Page 1

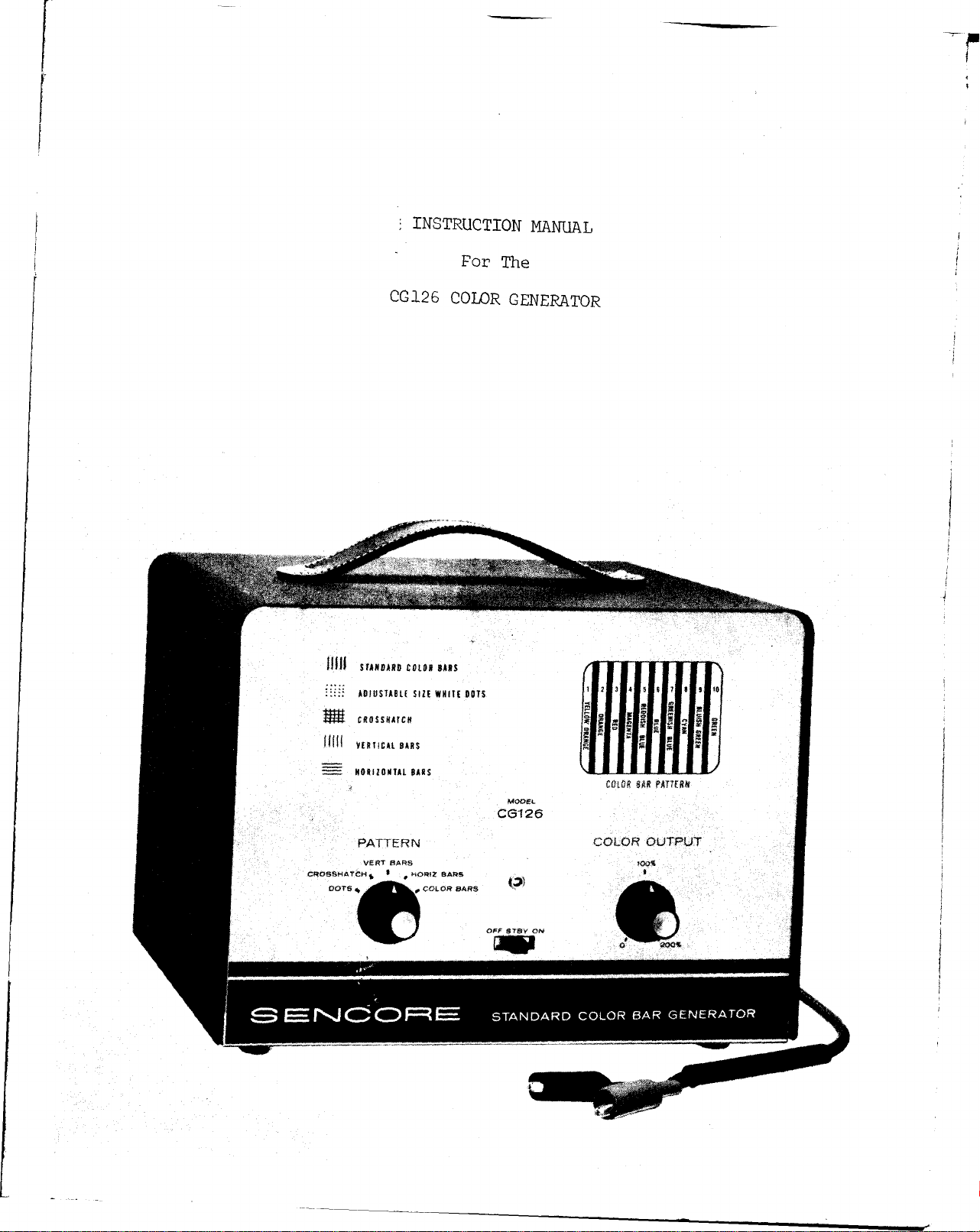

: INSTRUCTION MANUAL

For The

CG126 COLOR GENERATOR

Page 2

INSTRUCTION MANUAL

for the

CG126 COLOR GENERATOR

Recognizing the need for a stable, low cost generator that produces

all necessary patterns for accurate convergence and trouble shooting in

the home, SENCORE has developed the CG126 Standard Color Bar Generator.

The CG126 is the smallest, lightest, and least expensive generator

of any on the market and yet it provides the same stable patterns of

generators costing twice as much. The CG126 provides the following

patterns:

Ten Standard Color Bars: The type and phase that is fast becoming the

standard of the industry. Crystal controlled keyed bars (RCA type with

30 degrees phase change between each) as explained in most service lit

erature, offer a complete gamut of colors for every color circuit test.

Adjustable Size White Dots: New stabilized dots, a must for convergence,

are created by new SENCORE counting circuits. The size of the dots are

adjustable from the rear of the unit.

