Page 1

TGarage Door Operator

TM 50

TM 80

INSTALLATION AND

PROGRAMMING INSTRUCTIONS

TM50/80 MO911/1V0 SKRW433 SKR433-1

ENGLISH

Page 2

Content

Quick Reference for experienced Installers ���������������������3

Information and Remarks

Regulations and Usage ��������������������������������������������������4

Directives and Regulations

Use of the operators

Garage Doors

The installers declaration of conformity

Older Garage Doors

Instruction for the users

Safety Advises for the Installation ����������������������������������5

Installation

Conditions for Installation ����������������������������������������������6

Minimum Headroom

Door Hight

Door Arm Extension

Dimensions

Pre-Mounting ����������������������������������������������������������������6

Installation ���������������������������������������������������������������������7

Installation

Adjusting the Limit Blocks ����������������������������������������������8

The Emergency Release �������������������������������������������������9

When the garage door is the only entrance

When there is a second entrance to the garage

Remote Control

Registering and deleting Remote Devices ���������������������������������16

Starting the Registry

Registering a Device

HomeLink™

Erasing Remote Devices

General Remarks ���������������������������������������������������������������������17

Useable Batteries

Changing the transmitters‘ battery

Changing the wall push-buttons‘ battery

Synchronisation of the Rolling Code

Technical Information

Technical Data �������������������������������������������������������������������������18

Wiring Diagram �����������������������������������������������������������������������18

Internal Wiring

External connections

Devices for adjustments

Others

Troubleshooting �����������������������������������������������������������������������19

Error Messages

Messages by blinking integrated lighting

Additional messages from the LED „Diag“ only

If... then...

Declarations

EC-Declaration of Conformity ��������������������������������������������������20

Printed Circuit Board: Adjustments and Connectors

Control Elements ���������������������������������������������������������10

Connectors ������������������������������������������������������������������11

Push Button

Photo Cell / Hatch Door Contact

Printed Circuit Board: Adjustments and Connectors

Standard Programming ������������������������������������������������12

Programming Forces and Running Distance

Choosing the type of door

Programming Remote Components

Free Programming �������������������������������������������������������13

Setting the speeds

Setting the opening speed

Changing the length of Soft Stop

Automatic Closing �������������������������������������������������������14

Setting the time

Pre-Warning by internal lighting

Connecting a Photo-Cell

Performance of Control Devices

Avoiding automatic closing temporarily

Further Safety Advice for Automatic Closing

Adjusting the Lighting Duration �����������������������������������15

Page 2

Installation Instructions TM50/TM80 - MO911/1V0

Page 3

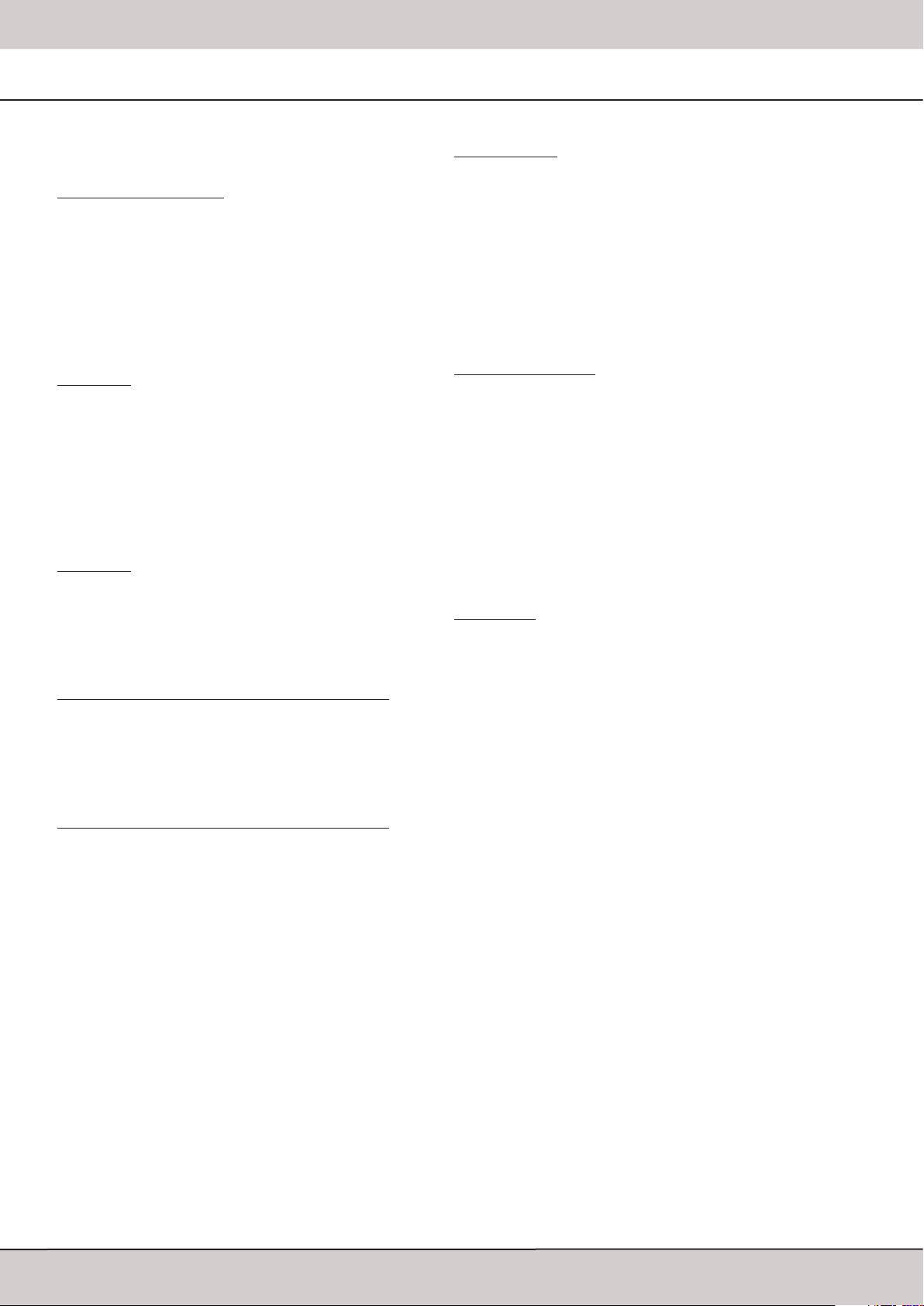

Adjusting the Door Type

Tilting Door

Canopy Type Doors

Canopy Type Doors

Sectionaldoor

Quick Reference for experienced Installers

Tilting Door

Canopy Type Doors

Free Programming

After changing the DIP-switch settings the operator MUST run through a learning cycle: keep the

LEARN button pressed for 3 seconds, release it and press it again shortly�

Increased Force shortly before reaching Closed Position

Standard

Pre-Warning Light (always active when using automatic closing, pls� refer to page 14 )

Off

Automatic Closing

None

Changing the DIP-switch settings must be conrmed by shortly pressing the LEARN button�

