Hex Half-Bridge Driver

NCV7723B

The NCV7723B is a six channel half−bridge driver with protection

features designed specifically for automotive and industrial motion

control applications. The product has independent controls and

diagnostics, and the drivers can be operated in forward, reverse, brake,

and high impedance states. The device is controlled via a 16 bit SPI

interface and is daisy chain compatible. Outputs 1 and 2 can be

controlled through an external PWM signal.

www.onsemi.com

Features

• Low Quiescent Current Sleep Mode

• High−Side and Low−Side Drivers

Connected in Half−Bridge Configurations

• Integrated Freewheeling Protection (LS and HS)

• 500 mA Typical, 1.1 A Peak Current

DS(on)

= 0.8 W (Typ)

• R

• OUT1 and OUT2 External PWM Control

• 5 MHz SPI Communication

• 16 Bit Frame Error Detection

• Daisy Chain Compatible with Multiple of 8 bit Devices

• Compliance with 3.3 V and 5 V Systems

• Undervoltage and Overvoltage Lockout

• Per Channel Fault Reporting

• Overcurrent Protection

• Overtemperature Protection

• Underload Detection (HS and LS)

• Exposed Pad Package

• NCV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q100

Qualified and PPAP Capable

• This is a Pb−Free Device

MARKING

DIAGRAM

NCV7723B

AWLYWWG

SSOP24 NB EP

CASE 940AK

NCV7723B = Specific Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

ORDERING INFORMATION

See detailed ordering and shipping information on page 23 of

this data sheet.

Typical Applications

• Automotive

• Industrial

• DC Motor Management for HVAC Application

© Semiconductor Components Industries, LLC, 2018

February, 2020 − Rev. 1

1 Publication Order Number:

NCV7723B/D

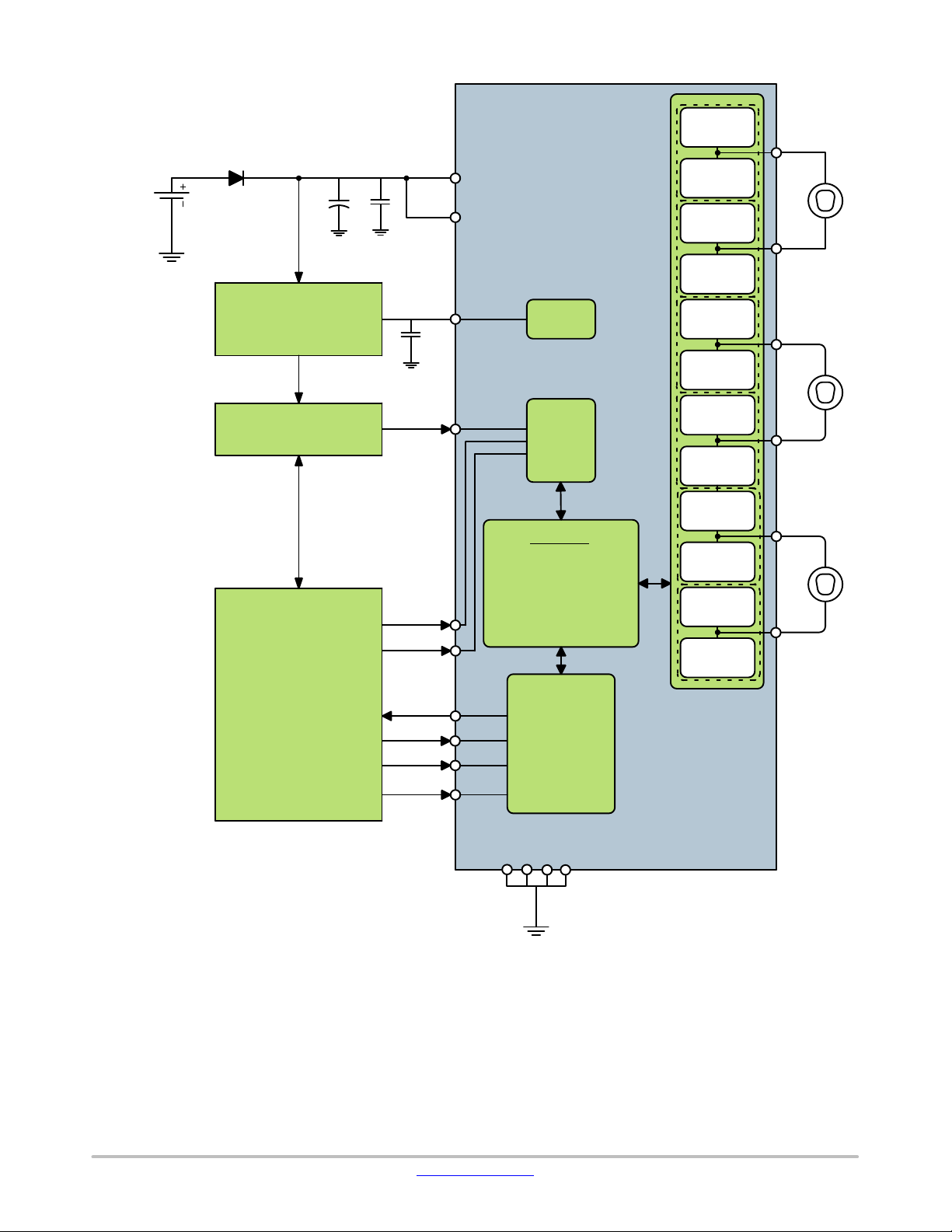

NCV7723B

13.2 V

10 mF 0.1 mF

Voltage

Regulator

Watchdog

VS1

VS2

VCC

0.1 mF

EN

PWM1

PWM2

NCV7723B

Power On

Reset

Control

Logic

Protection:

Under Load

Over Temperature

Under−voltage

Over−voltage

Over Current

High−side

Driver

Low−side

Driver

HS

LS

HS

LS

HS

LS

HS

LS

High−side

Driver

Low−side

Driver

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

uC

SO

SI

SCLK

CSB

16−Bit

Serial

Data

Interface

GND

Figure 1. Typical Application

www.onsemi.com

2

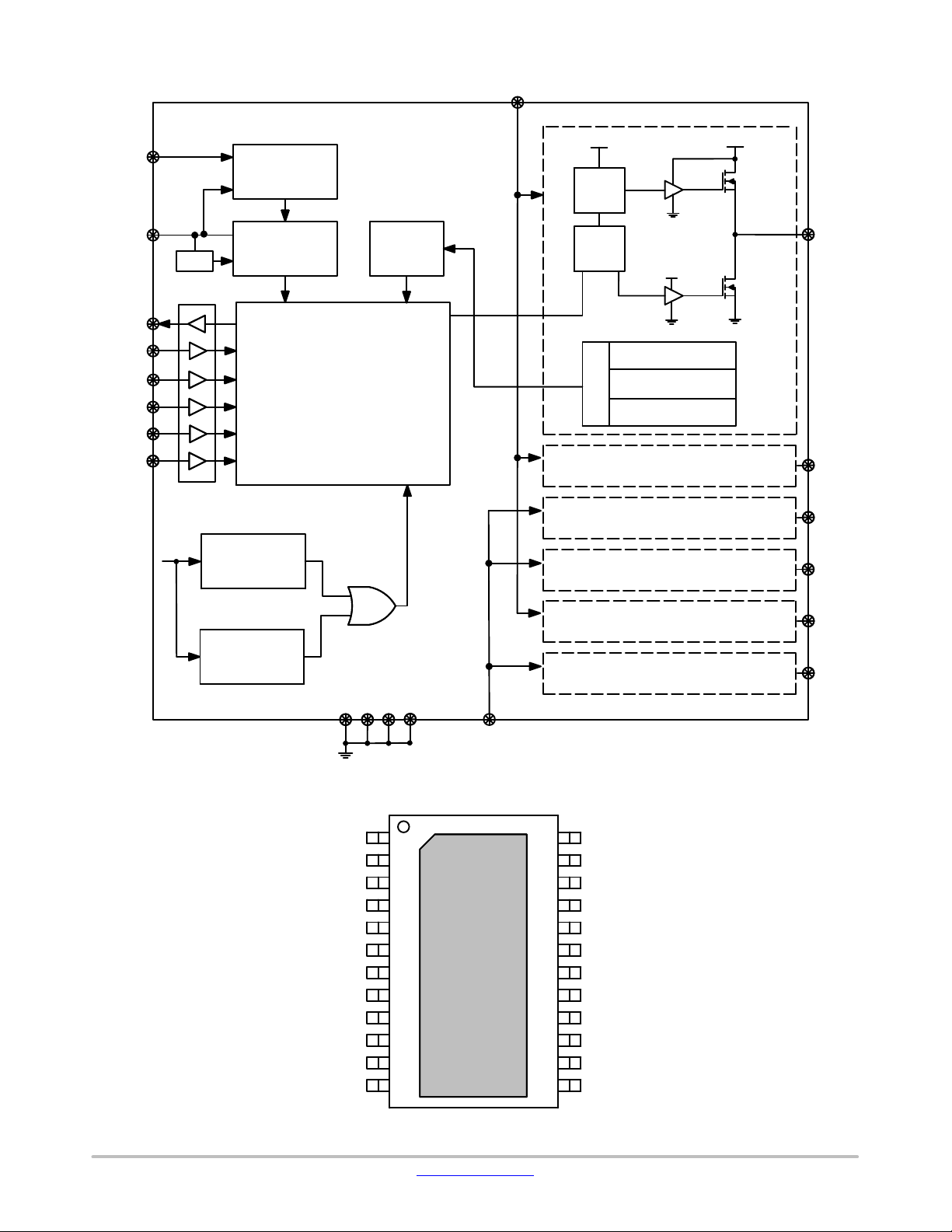

NCV7723B

VS1

EN

VCC

SO

SCLK

CSB

PWM1

PWM2

VS

ENABLE

POR

SI

VS1,

VS2

Overvoltage

BIAS

SPI and 16 Bit Logic Control

Lockout

Fault

Reporting

VS1

VS1

VS2

VS2

Charge

Pump

Control

Logic

Fault

DRIVE1

Wave Shaping

Wave Shaping

VS

HS+ LS Under Load

Overcurrent

Thermal Warning &

Shutdown

DRIVE 2

DRIVE 3

DRIVE 4

VS

High Side

Driver

OUT1

Low Side

Driver

OUT2

OUT3

OUT4

Undervoltage

Lockout

GND

GND

OUT1

OUT5

NC

VCC

SO

EN

NC

OUT6

OUT4

GND

SI

GND

GND

GND

Figure 2. Block Diagram

1

2

3

4

5

6

7

8

9

10

11

12 13

EPAD

VS2

24

23

22

21

20

19

18

17

16

15

14

VS1

VS2

GND

OUT2

NC

VS1

SCLK

CSB

PWM2

PWM1

VS2

NC

OUT3

GND

DRIVE 5

DRIVE 6

OUT5

OUT6

Figure 3. Pinout – SSOP24 NB EP

www.onsemi.com

3

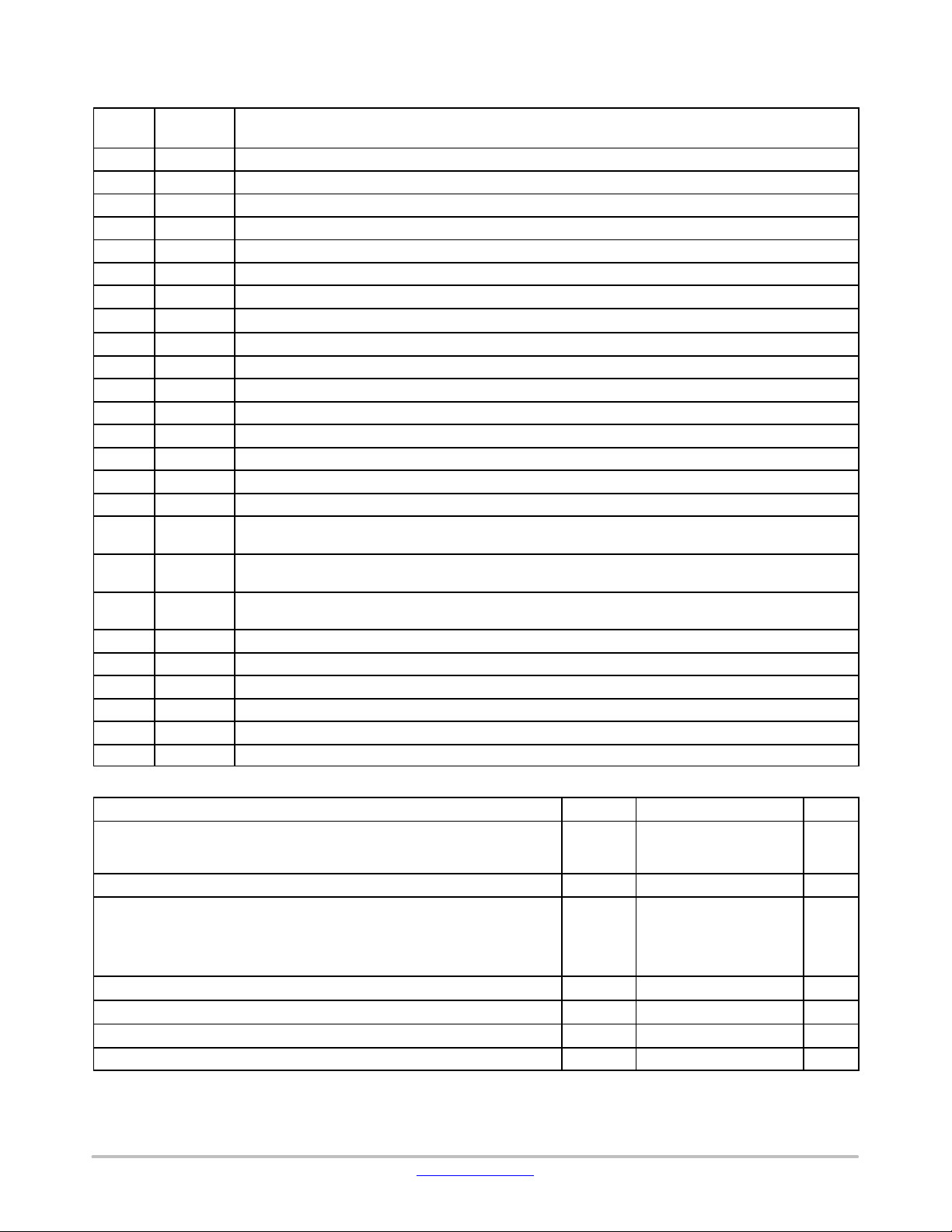

NCV7723B

PIN FUNCTION DESCRIPTION The pin−out for the Half−Bridge Driver in SSOP24 NB EP package is shown in the table below.

Pin#

SSOP24

1 GND Ground. Must be connected to other GND pins externally.

2 OUT1 Half−bridge output 1

3 OUT5 Half−bridge output 5

4 NC No Connection. This pin should be isolated from any traces or via on the PCB board.

5 SI 16 bit serial communication input. 3.3 V / 5 V (TTL) Compatible − internally pulled down.

6 VCC Power supply input for Logic.

7 SO 16 bit serial communication output. 3.3 V / 5 V Compliant

8

9 NC No Connection. This pin should be isolated from any traces or via on the PCB board.

10 OUT6 Half−bridge output 6

11 OUT4 Half−bridge output 4

12 GND Ground. Must be connected to other GND pins externally.

13 GND Ground. Must be connected to other GND pins externally.

14 OUT3 Half−bridge output 3

15 NC No Connection. This pin should be isolated from any traces or via on the PCB board.

16 VS2 Power Supply input for outputs 3, 4, and 6. This pin must be connected to VS1 externally.

17 PWM1 External PWM input for output 1. 3.3 V / 5 V (TTL) Compatible − internally pulled down. Connect to ground or

18 PWM2 External PWM input for output 2. 3.3 V / 5 V (TTL) Compatible − internally pulled down. Connect to ground or

19

20 SCLK Serial communication clock input. 3.3 V / 5 V (TTL) Compatible − internally pulled down.

21 VS1 Power Supply input for outputs 1, 2, and 5. This pin must be connected to VS2 externally.

22 NC No Connection. This pin should be isolated from any traces or via on the PCB board.

23 OUT2 Half−bridge output 2

24 GND Ground. Must be connected to other GND pins externally.

EPAD Exposed Pad Connect to GND or leave unconnected.

Symbol Description

EN Enable − active high; wakes the device from sleep mode. 3.3 V / 5 V (TTL) Compatible − internally pulled down.

leave floating if unused.

leave floating if unused.

CSB Chip select bar − active low; enables serial communication operation. 3.3 V / 5 V (TTL) Compatible − internally

pulled up.

MAXIMUM RATINGS (Voltages are with respect to GND)

Rating

VSx Pin Voltage (VS1, VS2)

(DC)

(AC), t < 500 ms, Ivsx > −2 A

Pin Voltage (Vcc, SI, SCLK, CSB, SO, EN, PWM1, PWM2) VioMax −0.3 to 5.5 V

OUTx Pin Voltage

(DC)

(AC)

(AC), t < 500 ms, IOUTx > −1.1 A

(AC), t < 500 ms, IOUTx < 1 A

OUTx Pin Current (OUT1, ..., OUT6) IoutxImax −2.0 to 2.0 A

Junction Temperature Range T

Storage Temperature Range Tstr −55 to 150 °C

Peak Reflow Soldering Temperature: Pb−free 60 to 150 seconds at 217°C (Note 1) 260 °C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. See or download ON Semiconductor’s Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

Symbol Value Unit

VsxdcMax

VSxac

VoutxDc

VoutxAc

J

−0.3 to 45

−1.0

−0.3 to 45

−0.3 to 45

−1.0

1.0

−40 to 150 °C

V

V

www.onsemi.com

4

NCV7723B

ATTRIBUTES

Characteristic Symbol Value Unit

Short Circuit Reliability Characterization AECQ10x Grade A

ESD Capability

Human Body Model per AEC−Q100−002 VSx, OUTx

All Other Pins

Charged Device Model per AEC−Q100−011

Moisture Sensitivity Level MSL MSL2

Package Thermal Resistance – Still−air

Junction–to–Ambient (Note 2)

Junction–to–Board (Note 2)

2. Based on JESD51−7, 1.6 mm thick FR4, 2S2P PCB with 600 mm2 2 oz. copper and 18 thermal vias to 80x80 mm 1 oz. internal spreader

planes. Simulated with each channel dissipating 0.2 W.

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Max Unit

Digital Supply Input Voltage VCCOp 3.15 5.25 V

Battery Supply Input Voltage (VS1 = VS2) VSxOp 5.5 32 V

DC Output Current IxOp − 0.5 A

Junction Temperature TjOp −40 125 °C

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

Vesd4k

Vesd2k

Vesd750

R

q

JA

R

Y

JBOARD

≥ ±4.0 kV

≥ ±2.0 kV

≥ ±750 V

32.1

21.8

°C/W

°C/W

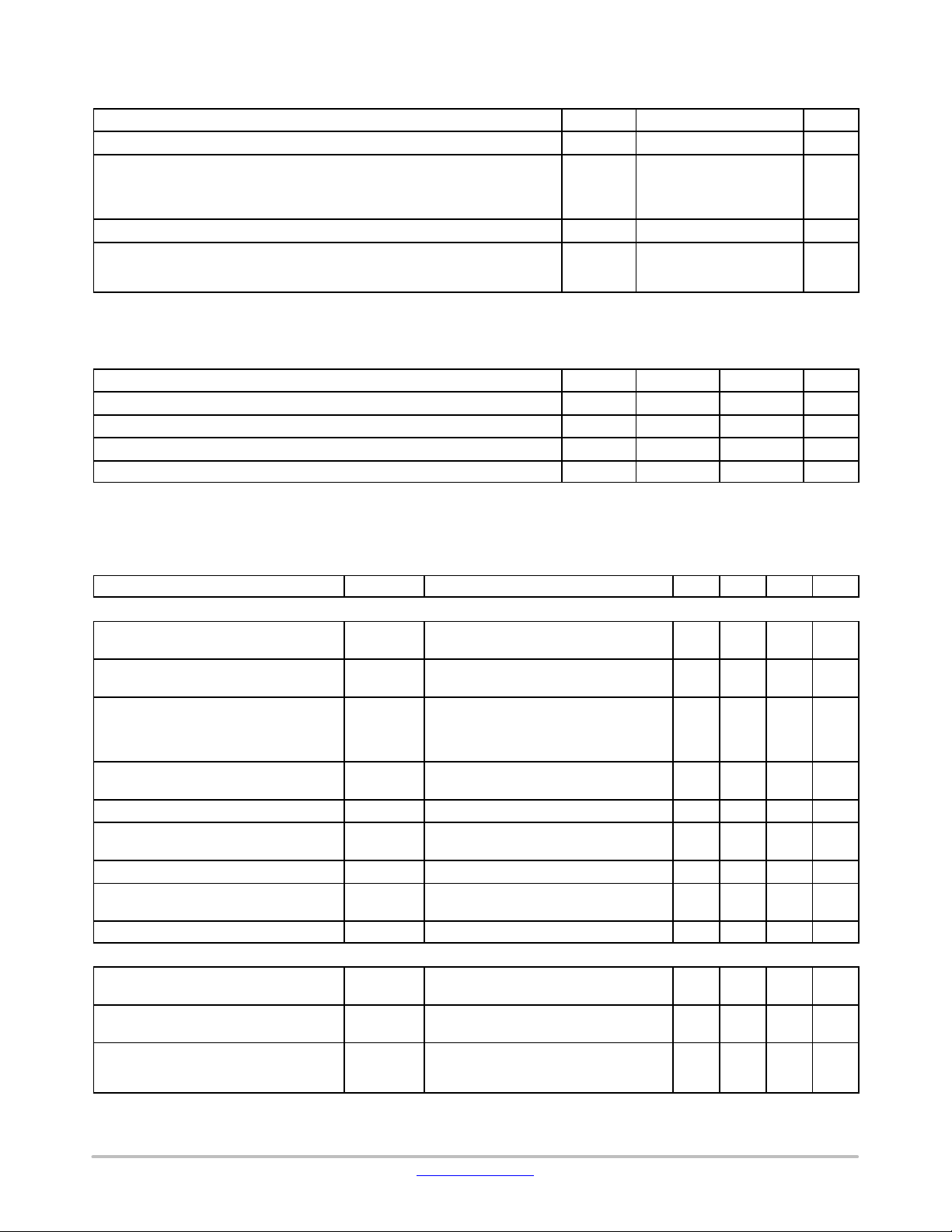

ELECTRICAL CHARACTERISTICS

(−40°C ≤ T

POWER SUPPLIES

Supply Current (VS1 + VS2)

