NCP1271

PW

M Controller, Soft-Skip &

trade; Standby, with

Adjustable Skip Level and

External Latch

The NCP1271 represents a new, pin to pin compatible, generation

of the successful 7−pin current mode NCP12XX product series. The

controller allows for excellent stand by power consumption by use of

its adjustable Soft−Skip mode and integrated high voltage startup

FET. This proprietary Soft−Skip also dramatically reduces the risk of

acoustic noise. This allows the use of inexpensive transformers and

capacitors in the clamping network. Internal frequency jittering, ramp

compensation, timer−based fault detection and a latch input make

this controller an excellent candidate for converters where

ruggedness and component cost are the key constraints.

Features

• Fixed−Frequency Current−Mode Operation with Ramp

Compensation and Skip Cycle in Standby Condition

• Timer−Based Fault Protection for Improved Overload Detection

• “Soft−Skip Mode” Technique for Optimal Noise Control in Standby

• Internal High−Voltage Startup Current Source for Lossless Startup

• "5% Current Limit Accuracy over the Full Temperature Range

• Adjustable Skip Level

• Internal Latch for Easy Implementation of Overvoltage and

Overtemperature Protection

• Frequency Jittering for Softened EMI Signature

• +500 mA/−800 mA Peak Current Drive Capability

• Sub−100 mW Standby Power can be Achieved

• Pin−to−Pin Compatible with the Existing NCP120X Series

• This is a Pb−Free Device

Typical Applications

• AC−DC Adapters for Notebooks, LCD Monitors

• Offline Battery Chargers

• Consumer Electronic Appliances STB, DVD, DVDR

http://onsemi.com

SOIC−7

D SUFFIX

CASE 751U

PDIP−7 VHVIC

P SUFFIX

CASE 626B

8

1

x = A or B

A= 65 kHz

B= 100 kHz

xxx = Device Code: 65, 100

A = Assembly Location

L, WL = Wafer Lot

Y, YY = Year

W, WW = Work Week

G or G = Pb−Free Package

(Note: Microdot may be in either location)

PIN CONNECTIONS

FB

CS

GND

1

2

3

4

(Top View)

Skip/latch

1

8

6

5

MARKING

DIAGRAMS

8

1271x

ALYWG

G

1

1271Pxxx

AWL

YYWWG

HV

V

CC

Drv

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques Reference

Manual, SOLDERRM/D.

© Semiconductor Components Industries, LLC, 2009

September, 2009 − Rev. 6

1 Publication Order Number:

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 19 of this data sheet.

NCP1271/D

NCP1271

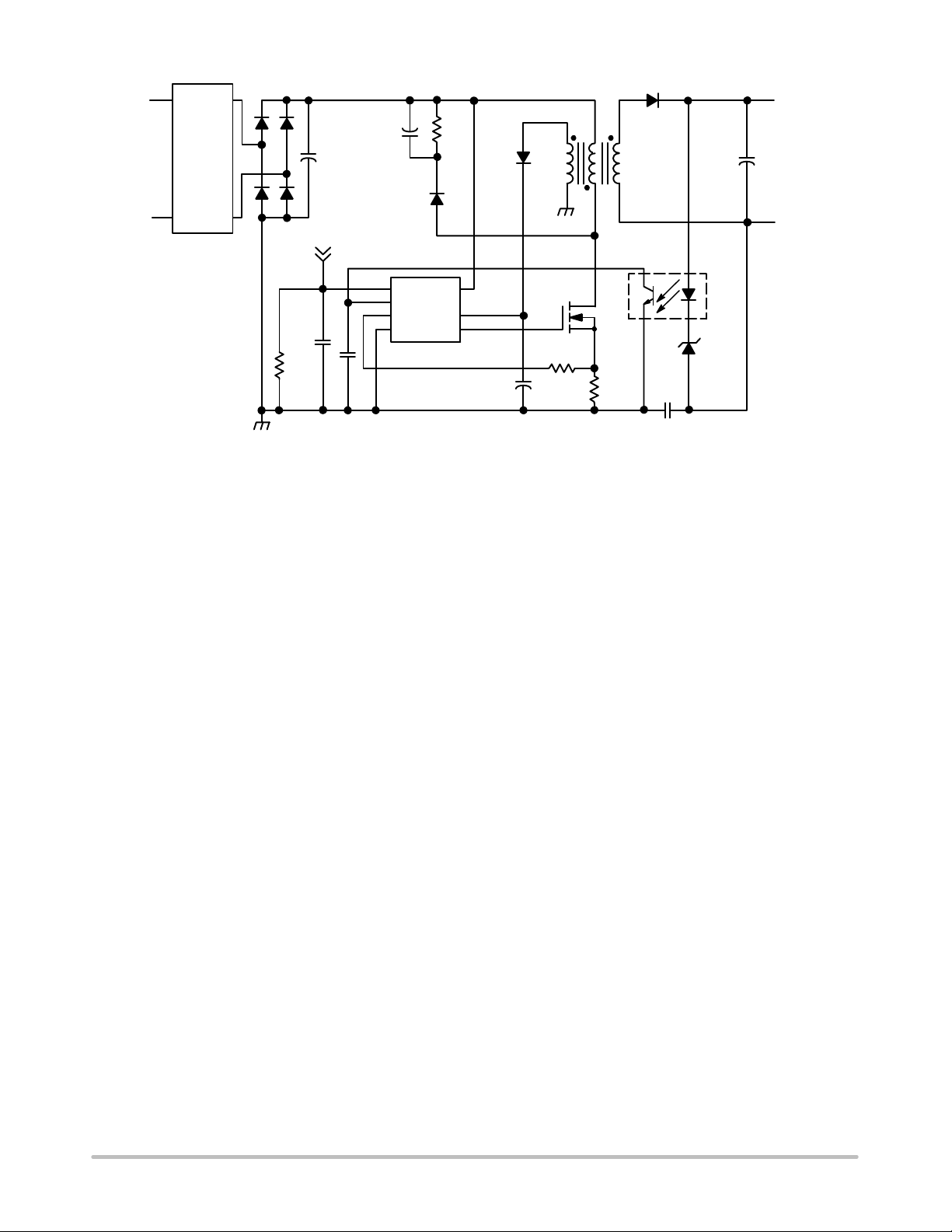

+

AC

Input

*Optional

EMI

Filter

R

skip

latch input*

skip/latch

FB

CS

Gnd

HV

Vcc

Drv

NCP1271

Figure 1. Typical Application Circuit

R

*

ramp

Output

Voltage

−

http://onsemi.com

2

NCP1271

MAXIMUM RATINGS (Notes 1 and 2)

Rating Symbol Value Unit

VCC Pin (Pin 6)

Maximum Voltage Range

Maximum Current

Skip/Latch, FB, CS Pin (Pins 1−3)

Maximum Voltage Range

Maximum Current

Drv Pin (Pin 5)

Maximum Voltage Range

Maximum Current

HV Pin (Pin 8)

Maximum Voltage Range

Maximum Current

Power Dissipation and Thermal Characteristics

Thermal Resistance, Junction−to−Air, PDIP−7, Low Conductivity PCB (Note 3)

Thermal Resistance, Junction−to−Lead, PDIP−7, Low Conductivity PCB

Thermal Resistance, Junction−to−Air, PDIP−7, High Conductivity PCB (Note 4)

Thermal Resistance, Junction−to−Lead, PDIP−7, High Conductivity PCB

Thermal Resistance, Junction−to−Air, SO−7, Low Conductivity PCB (Note 3)

Thermal Resistance, Junction−to−Lead, SO−7, Low Conductivity PCB

Thermal Resistance, Junction−to−Air, SO−7, High Conductivity PCB (Note 4)

Thermal Resistance, Junction−to−Lead, SO−7, High Conductivity PCB

Operating Junction Temperature Range T

Maximum Storage Temperature Range T

ESD Protection

Human Body Model ESD Pins 1−6

Human Body Model ESD Pin 8

Machine Model ESD Pins 1−4, 8

Machine Model ESD Pins 5, 6

Charged Device Model ESD

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. ESD protection per JEDEC JESD22−A114−F for HBM, per JEDEC JESD22−A115−A for MM, and per JEDEC JESD22−C101D for CDM.

This device contains latchup protection and exceeds 100 mA per JEDEC Standard JESD78.

2. Guaranteed by design, not tested.

3. As mounted on a 40x40x1.5 mm FR4 substrate with a single layer of 80 mm2 of 2 oz copper traces and heat spreading area. As specified for

a JEDEC 51 low conductivity test PCB. Test conditions were under natural convection or zero air flow.

4. As mounted on a 40x40x1.5 mm FR4 substrate with a single layer of 650 mm2 of 2 oz copper traces and heat spreading area. As specified

for a JEDEC 51 high conductivity test PCB. Test conditions were under natural convection or zero air flow.

