Page 1

Installation Instructions

for Automatic Garage Door Operators

Solar FR I

We disclaim all liability under the terms of the warranty for any damage caused by improper installation!

Please read these instructions carefully!

GB

V01-01 SOLDEC16

Approved according to the European Directives 89336 EEC and 73/23 EEC

Page 2

1 BEFORE GETTING STARTED...

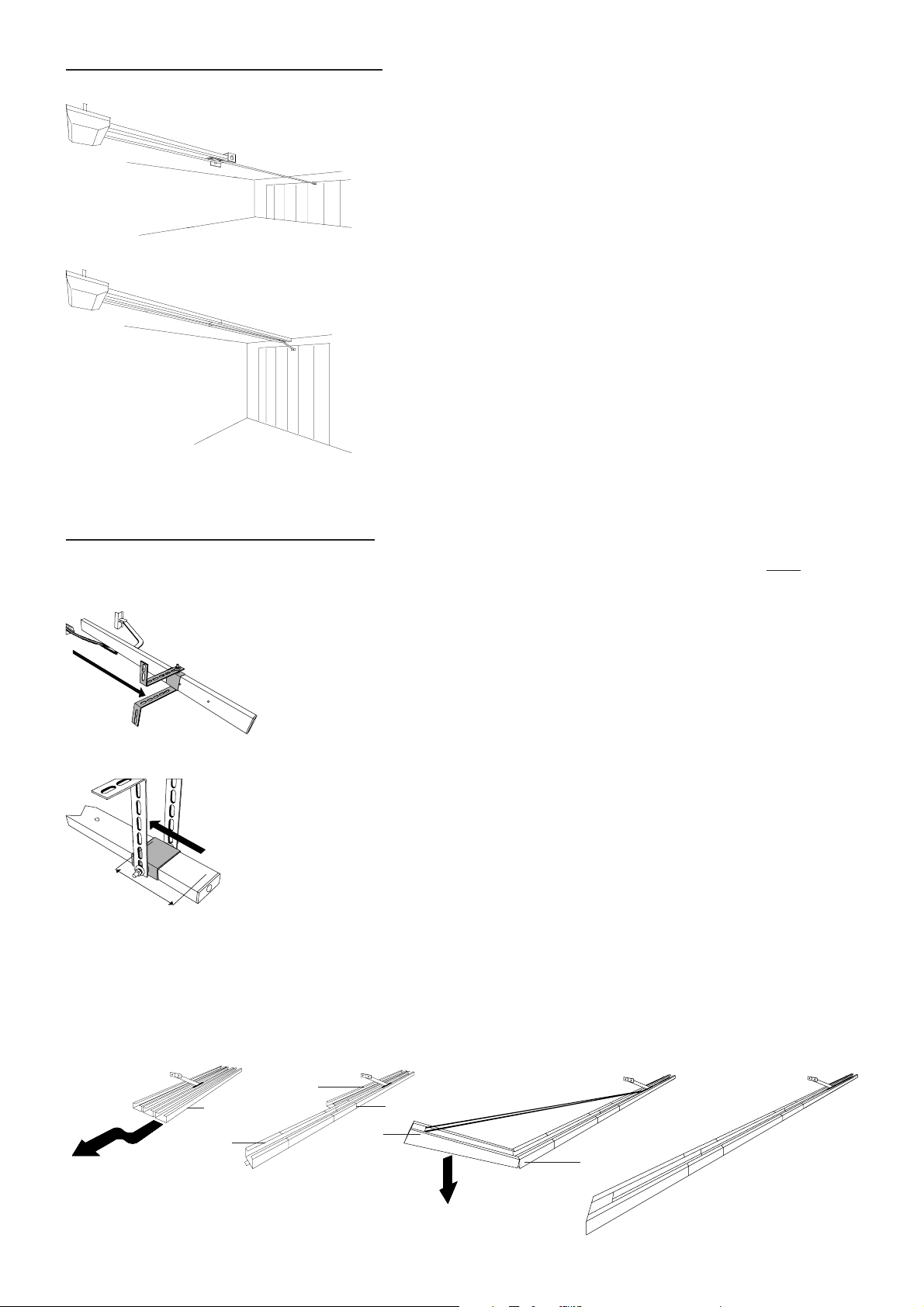

(1)

(2)

(1) If the minimum headroom above the garage door is less than 35 mm (see page 4)

you need a door-arm extension. The operator then must be mounted in the rear of

your garage.