Crosshatch Pattern: A basic requirement for fast CRT convergence, and,

also, for sweep linearity and "overscan" adjustments.

Vertical and Horizontal Bars: An added feature to speed up convergence,

not found on many other color generators.

SPECIFICATIONS

RF Output: Frequency i s factory set to Channel 4 . It can easily be

changed to Channel 3 or Channel 5, if Channel 4 is used in your

area.

Modulation: Any one of five patterns: Color Bars, Dots, Crosshatch,

Vertical Bars, or Horizontal Bars.

Tube Complement: 6-12AU7A, 2-12AZ7, 1-12BE6

Diode Complement: 2-1N295

Crystal Complement: 1-189KC t .005% for timer, 1-3563.795KC ί .001%

for color Lars.

Power Consumption: 35 watts at 117 VAC line .

Size: 11 inches wide by 8 inches high by 6 inches deep.

Net Weight: 9 1/2 pounds.

CONTROLS ON THE CG126

The CG126 is an extremely easy generator to set up and use. Only three

front panel controls are needed in normal use. These are the AC power switch,

the Pattern switch and the Color Output control. Additional adjustments for

the timing circuits, and for dot size, are available on the rear of the unit,

but these are all factory set and normally do not need to be changed.

2

Page 3

AC Power Switch: The AC power switch is used to turn the unit ON and OFF.

It also has a middle STANDBY position which is used whenever you wish to

disable the pattern and RF carrier, but still keep the tube filaments hot

for instant use.

Pattern Switch: The pattern switch selects one of the five patterns avail

able to modulate the RF carrier. Composite sync is fed to the modulator at

all times s o that the patterns will not jump or fall out of sync when

switching from one pattern to another. The following patterns are available

on the CG126, each for a specific function.

1. Dots - There are 117 small size dots available, primarily for DC

convergence. A color TV set that is properly converged will have

white dots in the center of the picture tube (all three guns hit

ting the same spot on the CRT). Static (or DC) convergence is

controlled by the 3 small magnets spaced at 120 degrees around

the neck of the color CRT plus the blue lateral positioning magnet.

2. Crosshatch - In the crosshatch position, 9 vertical and 13 hori

zontal visible bars are generated. The crosshatch pattern is used

for dynamic convergence adjustments, overscan adjustments (height

and width) and for linearity adjustments.

3 . Vertical Bars - Nine vertical bars are generated in the vertical

bar position. These are used primarily when adjusting the dynamic

vertical convergence controls.

4 . Horizontal Bars - Thirteen horizontal bars are provided and are

used primarily when adjusting the dynamic horizontal convergence

controls.

5. Color Bars - Ten color bars are generated for color alignment and

trouble shooting in the color circuits of the TV receiver. The

color output is controlled with a separate control. The colors

which would be displayed on a normal color set are shown on the

upper right of the panel.

Color Output Control: The color output control changes the amount of color

signal that is fed to the modulator. It is used primarily to check the color

sync abilities of the receiver. A setting of 100 percent is normal. With

most receivers, the control can be turned to almost zero percent before the

set will lose color sync. This i s indicated by diagonal bands of color

(barber pole effect) within each color bar .

The 200 percent setting of the control is used to force a defective

set to sync while trouble shooting.

OPERATING THE CG126

To use the CG126, plug the AC cord into a 117V AC outlet, turn the

unit on and let the generator warm up for approximately 10 minutes. Connect

the output cable to the antenna terminals of the TV set . Tune the TV set to

Channel 4, or to the same channel as the CG126 i f the CG126 has been reset

3

Page 4

to some other channel.

Turn the pattern switch to the desired pattern.

Sharp, well defined patterns are necessary for convergence adjust

ments and for trouble shooting. Since the settings of the TV controls

will affect the quality and sharpness of the patterns produced by the

CG126, we will discuss briefly how these TV controls should be set. In

all of the following steps, the CG126 is on and the output cable is con

nected to the TV antenna terminals. The TV is set to Channel 4 .

Fine Tuning - Turn the CG126 to color bars and adjust the TV fine tuning

control for sharp, clear bars with a minimum of smearing on the edges.

This is the best tuning point for the TV and the control should be left

at this setting for all black and white patterns, also.

Occasionally, however, a higher dot contrast range (dot brightness

versus background) can be achieved by mistuning the TV slightly to favor

the dot frequency.

Contrast and Brightness Controls - Since the CG126 has a minimum amount

of background "hash" on any of the patterns, the settings of the contrast

and brightness controls can be set to your liking. However, for conver

gence adjustments it is desirable to have a high contrast between the

pattern and the background level in which case the contrast control should

be turned to near maximum.

When viewing color bars it is sometimes desirable to eliminate the Y

signal completely by turning the contrast control to zero.

Vertical Hold - All color TV sets have vertical retrace blanking. If the

vertical hold is not adjusted properly, retrace lines can be seen in the

upper part of the picture. Adjust the vertical hold control for the mini

mum number of retrace lines consistent with good vertical hold.

