6

C on t rol s ................................................................. 8

Sup p lie d Acc essor i es........................................10

Op tio n a l Ac c e s s o r i e s

OPERATION

In tr o d u c t ion ..........................................................12

Pow er Co nn ec t ion

Fuse Repl ace me nt

Test Le ad s .............................................................12

Tes t Lead Mo un tin g Cl i p....................................12

Capacitor Testing

Spe cia l No t es on C a pa c ito r Tes ti ng

Cap a c it y M e as ur em e n t A c c ur a cy .....................13

To E lim i na t e Lead Capac i t y

Ch ec k in g C a pa c it o rs Beio w 2 pF.....................14

Inte r p re t in g “Z ME TER ” Value R e a ding s

Te s ti ng Large Scre w Term inal Lyt ics

Ch e c ki n g C a p a ci to rs fo r Leakag e

Ceramic, Paper, Mica, and Film Ty pe s .. . 16

Alu min u m Ly t i c s ..........................................16

Tanta lu m Lyt ics..........................................16

Leakage Char t s................................................... 17

Ide n ti fy in g C a p a ci to r Type s

Tan ta lu m Lytics

Cer am ic Discs

Film Types

Tes tin g fo r D ie l e ct ric Ab so r pt ion..

Ref or m in g Ly ti c s on the “Z METER”

Ref o rm in g Ly ti cs w it h a Power S upply

Capacitor Testing Application Tips

No Value Readi ng on Small Value

C ap aci t ors

Leakage in C era mic , Paper, Film, and

Mic a Capaci t or s

Ch ec k in g fo r Leakage Between S ect ion s

of a Mu l ti -S e c t io n Ly ti c

Large Flu ctu ati o n s in Lytic Leakage

Re a d i n g s

Leakage M eas ure me nts of Non-Polarized

L yt i cs........................................................... 21

Lyt ic s S it ti n g in S t o ck ................................ 21

Low Value L y tic s Used in High

Freq ue ncy Ci rcuit s..................................21

Inte r m i tt e n t Ca paci t or s

...................

.............................................

......................................................... 6

.........................................

...............................................

.............................................

.........................................

.............................................

..................................................18

.................................................

......................................

..................................................... 21

Inside Front Cover

...............

..............................

...................15

..............................

..................

...............

............................

..........................

.......

.............

...........

10

12

12

13

14

14

15

17

17

18

18

19

19

20

20

20

.21

Time Required to O b ta in a Value

Reading on a Cap a c i to r ...........................

4

Chec kin g C e ra m ic C a pa c ito rs for

Temper ature Sensi t i vi t y ...........................22

Chec kin g Film T yp e Ca p ac it or s f or

Temper ature Sensi t ivi t y...........................22

Testing Ca pa cit y of Si li co n Diodes

and Tr a ns i s t o r s

Tes tin g High V o lt a g e Di odes

Test ing Sil ico n C on tr o ll e d R e ctif ier s

(SCRs) and TRIACS

Testing SCRs and TR IACS fo r

DC L a tch i n g

Testing SCRs and TRIACS for AC Latch

and Unlatch Co nd i ti ons ...........................24

Determin ing the Len gth of RF Coaxial

C abl e............................................................24

How to Find a Short in a Coaxial Cable .. 25

How to Find the In d uc t an c e Per Foot of

Coaxial Cabl e............................................ 25

Inductor Testing

Checki ng In d uc to rs fo r Ind uct ance

V alue..........................................................

Balanci ng Out Lead I n du c t a n c e

Chec kin g Co ils B e lo w 2 M i c r o he n r ys . . .. 26

Open Wind in g in a Coi l

Chec kin g In d u ct a n ce I n- Ci r cu i t

Testing In du c to rs on Printed C irc u it

Bo ards ..........................................................27

Mutual i n duc t anc e

Value Reading on H ig h R es istan ce

C oi l s

.............................................................28

Indu ct or Cod i ng..........................................28

Checki ng In d uc to rs for Good or Bad

With the Rin g ing Test

Inductor Testing Applicat ion Tips

Qualit y T estin g on Gener al C oil s

and Transfo rm er s

Peaking C oi ls

Coils in Me tal Sh ield s.........................31

Ferrite Core Tran s fo r m er s and

Coiis....................................................31

Testing Flyb ack T r a ns fo r m er s and Yokes

With the R i ng i ng Te st .........................31

In-Circuit Qu i c k T e st...........................31

Testin g Yokes wi th t he R ing ing Test .... 31

Testing H or iz o n ta l Yoke Win d in gs

for Good or B ad

Testing V er ti c al Yoke W in d in g s for

Good or B ad

..........................................

...................

..................................

................................................ 23

...............

..............................

...............

......................................

..............................

......................................

................................

......................................

22

22

23

23

26

26

27

27

28

29

30

32

33

2

Page 3

MAINTE NAN CE

in t r oduc t i on

...............................................................34

A c c e ss / Disa s se mbl y ..............................................34

Equ ip m en t Required for Ca li bra tio n......................34

Meter Cali b r a t io n......................................................34

Input P rote ct ion Relay Trip Point Ad ju s t .............. 35

Indu c ta n ce C a lib r at io n............................................35

Ringin g Test Cali br at ion

Ca pa c it or C ali br a t i on

APPEN DIX

........................................

..............................................36

Cap ac it or Theory and the “Z METER” .................. 38

Ca pa c ito r Color Code and Marking C ha r t s

..........

Glos s ar y of Terms ....................................................46

35

42

SE RVI CE A N D WARRANTY

.................

Insid e Ba ck C o v e r

3

Page 4

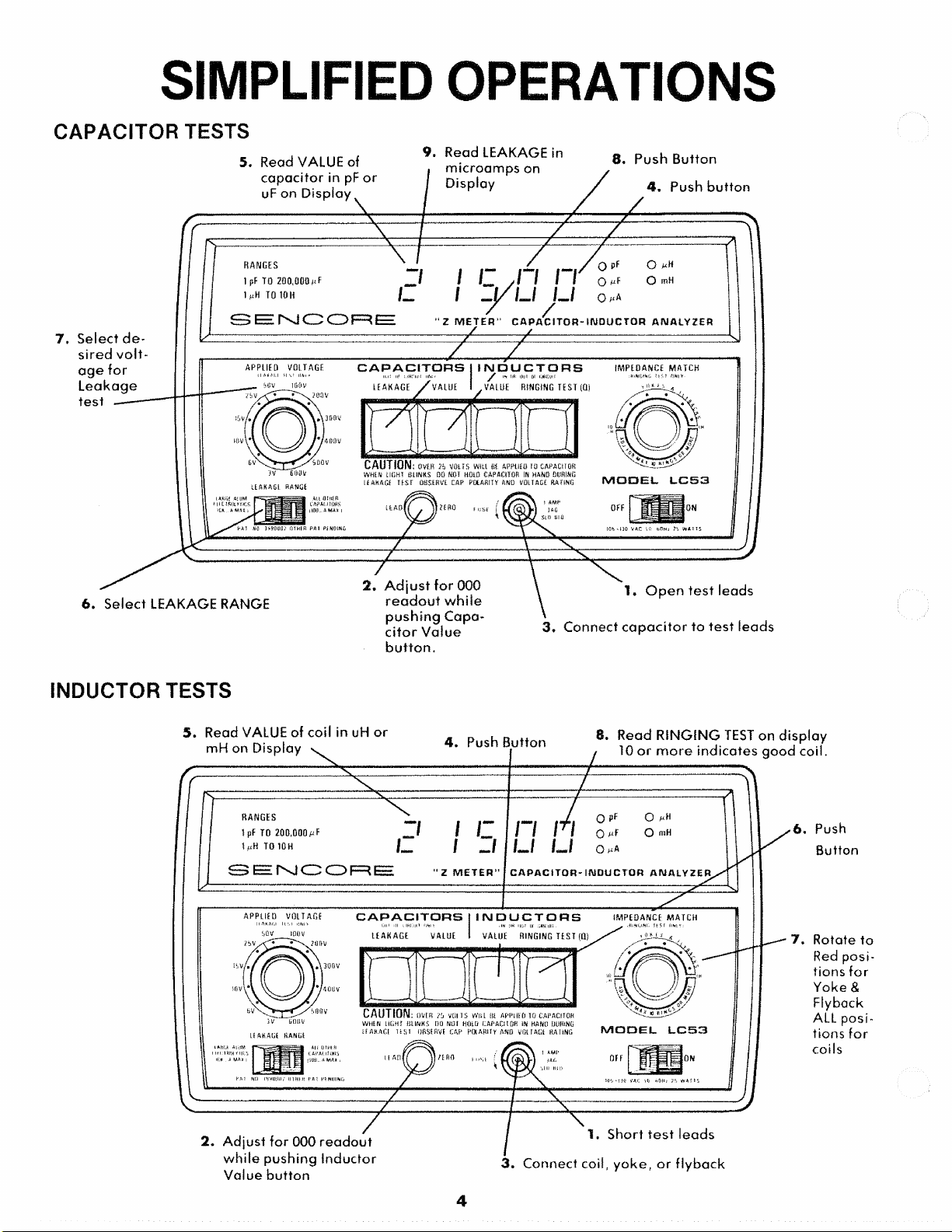

SI MP L IFI ED OPERATIONS

CAPA C IT OR TESTS

7. Select de

sir e d volt

ag e for

Le a k a ge

test

5. Read VALUE of

ca p aci t o r in pF o r

uF on D isp l a y

9. Read LEAKAGE in

mi c r o a mps on

8. Pu sh But to n

4. Push b u t to n

6

. S e le c t LEAKAGE RANGE

INDUC TOR TESTS

5. Read VALUE of co il in uH or

mH on Dis play

r,

2. Adj ust fo r 000

rea dou t wh i l e

pu sh ing Capa

c i t or Val u e

b u t t on.

4. Push Bu tt on

1. Ope n t e st leads

3. Connec t cap ac i t or t o test l eads

8. Read RIN G IN G TEST on d is pla y

10 o r mor e i n d i c a tes g o o d co il.

6

. Push

Button

7. Rotate t o

Red pos i

tions f or

Yoke &

Flyback

ALL p osi

tions f or

coils

2. Ad ju s t f or 000 re adout

w hil e p u s h in g I n d u c t o r

Val u e but ton

1. Short test lea ds

3. Conne ct coil, yok e , o r f l y ba ck

Page 5

Not es

5

Page 6

DE SC RI PT IO N

INTRODUCTION

The use of capac itors in electronics ha s d ramat ic all y

increas ed in t he p as t few y ea rs and t he for e ca st is for

even a g re a te r usage. The t ra n si st o r has g i v en wa y to

the IC, b u t due to t he n at ur e and c o n s tr uc t io n of the

cap ac ito r an d th e inductor, t hes e are n o t re pl ac ed with

ICs. The more ICs t h at are use d, the mo re ca pa ci tor s

and in du cto rs t h at will be used. The tol era nc e of the

capa cit or used to be 20%, b u t today, y o u will find

circu it s h av ing 5% to lerance capa cito rs as s tan d ar d.

The use of ele ctrolytic c apa cito rs has als o d ra stic all y

increased as well as the capaci ty range. Lyti cs of

10,000 uF can be found in m an y c on su m e r electronic

items. Now more t h an ever, the need to measure

cap ac ity value, leakage of the capacitor, i n d u ct o r value

and q ua li ty of the in duc tor has become v er y impor

ta n t. W i th ou t a good measur e of these i mpo r t a nt pa ra

me t e r s, pr o pe r ci r c u i t o p e r a t i o n b e comes m o re

difficult. Sencore has met the challenge head -on with

its all new, a u to ra ng in g “ Z ME T ER”, t h e LC53. Now

cap aci to rs can be checked for value a nd fo r l eak ag e a t

th e r at e d w o rk ing vol ta ge on a d i gi tal r ea d o ut .

Ind u ct o rs can be checked for induc ta nc e a nd for

qua li ty wi th the p a te nt e d Sencore rin g i ng test. The

LC53 is tru l y the firs t co mplete ca pac itor a n d in du cto r

analyzer.

FEATURES

SPECIF IC A TIO NS

DIGITAL RE A D O U T

TYPE: .5 ” , 7 seg m e n t LED .

ACCURACY: F un c ti o n accuracy ± resol utio n error .

RE S OL U T IO N : 3 sig n ific ant di gi ts ±2 cou nts on 3rd

digit (3Vi d ig i ts on capaci tor s of 100,000 uF to

200,000 uF).

A UT OR ANGING: Ful ly a ut omat i c d e ci mal

placement. On e o r two place holding zeros a d d e d as

needed (does n ot affect accuracy) to provide st a n d ar d

value read o u t s of uF, pF, u H, or mH .

RAN G E IN D IC A T O RS :

Type: LE D .

Operation: C ontr olled by t he au to r an g in g circui ts .

CAPAC IT ORS (O u t of Circuit):

Dynamic t e s t of capa ci ty value dete rm ine d by me a s ur

ing one RC tim e co n s ta n t when ca paci tor is ch a r ge d to

+5V through :

10 Megohm s for 0-9000 pF.

10 Kilohms for 9000 pF-90 uF.

100 Ohms for 90-199,900 uF.

ACCURACY: ±1% of re adi ng + re solu tion erro r.

±5% of re a d in g + resolutio n err or for c a ps over

1000 uF.

RAN GE : 1.0 pF to 199,900 uF in 10 a ut oma tic a ll y

selected ran ge s.

