Page 1

SMP100

User Guide

V2.0-N

Page 2

SMP00 User Guide

i

Revision History

Date

Version

Description

Author

2/30/2013

1.0

First Draft

AY

12/05/2016

1.06

New UI

MS

6/30/2017

2.0-N

Module Update

HL

This guide contains some symbols to call your attention.

DANGER

The DANGER symbol calls your attention to a situation that, if ignored, may cause

physical harm to the user.

CAUTION

The CAUTION symbol calls your attention to a situation that, if ignored, may cause

damage to Our product.

NOTE

The NOTE symbol calls your attention to important information.

TIP

The TIP symbol calls your attention to additional information that, if followed, can

make procedures more efficient.

Red Arrow

The Red Arrow symbols point to import details mention the context above or below

an image.

Blue Arrow

The Blue Arrow symbol indicates the motion path of an item in an operation step.

Thick Arrow

The thick Arrow symbol calls your attention to a serials of operation steps

mentioned in the context.

This guide also contains the following text conventions.

Bold Italic

The bold Italic text indicates a button to click, an item in the drop-down menu to

select, or a certain item in the UI.

Page 3

SMP00 User Guide

ii

Safety Instructions

Read these instructions

Keep these instructions

Follow all instructions

Heed all warnings

Do not use this unit near water.

Only use a damp cloth to clean chassis

Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat

Do not block any ventilation openings. Install in accordance with the manufacturer’s

instructions

This unit is grounded through the power cord grounding conductor. To avoid electrocution,

do not remove the power cord before the outlet is switched off or unplugged. If the plug does

not fit into your outlet, consult an electrician for replacement of the outlet.

Route power cords and other cables so that they are not likely to be damaged.

Only use attachments/accessories specified by the manufacturer.

Do not wear hand jewelry or watch when troubleshooting high current circuits.

Do not work on the system during periods of lightning.

Refer all servicing to qualified service personnel. Servicing is required when this unit has

been damaged in any way.

Damage Requiring Service: Unplug this product from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

When the power-supply cord or plug is damaged.

If liquid has been spilled, or objects have fallen into the product.

If the product has been exposed to rain or water.

If the product does not operate normally by following the operating

instructions. Adjust only those controls that are covered by the operating

instructions as an improper adjustment of the controls may result in

damage and will often require extensive work by a qualified technician to

restore the product to its normal operation.

If the product has been damaged in any way.

Replacement Parts: When replacement parts are required, be sure the service technician

uses replacement parts specified by the manufacturer. Unauthorized part substitutions made

may result in fire, electric shock or other hazards.

Page 4

SMP00 User Guide

iii

SAFETY PRECAUTIONS

There is always a danger present when using electronic equipment.

Unexpected high voltages can be present at unusual locations in defective equipment and

signal distribution systems. Become familiar with the equipment that you are working with

and observe the following safety precautions.

Every precaution has been taken in the design of the products to ensure that it is as safe as

possible. However, safe operation depends on you the operator.

Always be sure your equipment is in good working order. Ensure that all points of connection

are secure to the chassis and that protective covers are in place and secured.

Never work alone when working in hazardous conditions. Always have another person close

by in case of an accident.

Always refer to the manual for safe operation. If you have a question about the application or

operation contact the provider for assistance.

Electrostatic Discharge (ESD) Caution:

Always wear an ESD-preventive wrist or ankle strap when handling electronic components.

Handle cards by the faceplates and edges only. Avoid touching the printed circuit board and

connector pins.

Avoid touching any electronic components while holding any module in hands.

Danger of explosion if battery is incorrectly replaced.

Page 5

SMP100 User Guide

iv

Contents

PART 1 SMP100 CHASSIS OVERVIEW ···························································································································· 1

1.1 FRONT PANEL ································································································································································· 1

1.2 REAR PANEL ··································································································································································· 1

PART 2 RACK INSTALLATION ········································································································································· 2

PART 3 WEB GUI ··························································································································································· 3

3.1 WEB GUI OVERVIEW ······················································································································································· 3

3.1.1 Connecting to the Management Port ·················································································································· 3

3.1.2 Logging into the Web GUI ··································································································································· 4

3.1.3 Dropdown Menu ················································································································································· 4

3.1.4 Service Configuration ·········································································································································· 5

3.2 BASIC OPERATIONS ·························································································································································· 6

3.2.1 Configuring Network ··········································································································································· 6

3.2.2 Configuring Input ················································································································································ 7

3.2.3 Clear and Bypass the Input ································································································································ 10

3.2.4 Configuring Output ··········································································································································· 11

3.2.5 Delete an Output TS/Program/PID ···················································································································· 13

3.2.6 Version Information/Upgrade ··························································································································· 13

3.2.7 License ······························································································································································· 14

3.2.8 Import/Export Configuration ····························································································································· 15

3.2.9 Login User Management ··································································································································· 15

3.2.10 Log ··································································································································································· 15

3.3 ADVANCED OPERATIONS ················································································································································· 16

3.3.1 Edit Output TS ··················································································································································· 16

3.3.2 Edit Service Information for DVB Output ·········································································································· 17

3.2.2 Upgrading STB through SMP ···························································································································· 24

PART 4 MODULE CONFIGURATION ······························································································································ 25

4.1 INPUT AND OUTPUT MODULES ········································································································································ 25

4.1.1 ASI ····································································································································································· 25

4.1.2 DVBC·································································································································································· 26

4.1.3 DVBS2 ································································································································································ 27

4.1.4 DVBT2 ································································································································································ 28

4.1.5 8VSB ·································································································································································· 29

4.1.6 QAM ·································································································································································· 30

4.1.7 IQAM ································································································································································· 31

4.1.8 OFDM ································································································································································ 32

4.1.9 8VSBM ······························································································································································· 33

4.1.10 HDMI/SDI Decoder ·········································································································································· 34

4.1.11 Decoder-AV ····················································································································································· 35

4.1.12 ASI-Switch ························································································································································ 36

Page 6

SMP100 User Guide

v

4.2 ENCODING MODULES ····················································································································································· 39

4.2.1 EN4AV-4M2B ····················································································································································· 39

4.2.2 EN4SDI-2M2A ···················································································································································· 41

4.2.3 EN4HDMI-xM2A ················································································································································ 43

4.2.4 EN2SDI-2H ························································································································································· 46

4.3 TRANSCODING MODULES ················································································································································ 48

4.3.1 TC4-xM2A ·························································································································································· 48

4.4 SCRAMBLING/DESCRAMBLING MODULES ··························································································································· 51

4.4.1 CI Descrambling ················································································································································ 51

4.4.2 CI-BISS Descrambling ········································································································································ 54

4.2.3 Scrambler ·························································································································································· 55

PART 5 APPENDICES ···················································································································································· 59

APPENDIX A - ABBREVIATIONS ··············································································································································· 59

APPENDIX B – MODULES AVAILABLE IN DIFFERENT REGIONS ······································································································· 61

APPENDIX C - WARRANTY ····················································································································································· 62

APPENDIX D - AFTER-SALES SUPPORT ····································································································································· 62

Page 7

SMP100 User Guide

1

Part 1 SMP100 Chassis Overview

1.1 Front Panel

SMP100 is a 1-U multi-purpose content delivery platform. Equipped with three hot-swappable

modules, SMP100 supports almost any video delivery application with flexible combination of

receiving, de-scrambling, transcoding, re-multiplexing/grooming, scrambling, modulating and IP/ASI

turn around.