Supply Current (VS1 + VS2)

Supply Current (Vcc)

Total Sleep Mode Current

VCC Power−on Reset Threshold VCCpor V

VSx Undervoltage Detection Threshold VSxuv VSx decreasing

VSx Undervoltage Detection Hysteresis VSxuHys 100 − 450 mV

VSx Overvoltage Detection Threshold VsXov VSx increasing

VSx Overvoltage Detection Hysteresis VSxoHys − 2.5 − V

DRIVER OUTPUT CHARACTERISTICS

Output High R

Output Low R

Source Leakage Current

≤ 150°C, 5.5 V ≤ VSx ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified.)

J

Characteristic

Sleep Mode

Symbol Conditions Min Typ Max Unit

IqVSx85 VS1 = VS2 = 13.2 V, V

−40°C to 85°C

CC

= 0 V

IvsOp EN = VCC, 5.5V < VSx < 32 V

Active Mode

No Load,All Outputs Off

CSB = VCC, EN = SI = SCLK = 0 V

Sleep Mode

Active Mode

IqV

CC

IVCCOp

EN = CSB = V

−40°C to 85°C

, SI = SCLK = 0 V

CC

No Load, All Outputs Off

IqTot Sleep Mode, −40°C to 85°C

I(VS1) + I(VS2) + I(VCC)

VS1 = VS2 = 13.2 V, No Load

increasing − 2.70 2.90 V

CC

VSx increasing

VSx decreasing

(source) RDSonHS Iout = −500 mA, Vs = 13.2 V

DS(on)

(sink) RDSonLS Iout = 500 mA, Vs = 13.2 V

DS(on)

IsrcLkg13.2

IsrcLkg28

V

= 3.15 V

CC

V

= 3.15 V

CC

V

= 5 V, OUT (1−6) = 0 V, EN = 0/5 V

CC

VSx = 13.2 V

VSx = 28 V

− 1.0 2.5

−

0.5 1.0 mA

−

1.0

2.5

−

1.5

3.0

− 2.0 5.0

3.5

4.1

4.3

4.5

4.7

3.7

32

29.53633.54037.5

− 0.8 1.8

− 0.8 1.8

−1.0

−2.0−−

−

−

mA

mA

mA

mA

V

V

W

W

mA

mA

www.onsemi.com

5

NCV7723B

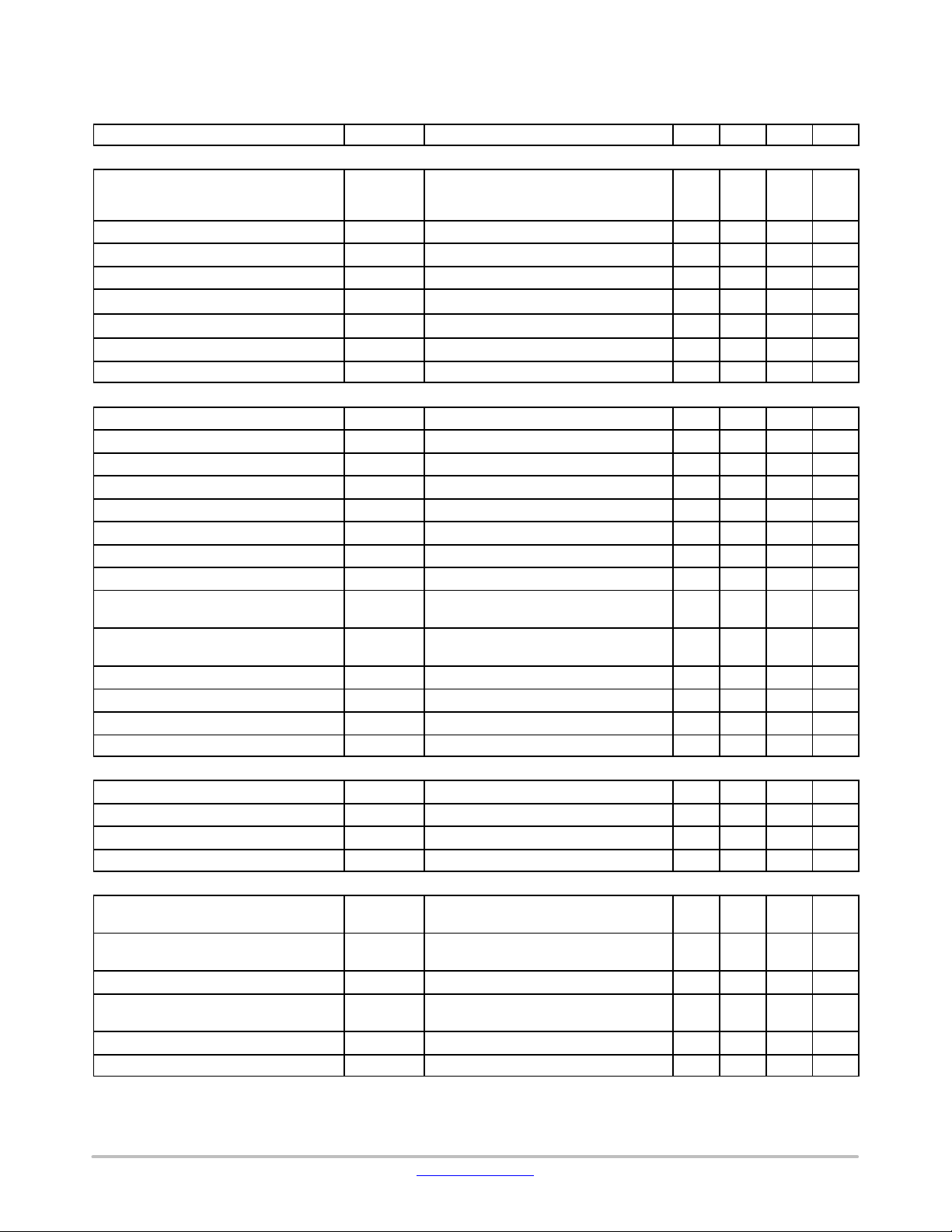

ELECTRICAL CHARACTERISTICS

(−40°C ≤ T

DRIVER OUTPUT CHARACTERISTICS

Sink Leakage Current

Overcurrent Shutdown Threshold (Source) IsdSrc V

Overcurrent Shutdown Threshold (Sink) IsdSnk V

Over Current Delay Timer TdOc 10 25 50

Underload Detection Threshold (Low Side) IuldLS

Underload Detection Threshold (High Side)

Underload Detection Delay Time TdUld V

Body Diode Forward Voltage IbdFwd If = 500 mA − 0.9 1.3 V

DRIVER OUTPUT SWITCHING CHARACTERISTICS

High Side Turn On Time

High Side Turn Off Time ThsOff

Low Side Turn On Time TlsOn

Low Side Turn Off Time TlsOff

High Side Rise Time ThsTr

High Side Fall Time ThsTf

Low Side Rise Time TlsTr

Low Side Fall Time TlsTf

High Side Off to Low Side On

Non−Overlap Time

Low Side Off to High Side On

Non−Overlap Time

PWM High to High Side On Time ThsOnPWM

PWM Low to High Side Off Time ThsOffPWM

PWM High to Low Side On Time TlsOnPWM

PWM Low to Low Side Off Time TlsOffPWM

THERMAL RESPONSE

Thermal Warning

Thermal Warning Hysteresis TwHy (Note 3) − 20 − °C

Thermal Shutdown Ts d (Note 3) 150 175 200 °C

Thermal Shutdown Hysteresis TsdHy (Note 3) − 20 − °C

LOGIC INPUTS − EN, SI, SCLK, CSB, PWM1, PWM2

Input Threshold High

Input Hysteresis − SI, SCLK, CSB, PWM1,

PWM2

Input Hysteresis − EN VthENHys 150 400 800 mV

Pull−down Resistance − EN, SI, SCLK,

PWM1, PWM2

Pull−up Resistance − CSB RpuCSB CSB = 0 V 50 125 250

Input Capacitance Cinx (Note 3) − − 15 pF

≤ 150°C, 5.5 V ≤ VSx ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified.) (continued)