The Sencore LC53 “Z METER” f e a tu r e s adva nce d

Digi tal Logic circuits t h a t provide a u t o r a n g in g of the

me te r when checking the values of c ap a c it y or ind uc

tance. Si mply hook u p the c apac itor o r th e inductor,

pre ss the prop er VA L UE bu tto n, and re ad t h e value on

the large dig ital readout.

The “Z METER” also checks c ap aci to rs for leakage

wit h two selectable cur re nt range s at the r ate d

work ing volta ge from 3 Volts to 600 Vo lts. An L ED

(located b etw een th e L E A K A G E bu t t on and the

A P PLI ED V O LTA GE switch) will flash on an d off as

a safe ty rem in der when th e leakage t es t v o l ta ge is set

to 50 Volts or above.

Th e Sencore p a te n t ed rin g in g t e st c he c k s coils,

deflection yokes, a nd non-iron core t r a n sf o r m e r s with

an a c cu ra te c heck of good or bad. Th ere ar e six sw itch

selectable impedance m at ch in g po sit ion s t o m a t c h the

coil to th e t e s t circ uit from 10 u l i to 10 I I. Good coils

will show 10 or more rin gin g cycles on t h e d igit al d is

play while bad ones will show less than 10.

A special L E A D ZERO control lets you balance out

the cap aci ty or i nductan ce of the t es t lead s I'or those

acc u ra te readin gs of the very small capa ci to rs and

coils th a t you may encoun ter. The “ Z ME TER” is also

pro te cte d a ga i ns t accide ntal app licatio n of vo lta ge s to

the tes t leads by a front panel repla ceab le fuse an d a

special relay inside the inst rum e nt.

CAP ACIT O R LE AK A GE

ACCURACY: ± 5% 4- reso luti on error.

RANG ES : 0 to 99.9 uA an d 0 to 9.99K uA in two

switch selec tab le ranges.

VOLT AG ES : 12 s electable DC vo lta ges from 3 VDC

to 10 VDC filtered and from 1.5 VDC to 600 VDC,

non-filtered. Availabl e at t e s t leads only when

LE A KA GE pu s h b u t to n is depressed. Cap a ci to r is

aut om a tic al ly di sch arg ed when b ut t on is released.

IND U C T A NCE (In- or Out-of Circuit)

Pa te n t pe nd in g dyn am ic te s t of in du cta nce va lue

determ ined by m ea su ri ng t he E MF caused by a con

sta nt ly vary i n g cur re nt throu g h t he coil u n de r test .

Current ra t e s are:

10 mA/usec - 0 to 90 uli .

1 mA/usec - 90 to 900 uli

.1 mA/ usec - 900 ul i to 9 mH.

.01 mA/u sec - 9 t o 90 mil .

1 uA/usec - 90 to 900 m il .

.1 uA/usec - 900 to 9,990 m il .

ACCURACY: ±2 % of reading -*■ resolution error.

RANGES: 1.0 uli to 9,990 mil in 6 auto m a tic a ll y

selected range s.

6

Page 7

RINGING TEST

Dynamic te s t of inductor q u al ity d ete rmi ned by c ou n t

ing the number of cycles the in d u ct or rings before

reaching a p re se t dam pi ng po i n t af te r a given exc itin g

pulse has been applied. (US pat e nt 3,879,749).

ACC E S S O R I E S (Optional)

39G85 T ouch Te st P robe

GENE R A L

EX C IT I N G PUL SE AMPL I T U DE : App rox im atel y 7

Volts peak.

ACC UR AC Y : ± 1 c ount from r ea d i n g s of 8 to 13.

ACCES S OR IE S (S up plie d)

39 G 143 Te st Leads *

39G144 Te st Lead A da pt or

39G145 Test B u tt o n Hold Dow n Rod (2 supplied) '

64G37 Test Lead M o unt in g Clip

68G34 Allen Wrench

44G20 Spare 1 A m p Slo-Blo F u se

“Specifica tions su bje ct to cha ng e w it h o u t not ice.”

T E MPERAT URE RAN G E S (Typical): Calibr ated at

70 °F. Rated accuracy range: 50-90 °F, Opera ting

rang e: 32-130°F.

PO W E R: 105-130 VAC, 60 Hz, 25 Wa tt s .

T E S T L E A D INP UT: Fuse p r o te c te d with in-line 1

Am p 3AG Slo-Blo fuse.

SIZ E : 6” x 9” x 11.5” (15.24 cm x 22.86 cm x 29.21 cm)

W E I GH T: 7.75 lbs. (3.56 Kg).

Page 8

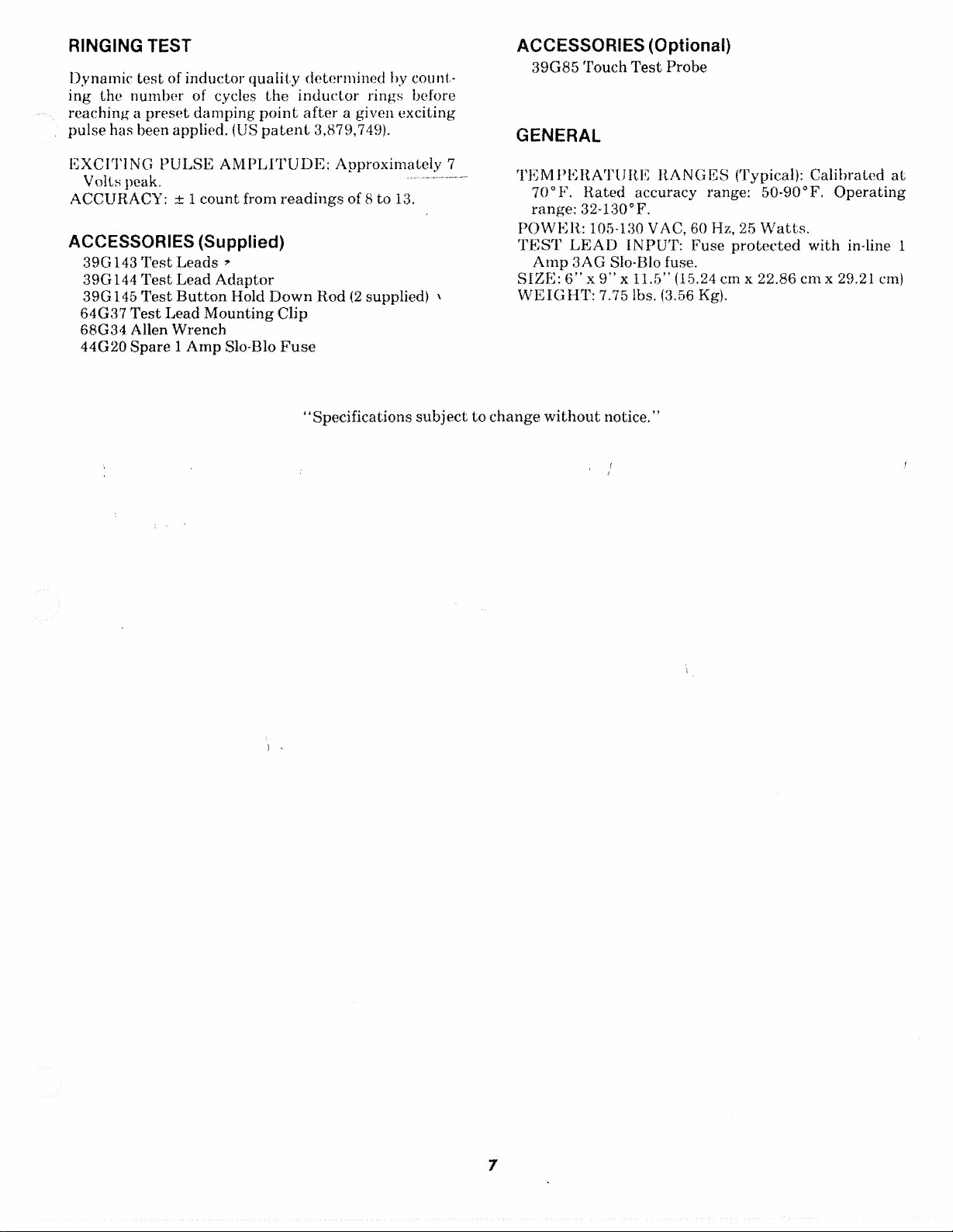

CONTROLS

1. Front panel digital readout, fi r s t th re e d igit s read

the value of capacity , inducta nce, l eak ag e curr en t or

ring ing test values, las t two di g it s are plac e holders

and only indicate 0 on larger va lue s of ca paci ty, ind uc

tance, or leakage c u rre nt so all rea di n gs are given as

pF, uF, uH, or mH.

2. a. Indic ato r LED, lights up when capa cito r re ad

ing is in picofarads (pF).

b. In dica tor LED, ligh ts up w hen capa cito r re ad

ing is in microfara ds (uF).

c. Indicator LE D, light s up wh en c ap acito r leak

age reading is in microamps (uA).

d. Indica tor LED, light s up wh en ind uct or rea d

ing is in m icrohe nrys (uH).

e. Indicator LED, lights up whe n i nd uct or r ea d

ing is in millih enrys (mH).

3. I M PE D A N C E MATCH s w itch , r o t a te d thro ug h

th e l as t 4 t es t po sitio ns when m a k i ng the r in gin g te s t

on yokes and flyba cks and thr o u gh all 6 positions

when te st ing ot her induct ors. A r e a d in g of 10 or more

indi ca tes a good inductor.

4. Power ON-OFF switch, co n tro ls th e AC line vol

tag e to the “Z M ET E R”.

13. LE A KA G E RA NG E switch, us ed to se lec t the

desired range of capacitor leakage current, 0 to 100 u A

or 10K uA .

14. APPLI ED VOLT AG E SWIT CH , used for

selecti n g the desired test v olta g e when ma kin g capaci

tor leakag e tes t s.

REA R PANE L

15. Rear panel meter zero adjust. A d just to zero

digital readout with all buttons out.

16. 39G145 T es t Button Hold Down Rod mounting

clip.

17. 39G144 Test Lead Ad aptor mou nt ing clip.

18. Cord wrapper for stori ng AC line cord and t es t

leads.

5. RINGIN G TE S T pushb utto n, depre sse d when

ma ki n g the p a te n te d Sencore rin g in g t e s t on induc

tors , yokes, an d flybacks to check the quality. Use

IM P E D AN C E M ATC H switch (3).

6. Tes t Lead Input jack. U nscre w j ac k for access to

in p u t protectio n fuse.

7. Inductor VALUE push bu tton , d ep ress ed when

te s ti n g induct ors for value of induct anc e.

8. Capacitor VA L U E p u s h b u tt o n , de pre ss ed when

tes t i n g capacitors for capac ity value.

9. Leakage chart on pull out.

10. LEAD ZERO adjust, u sed to balance ou t the

small value of capac ity or in d uc tan ce in t h e t e s t leads

when maki ng precise m ea su re m en ts of s mall v alues of

cap a ci ty or inductance.

11. LE A KA GE test pu shb utton, depress ed when

te s ti n g capa citors for leakage a f te r t he AP PL I ED

VO LT A G E switch (14) has been set to th e wor king vol

tag e of t he c apac itor a nd L EA KAG E RA N GE switch

(13) is s et to th e pr ope r value as i nd ic a te d in th e leak

age c h a rt (9).

12. Cautio n ind ic at o r LED, bl i n k s when the

A PP LI ED VO LTA GE switch (14) is se t to 50 Volts or

hig her as a warn ing to th e user. Vol ta ge is only pres en t

on te st leads when L EAKAGE b u tt o n (11) is

depres sed .

8

Page 9

Fig. 1 — Loc a t io n o f c on t ro ls a nd feature s of the LC53.

