Page 1

OPERATING INSTRUCTIONS

AIR NAILER

MODEL: F50F

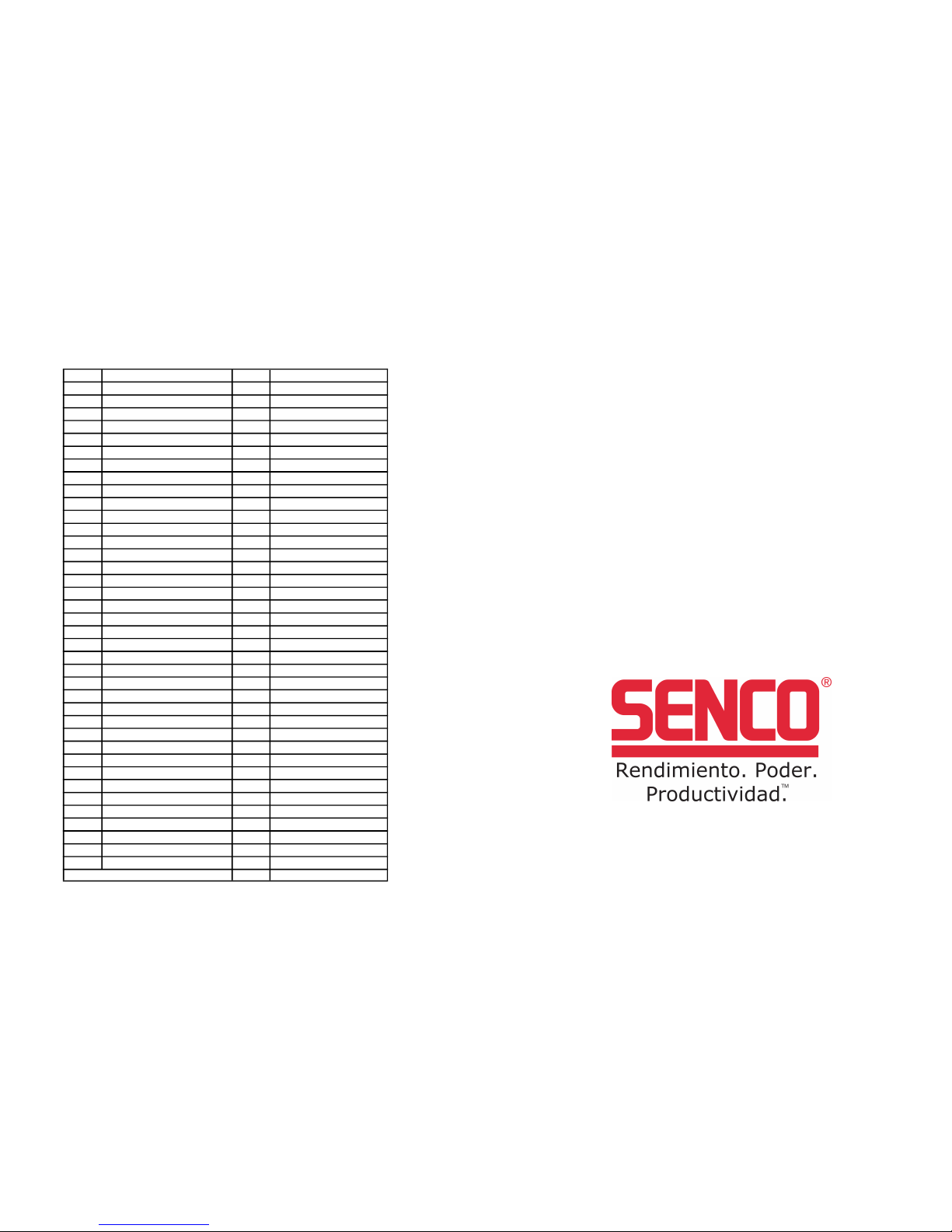

PARTS LIST

Refer to the Exploded View Drawing for the location of parts listed below

6

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

21A

22

23

24

25

26

27

28

28A

28B

29

30

31

32

32A

33

34

35

SCR EW

BUS HIN G

EXH AUST CO VER

DESC RIPTI ON

DESC RIPTI ON

WASH ER

SCRE W

WASH ER

CYLI NDER CAP

GASK ET

VALV E SEA L

SPRI NG

O-RI NG

O-RI NG

VALV E

O-RI NG

STOP PED W ASHER

COLL AR

O-RI NG

O-RI NG

PIST ON AS SEMBL Y

CYLI NDER

O-RI NG

O-RI NG

BUMP ER

BODY

JOIN T GUI DE

SPRI NG PI N

SAFE GUID E

SPRI NG

SAFE BRACK ET A

SAFE BRACK ET B

SAFE BRACK ET C

SEAL

TRIG GER V ALVE HEAD

SPRI NG

TRIG GER V ALVE STEM

O-RI NG

O-RI NG

TRIG GER V ALVE GUIDE

SPRI NG

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

52A

53

54

54A

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

ITEM

TRIG GER S PRING

SPRI NG PI N

TRIG GER

TRIG GER

WASH ER

SLEE VE

LATC H ASS EMBLY

SPRI NG PI N

PLAT E

SPRI NG PI N

SCRE W

FRON T PLA TE

SCRE W

DRIV E GUI DE

PIN

MOVA BLE M AGAZI NE

FEED ER SH OE

FEED ER SE T

SPRI NG

RAIL

PIN

FIXE D MAG AZINE

SCRE W

STOP PED P LATE

LOCK

SPRI NG