1. Indicators ( For Power, ASI, TS/IP and decoder status)

Red or Flashing Red : Error

Green: Normal

Flashing Green: Initialing or loading a board

2. LCD Screen

3. Up, Down, Left, and Right buttons

4. Menu, OK, and Esc buttons

1.2 Rear Panel

Note the position of each slot on rear panel. Fasten the modules in the chassis by screws to avoid

loose connection between the modules and mainboard.

1

2

3

4

Page 8

SMP100 User Guide

2

Part 2 Rack Installation

Rack Installation

The SMP100 is designed to be mounted in a standard 19” rack. It takes 1RU of rack space. To install

it into a rack, please use the following steps:

1. Determine the desired position in the rack for the SMP100. Make sure that the air intake

on the top of the unit and the exhausts on the back of the unit will not be blocked.

2. Install the brackets at desired position if there’s no supporting plate in the rack.

3. Insert the rack mount clips into place over the mounting holes in the rack.

4. Slide the SMP100 into the position in the rack.

5. Secure the chassis to the rack by installing the four supplied screws through the front

mounting holes and tightening.

AC Power Connection

Only use the supplied 3-prong power connector or one with equal specifications. NEVER tamper

with or remove the grounding pin. This could cause damage to the equipment, personnel, or

property. Make sure the power outlet is switched off before plug or unplug the power cable from the

back panel. Power unit is designed to work under condition of AC100~240V, 50/60Hz. Max

consumption is 50W.

When you move this device from a cold condition into a warmer condition, it should be

acclimated to the warm and humidity condition for at least 30 minutes. Powering up a nonacclimated unit may lead to shortcut or other damage to electronic components.

Page 9

SMP100 User Guide

3

Part 3 Web GUI

3.1 Web GUI Overview

3.1.1 Connecting to the Management Port

Factory network settings of the Management Port:

IP address 192.168.1.241

Subnet Mask 255.255.255.0

Gateway 192.168.1.1

Use the following step to access the Web GUI in a browser.

Connect both SMP100’s management port and the computer’s Ethernet port to a switch by

CAT5 straight-through cables. If you do not have a switch, you can connect the computer

directly to SMP100’s management port.

Set the IP address of the laptop/computer in the same network with the SMP100 management

IP address. For example, you can set the computer’s IP address to 192.168.1.242.

Check the physical connection via Command Prompt (Try to click the Windows Menu Icon in

the corner of the desktop, and hit “CMD “, then press “Enter”, you will open the Command

Prompt). Type “ping 192.168.1.241” or “ping 192.168.1.241 –t” and press “Enter” to check reply

status. Stable and constant replies from 192.168.1.242 (management computer’s IP address)

indicate a reliable physical connection. See the following image.

Page 10

SMP100 User Guide

4

3.1.2 Logging into the Web GUI

Type the SMP management IP address into the URL field of any recommended browser (IE8 or

above, Firefox, and Google Chrome) to access the logon page. By default, the admin user account

is admin with password admin. Click Login or strike Enter on the keyboard to login to the GUI.

We use only IE, Firefox and Chrome for testing procedures. If you use other browsers, like

Microsoft Edge, you may encounter incomplete UI layouts, and configure setting in these browsers

may lead to errors.

3.1.3 Dropdown Menu

On the top of the Web UI, you will find a couple of menu items. Move the cursor to each item to

navigate through the dropdown menus. Menu item with a small white arrow on the right contains

submenu items.

Menu Status pages summarize the input and output bitrate in each board.

Menu Module Configuration is where you set input and output parameters for each board.

Menu Service Configuration is where to distribute services.

Menu Equipment Configuration includes the basic settings for a SMP100 unit.

Page 11

SMP100 User Guide

5

3.1.4 Service Configuration

Service Configuration page, see the following image, is the main page to distribute input and

output services. In the input and output areas, only the slots with modules successfully loaded are

visible, except the scrambler which is hidden in Output Area and it is configurable by right-clicking

the programs in output ports. Board 1 in this page refers to the module in slot 1. Board 2 refers to

the module in slot 2, and so on.

Functions of the Main Buttons In this page:

Click Refresh to refresh input and output configuration or parameters. There are also Refresh

buttons of the same function in other pages.

Click Apply to apply the configuration you have just done. There are also Apply buttons in other

pages. Click Apply buttons every time you complete the settings in these pages.

Click Save to save all the configurations into the flash memory. Only in this way will the SMP100 be

able to restore all the configurations after power recycling.

Click Clear All to erase the configurations in Service Configuration. This operation does not

remove the configurations saved in flash memory unless you click Save after Clear All is done.

The login session will expire in 5 minutes without any active operation. Please click Apply at

least once every 5 minutes; otherwise, your work in the last few minutes might be futile because the

login session has stopped without notice.

Menu and Main Buttons

Slot and Module Name

Output Area

Quick Sort

Port and Port Number

Other PID Group

Input Area

TS

Service Group

Program Name

Page 12

SMP100 User Guide

6

3.2 Basic Operations

3.2.1 Configuring Network

Configuring the network parameters is the always the first step to configure a head-end unit. Go to

Equipment Configuration > System. As you can see in the following image, you are able to

assign a static IP address to SMP100.

Click Apply to activate settings in this page.

Click Refresh to acquire the system settings that is applied.

Click Default to restore factory settings. The unit will reboot by itself after factory setting is done.

And only the management IP address will remain after reboot. You may also find Default buttons in

other pages. Click these buttons to perform factory settings for a module seperately If you do not

want to factory set the whole unit. You should always click Reboot after Default is done.

Click Reboot to restart this unit. You may also find Reboot in other pages. Click these buttons to

reboot a module seperately.

If you change the IP address of the SMP100 in System page and click Apply, this unit will restart

itself to activate the new IP address.