(2) If your garage-door is higher than 2.25m a C-rail extension-piece is required.

Otherwise the garage-door will not open completely.

1. Make sure, that your garage-door runs smoothly. If necessary grease or oil certain

parts.

2. The enclosed fixing-material will be satisfactory for a standard-garage.

3. To explain the Fitting procedure we are using an up-and-over-door in this

handbook. The procedure remains the same for other types of door.

4. Pay attention to page 10 "Safety Instructions“

2 PRE-MOUNTING

Sketches on the left-hand side:

If the operator is to be fixed to the ceiling using the fixing-brackets in front of the

motor-head (looking from inside the garage to the garage door), then the fixing-profile

must be slid over the rail before premounting the whole rail. If the operator is to be

fixed to the ceiling from behind/above the motor-head the fixing-profile can be slid

over after the pre-assembly procedure.

During this procedure be careful not to twist the chain. Therefore do not lift the

parts; slide them along the floor.

1. The operator is laying unpacked in front of you. The motor-head unit is on your

right hand side.

2. Lay part (1) to the front.

3. Fix it through pushing the C-profile coupling piece (2) over it all the way home.

4. Slide C-rail part (3) in front of part (1)

5. Set part (3) in the C-rail coupling piece (4) at an angle, inserting it from above as

shown.

6. Press down part (3) to tension the chain.

7. Turn the operator over and screw in the milled nuts into the C-rail coupling pieces.

Your operator now is assembled for installation.

The chain has been pretensioned in the factory; do not change the chain tension!

ATTENTION:

The limit-switches of your operator have been put to a factory position. Do not change

this limit-switch adjustment until the operator is fitted to the ceiling and the garagedoor!

Otherwise the carriage could crash into the motor-head unit when the operator is

running without being fitted!

This would cause great damage to your operator!

(1)

(1)

(3)

(2)

(3)

(4)