V

max

I

max

V

max

I

max

V

max

I

max

V

max

I

max

R

q

JA

R

q

JL

R

q

JA

R

q

JL

R

q

JA

R

q

JL

R

q

JA

R

q

JL

J

stg

HBM

HBM

MM

MM

CDM

−0.3 to +20

100

−0.3 to +10

100

−0.3 to +20

−800 to +500

−0.3 to +500

100

142

57

120

56

177

75

136

69

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

−40 to +150 °C

−60 to +150 °C

2000

700

200

150

1000

V

mA

V

mA

V

mA

V

mA

V

V

V

V

V

http://onsemi.com

3

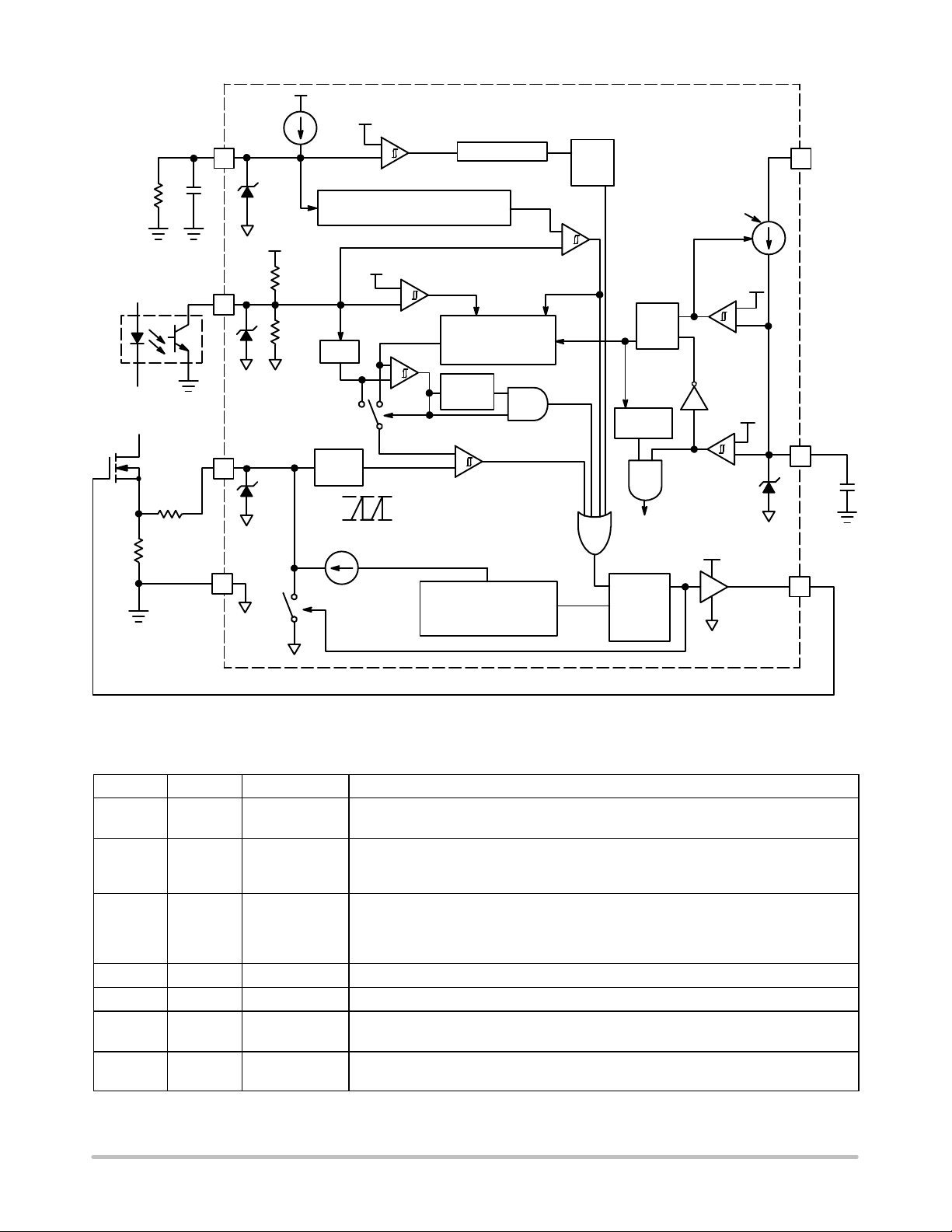

NCP1271

R

skip

Skip/ latch

R

ramp

R

CS

FB

CS

Gnd

I

skip

1

−

+

13 us filter

S

R

10V

V

= R

* I

skip

skip

or

skip

= 1.2 V when pin 1 is opened

V

skip

4.8 V

2.85 V

FB

16.7k

V

2

75.3k

1 / 3

10V

V

3

CS

V / 3

FB

0

180 ns

LEB

10V

TLD

−

+

V

ss

(1V max)

−

+

1

V

PWM

100uA

Soft start/ soft−skip

management

4 ms/ 300 us

130ms

delay

PWM

−

+

disable

soft

skip

V

V

skip

FB

&

skip

+

−

soft−skip

soft

start

short

circuit

fault

0

jittered ramp

current source

latch−off, reset

when Vcc < 4V

Q

4.1 mA when Vcc > 0.6 V

0.2 mA when Vcc < 0.6 V

S

Q

R

double

hiccup

B2

Counter

&

turn on internal bias

OR

turn off

V

−

+

UVLO

−

+

CC

12.6/

5.8 V

9.1 V

20V

8

HV

V

CC

6

Drv

8 V

4

1 0

7.5% Jittering

65, 100 kHz

Oscillator

R

S

Max duty

= 80%

Q

driver:

+500 mA

/ −800 mA

5

Figure 2. Functional Block Diagram

PIN FUNCTION DESCRIPTION

Pin No. Symbol Function Description

1 Skip/latch Skip Adjust or

Latchoff

A resistor to ground provides the adjustable standby skip level. Additionally, if this pin is

pulled higher than 8.0 V (typical), the controller latches off the drive.

2 FB Feedback An optocoupler collector pulls this pin low during regulation. If this voltage is less than

the Skip pin voltage, then the driver is pulled low and Soft−Skip mode is activated. If this

pin is open (>3 V) for more than 130 ms, then the controller is placed in a fault mode.

3 CS Current Sense This pin senses the primary current for PWM regulation. The maximum primary current

is limited to 1.0 V / RCS where RCS is the current sense resistor. Additionally, a ramp

resistor R

between the current sense node and this pin sets the compensation ramp

ramp

for improved stability.

4 Gnd IC Ground −

5 Drv Driver Output The NCP1271’s powerful output is capable of driving the gates of large Qg MOSFETs.

6 V

CC

Supply Voltage This is the positive supply of the device. The operating range is between 10 V (min) and

20 V (max) with a UVLO start threshold 12.6 V (typ).

8 HV High Voltage This pin provides (1) Lossless startup sequence (2) Double hiccup fault mode (3)

Memory for latch−off shutdown and (4) Device protection if VCC is shorted to GND.