9

Page 10

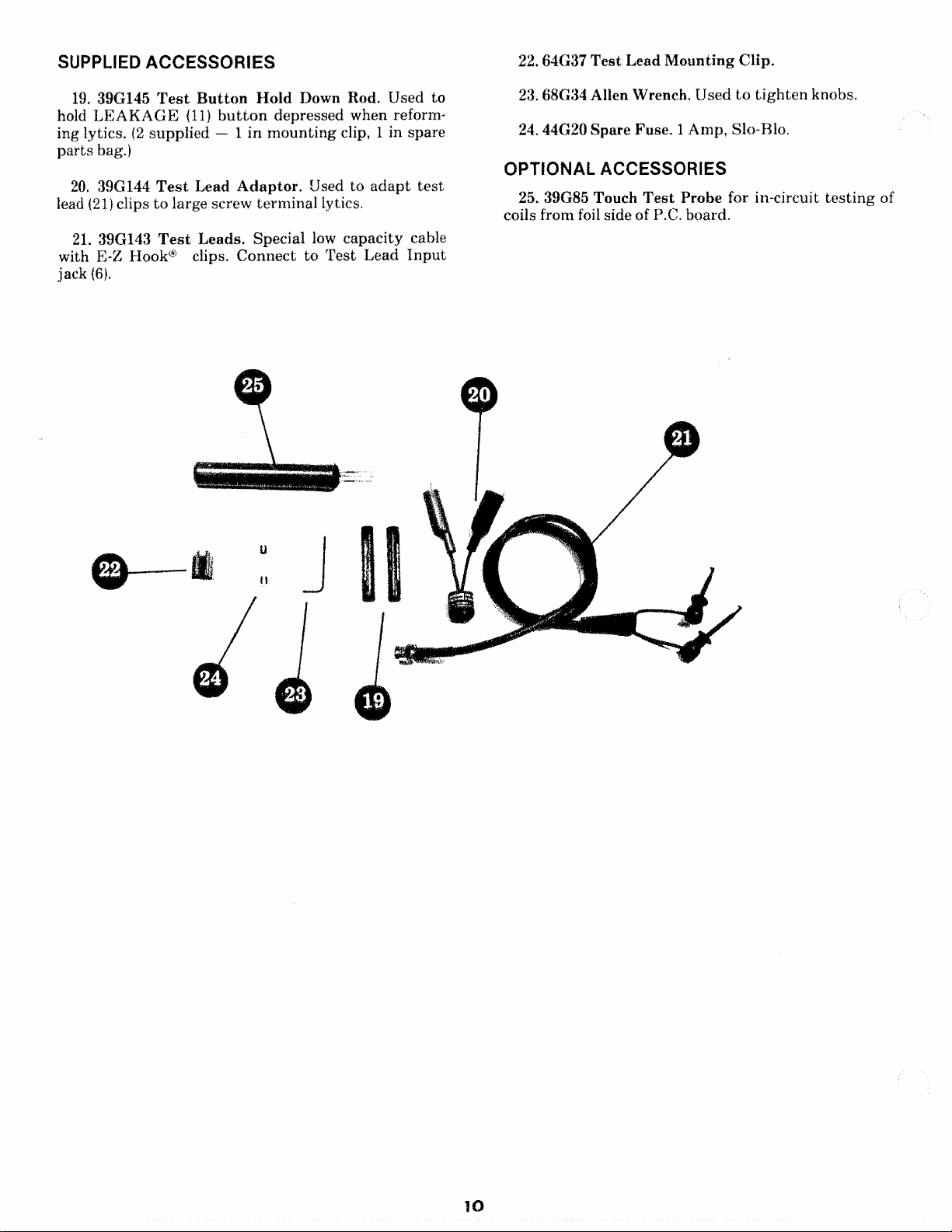

SUPPLIED ACCESSORI E S

22. 64G37 Tes t Le ad Mo un tin g Clip.

19. 39G145 Te s t Bu t t on Hold Down Rod. U sed to

hold L E AKA GE (11) but t o n d epres sed when ref or m

ing lytics. (2 s up plie d — 1 in m ou n tin g clip, 1 in spare

par ts bag.)

20. 39G144 T e s t Lead A da p t o r, Used to a d ap t t es t

lead (21) clips to large screw term ina l lytics.

21. 39G143 Te s t Leads. Special low capa city cable

with E-Z Hook® clips. Co nn e ct to T es t Lead Inpu t

jack (6).

23 . 68G34 Allen Wrench. Used to t ig h t e n knobs.

24. 44G20 Spare Fuse . 1 Amp, Slo-Blo.

OPT IO N A L A CC ES SO R IES

25. 39G85 Touch Te s t Probe for in-circuit t es ti n g of

coils from foil side of P.C. board.

Page 11

Not es

Page 12

OP ER AT IO N

INTR OD U CT IO N

Before usin g y o u r LC53 “Z ME TER” for the fir st

time, take a few min u t e s to read thr ou gh the o pe ra

tions an d ap p li ca ti on s s ectio n of t he manu al carefully

to ac q u a in t y o ur se lf w it h the featu res of th e LC53.

Once you are familiar w it h the general operation s,

m os t t e s t s can be p erf or me d with the info rma tion p ro

vided on t h e LC53 fro n t panel.

POW E R CO NN EC TION

The LC53 is design ed to be op erate d from 105-130

VAC (50/60 Hz). If 210-230 VAC operatio n is required,

the un it m ay be modifie d (at additi onal cost) by t h e

Sencore Service De pa r tme n t, 3200 Sencore Drive,

Sioux F alls , SD 57107.

To ope ra t e th e LC53 from t he AC line:

1. Co nn ec t t h e AC line cord to a 117 VAC (or 220

VAC for modified uni ts) outl et.

2. T u r n t he power sw it ch on.

3. The LC53 is im m ed ia tel y rea dy to mea sure ca p a

city or ind uc tan ce . If prec ise m ea su re me nt s are to be

made, th e u ni t sh ould be allowed to opera te for at l ea st

5 m i nu t e s to allow th e cir cu its to stabilize.

BLOW N FUS E CON D I T I O N S

FU S E

Test

Lead

Inp u t

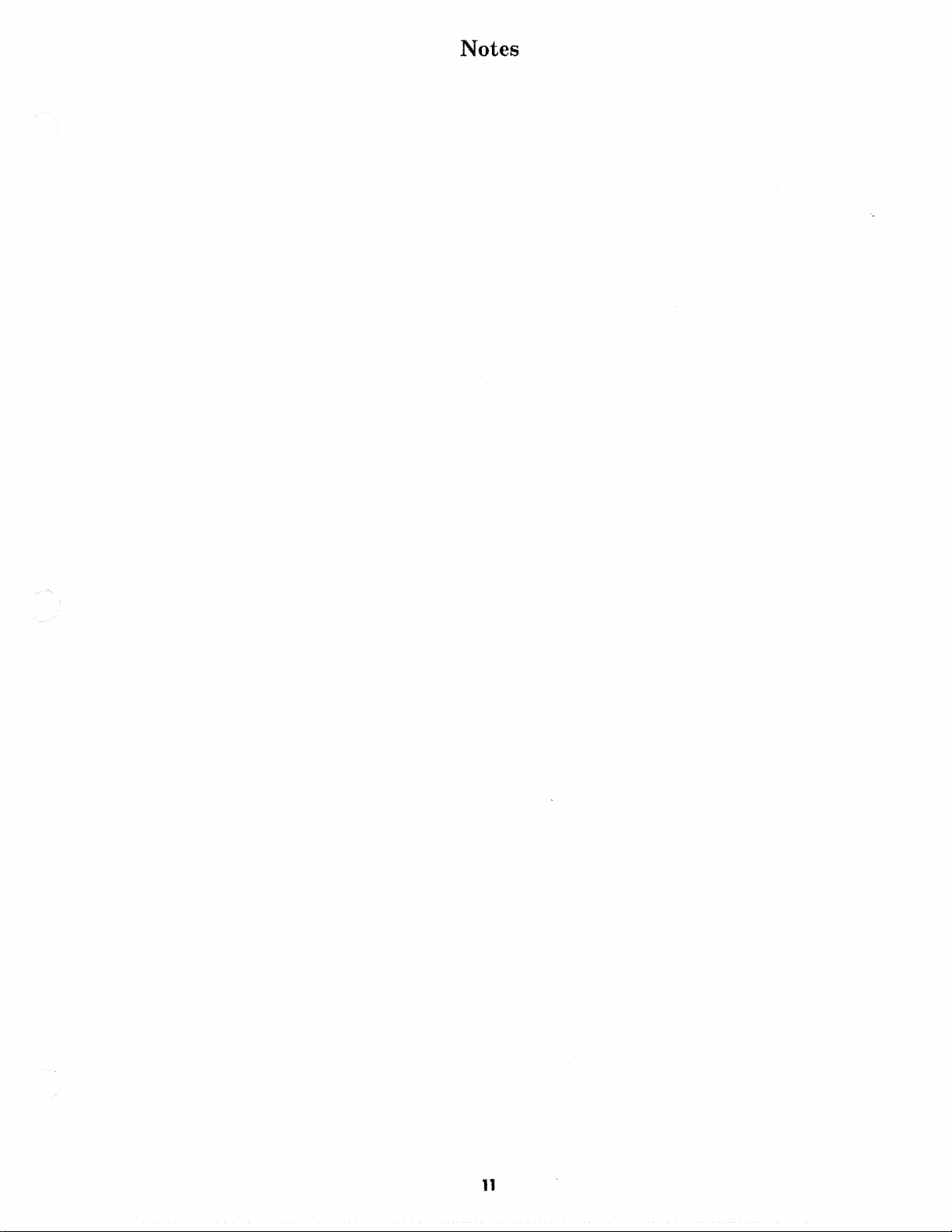

TE S T L E AD INP U T F USE RE P L A C E ME N T: The

fuse for the te s t lead i n pu t is lo cat ed behind the BNC

input jack. The fuse holder ma y be removed by tu rni ng

the BNC connecto r c o u n te r clockwise a nd u nscre wing

the connector until t h e fu se is free. The BNC connector

of a s et of test leads ma y b e us ed a s a “ W re n ch ” to aid

in the removal of th e fuse holder. W hen r eplacing the

fuse holder, m ake sure t h e holder is screwed in t igh tly

to pr ev en t t h e c onnect or fr o m tur ni ng wh en

connecting an d d is co nn ec ti ng t e s t leads. Replace the

fuse w ith a 1 A mp Slo-Blo 3 AG fuse only.

)L Q CAP ACITOR tU HA ND DURIN G

>0 L ARITY AND VOL TAGE RATIN G .

FUSE

TY P E CO ND I T I O N S

1 Amp

3 AG

Slo-Blo

No Lea k ag e rea di ng s

Ca p ac i ty re ad s a sma ll neg ative

valu e un c h an g ed b y L E AD

ZE R O a dj u s t me nt

In d u ct a n ce sh ow s fla shing 888

wi th 0 following ind ic ati ng open.

No indica ti o n on Rin g ing Test.

M O OE L LCJ

FUSE RE P L ACE MEN T

AC FUS E : T he LC53 does n ot use an AC line fuse. Th e

unit is pr o te c te d by a special th erm al sw itch in the

power tra ns fo rmer . If th e power tran sf or m er is o v er

loaded, the ther m a l sw itc h will open the prim a ry,

rem ov in g t he vol tag e from the unit. Simply allow th e

unit to cool down a nd the ther mal switch will close,

app ly i ng powe r to t he p ri m a ry and allowing the un i t to

ope ra te ag ain. If y o ur u n it goes off, allow it to cool

down and tur n it on before any troubl es hoo tin g is

st a r te d to allow the th er m a l switch to close if it h as

opened.

WAR N I N G

Alw a ys re pla ce t h e f use in th e t e s t lead with a 1

Amp , 3 AG, Slo-Blo ty pe. Any o th er ty p e or c ur

ren t ra t i n g m ay c au se in te rn al dam age to the un it

and will void all warr an ti es .

TES T L E AD F U S E : A 1 Amp, 3 AG, Slo-Blo fuse is

used in the te st lead inp u t on the “ Z M ETER”. Th is

pr o te c t s th e in p ut of the uni t from voltag e applied to

the i n p u t ac cid entl y. Replace with a 1 Amp, 3 AG, Slo-

Blo ty p e only.

Fig. 2 — The 1 Amp , S AGC Slo-Blo fuse is located

behind th e t e s t lead inp ut ja c k.

TEST LEADS

39G1.43 T E S T LE AD S: The t e s t leads (supplied with

the meter) use a special low c ap aci ty cable. The use of

any oth er cable will add e x tr a ca pa city to the meter

and may be out of range of th e L E A D ZE RO control. If

the t e st le a d s ev e r n e e d re p l ac ement , it is

recommended th at new leads (39G143) be ordered

directly from the Senc ore Service De pa rt me nt , 3200

Sencore Drive, Sioux- Falls, SI) 57 107.