Connectors

Push Button (potential free) A + B

after 30 sec� after 90 sec� after 120 sec�

Increased Force Changing the DIP-switch settings must be conrmed by shortly

pressing the LEARN button�

ON Changing the DIP-switch settings must be conrmed by shortly

pressing the LEARN button�

For free programming, pls�

refer to page 13�

Photo Cell and Hatch Door, 8�2 kOhm,

Remove resistor and connect it to the photo cell

by putting it in line with one impulse wire

24V AC Output, max� 200mAmp� 24 V

Programming

Running Length and Forces Keep the LEARN button pressed for 3 seconds, release it (the operators‘ light is now

Remote Components (Transmitters, Digi

Pad, Remote Wall Push Button)

Changing the Duration of the

Internal Lighting

LED-Indicators

Vp (yellow) On when 230V supply is o�k�

TEST/FUNK (green) On whilst an impuls is received from remote devices or a connected push-button (A+B)

8k2/Diag (red) On when an error from a connected safety device is received (connectors C+D) or

C + D

blinking) and press it again shortly

Keep the LEARN button pressed for 3 seconds, release it (the operators‘ light is now

blinking) and press the desired hand transmitter button

Keep the LEARN button pressed for 6 seconds, release it once the green LED starts

glowing� Press LEARN button once again shortly -> the green LED starts blinking� Each

blink stands for 10 seconds of light duration� Once the desired duration is reached,

press the LEARN button again shortly (e�g� after 6 blinks for a duration of 60 seconds)�

blinks in intervalls to indicate error messages (refer to page 19)

Installation Instructions TM50/TM80 - MO911/1V0

Page 3

Page 4

Information and Remarks

Regulations and Usage

It is within legal regulation and without restriction, to use a

Seip door operator with any garage door that has been approved for use with other certied door operators!

Directives and Regulations

The TM garage door operator comply to the latest European directives and regulations� The declaration of conformity is enclosed at

the end of these instructions�

Use of the operators

The operators were designed for the use with up-and-over doors

(tilting and canopy-type) and sectional doors�

All garage doors need to be maintained before automation� The

door must be easily opened and closed by hand� A garage door

must not be automated unless it is easy to open and close manually�

Garage Doors

In January 2001 the European regulations EN12604 and EN12605

became compulsory for garage doors� Before installing an automatic door operator it must be assured that the garage doors

applies to these regulations (the information can be obtained from

the manufacturers‘ declaration of conrmity)� A Seip door operator may be installed to any door that complies to the regulations�

Should a garage door not be compliant then please refer to the

chapter „older garage doors“�

The installers declaration of conformity

No matter whether a door operator was delivered together with a

garage door or seperately, the installer must issue a declaration of

conformity for the complete installation�

With this declaration the installer assures, that the installation

was made according to the instructions given by the manufacturers (e�g� the installation instructions of the garage door and the

operator)� This declaration can only be issued by the installer and

may not be issued from the manufacturer!

If both components comply to the directives and the installation

was made as to the manufacturers instructions the whole installation will normally be CE-compliant�

Older Garage Doors

When automating an older garage-door the TS-series will still

comply to the regulations - through the automatic force setting

the requested values for forces and reversion will be according to

the regulations�

But it needs to be taken in consideration that most older garage

doors do not meet the regulations EN 12604 and EN 12605 especially regarding security features� They might still have sharp

edges bearing the danger of severe injuries - for example sectional

doors might not have a nger protection between the sections�

Unfortunately the entire regulations do not mention how to

handle the automation of such an older garage door - the danger

basically is not the automation but the construction of the door�

Therefore we strongly recommend to

- check the garage door for sharp edges bearing danger when the

door is moving; take any necessary action to avoid the dangers

and make the door safer

- check the doors‘ springs and readjust them if necessary

- grease or oil the pivotal points and rollers of the garage door

- check that the door may be easily used by hand

If, however, the dangers cannot be avoided we recommend to use

the automatic pre-warning function of the operator� The operators‘ lighting will then be blinking for approx� 5 sec� before every

movement of the garage door� People inside the garage will be

warned before the opening and can step back from the garage

door in time�

Instruction for the users

Please instruct the users as follows:

- Use of the hand transmitter

- Use of the emergency release in case of a power failure

- Hand over the separate „User Manual“ to the customer

- Inform the user about the Security Advises in the User Manual

Page 4

Installation Instructions TM50/TM80 - MO911/1V0

Page 5

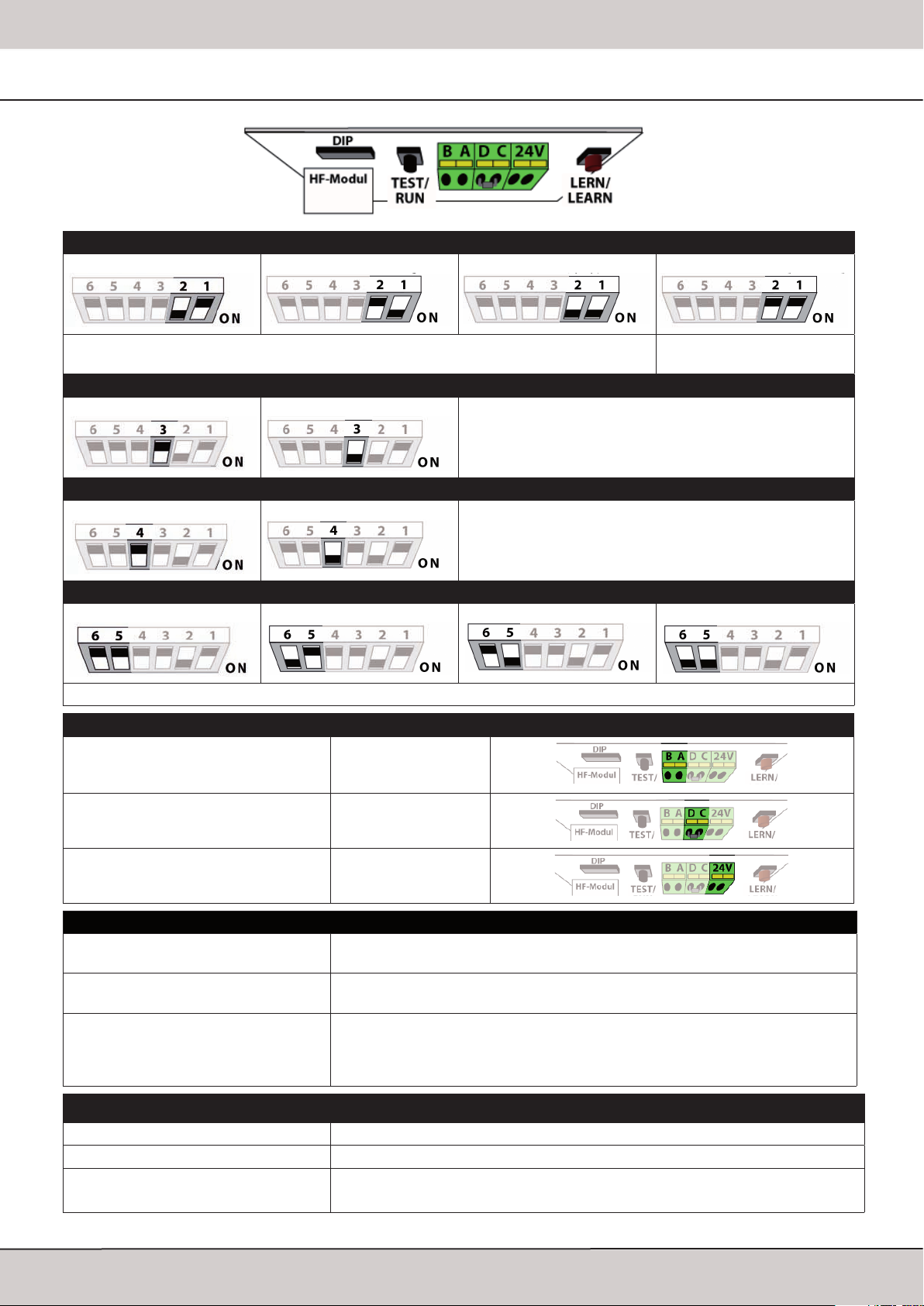

Information and Remarks

Safety Advises for the Installation

Important Safety Instructions for Installation

WARNING: INCORRECT INSTALLATION CAN LEAD TO SEVERE

INJURY

Follow all Installation Instructions.

- Read page 3 of this instruction carefully before the installation

- Before installing the drive, remove unnecessary ropes from the

existing installation

- Maintain the garage door according to the advises on page 3

and to the door manufacturer’s manual

- If possible, install the drive at a height of at least 2,10 m and the

manual release at a height less than 1,80 m

- Locate the push-button within sight of the door but away from

moving parts and at a minimum height of 1,50 m

- Fix the label warning against entrapment next to the pushbutton

- The label xed to the manual release may not be removed

- After installation, ensure that the mechanism is properly adjusted

and that the drive reverses when the door contacts a 40 mm high

object placed on the oor�

Installation Instructions TM50/TM80 - MO911/1V0

Page 5

Page 6

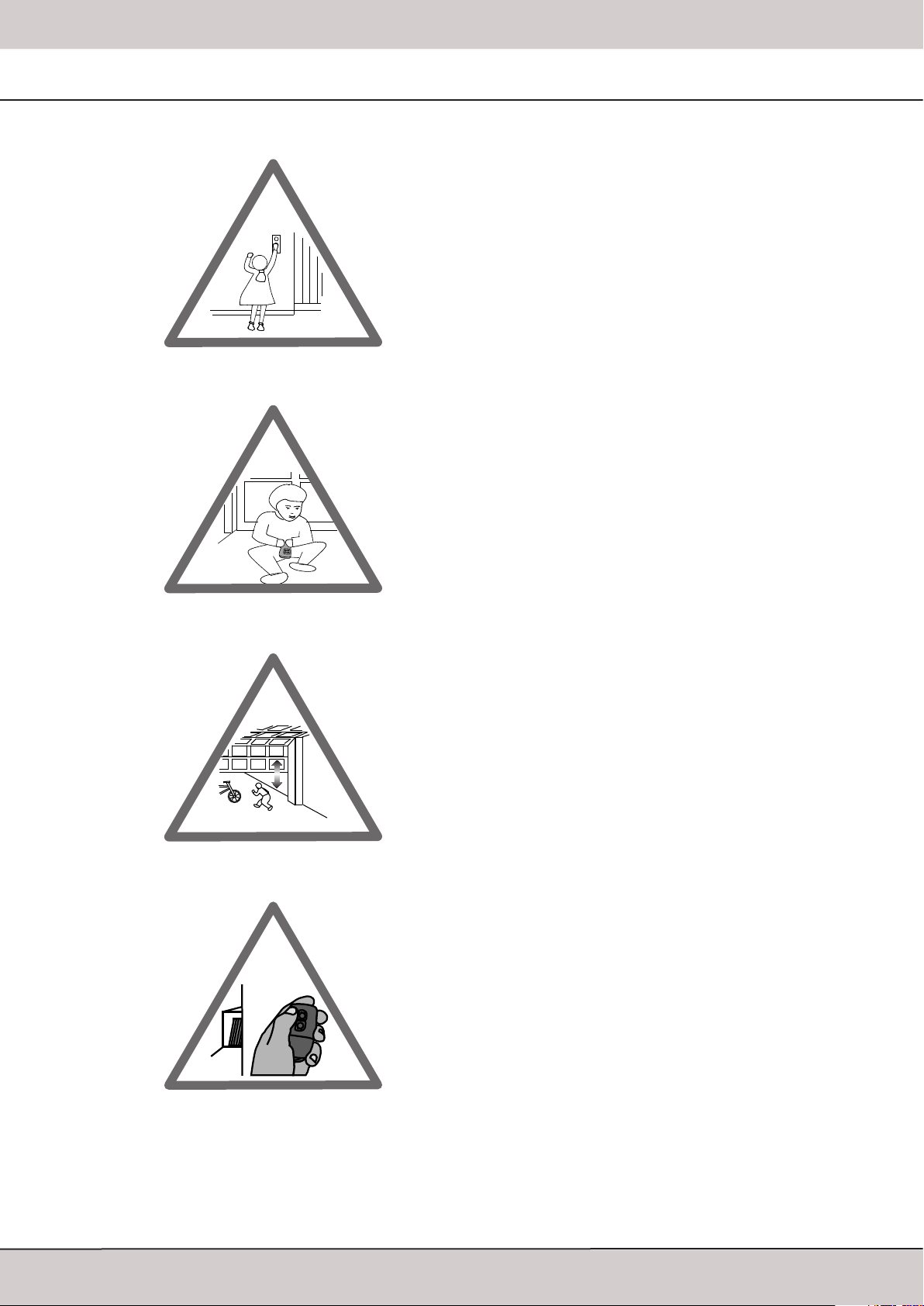

Installation

78 mm

Conditions for Installation

Minimum Headroom

A minimum distance of 35mm between the garage door and the ceiling is required�

Door Hight

No optionals are required for doors up to 2,250mm hight�

Between 2,250mm und 2,500mm: a lintel-sided extension for the rail might be

required� The operator will be set back by approx� 300mm in order to use the full

running length up to the front pulley (2,500mm max�)

Higher than 2,500mm: The C-rail must be extended� Extensions are available at

500mm and 1,000mm; the operator can be extended by 1,500mm in total� The

maximum door hight is 4,000mm

Door Arm Extension

Should the minimum space between the garage door and the ceiling be smaller than 35mm then a door arm extension is

needed� For an extension you can use a metal beam from any DIY-market� The beam should not be shorter than the door‘s

height�

Dimensions

>35mm

3.150 mm

800 mm

2.500 mm max.