Horizontal Hold - On some sets there may be a slight "fanning" at the top

of the picture of all vertical lines in the pattern if the horizontal hold

control is not adjusted properly. These can be virtually eliminated by

adjusting the horizontal hold control. A high contrast setting may also

cause this effect.

SETTING UP AND TROUBLE SHOOTING COLOR TV WITH THE CG126.

Setting up and trouble shooting color TV is easy with the CG126. In

addition to a good generator, however, an established procedure should be

followed so that time will not be wasted in following misleading conditions.

We like to think of color TV trouble shooting as a three step approach.

The first step is to be sure that the color CRT and associated circuits

are operating properly. This involves checking for purity and convergence.

The second step in the procedure is to get a good black and white picture.

If the trouble is not solved by the first two steps then it must be in the

color circuits which brings up the third step of trouble-shooting the color

section of the receiver

4

Page 5

Let’s see how this works with the following example. If a color set

is tilted on its side or even tilted up as little as 30 degrees the purity

of the CRT will go off (the electron beams from each gun will hit all three

colors of phospher dots instead of just their own color). Under this

condition the black and white patterns from the CG126 (do t s, crosshatch etc.)

will look quite presentable and you may not even be able to detect anything

as being wrong. However, if you switch to color bars, the colors will be

strange or completely gone and your first impression would be to start

analyzing the color circuits. Thus, you can see the importance of checking

for proper purity and convergence first.

Checking and Adjusting Purity. Tune the TV to an unused channel and ground

the blue and green grids on the CRT through 100K resistors. Slide the yoke

back and adjust the purity rings for a solid red spot that fills the center

of the screen. Slide the yoke forward until the screen becomes completely

red. At this point, connect the CG126 to the TV set, tune the set to

Channel 4, set the pattern switch to crosshatch, and check for proper over

scan adjustments. See Figure 1 for correct pattern.

Figure 1. Crosshatch pattern.

It is sometimes possible to get good purity only by pushing the yoke too

far forward, which, of course, reduces the width and height, such that the

set does not overscan properly. Refer to the manufacturer’ s service litera

ture for proper overscan.

If purity cannot be obtained by normal adjustments it is probable that

the CRT screen mask has become magnetized, in which case a degaussing coil

is needed. Move the coil around the picture tube screen for about one minute.

Then remove the coil about 6 feet from the set and turn it at right angles to

the CRT before turning it off.

Checking for Static and Dynamic Convergence. Connect the CG126 to the TV,

tune the TV to Channel 4, and set the pattern switch to dots. Observe the

dots near the center of the screen. The electron beams from all three guns

should hit the CRT at the same point. If they do not, adjust the beam posi

tioning magnets and the blue lateral magnet until they do. This i s known

as DC or static convergence. Note that only the dots in the center of the

screen are used in this check.

5

Page 6

For dynamic convergence the crosshatch, vertical bar and horizontal

bar patterns are used. Dynamic convergence procedures are slightly dif

ferent for each color set and to make these adjustments to specifications,

the service literature for the set should be followed.

The second part of the procedure is to check all of the circuits which

will affect the black and white picture. These circuits in color TV sets

do not differ appreciably from the circuits found in black and white sets

except for an additional group of controls used for black and white track

ing adjustments. This group consists of separate controls for the screen

voltage on each CRT gun plus a B gain, G gain and a CRT bias control. In

older sets "background" controls took the place of the B gain, G gain and

CRT bias controls.

To adjust these controls you should refer to service literature for

the set, but basically the screen controls are adjusted for equal intensity

of each color whereas the B gain, G gain and CRT bias controls are adjusted

for the best black and white picture, throughout the normal range of the TV

brightness and contrast controls.

Other slight differences in color TV circuits are a regulated high

voltage supply to reduce blooming and loss of convergence, a separate focus

voltage supply and a wider IF response to pass the color information.

If the CRT is functioning properly and a good black and white picture

can be obtained, then the third step on a defective color set is to check

the color circuits. The color circuits are not difficult to service if you

understand the various functions that they perform. They consist of the

following:

Band Pass Amplifier - The band pass amplifier is used to separate

and amplify, from the video signal, the band of frequencies from

3 to 4.1 megacycles. All of the transmitted color information is

within this band.

3.58 Megacycle Reference Oscillator - The reference oscillator

is used to restore the color carrier in the demodulator circuits

of the color TV set. It is kept in phase with the original car

rier at the transmitter by controlling it with the color bursts

which are on the horizontal back porch. The oscillator provides

two signals separated by a 90 degree phase shift for the demodu

lators .

Demodulators - The demodulators beat the reference oscillator

signals against the chroma signal from the band pass amplifier

to produce color information signals for the CRT grids. In Zenith

sets the color gun grids are driven directly from the demodulator

plates. In other sets, the color signals are amplified in R-Y,

G-Y and B-Y amplifiers before being applied to the grids.

