Seip TM50, TM80 User Manual

TGarage Door Operator

TM 50

TM 80

INSTALLATION AND

PROGRAMMING INSTRUCTIONS

TM50/80 MO911/1V0 SKRW433 SKR433-1

ENGLISH

Content

Quick Reference for experienced Installers ���������������������3

Information and Remarks

Regulations and Usage ��������������������������������������������������4

Directives and Regulations

Use of the operators

Garage Doors

The installers declaration of conformity

Older Garage Doors

Instruction for the users

Safety Advises for the Installation ����������������������������������5

Installation

Conditions for Installation ����������������������������������������������6

Minimum Headroom

Door Hight

Door Arm Extension

Dimensions

Pre-Mounting ����������������������������������������������������������������6

Installation ���������������������������������������������������������������������7

Installation

Adjusting the Limit Blocks ����������������������������������������������8

The Emergency Release �������������������������������������������������9

When the garage door is the only entrance

When there is a second entrance to the garage

Remote Control

Registering and deleting Remote Devices ���������������������������������16

Starting the Registry

Registering a Device

HomeLink™

Erasing Remote Devices

General Remarks ���������������������������������������������������������������������17

Useable Batteries

Changing the transmitters‘ battery

Changing the wall push-buttons‘ battery

Synchronisation of the Rolling Code

Technical Information

Technical Data �������������������������������������������������������������������������18

Wiring Diagram �����������������������������������������������������������������������18

Internal Wiring

External connections

Devices for adjustments

Others

Troubleshooting �����������������������������������������������������������������������19

Error Messages

Messages by blinking integrated lighting

Additional messages from the LED „Diag“ only

If... then...

Declarations

EC-Declaration of Conformity ��������������������������������������������������20