http://onsemi.com

4

NCP1271

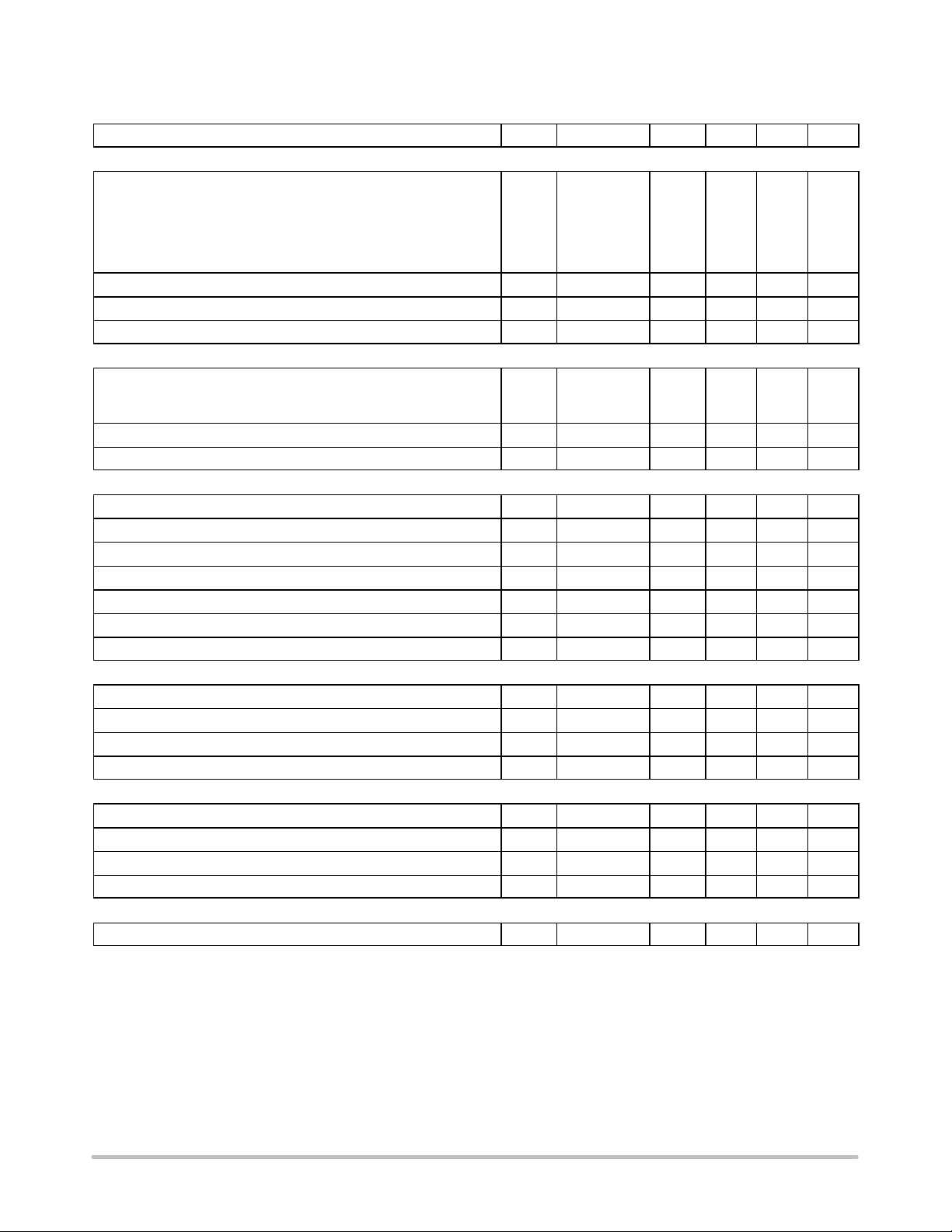

ELECTRICAL CHARACTERISTICS (For typical values T

= 25°C, for min/max values, TJ = −40°C to +125°C, VCC = 14 V,

J

HV = open, skip = open, FB = 2 V, CS = Ground, DRV = 1 nF, unless otherwise noted.)

Characteristic Pin Symbol Min Typ Max Unit

OSCILLATOR

Oscillation Frequency (65 kHz Version, T

= 25_C)

J

Oscillation Frequency (65 kHz Version, TJ = −40 to + 85_C)

Oscillation Frequency (65 kHz Version, T

Oscillation Frequency (100 kHz Version, T

= −40 to + 125_C)

J

= 25_C)

J

Oscillation Frequency (100 kHz Version, TJ = −40 to +85_C)

Oscillation Frequency (100 kHz Version, TJ = −40 to +125_C)

Oscillator Modulation Swing, in Percentage of f

osc

5 f

osc

61.75

58

55

95

89

85

65

65

65

100

100

100

68.25

69

69

105

107

107

5 − − "7.5 − %

Oscillator Modulation Swing Period 5 − − 6.0 − ms

Maximum Duty Cycle (VCS = 0 V, VFB = 2.0 V) 5 D

max

75 80 85 %

GATE DRIVE

Gate Drive Resistance

Output High (V

= 14 V, Drv = 300 W to Gnd)

CC

Output Low (VCC = 14 V, Drv = 1.0 V)

Rise Time from 10% to 90% (Drv = 1.0 nF to Gnd) 5 t

Fall Time from 90% to 10% (Drv = 1.0 nF to Gnd) 5 t

5

R

OH

R

OL

r

f

6.0

2.0

11

6.0

20

12

− 30 − ns

− 20 − ns

CURRENT SENSE

Maximum Current Threshold 3 I

Soft−Start Duration − t

Soft−Skip Duration − t

Leading Edge Blanking Duration 3 t

Limit

SS

SK

LEB

0.95 1.0 1.05 V

− 4.0 − ms

− 300 − ms

100 180 330 ns

Propagation Delay (Drv =1.0 nF to Gnd) − − − 50 150 ns

Ramp Current Source Peak 3 I

Ramp Current Source Valley 3 I

ramp(H)

ramp(L)

− 100 − mA

− 0 − mA

SKIP

Default Standby Skip Threshold (Pin 1 = Open) 2 V

Skip Current (Pin 1 = 0 V, TJ = 25_C) 1 I

Skip Level Reset (Note 5) 1 V

skip−reset

Transient Load Detection Level to Disable Soft−Skip Mode 2 V

skip

skip

TLD

− 1.2 − V

26 43 56 mA

5.0 5.7 6.5 V

2.6 2.85 3.15 V

EXTERNAL LATCH

Latch Protection Threshold 1 V

Latch Threshold Margin (V

latch−m

= V

CC(off)

− V

) 1 V

latch

latch

latch−m

7.1 8.0 8.7 V

0.6 1.2 − V

Noise Filtering Duration 1 − − 13 − ms

Propagation Delay (Drv = 1.0 nF to Gnd) 1 T

latch

− 100 − ns

SHORT−CIRCUIT FAULT PROTECTION

Time for Validating Short−Circuit Fault Condition 2 t

protect

− 130 − ms

5. Please refer to Figure 39 for detailed description.

6. Guaranteed by design.

kHz

W

http://onsemi.com

5

NCP1271

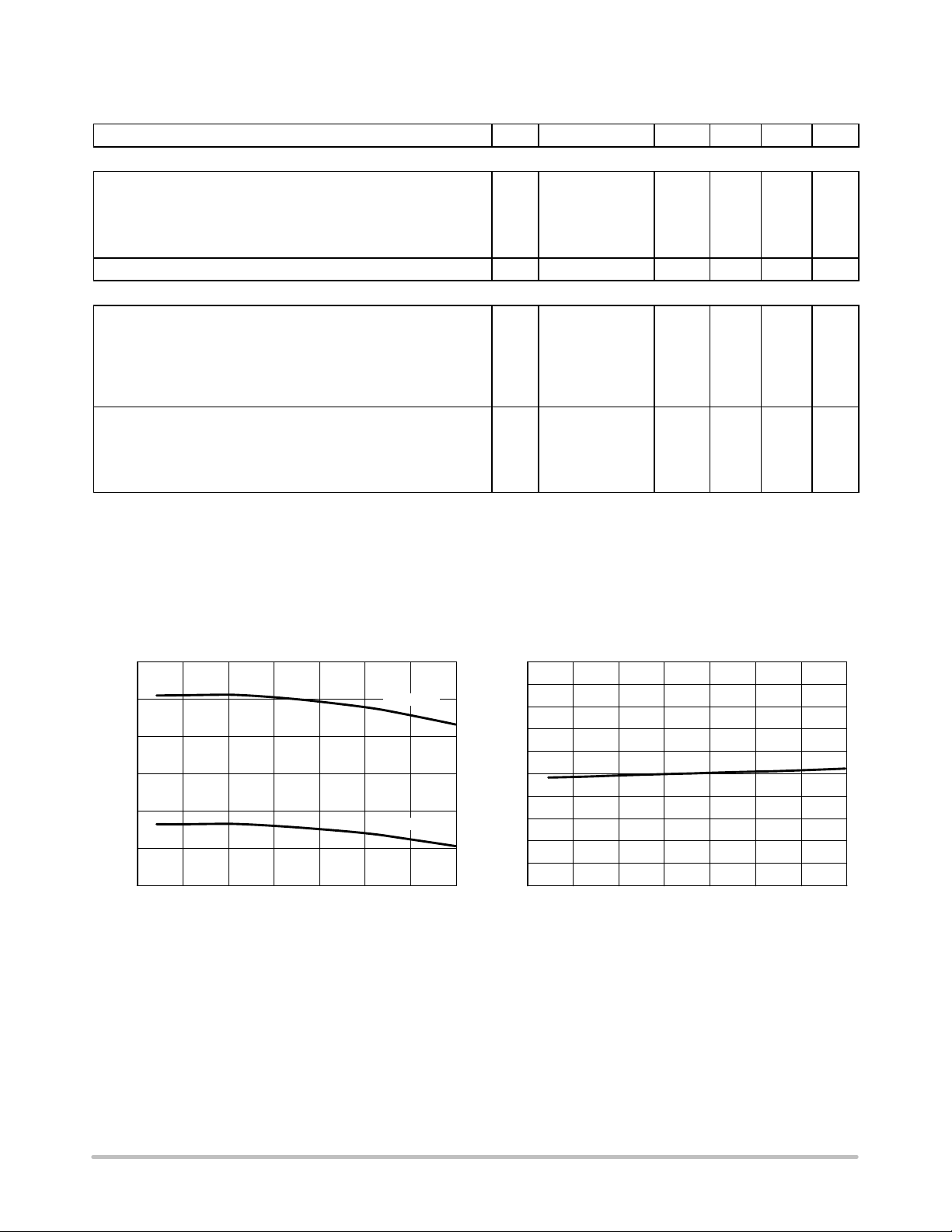

ELECTRICAL CHARACTERISTICS (continued) (For typical values T

= 25°C, for min/max values, TJ = −40°C to +125°C,

J

VCC = 14 V, HV = open, skip = open, FB = 2 V, CS = Ground, DRV = 1 nF, unless otherwise noted.)