Page 13

SMP100 User Guide

7

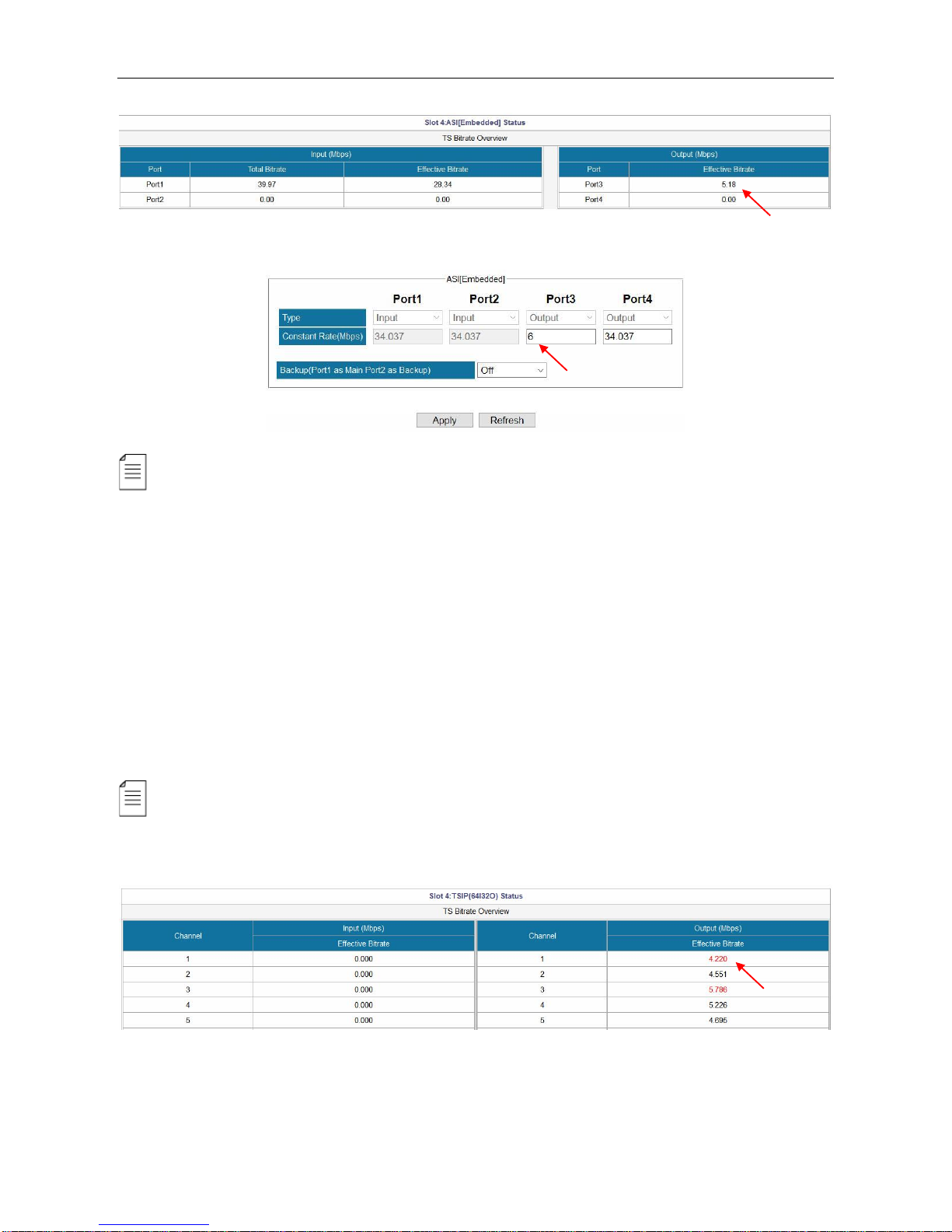

3.2.2 Configuring Input

Embedded ASI Input

There a four built-in ASI interfaces on the back panel of the SMP100 chassis.

Steps to configure an ASI input:

1. Go to Module Configuration > ASI [Embedded]. Enable an input channel or port. Since the

function of each ASI port is not editable, see the following image, you do not have to open or

close an ASI port. Port 1 and 2 are input ports. Port 3 and 4 are output ports.

2. Connect an ASI cable to ASI 1 IN interface.

3. Go to Status > ASI [Embedded] and verify the input bitrate of ASI port 1.

4. Go to Service Configuration. Right click the TS1 under Board4 [ASI] on the left of this page.

Click Scan TS (DVB) or Scan TS (ATSC) to search the input.

After a few seconds you will see a TS1 under Port 1, Board4. You click the plus icon ( ) in

front of TS1 to see the detailed list of all services. Click the minus icon ( ) to hide the details.

Page 14

SMP100 User Guide

8

Before you configure input, go to Equipment Configuration > System, and set the Output

TS Standard. By default, it is DVB.

Embedded TSIP Input

By default, the input and output TSIP channels are closed.

Steps to configure an IP input:

1. Go to Module Configuration > TSIP [Embedded] > Setup. Set the network parameters of the

built-in TSIP module. Click Apply in this page before next step.

2. Go to Module Configuration > TSIP [Embedded] > Channel (1-16). Check the boxes under

Channel Enable to open IP input channels. Enter the Source IP Address, Source Port and

Protocol (UDP/RTP). Click Apply in this page before next step.

Page 15

SMP100 User Guide

9

3. Connect the IP cable to the TS/IP port on the back panel of the SMP100.

4. Go to Status > TSIP [Embedded]. Verify the bitrates in the input channels.

5. Go to Service Configuration page. Scan the TS1 under Port1, Board5. Click Apply in this

page before next step.

Use Batch Scan in the following image to get more than one input TS’ by one scan step.

Note before you use this shortcut function, go to Status > TSIP [Embedded], verify all the input

channels you are going to Batch Scan present input bitrates.

To configure the input of other modules, follow the similar steps as how you configure ASI and

TSIP input. Summary of the steps:

1. Connect input cables

2. Open input channels and set input parameters.

3. Scan TS

4. Click Apply

Page 16

SMP100 User Guide

10

3.2.3 Clear and Bypass the Input

Clear the input TS

Use the Clear TS option right under Batch Scan to remove an input TS.

Bypass the input TS

Use the Bypass TS option to pass a whole TS to the output port or channel. A bypassed TS will not

be multiplexed. See the following image, a blue *[Bypass TS] follows the TS1 as a mark.

To cancel Bypass TS, right-click the TS and select Cancel Bypass TS.

Page 17

SMP100 User Guide

11

3.2.4 Configuring Output

Embedded ASI Output

Use the following two ways to create output TS:

1. Drag TS to TS

Click an input TS; drag and drop it on an empty output TS. Click Apply. See the following Image.

2. Drag Programs to Programs

Right-click an output TS. Click Add TS to assign Original Network ID and TS ID for this new TS.

Click OK, then an empty TS is created.

Click a service in the input port, drag and drop it on Program (0 Services) in the output area.

Click Apply before next step.

Go to Status > ASI [Embedded]. Verify the output Effective Bitrate of this ASI port.

Page 18

SMP100 User Guide

12

Go to Module Configuration > ASI [Embedded]. Set the Constant rate of this port. Click Apply.

EMM and Other PIDs (EIT, SDT, TDT and other PIDs) can be output by drag-and-drop

procedures.

Embedded TSIP Output

The steps to configure IP output are similar to the ways to configure ASI output:

1. Go to Module Configuration > TSIP [Embedded]. Open output channels and set output

parameters.

2. Distribute services in Service Configuration page.

3. Verify the output bitrate in Status.

4. Set the Constant Rate in Module Configuration for the output channels.

If the Constant Rate is lower than the Effective Bitrate at a time, it will cause packet loss

issue. In that case, the Effective Bitrate of the corresponding output TS will be highlighted in red.

See the following image.

Page 19

SMP100 User Guide

13

3.2.5 Delete an Output TS/Program/PID

Move the cursor to a TS, Program or PID until a red icon ( ) appears. Click the red icon to delete

the service or PID. Click Apply before next step.

3.2.6 Version Information/Upgrade

Version Information/Upgrade page presents the software information. Check Advanced to view

all the software that are loaded in this unit.

Updating software

Click Browse to select the software. Then click Upgrade to start update process.

If it is a mainboard upgrade, SMP100 will reboot itself after upgrade is finished. If it is module

upgrade, Go to Module Configuration and click Reboot to load the module again.

Page 20

SMP100 User Guide

14

Always contact provider if you have any software problem. Do not click Erase All to delete all

the software unless instructed to do so.

Do not upgrade any software unless instructed to do so. Do not disconnect the management

cable or power off the device during update process.

3.2.7 License

License page is where to check and update licenses. Note slot 0 refers to the Mainboard.

Updating License

1. Click Browse to select a license file.

2. Click the circle to select a slot number, then click Export License to save the license in the

computer. Better name the license files as smp241main.License, so that you know which license

is for which module in which unit.

3. Send the license file to the provider for update.

4. Once you have the new license file. Click Browse to select a license file in the computer, then

click Upgrade License to enter update process. When the update process succeeded, a

manual restart is required to activate the new license.

The license file is unique for each module. You are not supposed to export a license file from

one unit and upgrade it in another unit. Contact your provider if you need license updates.

Page 21

SMP100 User Guide

15

3.2.8 Import/Export Configuration

Export the configuration of a unit, then you can Import it to this unit for fast configuration recovery

when needed. To import the whole configuration from the sample unit to other duplicate units, the

module types and their positions in the duplicate units should be exactly the same with that in the

sample unit.