2

Page 3

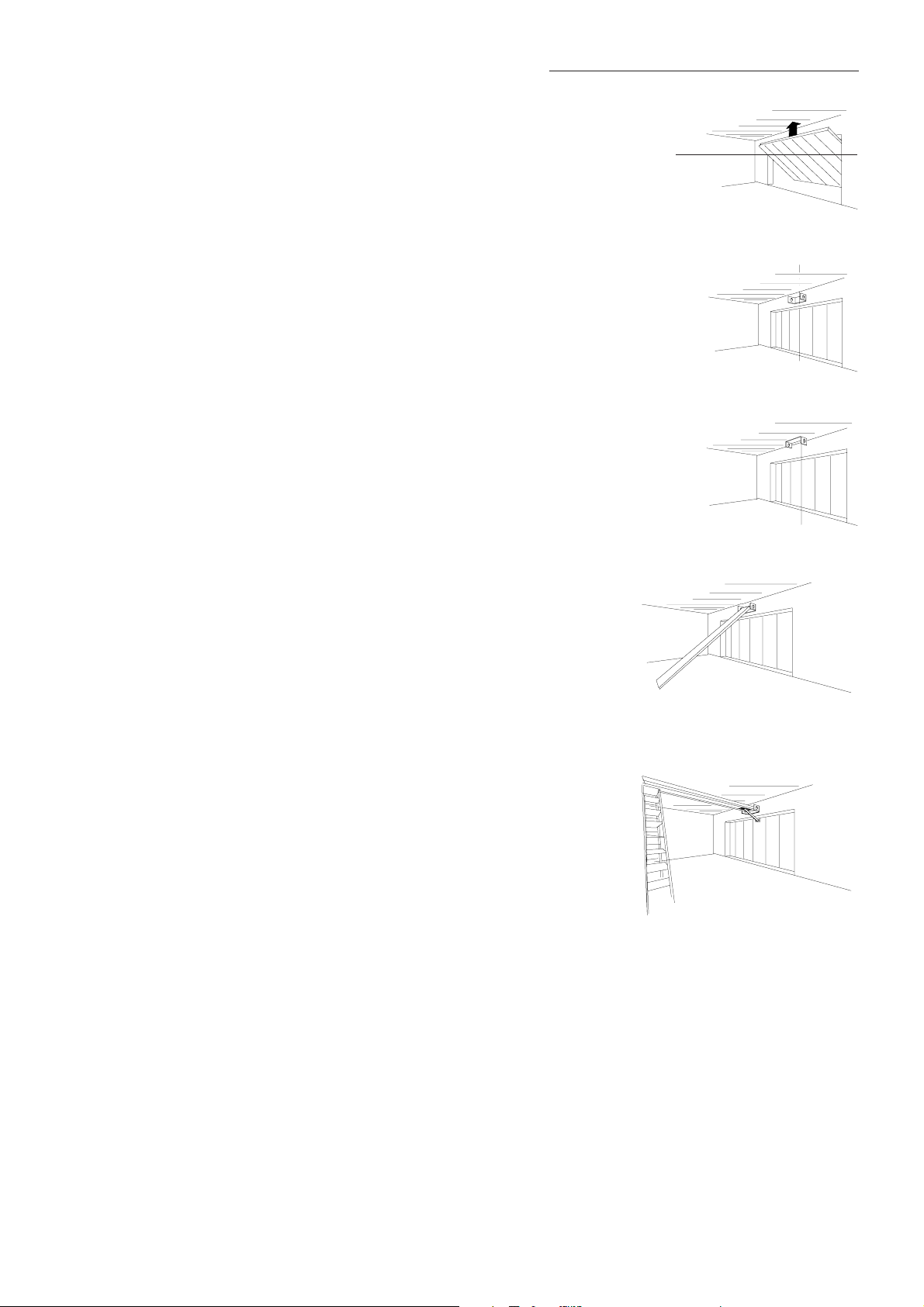

Before fitting the operator to the ceiling we recommend you detach the motorhead unit; mounting the C-rail will then be easier. You will find the instructions on

how to detach the motor-head on page 4.

Measure the distance between the ceiling and the highest point reached by the

garage door (1).

The minimum headroom necessary for mounting the operator is 35 mm. If there is

less headroom please pay attention to page 2.

The front fixing-angle can be mounted either on the lintel or on the ceiling.

1. Measure the middle of your garage-door and make a mark on the lintel and

the top of your door.

2. Fix the front fixing-angle in the middle- either on the lintel or on the ceiling.

(We recommend the lintel if possible).

3. Attach the C-rail to the front fixing-angle (4). Put a piece of cardboard under

the motor-head unit to avoid damage.

4. To fix the motor-head to the ceiling we recommend you use a ladder (5). When

the operator is laying on the ladder you can open the garage-door. Adjust the Crail according to the mark you made in the middle of the garage-door.

Fix the operator to the ceiling when you have made sure the C-rail is running

straight to the front.

5. Now fix the door-arm to the garage-door. Take care that the angle between

the operator and the door-arm does not exceed a max. of 45° (it may be less).

6. Before running the operator dismount the doors locking-bolts! Otherwise

the operator cannot open the door and this will lead to damage to your

operator and the garage door.

If you would like additional security you can have door bolts fitted; please ask

your dealer about our locking set, which is available as an optional extra.

MOUNTING 3

(1)

(2)

(3)

(4)

(5)

3

Page 4

4 CONNECTING THE BATTERY

To prevent the battery from discharging while in stock the Solar FRI is delivered with

one disconnected battery cable. To use the operator this cable must first be plugged

onto the open battery connector (please refer to the sketches aside) - or else the

operator will not work.

ATTENTION! The batteries are delivered fully charged - the capacity will allow up to 80

openings/closings. All the necessary adjustments during the installation can therefore

be made easily (generally 5 to 20 openings/closings). Nevertheless it is recommended

to avoid any unnecessary operation. If, however, the low-voltage indicator becomes

active (e.g. the battery-capacity is about to fall below the necessary minimum voltage)

then the operator automatically switches off until the batteries have been completely

recharged (by the solar panel)!