30 mm

35 mm

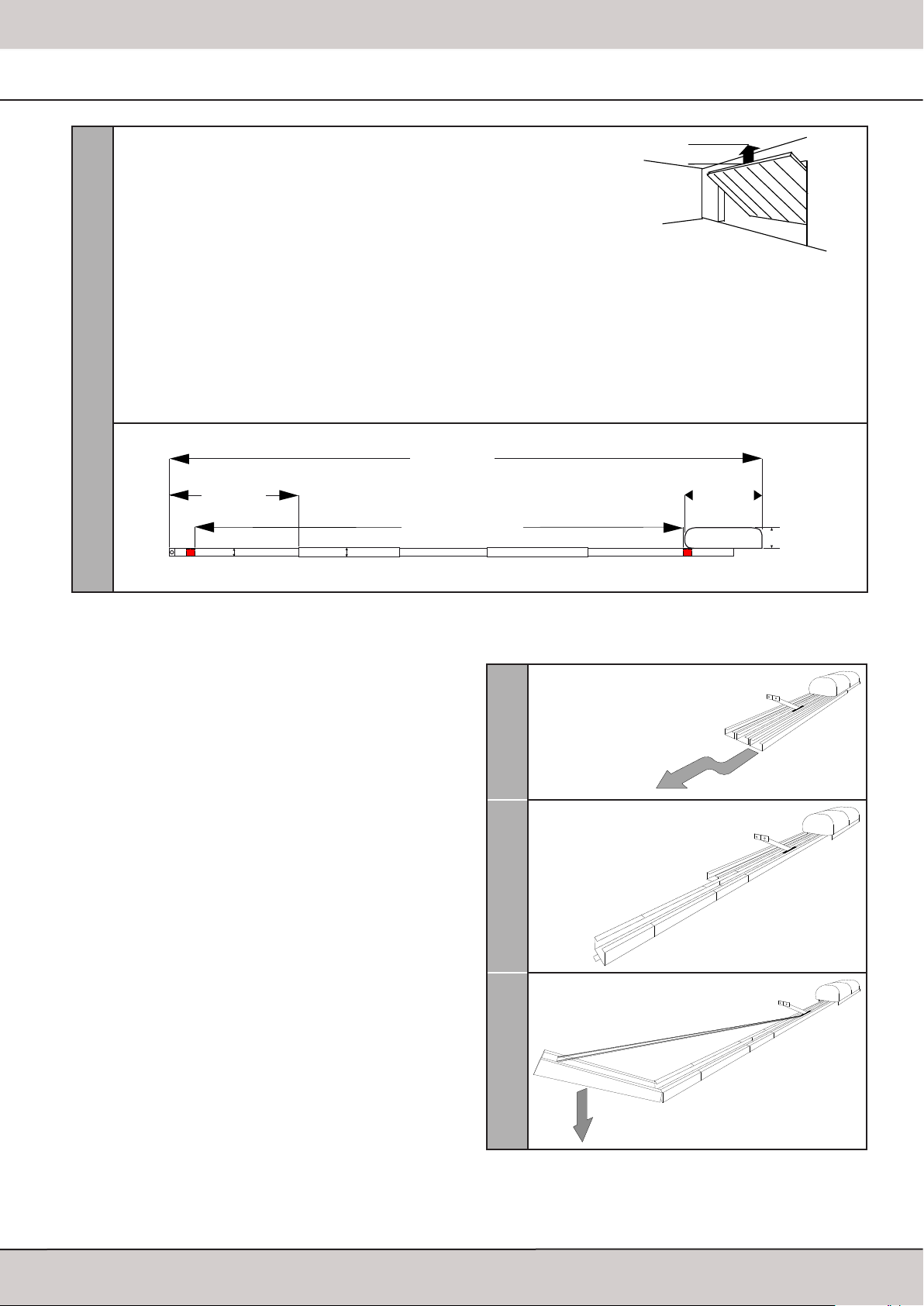

Pre-Mounting

Be aware not to twist the chain - rather slide the rail parts on the

oor than lift them�

The overall rail consists of three parts at 1m and two junction parts

which will keep the rails together�

1� The empty piece of rail must be joined to the rail which is xed

to the motor head� Run the junction-part over the joint till stop�

2� The junction-part in front shall prolude for approx� 1cm

3� Slide the last piece of rail, which carries the pulley in front, from

above into the proluding junction-part and press it down (the

chain will be tensioned)� Slide the junction-part over rail till stop�

4� Turn around the operator and tighten the grub-screws in the

junction-parts in order to keep them in place�

360 mm

1

2

The operator is now fully pre-mounted for installation�

The chain is factory pre-tensioned� Do not change the chain

tension.

ATTENTION: Before using the operator the limit-blocks must

be set up and the operator must be put in programming

mode. Otherwise the operator will produce an error message!

Page 6

3

Installation Instructions TM50/TM80 - MO911/1V0

Page 7

Installation

Installation

The front xing angle can be mounted either at the lintel or at the

ceiling�

1

1. Meassure the middle of your garage door and make a mark on

the lintel and the top of your door (1)�

2. Fix the front xing angle in the middle either at the lintel or at

the ceiling (lintel recommended) (1)�

2

3

4

3. Attach the C-rail to the front xing angle (2)� Put a carton piece

under the motor head unit to avoid damages�

4. To t the motor head to the ceiling it is recommend to use a

ladder (4)� When the operator is laying on the ladder you can

open the garage-door� Adjust the C-rail according to the mark you

made in the middle of the garage-door�

Fit the operator to the ceiling when you have made sure the C-rail

is running straight to the front� Use the supplied bracket to x the

C-rail to the ceiling (3)�

5. Now t the door arm to the garage door (5)� Take care that the

angle between the operator and the door arm does not exceed a

max� of 45° (it may be lower)�

6. The limit-blocks must be tightened and the programming

must be started before running the operator (page 8)!

The garage doors‘ locks must be removed before running

the operators - otherwise damages on the garage door or

operator might occure!

For additional security our locking set can be obtained as an

optional extra�

5

Installation Instructions TM50/TM80 - MO911/1V0

6

Page 7

Page 8

Installation

Adjusting the Limit Blocks

These adjustments must be made before the programming

of the forces and the running-length.

Starting the programming procedure without correctly adjusted blocks may lead to damages on the garage door and

the operator!

Vorgehensweise:

1� The operator is mounted and the door-arm is xed to the garage-door� The trolley is locked to the chain and stands somewhere

between the two blocks� If, however, trolley and chain need to be

moved you may do this using the TEST/RUN button�

2� Release the trolley (Pic� 1) and manually close the garage door�

3� The block for the closing direction is now right in front of the

trolley (Pic� 2)� If not, the block must be moved until it touches the

trolley�

4� Tighten the blocks‘ screw to keep it in place� Take care not to

tighten it too strongly - the c-rail should not be bended�

1

2

5� Now the garage door needs to be opened manually� The trolley

will lock into the chain - you have to release it once again to fully

open the garage door� (Pic� 1)�

6� The block for the opening direction is now right in front of the

trolley (Pic� 3)� If not, the block must be moved until it touches the

trolley�

7� Tighten the blocks‘ screw to keep it in place� Take care not to

tighten it too strongly - the c-rail should not be bended�

8. The trolley now needs to be locked back to the chain!

After that the programming procedure may be started (page 12

onwards)�

3

Page 8

Installation Instructions TM50/TM80 - MO911/1V0

Page 9

Installation

The Emergency Release

In case of a power failure the garage door can be opened by

hand� Therefore the operator rst needs to be released�

When the garage door is the only entrance

It is necessary to connect the emergency release to the door‘s

handle (pic� 1) otherwise the garage cannot be accessed in a

power failure situation�

1

2

Procede as follows:

1. Find out in which direction the door handle moves when opening the door�

2. Drill a hole in that side of the door handle which turns downwards�

3. Thread the cable through the hole and x it with the enclosed

metal-clamps� Be carefull not to put a high tension on the emergency release cable - the operator then might release from the

garage-door during a normal opening cycle�

4. Check the function of the emergency release together with a

second person� Stay inside the garage and close the door with

the operator� Let the second person open the door manually with

the door keys� If this works, the emergency-release is mounted

properly�

Do not leave the garage and close the garage-door with the

operator before you have tested the emergency-release!

