Page 1

3V1 SKR1W

English

Installation Instructions

for the garage door operator

This booklet must be handed over to the end-user

together with the user-manual.

RP60A

Page 2

2

Content

Information and Remarks

Directives and Regulations

Use of the operators

Garage Doors

The installers declaration of conformity

Older Garage Doors

Important Information for the Installer 3

Instruction for the users

Security Advises for the Installation 4

Installation

Different Conditions for Installation 5

Minimum space above the garage door

Door Arm Extension

C-Rail Extension

Pre-Mounting the operator 6

Installing the operator 6

Minimum head room above the door

Adjusting the running-length blocks 8

The Emergency Release 9

When there is a second entrance to the garage

When the garage door is the only entrance

Printed Circuit Board: Adjustments and Connections

Devices for Adjustments 10

TEST/RUN-Button (1)

LERN/LEARN-Button (2)

Jumper “KRAFT/PRESSURE” (3)

Combined TEST + LERN button functions

Programming Running-Length and Force 11

Information

1.) Adjusting the running-length blocks

2.) Starting the programming-mode

3.) Start the learning-cycle

Quick Reference

Special Functions 12

Readjusting the time for the internal light

Setting the pre-warning ON/OFF

Programming the Soft-Modes

The BOTTOM Soft-Stop

Programming the BOTTOM Soft-Mode

Enabling the TOP Soft-Modes

Reducing the Closing Speed

Why reduce the Closing Speed?

When to reduce the Closing Speed?

Programming the Closing Speed

External Connections 15

Push Button and Key Switch

Photo-Cell

24V AC Supply

Receiver-Module

LED-Lamps 16

LED “TEST“

LED “Diag“

LED “Vp“

Remote Control

Programming the Hand Transmitters 17

Basics

Programming Transmitter and Receiver

Clearing the receivers‘ memory

Additional Information 18

Criterias influencing the range

Use with a HomeLink© System

Technical Information

Technical Data 19

Wiring 19

External connections

Internal Wiring

Troubleshooting 20

Error Messages

Error messages via the operator‘s light

If... then...

Additional messages only via the LED “Diag“

Page 3

3

It is within legal regulation and without restriction, to use a

Seip door operator with any garage door that has been approved for use with other certified door operators!

Directives and Regulations

The garage door operator RP60 complies to the latest European

directives and regulations. The declaration of conformity is enclosed at the end of these instructions.

Use of the operators

The operators were designed for the use with up-and-over doors

(tilting and canopy-type) and sectional doors.

All garage doors need to be maintained before automation. The

door must be easily opened and closed by hand. A garage door

must not be automated unless it is easy to open and close manually.

Garage Doors

In January 2001 the European regulations EN12604 and EN12605

became compulsory for garage doors. Before installing an automatic door operator it must be assured that the garage doors

applies to these regulations (the information can be obtained from

the manufacturers‘ declaration of confirmity). A Seip door operator may be installed to any door that complies to the regulations.

Should a garage door not be compliant then please refer to the

chapter „older garage doors“.

The installers declaration of conformity

No matter whether a door operator was delivered together with a

garage door or seperately, the installer must issue a declaration of

conformity for the complete installation.

With this declaration the installer assures, that the installation

was made according to the instructions given by the manufacturers (e.g. the installation instructions of the garage door and the

operator). This declaration can only be issued by the installer and

may not be issued from the manufacturer!

If both components comply to the directives and the installation

was made as to the manufacturers instructions the whole installation will normally be CE-compliant.

Older Garage Doors

When automating an older garage-door the TS-series will still

comply to the regulations - through the automatic force setting

the requested values for forces and reversion will be according to

the regulations.

But it needs to be taken in consideration that most older garage

doors do not meet the regulations EN 12604 and EN 12605

- especially regarding security features. They might still have sharp

edges bearing the danger of severe injuries - for example sectional

doors might not have a finger protection between the sections.

Unfortunately the entire regulations do not mention how to

handle the automation of such an older garage door - the danger

basically is not the automation but the construction of the door.

Therefore we strongly recommend to

- check the garage door for sharp edges bearing danger when the

door is moving; take any necessary action to avoid the dangers

and make the door safer

- check the doors‘ springs and readjust them if necessary

- grease or oil the pivotal points and rollers of the garage door

- check that the door may be easily used by hand

If, however, the dangers cannot be avoided we recommend to use

the automatic pre-warning function of the operator. The operators‘ lighting will then be blinking for approx. 5 sec. before every

movement of the garage door. People inside the garage will be

warned before the opening and can step back from the garage

door in time.