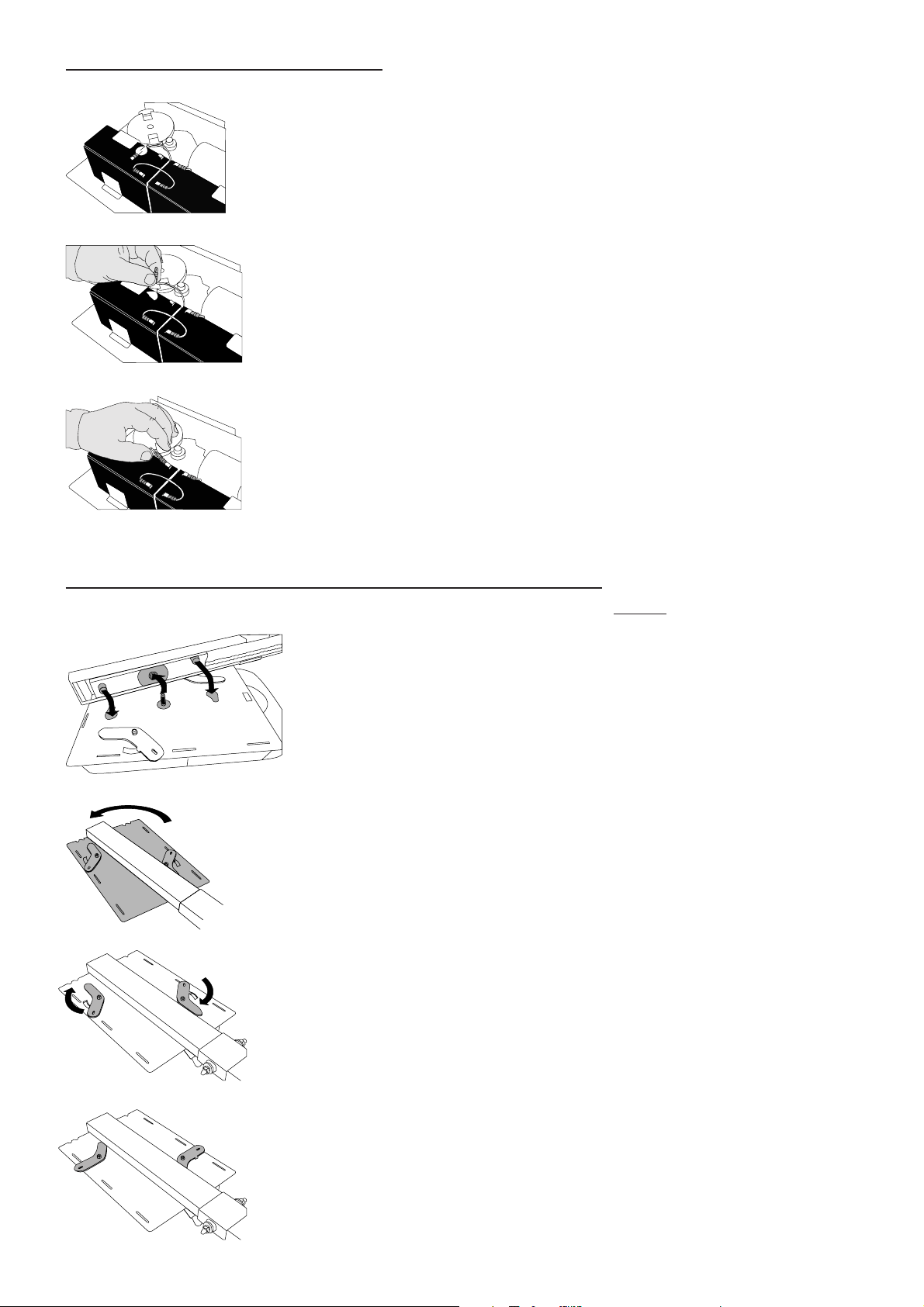

5 ATTACHING AND DETACHING THE MOTOR HEAD

The sketches on the left show the attachment-procedure.

For the easier mounting of the C-rail (please refer to page 3) and to exchange the

batteries we recommend you detach the motor head from the C-rail.

The motor head is held in position by two fixing brackets. The brackets are secured by

one fixing-screw each. Loosening the fixing-screws enables the brackets to be turned procede as follows (the operator is lying in front of you, the housing is facing towards

you):

1. Slightly lift the fixing-brackets (away from the base-plate) - turn them to release the

C-rail.