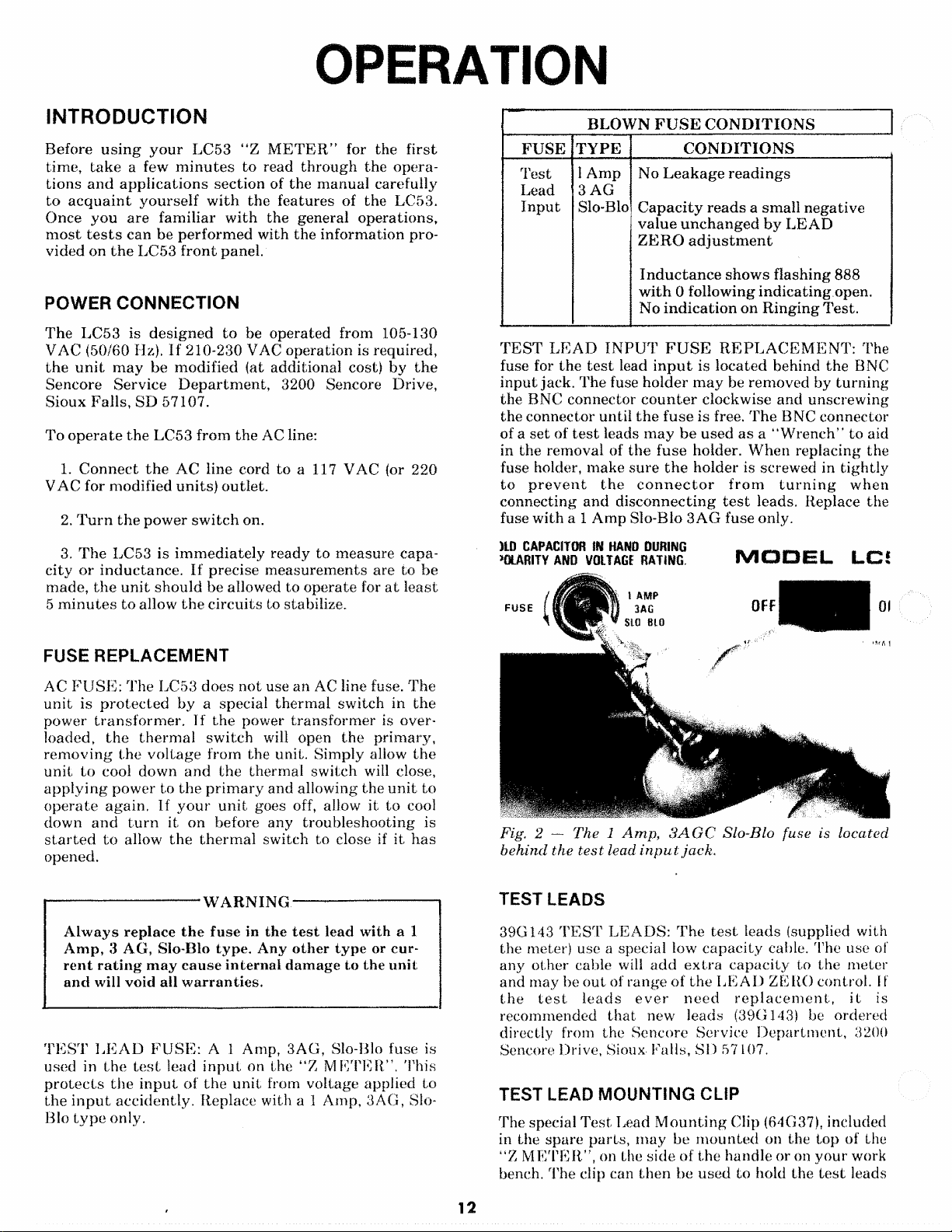

TEST LEAD M O U NTI N G CLIP

The special Tes t Lead M o u n ti n g Clip (64G37), included

in th e sp are pa rts , m ay be mo u nt ed on the top of the

“Z M ETE R”, on the side of the han dle or on you r work

bench. The clip can th en be us ed to hold th e t es t leads

12

Page 13

out of the way, b u t ready for use a t any tim e. To m ou nt

the t e s t lead clip, simply peel off the ba ck in g , place on

the s p o t to be mounte d, and p res s firmly.

NOT E: Do not mo u n t the T e s t L ea d Clip to t h e sid es o f

the “ Z M E TER" as it will interfere w i th t h e mov eme n t

o f the handle.

Fig, 3 — Th e special T e s t Le a d Mo u nt i n g Clip holds

the t e s t leads o ut of th e way, bu t ready fo r use at a n y

time.

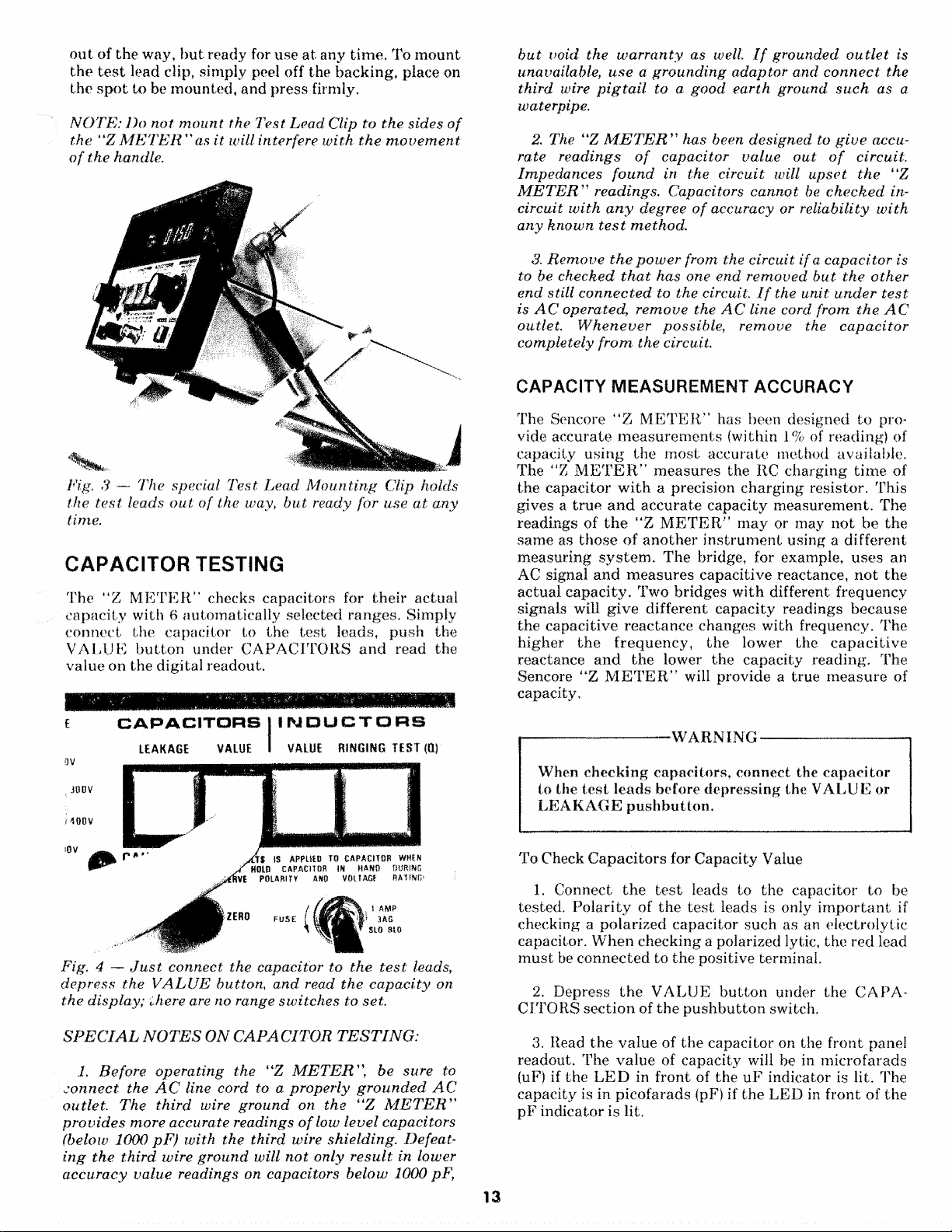

CAP A CIT O R TESTING

The “Z M ETER ” checks cap aci tors for th eir actual

cap a ci ty with 6 au tom a tica lly selected ra ng es . Simply

con ne ct the capacito r to the tes t leads, pu sh the

VA L U E b u tt o n under CAPA C IT O R S an d read the

value on the d igit al read out.

bu t void th e wa r r a n t y as well. I f grounded, out let is

unavailable, us e a g r o u n d in g a d ap to r a nd c o n n ect the

third wire pi gt ai l to a go od ea rt h gro un d suc h as a

waterpipe.

2. The “Z METER ” has been d es i gn e d to give accu

rate re a d in g s of cap a ci to r v a lue o ut of circuit.

Im p ed a n c e s f ou nd in the circu it will up s e t the “Z

MET ER'’'1 rea din gs. Capacitors c a n n o t be checke d in-

circuit wi t h any degree o f accuracy or re liab ili ty w it h

any k n o w n te st m et h od .

3. Re mo v e t he powe r from the cir cui t if a cap ac it o r is

to be c he ck ed t hat has one en d re mov e d bu t t h e oth er

end stil l c o n n e c t e d to the circuit. I f the un it u n d e r te s t

is AC oper ated , r e m o ve the AC line cord from t h e AC

outlet . W he n ev er poss ib le , r e m o v e the c a p ac i to r

com pl et el y f r o m th e circuit.

CAP A C IT Y MEA S U R E M E N T ACC U RA C Y

The Sencore “Z ME TE R” has been designed to p ro

vide acc ur ate me a su r em e n ts (within 1% of reading) of

capacity usin g the mo st accura te method available.

The “Z ME TER” me asu re s the RC c ha rgin g time of

the capacito r w i t h a precision c ha rgi ng resisto r. This

gives a t r ue a nd ac cu ra te c ap ac ity me asu rem en t. The

readi ngs of the ‘‘Z METE R” m ay or may no t be the

same as tho se of a n o th er i n st ru m e n t using a dif fe ren t

meas ur ing sy st em. Th e bridge, for example, use s an

AC signal a n d mea s ur es capac itiv e reactan ce, no t the

actua l c ap aci ty . Two b ridge s wit h different frequ enc y

signals will giv e different ca pac ity readings b ecau se

the capaci tive reac ta nc e c hang es with frequency. The

hig he r the freq u e nc y , the lower th e cap a c i ti v e

reactanc e a n d the lower the capa city readi ng. The

Sencore “ Z ME TER” will pr ovide a true me as u re of

capacity.

E

3V

; JOOV

/ 490V

10V

CAPACITORS I INDUCTORS

LEAK AGE VALU E I VA LUE R INGI NG T E ST (0}

Fig. 4 — Jus t co nn e ct th e capac itor to the t e st leads,

dep re s s th e VAL UE b utt o n, and read th e ca p a c it y on

the d isp la y; the re are no range switc h e s to set.

S PECIAL NOTES ON C APA CIT OR TESTING:

1. Be f o re op e ra ti n g t he “Z M E TE R ”, be sure to

co n n e ct th e AC line cord to a p r op er ly g r ou n de d AC

outl et . The third wire g r o u n d on the “Z ME T E R ”

pr o v i d e s mor e accurat e rea ding s of low le ve l capacito rs

(below 1000 pF) w i th the third wire s hie l di ng . Defea t

ing th e t h ir d wire gr o u nd will n o t only re su l t in lower

acc u ra cy value read ings on capacito rs belo w 1000 pF,

-WA R N IN G

When ch ec kin g c ap acitor s, conn ect the ca pa ci to r

to the te st le ads before d ep ress ing the V A L U E or

LE A K AG E p u s h bu t to n .

To Check Capa ci to r s for Capacity Value

1.. Connect t h e t e s t leads to the capacitor to be

tested. P ol a rit y of t he t e s t leads is only imp o r ta n t if

checking a polar ized capa cito r such as an ele ctrol ytic

capacitor. W h en checki ng a polarized lytic, the red lead

mu st be con n ect ed to th e posit ive terminal.

2. Depress the VAL U E bu t to n under the CA PA

CITO RS se ctio n of the pu s h b u tt o n switch.

3. Read th e v al ue of the cap aci tor on the f ron t panel

readout. The va lu e of ca pa cit y will be in m ic rof ara ds

(uF) if the L E D in f ro nt of the u F indica tor is lit. The

capacity is in picof ara ds (pF) if the LE D in fron t of th e

pF indic ator is lit.

13

Page 14

NOTE: Mo s t capa cito r values will read v e r y qu ic k ly ,

but e xtr e me l y large electr olytic capacitors (ove r 50,000

uP) m a y take a f ew seco?ids to come up to a r e ad in g

level. For example, a 50,000 uF will tak e abou t 5

se co n d s before a reading is seen on the d i gi ta l readou t.

An extr em ely large (100,000 uF) co m p ut e r -t y pe lyti c

m ay ta k e 10 secon ds before the value is d i s p l ay e d on

th e readout. If the value does no t read in th e ti me list

ed abov e, then the capacitor is either s h or t e d or v ery

leaky. In eith er case, it is p ro ba bl y defective. Rec h e c k

th e v alu e ag ain jus t to be sure.

the aut or a n gi ng circ uit . Values below 2 pF can be read,

however, by us in g th e L EAD ZE RO control to o ffs et

the met er zero.

To Read Cap ac it or s Le ss Tha n 2 pF

1. Place t he t e st le ad s (with no c ap aci to r conne cted)

on t he work are a in such a way t hat th ey will no t be

moved when the cap ac it or to be test ed is connected. Be

sure t ha t the t e s t leads are not on a m etal surf ace or

near AC power or an AC oper ate d device.

Th is pro cedu re pr ovides ac cur ate readings on t h e c ap a

cit or s being test ed. Small value readings (2 p F to 1000

pF) m a y be off sligh tly due to the capaci ty of t h e t e s t

leads. T his ca pac ity can be ba lance d out for ex tr em e ly

hig h ac cur acy r ead ing s wit h t he LE A D ZE R O co ntr ol.

The L E A D Z ER O control is auto ma tica lly switc h ed

out of circu it for capacity values above 10,000 pF.