Instruction for the users

Please instruct the users as follows:

- Use of the hand transmitter

- Use of the emergency release in case of a power failure

- Hand over the separate „User Manual“ to the customer

- Inform the user about the Security Advises in the User Manual

Important Information for the Installer

Information and Remarks

Up-and-over door

sectional door

Page 4

4

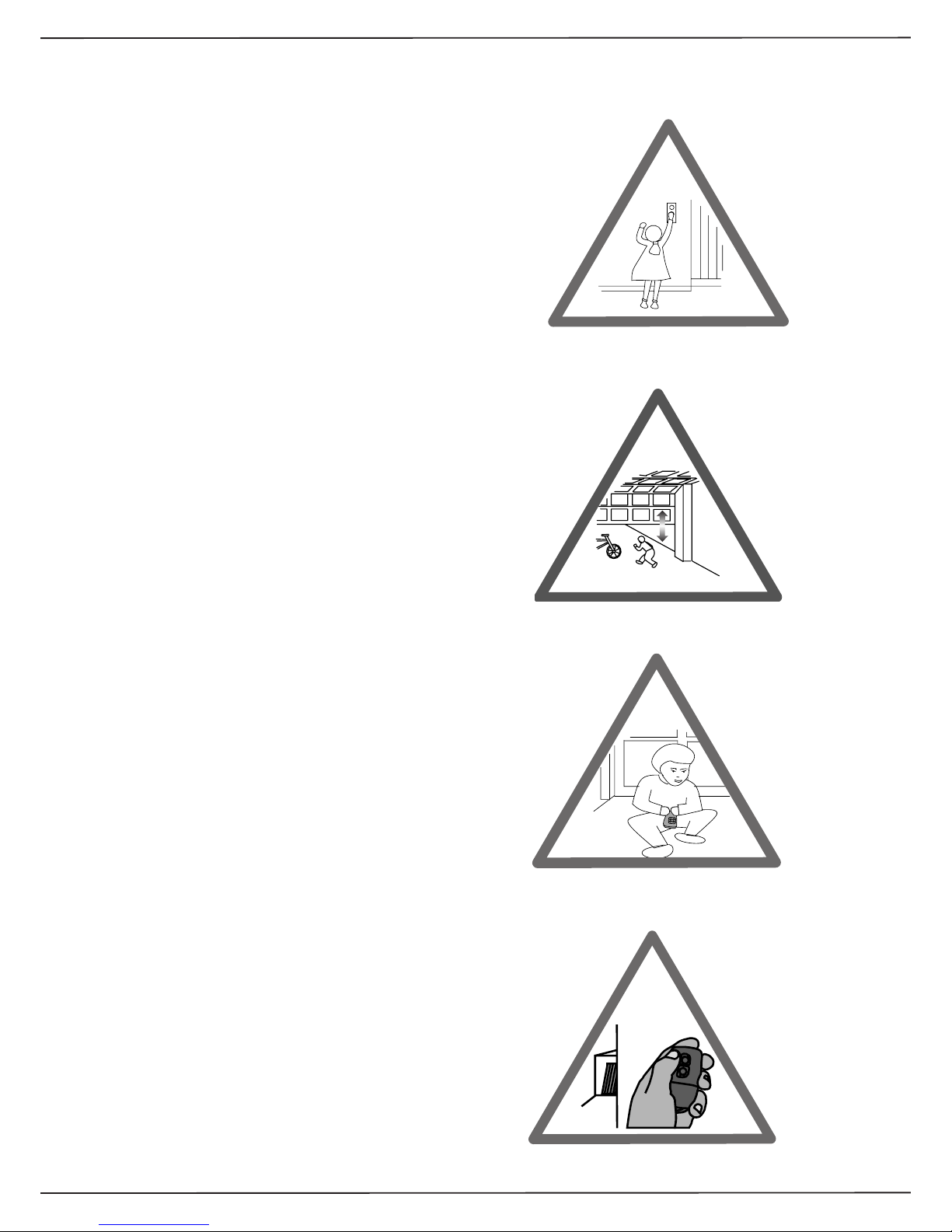

Security Advises for the Installation

Information and Remarks

Important Safety Instructions for Installation

WARNING: INCORRECT INSTALLATION CAN LEAD TO SEVERE

INJURY

Follow all Installation Instructions.

- Read page 3 of this instruction carefully before the installation

- Before installing the drive, remove unnecessary ropes from the

existing installation

- Maintain the garage door according to the advises on page 3

and to the door manufacturer’s manual

- If possible, install the drive at a height of at least 2,10 m and the

manual release at a height less than 1,80 m

- Locate the push-button within sight of the door but away from

moving parts and at a minimum height of 1,50 m

- Fix the label warning against entrapment next to the push-button

- The label fixed to the manual release may not be removed

- After installation, ensure that the mechanism is properly adjusted

and that the drive reverses when the door contacts a 40 mm high

object placed on the floor.