SCRE W

BUSH ING

JOIN T GUI DE

NUT

SUPP ORT

WASH ER

SCRE W

NUT

SOFT GRIP SLEE VE

O-RI NG

END CAP

AIR PLUG

Page 2

5

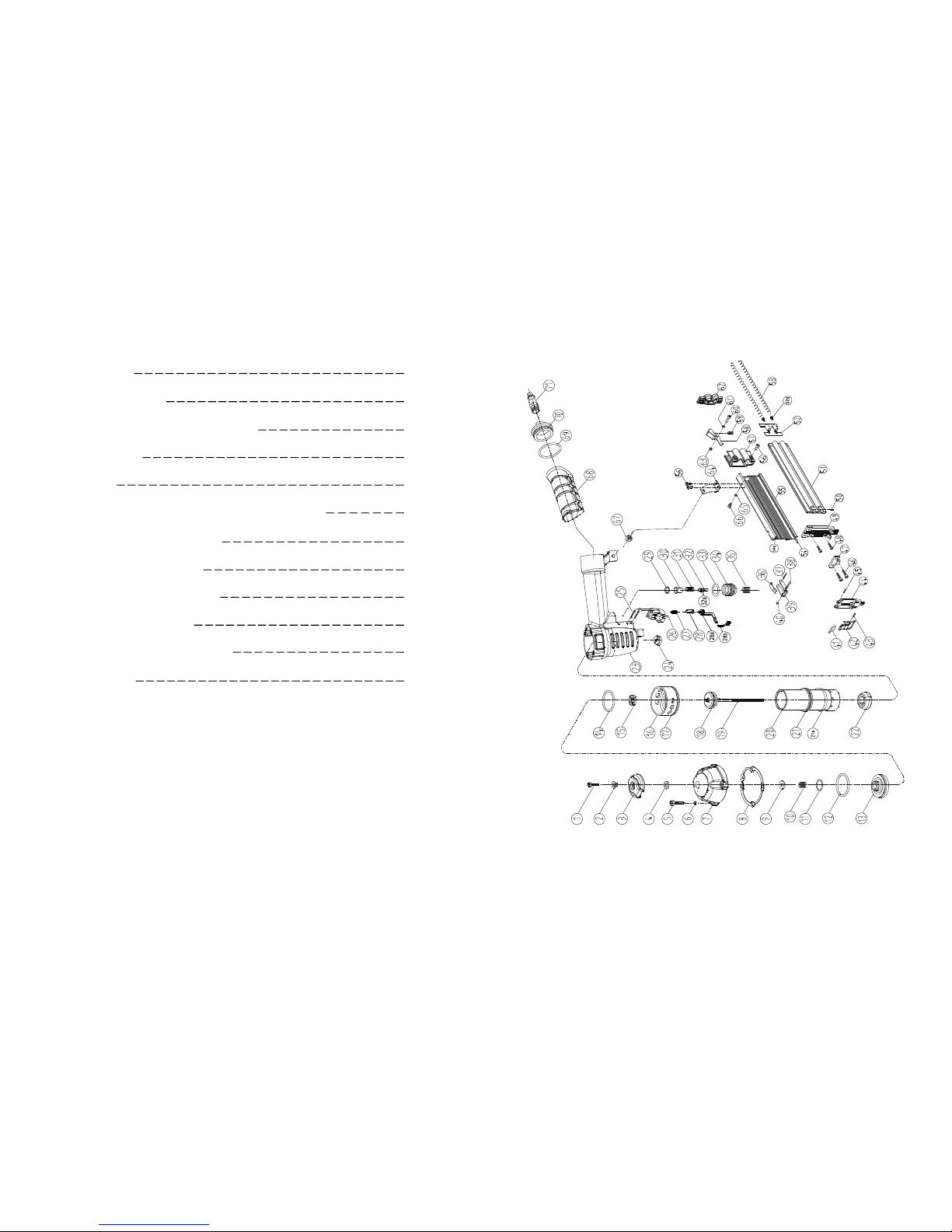

EXPLODED VIEW DRAWING

CONTENTS

SUMMARY

SPECIFICATIONS

SAFETY WARNINGS & CAUTIONS

UNPACKING

SETTING

CONNECTING THE TOOL TO AN AIR SUPPLY

LOADING THE FASTENERS

OPERATING THE TOOL

REGULAR MAINTENANCE

TROUBLE SHOOTING

EXPLODED VIEW DRAWING

PARTS LIST

1

1

1

2

2

3

3

3

3

4

5

6

Page 3

Characteristic

Minimum Operating Air Pressure

Maximum Operating Air Pressure

Nail Length Range

Nail Size

Nail Capacity

Air Inlet

Air Consumption

Tool Weight

Value

60 PSI

100 PSI

3/4" -- 2"

18 Gauge

100

1/4" NPT

1.8 CFM

3.1 lbs

1

SPECIFICATIONS

SUMMARY

You will need the instruction for the safety warning and precautions, assembly instruction, operating and maintains

procedures, part s list and diagram. Keep your invoice with this instruction. Write the invoice number on the inside of

the front cover. Keep the instruction and invoice in a safe and dry place for future reference.

READ ALL INSTRUCTIONS BEFORE OPERATING THE TOOL

1. Lubricat e as instructed.

2. Check air supply.

3. Replace spring.

4. Repl ace damaged int ernal

parts.