2. Turn the motor-head counter-clockwise as far as possible

3. Pull the motor-head upwards to disconnect it from the C-rail.

To attach the motor-head to the C-rail please follow the procedure as shown in the

sketches on the left. Tighten the screws in the fixing-brackets to stop the brackets

turning by accident.

ATTENTION! The fixing-brackets are connected to electronic security-switches. If the

motor-head is not attached and fixed correctly to the C-rail the electric circuit is broken

- the operator will not work!

If, however, the motor-head starts turning after several operations because of

incorrect fixing then the electric circuit will be broken as well and the operator will not

work until the problem has been fixed.

4

Page 5

Your garage door opener automatically stops when one of the red limit-switch

actuators trips a limit-switch (in either CLOSING or OPENING direction).

Adjust the limit-switches by hand.

OPENING direction

Please set the limit-switch actuator for the OPENING direction so that the door

comes to a halt about 30 mm (1.2") before its final resting position.

CLOSING direction

Please set the limit-switch actuator for the CLOSING direction so that the door

lightly touches the door frame when closed.

ATTENTION:

Fit the operator completetly to the garage-door before changing the limit-switch

position.

Even if the limit-switches are then adjusted wrongly, the operator will be stopped

by the garage doors stop-points.

Changing the limit-switch position without having fitted the operator to the

garage-door can lead to the destruction of the operator, when the carriage runs

into the motor-head unit!

Adjusting the OPENING limit-switch incorrectly (e.g. the limit-switch OPEN never

gets activated) will lead to the operator switching off because of increasing

pressure. This will sooner or later lead to damage of the gear - the life-cycle of

the operator decreases dramatically!

Adjusting the CLOSING limit-switch wrongly will lead to the door opening because

of the increasing pressure.

If the door fits too tightly in the frame when closed, the emergency-release will

be difficult to use.

LIMIT SWITCH SETTING 6

In case of a power-failure or an error with the operator you can open your garage

door manually. Therefore the operator must be disconnected from the garage

door.

If your garage has a separate entrance:

You may leave the Bowden-cable as it is. In the above mentioned cases you can

pull the cable to disconnect the operator from the garage door. To connect it

again, just switch on the operator.

If your garage door is the only entrance to your garage:

You have to connect the emergency release to your door-handle. Otherwise you

will not be able to open your door in one of the above mentioned cases.

Follow these steps:

1. Figure out in which direction the door-handle moves when opening the door.

2. Drill a hole in that side of the door-handle that turns downwards.

3. Thread the cable through the hole and fix it with the enclosed metal-clamps.

Be carefull not to put a high tension on the Bowden-cable - the operator then

might release from the garage-door during a normal opening-cycle.

4. Control the function of the emergency release together with a second person.

Stay inside the garage and close the door with the operator. Let the second

person open the door manually with the door-keys. If this works, the emergencyrelease is mounted properly.

Do not leave the garage and close the garage-door with the operator before

you have tested the emergency-release!

EMERGENCY RELEASE 7

5

Page 6

8 THE SOLAR PANEL

Together with the Solar FR I you receive a solar panel and a fixing-bracket (in 2 parts).

The panel transforms solar energy into electricity which is used to recharge the

batteries. With a supply of 7 Watts the panel is sufficient for the average day light all

year for most European countries.

If, however, the battery should run low (due to exceptionally heavy use) the lowvoltage protector becomes active. This will be indicated by a beeping tone - once this

tone has started you may use the operator for another two operations. Then the

operator will automatically be switched off until the batteries are fully recharged (the

recharging is done automatically by the operator - the user does not have to do

anything). During this recharging period the operator cannot be used. The recharging

is completed when the operator reacts again to signals from the hand-transmitter or

push-button.

Screws holding the panel

in the correct distance

from the ground

rubber bumpers

South

Fix the solar-panel to the bracket using the rubber-bumpers as shown in the sketches

on the left. The cable-connector must be positioned upwards. Two screws help keep

the correct distance from the ground.

.