Page 5

5

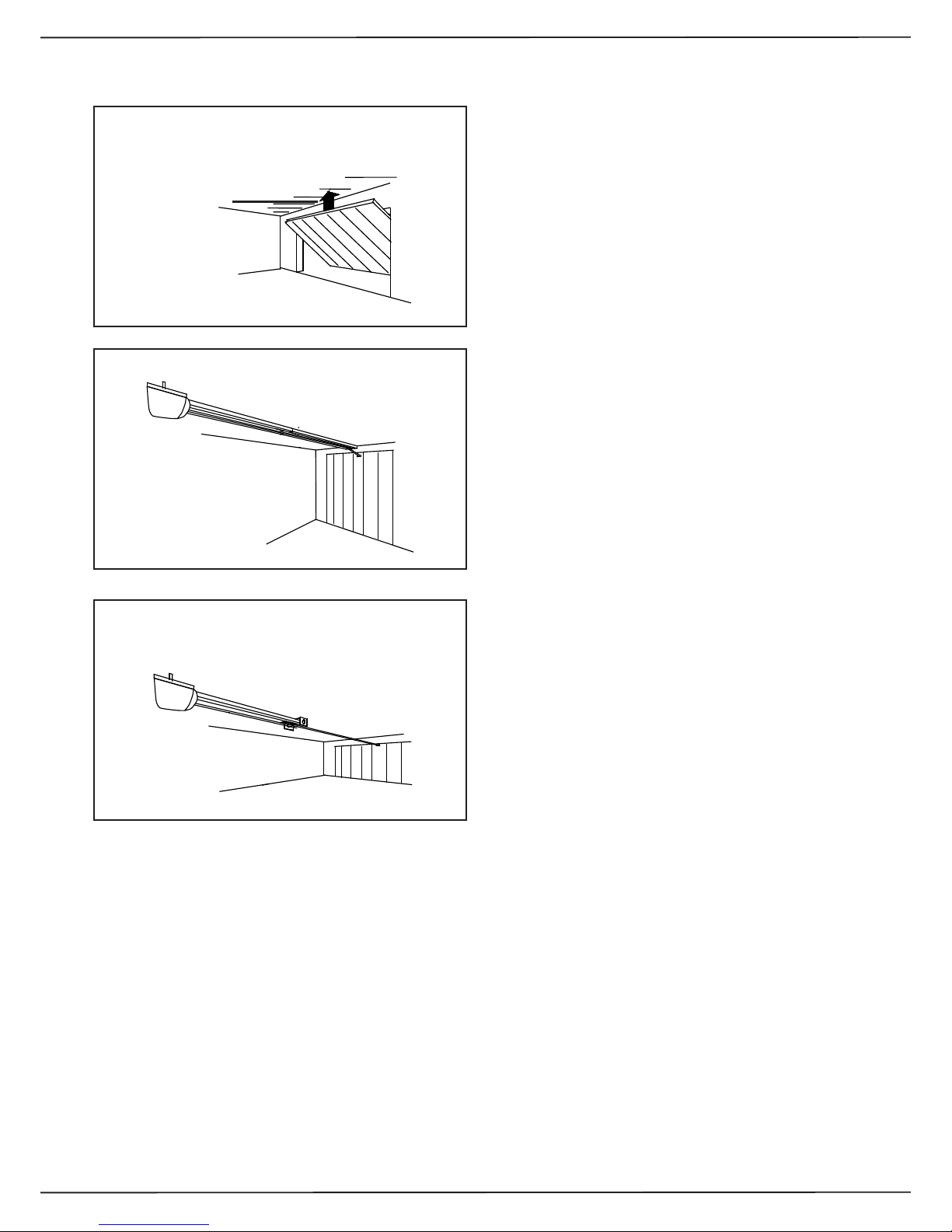

Different Conditions for Installation

Installation

35mm Minimum

Minimum space above the garage door

C-Rail Extension

Door Arm Extension

Before installing the operator you should check the garage for the

conditions of installation. You will need optional extras in either of

the following situations:

If the garage door is higher than 2.250 mm you will need a c-rail

extension. Two sizes of extensions are available: 500mm and

1.000 mmm.

The operator may be extended by a maximum of 1.500mm - the

maximum height of a garage door is 4.150mm.

Should the minimum space between the garage door and the ceiling be smaller than 35mm then a door arm extension is needed.

For an extension you can use a metal beam from any DIY-market.

The beam should not be shorter than the door‘s height.