When there is a second entrance to the garage

You can use the supplied handle for the emergency release (pic�

2)�

Thread the emergency release cable through the handle�

Fix the metal clamps to the cable where the handle shall be

placed�

Shorten the cable below the metal clamps - the handle is now being held by the clamps�

In case of a power failure the user can now open the garage

door by releasing the operator with the handle for the emergency

release�

Installation Instructions TM50/TM80 - MO911/1V0

Page 9

Page 10

Printed Circuit Board: Adjustments and Connectors

Control Elements

DIP

B A

D C 24V

TEST/RUN Button (black)

Standard Function

Function when Automatic Closing is active

Programming Functions

LERN/LEARN Button (red)

Standard Function

DIP-Switch Confirmation

HF-Modul

TEST/

RUN

Run the operator: Pressing the button runs or stops the operator� The function depends on the

entire status of the operator, following the sequence OPEN-STOP-CLOSE etc�

Opening command: Pressing the button gives an opening command� When the garage door is

open then presing the button will extend the opening time� When pressing the button during the

closing procedure, then the operator will stop and open the door again�

Adjusting the limit blocks: In programming mode the operator can be run by keeping the TESTbutton pressed� When the button is released, then the operator will stop - when pressing the

button again then the operator will run into the opposite direction�

Reducing the running speeds: When setting the opening and closing speed in „free programming“ mode then each press of the TEST-button will reduce the running speed by one level�

Starting the programming mode: The button must be kept pressed for approx� 3 seconds and

then must be released; the operators‘ light starts blinking and the operator is in programming

mode� Using the TEST-button the operator can be run to adjust the limit switches�

Starting the learning cycles: Once the operator is in programming mode, a short press on the

LEARN-button will start the learning cycles for the running length and the force-measurements�

Changing the settings of DIP-switches 3 to 6: Once the DIP-switch setting is changed, it must be

confirmed by shortly pressing the LEARN-button�

LERN/

LEARN

Changing the settings of DIP-switches 1 and 2: Keep the LERN-button pressed for approx� 3

seconds until the integrated lighting starts blinking� Release the LERN-button and press it once

again shortly to start the learning cycles� When set to „free programming“, then pls� refer to

page 13�

Programming Functions

Combined Functions of TEST and LERN Button

Change speed settings

when DIP-switches were

set to „free programming“

DIP-Switches

1+2

Standard: 1 OFF, 2 ON

3

Standard: OFF

4

Standard: OFF

5+6

Standard: OFF

Adjusting the time for the integrated lighting: The LERN-button must be pressed for approx� 6

seconds until the green LED starts blinking; then release the button� Pressing the button again,

will confirm the the new time for the integrated lighting�

Increasing the running speeds: When setting the opening and closing speed in „free programming“ mode then each press of the TEST-button will increase the running speed by one level�

The LERN-button must be kept pressed� In addition the TEST-button must be kept pressed� After

approx� 3 seconds the operators lighting starts blinking and the red LED starts blinking in a

sequence� Both buttons must now be released� The operator is now in the mode to adjust the

closing and opening speed, pls� refer to page 13�

Adjusting the type of garage door: It may be chosen either sectional door (standard adjustment),

tilting door, short running door (e�g� Canopy type doors) and free programming�

Additional force shortly before closed position: When using mechanical locking systems a higher

force might be necessary in order to ensure a proper locking� Setting the switch to ON increases

the force before reaching the closed position�

Pre-warning: When set to ON, the operators‘ lighting will blink for approx� 4 seconds before

every opening or closing�

When automatic closing is activated: When set to OFF, the operators‘ lighting will blink for 6 seconds before closing the door� When set to ON, it will be blinking before openings and closings�

Automatic closing: The time until the door will be closed can be set to 30, 90 or 120 seconds� For

programming pls� refer to page 14�

Page 10

Installation Instructions TM50/TM80 - MO911/1V0

Page 11

DIP

B A

Printed Circuit Board: Adjustments and Connectors

Connectors

D C 24V

HF-Modul

TEST/

RUN

Push Button

A + B

Standard function Pressing the push button will give a command to the operator� Whether this is an opening,

Function when using

the automatic closing

feature

Photo Cell / Hatch Door Contact

C + D

Connector for a wired wall push button

closing or stop command depends on the entire status of the operator�

Pressing the push button:

will give an opening command when the door is closed

will be ineffective when the operator is running into opening direction

will extend the time the door is kept open when the door is in open position already

will give an opening command when the operator is running into closing direction

To avoid the automatic closing occassionally, a standard wall switch may be connected� Whilst

it is switched on, the push button connector will be blocked and the operator cannot close the

door unless the wall switch is set to off position� It may be connected parallel together with a

wall push button�

Connector for the impulse wires of a photo cell or a hatch door contact� The 8�2kOhm resistor

is used to survey the wire� It must be removed from C+D and must be connected to the safety

device as shown below�

If both, a photo cell and a hatch door contact, must be used, then both items must be connected

in one line�

Photo Cell:

LERN/

LEARN

24 V

24V

24V

24 V

D

C

Hatch Door Contact:

Standard function Openings: If the device detects an obstacle within approx� 2 seconds after running from closed

position, then the operator will stop (e�g� hatch door is open)� After these 2 seconds the connector is not being checked anymore for the rest of the opening run�

Closings: The connector will be checked during the whole closing proceedure� Once an obstacle

is detected, the operator will reverse to fully open�

Function when using

the automatic closing

feature

24V AC Output (200mAmp max.)

24V

Openings: pls� refer above to „Standard function“

Closings: The connector will be checked during the whole closing proceedure� Once an obstacle

is detected, the operator will reverse to fully open� The adjusted time for automatic closing will

start running� If the obstacle will be removed after the automatic closing time has elapsed, then

the closing procedure will start immediately�

24V a/c (max� 200mAmp) power supply for external components (for example photo cells or

remote receivers)

8,2 kW

8,2 kW

C

D

N.C.