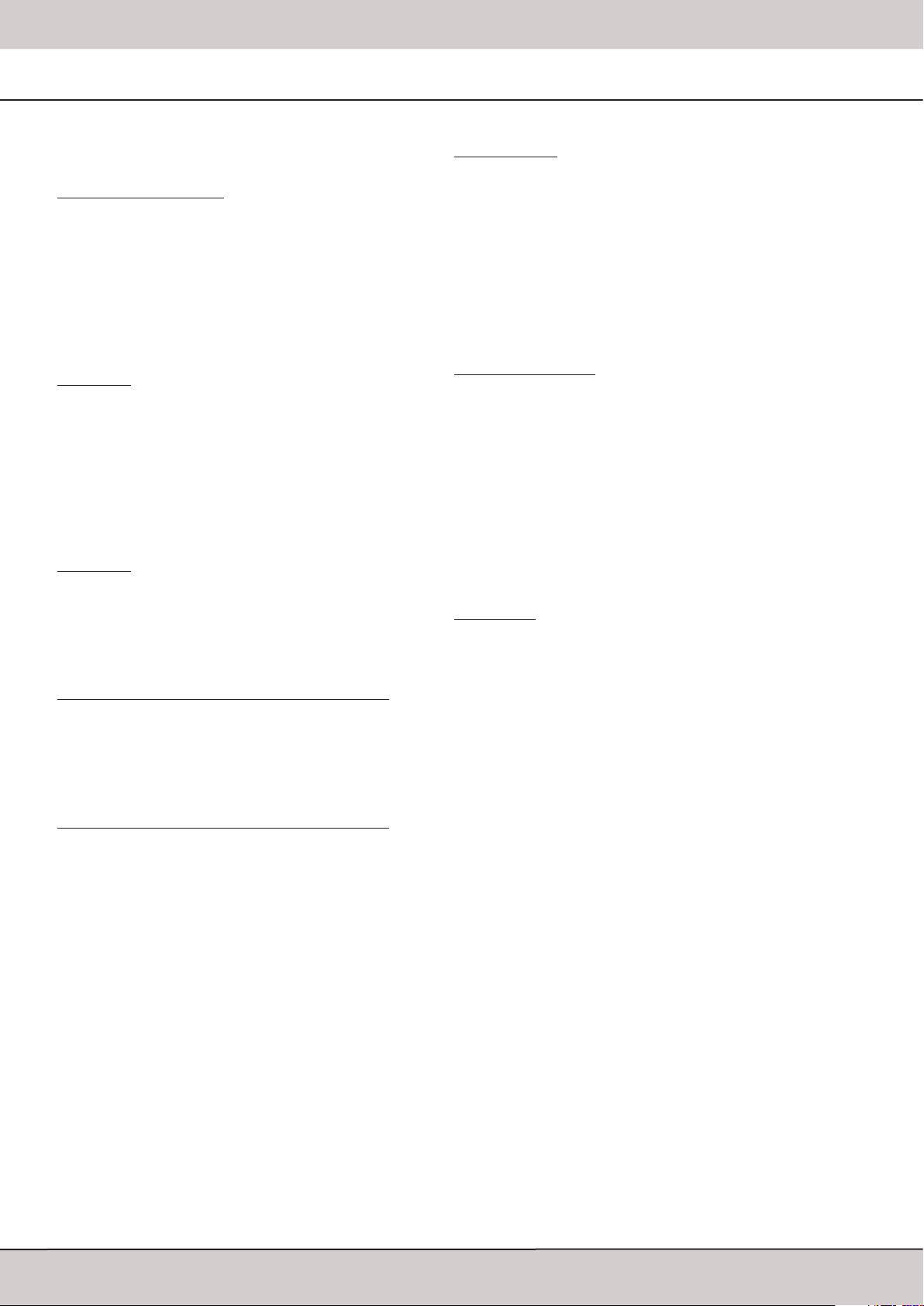

Printed Circuit Board: Adjustments and Connectors

Control Elements ���������������������������������������������������������10

Connectors ������������������������������������������������������������������11

Push Button

Photo Cell / Hatch Door Contact

Printed Circuit Board: Adjustments and Connectors

Standard Programming ������������������������������������������������12

Programming Forces and Running Distance

Choosing the type of door

Programming Remote Components

Free Programming �������������������������������������������������������13

Setting the speeds

Setting the opening speed

Changing the length of Soft Stop

Automatic Closing �������������������������������������������������������14

Setting the time

Pre-Warning by internal lighting

Connecting a Photo-Cell

Performance of Control Devices

Avoiding automatic closing temporarily

Further Safety Advice for Automatic Closing

Adjusting the Lighting Duration �����������������������������������15

Page 2

Installation Instructions TM50/TM80 - MO911/1V0

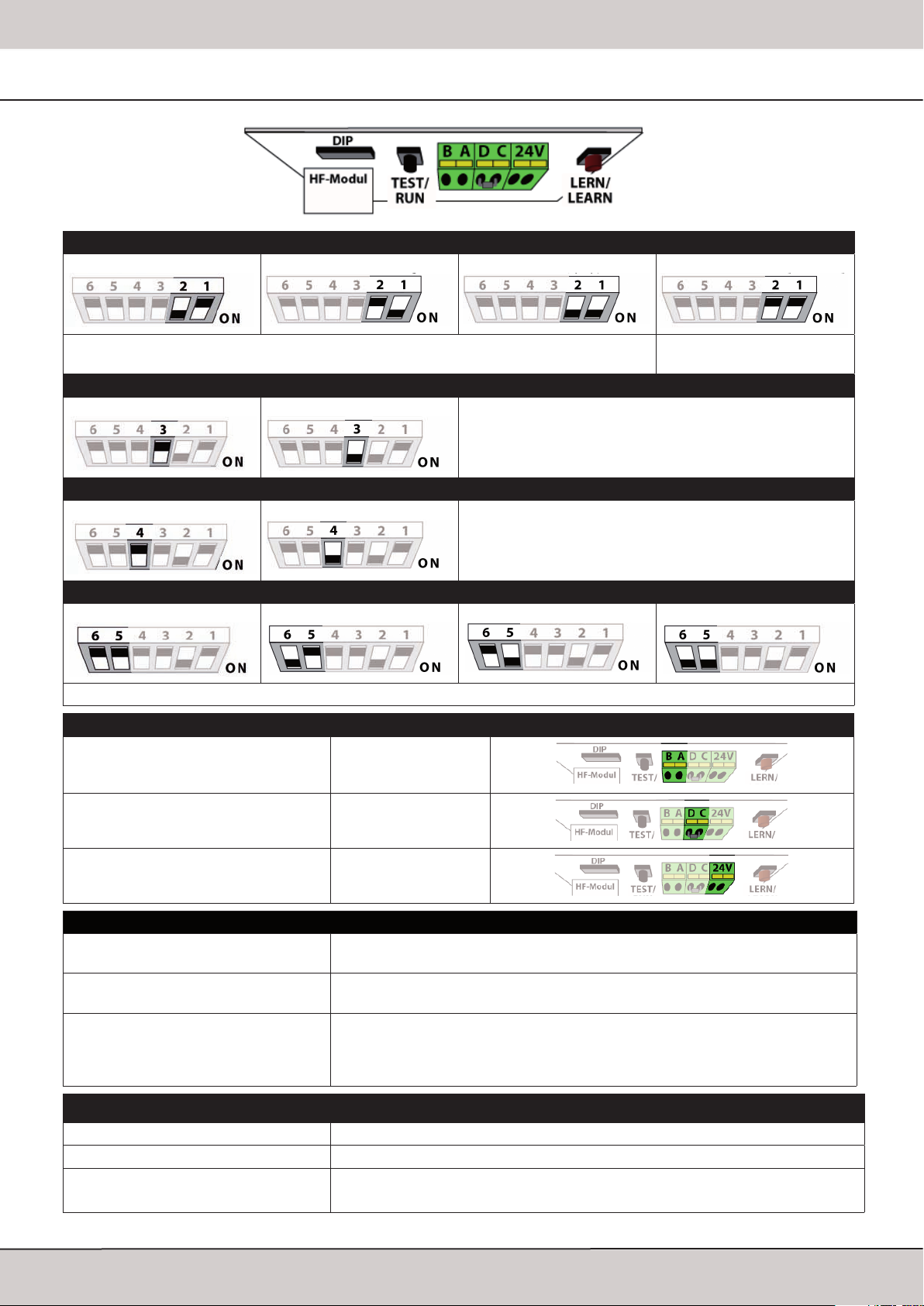

Adjusting the Door Type

Tilting Door

Canopy Type Doors

Canopy Type Doors

Sectionaldoor

Quick Reference for experienced Installers

Tilting Door

Canopy Type Doors

Free Programming

After changing the DIP-switch settings the operator MUST run through a learning cycle: keep the

LEARN button pressed for 3 seconds, release it and press it again shortly�

Increased Force shortly before reaching Closed Position

Standard

Pre-Warning Light (always active when using automatic closing, pls� refer to page 14 )

Off

Automatic Closing

None

Changing the DIP-switch settings must be conrmed by shortly pressing the LEARN button�

Connectors

Push Button (potential free) A + B