J

Characteristic UnitMaxTypMinConditionsSymbol

IsnkLkg13.2

IsnkLkg28

IuldHS

ThsOn

ThsOffLsOn

TlsOffHsOn

OUT (1−6) = VSx = 13.2 V

OUT (1−6) = VSx = 28 V

= 5 V, VSx = 13.2 V −2.0 −1.5 −1.1 A

CC

= 5 V, VSx = 13.2 V 1.1 1.5 2.0 A

CC

V

= 5 V, VSx = 13.2 V

CC

V

= 5 V, VSx = 13.2 V −7.5 −2.5 − mA

CC

= 5 V, VSx = 13.2 V 200 350 600

CC

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

Vs = 13.2 V, R

load

load

load

load

load

load

load

load

load

load

load

load

load

load

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

= 70 W

−

−

− 2.5 7.5

− 120 165

− 20 45

− 120 165

− 35 75

10 30 50

10 30 50

10 30 50

10 30 50

5 − −

5 − −

− 120 165

− 20 45

− 120 165

− 35 75

V

= 5 V, EN = 0/5 V

CC

Twr (Note 3) 120 140 170 °C

Low

VthInH

VthInL

2.0

−

VthInHys 50 150 300 mV

Rpdx EN = SI = SCLK = V

CC

50 125 200

−

1.0

−

2.0

mA

mA

ms

mA

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

−

−

0.6

−

V

V

kW

kW

www.onsemi.com

6

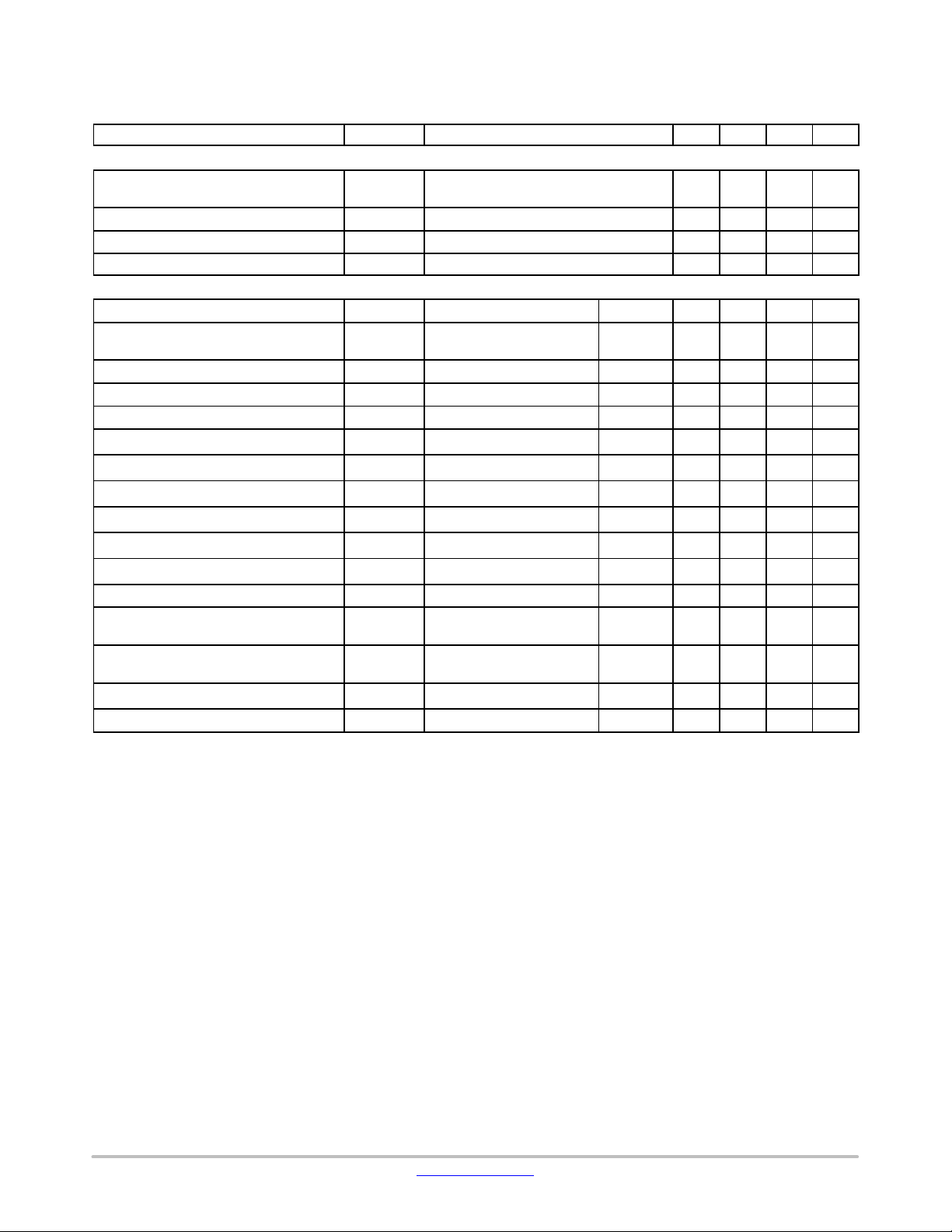

NCV7723B

ELECTRICAL CHARACTERISTICS

(−40°C ≤ T

LOGIC OUTPUT − SO

Output High

Output Low VsoL ISINK = 1.6 mA − − 0.4 V

Tri−state Leakage ItriStLkg CSB = 5 V −5 − 5

Tri−state Output Capacitance ItriStCout CSB = VCC, 0 V < V

SERIAL PERIPHERAL INTERFACE

SCLK Frequency

SCLK Clock Period TpClk V

SCLK High Time TclkH 1 85 − − ns

SCLK Low Time TclkL 2 85 − − ns

SCLK Setup Time TclkSup 3, 4 85 − − ns

SI Setup Time TsiSup 11

SI Hold Time TsiH 12

CSB Setup Time TcsbSup 5, 6

CSB High Time TcsbH (Note 4) 7

SO enable after CSB falling edge TenSo 8

SO disable after CSB rising edge TdisSo 9

SO Rise/Fall Time TsoR/F Cload = 40 pF (Note 3) − − 10 25 ns

SO Valid Time TsoV Cload = 40 pF (Note 3)

EN Low Valid Time TenL V

EN High to SPI Valid TenHspiV −

SRR Delay Between Consecutive Frames Tsrr (Note 5) −

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

3. Not production tested.

4. This is the minimum time the user must wait between SPI commands.

5. This is the minimum time the user must wait between consecutive SRR requests.

≤ 150°C, 5.5 V ≤ VSx ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified.) (continued)