Installation Instructions TM50/TM80 - MO911/1V0

Page 11

Page 12

Printed Circuit Board: Adjustments and Connectors

Standard Programming

Programming the Forces and Running Distance

Choosing the type of door

The standard pre-setting is „Sectional Door“; if this shall be used, then proceede with step 2�

For other types of doors the DIP-switches 1 and 2 must be adjusted accordingly�

Sectional Door

1

Tilting Door

Short Running Door

Free Programming

When the DIP-switch settings are changed, the red LED starts blinking in intervalls; proceede

as described below�

Keep the red LEARN-button pressed for approx� 3 seconds�

Release the button once the red LED and the operators‘ lighting start blinking�

2

Press the LEARN-button once again shortly�

3

The operator now starts with the learning cycles (force measurement and running distance):

- it hits the OPENING limit block

- it closes slowly until it reaches CLOSED-position

- it opens fast until it reaches OPEN-position

4

- it closes fast until it reaches CLOSED-position

The operators‘ light keeps blinking for a little while after the operator stops running� Once

the operators‘ light stops blinking the programming has been successful�

Pls� refer to chapter „Free

Programming“, Page 13�

Programming Remote Components

Keep the red LEARN-button pressed for approx� 3 seconds�

Release the button once the red LED and the operators‘ lighting start blinking�

1

Press the button on the remote component which is intended for use with the operator for approx� 1 second� The operators‘ light stops blinking and the component was programmed successfully�

2

Steps 1 and 2 must be repeated for each remote component�

For more information on remote components pls� refer to page 16�

Page 12

Installation Instructions TM50/TM80 - MO911/1V0

Page 13

Printed Circuit Board: Adjustments and Connectors

!

Free Programming

ATTENTION: Changing the running-speeds might result in non-conformant force values dependant on the door

type and the doors‘ weight. To ensure the installation is within legal regulations a force testing as to directive

EN13241-1 must be made.

Free Programming

1

Setting the speeds

Press the LEARN-button followed by the TEST-button and keep

both pressed for approx� 3 seconds� Release the buttons once

the red LED starts blinking�

2

The red LED will blink for up to 8 times followed by a break�

The mode for programming the speeds is active�

Setting the closing speed

The number of blinks of the red LED indicates the entire speed

setting:

8 blinks = maximum speed

1x blink = minimum speed

3

By means of the black TEST-button the speed can be reduced;

each press reduces the speed by one step� Wait for the break

after the blinks and then start counting to evaluate the entire

speed setting�

By means of the red LEARN-button the speed can be increased�

Opening and closing speeds can be set manually when running the free programming

mode� The length of the soft-stop in closing direction may also be set manually� When

running the free programming for the first time all speeds are set to maximum�

After changing the DIP-switch settings the red LED will start blinking in intervalls (2 blinks

- break - 2 blinks) - proceede with step 2�

Conrm the selected speed

Press the LEARN-button followed by the TEST-button; keep

both pressed for approx� 1 second and release them�

You are automatically in the mode for setting the opening

4

speed�

The program is now in the mode to set the opening speed�

Setting the opening speed

After completing step 4 the red LED is blinking up to 8 times followed by break� Setting the opening speed is made the

same way as described in step 3 and 4�

5

After confirming the selected opening speed the LED and the operators‘ lighting will be blinking regularily, the speeds have

been set successfully�

Starting the learning cycles

Shortly press the LEARN-button� The operator will first run in

opening direction and hit the upper limit block� If you wish

to keep the standard soft-stop in closing direction, no further

action is required� Wait until the operator has completed the

6

learning cycles (the door will then remain in closed position and

the operators‘ lighting will stop blinking)� The programming

then is completed�

Changing the length of Soft Stop

Once the learning cycles have started and the upper limit block was hit, the operator will run in closing direction� During

this first run in closing direction the soft stop may be altered: press the red LEARN-button and keep it pressed� The operator

7

will increase speed� Release the LEARN-button where you want the soft stop to start in later operation� The speed will be

reduced and the new soft stop setting will be safed� Wait until the operator has completed the learning cycles, then the

programming is completed�

Installation Instructions TM50/TM80 - MO911/1V0

Page 13

Page 14

Programming

!

Automatic Closing

WHEN USING THE AUTOMATIC CLOSING FEATURE A PHOTO-CELL MUST BE CONNECTED. A PHOTO-CELL IS A

NON-CONTACT SAFETY DEVICE AND WILL AVOID IN MOST CASES THAT USERS, CARS OR OTHER OBSTACLES

WILL BE HIT BY THE CLOSING GARAGE DOOR!

The closing procedure will be started automatically after the pre-set time; the door might be unattended at that time� Without a photo-cell the operator will only reverse when hitting an obstacle� Especially moving cars may cause severe damages

on both, car and garage door!

Setting the time

1

Automatic closing is disabled by factory presetting� Setting the time after which the automatic closing shall start enables the

feature� DIP-switches 5+6 must be used for the time setting:

disabled

After changing the DIP-switch settings the red LED will start blinking in intervalls� Shortly press the red LEARN-button to

confirm the new settings; the LED stops blinking and the automatic closing is now active�

Pre-Warning by internal lighting

2

When automatic closing is active the operator will allways pre-warn the users by a blinking internal lighting� The operator

will start closing the door after 6 seconds of pre-warning� By means of DIP-switch no� 4 the pre-warning can additionally be

enabled before openings:

Pre-warning before closings

External warning lights may connected together with the integrated operators lighting using the connectors 5+6 (230V,

160 Watts max�)� The operators housing must be removed in order to access the connectors� Cabling and connections of

230V components may only be done my authorised professionals.

Connecting a Photo-Cell

3

As a non-contact safety device a photo-cell must be connect

when using the automatic closing feature�

When the door is open and an obstacle is detected by the

photo-cell then the operator will not start the automatic

closing procedure�

When an obstacle is detected during the closing procedure

then the operator will reverse to fully open and it will restart

the count-down for automatic closing� It will then start the

closing procedure again�

after 30 seconds after 90 seconds after 120 seconds

Pre-warning before openings and closings

24 V

24V

24V

24 V

4

5

Page 14

D

C

Performance of Control Devices

When the automatic closing is active all incoming commands during the opening cycle will be ignored - the operator will

keep running until to fully open position�

Interrupting the opening procedure will only be possible by:

- Force detection (e�g� obstacle)

- Detection by Photo-Cell/Hatch Door connector for approx� 2 seconds after starting the opening procedure

When the door is in fully open position incoming commands will restart the count-down for the automatic closing, e�g� the

time will be extended�

Avoiding automatic closing temporarily

If the user would occassionally like to prevent the door from automatically closing, then an ordinary wall switch can be

connected to the push-button connectors A+B� The operator will remain blocked as long as the wall switch is switched on;

when switching it off the operator will close the door automatically again� A wall switch may be connected alongside a wall

push-button�

Installation Instructions TM50/TM80 - MO911/1V0

8,2 kW

N.C.