Page 6

(1)

(2)

(3)

(1)

(3)

(4)

(1)

(2)

(2a)

6

During this procedure be careful not to twist the chain. Therefore

do not lift the parts - slide them along the floor.

1. The operator is laying unpacked in front of you. The motor-

head unit is on your right hand side.

2. Lay part (1) to the front.

3. Fix through pushing the C-profile coupling piece (2) over it all

the way home.

4. Slide C-rail part (3) in front of part (1)

5. Set part (3) in the C-rail coupling piece (4) at an angle, inserting

it from above as shown.

6. Press down part (3) to tension the chain.

7. Turn around the operator and screw in the milled nuts into the

C-rail coupling pieces.

Your operator now is readily premounted for installation.

The chain has been pretensioned in the factory; do not change

the chain tension!

ATTENTION:

The RP60 is equipped with a fully automatic measurement for the

required running length. When shipped the operator is programmed with a standard running length for factory testings.

If you want to run the operator for testing purposes you must

fix the blocks inside the c-rail by tightening the screws. A test

run may only be done after making sure, that the blocks

are fixed properly. Otherwise damaged might apply to the

operator!

Pre-Mounting the operator

Installation

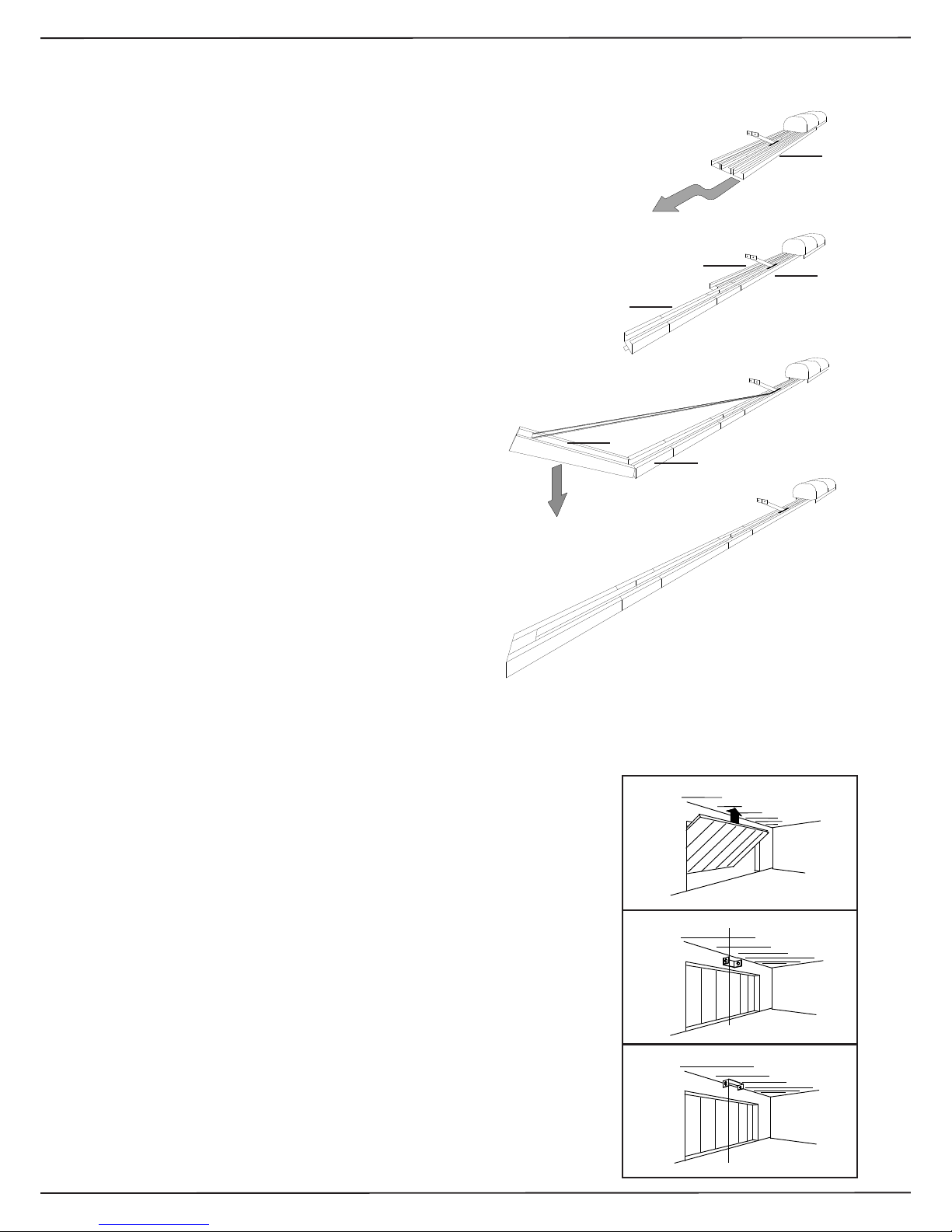

Installing the operator

Minimum head room above the door

Meassure the distance between the ceiling and the highest point

reached by the garage door (1).