To make the solar-panel work efficiently it should be adjusted to south as precisely as

possible - the more exact it faces south the better the output. The correct angle of

60° is held by the bracket.

Run the cable (total length: 7m) into the garage from the outer wall of the garage (do

not run it directly through the ceiling!). Make sure the cable rises from the outside to

the inside of the garage to keep water from flowing inside.

brown cabel = +

Connectors for the solar-panel

blue cabel = -

The cable should rise slightly from

the outside to the inside of the

garage

On the P.C.B. you will find two connectors to connect the solar-panel - they are

marked „Solar“.

IMPORTANT:

Connect the brown cable to the connector marked „

Connect the blue cable to the connector marked „

ATTENTION: if the cables are interchanged the batteries will not be recharged by the

solar-panel!

+“

-“

6

Page 7

The force needs to be adjusted separately for OPENING and CLOSING direction.

To get the forces right you might need a couple of tries. Please take your time for

these adjustments. You should not use more force than necessary to operate your

door (danger of injuries)!

Therefore please reduce both forces first. The operator will then stop during the

operation when the door gets too heavy. In this case you have to increase the

force one tiny step and run the operator again. Repeat this procedure until the

operator can completely open and close the door without stopping in between.

The force potentiometers:

For CLOSING direction: ZU

For OPENING direction: AUF

(Right turn: increasing force, left turn: reducing force)

External Wiring:

(Connectors that are needed or may be used during the installation)

Solar-panel

brown (+) on connector "Solar +“

blue (-) on connector "Solar -“

FORCE ADJUSTMENT 9

OPENING Force CLOSING Force

CONNECTORS ON THE P.C.B. 10

Push-Button/Key-Switch

Connector "Taster“

Connection with two cables, only resistance-free components, no electricity may

be brought onto the board.

When the operator is in standby mode (e.g. the operators lighting is off) it must

be switched on with the first impulse (e.g. press of the push-button, handtransmitter etc.) - on the second impulse the operator will start working.

Photo-Cell

Connector "SI-2“

If no photo-cell is connected the bridge between the connectors must remain without the bridge the operator does not work.

When connecting a photo-cell the bridge must be removed and the two impulsewires coming from the photo-cell must be connected.

24V/DC power-supply for external components

Connectors "SI-1“

This connector supplies voltage as long as the operator is switched active (e.g.

the operators’ lighting is on) - it can therefore not be used for external remotereceivers!

Internal Wiring:

(Only needed to replace internal components, for example the batteries)

Batteries

black (-) on connector "Bat. 24V -“

red (+) on connector "Bat. 24V +“

Lighting

Two blue cables on connector "Licht“

Motor

red on connector "Motor“, outer connector

green on connector "Motor“, inner connector

Do not interchange the red and green cable - or the motor works contrary to the

electronics software - the security features will then not work correctly (e.g. the

automatic reversion when hitting an obstacle in CLOSING direction)

Fixing-Brackets for motor-head unit

Two black cables coming from the security-switch to connector "SI-1“

The operator will not work unless:

1. the security-switch is not connected and

2. the security-switch is not pressed by the fixing-bracket

Battery cable, black (-)

Battery cable, red (+)

Solar-Panel, brown (+)

Solar-Panel, blue (-)

Lighting

2x blue

Push-Button

Motor, green

Motor, red

24V DC powersupply for external

components

Security switch

motor-head

Photo-Cell

7

Page 8

11 REMOTE-CONTROL

A

B

A - Receiver-module (HF-module)

Determines the frequency used (e.g. 40 or 433 Mhz)

B - Decoder board

Determines the coding-system: 12-bit or rolling code

(Description on the reverse side board:

Lern 12-bit = 12-bit decoder

Lern Rol. = rolling code)

C - MIDI transmitter, rolling-code

D - MIDI transmitter, 12-bit

Difference: 12-bit and rolling code

A 12-bit remote-control can be identified by the 10 or 12 switches on the inside of a

hand-transmitter (C). With those switches you can set any code you like - they provide

a maximum of 4096 different codes.

On a hand-transmitter with rolling-code no adjustments can be done. Transmitter and

receiver will change the code every time the hand-transmitter’s button is pressed. The

system will always pick one code by chance out of a pool with billions of different

codes.