J

Characteristic UnitMaxTypMinConditionsSymbol

VsoH ISOURCE = −1 mA V

< 5.25 V (Note 3) − − 15 pF

CC

CC

0.6

–

Fclk − − − 5.0 MHz

= 5 V

CC

V

= 3.3 V −

CC

200

500

50

50

100

5.0

−

−

10

−

SCLK ↑ to SO 50%

= 5 V; EN H → L 50% to

CC

OUTx turning off 50%

−

10

−

150

− − V

mA

−

−

−

ns

−

− − ns

− − ns

− − ns

− −

ms

− 200 ns

− 200 ns

50 100 ns

− −

− 100

− −

ms

ms

ms

www.onsemi.com

7

NCV7723B

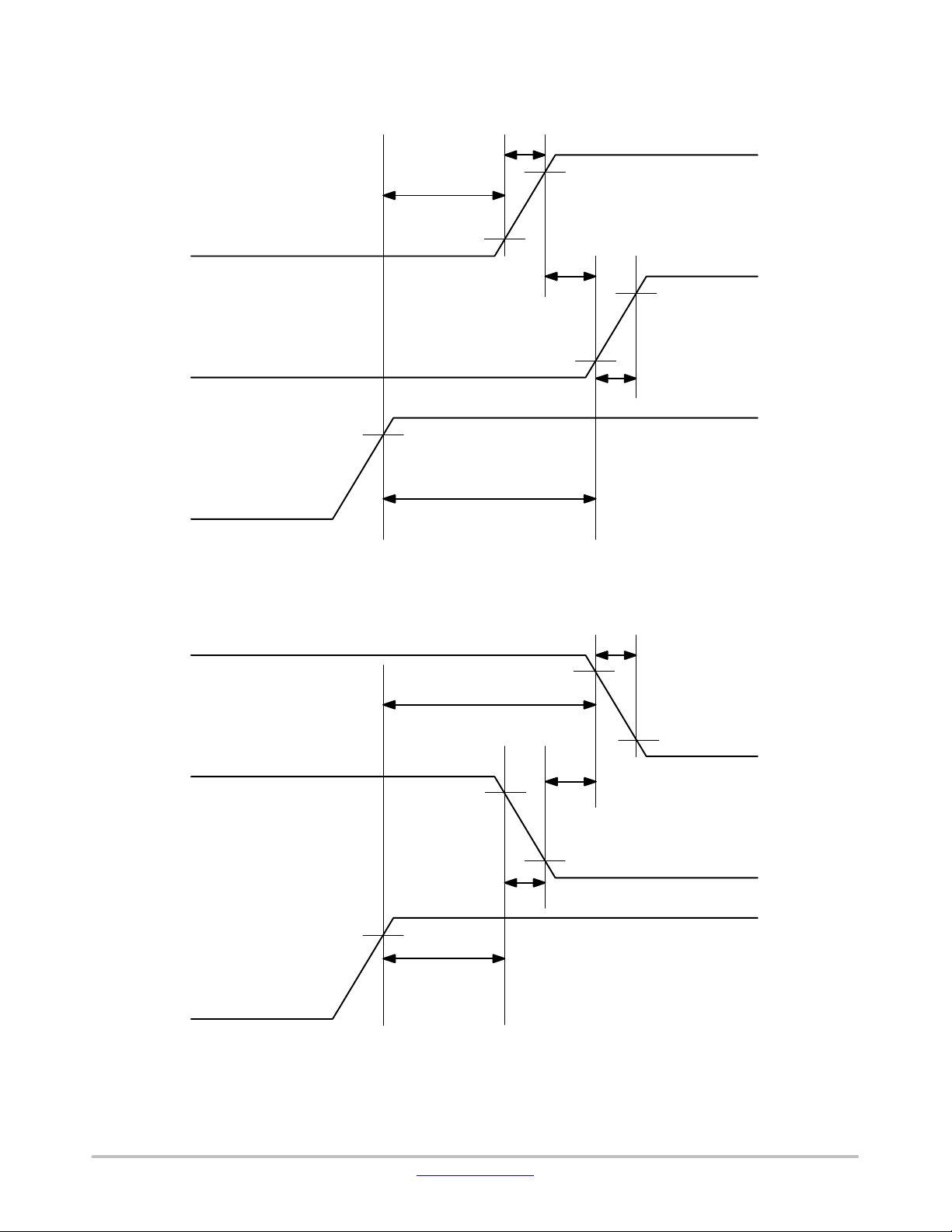

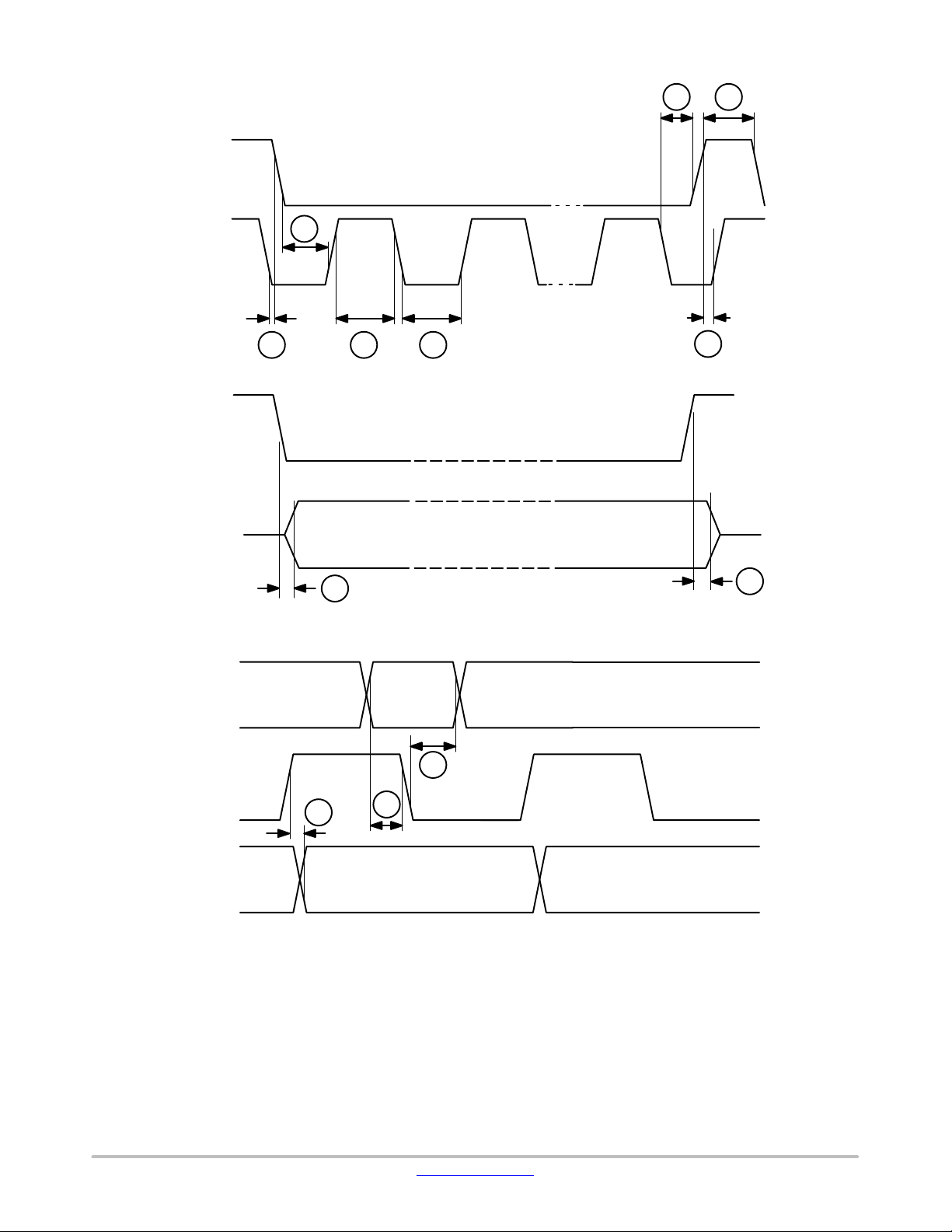

CHARACTERISTIC TIMING DIAGRAMS

TlsTr

TlsOff

90%

LS Turn OFF

HS Turn ON

CSB

LS Turn On

10%

TlsOffHsOn

90%

10%

ThsTr

90%

ThsOn

TlsTf

90%

TlsOn

HS Turn Off

CSB

10%

ThsOffLsOn

90%

10%

ThsTf

90%

ThsOff

Figure 4. Detailed Driver Timing

www.onsemi.com

8

NCV7723B

LS Turn On

HS Turn ON

PWMx

TlsTf

90%

TlsOnPWM

10%

90%

10%

ThsTr

90%

ThsOnPWM

LS Turn Off

HS Turn Off

PWMx

90%

TlsOffPWM

10%

90%

ThsOffPWM

TlsTr

90%

10%

ThsTf

Figure 5. Detailed Driver Timing (OUT1 / OUT2 PWM)

www.onsemi.com

9

CSB

SCLK

NCV7723B

4 7

5

CSB

SO

SI

SCLK

3 1 2

8

12

10

11

6

9

SO

Figure 6. Detailed SPI Timing

www.onsemi.com

10

NCV7723B

TYPICAL PERFORMANCE GRAPHS

3.5

3.0

2.5

2.0

1.5

1.0

0.5

IqTot, TOTAL SLEEP MODE CURRENT (mA)

1.8

1.6

1.4

(W)

1.2

DS(on)

R

1.0

0.8

0

VSx = 13.2 V

1.40

VSx = 13.2 V

VSx = 13.2 V

VCC = 5.25 V

VCC = 5 V

1.38

1.36

1.34

1.32

CURRENT (mA)

1.30

CC

1.28

150°C

25°C

1.26

VCC = 3.15 V

0 100

15050−50

1.24

1.22

ACTIVE MODE V

1.20

−40°C

TEMPERATURE (°C) VCC VOLTAGE (V)

Figure 7. IqTot vs. Temperature Figure 8. I(VCC) Active Mode vs. V(VCC)

1.0

If = 0.5 A

0.95

0.9

HSx

LSx

0.85

LSx

0.8

HSx

5.55.04.54.03.53.0

0.6

TEMPERATURE (°C)

Figure 9. R

DS(on)

1.7

1.6

1.5

1.4

VSx = 13.2 V

= 5.0 V

V

1.3

CC

IsdSrc, IsdSnk OVERCURRENT (A)

1.2

TEMPERATURE (°C)

Figure 11. Overcurrent vs. Temperature Figure 12. Leakage vs. Temperature

0.75

BODY DIODE FORWARD VOLTAGE (V)

150100500−50

TEMPERATURE (°C)

vs. Temperature Figure 10. Body Diode vs. Temperature

0.2

VSx = 13.2 V

LSx

HSx

0.18

0.16

0.14

(mA)

0.12

0.1

snkLkg

, I

0.08

0.06

srcLkg

I

0.04

0.02

150100500−50

0

= 5 V

V

CC

I

snk

I

src

TEMPERATURE (°C)

150100500−50

150100500−50

www.onsemi.com

11

NCV7723B

DETAILED OPERATING DESCRIPTION

General Overview

The NCV7723B is comprised of twelve NMOS power

drivers. The drivers are arranged as six half−bridge output

channels, allowing for three independent full−bridge

configured loads. Output control and status reporting is

handled via the SPI (Serial Peripheral Interface)

communications port. OUT1 and OUT2 can be controlled

with an external PWM signal.

Each output is characterized for a typical 0.5 A DC load

and has a maximum 2.0 A surge capability (at VSx =

13.2 V). Maximum allowable junction temperature is

150°C and may constrain the maximum load current and/or

limit the number of drivers active at once.

An active−high enable function (EN) allows global

control of the outputs and provides a low quiescent current

sleep mode when the device is not being utilized. An internal

pull−down resistor is provided on the input to ensure the

device enters sleep mode if the input signal is lost.

After EN transitions from low to high, the V

POR cycle

CC

will proceed and bring the device into normal operation. The

device configuration registers can then be programmed via

SPI. Bringing EN low clears all registers (no configuration

or status data is stored), disables the drivers, and enters sleep

mode.

SPI Communication

16−bit full duplex SPI communication has been

implemented for device configuration, driver control, and

reading the status data. In addition to the 16−bit status data,

a pseudo−bit (PRE_15) can also be retrieved from the SO

output.

The device must be enabled (EN = H) for SPI

communication. The SPI inputs are TTL compatible and the

SO output high level is defined by the applied V

CC

. The

active−low CSB input has a pull−up resistor and the

remaining inputs have pull−down resistors to bias them to

known states when SPI communication is inactive.

The latched thermal shutdown (TSD) status bit PRE_15

is available on SO until the first rising SCLK edge after CSB

goes low. The following conditions must be met for a valid

TSD read to be captured:

1. SCLK and SI are low before the CSB cycle;

2. CSB transitions from high to low;

3. CSB setup time (TcsbSup: Figure 6, #5) is

satisfied.

Figure 13 shows the SPI communication frame format,

and Tables 1 and 2 define the command input and diagnostic

status output bits.

CSB

SI

SCLK

SO

PRE_15

PSEUDO−BIT

SRR HBSEL ULDSC

15 14 13 0

OCS PSF ULDTSD TW

Figure 13. SPI Communication Frame Format

Communication is implemented as follows and is also

illustrated in Figures 13 and 15:

1. SI and SCLK are set low before the CSB cycle.

2. CSB goes low to begin a serial data frame;

pseudo−bit PRE_15 is immediately available at

SO.

3. SI data is shifted in on every rising edge of SCLK,

starting with the most significant bit (MSB), SRR.

4. SI data is recognized on every falling edge of the

SCLK.

B[12:7] → HBEN[6:1]

B[12:7] → HBST[6:4]

Communication is implemented as follows and is also

illustrated in Figures 13 and 15:

1. SI and SCLK are set low before the CSB cycle.

2. CSB goes low to begin a serial data frame;

pseudo−bit PRE_15 is immediately available at

SO.

3. SI data is shifted in on every rising edge of SCLK,

starting with the most significant bit (MSB), SRR.

4. SI data is recognized on every falling edge of the

SCLK.

B[6:1] → HBCNF[6:1]

B[6:1] → HBST[3:1]