The minimum-headroom necessary for mounting the operator is

35 mm. If there is less headroom please pay attention to page 5.

The front fixing angle can be mounted either at the lintel or at the

ceiling.

1. Meassure the middle of your garage door and make a mark on

the lintel and the top of your door (2+2a).

2. Fix the front fixing angle in the middle either at the lintel or at

the ceiling. (We recommend the lintel if possible) (2+2a).

Page 7

(3)

(3a)

(4)

(5)

(6)

(7)

(4a)

7

Installing the operator

Installation

3. Attach the C-rail to the front fixing angle (3). Put a carton piece

under the motor head unit to avoid damages.

4. To fix the motor head to the ceiling we recommend you to use

a ladder (4). When the operator is laying on the ladder you can

open the garage-door. Adjust the C-rail according to the mark you

made in the middle of the garage-door.

Fix the operator to the ceiling when you have made sure the C-rail

is running straight to the front. Use the supplied bracket to fix the

C-rail to the ceiling (pic. 4 and 4a).

5. Now fix the door arm to the garage door (6). Take care that the

angle between the operator and the door arm does not exceed a

max. of 45° (it may be lower).

6. The limit-blocks must be tightened before running the

operator!

The garage doors‘ bolts must be removed before running

the operators - otherwise damages on the garage door or

operator might occure!

For additional security our locking set can be obtained as an

optional extra.