1. Replace joint guider.

2. Use the r ecommend ed and

undamaged faste nerls.

3. Tighten scr ews.

4. Replac e piston assembly.

1. Replac e piston assembly.

2. Adj ust to ad equ at e ai r

pressure .

3. Check cylindre cap spring for

broken c oils or reduce d length.

Check i f exhaust port of cylinder cap is restr icted.

1. Repl ace bumper or pusher

spring.

2. Cl ean drive channel of fr ont

plate.

3. Check hose and co mpressor

fittings.

4. Replace O-ring or lubricate.

5. Replace O-r ing.

6. Repl ace seal.

4

TROUBLE SHOOTING

PROBLEM

Air leaking at

Trigger area

PROBLEM CAUSE

SOLUTION

1. O-ring in trigger valve are damaged.

2. Trigger valve head are damaged.

3. Trigger valve st em, seal or O-ring a re

damaged.

1. Check and replace O-ri ng.

2. Check and repl ace trigger

valve head.

3. Check and repl ace trigger

vlave stem, seal or O-r ing.

Air leaking between

body and front plate

Damaged piston O-ring or bumper.

Air l eaking betw een

body and cylinder cap

1. Screw loose.

2. Damaged seal.

1. Tighten screws.

2. Check and replace seal.

Blade driving fastener

too deeply

1. Worn bumper .

2. Air pressure is too higher.

1. Replac e bumper.

2. Adjust the air pressur e.

Check and replace O-ring or

bumper.