OVLO

www.onsemi.com

12

NCV7723B

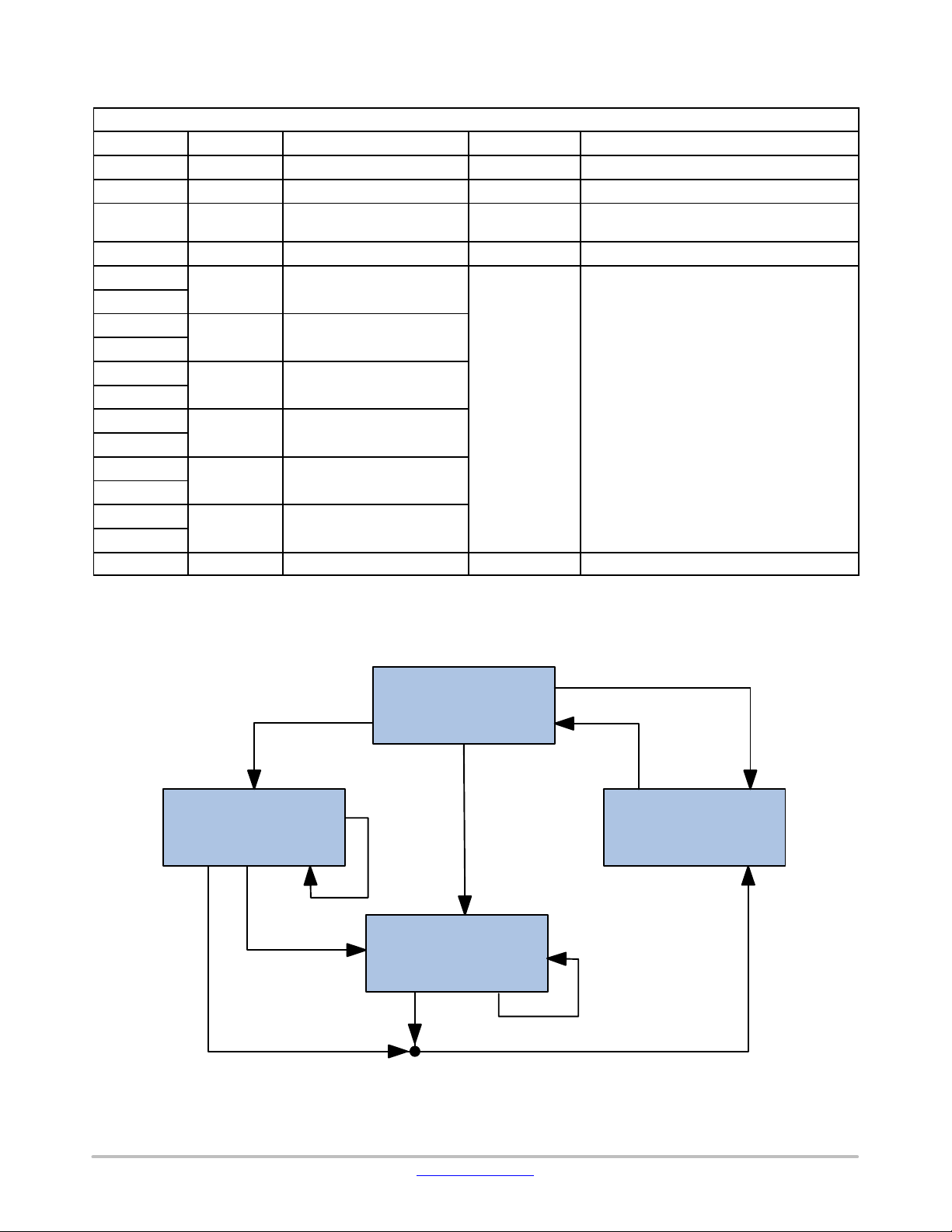

Table 1. SPI COMMAND INPUT DEFINITIONS

Channels 6 – 1

Bit# Name Function Status* Scope

15 SRR Status Register Reset** 1 = Reset Global Status Reset

14 HBSEL*** Half Bridge Selection Reserved −

13 ULDSC Underload Shutdown Control 1 = Enabled Per Half−Bridge Operation

12 HBEN6 Enable Half−Bridge 6

11 HBEN5 Enable Half−Bridge 5

10 HBEN4 Enable Half−Bridge 4

9 HBEN3 Enable Half−Bridge 3

8 HBEN2 Enable Half−Bridge 2

7 HBEN1 Enable Half−Bridge 1

6 HBCNF6 Configure Half−Bridge 6

5 HBCNF5 Configure Half−Bridge 5

4 HBCNF4 Configure Half−Bridge 4

3 HBCNF3 Configure Half−Bridge 3

2 HBCNF2 Configure Half−Bridge 2

1 HBCNF1 Configure Half−Bridge 1

0 OVLO VSx Overvoltage Lockout 1 = Enabled Global Lockout

*All command input bits are set to 0 at V

**Latched faults are cleared and outputs can be re−programmed if no fault exists after SRR asserted.

***HBSEL enables channel group selection for family devices with more than 6 channels. In the NCV7723B it is recommended to set the HBSEL

bit to 0.

power−on reset.

CC

0 = Hi−Z

1 = Enabled

0 = LS On, HS Off

1 = LS Off, HS On

Per Half−Bridge

Per Half−Bridge

www.onsemi.com

13

NCV7723B

Table 2. SPI STATUS OUTPUT DEFINITIONS

Channels 6 – 1

Bit# Name Function Status* Scope

PRE_15 TSD Latched Thermal Shutdown 1 = Fault Global Notification; Per Half−Bridge Operation

15 OCS Latched Overcurrent Shutdown 1 = Fault Global Notification; Per Half−Bridge Operation

14 PSF

13 ULD Underload Detect 1 = Fault Global Notification; Per Half−Bridge Operation

12

11

10

9

8

7

6

5

4

3

2

1

0 TW Thermal Warning 1 = Fault Global Notification; Per Half−Bridge Operation

*All status output bits are set to 0 at Vcc power−on reset (POR).

HBSTx[1:0] bits are priority encoded to provide the status information of each of the half−bridge outputs. Figure 14 shows the priority encoding

state diagram for the HBSTx[1:0] bits.

HBST6[1:0] Half Bridge 6 Output Status

HBST5[1:0] Half Bridge 5 Output Status

HBST4[1:0] Half Bridge 4 Output Status

HBST3[1:0] Half Bridge 3 Output Status

HBST2[1:0] Half Bridge 2 Output Status

HBST1[1:0] Half Bridge 1 Output Status

VS1 and/or VS2

Undervoltage or Overvoltage

1 = Fault Global Notification; Global Operation

0x00b – Output

Disabled

0x01b − OCS

0x10b − ULD

0x11b − Output

Enabled

Per Half−Bridge

PSF, TSD

HBENx = ‘0’

Power On Reset

Under

Load

ULD

“10”

Over

Current

*PSF Recovery: VSx rising above the undervoltage threshold or falling below the overvoltage threshold (OVLO = 1)

**TSD Recovery: Sending SRR after junction temperature has fallen below the thermal shutdown threshold

PSF

TSD

Output Enabled

“11”

Over

Current

OCS

“01”

HBENx = ‘1’

PWMx = ‘1’

PSF Recovery*

TSD Recovery**

Output Disabled

“00”

(default)

PSF

TSD

SRR = ‘1’

Power On Reset

Figure 14. SO HBSTx [1:0] Priority Encoding State Diagram

www.onsemi.com

14

NCV7723B

Priority Encoding

If an under load event precedes an over current event on

the same half−bridge, the device will report HBSTx = ‘10’

and then HBSTx = ‘01’ as shown in Figure 14. An over

current event preceding an under load event will report

HBSTx = ‘01’ since there is no direct path from the OCS

state to the ULD state. Thus an over current shutdown fault

must be cleared before an underload fault is reported on the

same half−bridge.

Frame Error Detection

The NCV7723B employs frame error detection to help

ensure input data integrity. SCLK is compared to an n x 8 bit

counter and a valid frame (CSB H−L−H cycle) has integer

multiples of 8 SCLK cycles. For the first 16 bits shifted into

SI, SCLK is compared to a modulo16 counter (n = 2), and

SCLK is compared to a modulo 8 counter (n = 1, 2, ...m)

thereafter. This variable modulus allows for daisy chain

operation with devices using different word lengths.

The last 16 bits clocked into SI are transferred to the

NCV7723B’s data register if no frame error is detected,

otherwise the entire frame is ignored and the previous input

data is preserved.

Daisy Chain Operation

Daisy chain operation is possible with multiple 16−bit and

8−bit devices that have a compatible SPI protocol. The clock

phase and clock polarity with respect to the data for all the

devices in the chain must be the same as the NCV7723B.

CSB and SCLK are parallel connected to every device in

the chain while SO and SI are series connected between each

device. The master’s MOSI is connected to the SI of the first

device and the first device’s SO is connected to the next

device’s SI. The SO of the final device in the chain is

connected to the master’s MISO.

The hardware configuration for the NCV7723B daisy

chained with an 8−bit SPI device is shown in Figure 15.

A24−bit frame made of 16−bit word ‘A’ and 8−bit word ‘B’

is sent from the master. Command word B is sent first

followed by word A. The master simultaneously receives

status word B first followed by word A. The progression of

data from the MCU through the sequential devices is

illustrated in Figure 15.

Compliance with the illustrated frame format is required

for proper daisy chain operation. Situations should be

avoided where an incorrect multiple of 8 bits is sent to the

devices, but the frame length does not cause a frame error in

the devices. For example, the word order could be

inadvertently interleaved or reversed. Invalid data is

accepted by the NCV7723B in such scenarios and possibly

by other devices in the chain, depending on their frame error

implementation. Data is received as a command by the

device at the beginning of the chain, but the device at the end

of the chain may receive status data from the preceding

device as a command.

MISO

MCU

Master

CSB

SCLK

MOSI

CMD [x, n] = Command Word to Device ‘x’, Length ‘n’

STA [x, n] = Status Word from Device ‘x’, Length ‘n’

NCV7723B

16−bit Device

CSB

SCLK

SO

STA [A, 16]

CMD [B, 8]

CMD [B, 8]

+

CMD [A, 16]

Figure 15. Daisy Chain Configuration

SI

Device A

8−bit Device

CSB

SCLK

SI

+

Device B

SO

STA [B, 8]

+

STA [A, 16]

www.onsemi.com

15

CSB

NCV7723B

24 bit Frame

Word B − 8 bits Word A − 16 bits

SCLK

SI

TSDSO MSB

7 6 1 0 15

MSB

SI data is recognized on the falling SCLK. edge

SO data is shifted out on the rising SCLK edge.

Modulo 16 counter begins on the first rising SCLK edge after CSB goes low.

Modulo 16 counter ends − 16 bit word length valid.

Modulo 8 counter begins on the next rising SCLK edge.

Modulo 8 counter ends − 8 bit word length valid. valid n*8 bit frame.

Figure 16. Daisy Chain – 24 bit Frame Format

TSD Bit in Daisy Chain Operation

The SO frame is designed to allow TSD status retrieval in

a daisy chain configuration using NCV7723B or other

devices with identical SPI functionality. The TSD status bit

is OR’d with SI and then multiplexed with the device’s usual

status data (Figure 17).

CSB is held high and SI and SCLK are held low by the

master before the start of the SPI frame. TSD status is

immediately available as bit PRE_15 at SO (SO = TSD)

when CSB goes low to begin the frame. The usual status data

(SO = STA) becomes available after the first rising SCLK

edge.

The TSD status automatically propagates through the

chain from the SO output of the previous device to the SI

input of the next. This is shown in Figures 18 and 19, first

without a TSD fault in either device (Figure 18), and then

subsequently with a latched TSD fault (TSD = 1) in device

“A” propagating through to device “B” (Figure 19).

0

LSB

LSB

LSB

LSB

8 7

MSB

MSB

Since the TSD status of any device propagates

automatically through the entire chain, it is not possible to

determine which device (or devices) has a fault (TSD = 1).

The usual status data from each device will need to be

examined to determine where a fault (or faults) may exist.