Characteristic Pin Symbol Min Typ Max Unit

STARTUP CURRENT SOURCE

High−Voltage Current Source

Inhibit Voltage (I

Inhibit Current (V

Startup (V

= 200 mA, HV = 50 V)

CC

= 0 V, HV = 50 V)

CC

= V

CC

CC(on)

− 0.2 V, HV = 50 V)

Leakage (VCC = 14 V, HV = 500 V)

Minimum Startup Voltage (VCC = V

– 0.2 V, ICC = 0.5 mA) 8 V

CC(on)

6

6

6

8

V

inhibit

I

inhibit

I

HV

I

HV−leak

HV(min)

SUPPLY SECTION

VCC Regulation

Startup Threshold, VCC Increasing

Minimum Operating Voltage After Turn−On

V

Operating Hysteresis

CC

Undervoltage Lockout Threshold Voltage, V

Logic Reset Level (V

CC(latc h)

–V

CC(reset)

Decreasing

CC

> 1.0 V) (Note 7)

VCC Supply Current

Operating (VCC = 14 V, 1.0 nF Load, VFB = 2.0 V, 65 kHz Version)

Operating (VCC = 14 V, 1.0 nF Load, VFB = 2.0 V, 100 kHz Version)

Output Stays Low (VCC = 14 V, VFB = 0 V)

Latchoff Phase (VCC = 7.0 V, VFB = 2.0 V)

6

V

CC(on)

V

CC(off)

V

− V

CC(on)

V

CC(latc h)

V

CC(reset)

6

I

CC1

I

CC1

I

CC2

I

CC3

7. Guaranteed by design.

CC(off)

190

80

3.0

10

600

200

4.1

25

800

350

6.0

50

− 20 28 V

11.2

8.2

3.0

5.0

12.6

9.1

3.6

5.8

−

−

−

−

−

4.0

2.3

3.1

1.3

500

13.8

10

4.2

6.5

−

3.0

3.5

2.0

720

mV

mA

mA

mA

V

V

V

V

V

mA

mA

mA

mA

110

100

90

80

70

60

OSCILLATION FREQUENCY (kHz)

50

−25 −25

Figure 3. Oscillation Frequency vs.

TYPICAL CHARACTERISTICS

85

84

100 kHz

65 kHz

1251007550250−50

TEMPERATURE (°C) TEMPERATURE (°C)

Temperature

83

82

81

80

79

78

77

MAXIMUM DUTY CYCLE (%)

76

75

Figure 4. Maximum Duty Cycle vs.

Temperature

1251007550250−50

http://onsemi.com

6

NCP1271

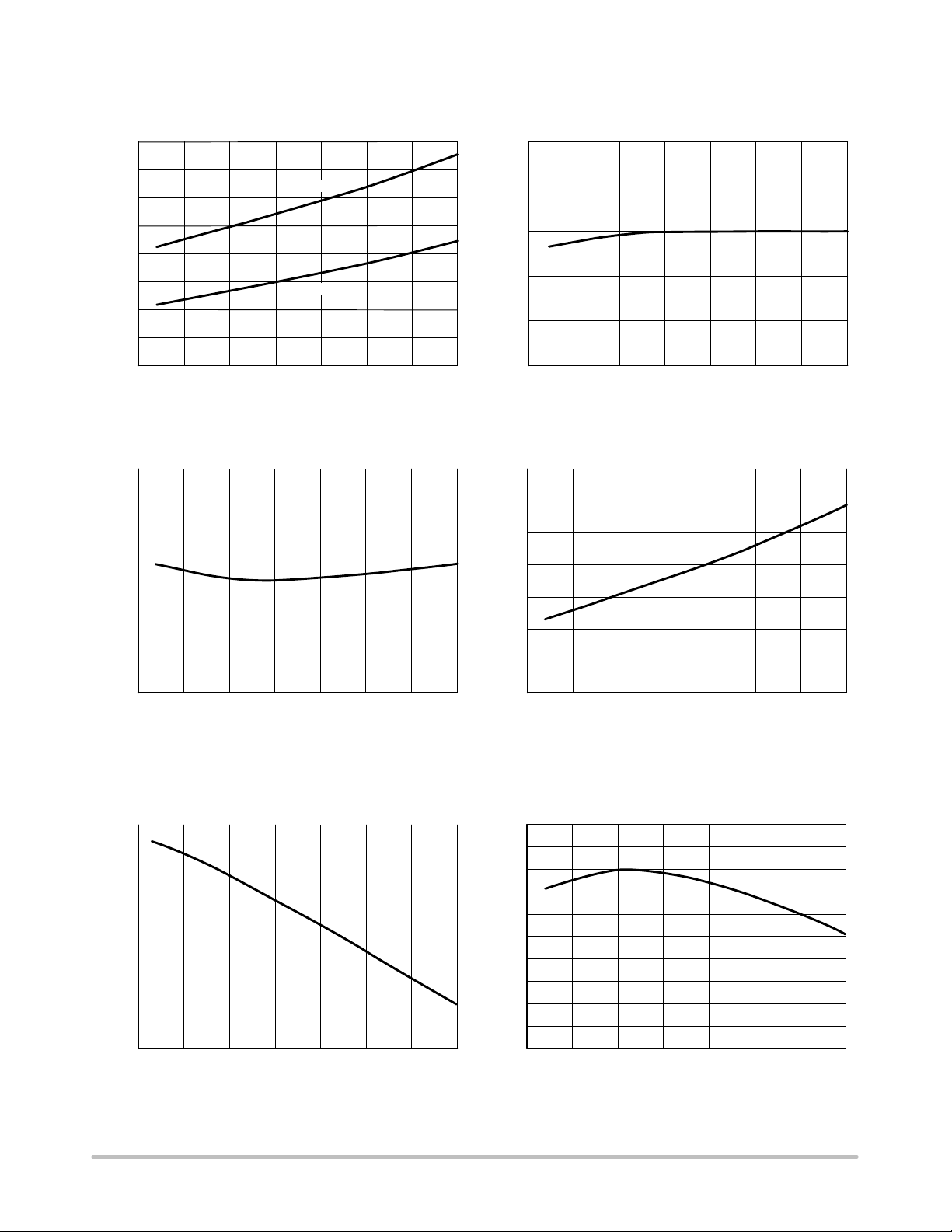

5

5

TYPICAL CHARACTERISTICS

16

14

12

10

8

6

4

2

0

OUTPUT GATE DRIVE RESISTANCE (W)

8

7

6

5

4

3

2

1

SOFT−START DURATION (ms)

0

1.04

R

OH

R

OL

−25 −25

TEMPERATURE (°C) TEMPERATURE (°C)

1251007550250−50

1.02

1.0

0.98

CURRENT LIMIT (V)

0.96

0.94

Figure 5. Output Gate Drive Resistance vs.

Temperature

350

300

250

200

150

100

50

LEADING EDGE BLANKING TIME (ns)

−25

1251007550250−50

TEMPERATURE (°C)

0

Figure 6. Current Limit vs. Temperature

−25

TEMPERATURE (°C)

1007550250−50

1251007550250−50

12

Figure 7. Soft−Start Duration vs. Temperature Figure 8. Leading Edge Blanking Time vs.

1.40

1.30

1.20

1.10

DEFAULT SKIP LEVEL (V)

1.00

−25

Figure 9. Default Skip Level vs. Temperature Figure 10. Skip Pin Current vs. Temperature

TEMPERATURE (°C)

45

44

43

42

41

40

39

38

37

SKIP PIN CURRENT (mA)

36

1251007550250−50

35

http://onsemi.com

7

−25

Temperature

TEMPERATURE (°C)

12

1007550250−50

NCP1271

5

TYPICAL CHARACTERISTICS

6.0

5.9

5.8

5.7

5.6

SKIP LEVEL RESET THRESHOLD (V)

5.5

−25

TEMPERATURE (°C)

Figure 11. Skip Level Reset Threshold vs.

Temperature

8.5

8.4

8.3

8.2

8.1

8.0

7.9

7.8

7.7

7.6

LATCH PROTECTION LEVEL (V)

7.5

−25

TEMPERATURE (°C)

Figure 13. Latch Protection Level vs.

Temperature

3.0

2.9

2.8

2.7

2.6

TRANSIENT LOAD DETECT LEVEL (V)

1251007550250−50

2.5

−25

TEMPERATURE (°C)

12

1007550250−50

Figure 12. Transient Load Detection Level vs.

Temperature

150

145

140

135

130

125

120

115

110

FAULT VALIDATION TIME (ms)

105

1251007550250−50

100

−25

TEMPERATURE (°C)

1251007550250−50

Figure 14. Fault Validation Time vs.