Burst Amplifier - The burst amplifier separates and amplifies the

burst pulse from the video signal to control the 3.58 megacycle

reference oscillator.

6

Page 7

Color Killer - The color killer circuit produces a negative bias

in the absence of a color signal to cut off the.band pass ampli

fier. It is controlled by the output of the phase detector.

Phase Detector - The phase detector compares the burst signal

from the burst amplifier with the reference oscillator signal.

It controls the phase of the reference oscillator signal and,

also, controls the color killer.

To troubleshoot these circuits, you need the CG126 set to the color

bar pattern and a good wide band service oscilloscope with a low capacity

probe such as the SENCORE Model PS120.

Let's start with the band pass amplifier. Zenith uses a two stage

amplifier, See Figure 2 , whereas RCA uses a single stage amplifier, See

Figure 3 . Waveforms (Wl , W2 etc.) that you should get with the CG126 are

shown at each input and output of the amplifiers.

1 V PP

4V PP

8V P P

Fig. 2. T wo -sta ge bandpa ss amp lifie r in Zenith Chassis 27 KC 20 receives input from video detector.

7

Page 8

50 V PP

t '

νΛΛΛΛΛΛΛΑΑ |ΐ»ι»»Μ

» 6.5V PP

Fig. 3 In RCA Chassis C TC 1 2 , c h ro m a sign al passes t h ro u g h first vid e o am p li fi e r an d on e b a n d pa s s stage.

Some of the main differences between the circuits are these: (1) Zenith

picks up the color input from the video detector; RCA from the first video

amplifier, (2) Zenith has the burst pickoff after the signal passes through

the 1st chroma amplifier; RCA picks off the burst at the input to the band

pass amplifier, (3 ) The burst signal appears at the output of the Zenith

amplifier whereas in the RCA it is gated out because of a positive gate

pulse applied to the amplifier cathode, (4 ) Zenith has an additional feature-

ACC (Automatic Color Control) applied to the grid of the first amplifier

which keeps the gain of this stage constant during minor changes in the

amplitude of the incoming color signal.

The waveform at the plate of the burst amplifier is shown in Figure 4.

This signal will exist only when color is being transmitted. If you switch

the CG126 to a black and white pattern, the burst will disappear although

the base line will still show traces of the horizontal gate pulse.

8

Page 9

Figure 4. Waveform at plate of burst amplifier.

The waveforms at the output of the 3.58 megacycle reference oscillator

and the waveforms at the oscillator inputs to the demodulators are continuous

3.58 megacycle sine wave signals and are present at all times. Refer to the

service literature for the amplitude of these signals. The waveforms at the

output of the demodulators or at the CRT grids in those sets that use ampli

fiers are shown in Figure 5 . The demodulator phasing adjustments can be done

with an oscilloscope or quite accurately without an oscilloscope. The latter

method is faster while the scope method is more positive.

123454719 10

I 2 3 * 5

*—Y

«7 β » 10

3 4 9*78

U U υ Ί . ·

Fig. 5 . Displays at red,^.

blue and green grids (top

to bottom) as seen with

scope.

Demodulator Phasing Adjustment Without Scope

1. Set the tint control in the TV for mid range.

2. Ground the blue and green color gun grids through 100K resistors. The

sixth bar from the left of the screen on the color bar pattern should blend

with the background. If the sixth bar does not blend with the background,

adjust the burst amplifier transformer slugs so that blend is correct.

3. Return the blue gun to normal and ground the grids of the red and green

guns through 100 K resistors. The third and ninth bars of the pattern should

blend with the background. If not, adjust the "CW,T driver transformer to

obtain correct blend.

Page 10

4. Return the green gun to normal and ground the grids of the red and blue

guns through 100K resistors. The first and seventh bars of the pattern

should blend with the background. If this is not obtained, repeat the com

plete demodulator phasing adjustment procedure above.

When using an oscilloscope to make these adjustments, proceed as above

but make the grid patterns identical to those shown in Figure 5.

THE CG126 PRODUCES STANDARD COLOR BARS

The color bar pattern, used in the above trouble shooting procedure,

is fast becoming the standard of the industry. It is simple to use for

analyzing and adjusting color TV circuits, because one pattern covers the

full color range eliminating confusion and guesswork.

The principle behind this type of pattern is simple. An oscillator

that is operating at a frequency of 3563795 cycles (the color carrier fre

quency 3579545 cycles minus the horizontal line frequency) will appear as

a 3.58 megacycle signal that is constantly changing in phase, when com

pared to the 3.58 megacycle reference oscillator signal in the TV, such

that there is a complete change in phase of 360 degrees for each horizontal

line o f sweep. Thus, a complete range of colors is produced during each

horizontal line . Each line displays all colors the same since the phase

difference between both oscillators at the beginning of the sweep is always

zero. (If the phase changes 360 degrees during one sweep starting with

zero phase difference at the beginning of the sweep, then it will also be

zero at the beginning of the next sweep, etc.).