Runs sl owly o r has

power lo ss

Tool skip a fasteners

Fasteners are jammed

Tool will not d rive

down tight

1. Insufficient oil.

2. Insufficient air supply.

3. Broken spring in cylinder cap.

4. Exhaust port in cylinder cap is blocked.

1. Worn bumper or d amaged spring (53).

2. Dirt in front plate.

3. Inadequate airflow to tool.

4. Worn or dry O-ring on piston.

5. Damaged O-ring on trigger valve.

6. Cylinder cap seal leaking.

1. Joint guider is worn.

2. Fa steners are wro ng size or d amaged.

3. Magazine or front plate screw s are loose.

4. Blade in pi ston assembly is damaged.

1. Worn blade in piston assembly.

2. Lack o f power.

3. Slow cycling and loss of power.

STO P USIN G THE TOOL IM MEDIATE LY IF ANY OF THE FOLL OWING PROB LEMS

OC CUR. SER IOUS PERS ONAL INJURY COU LD O CCUR. ANY REPAI RS OR R EPLA CEMENTS MUST B E DONE BY A QUALIFIED PERSON OR AN AUTHO RIZED SERVICE CENTER

ON LY.

SAFETY WARNINGS& CAUTIONS

1. KEEP WORKING AREA CLEAN. Cluttered areas invite injuries.

2. DON’T ALLOW CHILDREN KEEP AT THE WORKING AREA. Don’t let them handle the tool.

3. DO NOT OPERATE THIS TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS. Read

warning label on prescriptions to determine if your judgment or reflexes are impaired while taking drugs. If there

is any doubt, do not attempt to operate.

4. USE SAFETY GLASSES. Safety glasses should conform to ANSI Z87.1 specifications. Before operating,

wear safety glasses against flying debris from the front and side. Safety glasses should be worn when loading,

operating, unloading or servicing this tool.

5. USE EAR PROTECTION. The working area may be exposed to high noise levels that can lead to hearing

damaged.

6. NEVER USE OXYGEN COM BUSTIBLE GASES, BOTTLED GASES OR HIGH PR ESSURE

COMPRESSED GAS AS A POWER SOURCE FOR THIS TOOL. The tool may explode and cause

serious injury.

7. DRESS SAFELY. Protective gloves and nonskid footwear or safety shoes are recommended when working

with and operating this tool. Don’t wear loose clothing or jewelry. They can get caught in moving parts. Also,

wear a protective hair covering to prevent long hair from getting caught in the tool.

8. DO NOT FIRE TO HARD MATERIALS. Do not attempt to shoot toward hard or brittle material such as

concrete, steel or tile.

9. WHEN OPERATING TOOL. keep the proper footing and balance to avoid damaged resulting from losing

balance.

10. CHECK DAMAGED PARTS. Before using tool, carefully check if there is any part damaged.

11. REPLACE PARTS AND ACCESSORIES. Only allow use same replacement parts while servicing. Ap-

proved accessories and replacement parts are available.

12. KEEP ALERT. Watch what you are doing. Use common sense. Do not operate any tool when you are tired.

Page 4

CONNECTING THE TOOL TO AN AIR SUPPLY

1. Determine if the tool needs oil and, if necessary, place two drops of oil in

the AIR PLUG(71) as shown in Figure 2. If you are using an automatic in-line

oiler, check and add oil if necessary.

2. Turn the compressor on and set the regulator to the prope r pressure for the

size and type of fastener being used.

3. Co nnec t the tool to the air supply (see S etup for air supp ly connecti on

recommendations).

Figure 2

Figure 3

LOADING THE FASTENERS

1. Depress the LOCK(58) to release the MOVABLE MAGAZINE (51)

and pull the magazine out fully as shown in Figure 3.

2. Place a full clip of the specified type and siz e faste ners on the

FIXED MAGAZINE (55), up t o 100 fasteners may be loaded in the

magazine.

3. P ush the MOVABLE MAGAZINE ASSEMBLY forw ard until it

was locked .

OPERATING THE TOOL

Test the driving depth in a sample p iece of wood before using. If t he fasteners are b eing driven too far or not far

enough, adjust the regulator to p rovide less a ir pressure or more air pressure.

1. Connec t the to ol t o the air supp ly. Make sure the air pressu re is in cor rect range deno ted in se ction of

SPECI FICATI ONS.

