Page 1

FinishPro®25XP

XtremePro™ 18 Gauge Brad Nailer

The SENCO FinishPro

category! This lightweight, power-packed nailer is loaded with all

the features you need, plus a few more. The FinishPro 25XP

drives both slight and medium headed 18 ga. brads from

5/8" to 2-1/8" into the hardest woods. The “on-tool” power

adjustment allows the user to increase power by 30%. All this,

plus SENCO’s exclusive NeverLube

work surface oil free.

®

25XP has redefined the brad nailer

®

design to keep your

Tool Specifications:

Item#: 760102N Sequential Actuation (Restrictive)

Weight: 2.7 lbs (1.227 kg)

Height: 10" (251.46 mm)

Length: 10" (254 mm)

Width: 2.2" (55.88 mm)

Nail Capacity: 110

Operating Pressure: 70-120 psig

Mode of Operation: Restrictive Trigger only

Fastener Specifications:

The FinishPro 25XP drives both slight headed and medium headed

18 gauge brads from 5/8" to 2-1/8".

Power Adjustment:

Applications:

Molding and decorative trim, furniture trim, window beading,

blind pinning of upholstered and trim panels, rattan, scribe

molding, cabinets, drawers and picture frame assembly

Features and Benefits:

• Five-year limited warranty

•Comfort and convenient features include: overmold

comfort grip, overmold trigger, “on-tool” power adjustment,

360º adjustable exhaust, and belt hook

• Lightweight at 2.7 lbs for easy maneuvering and all day work

• Drives slight and medium head 18 gauge brads from 5/8"

(15mm) to 2-1/8" (55mm)

• On-tool power adjustment to lengthen the life of the tool when

used primarily with shorter fasteners

• Wrenches onboard to make the adjustment fast and easy

• NeverLube technology – no lubrication required

The FinishPro 25XP has the unique ability to increase or decrease the

power output with a simple adjustment located on the tool. The Standard

setting for the FinishPro 25XP allows you to accomplish most jobs. This

is the factory setting. The Turbo setting on the FinishPro 25XP gives you

a 30% increase in power for longer brads and harder wood applications.

For complete details on how to operate the power adjustment, please refer

to the operators manual.

Standard Setting Turbo Setting

©2007 Senco Products, Inc.