Page 8

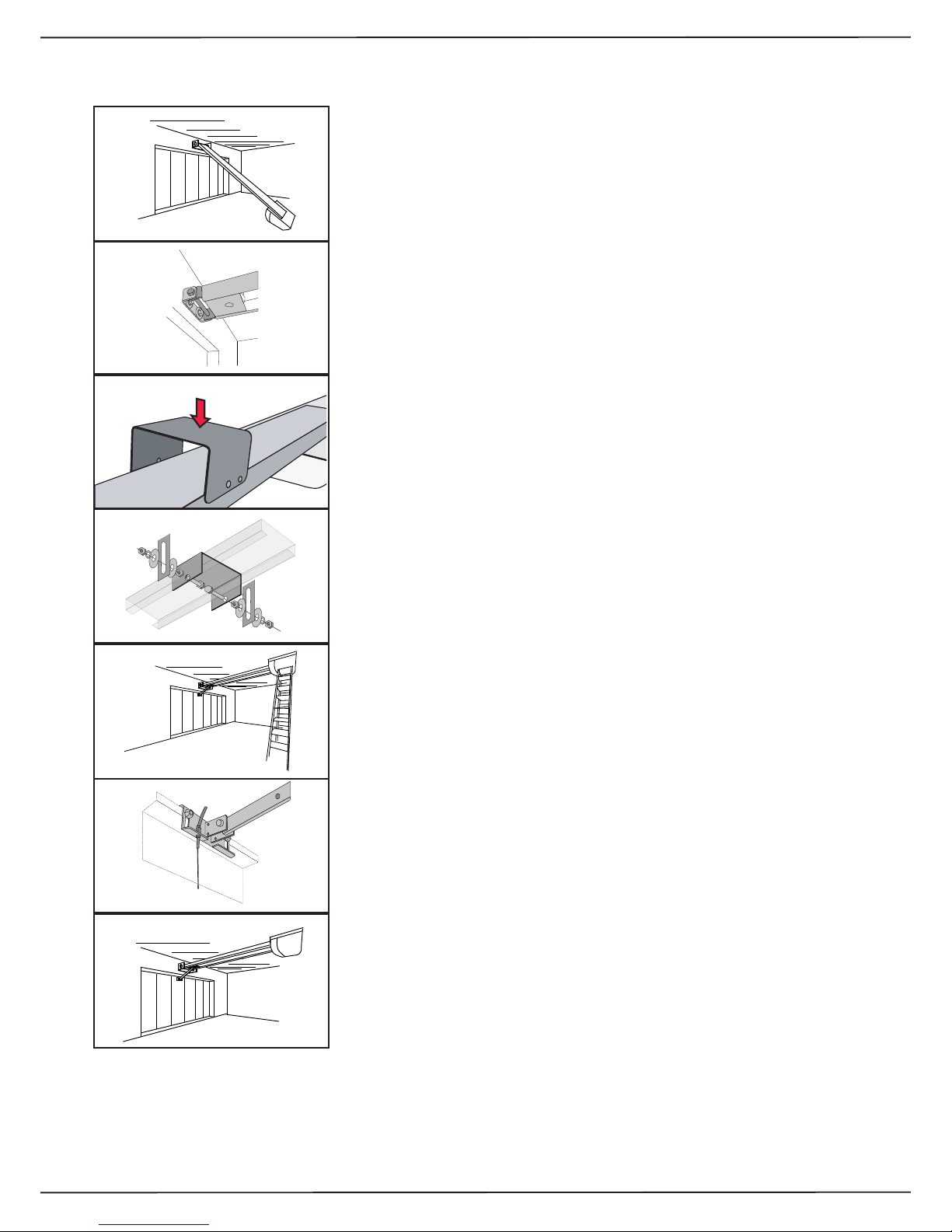

8

Installation

Adjusting the running-length blocks

These adjustments must be made before the programming

of the forces and the running-length.

Starting the programming procedure without correctly adjusted blocks may lead to damages on the garage door and

the operator!

Vorgehensweise:

1. The operator is mounted and the door-arm is fixed to the garage-door. The trolley is locked to the chain and stands somewhere

between the two blocks. If, however, trolley and chain need to be

moved you may do this using the TEST/RUN button.

2. Release the trolley (Pic. 1) and manually close the garage door.

3. The block for the closing direction is now right in front of the

trolley (Pic. 2). If not, the block must be moved until it touches the

trolley.

4. Tighten the blocks‘ screw to keep it in place. Take care not to

tighten it too strongly - the c-rail should not be bended.

5. Now the garage door needs to be opened manually. The trolley

will lock into the chain - you have to release it once again to fully

open the garage door. (Pic. 1).

6. The block for the opening direction is now right in front of the

trolley (Pic. 3). If not, the block must be moved until it touches the

trolley.

7. Tighten the blocks‘ screw to keep it in place. Take care not to

tighten it too strongly - the c-rail should not be bended.

8. The trolley now needs to be locked back to the chain!

After that the programming procedure may be started (page 10

onwards).

Page 9

9

In case of a power failure the garage door can be opened by

hand. Therefore the operator first needs to be released.

When the garage door is the only entrance

It is necessary to connect the emergency release to the door‘s

handle (pic. 1) otherwise the garage cannot be accessed in a

power failure situation.

Procede as follows:

1. Find out in which direction the door handle moves when opening the door.

2. Drill a hole in that side of the door handle which turns downwards.

3. Thread the cable through the hole and fix it with the enclosed

metal-clamps. Be carefull not to put a high tension on the emergency release cable - the operator then might release from the

garage-door during a normal opening cycle.

4. Check the function of the emergency release together with a

second person. Stay inside the garage and close the door with

the operator. Let the second person open the door manually with

the door keys. If this works, the emergency-release is mounted

properly

.

Do not leave the garage and close the garage-door with the

operator before you have tested the emergency-release!

The Emergency Release

When there is a second entrance to the garage

You can use the supplied handle for the emergency release (pic.

2).

Thread the emergency release cable through the handle.

Fix the metal clamps to the cable where the handle shall be

placed.

Shorten the cable below the metal clamps - the handle is now being held by the clamps.

In case of a power failure the user can now open the garage

door by releasing the operator with the handle for the emergency

release.

Installation

Pic. 1

Pic. 2

Page 10

MO910-V2

Prä ge.

Uext

HF-MODUL/RECEIVER CARD

Ant

A B

C

D

24 V

1 2 3

10

Printed Circuit Board: Adjustments and Connections

Devices for Adjustments

TEST/RUN-Button (1)

With this button you put the operator into operation. The button

works on the OPEN-STOP-CLOSE principle, e.g. the first push

opens the door, the second push stops the door and the third

push closes the door etc.

The LED-lamp “TEST“ is switched on as long as you press the

TEST-button and shows that the impulse was received an recognised by the electronics.

LERN/LEARN-Button (2)

This button fulfills the following functions:

1. Learning the forces

2. Registering (learning) a hand-transmitter

3. Ajusting the length of the CLOSING Soft-Stop

4. Starting advanced programming functions

The LERN/LEARN-button must be pressed for approx. 3 sec.; the

button can be released once the operator‘s light starts blinking.

Whilst the operator‘s light is blinking you can either register a new

hand-transmitter by pushing the hand transmitters button O R

you may start the learning of forces by pressing the button once

again.

Details on both procedures can be obtained from the chapters

“Automatic Force Setting“ on page 11 and “Remote Control“ on

page 15.