3.2.9 Login User Management

By default, the administrator user name and password are both admin. If the admin password is lost

or admin user is deleted, you will have to perform factory setting on the front panel by pressing the

buttons to restore the default login account. In that case, you will lose the configuration of this unit.

3.2.10 Log

Log records the operations and activities of a SMP100. We may request an exported log file from

user for troubleshooting or other use.

Page 22

SMP100 User Guide

16

3.3 Advanced Operations

3.3.1 Edit Output TS

Right-click any output TS and select Edit TS Info.

When the Output TS Standard in the System page is DVB, you have the following editable items.

Name

Range

Name

Range

Original Network ID

0~65535

Service Type

0~255

TS ID

0~65535

ES PID

32~8190

Service Name

Max 32 letters

Priority

1, 2, 3

Provider Name

Max 32 letters

Running Status

0~7

Service ID

0~65535

Free CA Mode

0~1

PMT PID

32~8190

EIT Schedule Flag

0~1

PCR PID

32~8190

EIT Present Following Flag

0~1

Page 23

SMP100 User Guide

17

PID 8191 is taken as the PID for null (stuffing) packets.

When the Output TS Standard in the System page is ATSC, you have the following editable items.

Name

Range

Name

Range

Service Name

Max 32 letters

ES PID

32~8190

Service ID

0~65535

Running Status

0~7

Channel Number

Format: x-x

Free CA Mode

0, 1

Channel TS ID

0~65535

EIT Schedule Flag

0, 1

PCR PID

32~8190

EIT Present Following Flag

0, 1

Service Type

0~255

3.3.2 Edit Service Information for DVB Output

Right-click an output TS to enter SI Setting (DVB).

Page 24

SMP100 User Guide

18

Add Network Information Table (NIT)

See the following image. Board3 [QAM A/C] is streaming output TS1, TS2 and TS3. Original

Network ID is 1. TS ID’s are 1, 2 and 3. The frequency of TS1 is 474000 KHz, and TS2 482000

KHz, TS3 490000 KHz. Suppose 474 MHz (TS1) is the center frequency.

Steps to add NIT:

1. Right-click NIT Actual to edit Network ID and Network Name.

2. Right-click transport_streams to add TS1 (Original Network ID:1 and TS ID:1) .

Page 25

SMP100 User Guide

19

3. Right-click transport_descriptors in transport_stream_id:1 to add Cable Descriptor for TS1.

4. Repeat Step 2 to add TS2 and TS3. Repeat Step 3 to add cable descriptors for these two TS’.

5. Click Apply, and go to Service Configuration page, click Apply again.

Right-click version_number to change its value if necessary. Once you have added NIT, you

are able to export it. Wherever you can find the cross icon ( ), you can click this icon to delete that

item.

Page 26

SMP100 User Guide

20

Add Logical Channel Number (LCN)

LCN is used to sequence the channels in the Set Top Box. See the following image, we have a SI

tree with Cable Descriptors added in transport_stream_id:1, transport_stream_id:2,

transport_stream_id:3.

Steps to add LCN for the output services (CCTV2, CCTV7, CCTV10, CCTV11, CCTV 12, and

CCTV15):

1. Right-click transport_descriptors under transport_stream_id:1, then select Add LCN

Description to enter edit page.

TS1 with Cable Descriptor

TS2 with Cable Descriptor

TS3 with Cable Descriptor

Page 27

SMP100 User Guide

21

2. Select Board1 [QAM (A/C)], Port1, TS1 by clicking the circle in front of it. Then CCTV2 and

CCTV7 in TS1 will be in Services box on the right side. Click Add in front of CCTV2 (service ID

302) and CCTV7 (service ID 303), they will be added to LCN box. Enter numbers in Logic

Channel Number text field. Click Add, then Exit.

Page 28

SMP100 User Guide

22

3. Check the LCN descriptors of CCTV2 and CCTV7 that you configured.

4. Right-click transport_descriptors under transport_stream_id:2, then select Add LCN

Description. Select Board1 [QAM (A/C)], Port1, TS2 add LCN for CCTV10 (service ID 304)

and CCTV10 (service ID 305). Click Add and Exit.

Page 29

SMP100 User Guide

23

5. Repeat Step 4 to add LCN for CCTV12 and CCTV15 under transport_stream_id:3. Once you

have added LCN for these 6 services, click Apply in the following page.

6. Go to Service Configuration.

Click Apply and Save.

Page 30

SMP100 User Guide

24

3.2.2 Upgrading STB through SMP

To update the software for a number of STB’s, use the following steps:

1. Feed the update stream to SMP by the embedded ASI or IP port.

2. Drag the update PID to QAM output port. See the following image, an update stream is taken as

other PID 8001 in SMP.

3. Add update descriptor in the NIT. Go to SI Edit page of the center TS. Add Network Descriptor

by right click on network_descriptors. Generally, the descriptor is from STB manufacturer.

4. Click OK to confirm. See the following image, the update descriptor is crated under NIT Actual.

5. Go to Service Configuration. Click Apply and Save.

Page 31

SMP100 User Guide

25

Part 4 Module Configuration

4.1 Input and Output Modules

4.1.1 ASI

ASI is a 4-channel ASI I/O module. Each ASI port can be set as either input port or output port

separately.

Module configuration > ASI

Name

Range

Description

Type

Input, Output

Select to determine the port to be input or output.

Constant Rate (Mbps)

0~100

Max rate of ASI is 100Mbps

PCR Adjust Mode

Wellav Adjust Mode

Real-time Stamp Mode

Page 32

SMP100 User Guide

26

4.1.2 DVBC

DVBC is a 4-channel DVBC receiving module.

Module Configuration > DVBC

Name

Range

Frequency (KHz)

48000~870000

Symbol Rate (KSym/s)

3000~7000

Constellation

QAM16/32/64/128/256

Lock Status

Lock/Un-lock

Page 33

SMP100 User Guide

27

4.1.3 DVBS2

DVBS2 is a 4-channel DVBS2 receiving module.

Module Configuration > DVBS2 (V2)

Name

Range

Description

Mode

4CH Mode(Normal)

2CH Mode(Advanced)

4CH Mode: QPSK, 8PSK

2CH Mode: QPSK, 8PSK, 16APSK,

32 APSK.

Symbol Rate (Ksym/s)

1000~45000

Page 34

SMP100 User Guide

28

LNB Type

Single Band, Dual Band

Band Selection

Auto, Forced Low, Forced High

Bias

Disable/Enable

Available in Port2 and Port4

Polarization

13V (V)

18V (H)

Vertical

Horizontal

Lock Status

Lock/Un-lock

To indicate the input is locked or not.

Contact service provider for input information or visit www.lyngsat.com for the latest information of

satellite Radio & TV channels.

4.1.4 DVBT2

DVBT2 is a 4-channel DVBT/DVBT2 receiving module.

Module Configuration > DVBT2

Page 35

SMP100 User Guide

29

Name

Range

Description

Tuner Mode

DVB-T

DVB-T2

DVB-T: QPSK, 16/64QAM

DVB-T2: QPSK, 16/64/256QAM

Frequency(KHz)

48000~862000

Bandwidth

6M, 7M, 8M

Depends on the standard in your country.

PLP Mode

A, B

Available when Tuner Mode is DVB-T2.

PLP ID

Available when PLP Mode is B.

4.1.5 8VSB

8VSB is a 4-channel 8VSB receiving module.

Module Configuration > ATSC

Page 36

SMP100 User Guide

30

Name

Range

Description

Channel

57~803MHz

Refer to American ATSC (8-VSB) Channel List

4.1.6 QAM

QAM module supports modulating 8 adjacent channels. The left connector is for local monitoring.