Temperature

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

STARTUP INHIBIT VOLTAGE (V)

0.1

0

−25

TEMPERATURE (°C)

Figure 15. Startup Inhibit Voltage vs.

Temperature

300

250

200

150

100

50

STARTUP INHIBIT CURRENT (mA)

0

1251007550250−50

http://onsemi.com

8

VCC = 0 V

−25

TEMPERATURE (°C)

Figure 16. Startup Inhibit Current vs.

Temperature

1251007550250−50

NCP1271

5

5

TYPICAL CHARACTERISTICS

4.5

VCC = V

4.4

4.3

4.2

4.1

4.0

3.9

3.8

3.7

STARTUP CURRENT (mA)

3.6

3.5

CC(on)

−25 2

Figure 17. High Voltage Startup Current vs.

40

35

30

25

20

15

10

5

STARTUP LEAKAGE CURRENT (mA)

0

−25

Figure 19. Startup Leakage Current vs.

− 0.2 V

1251007550250−50

TEMPERATURE (°C) VCC, SUPPLY VOLTAGE (V)

6

5

4

3

2

STARTUP CURRENT (mA)

1

0

Figure 18. Startup Current vs. VCC Voltage

Temperature

25

24

23

22

21

20

19

18

17

16

MINIMUM STARTUP VOLTAGE (V)

1251007550250−50

15

TEMPERATURE (°C)

−25

TEMPERATURE (°C)

Figure 20. Minimum Startup Voltage vs.

Temperature

Temperature

25°C

1007550250−50

125°C

−40°C

12108640

12

14

12

10

8

6

4

2

SUPPLY VOLTAGE THRESHOLD (V)

0

−25

Figure 21. Supply Voltage Thresholds vs.

TEMPERATURE (°C)

Temperature

V

CC(on)

V

CC(off)

V

CC(latc h)

V

CC(reset)

1251007550250−50

http://onsemi.com

9

3.5

3.0

2.5

2.0

1.5

1.0

SUPPLY CURRENT (mA)

0.5

0

−25

Figure 22. Supply Currents vs. Temperature

TEMPERATURE (°C)

I

CC1

I

CC1

(100 kHz)

(65 kHz)

I

CC2

I

CC3

1007550250−50

12

NCP1271

OPERATING DESCRIPTION

Introduction

The NCP1271 represents a new generation of the

fixed−frequency PWM current−mode flyback controllers

from ON Semiconductor. The device features integrated

high−voltage startup and excellent standby performance.

The proprietary Soft−Skip Mode achieves extremely

low−standby power consumption while keeping power

supply acoustic noise to a minimum. The key features of

the NCP1271 are as follows:

• Timer−Based Fault Detection: In the event that an

abnormally large load is applied to the output for more

than 130 ms, the controller will safely shut the

application down. This allows accurate overload (OL)

or short−circuit (SC) detection which is not dependent

on the auxiliary winding.

• Soft−Skip Mode: This proprietary feature of the

NCP1271 minimizes the standby low−frequency

acoustic noise by ramping the peak current envelope

whenever skip is activated.

• Adjustable Skip Threshold: This feature allows the

power level at which the application enters skip to be

fully adjusted. Thus, the standby power for various

applications can be optimized. The default skip level

is 1.2 V (40% of the maximum peak current)

.

• 500 V High−Voltage Startup Capability: This

AC−DC application friendly feature eliminates the

need for an external startup biasing circuit, minimizes

the standby power loss, and saves printed circuit board

(PCB) space.

• Dual High−Voltage Startup−Current Levels: The

NCP1271 uniquely provides the ability to reduce the

startup current supply when Vcc is low. This prevents

damage if Vcc is ever shorted to ground. After Vcc

rises above approximately 600 mV, the startup current

increases to its full value and rapidly charges the Vcc

capacitor.

• Latched Protection: The NCP1271 provides a pin,

which if pulled high, places the part in a latched off

mode. Therefore, overvoltage (OVP) and

overtemperature (OTP) protection can be easily

implemented. A noise filter is provided on this function

to reduce the chances of falsely triggering the latch. The

latch is released when Vcc is cycled below 4 V.

• Non−Latched Protection/ Shutdown Option: By

pulling the feedback pin below the skip threshold

level, a non−latching shutdown mode can be easily

implemented.

• 4.0 ms Soft−Start: The soft start feature slowly ramps

up the drive duty cycle at startup. This forces the

primary current to also ramp up slowly and

dramatically reduces the stress on power components

during startup.

• Current−Mode Operation: The NCP1271 uses

current−mode control which provides better transient

response than voltage−mode control. Current−mode

control also inherently limits the cycle−by−cycle

primary current.

• Compensation Ramp: A drawback of current−mode

regulation is that the circuit may become unstable

when the operating duty cycle is too high. The

NCP1271 offers an adjustable compensation ramp to

solve this instability.

• 80% Maximum Duty Cycle Protection: This feature

limits the maximum on time of the drive to protect the

power MOSFET from being continuously on.

• Frequency Jittering: Frequency jittering softens the

EMI signature by spreading out peak energy within a

band +/− 7.5% from the center frequency.

• Switching Frequency Options: The NCP1271 is

available in either 65 kHz or 100 kHz fixed frequency

options. Depending on the application, the designer

can pick the right device to help reduce magnetic

switching loss or improve the EMI signature before

reaching the 150 kHz starting point for more

restrictive EMI test limits.

NCP1271 Operating Conditions

There are 5 possible operating conditions for the NCP1271:

1. Normal Operation – When V

(9.1 V typical) and the feedback pin voltage (VFB)

is within the normal operation range (i.e.,VFB < 3.0

V), the NCP1271 operates as a fixed−frequency

current−mode PWM controller.

2. Standby Operation (or Skip−Cycle Operation)

When the load current drops, the compensation

network responds by reducing the primary peak

current. When the peak current reaches the skip

peak current level, the NCP1271 enters Soft−Skip

operation to reduce the power consumption. This

Soft−Skip feature offers a modified peak current

envelope and hence also reduces the risk of audible

noise. In the event of a sudden load increase, the

transient load detector (TLD) disables Soft−Skip

and applies maximum power to bring the output

into regulation as fast as possible.

3. Fault Operation – When no feedback signal is

received for 130 ms or when V

V

as a fault condition. In this fault mode, the Vcc

voltage is forced to go through two cycles of slowly

discharging and charging. This is known as a

“double hiccup.” The double hiccup insures that

ample time is allowed between restarts to prevent

overheating of the power devices. If the fault is

(9.1 V typical), the NCP1271 recognizes it

CC(off)

is above V

CC

drops below

CC

CC(off)

http://onsemi.com

10

NCP1271

cleared after the double hiccup, then the application

restarts. If not, then the process is repeated.

4. Latched Shutdown – When the Skip/latch pin (Pin

1) voltage is pulled above 8.0 V for more than

13 ms, the NCP1271 goes into latchoff shutdown.

The output is held low and V

stays in hiccup

CC

mode until the latch is reset. The reset can only

occur if Vcc is allowed to fall below V

CC(reset)

(4.0 V typical). This is generally accomplished by

unplugging the main input AC source.

5. Non−Latched Shutdown – If the FB pin is pulled

below the skip level, then the device will enter a

non−latched shutdown mode. This mode disables

the driver, but the controller automatically recovers

when the pulldown on FB is released. Alternatively,

Vcc can also be pulled low (below 190 mV) to

shutdown the controller. This has the added benefit

of placing the part into a low current consumption

mode for improved power savings.

Biasing the Controller

During startup, the Vcc bias voltage is supplied by the

HV Pin (Pin 8). This pin is capable of supporting up to

500 V, so it can be connected directly to the bulk capacitor.

Internally, the pin connects to a current source which

rapidly charges VCC to its V

threshold. After this

CC(on)

level is reached, the controller turns on and the transformer

auxiliary winding delivers the bias supply voltage to V

CC.

The startup FET is then turned off, allowing the standby

power loss to be minimized. This in−chip startup circuit

minimizes the number of external components and Printed

Circuit Board (PCB) area. It also provides much lower

power dissipation and faster startup times when compared

to using startup resistors to VCC. The auxiliary winding

needs to be designed to supply a voltage above the V

CC(off)

level but below the maximum VCC level of 20 V.

For added protection, the NCP1271 also include a dual

startup mode. Initially, when V

voltage V

(600 mV typical), the startup current source

inhibit

is below the inhibit

CC

is small (200 uA typical). The current goes higher (4.1 mA

typical) when VCC goes above V

. This behavior is

inhibit

illustrated in Figure 23. The dual startup feature protects

the device by limiting the maximum power dissipation

when the VCC pin (Pin 6) is accidentally grounded. This

slightly increases the total time to charge VCC, but it is

generally not noticeable.

Startup current

4.1 mA

200 uA

0.6 V

V

CC(latch)

V

CC(on)

V

CC

Figure 23. Startup Current at Various VCC Levels

VCC Double Hiccup Mode

Figure 24 illustrates the block diagram of the startup

circuit. An undervoltage lockout (UVLO) comparator

monitors the V

V

, then the controller enters “double hiccup mode.”