Jumper “KRAFT/PRESSURE” (3)

It is possible to have the garage door locked by mechanical bolts

in addition to the operators’ self-locking motor. Some of these

mechanical bolts are driven by a system of beams and springs

which require a higher force to ensure that the bolts are locked

in correctly. With the standard setting (Jumper plugged on) this

might sometimes lead to unwanted reversions shortly before the

bolts lock in.

It is therefore possible to increase the force slightly during the

CLOSING Soft-Stop; the operator will then react less sensitive

which allows the bolts to lock in:

- Jumper is plugged on: normal force (standard-setting)

- Jumper is removed: higher force during CLOSING Soft-Stop

ATTENTION: for this setting you must remove the jumper

ONLY AFTER THE FORCES AND LIMITS WERE PROGRAMMED!

Should the jumper be removed before the learning-cycles,

then the TOP Soft-Start will be disabled (please refer to

pages 12+13 “Special Functions”).

TIP: if you decide to remove the jumper, then plug it back

onto one pin only - so it remains available on the P.C.B. for

later use.

Combined TEST + LERN button functions

Through a combined use of TEST and LERN button the following

special functions can be adjusted:

1. Pre warning light

2. Durance of the internal light

How to adjust these functions is explained on page 12 “Special

Functions”.

This page only shows the functions of the buttons and potentiometers on the P.C.B.. To programme the operator please refer to page 10 onwards.

Page 11

MO910-V2

Prä ge.

Uext

HF-MODUL/RECEIVER CARD

Ant

A B

C

D

24 V

1 2

3

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

RA

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

RA

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

11

Pictures:

1: TEST/RUN-Button

2: LERN/LEARN-Button

3: Jumper for additional force

Information

To properly use the operator it is necessary to programme the running-length and the force. Using the operator without these

important adjustments may lead to damages on the garage

door and the operator. For test-runs without a garage door

the running-length blocks must be tightened (please refer

to page 8 “Adjusting the running-lenth blocks”).

The programming procedure is done completely automatic with

an automated procedure. The programming-mode needs to be

started first - it will be indicated by the blinking operators’ light.

The quick-reference on this page shows a short summary of the

procedure.

1.) Adjusting the running-length blocks

This step is descriped on page 8, “Adjusting the running-length

blocks”. (Remark: the blocks are fixed by tightening the

screw).

2.) Starting the programming-mode

Keep the LERN/LEARN button (2) pressed for 3 seconds - release

it once the operators‘ light begins blinking. The operator is now

running in programming-mode.

3.) Start the learning-cycle

Shortly press the LERN/LEARN button (2) once again. The operator

now starts three fully automatic measurement-runs:

3.1. First the block for OPENING direction is searched for

3.2. Second the operator closes the garage door with low speed

(during this run you may also change the length of the factory

pre-set soft-stop, as described on page 13).

3.3. The operator stops when the garage door ist closed - the

measured running-length is now stored in the memory

3.4. The operator opens the garage door and measures the required opening-force

3.5. The operator closes the garage door and measures the required closing-force

3.6. The operator stops in closing position and remains blinking

for a couple of seconds.

Once all the measures values have saved in the memory the operators’ light stops blinking - now the operator is ready for use.

Procede with the programming of hand-transmitters on page 15.

Programming Running-Length and Force

Printed Circuit Board: Adjustments and Connections

Quick Reference

1.) Adjustment of blocks The running-length blocks for

opening and closing direction

must be properly adjusted (please

refer to page 8)

2.) Start programming

mode

Press the LERN/LEARN button for

approx. 3 seconds. The operators’

light begins blinking - release the

LERN/LEARN button

3.) Start the learning-cycle Press the LERN/LEARN button

once again shortly: the operator

now starts three fully automatic

measurement-runs.

The learning cycle stops after the three runs. The garage door

is then closed and the operators’ light stops blinking. The programming is now complete.

4.) You may now procede with chapter “Remote Control“ on

page 15

INFORMATION:

When the learning-cycles are made as to the procedure

described on this page, then the operator will be programmed with the standard values for the soft-modes.

Shall the soft-modes be changed or disabled, then please

refer to page 13.

The learning-cycle can be repeated at any time. Running

a new learning-cycle will overwrite the old values and

substitute them with the new ones.

Page 12

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8k

2/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

RA

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

RA

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

RA

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

12

Printed Circuit Board: Adjustments and Connections

Special Functions

Readjusting the time for the internal light

The time for the internal light may be adjusted from 10 seconds to

5 minutes. The factory setting is 3 minutes.

To readjust the time procede as described below:

1. Keep the LERN/LEARN button pressed for 6 seconds. Release

the button once the green LED „TEST/FUNK“ turnes on.