after 30 sec� after 90 sec� after 120 sec�

Increased Force Changing the DIP-switch settings must be conrmed by shortly

pressing the LEARN button�

ON Changing the DIP-switch settings must be conrmed by shortly

pressing the LEARN button�

For free programming, pls�

refer to page 13�

Photo Cell and Hatch Door, 8�2 kOhm,

Remove resistor and connect it to the photo cell

by putting it in line with one impulse wire

24V AC Output, max� 200mAmp� 24 V

Programming

Running Length and Forces Keep the LEARN button pressed for 3 seconds, release it (the operators‘ light is now

Remote Components (Transmitters, Digi

Pad, Remote Wall Push Button)

Changing the Duration of the

Internal Lighting

LED-Indicators

Vp (yellow) On when 230V supply is o�k�

TEST/FUNK (green) On whilst an impuls is received from remote devices or a connected push-button (A+B)

8k2/Diag (red) On when an error from a connected safety device is received (connectors C+D) or

C + D

blinking) and press it again shortly

Keep the LEARN button pressed for 3 seconds, release it (the operators‘ light is now

blinking) and press the desired hand transmitter button

Keep the LEARN button pressed for 6 seconds, release it once the green LED starts

glowing� Press LEARN button once again shortly -> the green LED starts blinking� Each

blink stands for 10 seconds of light duration� Once the desired duration is reached,

press the LEARN button again shortly (e�g� after 6 blinks for a duration of 60 seconds)�

blinks in intervalls to indicate error messages (refer to page 19)

Installation Instructions TM50/TM80 - MO911/1V0

Page 3

Information and Remarks

Regulations and Usage

It is within legal regulation and without restriction, to use a

Seip door operator with any garage door that has been approved for use with other certied door operators!