Page 15

Programming

!

i

Automatic Closing

Further Safety Advice for Automatic Closing

Once the user gets into the car, he might not recognize the operators‘ integrated blinking light before the automatic closing

starts� This may be down to light conditions or the cars‘ roof� Therefore it is strongly recommended to install an external

warning-light which is visible from inside the car�

This is similar for users approaching the garage; dependant on light conditions the blinking integrated lighting might not be

recognized in time� Therefore a further warning-light should be installed outside the garage in order to maximize the safety

in use�

Adjusting the Lighting Duration

The integrated lighting will be switched on with every incoming command� The adjusted time will run from the moment the

command was received�

Factory pre-set the light will stay on for 3 minutes� This time may be changed in steps of 10 seconds up to a total of

10 minutes�

To change the time proceede as follows:

Keep the red LEARN-button pressed for 6 seconds�

Release the button once the green LED comes on�

1

Press the red LEARN-button once again shortly�

The green LED now starts blinking: each blink stands for 10

seconds of lighting duration�

6 blinks = 1 minute

2

12 blinks = 2 minutes

18 blinks = 3 minutes

24 blinks = 4 minutes

30 blinks = 5 minutes

����

100 blinks = 10 minutes

Press the red LEARN-button shortly once the require time is reached� The green LED stops blinking and the new

3

duration for the integrated lighting has been stored�

Installation Instructions TM50/TM80 - MO911/1V0

Page 15

Page 16

Remote Control

i

Registering and deleting Remote Devices

In order to use a remote device it must first be registered with the operator� A total of 10 remote devices may be registered

with one operator, the registration must be made seperately for each device�

If the total of 10 devices is exceeded, the last registered device will be overwritten by the new one�

It is not possible to register more than one button of the same hand transmitter with the operator�

Starting the Registry

1

Keep the red LEARN-button pressed for 3 seconds� Release it once the red LED and the operators‘ lighting start blinking�

The operator now is in programming mode and awaits the signal from a remote device�

Registering a Device

2

Press the button that shall be used for controlling the operator for approx� 1 sec�

The red LED and the operators‘ lighting stop blinking - the device was programmed successfully� Pressing the devices‘ button again will run the operator�

Repeat steps 1 and 2 for any further device�

HomeLink™

Integrated car remotes usually use the HomeLink™ system by Johnson Controls� Systems from version 6 or higher are compatible with the operator�

First the hand transmitter must be copied into the HomeLink™ module (closer information on your specific system can be

found on the internet: www�eurohomelink�com)�

The programmed HomeLink™ button will turn to a new Seip-compatible remote device� It therefore must be registered

with the operator just like any other remote device� Proceede as described in steps 1 + 2�

Erasing Remote Devices

The receivers‘ memory can be erased completely; it is not possible to delete single devices� To erase the receivers‘ memory

keep the red LEARN-button pressed for 10 seconds:

After 3 seconds the red LED and the operators‘ lighting will start to blink; after 10 seconds the red LED will come on permanently, release the LEARN-button then� The memory now is empty�

Page 16

Installation Instructions TM50/TM80 - MO911/1V0

Page 17

!

Useable Batteries

i

Eine Batterie des Typs A23, 23A, 23L, EL12, VR 22 oder MN 21; Versorgungsspannung: 12V

Verbrauchte Batterien müssen nach den nationalen Bestimmungen entsorgt werden!

Changing the transmitters‘ battery

Open the transmitter Take off lid Change battery

Changing the wall push-buttons‘ battery

Remote Control

General Remarks

Open the wall push-button Change battery

12V

A23S

Range

The TM operator is equipped with a high quality remote control set as a standard!

However, the remote control is the part of the operator which might be inuenced by circumstances in the surroundings

of the garage� With our standard remote control you might reach a range of more than 100 meters�

The range is inuenced by:

- old batteries: if you should experience a problem with the range, please change the batteries rst� The lower the batteries run the lower the range will be�

- Building materials of the garage: In a garage made of concrete and steel you might reach a lower range than in an ordinary garage build of stone� The more steel was used for the walls the shorter the range of your remote-control�

Remote-control activity in the area: Radio and television transmitters close to your garage might reduce the range�

Older baby-phones and other household remote equipment: Some equipment like remote head-phones and baby-phone

might prodecure strong disturbant signals which could reduce the range of other remote devices�

It is extreemely unlikely that the range will drop to an unacceptable distance� If, however, problems should occure we will

like to be helpful�

Synchronisation of the Rolling Code

With each command given by a remote device a new code for the next command is created; this new code will be agreed

with the receiver� If a device is subsequently used for approx� 30 times out of reach of the receiver, then it will not be

accepted by anymore - the latest code is unknown to the receiver� The device must rst be registered with the operator

again in order to use it (refer to page 16)�

Installation Instructions TM50/TM80 - MO911/1V0

Page 17

Page 18

Technical Information

Technical Data

TM 50 TM 80

Nominal Pulling Force 50 kg 80 kg

Peak Pulling Force 60 kg 90 kg

Force-Setting for Operation automatic

Motor 24V DC, low-noise

Max� Running Speed 18 cm/sec� 14 cm/sec�

Speed in Soft Mode 8 cm/sec� 8 cm/sec�

Time for 2,10m opening 11,5 sec� 16 sec�

Lighting 230V AC, max� 40W

Lighting Durance (adjustable) 10 sec� to 10 minutes

Duty Cycle 50%

Stand By Power Consumption 2�0 watts

Power Supply 190-250V AC

Transformer 230V AC, 24V AC

Pre-Warning Light adjustable

Automatic closing adjustable

Wiring Diagram

TM 50 TM 80

Net Running Length 2,500 mm

Max� Running Length extended 4,000 mm

Overall Length 3,150 mm

Height Motor Head 80 mm

Length Motor Head 360 mm

Width Motor Head 180 mm

Minimum Space above the door 35 mm

Weight including packaging 18 kg

Noise Emissions ≤ 60 dB(A)

Programmable Remotes 10 max�

Max� number of cars/garage 1 3

Subject to technical alterations!

Maintenance: The operator is maintenance free! Do not

grease or oil the chain!

Internal Wiring

1 Blue, mains supply, 230V

2 Brown, mains supply, 230V

3 Black, transformer, 230V

4 Black, transformer, 230V

5 Brown, Lighting, 230V

6 Blue, Lighting, 230V

External connections

A + B Floating connector for push-button, key-switch

and the impulse cables of an external receiver

C + D Floating connector with a 8,2kOhm resistor for

impulse cables from a photo-cell receiver

24V 24V AC for a photo cell transmitter when a

self test before every movement of the door is

required

Devices for adjustments

Button

„Test/Run“

Button

„Lern/Learn“

Jumper

“FORCE/PRESSURE”

Runs the operator - OPEN-STOP-CLOSE

For automatic force setting and registration

of hand transmitters

Setting of lower or higher force

7 White, transformer, 24V

8 White, transformer, 24V

9 MOTOR Connector for the plug from the motor

PE Earthing from P�C�B� to base plate

Earthing of

the mains

supply

The earthing of the mains supply (green/yellow)

is connected to the base plate with a screw (the

screw is marked with a earthing symbol)

Others

HF-Modul/Receiver

Card

FUSE Fuse T1,6A 250V

Plug for receiver module, 433 MHz

Page 18

Installation Instructions TM50/TM80 - MO911/1V0

Page 19

Error Messages

The operator will show error messages either by a blinking operators‘ lighting or the red LED�

Technical Information

Troubleshooting

Messages by blinking integrated lighting

2 blinks

DIP-switch message: the DIP-switch setting was changed� Either

press LEARN-button to conrm the change or start the learning

cycles (page 12)�

3 blinks

The end position could not be reached, the operator switched

off at time limit� Possible reason: motor damage or other mechanical problem�

5 blinks

Loss off data in the micro processor - try to start the learning

cycles (page 12)� If this does not work the electronics must be

exchanged�

6 blinks

EEPROM error: The electronics must be exchanged

7 blinks

Relais damage - the electronics must be exchanged�

8 blinks

No impulses from the motors‘ hall-sensor� Possible reasons:

damaged hall-sensor, loose contact on the motor plug or damaged motor�

9 blinks

Amplier for motor control is defective, the electronics must be

exchanged�

Additional messages from the LED „Diag“ only

4 blinks

An error occured when testing the photo-cell connector� Either

the 8�2kOhm resistor is defective or the photo-cell/hatch-door

produced an error�

If... then...