By gating the 3.56 megacycle oscillator at a frequency 1 2 times

than the horizontal sweep frequency, color bars can be produced that

exactly 3 0 degrees apart all around the color spectrum. When viewed

picture tube in a normal operating set, they will appear as shown in

_ Ο σ ® _*(£

+- + Ϊ + + i T +

Fig. 6. Color Bar Pattern.

higher

are

on the

Figure 6 .

Note that of the 12 gated bursts only 10 show on the picture tube as

color bars. This is because one of the bursts occurs at the same time as

the horizontal sync pulse and, thus, is eliminated and the other occurs

immediately after the horizontal sync pulse and becomes the color sync

burst, which is used to control the 3.58 megacycle reference oscillator in

the TV set.

10

Page 11

MAKING CG126 AD JU ST MEN TS

Adjusting the Timer. The timer on the CG126 has been designed with

the fewest number of countdown stages of any generator on the market. This

has one very important advantage; it permits the timer to be adjusted without

taking the unit apart and it does not require an oscilloscope to make these

adjustments. If the timer on the CG126 should become unlocked from the

crystal controlled master oscillator (usually indicated by a weaving in the

pattern) it is easy to reset the timer using an operating TV set. The timer

adjustments are on the rear of the unit.

1. Set up the TV set from a station and center the horizontal hold and

vertical hold controls within the locking range.

2. Remove the antenna from the TV set and feed in a signal from the

CG126. Set the pattern switch to crosshatch and let the generator warm

up for approximately 15 minutes.

Before proceeding with the adjustments, a discussion of what a "locked”

pattern is should be explained. The CG126 produces interlace scanning just

like a TV station and will cause the horizontal lines to appear as a fast

intensity variation. In other words, the pattern will appear soft or have

a slightly dulled appearance as opposed to a pattern that is not locked in

and consequently not interlaced.

3. If the pattern has just a slight weave, mark tne position of each

of the controls, except the 15750, on the back of the unit, and then

adjust each one slightly in each direction until the pattern locks.

If the timer is too far out o f adjustment proceed with Step 5 .

4. If the vertical lines in the pattern slope to the left or right,

adjust the 15750 cycle control until 9 vertical bars are present on the

picture tube. (If the raster on TV were pulled in, you would see 11

bars). Set the control to the center of the locking range.

5. Set the 60 cycle, 900 cycle and 13 50 0 cycle controls fully counter

clockwise. Adjust the 60 cycle control for the slightest amount of

weaving in the pattern.

6 . Adjust the 900 cycle control for 13 horizontal bars on the picture

tube. (If the raster on the TV were pulled in , you would see 1 4 bars).

7 . Repeat the adjustments of the 60 cycle and 900 cycle controls until

you can get 13 bars with the slightest amount of weaving in the pattern.

8. Adjust the 13500 cycle control on the CG126 until the pattern be

comes locked (does not weave), and the horizontal lines have a soft

appearance as described above.

9. Set the 60 cycle, 900 cycle and 13500 cycle controls to the center

of the locking range.

If you should desire to use an oscilloscope to set the timers, observe

the waveforms on the common cathodes of each of the multivibrators (See

Figure 7). Set the 15750 cycle MV (V 6 ) for a 12 to 1 countdown; the 13,500

cycle MV (V2) for a 14 to 1 countdown; the 90 0 cycle MV (V3) for a 15 to 1

countdown and the 60 cycle MV (V 4) for a 15 to 1 countdown.

11

Page 12

fl II

56 K

η

MODEL CG 126 SCHEMATIC DIAGRA M

Page 13

Dot Size Adjustment. The CG126 has an external dot size adjustment,

on the back of the unit, which can be used to change the width of the dots

or the vertical lines, in the dot, crosshatch and vertical bar patterns.

The smaller the dots are made, the more readily you can notice convergence

errors. However, the dots should not be made so small that they are diffi

cult to see clearly. You should adjust the dot size trimmer to your own

liking while observing the pattern on a TV.

Color Frequency Adjustment. The frequency of the color carrier must

be quite accurate. This can be adjusted without using laboratory equip

ment by using the bursts from a color program as a standard.

To do this you must first tune in a color program on an operating

color TV set. Remove the correction voltage to the 3.58 megacycle refer

ence oscillator in the TV and adjust the reference oscillator in the TV

until a beat is seen in the picture. Connect the CG126, after it has

warmed up for approximately 10 minutes, to the color set and adjust for

a color bar pattern. With the correction voltage to the 3.58 megacycle

reference oscillator in the TV still disabled, adjust C14 (See Fig. 7)

for a zero beat in the color bar pattern. For best results you should go

through this procedure twice.