Directives and Regulations

The TM garage door operator comply to the latest European directives and regulations� The declaration of conformity is enclosed at

the end of these instructions�

Use of the operators

The operators were designed for the use with up-and-over doors

(tilting and canopy-type) and sectional doors�

All garage doors need to be maintained before automation� The

door must be easily opened and closed by hand� A garage door

must not be automated unless it is easy to open and close manually�

Garage Doors

In January 2001 the European regulations EN12604 and EN12605

became compulsory for garage doors� Before installing an automatic door operator it must be assured that the garage doors

applies to these regulations (the information can be obtained from

the manufacturers‘ declaration of conrmity)� A Seip door operator may be installed to any door that complies to the regulations�

Should a garage door not be compliant then please refer to the

chapter „older garage doors“�

The installers declaration of conformity

No matter whether a door operator was delivered together with a

garage door or seperately, the installer must issue a declaration of

conformity for the complete installation�

With this declaration the installer assures, that the installation

was made according to the instructions given by the manufacturers (e�g� the installation instructions of the garage door and the

operator)� This declaration can only be issued by the installer and

may not be issued from the manufacturer!

If both components comply to the directives and the installation

was made as to the manufacturers instructions the whole installation will normally be CE-compliant�

Older Garage Doors

When automating an older garage-door the TS-series will still

comply to the regulations - through the automatic force setting

the requested values for forces and reversion will be according to

the regulations�

But it needs to be taken in consideration that most older garage

doors do not meet the regulations EN 12604 and EN 12605 especially regarding security features� They might still have sharp

edges bearing the danger of severe injuries - for example sectional

doors might not have a nger protection between the sections�

Unfortunately the entire regulations do not mention how to

handle the automation of such an older garage door - the danger

basically is not the automation but the construction of the door�

Therefore we strongly recommend to

- check the garage door for sharp edges bearing danger when the

door is moving; take any necessary action to avoid the dangers

and make the door safer

- check the doors‘ springs and readjust them if necessary

- grease or oil the pivotal points and rollers of the garage door

- check that the door may be easily used by hand

If, however, the dangers cannot be avoided we recommend to use

the automatic pre-warning function of the operator� The operators‘ lighting will then be blinking for approx� 5 sec� before every

movement of the garage door� People inside the garage will be

warned before the opening and can step back from the garage

door in time�

Instruction for the users

Please instruct the users as follows:

- Use of the hand transmitter

- Use of the emergency release in case of a power failure

- Hand over the separate „User Manual“ to the customer

- Inform the user about the Security Advises in the User Manual

Page 4

Installation Instructions TM50/TM80 - MO911/1V0

Information and Remarks

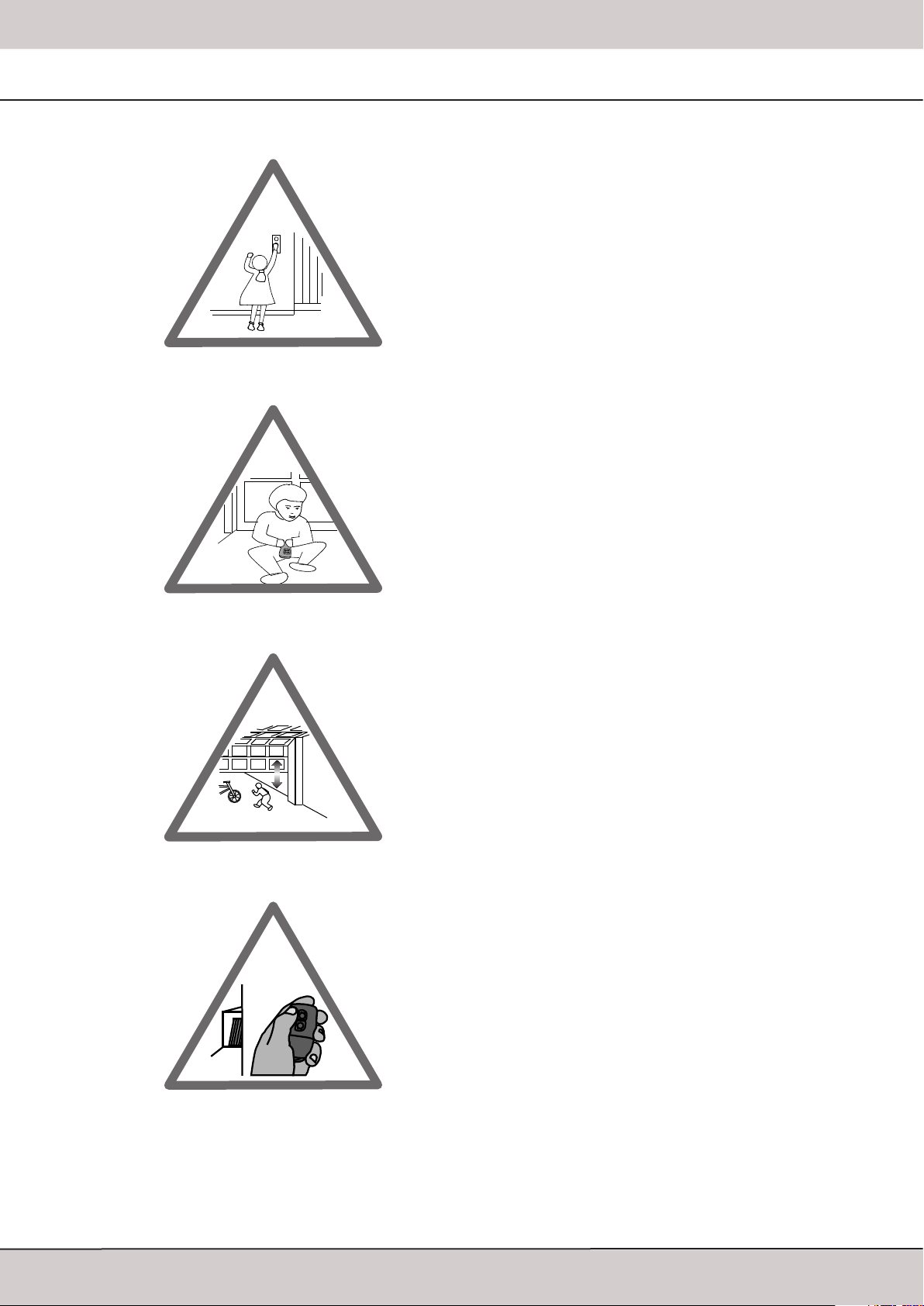

Safety Advises for the Installation

Important Safety Instructions for Installation

WARNING: INCORRECT INSTALLATION CAN LEAD TO SEVERE

INJURY

Follow all Installation Instructions.