SI

TSD

SO

SI

SPI

SEL

Figure 17. TSD SPI Link

M

U

X

SO

MISO

MCU

Master

NCV7723B

CSB

SCLK

MOSI

1 → 0

0

0

CSB

SCLK

SI

Device A

No TSD No TSD

SO

Figure 18. Daisy Chain Without TSD Fault

www.onsemi.com

16

Z → 0

CSB

SCLK

SI

NCV7726B

or NCV7723B

Device B

SO

Z → 0

NCV7723B

NCV7723B

CSB

SCLK

SI

Latched TSD No TSD

MISO

MCU

Master

CSB

SCLK

MOSI

1 → 0

0

0

Figure 19. Daisy Chain With TSD Fault

Power Up/Down Control

The V

V

CC

power−up/down. V

supply input powers the device’s logic core. A

CC

power−on reset (POR) function provides controlled

POR initializes the command input

CC

and status output registers to their default states (0x00), and

ensures that the bridge output and SO drivers maintain Hi−Z

as power is applied. SPI communication and normal device

operation can proceed once V

rises above the POR

CC

threshold and EN remains high.

The VS1 and VS2 supply inputs power their respective

output drivers (refer to Figure 2 and the PIN FUNCTION

DESCRIPTION). The VSx inputs are monitored to ensure

that the supply stays within the recommended operating

range. If the VSx supply moves into either of the VS

undervoltage or overvoltage regions, the output drivers are

switched to Hi−Z but command and status data is preserved.

Output drivers will remain on if OVLO = 0 during an

overvoltage condition.

Driver Control

The NCV7723B has the flexibility to control each

half−bridge driver channel via SPI. Actual driver output

state is determined by the command input and the current

fault status bits.

High−side (HSx) and low−side (LSx) drivers of the same

channel cannot be active at the same time, and non−overlap

delays are imposed when switching between HSx and LSx

drivers in the same channel, preventing current

shoot−through.

After the device has powered up and the drivers are

allowed to turn on, the drivers remain on until commanded

off via SPI or until a fault condition occurs.

PWM Control

Outputs 1 and 2 can be controlled in two ways: through

normal SPI control (see Table 1) or from an external PWM

signal. OUT1 can be turned on/off using the HBEN1 bit or

NCV7726B

or NCV7723B

CSB

SCLK

Device A

SO

Z → 1

SI

Device B

SO

Z → 1

applying a logic level signal to pin 17 (PWM1). OUT2 can

be turned on/off using the HBEN2 bit or applying a logic

level signal to pin 18 (PWM2). Simplified logic functions

are shown below in Figure 20.

PWM Example: Turn on OUT1 High Side

To use OUT1 High Side with external PWM control,

perform the following steps:

1. Send command 0b0000000000000010 (0x0002)

♦ Configures OUT1 to High Side (HBCNF1)

♦ Disables OUT1 SPI Enable (HBEN1)

2. Apply logic level PWM signal to PWM1

To use OUT1 Low Side with external PWM, set the

HBCNF1 bit to 0 during step 1.

HBCNFx

HSx

HBENx

PWMx

LSx

PWMx HBENx HBCNFx HSx LSx OUTx

0 0 x OFF OFF Z

x 1 0 OFF ON Low

x 1 1 ON OFF High

1 x 0 OFF ON Low

1 x 1 ON OFF High

Figure 20. PWM Control Logic

VS

OUTx

GND

www.onsemi.com

17

NCV7723B

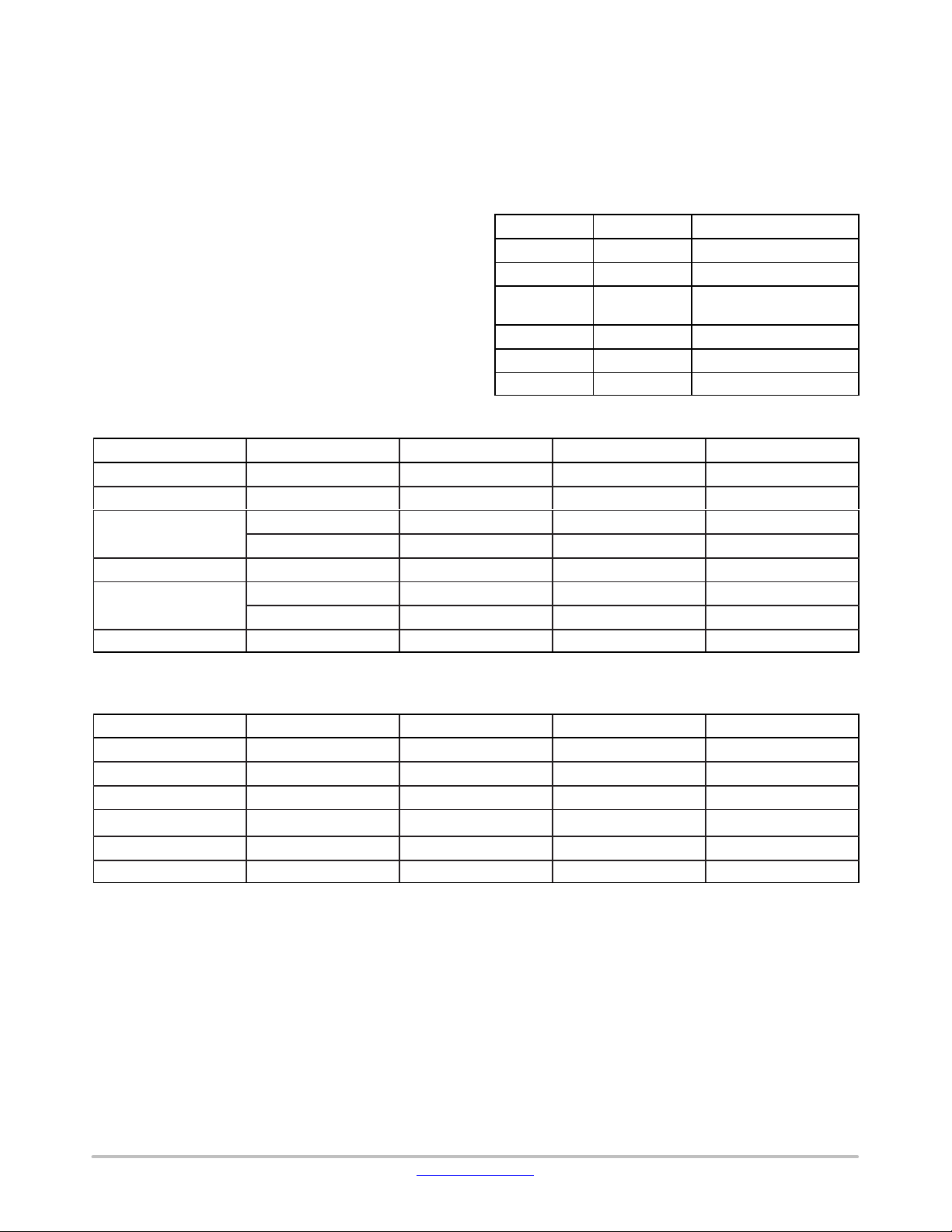

DIAGNOSTICS, PROTECTIONS, STATUS REPORTING AND RESET

Overview

The NCV7723B employs diagnostics designed to prevent

destructive overstress during a fault condition. Diagnostics

resolved. Table 4 shows output states during faults and

output recovery modes, and Table 5 shows the status

memory and memory clear modes.

are classified as either supervisory or protection functions

(Table 3). Supervisory functions provide status information

about device conditions. Protection functions provide status

Table 3. DIAGNOSTIC CLASSES AND FUNCTIONS

information and activate fault management behaviors.

Diagnostics resulting in output shutdown and latched status

may depend on a qualifier and may require user intervention

for output recovery and status memory clear. Diagnostics

resulting in output lockout and non−latched status (VSOV

or VSUV) may recover and clear automatically. Output

configurations can be changed during output lockout.

Outputs assume the new configurations or resume the

HBSTx[1:0] Supervisory Half−Bridge X Output Status

previous configurations when an auto−recover fault is

Table 4. OUTPUT STATE VS. FAULT AND OUTPUT RECOVERY

Fault Qualifier OUTx State OUTx Recovery OUTx Recovery Scope

TSD − → Z Send SRR All Outputs

OCS − → Z Send SRR All Outputs

PSF – VSOV

PSF – VSUV − → Z → Y

ULD

TW − Unaffected − −

*OUTx returns to its previous state (Yn) or new state (Yn+1) if fault is removed.

OVLO = 1 → Z → Y

OVLO = 0 Unaffected − −

ULDSC = 1 → Z Send SRR All Outputs

ULDSC = 0 Unaffected − −

| Y

n

n+1

| Y

n

n+1

Name Class Function

TSD Protection Thermal Shutdown

OCS Protection Overcurrent Shutdown

PSF Protection Under/overvoltage Lockout

(OVLO = 1)

ULD Protection Underload Shutdown

TW Supervisory Thermal Warning

Auto* All Outputs

Auto* All Outputs

Table 5. STATUS MEMORY VS. FAULT AND MEMORY CLEAR

Fault Qualifier Status Memory Memory Clear Memory Clear Scope

TSD − Latched Send SRR Global

OCS − Latched Send SRR Global

PSF – VSOV OVLO = X Non−Latched Auto* Global

PSF – VSUV

ULD ULDSC = X Latched Send SRR Global

TW − Non−Latched Auto* Global

*Status memory returns to its no−fault state if fault is removed.

−

Status Information Retrieval

Current status information is retrieved during each SPI

frame. To preserve device configuration and output states,

the previous SI data pattern must be sent during the status

retrieval frame.

Status information is prevented from being updated

during a SPI frame but new status becomes available after

CSB goes high at the end of the frame provided the frame did

not contain an SRR request. Status information includes

both global and per channel fault notification. To determine

the channel(s) affected after detecting a global fault,

examine driver output status and input configuration.

Non−Latched Auto* Global

Status Register Reset − SRR

Sending SRR = 1 clears status memory and re−activates

faulted outputs for all channels. The previous SI data pattern

must be sent with SRR to preserve device configuration and

output states.

At the rising edge of CSB, the SRR function is activated

and an internal timer (Tsrr) is started. Tsrr is the minimum

time the user must wait between consecutive SRR requests.

If a fault is still present when SRR is sent, protection will be

re−engaged and shutdown will recur. The status registers can

also be reset by toggling the EN pin or by VCC power−on

reset.

www.onsemi.com

18

NCV7723B

Diagnostics Details

The following sections describe individual diagnostics

and behaviors. In each description and illustration, a SPI

frame is assumed to always be valid and the SI data pattern

sent for HBCNFx and HBENx is the same as the previous

frame. Actual results can depend on asynchronous fault

events and SPI clock frequency and frame rate.