Module Configuration > QAM

Page 37

SMP100 User Guide

31

Name

Range

Name

Range

RF Level(dBuV)

90~106

Enable

Disable, Enable

Bandwidth

6M, 7M, 8M

Frequency (KHz)

47000~862000

Symbol Rate (KBaud)

4400~6956

Constellation

QAM64/128/256

Spectrum Shaping

Disable, Enable

Max Rate (Mbit)

Automatically calculated

4.1.7 IQAM

IQAM module supports modulating 16 non- adjacent channels.

Module Configuration > IQAM

Page 38

SMP100 User Guide

32

4.1.8 OFDM

OFDM is a 4 channel modulating module. The left connector is for local monitoring.

Module Configuration > OFDM

Name

Range

Name

Range

Bandwidth

6M, 7M, 8M

Guard Interval

1/4, 1/8, 1/16, 1/32

RF Level(dBuV)

90~109

Mode

2k, 8k

Spectrum Shaping

Disable/Enable

Constellation

QPSK, QAM16/64

Enable

Disable/Enable

FEC HP

1/2, 2/3, 3/4, 5/6, 7/8

Frequency (KHz)

40000~862000

Max Rate (Mbit)

Automatically calculated

Page 39

SMP100 User Guide

33

4.1.9 8VSBM

8VSBM is compliant with the modulation method used for broadcast in the ATSC digital television

standard.

Module Configuration > ATSCM

Name

Range

Name

Range

RF level

80~107 dB, -27~0 dBm

Channel Select

57~803 MHz

Spectrum Shaping

Disable, Enable

Frequency (KHz)

44000~999000

Channel Plan

OTA, STD, IRC, HRC

Page 40

SMP100 User Guide

34

4.1.10 HDMI/SDI Decoder

HDMI/SDI Decoder supports decoding 2 programs in two HDMI ports and two SDI ports.

Module Configuration > HDMI/SDI Decoder

Name

Range

Name

Range

Aspect Ratio

Conversion

Automatic

4:3 Letterbox

4:3 Pan and Scan

16:9 Letterbox

16:9 Pan and Scan

Output Resolution

1920x1080_50i/60p/59.94p/

59.94i/60i/30p/29.97p/24p

1280x720_60p/50p/59.94p

720x480_60i

720x576_50i

Audio Volume (0-49)

0~49

One decoder channel decodes only one service.

Page 41

SMP100 User Guide

35

4.1.11 Decoder-AV

Module Configuration > Decoder-AV

Name

Range

Name

Range

Aspect Ration Conversion

4:3 Letterbox

4:3 Pan and Scan

16:9 Letterbox

16:9 Pan and Scan

Audio Volume

0~49

Output Video Resolution

720x576_50i

720x480_60i

Mixer

Stereo, Left, Right,

Mono, Dual

One decoder channel decodes only one service.

Page 42

SMP100 User Guide

36

4.1.12 ASI-Switch

ASI-Switch is a 3in2out board for ASI input redundancy application. The three ports on the right are

primary, secondary (it could be a copy of the main), and fail-safe input. The two ports on the left are

both output 1 and output 2 interfaces.

Steps to get input services:

1. Connect ASI cables with valid signals to the three ASI input ports.

2. Go to Service Configuration, scan the three input TS. You will see the input TS’ as in the

following image.

3. Click Apply and Save button in this page.

4. Go to Module Configuration > SWITCH. Set the switching conditions and thresholds.

Module Configuration > SWITCH > Backup

By default, Switch level settings is Port-level, and Port-switch mode selection is Automatic

switch. See the following image. Automatic switch means this unit will monitor the input according

to the conditions that has been checked in Port-switch condition selection.

Page 43

SMP100 User Guide

37

Some options in Port automatic switch settings:

Automatic switch mode

Use Primary program first, this module will activate switch

function. Select Switch Lock to disable this feature.

Min/Max total bitrate of primary,

secondary and fail-safe port

Configure Minimum and Maximum rates to define the

normal rate ranges for the input ports.

Switch-back delay

Once the primary recovered, this module will switch to

primary input after a scheduled period.

If you use Manual switch for Port switch mode selection, the UI will be the following image.

Page 44

SMP100 User Guide

38

If you choose Program-level for Switch level settings, the UI will be like this:

As you can see in the image above, you have to configure Program-switch condition selection

and Program Setup.

Module Configuration > SWITCH > Output

ASI Out 1 bitrate

Configure the constant bitrate for the output ASI port 1. This constant rate

should be larger than the effective rate of the input streams.

Other output port

bitrate

Configure the constant bitrate for the output ASI port 2. This constant rate

should be larger than the effective rate of the input streams.

Output stream

selection of other

output ports

ASI Switch module will output one of the following four inputs even the whole unit

is off: Same signal output as ASI Out 1, Pass-through ASI In 1 (Primary), Passthrough ASI In 2 (Secondary), Pass-through ASI In 3 (Fail-safe)

Pass-through

mode for power off

ASI Switch module will output one of the following three inputs even the whole

unit is off: Pass-through ASI In 1 (Primary), Pass-through ASI In 2 (Secondary),

Auto

Page 45

SMP100 User Guide

39

4.2 Encoding Modules

4.2.1 EN4AV-4M2B

EN4AV-4M2B is a 4-channel CVBS encoder that supports H.264 and MPEG-2 encoding. It can be

licensed to support MPEG-2 encoding only.

Module Configuration > EN4AV-4M2B

Page 46

SMP100 User Guide

40

Name

Range

Name

Range

Video Encoder Type

H264, MPEG2

PCR PID

32~8190

Audio Encoder Type

OFF,MPEG1_Layer2, MPEG4_AAC

AC3 (optional), MPEG2_AAC

Video PID

32~8190

Video Encode Mode

CBR, VBR

Audio PID

32~8190

Video Max Encode Rate

1.5~2 times of Video Encode Rate

PMT PID

32~8190

Video Min Encode Rate

0~0,75times of Video Encode Rate

Program Name

Max 32 letters

Video Encode Rate

600~6000

Provider Name

Max 32 letters

Audio Encode Rate

64~384

Video Vlc Mode

CABAC, CAVLC

Total Encode Rate

Automatically Calculated

Video Profile

Main, High

Audio Volume

0~8

Video Level

3.0, 3.1, 3.2, 4.0, 4.1, 4.2

GOP Structure

IBBP, IPPP, IBP

Brightness

0~255

GOP Size

6~63

Contrast

0~255

GOP Close

Enable, Disable

Saturation

0~255

Hue

-180~180

Page 47

SMP100 User Guide

41

4.2.2 EN4SDI-2M2A

EN4SDI-2M2A module supports encoding 2 H.264 HD/SD channels or 2 MPEG-2 SD channels via

SDI/CVBS input. AAC and AC3 audio encoding is available with optional hardware and license.

Module Configuration > EN4SDI-2M2A

Page 48

SMP100 User Guide

42

Name

Range

Name

Range

Video Source

SDI

CVBS

Aspect Ratio

Automatic, 16x9_LetterBox

16x9_CutOff, 4x3_PillarBox

Video Encoder Type

H264, MPEG2

Video Standard

Auto, Downscale

Video Encode Rate

(Payload)(Kbps)

600~6000

PCR PID

32~8190

Video Encode Mode

CBR, VBR

Video PID

32~8190

Video Max Encode

Rate (Payload)(Kbps)

1.5~2 times of Video

Encode Rate

Service PID

32~8190

Video Min Encode

Rate (Payload)(Kbps)

0~0,75 times of Video

Encode Rate

PMT PID

32~8190

Audio Source

Program Name

Max 32 letters

Audio Encoder Type

OFF, MPEG1_Layer2

AC3 (optional)

Provider Name

Max 32 letters

Page 49

SMP100 User Guide

43

MPEG2_AAC

MPEG4_AAC

AC3 AC Mode

1+1

Latency adjustment

(ms)

Enter a value to adjust the

audio and video

synchronization. Enter a

positive value to delay audio

encoding.