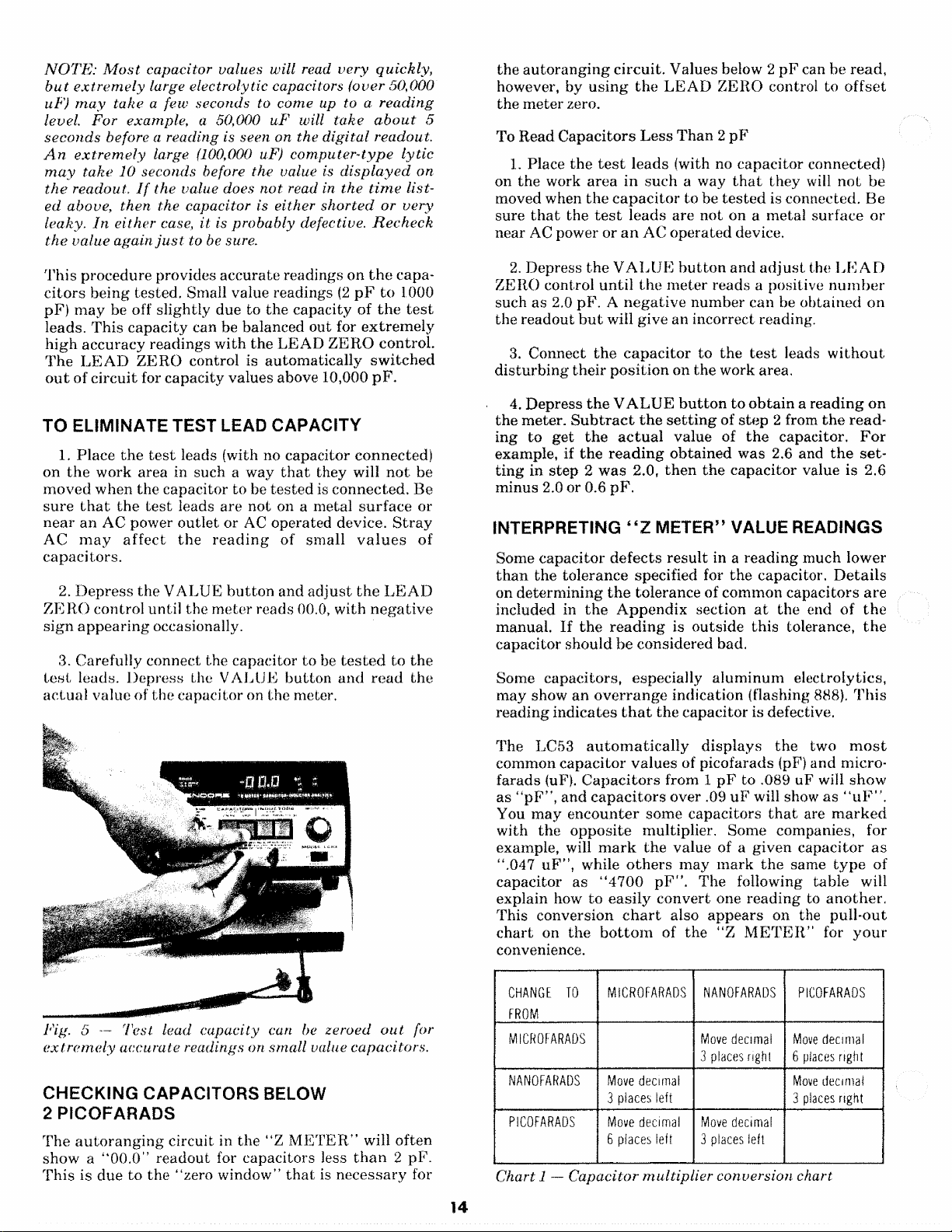

TO ELIMINA T E TES T LEAD CAPA C IT Y

1. P lace t he te s t leads (with no capaci tor con necte d)

on th e work area in such a way t h a t they will no t be

moved when the c apac itor to be teste d is conn ect ed. Be

sure tha t the t e st leads are not on a met al s ur fa c e or

nea r an AC power o utle t or AC operated device. St r ay

AC ma y aff e c t the r e a d i n g of small v a l u e s of

capa ci tor s.

2. D ep re ss th e VA LU E bu t to n and ad ju s t t h e L EAD

ZE R O control un til the me ter reads 00.0, with n eg a ti ve

sign a p pe ar in g occasionally.

3. Ca refully connect the capa citor to be t e s te d to the

Lest leads. D epre ss the VALU E b ut ton an d re a d the

act ua l value of the capacitor on the meter.

2. Depre ss th e V A L U E b u t t on and a d j u s t the L E AD

ZERO control u nt il t he m et er read s a positive n u m b er

such as 2.0 pF. A n eg a ti ve nu m ber can be obt ain ed on

the reado ut b u t will give an incorrect reading.

3. Connect the c a pa ci to r to th e t e s t leads wi th o u t

dist ur b in g the ir p os iti on on the work area.

4. D epr ess th e VA L UE b ut to n to obta in a read ing on

the meter. S ub t r a c t t h e se tt in g of ste p 2 from th e r e a d

ing to get the actu a l value of t h e capacitor. F o r

example, if t he re a d in g o bt ain ed wa s 2.6 and the se t

ting in s tep 2 was 2.0, t h en the ca pa ci tor value is 2.6

minus 2.0 or 0.6 pF .

INTERPRETING “ Z METER” VALUE READINGS

Some capac ito r d ef ec ts r esu lt in a r ea di ng much lower

th a n the tole ranc e specified for t he capacitor. D et ai ls

on determ inin g t h e to leranc e of common capa cito rs a re

included in th e Appe nd ix section at the end of t he

manual. If th e rea d i ng is outsi de this tolerance, the

capacito r sho uld be consider ed bad.

Some capacito rs, especially aluminu m electrolytics,

may show an o v e rr a ng e indic ation (flashing 888). T h is

read ing indica tes that th e cap acito r is defective.

Fig. 5 Tes t lead capa cit y can be zeroed o u t for

ex t r em ely acc ura te readi ngs on sm all value capacitors.

CH E CKI N G CA P A C IT O R S BELOW

2 P I C OFA R A D S

The a u t o ra n g in g circuit in th e “ Z MET ER” will ofte n

show a “0 0 .0 ” r ea do ut for ca pacito rs less tha n 2 pF .

This is du e to the “zero win dow ” t h a t is ne ce ss ary for

The LC53 au to ma t i c a ll y dis pl ay s the two m o s t

common capa cit or va lue s of picofara ds (pF) and m ic ro

farads (uF). C a pa c it or s from 1 p F to .089 uF will show

as “ pF” , a nd c a p ac i to rs over .09 uF will show as “uF” .

You m ay en c ou n te r s ome capa cito rs t h a t are m ar k e d

with the op po sit e multiplier. Some companies, for

example, will m a r k the value of a gi ven c apa cito r as

“.047 uFM, while ot h er s may m ar k the same t yp e of

capac ito r as “ 4700 p F " . Th e following table will

explain how to ea sil y conv ert one rea din g to an o th er .

This conversion ch a r t also appe ar s on the pull-o ut

cha r t on th e bo t t o m of the “Z M E TER ” for you r

convenience.

CHANGE TO

FROM

MICROFARAD S

NANOFARADS Mov e de c i ma l

PICOFARADS Move d e c i m a l

MIC RO FAR ADS NANOFARA DS PICOFARADS

3 pla c es lef t

6 pla c es lef t

Move d ec i ma l

3 pla ce s r i gh t

Move d ec i m a l

3 pl ac es le f t

Move d e c i m al

6 places r ig h t

Move de c i mal

3 places r ig h t

Chart 1 — Ca pa cito r mul ti pl ie r conver sio n chart

14

Page 15

TESTING LARGE SCREW T ERMIN A L LYTI CS

Some lytics, especially in in d us tr ia l ap plic atio ns, use

rat he r large screw terminals rat h er than the conven

tional solder terminals. The 39(1144 TES T LEA D

Ada p to r (supplied with the LC53) should be used to

con ve rt the small E-Z 1 look “ clips to large alligato r

clips to fit the large screw te rmin als . A special clip is

moun ted on the back of the LC53 to s to re the 39 GI4 4

when it's not in use.

Fig. 6 — The 39G144 Tes t L e ad a d a ptor allows even

the large screw te rm in a l ca pacito rs t o be co n ne ct ed to

the LC53 for testing.

To Use the 39G144:

1. Connect the Red E-Z Hook" on the LC53 te s t

leads to the red term inal of the 39G14 4 T ES T L E A D

ADAP TO R. Co nnect t he Black clip to the other

terminal.

2. Connect th e Red alligator clip of the 39G.144 to the

posit ive screw term inal and th e Bla ck all iga tor clip to

the n egativ e termina l.

3. Tes t the cap aci tor in the u su al m an ner .

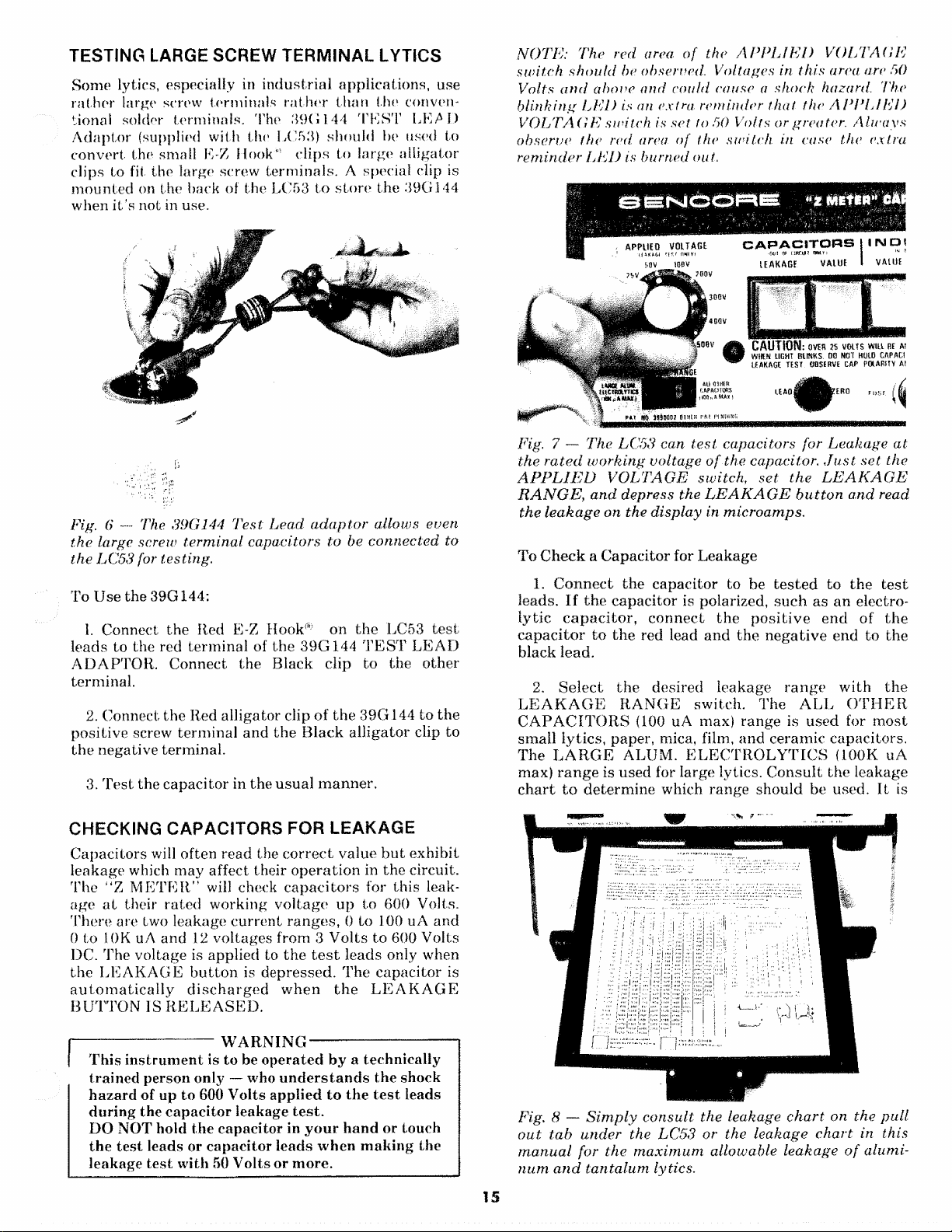

NO T E: The red area, o f the APP LIED VOLTA GE

sw it c h s ho u ld be observed. Voltages in this area are 50

Volts an d above and could cause a shock hazard. The

blin k i ng L ED is an extr a r emin d er th at the APPL I ED

V OL TAGE switc h is set to 50 Volts or greater. A l w a y s

obse rv e the red area o f the sw i tc h in case the extr a

remi n de r L ED is burned out.

Fig. 7 —- T he LC 53 can te st ca pacitors for L e ak a ge at

the ra t e d w o r ki ng volta ge of the capacitor. Just set, the

APPLIED V OL TA GE swit ch, set the LEAKAG E

R ANGE , a n d dep ress the LEA KAGE b u t t o n an d read

the leak a ge on the displ ay in microamps .

To Check a Capacitor for Leakage

1. Conne ct the capac itor to be test ed to the test

leads. I f th e c apacit or is polarized, such as an e lectro

lytic cap a ci to r , c on ne ct the p o si ti ve en d of the

cap ac ito r to t he red lead a nd t he neg at iv e end to the

black lead.

2. Se lec t t he desired leakage rang e with the

LEAKA GE R A NG E switch. The AL L OT H E R

CA P A C IT O R S (100 uA max) range is used for mo st

small ly tics, paper, mica, film, and ceramic capacitors.

The L A RG E ALUM. ELE CT R O LY T IC S (100K uA

max) ra n ge is used for large lytics. Consult th e leakage

ch ar t t o d eterm ine which range should be used. It is

CHECK ING CA PA C IT O R S FOR LEA K AG E

Capa cit ors will often read the co r re ct value b u t e xhibit

leakage which may affect th eir op e ra tio n in th e circuit.

The “Z MET ER” will check cap a ci to rs for this leak

age a t their ra ted working volt ag e up to 600 Volts.