Undervoltage Lockout

Global Notification, Global Operation

Undervoltage detection and lockout control is provided

by monitoring the VS1, VS2 and VCC supply inputs.

Undervoltage hysteresis is provided to ensure clean

SO

Status

Output

State

SI

OUTx

LS

X

?

?

OUTx

LS

No

Fault

No Fault

OUTx GND

OUTx

LS

PSF

PSF

ALL

Z

detection transitions. Undervoltage timing is shown in

Figure 21.

Undervoltage at either VSx input turns off all outputs and

sets the power supply fail (PSF) status bit. The outputs return

to their previously programmed state and the PSF status bit

is cleared when VSx rises above the hysteresis voltage level.

SPI communication is available and programmed output

enable and configuration states are maintained if proper

VCC is present during VSx undervoltage. Output enable and

configuration states can also be programmed during VSx

undervoltage if proper VCC is present, and state changes

will take effect as VSx rises above the undervoltage

threshold level.

OUTx

LS

No

Fault

No

Fault

OUTx GND

OUTx

HS

Z

?

ALL

Z

OUTx

HS

0x00

0x00

OUTx

HS

No

Fault

No

Fault

OUTx VS

VSx

VSUV

Vcc

Figure 21. Undervoltage Timing

Overvoltage Lockout

Global Notification, Global Operation

Overvoltage detection and lockout control is provided by

monitoring the VS1 and VS2 supply inputs. Hysteresis is

provided to ensure clean detection transitions. Overvoltage

timing is shown in Figure 22. Overvoltage at either VSx

input turns off all outputs if the overvoltage lockout input bit

is set (OVLO = 1) and sets the power supply fail (PSF) status

bit (see Tables 4 and 5). The outputs return to their

previously programmed state and the PSF status bit is

cleared when VSx falls below the hysteresis voltage level.

VccUV

t

Output enable and configuration states can also be

programmed during an overvoltage lockout event but will

not change state until VSx falls below the overvoltage

threshold level.

NOTE: to reduce stress, it is recommended to operate the

device with OVLO bit asserted to ensure that the

drivers turn off during a load dump scenario. If

OVLO = 0 during an overvoltage condition,

outputs will remain on and the PSF status bit will

be set.

www.onsemi.com

19

NCV7723B

SO

Status

Output

State

VSx

SI

OUTx ON

OVLO = 0

X

?

?

OUTx

ON

No

Fault

No

Fault

OUTx

ON

PSF

PSF

OUTx

ON

VSOV

Figure 22. Overvoltage Timing

Overcurrent Shutdown

Global and per Channel Notification

Per Half−Bridge Operation

Overcurrent detection and shutdown control is provided

by monitoring each HS and LS driver. Overcurrent timing is

shown in Figure 23. Overcurrent in either driver starts a

channel’s overcurrent delay timer (TdOc). If overcurrent

exists after the delay, both drivers are latched off and the

OUTx ON

OVLO = 1

No

Fault

No

Fault

OUTx

ON

PSF

PSF

ALL

VSOV

OUTx

OFF

No

Fault

No

Fault

OUTx

Z

ON

No

Fault

OUTx Z

t

global overcurrent (OCS) status bit is set. The channel’s

corresponding HBSTx[1:0] bits are also set to “01” to

indicate an OCS fault. Note that OCS fault reporting has

priority over other faults as shown in Figure 14. The global

OCS bit and individual channel bits are cleared and channels

are re−activated by sending SRR = 1.

A persistent overcurrent cause should be resolved prior to

re−activation to avoid repetitive stress on the drivers.

SI

SO

Status

Output

State

Output

Current

OUTx ON

SRR = 0

No

Fault

No

Fault

OUTx

ON

OUTx

ON

No

Fault

TdOc

OUTx

ON

OCS

OCS

OUTx Z

IsdSxx

Figure 23. Overcurrent Timing

OUTx ON

SRR = 1

OCS

OUTx

ON

No

Fault

No

Fault

OUTx

ON

OUTx

ON

OCS

OCS

OUTx Z

TdOc

t

www.onsemi.com

20

NCV7723B

Underload Shutdown

Global and per Channel Notification

Global Shutdown Control, Per Half−Bridge Operation

Underload detection and shutdown control is provided by

monitoring each half bridge driver. Underload timing is

shown in Figure 24. Underload at any driver starts the global

underload delay timer. If underload occurs in another

channel after the global timer has been started, the delay for

any subsequent underload will be the remainder of the timer.

If underload exists after the global delay timer and if the

underload shutdown (ULDSC) command bit is set, both

HSand LS drivers are latched off and the global underload

SO

Status

Output

State

Output

Current

SI

LSx ON

ULDSC = 0

No

Fault

No Fault

OUTx

ON

LSx

ON

No

Fault

TdUld TdUld

LSx ON

SRR = 1

ULD

ULD

OUTx GND

(ULD) status bit is set along with the corresponding per

channel status bits HBSTx[1:0] set to “10”. Drivers will

remain on if the ULDSC input bit is 0 (see Table 4 and 5).

The global ULD bit and per channel HBSTx bits are cleared

and channels are re−activated by sending SRR = 1.

NOTE: underload may result from a fault (e.g. open−load)

condition or normal circuit behavior (e.g. L/R

tau). In motor applications it is often desirable to

actively brake the motor by turning on both HS or

LS drivers in two half−bridge channels which may

result in an underload condition as current decays.

LSx

ON

No

Fault

No Fault

OUTx GND

No

Fault

IuldLS

LSx ON

ULDSC = 1

ULD

LSx ON

SRR = 1

ULD

ULD

OUTx

Z

TdUld

Figure 24. Underload Timing

t

www.onsemi.com

21

Thermal Warning and Thermal Shutdown

NCV7723B

Global Notification, Per Half−Bridge Operation

Thermal warning (TW) and thermal shutdown (TSD)

detection and control are provided for each half−bridge by

monitoring the driver pair’s thermal sensor. Thermal

hysteresis is provided for each of the warning and shutdown

functions to ensure clean detection transitions. Software

polling of the TW bit allows for avoidance of thermal

shutdown since TW notification precedes TSD notification.

Thermal warning and shutdown timing is shown in

Figure 25.

SI

SO

Status

Output

State

T

TSD

OUTx

ON

No

Fault

No

Fault

J

OUTx

ON

TW

TW

OUTx ON

OUTx

ON

No

Fault

No

Fault

The TW status bit is set when a half−bridge’s sensor

temperature exceeds the warning level (T

> Twr), and the

J

bit is automatically cleared when sensor temperature falls

below the warning hysteresis level (T

< TwHy). A channel’s

J

output state is unaffected by TW.

When sensor temperature exceeds the shutdown level

(T

> Tsd), the channel’s HS and LS drivers are latched off,

J

the TW bit is/remains set, and the TSD (PRE_15) bit is set.

The TSD bit is cleared and all affected channels are

re−activated (T

OUTx

ON

TW

TW

< TsdHy) by sending SRR = 1.

J

OUTx ON

SRR = 1

TSD

TW

TSD

TW

TsdHy

OUTx ON

SRR = 1

TW

TW

OUTx Z

TW

OUTx

ON

TWR

TwHy

Figure 25. Thermal Warning and Shutdown Timing

The latched thermal shutdown (TSD) information is

available on SO after CSB transitions from high to low and

before the first rising SCLK edge. The following procedures

must be met for a true TSD reading:

1. SCLK and SI are low before the CSB cycle.

Violating these conditions will results in an

t

undetermined SPI behavior or/and an incorrect

TSD reading.

2. CSB transitioning from high to low.

3. CSB setup time (TcsbSup) is satisfied and the data

is captured before the first SCLK rising edge.

www.onsemi.com

22

NCV7723B

†

THERMAL PERFORMANCE ESTIMATES

Figure 26. Transient R(t) vs. Pulse Time for 2 oz Spreader

ORDERING INFORMATION

Device Package Shipping

NCV7723DQBR2G SSOP24 NB EP

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

2500 / Tape & Reel

www.onsemi.com

23

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

2X

NOTE 4

D

A

B

TOP VIEW

SIDE VIEW

NOTE 8

D2

BOTTOM VIEW

5.63

13

24X

A1

EE1

b

M

0.12 DC

E2

NOTE 8

2X

24X

0.20 C

NOTE 5

PIN 1

REFERENCE

0.10 C

0.10

M

0.15 DC

NOTE 6

24

112

e

NOTE 6

A

C

A-B

RECOMMENDED

SOLDERING FOOTPRINT

SSOP24 NB EP

CASE 940AK

C

A-B0.20

D

H

A1

0.20 C

2X 12 TIPS

A-B

A2

SEATING

C

PLANE

M

0.15 DC

ISSUE O

L

DETAIL A

NOTE 7

h

c

END VIEW

A-B

L1

DATE 24 APR 2012

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

BE 0.10 MAX. AT MMC. DAMBAR CANNOT BE

L2

GAUGE

PLANE

SEATING

C

PLANE

DETAIL A

h

LOCATED ON THE LOWER RADIUS OF THE

FOOT. DIMENSION b APPLIES TO THE FLAT

SECTION OF THE LEAD BETWEEN 0.10 TO 0.25

FROM THE LEAD TIP.

4. DIMENSION D DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS. MOLD

FLASH, PROTRUSIONS OR GATE BURRS SHALL

NOT EXCEED 0.15 PER SIDE. DIMENSION D IS

DETERMINED AT DATUM PLANE H.

5. DIMENSION E1 DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH

OR PROTRUSION SHALL NOT EXCEED 0.25 PER

SIDE. DIMENSION E1 IS DETERMINED AT DATUM PLANE H.

6. DATUMS A AND B ARE DETERMINED AT DATUM

PLANE H.

7. A1 IS DEFINED AS THE VERTICAL DISTANCE

FROM THE SEATING PLANE TO THE LOWEST

POINT ON THE PACKAGE BODY.

8. CONTOURS OF THE THERMAL PAD ARE UNCONTROLLED WITHIN THE REGION DEFINED

BY DIMENSIONS D2 AND E2.

M

MILLIMETERS

DIM MIN MAX

A 1.70

---

A1 0.00 0.10

A2 1.651.10

b 0.19 0.30

c 0.09 0.20

D 8.64 BSC

D2 5.28 5.58

E 6.00 BSC

E1 3.90 BSC

E2 2.44 2.64

e 0.65 BSC

h 0.25 0.50

L 0.40 0.85

L1 1.00 REF

L2 0.25 BSC

M 0 8

__

GENERIC

MARKING DIAGRAM*

XXXXXXXXXG

AWLYYWW

24X

1.15

2.84

6.40

XXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

24X

0.40

1

0.65

PITCH

DIMENSIONS: MILLIMETERS

not follow the Generic Marking.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON79998E

SSOP24 NB EP

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...