www.senco.com

®

Page 2

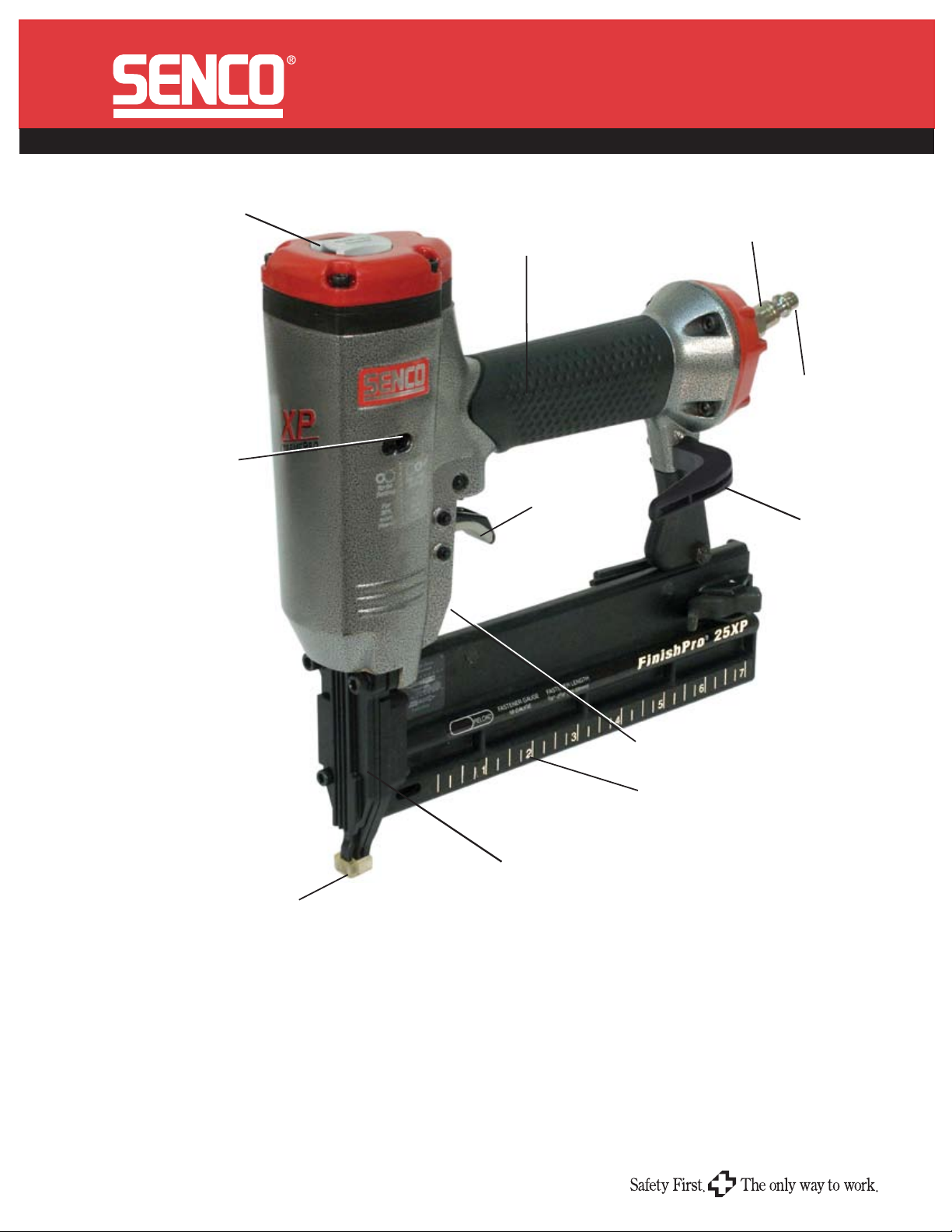

Adjustable Exhaust –

No tools required

On-tool Power Adjustment –

Lengthens the life of the tool by

allowing the user to choose the

right power setting for the job.

Wrenches provided onboard to

make the adjustment fast and

easy

FinishPro®25XP

XtremePro™ 18 Gauge Brad Nailer

Angled Air Inlet

Overmold Grip –

Reduces vibration and fatigue,

increases productivity

Overmold Trigger –

Reduces fatigue

Keeps the hose off the work

surface when the tool is in the

vertical position

NeverLube® Technology –

Requires no tool oil

Belt Hook

Lets the tool go

where you go

Lightweight & Maneuverable –

At only 2.7 lbs, for easy

maneuvering and light enough

for all day work

No-Mar Pad & Square Nose Safety –

Protects work surface and the square nose safety

design keeps the tool from slipping out of position

Choose the right trigger system for your specific needs!

Sequential Actuation Trigger (also known as restrictive trigger or trigger fire) operates in

the following a sequence - depress the safety element at the nose of tool against the work

surface then pull the trigger. After each fastener is driven, release the trigger and lift the

tool off the work surface before starting the sequence again. This trigger is recommended

and acceptable for most applications.

Contact Actuation Trigger (also known as dual action, bounce or bottom fire) operates in

the following sequence- pull the trigger first and keep the trigger pulled while moving the

tool along the work surface with a bouncing motion, depressing the safety element at the

nose of the tool against the work surface where the fastener is to be driven. This trigger is

recommended for use by trained professionals only in high production or volume

applications.

©2007 Senco Products, Inc.

www.senco.com

Thumb Wheel Adjustable Depth-of-Drive –

Drives nails to a consistent and controllable depth

Construction Ruler –

For quick measurements

Last Brad Lock Out –

Lengthens the life of the tool

Alw ays read the Operators Manual and Safety Instruction s wi th all tool s to ensu re

prop er use and safety precautio ns. For addi tio nal info rmation on trigg er systems and

ho w SENCO wi ll save you time, reduce costs, an d in crease q uality, call our to ll -free

Actio n Li ne: 80 0-543 -4596 to find your nearest Au thorized Senco Dealer, Distributo r

or visit o ur web site at: www .senco .com

®

Loading...

Loading...