Ther e are two leakage c urr en t ra n ge s , 0 to 100 uA and

0 to 10K uA and 12 vo ltage s from 3 Vo lts to 600 Volts

DC. The volta ge is applied to th e t es t le ads only when

the LE A KA G E bu t to n is depre sse d. The cap aci tor is

au t oma t i c a l l y d i sc h a r g e d w he n th e LEAKA GE

BUT TO N IS RE L EA S ED .

|

---------------------------

1 This in st ru m en t is to be opera ted by a technically

trained p erson only — who und e rs t a n d s the shock

hazard of up to 600 Volts applied to th e t es t leads

during the capac ito r leakage test.

DO NOT hold the capacitor in you r h an d or touch

the tes t leads or capacit or leads whe n m akin g the

leakage tes t with 50 Volts or more.

W ARNI N G

------------------------------

Fig . 8 — Si mp l y c on su lt the leakage ch a rt on the pu ll

ou t ta b unde r the LC 53 or the leaka ge ch a r t in this

man u a l for the ma x i m u m allowable leak ag e of a l um i

num a n d t an t al u m lytics.

15

Page 16

bes t to s t a r t with the hi gh est range (Large Aluminum

Electro lytic s) if you are not sure which r an ge to use. If

the display shows “000", then s w it ch to the other

rang e. You can switch ran ges of the L E A K AG E

RA N G E switch while holding the L EAK AGE bu tto n

in if you have selected the wr ong ran ge or merely wish

to sw itch ranges.

3. Select the normal DC working vo l ta g e of the ca pa

cit or to be tested w ith the A PPLI ED VOLTA G E

switch . If the normal wo rking v oltag e of th e ca pacito r

falls between the range s on the switc h, select the nex t

low e r range. For example, if the wo rk in g vol tag e of the

ca pa c it or to be test ed is 35 Volts, s ele ct th e 25 Volt

pos it io n of the APPL I ED VO LT A GE switc h.

4. Depress the L E A K A G E bu tt o n and read the

valu e of leakage cu rr ent in m icroamps on the display.

Cap ac it or s will take a specific a m o u n t of time to

cha r ge and give an a ccu ra te reading of th e leakage

cur re nt . Consult t he typ e of ca pacito r you are t es tin g

in the following listing for time require d to show a

display.

CER AM I C, PAPER, M ICA, AND FILM TY P ES:

Us e the ALL OT H ER CA P AC I TO R S posit io n of the

L E AKAGE R ANG E switch when t e s t in g t hes e c ap a

cit or s for leakage. The leakage r ea d i n g should take

only 2 to 3 seconds for an a ccu ra te dis pla y. In some

case s, w ith a very large value of c ap ac ity , a low leakage

re ad i n g may appear in the first second o r two and th en

cha n g e to 00.0. This is a normal cond itio n and merely

sho w s the capacitor is charging . If a re ad in g is still

pr e s en t after about five seconds, the cap ac ito r has

exces siv e leakage and should be conside red defective.

circuits. Wh en a lytic is fully ch arged, th e rea d in g will

change in small st ep s up and down showi ng th e ca p a

citor is charg ed . T he se small step s s impl y in di ca te t h a t

the c a p ac i to r und er tes t is a t te mp t in g t o filter small

changes in th e AC power line voltage. I t is not neces

sary, in mo s t ca ses, to wai t un til t he ca p ac it o r is fully

charged to de ter m ine if it is good. Just d e p re ss the

LE AKA GE b u t t o n until the leakage d ro ps below the

max im um allo wable level as shown on t he c h a r t in the

manu al or o n the pull out table on the bo t t o m of the “ Z

M ETER”.

If th e LAR GE ALUM . EL E C T RO L Y T IC (L0K uA

max) r an g e is used first a nd the rea din g d r o p s to 000,

simply c h an g e t he L E A K A G E RAN G E s w it ch to the

ALL OTH ER C A PA C IT OR S (100 uA max) range

while de pr e ss i ng the LEA K A G E b ut to n. Ignore the

first tw o r e ad i ng s a ft er ch ang ing ra ng es a s the rang e

switch ing cha ng es the series imped ance which in tu rn

causes a m o m e nt ar y cha nge in the charg ing ra te .

130

S PECIAL NOTE O N L OW V OL TAGE C ER AMI CS :

Ceram ic capacitors of 50 wo rk in g vol ts or gre at er hav e

a ver y high insulation re sistan ce an d s ho u l d no t sh ow

a n y leakage on the lea kage test. Ceramic capacitors

w i t h a lower w o rki ng voltag e tha n 50 Vo lt s have a

m u ch lower i nsulat ion resi sta nc e a n d m ay shoiv lea k

age on the leakage test. The act ua l in su l a ti o n r esi s

tan c e va ries fro m m a n uf a ct ur e r to m an uf a ct ur e r, bu t a

gen e ra l rule o f th u m b is: 16 wo r ki ng vo lt capacitors

ma y sho w as muc h as 16 u A o f lea ka ge and be w it hi n

tolerance. 25 Volt ceramic capacit ors m ay show up to

2.5 u A of leakage. It is b es t to m a k e a com p a r is o n test,

i f po ss ib le, with a kn o w n g o od ca p a ci to r a n d the su s

p ect ca pacit or wh en in doub t I n most cases, t he se low

vo lt a g e capacitors will on l y be u s e d in circu its where

th is hig h leakage will not u p s e t th e cir c u it operation.

AL UM INU M LYTICS:

Th e alu min um lytic charg ing time will v a ry w ith t he

ca pa c it y and th e applied leakage vo ltag e. On larger

lytic s, the m eter will overra nge (showing flas hing 888)

un ti l the c hargin g cur re nt drops b elow 10 mA. The

ty pi ca l amo un t of time tha t the m et e r will o verr ange

can be determined from cha rt 2. The d ispl ay will

usu al ly begin a t a high leakage r ea d in g an d then drop

wi t h each u pda te of the digital di spla y. Th is show s the

c h argi ng ac ti o n of th e ca pa ci t or thr ough th e

imp ed an ce of the APP L I ED V O L TA G E power sup ply

Capacity (u F)

Chart 2 — Me t er overrange tim e ve rsus c ap ac it or value

and app li e d v olt a ge .

NO T E: S ome lyt i cs may sho w a good value reading

and a lo w l eak ag e reading a nd be a q u es t io n a b le co m

ponent. If th e value is rechecked a fte r the leak age is

chec ked an d the capacit y is lowe r than f i r st chec ke d

and b eg i n s to increase to wa rd the original value, the

lytic is e x hi b i t i n g dielectric abs orption. T h is ge ne rall y

occurs w h en the electrolite in the lyti c begin s to d ry

out. Th e capa c ito r does n ot c o m p le te ly d is ch a rg e and

the re sid u al volta g e reduces th e c h ar gin g time ma k i n g

the ca p ac it or appear to be a smalle r value. I f a capa

citor ex h i bi ts dielectric absorption, try r e fo r m i n g the

capacitor as ex p la in ed in “Ref o rmi n g Ly t ic s on the “Z

METER ” or ‘ Ref o rmin g L yti c s with a Po w er S u pp l y ”

covere d l a t e r in t hi s manual. I f the ly ti c stil l sh o w s

dielectric ab so r pt io n a fte r reforming, the l y t i c s h ou ld

be con si de r ed defect ive.

TANTALU M LYT IC S :

Ta n ta l u m ly tics have a much lower l eaka ge comp ared

to alum in u m lytic s for the sa me cap aci ty and working

voltage. T a n t al u m lytics should, in mo s t cases, be

checked on the AL L O TH E R C A P A C IT O R S r ang e of

the L EAKAG E RA NG E switch. T a n t al u m l ytics will

give a leak ag e rea di ng in a very s h or t peri od of time,

ju s t a ma t t e r of 2 to 5 seconds.

16

Page 17

LEAKAGE CHARTS

The following leakage c h a r t s ar e the s ame ch a rt s t h a t

you will find on the pull ou t t ra y on the LC53 *'Z

vIETER". They show the ma x imu m allowable leakage

of common lytics and t a nt a l u m lytics. Note t h a t these

figures are t he wors t case c on di tio ns as specified by

the Ele ctronics In du st ry As so ci at ion (El A) s ta n da r d s

ItS-345, and m an y lytics will show leakage values well

below these figures.

MA XIM UM A L LOWABLE LEA K AGE (in micro a mps)

Sta n d a r d Al uminu m Electr o l y tic Ca p a c it o r s Stand a rd T a ntal um Ca p acit ors

Capacity

in ijF

1,000

1,500 400

2,000 470

5,000 740

10,000 Ί

20,000 1470

50,000 1700

100,000 3300

200,000

3V

1

3

5

10 5

15

20 5

25 5

30

35 6

40 6

50 8

70 11

100

150

2"0

250

300 45

400 200

500 230

750 290

40

340

1040

4650 6600 8 500

15

22

30

1 0 V 1 5V

6V

5

5

5

5 5

5

5 5 5

5 5 8

5

5 8 13

10 15

6

13 20

8

5

9 15 25

10

18

12 20

15 25 40

20 35 190

30 50 230

45 230 280

200 270 330

230 300

250 330

290 38D 470

330 4 20

520 640

400

470 600 740

740 900

570

660 850

1040 1340

1470 1900 2320

2070 26 80 3290

2340 4 24 0 5200

4650 6000

50 V 10 0V

25 V

5

5

5 5

5

5 8

6 13

13 25 50 270

20 40

5Π

25

30 220 300 420

40

230 330 460

28

45 250 360 500

30

190

270 380

210 300 420

250 350 500

300 420 600 850

370 520 730

420 600

370

470 670

400

S20 730

660 850 1200 1700

520

670 950 1340 1900

820 1160

950 1340

1160 1640 2320

1040

1340 1900

1640

2120 3000

3000

424Θ

6000

4240

9500

6700

7350

9500

200 V

5

15 30

25 50

230

270

1040

850 1200

950 1340

1040 1470

1640 2320

1900 2680

3286

2700

4240

300 V

15 20

10

45 200 below

230 270

330

330

400 4 60

460 540

380

520 600

570 660

620

540

660 760

600

730 850

710

870 1000

1040 1200

1300 1470

1470

1640

1800

2Q8Q

2320

2450

Non-polarized lytics should be m ea s ur e d for leakage in

bo th directions. Make the leak a ge t es t, then reverse

the te st leads an d r e pe at the te s t. Some non-polarized

lytic s have one lead connec ted to the case. The

allowable leakage on these ty p es is twice t h a t of a

reg u la r lytic of the same cap aci ty a n d v olta ge r at in g in

bo t h directions.

400 V

380 3.3

700

1550 220

Capacity

in u F

1.5 and

2.2

4.7

6.8

10

15

22

33

47

68

100

150

330

470

680

3V 8V 1 0 V

ALL CAPA CITOR S IN

THI S A RE A SH OUL D

J>hUW IMU

L EA KAGE

1.5

2.5

1.5

2 3.5

1.5 3 5

2 4.5 7

14

22

10

20

3 6.5

5 10 15

7

10.5 20

15

20

1 5 V 25V 50 V

1.5

2 3.5

2 2.5

2.5 4 6

3.5

5.5 10

8.5

5

7.5 12 20

11 15

16

20

14

20

1.5

2

2.5

5

Use LARGE ALU M I

NUM ELECTROLYTICS

Use ALL OTHER

CAPACITORS Range

Range

Chart 3 — Max i mu m a llo w a b le lea kage for Al umi nu m and

IDENT IF Y IN G CA P AC ITOR TYPES

The capacito r ha s i ncreased in use tr em endo us ly in the

pa s t few yea rs. M any new type s and i mproved

versions are now in use. The following info rma tion is

orovided as a guide to aid in th e identif icatio n of the

,ype of cap ac ito r a nd its valu e. Th e color code ch a rt s

cover mo st of t he v ar ia tio n s t hat will be encou ntered.

There may be oth er s not cov ere d here an d in those

cases, c on su lt t he m a n u fa c t u re r of the eq ui pm e nt for

information.

Tan t a l um ly ti c s per El A sta n dar ds .

TANTA LU M LYTIC S :

Ta n t a lu m l ytic s are be ing f ou nd in m or e electronic cir

cui ts th a n ever before. Its low leakage curr e nt and

sma ll er phys ical size has m a de it a st a n d o u t for solid-

st a t e circuits. The tan t a l u m lyti c s can be m ade to

tigh t e r tolerances tha n alum in um lytics. Tan ta lu m s

are no t mark ed as such and th e sche m ati c generally

does n o t indica te t he lytic as a t a n talum . The ta n t al u m

lytic is smaller (abou t one-half or less) tha n t he same

ca pa c it y a nd voltage a lum i nu m lytic. The ta n ta lu m

17

Page 18

comes in m an y sizes and s ha p es as shown in figure 9.

Some use a color code like t ha t s h ow n in figure 9. No te

th a t the color coding can show the p ositi ve lead. Some

tan t al u m s are m ark ed with t h e v al ue a nd a + on the

posit ive lead. Oth e r t a n ta l u m s use th e shape of the

lead or a r ou nd in g of a corner to indic a te the p ositiv e

lead.

Typ i c a l Physical Sha pe s of

Commo n Ta n t a l u m C apaci t ors

FILM TYP E S:

The s e are th e h a r de s t to identify as t o t h e t yp e of film

bei ng used. The typ e of film is no t ge ne ral ly m ark ed

and i t could be any one of at leas t five t ype s. On these

cap ac it or s, you will have to cons ult t he ma n u f a ct u r e r ’s

service infor ma tion for t he co rrec t typ e. It shou ld be

no t e d t ha t a Mylar® ca pacito r is not a universal

rep la ce m en t for any film typ e cap ac ito r. Ea c h film has

diff e ren t cha rac te ris tic s a nd m u s t be r ep lace d wi th the

sa m e ty pe of film used in the circuit. T hi s is especially

tru e in t ho se a rea s of s che ma tics that are de sign ed as

“ S af e ty C riti ca l” .