Audio Encode Rate

(Payload)(Kbps)

64~384

Vlc Mode

CABAC

CAVLC

Belong to

Program-1

Profile

Main, High

Audio Volume

0~8

Level

3.0, 3.1, 3.2, 4.0, 4.1, 4.2

Audio PID

32~8190

Sample Rate

32KHZ, 44.1KHZ,48KHZ

GOP Structure

IBBP, IPPP, IBP

Brightness

0~255

GOP Size

6~63

Contrast

0~255

GOP Close

Enable, Disable

Saturation

0~255

Hue

-180~180

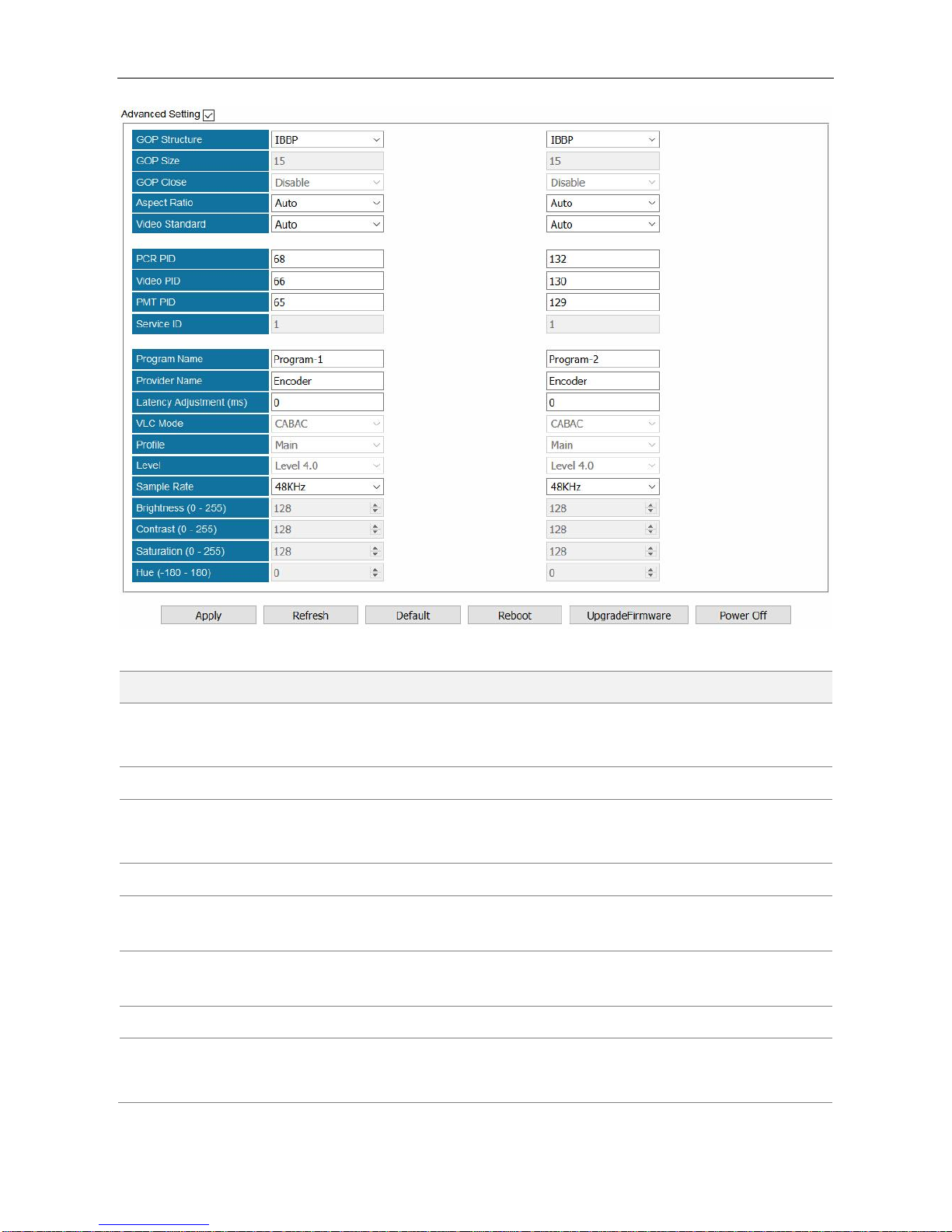

4.2.3 EN4HDMI-xM2A

EN4HDMI-4M2A supports encoding 4 H.264/MPEG-2 SD channels or 4 H.264 HD channels.

EN4HDMI-2M2A supports encoding 2 H.264/MPEG-2 SD channels or 2 H.264 HD channels. AAC

and AC3 audio encoding is available with optional hardware and license.

Page 50

SMP100 User Guide

44

Module Configuration > EN4HDMI-4M2A

Page 51

SMP100 User Guide

45

Name

Range

Name

Range

Video Encoder Type

H264, MPEG2

GOP Structure

IPPB, IPPP, IBP

VLC Mode

CABAC, CAVLC

GOP Size

6~63

Profile

Main, High

GOP Close

Disable, Enable

Level

3.0, 3.1, 3.2,

4.0, 4.1, 4.2

Sample Rate

32KHZ, 44.1KHZ,

48KHZ

Video Encode Rate

(Payload)(Kbps)

Video Standard

Auto

Downscale

Video Encode Mode

CBR, VBR

Aspect Ratio

Automatic

16x9_LetterBox

16x9_CutOff

4x3_PillarBox

Video Max Encode

Rate (Payload)(Kbps)

1.5~2 times of Video

Encode Rate

PCR PID

32~8190

Video Min Encode Rate

(Payload)(Kbps)

0~0,75 times of Video

Encode Rate

Video PID

32~8190

Audio Encoder Type

OFF, MPEG1_Layer2

AC3 (optional)

MPEG2_AAC

MPEG4_AAC

PMT PID

32~8190

AC3 AC MODE

1+1(L, R)

1/0(C)

2/0(L, R)

Program Name

Max 32 letters

Audio Encode Rate

(Payload)(Kbps)

48~448

Provider Name

Max 32 letters

Audio Volume

0~8

Source Check

Disable, Enable

Audio PID

32~8190

Encoder Rate Check

Disable, Enable

The Status >EN4HDMI only presents the Video Resolution when of the input content is

protected by HDCP. In that case, the Total Bitrate and Effective Bitrate will be 0.000 Mbps and

Scan TS will fail.