2. Load fastener above as the direction given i n the section called LOAD THE FASTENE R.

3. Hold the Body (23) and press the Drive guide (49) to work surface , be sure the tool is straight and then gently depress

the Trigger (39) to drive the fastener.

4. Lift the tool off the work surface.

5. The tool has two driving modes:

1). P ut the nose on the working surface, lightly push he tool to ward the working surface until the Safe br acket

is depressed, t hen, depr ess the trigger t o drive the fasteners.

2). First, depress the Trigger, then, repeatedly impact the Safe bracket, the tool can repeatedly drive the fasteners.

The tool will drive one fastener when the Safe bracket is impacted one ti me.

3

REGULAR MAINTENANCE

1. Frequent, but not excessive, lubrication i s required for best perfor mance. Oil add ed thro ugh the airline connection

will lubrica te internal parts. An automatic ai rline oilier is recommended but oil may be added manually before every

operation or after about 1 hour of continuous use. Only a few drops of oil at a time are necessary. Too much oil wi ll

collect inside the tool and be blown out during the exhaust cycle. ONLY USE PNEUMATIC TOOL OIL. Do not

use detergent oil or additi ves, as these lubricants wi ll cause accelerated wear t o the seal in the tool.

2. Use a small amount of oil on all moving surface and pivots.

3. D irt and water in the a ir suppl y are major causes of pneumatic too l wear. Use a fil ter/oi ler fo r better perfor -

mance and longer life. The fi lter must have adeq uate fl ow c apacit y fo r the sp ecific ap plicat ion. Consult t he

manufacturer's instructions for proper maintenance of you filte r.

4. Keep t ools cl ean for better and safer performance. Use nonflammable c leaning soluti ons ( CAU TION: Suc h

solutions may damaged O-ring and other tool parts) only if necessary- DO NOT SOAK.

Description

Nailer

S3 Hex Key

S4 Hex Key

Air Tool Oil

Operating instruction

Qty

1

1

1

1

1

2

Figure 1

SETTING

Your air tool is fully assembly when you recei ve i t. Before using it, attach the air line and desired air system

accessories. See Figure 1 for the recommended accessories and connecti on order. Be sure the air hose is dep ressur-

ized when installing or removing adapters to the air line.

WARNING: The warning, caution, and instructions explained in this instruction manual cannot cover

all possible conditions and situations that may occur. It must be understood by the operator that COM-

MO N SENSE AND CAUTI ON AR E FA CTORS WH ICH C ANN OT BE BUI LT INTO THIS

PRODUCT, BUT MUST BE SUPPLIED BY THE OPERATOR.

UNPACKING

When unpacking, check and make sure that all the accessories are included. If anyone is missed or broken,

please call seller for help. Refer to the follow lists.

13. STORE THE TOOL. When not in use, tool should be cleaned, fully assembled and then, stored in a dry

location to reduce rust. For safety, keep out of reach of children.

14. OUTDOORS EXTENSION CORDS. When air compressor is used outdoors, use only rounded jackets

extensions cords intended for outside use. See manufacturer’s manual for the AWG required for the compressor’s

amperage draw.

15. PAY ATTENTION TO AIR HOSE AND THEIR CONNEATIONS. Don’t trip over hoses. Make sure all

connections are tight.

16. AFTER LOADING THE FASTENERS. never point the tool at yourself or bystanders.

17. USE THE CORRECT AIR CONNECTOR. The connector on the tool must not hold pressure when the air

supply is disconnected. If the wrong fitting is used, the tool can be charged with air after being disconnected and

still be able to drive a fastener.

18. WHEN CONNECTING THE AIR. The tool can possibly fire the fasteners. Therefore, remove all the fasteners before connecting to the air.

19. DO NOT DEPRESS THE SAFE BRACKET AND THE TRIGGER WHEN LOADING.

20. IF THE FASTENERS ARE JAMMED. Disconnect the tool from the air and remove the jammed fasteners

out.

LOC K

NAIL ER

QUI CK

CONN ECTOR

OILE R

REGU LATOR

AIR H OSE

AIR SU PPLY

FILTER

Loading...

Loading...