TE S T I N G FOR DIELECTRIC A B SORPT I O N

Dielectri c abs or pt ion is the inab ili ty of a cap aci tor to

com ple te ly d ischa rge to zero. This is s o me ti m es called

“ba t t e r y a c ti o n ” or “c apa cito r me mo r y ” a n d is due to

the dielectric of th e c apac itor r e t a in i n g a c harg e. All

ca pa c it or s have some dielectric ab s or p t io n , b u t electr o

lytic ca pa ci tor s have th e hi gh est a mo u nt an d will often

affe c t cir cuit op er atio n if it b eco mes excessive. You

can c heck lytics for dielectric a b s o rp t io n d u r in g the

no rm a l t e s t for c ap aci tor value an d lea ka ge by simply

ree he ck ing th e valu e of th e ca p ac ito r a f te r the lea kage

te s t in th e following man ner.

Fig. 9 — T a n ta l u m lyt ics co m e i n all size s a nd shapes.

The m o s t co m mon shap es are s ho wn here for identifi~

catio n o f the pos i ti ve lead.

CE R AMIC DISCS:

The ceramic disc is well-known an d c an be identified by

its round sh ape and generally b r o w n color. Some cer a

mic discs come in different co lors such as blue and

green due to a different co a t i n g materi al on the

outside. M o st ceramic discs a re m a r ke d wit h the value

and the tolerance. T he m ost c o m m on wo rkin g vol tage

(500 Volts) is gene rally not m a r ke d , b u t a n yth in g dif

ferent is normally found on t he cap ac i to r body. Th ere

are ot her marki ng s such a s NP O , GMV, N1500, or

similar. These a re th e t e mp e ra t u re coefficients or how

muc h the ca pa ci tor will ch a ng e with a change in

tem pe ra tu re. W he n repla cing a ce ram ic disc, be sure to

use the s ame ex a ct type t ha t w as use d in the original

circuit. NPO s t a n d s for Ne gativ e-Pos itive-Z ero or no

chang e in capaci ty. GMV is Guar a nt ee d Minimum

Value and th e a ctu al value could be muc h higher. Th e

let te r N in dicate s tha t the ca p a c i ty will decrease wit h

an increase in t em p er at ur e, an d if yo u find one w it h a

let te r P, t h a t one will incre ase in capacity with an

increase in tem p er at ur e. Fu r the r information will be

found in t he sectio n on “ C a p ac i to r Theory and th e ‘Z

METER’ ” a nd in the G lo s sa ry at the back of the

manual.

1. Co nne ct t he cap ac ito r to t he t e s t le ad s a n d t e st for

the c a pa ci tor value in the n ormal ma nn er . Note the

valu e of the capacitor.

2. T e s t the ca pac itor for l eakage a t t he ra te d work

ing v o lta g e of the capa citor. Allow t h e le aka ge c urr ent

sho w n on th e display to dro p to th e max i m um allow

able lea kage or below as shown on th e l eaka ge c h ar t in

the ma nu a l or on the pull out t ab u n de r t he meter.

3. Re lease t he L E A KA GE bu t t o n a n d allow th e d is

play to dro p to 000 and then i m m ed ia te ly depr es s the

VAL U E b u t t o n and note th e ca pa ci to r reading.

a. If th e c apa ci ty re ad ing is wi th in 5% of the origi

nal value and the re adi ng i nc re ase s slowly upward

tow a r d the original value, or th e re is no difference

in t h e r eading s, th e ca pacito r ha s v ery l ittle dielec

tric abs or pt ion and is good.

b. I f th e value re adi ng difference is gr ea t er th a n 5%

b u t less tha n 15%, the capa c it or m ay require

refo rm in g a s desc ribed later. So me of th e dielectric

oxide h as de te rio ra te d a nd r ef or m in g t he lytic m ay

br in g it back to a us eful life. R e ch eck for dielectric

abs or pt io n o ften a tt e m p t in g t o re for m t he capacitor.

c. If the valu e rea din g difference is gr ea t er than

15% and the rea din g c ha ng es u p w a rd rapidly

tow a rd th e origin al value, t h e ca p ac it or has exc es

sive dielectric ab sorp tio n. E le ct ro l yt ic capac itor s

exh ib iti ng t his much dielectric a b s o rp t io n may be

refor me d in some cases. If th e c a pa c ito r exhibi ts

simi lar dielectric abso rpt io n a f ter reform in g hai

been a tt e m p te d , it s hould be r epl ace d as it will give

tro ub le in the circuit.

N OT E: If a mi ca or film ty p e cap a ci to r s h o w s any

dielectric absorption, i t can be cons id e re d “b ad”

an d sho u ld be replaced.

18

Page 19

REF O R M IN G L Y TIC S ON THE “ Z ME TER ”

Alum in um lyti cs will ofte n show low value or hi gh

leakage if th e y hav e been s i tt in g on a shelf for a long

period of time. Ge ner al ly any alum inu m electrolytic

capac ito r sit t i n g on the shelf for over one year will

show up in this m a nn e r. This is caused by a loss of

some of th e oxide c o at in g t h at forms the dielectric of

the capa cito r. In m a n y case s, th e oxide coatin g may be

reformed with the a pp li ca tio n of a DC volta ge for a

period of time. The “Z METER” can reform the

dielectric m a te ri al by u si n g t he same DC power sup ply

tha t is used for leak a ge tes ting . R eform in g ma y

require m ore th a n an ho ur before the c ap aci to r r et u r ns

to its no rm al cond itio n. The 39G145 T E S T B U TT O N

HOL D D O W N R OD is includ ed with the “Z M E TE R”

to hold the LEAK AGE b u tt o n down for re form ing

lytics. A spe cial clip is mounted on th e rear of th e

in st r u m e n t for s t o ra g e of t h e 39G145 when it is no t in

use.

W A RN I NG

Use the 39G145 wi th extre me caution! Do not

touch the t e s t le ad s or t he capacitor leads while

the 39G145 is being used. Make su re tha t the

cap ac ito r being re fo rm e d will not to uch any

metal or come in co n t a ct with any me tal object

while it is being re fo rm ed . The vo lta ge from the

A PPLI ED VOL T A G E switch is pr es en t on the

te s t lea d s when the LE AK AG E b ut ton is

depres se d.

S PECI AL N OT E : This met hod of hold i n g the

L EAKAGE but to n in pro vid es a greater degree of

saf e ty than a “lat c hing " typ e of s w it c h . A lway s

observ e ex tr eme cau tion when y ou see the handle in

fro n t of the s wi tch es as t h i s will tell you voltage is

being ap plied to the test leads and. capacitor. Neve r

at t e mpt to operate any o t h e r fun ct io n pus hb u t t o ns

when the 3 9 G145 is being used.

iAPACITORS | INDUCTORS

w um'tiT o w n I ftN w our w fjn c iim

LEAKAGE V AtU t I VALUE RINGING TEST (G)

Fig. 10 ~ Th e 39G145 Tes t bu t t on H o l d D ow n R o d can

be used to k ee p the LE A KAG E bu tt on depressed

when refo r mi ng a lytic on th e “ZM ETER".

REFORM ING LYTICS WIT H A POWER SUPPLY

NO T E : Ob s er v e th e red area on the APPLI ED

V OLTAGE sw i tc h . This i7idicat.es a voltag e of 50 to

600 Vol ts DC an d can be dangerous. The specia l LED

will also blink on a n d o f f to indicate th a t the

APPL IED V O LTAGE s w i t c h is se t to 50 to 600 Volts

bu t rely on t h e red area of th e s w i tc h in case th e LED

burns out.

To Use the 39 G145 Te s t B u t t o n Hold Down Rod:

1. C onn ect the lytic to be reformed to the t e s t leads

obse rvin g pol ari ty ,

2. Select t h e pr o p er vo lta ge with the AP P L I ED

VOL T A GE sw itc h. O b s er v e the above w arn ing when

using 50 Volts or more.

3. Dep r e s s th e LEAK AGE but ton , a n d wh ile

holding th e b ut ton in, plac e th e 39G145 on th e b u tt on .

Bring th e h an dl e to t he fr on t of th e mete r and wedge

the 39G145 b et we en th e hand le and the LEA K A G E

bu tt o n so that the rod holds t he L E AK AG E butt on

depress ed.

4. A fte r the c a p ac i to r h as been refo rmed for at le ast

one hour, i t s ho uld be allowed to d isch arge an d sit for

ab ou t 30 min ut es . T he n rechec k the value and t h e leak

age to see if th e r ef or m in g pr ocess ed ha s impro ved the

capacito r.

A s ep a ra te DC power s up p ly ma y be used to reform a

capacitor. The power su p pl y mu s t have a vol tage

ou t p u t equal to the c ap a c ito r s working voltage, and

should be ad ju sta bl e from zero to allow the vol tage to

be increas ed slowly. The po we r supp ly should also

have a DC cu rr en t m e ter or an e xt er na l m eter m u s t be

used to mo nit or the ch a rg in g curr en t.

■CAUTION·

Always use a series li m it in g r e si st or when apply*

mg v olta ge from an ex t e rn a l po wer su pply. This

will prev en t th e c ap ac ito r fro m cha rgi ng too f as t

which may cause p e rma ne n t dama ge to the

capacitor.

-W A R N ING -

Voltag es from 50 to 600 Vo lts can be dangerou s.

Do not to uch th e leads fro m th e power sup ply or

the leads of th e capa cito r. Do n o t allow the ca pa

citor to come in co nt ac t wit h m et al or any metal

object while the vo lta ge is be ing applied. A w a rn

ing sign shou ld be place d on or n ext to the unit

while the capacitor is bein g reformed.

19

Page 20

To Use the E x t e rn a l Po we r Su pp ly to Reform Lytics:

1. W it h the power su p p ly turn e d OFF, connect the

positive power sup pl y t er min al, t hr o ug h a 1000 Ohm, 5

Wa tt re sis to r and the ex te rn al cur ren t met er (if

required) to the p o sit iv e term ina l of th e lytic to be

reformed.

2. Connect th e ne g ati ve te rm ina l oi' the power supply

to the negativ e ter m ina l of the lytic.

3. Set the ou t p ut vo lt a ge contr ol on the power supply

to minimum.

4. T ur n t he po wer s up p l y to ON and slowly increase

the volta ge while w a tc h in g the c ur re nt met er. Do not

allow the ch ar gi ng c u r re n t to go above 50 mA. If the

meter re ad s h ig her th a n 50 mA, stop in cre asing the

voltage until th e cu r re n t dro ps below th is level. Then

slowly i ncrease t he vol tag e aga in while w atc hin g the

current me ter unti l the DC working v olta ge of the

capacitor is reached . Allow the ca pac itor to rem ain a t

its full rated wo rki ng vol ta g e for at least 30 m in ut es to

one hour.

5. After one hour, t u r n the power supply off and

allow the capa ci to r to di sch ar ge . After th e cap acito r

has disch arg ed for at l ea s t one hour, recheck t he value

and leakage on the “ Z M ETER ” to see if further

reforming is necessa ry.

LEAKAGE IN CERA M IC, P AP E R , FILM, AND

MICA C A P AC IT O R S

Ceramic, paper, film, and mica t y p e c ap aci tor s should

not show any lea kage at all. T he m a xi mu m allowable

leakage is below the s e ns it iv it y of the m ea sur ing

circuit. If any of thes e t ype c a pa c it o r s e xhibit leakage,

they are defective.

CHEC K ING FOR LEAKAG E B ET W EE N

SEC T IO N S OF A M ULT I-SEC T I O N LYTIC

Multiple section lytics are co m m on in m an y power

supplies. Lea kage so me tim es d ev elo ps b etw een two or

more sections of a multiple secti on type. This leakage

may be due to an i nte rn al sh o r t circ uit , or a build-up of

di rt between the term ina ls on the outside of the

capacitor. This t yp e of leakage is p a rti cu la rl y difficult

to tro ubl esho ot bec ause th e s ig na l f rom one section of

the ca paci tor is coupled to the o th er section which

res ul ts in multipl e sym p t om s in the o pe ratio n of the

device in which the capac itor is used.

An ohm m et er will often fail to show this leakage

because it only occurs at or nea r the capaci tor 's

ope ra tin g voltage.

The “Z M E TE R” will quickly lo cate thi s type of leak

age while p erfo rmi ng the st a n da r d leakage test. The

sections t h a t are n o t b ein g t e sted for leakage are

simply shorte d out while t he leak age of the first

section is being m onit ore d wi th the LC53 cu rre nt

meter. An increase in l eakage in di ca te s interna l leak

age between sect ions and a bad c ap aci tor.

Fig. 11 — A lyt i c ma y be refo rm ed with an externa l

pow er s u p ply bein g sure to us e a series re sis tor a n d a

current m e t e r to m on it o r t he r efo rm in g cu r r e n t

CAPACITOR TEST ING

APPLICATION TIPS

NO VALU E REA D ING ON SM A LL

VALUE CAP ACI T ORS

A sh ort ed cap a ci to r will n orm ally give a 000 read out.