Standard equipment is a remote-control set with rolling-code on 433MHz - dependant

on the distribution line another remote-control might have been delivered to you.

Please ask your dealer.

Adjusting the antenna (not for 433 MHz)

Fully unroll the antenna and try putting the antenna in different directions (to the

back, to the front, to the side of the garage) and choose the position where the result

is the best. Avoid putting the antenna in contact with metal or electrical wires

(otherwise the range might be reduced dramatically).

433 MHZ RECEIVER-MODULE

Using a 433 MHz receiver-module the antenna must be shortend to a length of

approx. 35cm. Otherwise only a short range can be reached. The antenna can be left

inside the motor-head unit.

Our standard receivers are self-learning: the code is simply transmitted from the

transmitter to the receiver. The receiver will save the code in its memory.

Clearing the receiver’s memory

ATTENTION: for testing purposes there is a factory-code saved in the receiver’s

memory; this code must be cleared out of the memory first!

Press the button on the decoder-board for approx. 10 sec.. You can release the button

when the LED-light goes on; the memory then is cleared.

Coding the hand transmitter (only applies to 12-bit remote-controls)

If your operator has been delivered with a 12-bit remote-control you must set up a

code on your hand transmitter first. Open your transmitter (as shown on drawing C)

and set the switches to any code you like (avoid putting all the switches to ON or

OFF). After you set up the transmitter’s code you can start sending the code to the

receiver.

Sending the code from the transmitter to the receiver

C

D

1. Briefly press the button on the Decoder-board (B). The LED-lamp starts flashing.

2. Press the hand-transmitter button you want to use with the receiver. (Do not go too

close to the receiver). The LED-lamp starts flickering when the signal receiver

recognizes the incoming signal. The LED will go off after a short while and the

operator will start running; your hand-transmitter has then been programmed

successfully into the receiver. You can now activate your operator with the handtransmitter.

Maximum quantity of hand-transmitters

The 12-bit receiver allows a maximum of 5 different codes. E.g. you can use as many

transmitters with the same code as you like, but only 5 with different codes.

The receiver with rolling code allows a maximum of 16 transmitters to be used.

Using the hand-transmitter

The solar operator will cut the power-supply for the main-electronics in stand-by mode;

only the receiver is supplied with voltage. Two impulses are needed to operate the

door: the first impulse will switch on the main electronics, the second impulse will

make the operator run.

Therefore you must either

1.) press the hand-transmitters’ button twice quickly or

2.) press the hand-transmitters’ button for approx. 3 seconds

to open the garage door.

As long as the operators’ lighting stays on only one press of the hand-transmitter’s

button is required to set the operator in motion.

This procedure is the same for push-buttons, key-switches and other external controldevices - the first impulse switches on the operator, the second sets the operator in

motion.

8

Page 9

TECHNICAL DATA 12

Technical Data

Motor 24V DC, low-noise

Gear self-locking, 70kg

Running Speed 13 c m/sec.

Max. OPENING-CLOSING force 75 kg

Power Supply Solar/Battery Lead-Gelly, 24V

Lighting 24V, 15W, 1.5 min./Cycle

Lighting Duration 90 sec.

Energy-Management permanent supply

Use 5 OPENING/CLOSING Cycles/Day

Solar-Panel 7 Watt/polycrystallin

Battery 7.2Ah (20 h), 2 units à 12V

Power Consumption in Stand-By 2.6 mAmp.

Batteries’ Spare Energy 15 Days

Minimum Sunlight 0.87 kWh/m2 x day

Panel Position 60° (south +/-10°)

Low Voltage Protector yes, with sonic indication

Overload Protector yes, constructionwise

Nett running Length 2,640 mm

Overall Length 3,215 mm

Motor-Head Height 170 mm

Motor-Head Length 370 mm

Motor-Head Width 260 mm

Min. Headroom above Door 35 mm

Weight 25 kg

Solar FR I

Solar-Panel

Positioned in a southerly direction with an angle of 60° (held by the supplied

metal-bracket) a daily sunlight of 600 Wh/m2 is required to recharge the battery.

Information: the average sunlight in December in Brimingham is approx. 800 Wh/

m2 , 33% higher than required.

Batteries

The expected life-time of the batteries is approx. 7 years.