Modulation Level. The modulation level control (R53) can be adjusted

while observing the crosshatch pattern on a TV set. Observe the points in

the pattern where the horizontal and vertical lines cross. Notice that as

the modulation level control is turned up , a point is reached where the

brighter crossover points start to compress (get dimmer). This represents

100 percent modulation and the control should be backed off from this point

slightly for the proper setting.

You may desire to eliminate the bright crossover dot by turning the

modulation level up. This can be done without any harmful effects to the

other patterns.

RF Oscillator Adjustment. The RF oscillator can be adjusted using a

TV set or, for more accuracy, with a frequency standard to beat against.

The oscillator is set at the factory to 67.25 megacycles (Channel 4). If

Channel 4 is used in your area and is quite strong, such that it interferes

with the patterns, it would be best to change the CG126 frequency to Channel

3 or to Channel 5.

To do this using a good color TV set, proceed as follows: First, tune

the TV to the station signal on Channel 4 . Without moving the fine tuning

control,switch the set to Channel 3 or 5. Connect the CG126 to the set and

set the Pattern switch to color bars. Adjust trimmer C32 on the CG126 until

the color bar pattern is properly displayed on the screen. Check other

patterns to see that they are also tuned in properly.

Disassembly Instructions. To remove the CG126 panel and chassis from

the case, remove the two screws that hold the cord wrapper on the back of

the unit, and remove the two screws that hold the panel to the bottom of the

unit. The panel and chassis will then slip out from the front of the case.

13

Page 14

CIRCUIT DESCRIPTION

Timer.

The heart of the CG126 is the timer which consists of five separate

oscillators, (See Fig. 7) ; a 189 kc crystal controlled Pierce oscil

lator and four countdown or dividing stages. A sine wave from the

plate (p in 1 ) of the 189 kc oscillator is coupled through capacitor

divider C3 S- C4 to the grid (pin 2) of the 13,500 cycle multivibrator V2.

V2 synchronizes to every 14th pulse from the 189 kc osc. and generates

new pulses at a 13,500 cycle rate. In other words, the 189 kc frequency

is divided by 14 and the result is a new frequency at 13,500 cycles.

Each of the three other countdown multivibrators operate in exactly the

same way. The 900 cycle MV V3 synchronizes to every 15th pulse from V2

(13,500 MV) and the 60 cycle MV V4 synchronizes to every 15th pulse

from V3 (900MV). The 15,750 cycle MV V6 synchronizes to every 12th

pulse from the 189 kc oscillator. Since all of these oscillators are

locked to the 189 kc crystal controlled oscillator, the pattern and sync

signals which are developed from them will all be locked together and

will be in the correct time relationship to each other.

Each of the four countdown oscillator circuits are cathode coupled

multivibrators and are identical except for the components that deter

mine the frequency.

The frequency of each countdown multivibrator is controlled by changing

the voltage to the grid of the 2nd section with controls R10, R17, R24

and R37. This changes the rate at which the grid rises and, thus, con

trols the frequency.

A sharp negative pulse is available at the 2nd section plate of each

multivibrator pin 6 . The pulses from the 15,750 cycle and 60 cycle

multivibrators will be mixed to generate sync pulses. The pulse from

the 900 cycle multivibrator is used for part of the video signal, and is

also used to sync the 60 cycle MV. The pulse from the 13,500 cycle MV

is used only to sync the 900 cycle MV.

A signal from pin 2 of VI the 189kc oscillator is fed through C2 to

the grid of the 2nd section of VI . This stage is a shaping stage which

is driven into saturation on the positive half cycle and into cutoff on

the negative half cycle of the signal, generating a square wave in the

output. The output, pin 6 of VI is used in three ways. First, the

square wave is differentiated by C22, C23 and R39 when generating dots,

crosshatch and vertical bar patterns. Second, it is used to drive the

3.56 MC gate, 2nd section of V5, when generating the color bar pattern.

The 3.56 megacycle oscillator is a crystal controlled Pierce type

oscillator that generates a 3.56 MC sine wave. It is turned on when the

pattern switch SI is in the color bar position by applying B+ to the

plate load resistor R27. The signal from the plate, pin 1 , is coupled

rhrough C16 to the grid, pin 7 , of the second section of V5. The 189 kc

square wave also feeds the same grid through C17 and R30. The two sig

nals are added across R28. The negative cycle of the 189 kc square wave

14

Page 15

drives the tube into cutoff so that on the plate, pin 6 , bursts of 3.56

signal are riding on the negative portion of the 189'kc square wave

that is present. The signal is coupled through C18 to R31, the chroma

control and thence to the signal mixer. C18 and R31 differentiate the

189 kc portion of the signal such that when color bars are displayed on

the TV the leading edges of the bars are bright and the trailing edges

are dark.