- Read page 3 of this instruction carefully before the installation

- Before installing the drive, remove unnecessary ropes from the

existing installation

- Maintain the garage door according to the advises on page 3

and to the door manufacturer’s manual

- If possible, install the drive at a height of at least 2,10 m and the

manual release at a height less than 1,80 m

- Locate the push-button within sight of the door but away from

moving parts and at a minimum height of 1,50 m

- Fix the label warning against entrapment next to the pushbutton

- The label xed to the manual release may not be removed

- After installation, ensure that the mechanism is properly adjusted

and that the drive reverses when the door contacts a 40 mm high

object placed on the oor�

Installation Instructions TM50/TM80 - MO911/1V0

Page 5

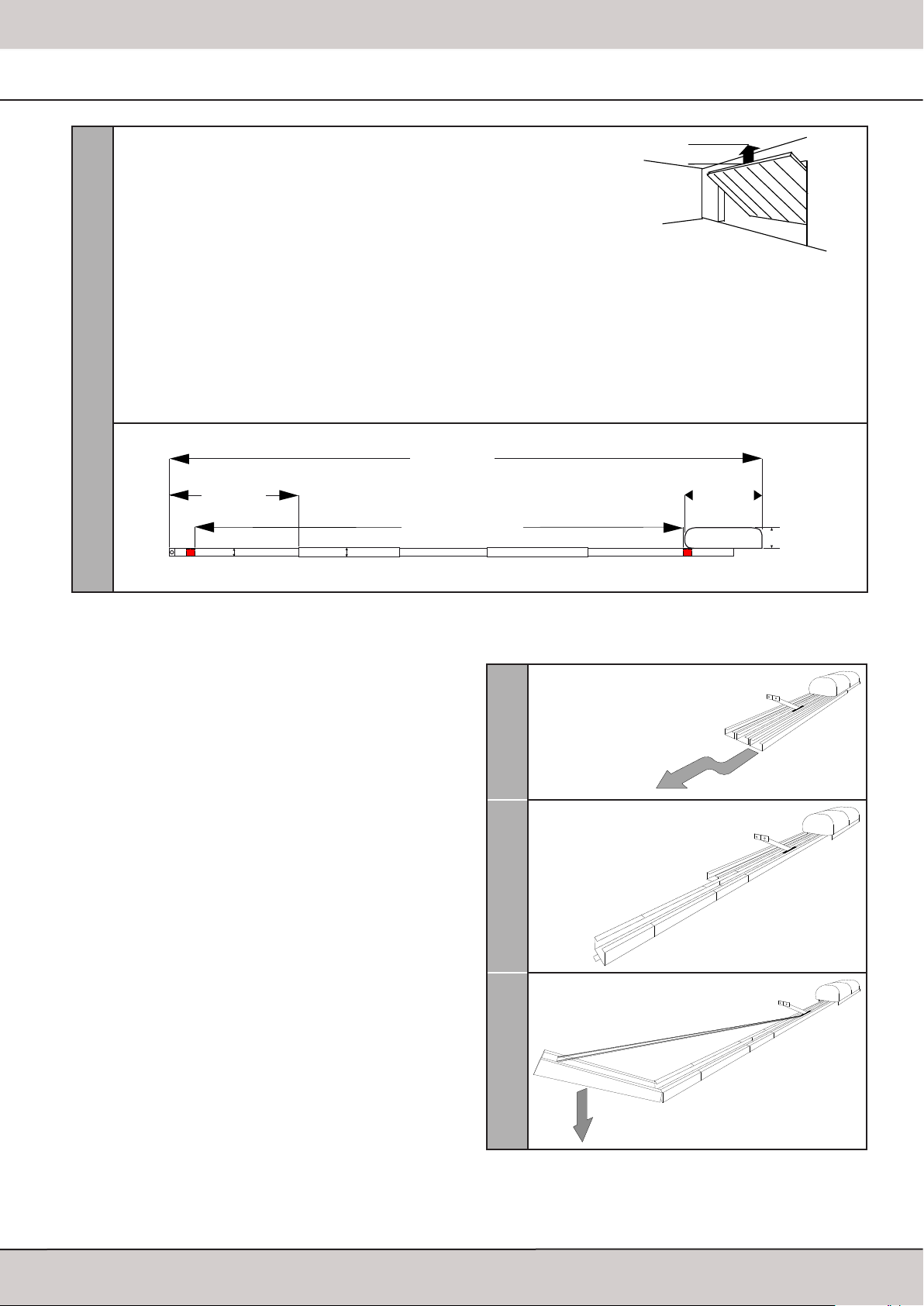

Installation

78 mm

Conditions for Installation

Minimum Headroom

A minimum distance of 35mm between the garage door and the ceiling is required�

Door Hight

No optionals are required for doors up to 2,250mm hight�

Between 2,250mm und 2,500mm: a lintel-sided extension for the rail might be

required� The operator will be set back by approx� 300mm in order to use the full

running length up to the front pulley (2,500mm max�)

Higher than 2,500mm: The C-rail must be extended� Extensions are available at

500mm and 1,000mm; the operator can be extended by 1,500mm in total� The

maximum door hight is 4,000mm

Door Arm Extension

Should the minimum space between the garage door and the ceiling be smaller than 35mm then a door arm extension is

needed� For an extension you can use a metal beam from any DIY-market� The beam should not be shorter than the door‘s

height�

Dimensions

>35mm

3.150 mm

800 mm

2.500 mm max.

30 mm

35 mm

Pre-Mounting

Be aware not to twist the chain - rather slide the rail parts on the

oor than lift them�

The overall rail consists of three parts at 1m and two junction parts

which will keep the rails together�

1� The empty piece of rail must be joined to the rail which is xed

to the motor head� Run the junction-part over the joint till stop�

2� The junction-part in front shall prolude for approx� 1cm

3� Slide the last piece of rail, which carries the pulley in front, from

above into the proluding junction-part and press it down (the

chain will be tensioned)� Slide the junction-part over rail till stop�

4� Turn around the operator and tighten the grub-screws in the

junction-parts in order to keep them in place�

360 mm

1

2

The operator is now fully pre-mounted for installation�

The chain is factory pre-tensioned� Do not change the chain

tension.

ATTENTION: Before using the operator the limit-blocks must

be set up and the operator must be put in programming

mode. Otherwise the operator will produce an error message!

Page 6

3

Installation Instructions TM50/TM80 - MO911/1V0

Loading...

Loading...