CC(off)

4.1 mA when Vcc > 0.6 V

200 uA when Vcc < 0.6 V

B2

Counter

turn on internal bias

supply voltage. If V

CC

8

turn off

UVLO

Q

S

R

double

hiccup

&

+

−

−

+

12.6/

5.8 V

9.1 V

6

20V

Figure 24. VCC Management

falls below

CC

V

bulk

HV

10−to−20V biasing voltage

Vcc

(available after startup)

During double hiccup operation, the Vcc level falls to

V

CC(latch)

turned back on and charges VCC to V

VCC then slowly collapses back to the V

(5.8 V typical). At this point, the startup FET is

(12.6 V typical).

CC(on)

CC(latch)

level. This

cycle is repeated twice to minimize power dissipation in

http://onsemi.com

11

NCP1271

external components during a fault event. After the second

cycle, the controller tries to restart the application. If the

restart is not successful, then the process is repeated.

During this mode, V

reset level. Therefore, latched faults will not be cleared

unless the application is unplugged from the AC line (i.e.,

V

discharges).

bulk

Figure 25 shows a timing diagram of the V

hiccup operation. Note that at each restart attempt, a soft

start is issued to minimize stress.

Supply voltage, V

12.6 V

9.1 V

never drops below the 4 V latch

CC

CC

CC

double

12.6 V

9.1 V

0.6 V

12.6 V

9.1 V

V

V

t

startup

Output waveforms with a large enough VCC capacitor

Desired level of V

V

CC

out

CC

time

out

5.8 V

time

t

Drain current, I

D

startup

time

Switching is missing in

every two VCC hiccup cycles

featuring a “double−hiccup”

Figure 25. VCC Double Hiccup Operation in a Fault

Condition

VCC Capacitor

As stated earlier, the NCP1271 enters a fault condition

when the feedback pin is open (i.e. FB is greater than 3 V)

for 130 ms or V

Therefore, to take advantage of these features, the V

drops below V

CC

(9.1 V typical).

CC(off)

CC

capacitor needs to be sized so that operation can be

maintained in the absence of the auxiliary winding for at

least 130 ms.

The controller typically consumes 2.3 mA at a 65 kHz

frequency with a 1 nF switch gate capacitance. Therefore,

to ensure at least 130 ms of operation, equation 1 can be

used to calculate that at least an 85 mF capacitor would be

necessary.

t

startup

+

C

VCC

I

CC1

85 mF · (12.6 V−9.1 V)

DV

+

2.3 mA

+ 130 ms

(eq. 1)

If the 130 ms timer feature will not be used, then the

capacitance value needs to at least be large enough for the

output to charge up to a point where the auxiliary winding

can supply VCC. Figure 26 describes different startup

scenarios with different V

capacitor values. If the V

CC

CC

cap is too small, the application fails to start because the

bias supply voltage cannot be established before VCC is

reduced to the V

CC(off)

level.

5.8 V

0.6 V

Output waveforms with too small of a VCC capacitor

V

out

time

Figure 26. Different Startup Scenarios of the

Circuits with Different V

It is highly recommended that the V

close as possible to the V

and ground pins of the product

CC

Capacitors

CC

CC

capacitor be as

to reduce switching noise. A small bypass capacitor on this

pin is also recommended. If the switching noise is large

enough, it could potentially cause V

to go below V

CC

CC(off)

and force a restart of the controller.

It is also recommended to have a margin between the

winding bias voltage and V

so that all possible

CC(off)

transient swings of the auxiliary winding are allowed. In

standby mode, the V

the low−frequency skip−cycle operation. The V

voltage swing can be higher due to

CC

CC

capacitor also affects this swing. Figure 27 illustrates the

possible swings.

Supply voltage, V

Feedback pin voltage, V

Drain current, I

CC

9.1 V

time

FB

V

skip

time

D

time

Figure 27. Timing Diagram of Standby Condition

http://onsemi.com

12

NCP1271

Soft−Start Operation

Figures 28 and 29 show how the soft−start feature is

included in the pulse−width modulation (PWM)

comparator. When the NCP1271 starts up, a soft−start

voltage VSS begins at 0 V. VSS increases gradually from 0 V

to 1.0 V in 4.0 ms and stays at 1.0 V afterward. This voltage

V

is compared with the divided−by−3 feedback pin

SS

voltage (V

/3). The lesser of V

FB

modulation voltage V

PWM

and (V

SS

in the PWM duty cycle

/3) becomes the

FB

generation. Initially, (VFB/3) is above 1.0 V because the

output voltage is low. As a result, V

is limited by the

PWM

soft start function and slowly ramps up the duty cycle (and

therefore the primary current) for the initial 4.0 ms. This

provides a greatly reduced stress on the power devices

during startup.

V

SS

V / 3

FB

Figure 28. V

Soft−start voltage, V

PWM

is the lesser of VSS and (VFB/3)

0 1

SS

−

+

V

PWM

1 V

Current−Mode Pulse−Width Modulation

The NCP1271 uses a current−mode fixed−frequency

PWM with internal ramp compensation. A pair of current

sense resistors R

CS

and R

sense the flyback drain

ramp

current ID. As the drain current ramps up through the

inductor and current sense resistor, a corresponding voltage

ramp is placed on the CS pin (pin 3). This voltage ranges

from very low to as high as the modulation voltage V

PWM

(maximum of 1.0 V) before turning the drive off. If the

internal current ramp is ignored (i.e., R

maximum possible drain current I

ramp

D(max)

≈ 0) then the

is shown in

Equation 2. This sets the primary current limit on a cycle

by cycle basis.

PWM

Output

Q

80%

max duty

R

S

Clock

I

D(max)

1V

+

R

CS

I

ramp

V

180ns

+

−

LEB

V

PWM

(1V max. signal)

CS

CS

3

1 0

R

ramp

(eq. 2)

V

bulk

I

R

D

CS

4 ms

Feedback pin voltage divided−by−3, VFB/3

time must be less than130 ms

to prevent fault condition

Pulse Width Modulation voltage, V

4 ms

Drain Current, I

4 ms

D

PWM

1 V

1 V

time

time

time

time

Figure 30. Current−Mode Implementation

PWM

Output

V

PWM

V

CS

clock

Figure 31. Current−Mode Timing Diagram

The timing diagram of the PWM is in Figure 31. An

internal clock turns the Drive Output (Pin 5) high in each

switching cycle. The Drive Output goes low when the CS

(Pin 3) voltage VCS intersects with the modulation voltage

V

. This generates the pulse width (or duty cycle). The

PWM

maximum duty cycle is limited to 80% (typically) in the

output RS latch.

Figure 29. Soft−Start (Time = 0 at VCC = V

)

CC(on)

http://onsemi.com

13

NCP1271

Ramp Compensation

Ramp compensation is a known mean to cure

subharmonic oscillations. These oscillations take place at

half the switching frequency and occur only during

continuous conduction mode (CCM) with a duty−cycle

greater than 50%. To lower the current loop gain, one

usually injects between 50 and 75% of the inductor down

slope. The NCP1271 generates an internal current ramp

that is synchronized with the clock. This current ramp is

then routed to the CS pin. Figures 32 and 33 depict how the

ramp is generated and utilized. Ramp compensation is

simply formed by placing a resistor, R

, between the CS

ramp

pin and the sense resistor.

Ramp current, I

100uA

0

Figure 32. Internal Ramp Current Source

ramp

time

80% of period

100% of period

R

ramp

It is recommended that the value of R

43 mVńms

+

8.1 mAńms

+ 5.3 kW

ramp

(eq. 4)

be limited to

less then 10 kW. Values larger than this will begin to limit

the effective duty cycle of the controller and may result in

reduced transient response.

Frequency Jittering

Frequency jittering is a method used to soften the EMI

signature by spreading the energy in the vicinity of the main

switching component. The NCP1271 switching frequency

ranges from +7.5% to −7.5% of the switching frequency in

a linear ramp with a typical period of 6 ms. Figure 34

demonstrates how the oscillation frequency changes.