Signal Mixers.

Now that we have seen how the required signals have been generated in the

crystal oscillators and multivibrators we will see how they must be mixed

to produce the composite color TV signal. The sync signals are mixed or

added together across the common grid resistor R47, of the video inverter

stage V8. These signals are both sharp negative pulses, one a 15.75 kc

pulse fed through isolating resistor R52 and the other a 60 cycle pulse

fed through R25. At the same time V8 receives video signals from the

Signal Mixer stage (V7) through a resistive-capacitive network R46, R47

and C27. In the "Dot Pattern" position, a diode CR2 is switched in series

with this network which allows only the most positive peaks to pass through

it which produces white dots in the output.

The output of V8 is fed to the modulator through C30. The modulation

level is controlled by R53.

The Signal Mixer stage V7 consists of two triodes of which each grid is

fed with, a different signal. The mixed output appears across the common

plate load resistor R42. R43 attenuates the signal from the second triode

section so that equal outputs from each triode section appear across R42.

The seco.i d triode section receives a sharp negative 900 cycle pulse from

V3. This signal is shorted out when vertical bars or color bars are

selected to prevent interference. The input to the first triode section

depends on the setting of the pattern switch. In the first 3 positions

of this switch 189 kc square wave pulses are applied through a differen

tiating circuit C22, C23 and R39 to the control grid of V7. CR1 removes

the positive spike developed by the differentiating circuit which is

undesirable. Without CR1 a black vertical bar would appear between every

white vertical bar. In the 4th position (Horizontal bars) the grid is

grounded. In the last position of the pattern switch (Color Bars) the

3.56 me osc. is turned on and a 3.56 me signal gated at a 189 kc rate is

applied to the control grid of V7. This is the color pattern with black

bars separating each color. The amount of signal is selected with the

color output control.

Power Supply.

The power supply is of conventional design consisting of a half wave

silicon rectifier followed by pi filters, R49 is a surge limiting and

protecting resistor. B+ is distributed through 3 resistor-capacitor

networks to the various stages in the CG126 to provide adequate filter

ing and good isolation. R64 and C28D constitute a low frequency boost

circuit for the video inverter to insure even background intensity on

all patterns.

15

Page 16

Tuner. The tuner in the CG126 consists of one half of V8 which is

used as an RF oscillator, and V9 which is the modulator and output

tube.

The RF oscillator is of the Hartly type and is tuned with C32

across LI. The frequency is set at the factory to 67.25 megacycles

(Channel 4). C29 is an RF bypass condenser from the plate of the

oscillator (pin 6) to ground.

The modulator receives RF signals from the oscillator through C33

to the grid (pin 1 ) and composite video signals to the second con

trol grid pin 7. C34 bypasses the screen (pin 6) for RF frequencies.

The output of the modulator appears across plate load resistor R60

and across the output cable through C36. R61, R62, and R63 serve

to terminate the cable properly such that there are no standing

waves.

CG126 TROUBLE CHART

NOTE: Make certain TV set is operating correctly before determining trouble

definitely is in the CG126.

Symptom

Vertical lines

slant to the

left or right

Slow horizontal

wiggle of ver

tical line

Pattern has

rapid wiggle

in both

directions

Pattern has slow

wiggle in both

directions

Probable Cause

15.75 kc MV V6

900 MV V3

60 MV V4

13.5 Kc MV V2

Corrective Measure

Adjust Freq. control R37. If trouble can

not be corrected, remove unit from case .

Check waveform at cathode (Pin 3) of V6 ;

See Fig. 7 . Replace V6. Check value of

R32, R35 and R36 and check C19, C20 and

C21 for leakage using ohmmeter.

Adjust Frequency control R17. Check

waveform at cathode (pin 3) of V3. See

Fig. 7. Replace V3. Check value of R12,

R15 and R16 and check C6, C7 , C8, C9 and

CIO for leakage using ohmmeter.

Adjust Freq. control R24. Check waveform

at cathode (pin 3) of V4. See Fig. 7.

Replace V4. Check value of R19, R21 and

R23 and check C9, Cll and C12 for leakage

using ohmmeter.

Adjust Freq. control RIO. Ch^ck waveform

at cathode (pin 3) of V2. See Fig. 7 .

Replace V2. Check value of R5, R 8 , and

R9 and check C3, C4, C5 and C6 for leakage

using ohmmeter.

Faint cross-

hatch appears

in Dot posi

tion of Pat

tern Switch

Brightness set

ting too high

on TV set. Leak

age through

diode CR2

Reduce brightness of TV set. Check for

ward to reverse resistance of CR2 and

replace if required.

16

Page 17

CG126 TROUBLE CHART (Cor^t.)

Symptom

____ __ __

Excess snow

in Pattern

No color bars

Loss of detail

in patterns

Faint light

or dark band

moves verti

cally thru

pattern

Probable Cause

Incorrect tuning

of TV set. RF

osc. V8, modula

____________ ___

Retune fine tuning on TV set to remove

snow. Check V8 and V9 and replace if

necessary.