However, th ere a re some capac itor s, generally below

1000 pF, th a t are not s ho rt ed , bu t will still give a 000

readou t on c ap ac it or VA L U E . If the leakage of these

capacitors is measure d, it will be discovered a low

value leak age c u rr e n t is pr ese nt. This small' value of

leakage cur re n t will u p s e t the capacity measuring

circuit of the ” Z METE R” and cau se the 000 readout.

----------------------------

The following procedure sh ou ld only be per

formed by a qualified pe rso n who un de rs ta nd s

the potential hazar d of up to 600 Volts being

applied to the te s t leads while mak in g the leak

age test. Do not touch th e R ed te s t lead clip or the

capacitor term inal it is conn ect ed to du ring the

tes t or while the LE A K A G E b u t t o n is depressed.

To tes t for leakage be tween s ect io ns of multi-section

capacitor:

1. Connect one section of the cap aci tor to th e tes t

leads observing polarity.

2. Set the APP L I E D v ol ta ge swi tch to th e proper

voltag e for the sect ion being t es te d . Be sure to use the

correct vo lta ge as ma ny multi- se ctio n ca pacit ors have

different voltages for each section.

3. Dep ress the L E AK AG E b u t t o n and obs erve the

leakage curren t read ing on the display.

4. Using a s ho r t jum per, con ne ct one end to the

common terminal of the c ap ac it or and th en while

depre ssin g the LE A K A G E bu t to n , connect the other

end of the ju mp er to one of t h e o th e r term inals of th e

capacitor not connected to th e t e st leads. A good lytic

will show no ch ange in the lea kag e r eading. A ca paci

tor with leak ag e be tw ee n s e ct i o n s will show an

W ARNI NG

-----------------------------

20

Page 21

incr ea se in l eaka ge when the sh o rt is ap plied to the

unt e s t e d ter mina l.

NOTE : Be su re to te s t all th e terminal s of the mu l t i-

se c ti o n lyti c a ga in s t each oth e r for leakage b e t we e n

sect io n s.

Fig. 12 — Te s t the l eakage of one sect ion an d then

sh or t one o f t h e oth e r se cti ons to ground. An incre as e

in l ea k ag e c u rr e nt s h o w s l eak age b etw e en th at s e c ti o n

and t h e one u n d er test.

LARG E F L U C T UAT IO NS IN LYTIC

LEA KAG E R EAD IN GS

often be refor med to i ts o rigin al ca pac ity wi th the “Z

M ETER” or powe r supply or when placed in the

circuit and allowed to ru n for a period of time.

LOW VALUE LYT I CS USED IN HIGH

FREQUENCY CIRCU IT S

Low value ly tics (1 u F to 1000 uF) used in high fr e

quency filtering ap pl ic at io n s s uc h as switc hing powe r

supplies and AGO ci rc uit s in television can develop an

above normal i nt er na l series res istanc e. In these app li

cations, the series re si sta nc e will interfere with the

filtering action of th e capa ci tor and imprope r ci rc uit

action will result. I n th ese rare occasions, the c ap aci to r

could be p ut to u se in a con ven tion al 60 H ertz pow er

supp l y an d funct ion n or mal l y . B e c a u s e thes e

capacito rs will fun ct io n norma lly at 60 Hertz, t hey

may no t show up a s b ad on the “Z ME T ER” . In fact,

the leakage of th e h ig h in ter nal series r esis tan ce c a p a

citor m ay even be lower th an a good capacitor. If th is

is the case, conne ct a scope us in g t he Lo Capaci ty

probe across the capa c ito r an d observe the ripple

waveform when che ck ing leakage. If the waveform ha s

tips, as shown in F ig ur e 13B, the ca pacito r has a series

inte rna l r esis tan ce t hat will in terfere with circuit o p er

ation an d should be replaced. If no tip s are ob served,

as shown in F i g ur e 13A, then the cap aci tor ha s ve ry

low or normal inter n al series resistanc e.

Lea k a ge rea d in gs on lytics will normally st ar t at som e

hig h va lue and then de crease a s the c apac ito r c ha r ge s

up. When t he ca p ac ito r is fully cha rged, th ere will be a

sma ll var ia tio n in the l eakage rea ding i nd ic at in g t h at

the ca p ac it or is tr yi n g to filter out the small v a ri a ti o n s

in t h e line volta ge. When th e va ria ti on s bec ome r a th e r

la r g e a n d c ha n ge in la rg e jump s , s us pect an

in t e r mi t t e n t lytic. Lytics t ha t e xhibit this s y mp t o m

will give tro ub le in the circuit an d should be rejecte d.

LEA KAG E M E A S U R E M E N T S OF

NO N-P O LAR I Z E D LYTICS

Le a ka g e m e as u r eme n ts on non-polarized ly ti cs mu s t

be ma d e in b o t h di rectio ns. Simply make th e lea ka g e

te s t, note the leakage c urre nt, and then reve rs e the

lea ds and ma ke th e le akage t e s t again. If bo t h e n d s of

th e no n-polar ized lyti c are i ns ul at ed from th e c ase, th e

ma x imu m allowabl e leaka ge is the sam e as lis ted in t h e

leak a ge c ha rt . If o ne end is co nnect ed to the c ase, the

allow abl e le ak ag e is doubled.

LY TICS SIT T I N G IN S TO CK

Ly t i c s t h a t hav e been s it ti ng on the shelf ma y show

high leak age whe n checked. Th ese lytics should be re

form e d accor di ng to the inform atio n in this ma n u al

un d e r “Refo rm ing Lytics with the ‘Z M ET ER ” ’ or

“ R ef o rm i n g L yt ic s with a Po wer S u pp l y” . G en era lly , a

lytic t ha t h as been s it ti ng a nd is checked for valu e a nd

th en le aka ge m a y i ndic ate a larg er capac ity v al ue wh en

the valu e is rec hecked. For example, the l yt ic m a y

m ea s u re 1000 u F when tes te d before p er fo rm i ng th e

lea ka g e check. W hen the va lue is checked a f te r the

leak a ge t est , t h e value may now be as high as 1100 uF .

Th i s ind ic at es th a t the lytic was p art ial ly refor me d

whe n the lea ka ge wa s t est ed. This type of ly tic c an

Good 2 .2 uF leakage rip pie .BV /Pi v.

Defective 2u F leakage r ipp le ,5V /0 iv.

Fig. 13 — T he sc o p e wa v ef o rm sh o w n in A is a g oo d

capacito r w it h no i nt e r na l series resistance. B sh o ws a

def ec ti ve c apac itor wit h inte rn al series resis tan ce as

det e c te d by the s p i ke s a t the top of the waveform.

INTE R M IT T EN T C A PACITORS

Occasionally, a cap ac i to r can become i n te rmit te n t. A

poor weld of t h e lead to the foil or oth er m echanica l

malfunctio n ca n c a us e t he ca pac ito r to opera te in a

rand om fashion. Th e leads of t he susp ect ed capac ito r

should be moved a ro u n d or pulled on when m ak ing t he

Value te st. A ch a n ge in cap ac ity indic ates an int e r

m it te n t problem.

21

Page 22

An in t e r mi t t e n t c au s ed by a ba d weld can s om etim e s

show up as f las hin g 888 on the meter. This is due to th e

cap aci ty c h a n g in g a t t he time the V A LU E b u tt o n is

depr es se d a n d the m e te r can no t lock in on a range.

INTERNAL CONSTRUCTION OF

ALUMINUM ELECTROLYTIC

Ins ula t o r

Posi tiv e

Lead

Tab C o n ne c ted

To An o de Foil

Tab

We ld e d

To Lead

Paper

Impre gn a te d

With

Elec tro ly te

Tab Conn e cte d

Rolled

to Other Foil

Foil

Alum in um Lead

Case

Tab Wel de d to

Alum i n u m Case

Neg a t iv e

Fig. 14 — A lyt i c can be come i n t e rmit t en t if the wel d is

not pr oper on e i th e r tab or becomes corroded a f t e r a

long peri o d o f use.

TIM E REQU IR ED TO OBTAIN A VALUE

READ IN G ON A C A PACIT O R

Cap ac it or s of 1000 u F and below will read almo s t

ins ta n ta n e o us l y. More t ime is required for c ap aci tor s

above th is value. Th e a ctu al time dep end s upon t h e RC

time c o ns t a n t of t h e capacitor. For example, a 50,000

uF will re a d in only 5 seconds an d a 100,000 u F ta k es

only 10 secon ds. The meter will re ad 000 until the

cou n ti ng c ir cu it h as reac hed the pro per level a nd the n

the ca p a c it y re ad i ng will app ear on the display.

soldering iron or h e a t g un , the te m pe ra tu re va ria tion

can be seen. If the c a p a c it o r is ma rke d COG or NPO,

for example, the ca pa c it y sh ould no t chan ge or cha nge

only slightly. If t he c a pa c it or is mar ke d with an N,

such as N1500, t hen th e c ap a ci ty will decrease as long

as the h ea t is applied un ti l the lower limit is reached.

Capacito rs m ark ed wi th th e lette r P (not in common

usage) will increase ca pa c it y with th e application of

heat.

CHECKIN G FILM TYPE C A P ACIT ORS FOR

TEMPERATURE SEN S I TIV I TY

Fil m ty pe c a pa ci t o rs ca n bec o m e t e mp er at ur e

sensitive and cause pr o bl e m s in the circuit. By con

necting th e su spe ct c a p ac it o r to t he “ Z METER” and

tes tin g the capa city whil e a pply in g he a t from a sold er

ing iron or he at gun or s p r a y in g w ith a “freeze spr a y ”,

the change in capacity c an be seen. Mo s t film ty pe cap

acitors should change very little in capacity. If a

dras ti c change is seen, t he capa cito r has become

tem pe ra tu re sen sitive an d sho uld be replaced. A word

of c autio n here — do no t to u ch the sold ering iron to the

capacitor. The heat c an da m a g e the sens itive plastic

film used as a dielectr ic and mak e the capacito r

useless.

TESTIN G C A P A CITY OF SIL IC O N DIODES

AND TRA N SIS T OR S

The “ Z ME T E R " can me as u re the cap acity of silicon

diodes and tr an si st or s. T h e reverse leakage paths

aroun d t he tra ns is to r a n d diode can also be measu red

within the limits of th e le ak a ge power supp ly of the “Z

M ETER”. The c on ne ctio ns to m easu re capacity and

leakage are the s ame a n d th e prope r lead connections

are shown in figure 15. i f th e rea do ut shows 000 when

tes t in g for ca pac ity or fla shin g 888 when t es tin g

leakage, the leads a re rev ers ed. No p rec auti ons are

necessary when t e s ti n g ca pac ity , but the following

guidelines should be o b se rv e d when te s t in g leakage.

1. Use only the 3 V o lt position of the AP P L IED

VOLT AGE switch wh en t es t i n g Ibeo.

On ver y lar ge c ap ac it or s, generally ove r 100,000 uF ,

the f ir st r e a d in g m a y differ from l ater read ings by a s

mu ch as 10 p er ce nt. This is normal an d cause d by th e

dielectric ab so r p t io n f ound in mo s t type s of c ap ac i

tors. Th is s li gh t cha ng e in read ings shou ld c ause no

prob le m b e ca us e t h e tolera nces of thes e ca pa cito rs a re

gene rall y -20%, + 80% which m ea ns th a t the fi r st

read i ng will be close e no ug h to locate ca pac ito rs t hat

have ch a n ge d va lue ou tsi de the tolerance limits. I f you

requi re a v ery pr ecise reading, simply leave th e

Cap a cit or V AL U E b u t t o n depres sed until the “ Z

METE R” has gone th r ou g h a t l eas t 2 co mplete r e a d

ing cycles.

CH E CK ING CERA M IC CA PA C IT O R S FOR

TEM P ERA T U R E SE N S IT IV IT Y

Cer a mi c cap a ci tor s (often called disc ca p a c i to r s

becaus e of the ir phys ical appearance) come in a wide

var ie ty of c ap a ci ty valu es an d t em p e rat u re toleran ces.

By c o nn e ct in g th e ca pac itor to the “ Z MET ER" and

check ing the ca p ac it y and t hen a pply ing he at fr om a

2. Use the setti n g of th e AP PL I ED V OL TAG E

switch t h a t m at ch es th e m ax im um applied voltag e to

the tr a ns is t or when te s t i n g Icbo or Iceo. Do not exceed

the ra ti ng s of the tra n s is t o r. The t r an s is t o r will go into

a zener mode and gi ve a n inco rrec t leakage reading. If

left in this manner, it could da ma ge th e tra ns ist or.

NO TE : The capac ity of g e r ma n i u m transi sto rs and

diodes ca nn ot be m ea u sr e d. T h e high leakage of these

devices will up set t h e c a p a c i ty m e a su r in g circuit o f the

“Z ME TER ' ’" and th e re a d o u t will sh ow flas h in g 888

when the V AL UE but t on is depresse d. The leak age o f

ger m a n i u m dev ices can be mea s ur e d with the leakage

te s t th e s a me as t he s il ico n devices. D o not exc ee d th e

voltage rating o f the d e v ic e as ge r m a n iu m devic es cun

be dam a g e d quite easily.

22

Page 23

PNP

Black

ICBO and

B to C Capacity

/

Red

ICE O a n d

*

Red

\

IBEO and

B to E Capacity

' Black·**

E to C Capacity

NPN

^Red-#*.

ICBO and

B to C Capacity

Black

4

Black