Low Voltage Protection

Should the battery capacity show a critically low voltage then an automatic low

voltage protector becomes active.

If, however, the battery should run low (due to exceptionally heavy use) the lowvoltage protector becomes active. This will be indicated by a beeping tone - once

this tone has started you may use the operator for another two operations. Then

the operator will automatically be switched off until the batteries are fully

recharged (the recharging is done automatically by the operator - the user does

not have to do anything). During this recharging period the operator cannot be

used. The recharging is completed when the operator reacts again to signals from

the hand-transmitter or push-button.

9

Page 10

13 SAFETY INSTRUCTIONS

!!

!

!!

Important Safety Instructions for Installation

WARNING: INCORRECT INSTALLATION CAN LEAD TO SEVERE INJURY

Follow all Installation Instructions.

- Before installing the drive, remove unnecessary ropes from the existing installation

- If possible, install the drive at a height of at least 2.10 m and the manual release at

a height less than 1.80 m

- Locate the control actuator within sight of the door but away from moving parts and

at a minimum height of 1.50 m

- Fix the label warning against entrapment next to the control actuator

- The label fixed to the manual release may not be removed

- After installation, ensure that the mechanism is properly adjusted and that the drive

reverses when the door contacts a 40 mm high object placed on the floor.

Important Safety Instructions

WARNING - IT IS VITAL FOR THE SAFETY OF PERSONS TO FOLLOW ALL

INSTRUCTIONS

Keep these Instructions

- Do not allow children to play with door controls. Keep remote controls away from

children.

- Watch the moving door and keep people away until the door is completely closed.

- Use caution when operating the manual release with the door open since it may fall

rapidly due to weak or broken springs. Details on how to use the manual release will

be given.

- Frequently examine the installation for signs of wear, damage or improper balance.

Do not use before repair or adjustment.

- Each month check that the drive reverses when the door contacts a 40 mm high

object placed on the floor. Recheck after adjustement.

To change the bulb unplug the power cable and then take off the small housing on

the front of the operator.

The operators’ case may only be taken off by a professional installer. If your

operator does not work refer to a professional installer. Repairs and replacing

parts may only be done by a professional installer.

www.seip.com

Page 11

EC Declaration of Confirmity

in accordance with the Radio and

Telecommunications Terminal Equipment Act

(FTEG) and Directive 1999/5/EC (R&TTE

Directive)

EG-Konformitätserklärung

gemäß dem Gesetz über Funkanlagen und

Telekommunikationsendeinrichtungen (FTEG)

und der Richtlinie 1999/5/EG (R&TTE)

We,

Wir,

Grombacher Straße 83, 75045 Walzbachtal-Jöhlingen, Deutschland

Seip Antriebstechnik

declare that the product

erklären, daß das Produkt

433 RC AM

Hand-Transmitter as remote-control for garage door operators

Handsender als Fernbedienung für Garagentorantriebe

(Funkgerät geringer Reichweite (SRD))

complies with the essential requirements of §3 and the other relevant provisions of the FTEG (Article 3 of the R&TTE Directive), when used for its intended

bei bestimmungsgemäßer Verwendung den grundlegenden Anforderungen des §3 und den übrigen einschlägigen

Bestimmungen des FTEG (Artikel 3 der R&TTE) entspricht.

§3(1)1, (Article 3(1)a)) does not refer to this type of product.

§3(1)1, Artikel 3(1)a) bezieht sich nicht auf diesen Produkttyp, es gibt hierzu keine Norm

(Short Range Device)

purpose.

Protection requirement concerning electromagnetic compatibility §3(1)(2), (Article 3(1)(b))

Schutzanforderungen in Bezug auf die elektromagnetische Verträglichkeit §3(1)2, Artikel 3(1)b))

EN 300 220-1/1997

EN 300 683/1997

EN 60950:2000

NSR / Low Voltage Directive 73/23/EEC;93/68/EEC

EMV / EMC Directive 89/336/EEC;92/31/EEC;93/68/EEC

Walzbachtal, 17.04.2001

Grombacher Straße 83

75045 Walzbachtal-Jöhlingen

Germany

www.seip.com

11

Page 12

12

Loading...

Loading...