Corrective Measure

tor V9.

Color output

Increase Output with output control check

control set to V5 and replace if necessary; check patteri

low, 3.56 me

switch SI for poor contacts.

osc., pattern

switch

Incorrect tuning

of TV set. Video

mixer stage V8,

Retune fine tuning on TV set to improve

pattern detail. Check V8 and replace if

necessary. Check frequency of RF osc.

Setting of C32. and reset if necessary.

Pickup on output

Make connection between 1 antenna termi

cable. nal and TV chassis ground.

Patterns

weak

Dead set

(no output)

V9 , R53

On-Off switch

S2, rectifier

CR 3 , R49, C28

Check and replace V9 and V8 i f necessary.

Check R53 value and setting.

Check if S2 is in stdby position. Check

CR3 and replace if necessary. Check

value of R49 and check sections of C28

for excess leakage using ohmmeter. Also,

check for B+ short.

CG126

PARTS LIST

CAPACITORS

Ref. N o.

Cl, C2, C31

Description

100MMF 20% 500V

Stock No.

24G82

C3, C 6 , C15 ,

C18, C19, C22

33 MMF 10% 500V 24G83

C4 , C20 100MMF 5% 500V 24G70

C5

27MMF 5% 500V

C7 330MMF 5% 250V

C8

270MMF 5% 250V 24G79

24G7 5

24G78

C9, CIO 220MMF 20% 600V 24G25

Cll .001 MF 5% 250V

24G80

C12 .0062 MF 5% 250V 24G81

C13 390MMF 10% 500V 24G49

C14

C16

5-50MMF trimmer

10MMF 10% 500V

24G47

24G86

17

Page 18

CG126 PARTS LIST ( C o n Tt.)

CAPACITORS

Ref. No. Description Stock No.

C17,

C36

C21

C23

C2 4, C30

C25

C26

C27, C33

C28

C2 9,

C34, C35

C32

RESISTORS

Rl , R 1 8 ,

R57

R 2 , R58

R 3 , R4 6,

R 4 , R26

R5, R32

R 6, R13 ,

R 2 8 , R33

R47

R 7 , R21,

R 8 , R2 2 ,

R 9 , R 1 6 ,

R36

RIO , R 1 7,

R37

R ll

R12

R1 4, R 15 ,

R34

R19

R 2 5 , R52

R 2 7 , R41,

R31

R 3 8 , R44

R40

R42

R43

R45

R49

R50

R51

R53

R54

R59

R60

R61, R6 2 ,

R64

R48,

R56

R20,

R39.

R35

R29

R23,

R2 4 ,

R30,

R55

R63

. 0015MF 20% 600V

20MMF 5% 500V

5-5-MMF trimmer with bracket

.1 MF 20% 200V

.0022 MF GMV 1000V

.5MF 20% 200V

4MMF 10% 500V

120, 10 0, 35, 3MF § 17 5 , 150 , 12 5 ,

10 OV

.00 5MF 20% 500V

1.5-10MMF trimmer

10OK %W 10%

1.5 Meg %W 10%

2.7K 10%

330K i$W 10%

1.5 Meg 5%

39K ijW 10%

1.8K 10%

1.2K %W 10%

10 Meg %W 5%

250K pot lin 30%

56K %W 10%

5.6 Meg %W 5%

2.2K %W 10%

8.2 Meg %W 5%

27K %W 10%

33K %W 10%

2K pot lin 10%

10 Meg %W 10%

10K %W 10%

2.7K 1W 10%

4.7K %W 10%

3.3 Meg %W 10%

27 ohm %W 10%

IX 5W 10%

IK 1W 10%

IK pot lin 10%

IK 10%

5. 6K 10%

100 ohm 10%

110 ohm %W 5%

18K 10%

24G74

24G77

24G98

24G27

24G26

24G30

24G72

24G97

24G9

24G99

14G39

14G189

14G18 5

14G20

14G184

14G16

14G2

14G82

14G85

15G27

14G38

14G187

14G78

14G188

14G15

14G36

15G24

14G48

14G34

14G37

14G46

14G64

14G66

14G174

14G60

15G28

14G1

14G53

14G74

14G190

14G3 5

18

Page 19

MISC.

Ref. No ■

CG126 PARTS LIS T (C o n ’t.)

Description

Stock No.

LI

51

52

T1

CR1j CR2

CR3

.35 micro H coil

4P5P rotary switch

2P3P slide switch

Power transformer

IN295 diode

.5A § 400PIV rect.

Knob

189 KC crystal

3563.795 KC crystal

46G 7

25G67-1

25G64

28S23-1

19G2

16 S 5

21G13

47 G 1

47G3

19

L

Loading...

Loading...