Oscillator Frequency

107.5 kHz

100 kHz

92.5 kHz

6 ms

time

DRIVE

Clock

Current

Ramp

Oscillator

100 mA Peak

CS

R

R

ramp

sense

Figure 33. Inserting a Resistor in Series with the

Current Sense Information brings Ramp Compensation

For the NCP1271, the current ramp features a swing of

100 mA. Over a 65 kHz frequency with an 80% max duty

cycle, that corresponds to an 8.1 mA/ms ramp. For a typical

flyback design, let’s assume that the primary inductance

(Lp) is 350 mH, the SMPS output is 19 V, the Vf of the

output diode is 1 V and the Np:Ns ratio is 10:1. The OFF

time primary current slope is given by:

Lp

Np

Ns

+ 571 VńmH + 571 mAńms

(eq. 3)

(Vout ) Vf) @

When projected over an Rsense of 0.1 W (for example),

this becomes or 57 mV/ms. If we select 75% of the

downslope as the required amount of ramp compensation,

then we shall inject 43 mV/ms. Therefore, R

ramp

is simply

equal to:

Figure 34. Frequency Jittering

(The values are for the 100 kHz frequency option)

Fault Detection

Figure 35 details the timer−based fault detection

circuitry. When an overload (or short circuit) event occurs,

the output voltage collapses and the optocoupler does not

conduct current. This opens the FB pin (pin 2) and V

FB

is

internally pulled higher than 3.0 V. Since (VFB/3) is greater

than 1 V, the controller activates an error flag and starts a

130 ms timer. If the output recovers during this time, the

timer is reset and the device continues to operate normally.

However, if the fault lasts for more than 130 ms, then the

driver turns off and the device enters the VCC Double

Hiccup mode discussed earlier. At the end of the double

hiccup, the controller tries to restart the application.

4.8V

V

FB

FB

2

V

FB

3

V

SS

Softstart

1V max

+

−

130ms

delay

&

Fault

disable Drv

Figure 35. Block Diagram of Timer−Based Fault

Detection

http://onsemi.com

14

NCP1271

Besides the timer−based fault detection, the NCP1271

also enters fault condition when V

drops below V

CC

CC

(off

(9.1 V typical). The device will again enter a double hiccup

mode and try to restart the application.

Operation in Standby Condition

During standby operation, or when the output has a light

load, the duty cycle on the controller can become very

small. At this point, a significant portion of the power

dissipation is related to the power MOSFET switching on

and off. To reduce this power dissipation, the NCP1271

“skips” pulses when the FB level (i.e. duty cycle) drops too

low. The level that this occurs at is completely adjustable

by setting a resistor on pin 1.

By discontinuing pulses, the output voltage slowly drops

and the FB voltage rises. When the FB voltage rises above

the V

level, the drive is turned back on. However, to

skip

minimize the risk of acoustic noise, when the drive turns

back on the duty cycle of its pulses are also ramped up. This

is similar to the soft start function, except the period of the

Soft−Skip operation is only 300 ms instead of 4.0 ms for the

soft start function. This feature produces a timing diagram

shown in Figure 36.

V

skip

FB

I

D

Soft Skip

Skip Duty Cycle

)

Skip peak current, %Ics

, is the percentage of the

skip

maximum peak current at which the controller enters skip

mode. Ics

can be any value from 0 to 100% as defined

skip

by equation 5. However, the higher that %Ics

greater the drain current when skip is entered. This

increases the risk of acoustic noise. Conversely, the lower

that %Ics

is the larger the percentage of energy is

skip

expended turning the switch on and off. Therefore it is

important to adjust %Ics

to the optimal level for a given

skip

application.

V

%Ics

skip

+

skip

3V

· 100%

Skip Adjustment

By default, when the Skip/latch Pin (Pin 1) is opened, the

skip level is 1.2 V (V

40% Ics

skip

(%Ics

= 1.2 V). This corresponds to a

skip

= 1.2 V / 3.0 V 100% = 40%).

skip

Therefore, the controller will enter skip mode when the

peak current is less than 40% of the maximum peak current.

However, this level can be externally adjusted by placing

a resistor R

between skip/latch pin (Pin 1) and Ground

skip

(Pin 4). The level will change according to equation 6.

V

+ R

skip

To operate in skip cycle mode, V

0 V and 3.0 V. Therefore, R

I

skip

skip

skip

must be between

skip

must be within the levels

given in Table 1.

skip

is, the

(eq. 5)

(eq. 6)

Figure 36. Soft−Skip Operation

Table 1. Skip Resistor R

%Ics

skip

0% 0 V 0 W Never skips.

12% 0.375 V 8.7 kW −

25% 0.75 V 17.4 kW −

40% 1.2 V 28 kW −

50% 1.5 V 34.8 kW −

100% 3.0 V 70 kW Always skips.

Range for D

skip

V

skip

or V

pin1

= 80% and I

max

R

skip

skip

= 43 mA

Comment

http://onsemi.com

15

NCP1271

Recover from Standby

In the event that a large load is encountered during skip

cycle operation, the circuit automatically disables the

normal Soft−Skip procedure and delivers maximum power

to the load (Figure 37). This feature, the Transient Load

Detector (TLD), is initiated anytime a skip event is exited

and the FB pin is greater than 2.85 V, as would be the case

for a sudden increase in output load.

output voltage

load current

V

FB

I

D

Figure 37. Transient Response from Standby

300 ms max

V

V

TLD

skip

Maximum current available

when TLD level is hit

External Latchoff Shutdown

When the Skip/Latch input (Pin 1) is pulled higher than

V

(8.0 V typical), the drive output is latched off until

latch

V

drops below V

CC

CC(reset)

(4.0 V

). If Vbulk stays

typical

above approximately 30 Vdc, then the HV FET ensure that

V

remains above V

CC

CC(latch)

(5.8 V

). Therefore, the

typical

controller is reset by unplugging the power supply from the

wall and allowing V

the timing diagram of V

Startup current source is

charging the VCC capacitor

12.6 V

to discharge. Figure 38 illustrates

bulk

in the latchoff condition.

CC

Startup current source is

off when VCC is 12.6 V

to be opened. The skip level V

is restored to

skip

the default 1.2 V.

3. When the voltage is between about 3.0 V and

V

skip−reset

, the V

level is above the normal

skip

operating range of the feedback pin. Therefore,

the output does not switch.

4. When the voltage is between 0 V and 3.0 V, the

is within the operating range of the

V

skip

feedback pin. Then the voltage on this pin sets

the skip level as explained earlier.

V

pin1

10 V (max limit)

Output is latched off here.

8V (V )

latch

Pin 1 considered to be opened.

V

is reset to default level 1.2 V.

skip

5.7 V (V )

skip−reset

Output always low (skipped) here.

3.0 V (always skip)

Adjustable V range.

skip

0 V (no skip)

Figure 39. NCP1271 Pin 1 Operating Regions

The external latch feature allows the circuit designers to

implement different kinds of latching protection. The

NCP1271 applications note (AND8242/D) details several

simple circuits to implement overtemperature protection

(OTP) and overvoltage protection (OVP).

In order to prevent unexpected latchoff due to noise,

it is very important to put a noise decoupling capacitor

near Pin 1 to increase the noise immunity. It is also

recommended to always have a resistor from pin 1 to GND.

This further reduces the risk of premature latchoff. Also

note that if the additional latch−off circuitry has leakage,

it will modify the skip adjust setup.

5.8 V

Startup current source turns

on when VCC reaches 5.8 V

CC

Figure 38. Latchoff VCC Timing Diagram

Figure 39 defines the different voltage regions of the

Skip/latch Pin (Pin 1) operation.

1. When the voltage is above V

(7.1 V min,

latch

8.7 V max), the circuit is in latchoff and all drive

pulses are disabled until VCC cycles below 4.0 V

(typical).

2. When the voltage is between V

min, 6.5 V max) and V

, the pin is considered

latch

skip−reset

(5.0 V

http://onsemi.com

External Non−Latched Shutdown

Figure 40 illustrates the Feedback (pin 2) operation. An

external non−latched shutdown can be easily implemented

by simply pulling FB below the skip level. This is an

inherent feature from the standby skip operation. Hence, it

allows the designer to implement additional non−latched

shutdown protection.

The device can also be shutdown by pulling the V

to GND (<190 mV). In addition to shutting off the output,

this method also places the part into a low current

consumption state.

16

CC

pin

NCP1271

V

FB

Fault operation when staying

in this region longer than 130 ms

3 V

PWM operation

V

skip

0 V

Figure 40. NCP1271 Operation Threshold

opto

coupler

Figure 41. Non−Latchoff Shutdown

Non−latched shutdown

OFF

1

2

3

4

8

6

5

NCP1271

Output Drive

The output stage of the device is designed to directly

drive a power MOSFET. It is capable of up to +500 mA and

−800 mA peak drive currents and has a typical rise and fall

time of 30 ns and 20 ns with a 1.0 nF load. This allows the

NCP1271 to drive a high−current power MOSFET directly

for medium−high power application.

Noise Decoupling Capacitors

There are three pins in the NCP1271 that may need

external decoupling capacitors.

1. Skip/Latch Pin (Pin 1) – If the voltage on

this pin is above 8.0 V, then the circuit enters

latchoff. Hence, a decoupling capacitor on this

pin is essential for improved noise immunity.

Additionally, a resistor should always be placed

from this pin to GND to prevent noise from

causing the pin 1 level to exceed the latchoff

level.

2. Feedback Pin (Pin 2) – The FB pin is a high

impedance point and is very easily polluted in a

noisy environment. This could effect the circuit

operation.