The operator does neither react on the transmitter nor on the pushbutton

Power failure? Disconnect and connect the operator� Is the door stuck

because of snow and ice? Check the lines and the connections of the

push-button switch� Is there water in the push-button switch or in the key

operated switch? Disconnect alle external components and try running the

operator via the TEST/RUN button�

The operator reacts on the transmitter but not on the push-button

switch

Check the line of the push-button switch� Does the push-button switch

work, when the remote receiver is disconnected? If so, the remote transmitter or receiver might be defective�

The operator reacts on the push-button but not on the transmitter

Check the battery of the transmitter� Try registering the transmitter with

the operator (page 16)�

The operator neither reacts on the push-button nor on the

transmitter

Disconnect the receiver or remove the transmitter battery� Use your pushbutton switch only� If this solves the problem, your transmitter may be

defective� Disconnect the push-button switch and use your transmitter

only� If this solves the problem, the push-button switch or the line of the

push-button switch may be defective�

The door doesn’t close completely and opens again

Is the door jamming while closing? Unlock the carriage manually (make

the door running well)� Lubricate and oil the pivotal points of the door�

Run through the automatic learning cycle once again (page12)�

The light doesn’t work

Replace the bulb (230 V, max� 40 Watt)

The operator isn’t running smooth

Unlock the carriage of the opener� Move the door manually and make sure

that the door is well balanced (must come to a stop at each position)�

The spring tension is too high or there is even a spring fracture�

The motor is buzzing but the door doesn’t move

The door is jamming�

The operator works, but the door doesn’t move

The carriage is unlocked� If you want to lock it, open the door, but not

completely, and let the opener run� The carriage locks in automatically�

The operator doesn’t work due to a power failure

Unlock the carriage with the help of the emergency release and open

the door manually� (If you have a garage where you can only enter from

outside: Unlock the door with the key and turn the door-handle, then your

opener will be unlocked� If you have a garage where you can also enter

from inside: pull at the Bowden cable hanging from the carriage�)

Installation Instructions TM50/TM80 - MO911/1V0

Page 19

Page 20

Declarations

EC-Declaration of Conformity

Document No� AN-02122011

Dokument Nr. AN-02122011

As to European Directives

Low Voltage Directive 2006/95/EC

Electro Magnetic Compatibility 2004/108/EC

im Sinne der EG-Richtlinien

Niederspannungsrichtlinie 2006/95/EC

Elektromagnetische Verträglichkeit 2004/108/EC

We,We hereby declare, that the following products comply to the

mentioned EC-regulations�

Wir erklären hiermit, daß die nachfolgenden genannten Produkte

den unten angegebenen EG-Richtlinien entsprechen.

Type of Product /

Produktart

Product Name / Modell TM 50 / TM 80

Approved according to 2006/95/EC and 2004/108/EC / Geprüft nach 2006/95/EC

und 2004/108/EC

Referring EC-regulations: / Angewandte harmonisierte Normen:

Electromagnetic

Compatibility /

Elektromagnetische

Verträglichkeit

Low-Voltage

Directive /

Niederspannungsrichtlinie

Safety in Use /

Nutzungssicherheit

Forces

Betriebskräfte

Garage Door Operator / Torantrieb

EN 61000-3-2

Limits for harmonic current emissions /

Grenzwerte für Oberschwingströme

EN 61000-3-3

Limitation of voltage changes, voltage uctuations

and icker in publik low-voltage supply systems /

Grenzwerte für Spannungsschwankungen und Flicker

EN 61000-6-3

Emission standard for residential, commercial and

light-industrial environments /

Störaussendung für Wohnbereich, Geschäfts- und

Gewerbereiche sowie Kleinbetriebe

EN 61000-6-2

Generic standards - Immunity for industrial environments

Fachgrundnorm - Störfestigkeit - Industriebereich

EN 60335-2

Particular requirements for drives for vertically moving

garage doors for residential use /

Anforderungen für Antriebe von Garagentoren mit

Senkrechtbewegung zur Verwendung im Wohnbereich

EN 60335-1

Safety of household and similar electrical appliances /

Sicherheit elektrischer Geräte für den Hausgebrauch

EN 12453

Safety in use of power operated doors, requirements /

Nutzungssicherheit kraftbetätigter Tore, Anforderungen

EN 12445

Safety in use of power operated doors, Test methods /

Nutzungssicherheit kraftbetätigter Tore, Prüfverfahren

EN 13241-1

Applied for testings for Up-and-Over Doors and

Sectionaldoors up to 5m wide and 2,50m high as to

06�02�2012

Prüfungen beantragt für Kipp- und Sektionaltore bis

zu 5m Breite und 2,50m Höhe

Stand 06.02.2012

in accordance with the Radio and Telecommunications Terminal Equipment Act (FTEG) and Directive 1999/5/EC (R&TTE

Directive)

Gemäß dem Gesetz über Funkanlagen und Telekommunikationsendeinrichtungen (FTEG) und der Richtlinie 1999/5/EG (R&TTE)

We,We hereby declare, that the following products comply to the

mentioned EC-regulations�

Wir erklären hiermit, daß die nachfolgenden genannten Produkte

den unten angegebenen EG-Richtlinien entsprechen.

SKR 433-1

Code B43A023004-1

Hand Transmitter as remote control for garage door operators

Handsender als Fernbedienung für Garagentorantriebe

(Short Range Device/Funkgerät geringer Reichweite (SRD))

and / und

SKR1W433

Code B443A623001

Wall Transmitter as remote control for garage door operators

Wandsender als Fernbedienung für Garagentorantriebe

(Short Range Device(Funkgerät geringer Reichweite (SRD))

comply with the essential requirements of §3 and the other relevant provisions of the

FTEG (Article 3 of the R&TTE Directive), when used for its intended purpose�

bei bestimmungsgemäßer Verwendung den grundlegenden Anforderungen des

§3 und den übrigen einschlägigen Bestimmungen des FTEG (Artikel 3 der R&TTE)

entsprechen.

§3(1)1, (Article 3(1)a)) does not refer to this type of product�

§3(1)1, Artikel 3(1)a) bezieht sich nicht auf diesen Produkttyp, es gibt hierzu keine

Norm

Protection requirement concerning electromagnetic compatibility §3(1)(2), (Article

3(1)(b))

Schutzanforderungen in Bezug auf die elektromagnetische Verträglichkeit §3(1)2,

Artikel 3(1)b))

EN 300 220-1 V2.1.1

EN 300 220-2 V2.1.2

EN 301 489-1 V1.6.1

EN 301 489-3 V1.4.1

EN 60950-1:2006

EMV / EMC Directive 2006/95/EC;2004/108/EC; 99/5/EC

Page 20

Myke Seip, Walzbachtal-Jöhlingen, 06�02�2012

Grombacher Straße 83

75045 Walzbachtal-Jöhlingen

Germany

www�seip�com

Installation Instructions TM50/TM80 - MO911/1V0

Loading...

Loading...