Page 52

SMP100 User Guide

46

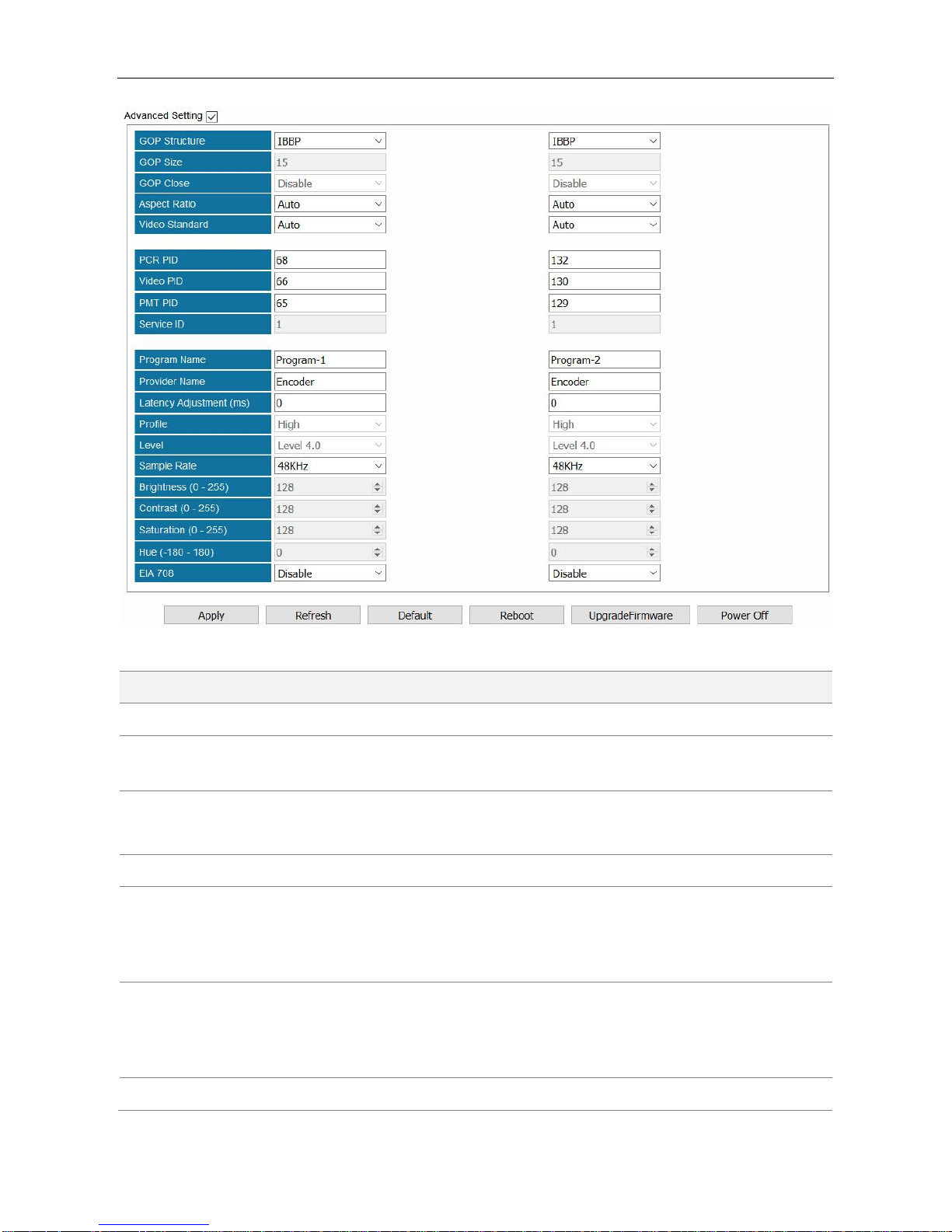

4.2.4 EN2SDI-2H

EN2SDI-2H is a 2-channel H.264/MPEG-2 HD/SD encoder via SDI/CVBS input.

Module Configuration > EN2SDI-2H

Page 53

SMP100 User Guide

47

Name

Range

Name

Range

Video Source

SDI, CVBS

Video PID

32~8190

Video Encoder

Type

H264, MPEG2

PMT PID

32~8190

Video Encode Rate

(Payload)(Kbps)

600~20000

Service ID

0~65535

Video Encode Mode

CBR, VBR

Program Name

Max 32 letters

Audio Source

L1-XLR1-R1,SDIx-Audio1/2

SDIx-Audio3/4,SDIx-Audio5/6

SDIx-Audio7/8

Provider Name

Max 32 letters

Audio Encoder

Type

OFF, MPEG1_Layer2

AC3 (optional), MPEG2_AAC

MPEG4_AAC

Latency

Adjustment (ms)

Enter a positive value to

delay audio encoding.

Belong to

Progrma-1

Profile

Main, High

Page 54

SMP100 User Guide

48

Audio Volume

0~8

Level

3.0, 3.1, 3.2, 4.0, 4.1, 4.2

Audio PID

32~8190

Sample Rate

32KHZ, 44.1KHZ,48KHZ

GOP Structure

IPPB, IPPP, IBP

Brightness

0~255

GOP Size

6~63

Contrast

0~255

GOP Close

Disable, Enable

Saturation

0~255

Aspect Ratio

Auto, 16x9_LetterBox

16x9_CutOff, 4x3_PillarBox

Hue

-180~180

Video Standard

Auto, Downscale

EIA 708

Disable, Enable

PCR PID

32~8190

4.3 Transcoding Modules

4.3.1 TC4-xM2A

TC4-xM2A module refers to TC4-2M2A or TC4-4M2A modules. TC4-2M2A supports transcoding to

2 H.264 HD/SD channels or 2 MPEG-2 SD channels. TC4-4M2A supports transcoding to 2 H.264

HD/SD channels or 4 MPEG-2 SD channels. AAC and AC3 audio encoding is available with

optional hardware and license.

Module Configuration >TC4-XM2A01

Page 55

SMP100 User Guide

49

Name

Range

Name

Range

Video Encode Rate

(Payload)(Kbps)

600~15000

Video Profile

Main, High

Audio Encode Rate

(Payload)(Kbps)

64~384

Video Level

3.0, 3.1, 3.2,

4.0, 4.1, 4.2

Audio Volume

(Transcode)(dB)

0~8

Video Vlc Mode

CABAC, CAVLC

GOP Structure

IPPB

IPPP

IBP

Audio Encoder Type

OFF, MPEG1_Layer2

AC3 (optional)

MPEG2_AAC

MPEG4_AAC

Page 56

SMP100 User Guide

50

GOP Size

6~63

AC3 AC Mode

1+1(L, R)

1/0(C)

2/0(L, R)

GOP Close

Disable, Enable

Aspect Ratio

Conversion

Automatic, 16x9_LetterBox

16x9_CutOff, 4x3_PillarBox

4x3_CutOff

Same PID for PCR

and Video

Video Max Encode Rate

(Payload)(Kbps)

Output Resolution

720x480_60i

720x576_50i

1920x1080_60i/50i

1208x720_60p/50p

Video Min Encode Rate

(Payload)(Kbps)

Video Encoder

Type

H264, MPEG2

Latency Adjustment

(ms)

Enter a value to adjust the audio

and video synchronization. Enter

a positive value to delay audio

encoding. Enter a negative value

to hasten audio encoding.

SDHD

4SD/2HD channel mode.

Drag a program to a TC4 output port for transcoding process. The transcoded program will be in the

corresponding TC4 input port. Then the transcoded program can be sent to an output port.

Page 57

SMP100 User Guide

51

4.4 Scrambling/Descrambling Modules

4.4.1 CI Descrambling

One CI module allows the user to insert two pairs of CAM and smartcard into two independent slots.

The top slot is slot 1. The bottom slot is slot2. The user can either select Auto Reset or click Reboot

to reset CAM modules. MMI button is used to read CAM and smartcard information.

Module Configuration > CI

Configuring Service Descrambling

In the following image, a TS that contains 9 scrambled services comes from ASI input port.

1. Go to Status > CI and check the CAM Insert Status, CAM Initialization status, CAM Name,

and CA System ID. Take the following figure for example, the CAM module is successfully

loaded in CI Port.