3. VCC Pin (Pin 6) – The circuit maintains normal

operation when VCC is above V

typical). But, if VCC drops below V

CC(off)

CC(off)

(9.1 V

because

of switching noise, then the circuit can incorrectly

recognize it as a fault condition. Hence, it is

important to locate the VCC capacitor or an

additional decoupling capacitor as close as possible

to the device.

http://onsemi.com

17

NCP1271

Fuse 2A

85 to

265 Vac

D1 − D4

1N5406 x 4

C1 0.1 uF

Common

T1

E3506−A

C6 1.2 nF

R5 30.1k

Flyback transformer :

Cooper CTX22−17179

Lp = 180uH, leakage 2.5uH max

np : ns : naux = 30 : 6 : 5

Hi−pot 3600Vac for 1 sec, primary to secondary

Hi−pot 8500Vac for 1 sec, winding to core

C2 0.1 uF

Mode Choke

IC1 NCP1271A

C7 1.2 nF

C3 82uF / 400V

D6 MRA4005T3

R2 10

C4 100uF

D10 MZP4746A (18V)

C5 10 nF

R1 100k / 2W

C13 100uF

D5 MMSZ914

D7 MURS160

R6 10

R7 511

R8

0.25 / 1W

C11 1nF/ 1000V

D8 MBR3100

Q1 SPP06N80C3

IC3 SFH615AA−X007

IC4 TL431

C9 2200 uF

C10 2200 uF

C12

0.15 uF

R10 1.69k

+

19 V / 3 A

−

R9 1.69k

R11 15.8k

R12 2.37k

Figure 42. 57 W Example Circuit Using NCP1271

Figure 42 shows a typical application circuit using the

NCP1271. The standby power consumption of the circuit

is 83 mW with 230 Vac input. The details of the application

95

90

120 Vac

85

230 Vac

80

75

EFFICIENCY (%)

70

65

60

10

Figure 43. Efficiency of the NCP1271 Demo

Board at Nominal Line Voltages

circuit are described in application note AND8242/D. The

efficiency of the circuit at light load up to full load is shown

in Figure 43.

60504030200

P

(W)

out

http://onsemi.com

18

NCP1271

ORDERING INFORMATION

Device Frequency Package Shipping

NCP1271D65R2G 65 kHz SOIC−7

(Pb−Free)

NCP1271D100R2G 100 kHz SOIC−7

(Pb−Free)

NCP1271P65G 65 kHz PDIP−7

(Pb−Free)

NCP1271P100G 100 kHz PDIP−7

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

2500 / Tape & Reel

2500 / Tape & Reel

50 Units / Rail

50 Units / Rail

†

Soft−Skip is a trademark of Semiconductor Components Industries, LLC (SCILLC).

The product described herein (NCP1271), may be covered by the following U.S. patents: 6,271,735, 6,362,067, 6,385,060, 6,597,221, 6,633,193. There may

be other patents pending.

http://onsemi.com

19

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

PDIP−7 (PDIP−8 LESS PIN 7)

SCALE 1:1

NOTE 8

A1

D1

D

14

TOP VIEW

e/2

e

SIDE VIEW

STYLE 1:

PIN 1. AC IN

2. DC + IN

3. DC − IN

4. AC IN

5. GROUND

6. OUTPUT

7. NOT USED

8. V

CC

A

58

H

E1

b2

B

A2

A

NOTE 3

L

SEATING

PLANE

C

8X

b

M

0.010 CA

MBM

CASE 626B

ISSUE D

E

END VIEW

WITH LEADS CONSTRAINED

NOTE 5

M

eB

END VIEW

NOTE 6

DATE 22 APR 2015

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. DIMENSIONS A, A1 AND L ARE MEASURED WITH THE PACKAGE SEATED IN JEDEC SEATING PLANE GAUGE GS−3.

4. DIMENSIONS D, D1 AND E1 DO NOT INCLUDE MOLD FLASH

OR PROTRUSIONS. MOLD FLASH OR PROTRUSIONS ARE

NOT TO EXCEED 0.10 INCH.

5. DIMENSION E IS MEASURED AT A POINT 0.015 BELOW DATUM

PLANE H WITH THE LEADS CONSTRAINED PERPENDICULAR

TO DATUM C.

6. DIMENSION eB IS MEASURED AT THE LEAD TIPS WITH THE

LEADS UNCONSTRAINED.

c

7. DATUM PLANE H IS COINCIDENT WITH THE BOTTOM OF THE

LEADS, WHERE THE LEADS EXIT THE BODY.

8. PACKAGE CONTOUR IS OPTIONAL (ROUNDED OR SQUARE

CORNERS).

INCHES

DIM MIN MAX

A −−−− 0.210

A1 0.015 −−−−

A2 0.115 0.195 2.92 4.95

b 0.014 0.022

b2

0.060 TYP 1.52 TYP

C 0.008 0.014

D 0.355 0.400

D1 0.005 −−−−

E 0.300 0.325

E1 0.240 0.280 6.10 7.11

e 0.100 BSC

eB −−−− 0.430 −−− 10.92

L 0.115 0.150 2.92 3.81

M −−−− 10

MILLIMETERS

MIN MAX

−−− 5.33

0.38 −−−

0.35 0.56

0.20 0.36

9.02 10.16

0.13 −−−

7.62 8.26

2.54 BSC

−−− 10

°°

GENERIC

MARKING DIAGRAM*

XXXXXXXXX

XXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

AWL

YYWWG

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON12198D

PDIP−7 (PDIP−8 LESS PIN 7)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

SOIC−7

CASE 751U−01

ISSUE E

DATE 20 OCT 2009

−A−

58

S

1

4

−B−

0.25 (0.010)

M

B

G

−T−

C

SEATING

PLANE

H

D

7 PL

0.25 (0.010) T

M

B

SAS

R

X 45

_

M

SOLDERING FOOTPRINT*

1.52

0.060

7.0

0.275

0.6

0.024

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

4.0

0.155

1.270

0.050

SCALE 6:1

ǒ

inches

mm

Ǔ

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B ARE DATUMS AND T

IS A DATUM SURFACE.

M

J

K

4. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

5. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

____

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

GENERIC

MARKING DIAGRAM

8

XXXXX

ALYWX

G

1

XXX = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON12199D

7−LEAD SOIC

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

SOIC−7

CASE 751U−01

ISSUE E

DATE 20 OCT 2009

STYLE 1:

PIN 1. EMITTER

2. COLLECTOR

3. COLLECTOR

4. EMITTER

5. EMITTER

6.

7. NOT USED

8. EMITTER

STYLE 4:

PIN 1. ANODE

2. ANODE

3. ANODE

4. ANODE

5. ANODE

6. ANODE

7. NOT USED

8. COMMON CATHODE

STYLE 7:

PIN 1. INPUT

2. EXTERNAL BYPASS

3. THIRD STAGE SOURCE

4. GROUND

5. DRAIN

6. GATE 3

7. NOT USED

8. FIRST STAGE Vd

STYLE 10:

PIN 1. GROUND

2. BIAS 1

3. OUTPUT

4. GROUND

5. GROUND

6. BIAS 2

7. NOT USED

8. GROUND

STYLE 2:

PIN 1. COLLECTOR, DIE, #1

2. COLLECTOR, #1

3. COLLECTOR, #2

4. COLLECTOR, #2

5. BASE, #2

6. EMITTER, #2

7. NOT USED

8. EMITTER, #1

STYLE 5:

PIN 1. DRAIN

2. DRAIN

3. DRAIN

4. DRAIN

5.

6.

7. NOT USED

8. SOURCE

STYLE 8:

PIN 1. COLLECTOR (DIE 1)

2. BASE (DIE 1)

3. BASE (DIE 2)

4. COLLECTOR (DIE 2)

5. COLLECTOR (DIE 2)

6. EMITTER (DIE 2)

7. NOT USED

8. COLLECTOR (DIE 1)

STYLE 11:

PIN 1. SOURCE (DIE 1)

2. GATE (DIE 1)

3. SOURCE (DIE 2)

4. GATE (DIE 2)

5. DRAIN (DIE 2)

6. DRAIN (DIE 2)

7. NOT USED

8. DRAIN (DIE 1)

STYLE 3:

PIN 1. DRAIN, DIE #1

2. DRAIN, #1

3. DRAIN, #2

4. DRAIN, #2

5. GATE, #2

6. SOURCE, #2

7. NOT USED

8. SOURCE, #1

STYLE 6:

PIN 1. SOURCE

2. DRAIN

3. DRAIN

4. SOURCE

5. SOURCE

6.

7. NOT USED

8. SOURCE

STYLE 9:

PIN 1. EMITTER (COMMON)

2. COLLECTOR (DIE 1)

3. COLLECTOR (DIE 2)

4. EMITTER (COMMON)

5. EMITTER (COMMON)

6. BASE (DIE 2)

7. NOT USED

8. EMITTER (COMMON)

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON12199D

7−LEAD SOIC

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor ’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...