Page 58

SMP100 User Guide

52

2. Go to Service Configuration. Bypass the input TS and drag it to output Board3 [CI] on the

right side. Then on the left side in Board3 [CI] Port1 the processed TS is listed as an input

again.

3. Right-click a program in the output CI port to descramble this service by the CAM in Port 1.

[Descramble] follows the service that is descrambled as a mark. To cancel the descrambling

process for the service, right-click it and click Non-descramble. Click Apply.

4. Drag the service that has been descrambled from input Board3 [CI], Port1 to output port.

Page 59

SMP100 User Guide

53

5. Go to Status > CI, check the Service Descramble Status. In the following figure, three services

are descrambled successfully.

Page 60

SMP100 User Guide

54

4.4.2 CI-BISS Descrambling

CI module can be converted to CI-BISS module by a different license and loading CI-BISS module

software. BISS descrambling does not require any CAM module. Use the similar way as in Chapter

4.2.1 CI Descrambling to configure CI-BISS Descrambling.

1. Bypass the input TS and drag it to output CI port.

2. Right-click a program and click BISS-Descramble.

3. Configure BISS Mode and BISS Key (and Injected ID in BISS-E Mode). Click Apply and then

click Back to return to Service Configuration. [BISS_1] and [BISS_E] follow the descrambled

services as a label.

Page 61

SMP100 User Guide

55

4. Drag the descrambled services to output port.

5. Check descrambling status in Status > CI.

To ensure CA PMT is updated in CI, better bypass the input TS before drag it to CI. Otherwise,

descrambling process may fail.

4.2.3 Scrambler

The scrambler module is use to work with CAS systems to encrypt programs. It supports scrambling

up to 150 services. Besides, it support BISS-1/BISS-E scrambling without extra license. AES-CBC

mode is optional.

Page 62

SMP100 User Guide

56

Overview of Scrambler+ menu structure:

Configuring Scrambler+ Setup

Go to Module Configuration >Setup. Enter the IP Address, Subnet Mask, Gateway, and Speed

Mode for this scrambler. The IP Address should be in the same network with that of the CAS

server. The Speed mode should be the same with the Ethernet of CAS server. Turn on CA System

1 and keep unused CA Systems Off. Use a cross-through RJ45 cable to connect scrambler to CAS

server’s Ethernet port. Check the connection by pinging scrambler’s IP address in the Command

Prompt of CAS server.

Configuring ECMG connection.

Enter System ID, Sub System ID (keep it 0 if not required), ECMG IP Address, and ECMG Port.

Click Apply. Check ECMG Communication Status in Status > Scrambler+. When the connection

is liable, the status is a green Connected. See in the following figure.

Page 63

SMP100 User Guide

57

Configuring EMMG connection.

Enter EMMG TCP Port, EMMG UDP Port (keep it 0 if EMM Send Type is TCP), EMM Send Type,

EMM PID, and EMM Bandwidth. Click Apply. Check EMMG Communication Status in

Status >Scrambler+. When the connection is stable, the status should be a green Connected.

Configuring ECM

Add the AC Data that is created in CAS server into ECM List.

Page 64

SMP100 User Guide

58

Scrambling Programs

Once the ECMG, EMMG connection is done and ECM is added, go to Service Configuration and

right-click a program in output port to Program Scramble Setting.

Select Slot (the slot in which Scrambler+ is installed), CA Stream ID for each program and click

Apply to scramble them. Go to Status > Scrambler+ and check ECM Count. The count number

should be the same with the number of scrambled programs.

To cancel the scrambling process for a scrambled program, go to Program Scramble Setting

again, change Slot to None and apply Non-scramble for this program.

BISS-1/BISS-E Scrambling

BISS scrambling does not require a CAS server. Right-click an output program to Program

Scrambling Setting. Select BISS-1/BISS-E in Scrambling Type and enter BISS keys to scramble

the programs.

Page 65

SMP100 User Guide

59

Part 5 Appendices

Appendix A - Abbreviations

8VSB

Vestigial sideband modulation with 8 discrete amplitude levels

16VSB

Vestigial sideband modulation with 16 discrete amplitude levels

AAC

Advanced Audio Coding

AC-3

Also known as Dolby Digital

ASI

Asynchronous Serial Interface

ATSC

Advanced Television Systems Committee

AV

Audio Video

BAT

Bouquet Association Table

BER

Bit Error Ratio

Bit Rate

The rate at which the compressed bit stream is delivered

BNC

British Naval Connector

CAM

Conditional Access Module

CAT

Conditional Access Table

CAT6

Category 6 – Cable standard for gigabit Ethernet

CBR

Constant Bitrate

CI

Common Interface

CVBS

Composite Video Broadcast Signal

dB

Decibel

DVB

Digital Video Broadcasting

EIT

Event Information Table

EPG

Electronic Program Guide

FEC

Forward Error Correction

GOP

Group of Pictures

HD

High Definition

HDCP

High-bandwidth Digital Content Protection

HDMI

High Definition Multimedia Interface

I/O

Input/output

Page 66

SMP100 User Guide

60

Kbps

1000 bit per second

LCN

Logical Channel Number

LNB

Low-Noise Block

LO

Local Oscillator

Mbps

1,000,000 bits per second

MER

Modulation Error Ratio

MIB

Management Information Base

MPTS

Multi-program Transport Stream

NIT

Network Information Table

OFDM

Orthogonal Frequency-Division Multiplexing

PAT

Program Association Table

PCR

Program Clock Reference

PID

Packet Identifier

PMT

Program Map Table

PSI

Program Specific Information

PSU

Power Supply Unit

QAM

Quadrature Amplitude Modulation

QPSK

Quadrature Phase-Shift Keying

SD

Standard Definition

SDI

Serial Digital Interface

SDT

Service Description Table

SI

Service Information

SNMP

Simple Network Management Protocol

SNR

Signal Noise Ration

SPTS

Single Program Transport Stream

TDT

Time and Date Table

TS

Transport Stream

VBR

Variable Bitrate

Page 67

SMP100 User Guide

61

Appendix B – Modules Available In Different Regions

Check the following sheet to find out which modules are available for SMP100 in certain regions.

Module Name

North America

Europe

TSIP+

DVBC

DVBS2

DVBT2

8VSB

QAM-A/C

QAM-B

IQAM

OFDM

8VSBM

HDMI/SDI Decoder

EN4SDI

EN4HDMI

EN2SDI-2H

TC4

CI

CI-BISS

LQAM-A/C

LQAM-B

Available

Page 68

SMP100 User Guide

62

Appendix C - Warranty

We warrants this instrument against defects from any cause, except acts of God and abusive use,

for a period of 1 (one) year from date of purchase. During this warranty period, we will correct any

covered defects without charge.

Appendix D - After-Sales Support

Please contact our sales/regional representatives for any help, product information, and

troubleshooting.

Returning Products for Service

The SMP100 is a delicate piece of equipment and needs to be serviced and repaired by the

manufacturer. In order to expedite this process please carefully read the following items.

Confirm the required component

Before any product can be returned for service, the client ought to contact our sales representatives

and after-sales support department by means of email to confirm the need to return the product or

part of the product.

Collect the Serial Numbers to obtain RMA Number

Serial Number (SN) is printed on a label on the chassis and modules. To create a RMA number, SN

must be submitted to support department. Once the RMA number has been issued to the client, the

unit/component needs to be packaged and shipped back to the manufacturer. It’s best to use the

original box and packaging for the product but if this not available, check with the service

department for the proper packaging instructions. RMA Number should be specified in the delivery

bill or written on the package.

Do not return any power cables or accessories unless instructed to do so.

Loading...

Loading...