2. Shortly press the LERN/LEARN button again.

3. The green LED „TEST/FUNK“ now starts blinking at 1 second

intervalls - each blinking increases the time by 10 seconds.

5. Once the required time is reached, press again the LERN/LEARN

button shortly. The value is then saved in the memory - the programming is finished.

LED TEST/FUNK blinks .... times Time for light is:

6 x 1 minute

12 x 2 minutes

18 x 3 minutes

24 x 4 minutes

30 x 5 minutes

Setting the pre-warning ON/OFF

1. Keep the LERN/LEARN button pressed for 6 seconds. Release

the button once the green LED „TEST/FUNK“ turnes on.

2. Shortly press the TEST/RUN button

3. The green LED TEST/FUNK indicates whether the pre-warning

is switched ON or OFF:

LED TEST/FUNK is off: pre-warning is OFF

LED TEST/FUNK is glowing: pre-warning is ON

4. by shortly pressing the TEST/RUN button the pre-warning

can be switched ON and OFF

5. after making your choice shortly press the LERN/LEARN button - the setting will be saved to the operators‘ memory.

Quick Reference „Time for internal light“

1.) Keep the red LEARN

button pressed for 6

seconds

After 3 seconds the operators‘

light starts blinking, after 6

seconds the green LED „TEST/

FUNK“ turnes on

2.) Release LERN/LEARN

button

LED „TEST/FUNK“ is on

3.) Shortly press LERN/

LEARN button

LED „TEST/FUNK“ begins blinking

at 1 second intervalls. Each

blinking adds 10 seconds to the

time (starting from zero)

4.) Press LERN/LEARN

button shortly when

required time is reached

The adjusted time will be saved in

the memory.

Quick Reference „Pre-Warning“

1.) Keep the red LEARN

button pressed for 6

seconds

After 3 seconds the operators‘

light starts blinking, after 6

seconds the green LED „TEST/

FUNK“ turnes on

2.) Release LERN/LEARN

button

LED „TEST/FUNK“ is on

3.) Shortly press the black

TEST/RUN button

LED „TEST/FUNK“ indicates

status:

LED on: pre-warning ON

LED off: pre-warning OFF

4.) Shortly press the

TEST/RUN button

By pressing the TEST/RUN button

the pre-warning is switched on

and off:

LED on: pre-warning ON

LED off: pre-warning OFF

5.) Shortly press the red

LERN/LEARN button

The chosen adjustment is saved

into the memory.

Page 13

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

ST

/

F

U

N

K

8

k

2

/

D

I

AG

H

F

-

M

O

D

U

L

/

R

E

C

E

I

VE

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

H

F

-

M

O

D

U

L

/

R

E

C

E

I

VE

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

UNK

8

k

2

/

D

I

A

G

13

Printed Circuit Board: Adjustments and Connections

Programming the Soft-Modes

The RP60 is shipped with factory pre-set values for the SoftModes; if the learning cycle is run without any changes to the

factory-settings, then the pre-set values will be programmed

automatically.

The BOTTOM Soft-Stop

The length of the BOTTOM Soft-Stop may be changed during the

first run of the learning-cycle in closing direction.

- Extending the BOTTOM Soft-Stop is recommended, if the

garage door slams on closing.

- Reducing or disabling the BOTTOM Soft-Stop is recommended, when the bottom of the garage door does not close completely. Expecially when mechanical spring-locks are installed, these

might not engage. When the BOTTOM Soft-Stop is disabled, the

garage door reaches the closing position with a higher speed. This

gives the door a higher momentum and the bottom can fall into

the doors‘ frame - the locks can then engage.

Programming the BOTTOM Soft-Mode

The length of the soft-stop can be adjusted during the first automatic measurement-run in closing direction. Please proceed as

described below:

1. Start the learning cycle (refer to page 11)

2. the operator runs in closing direction with low speed

3. press the LERN/LEARN button and keep it pressed - the operator

is now increasing the speed

4. release the LERN/LEARN button at the position where the softstop shall begin (the operator will safe this position as the

beginning of the BOTTOM soft-stop)

If the Soft-Stop is to be disabled, then the LEARN button must be

pressed until the door is completely closed.

5. the operator will reduce speed with a short delay and then

reach the closing position

6. the operator will procede with the remaining measurementruns

When the operators‘ light stops blinking, all measured values

are saved in the memory - the BOTTOM soft-stop now is in the

programmed position.

Enabling the TOP Soft-Modes

The RP60 will start the closing procedure from OPENING position with slow speed (e.g. TOP Soft-Mode). Dependant on the

performance of the garage door it might be necessary to enable

this Soft-Mode, especially when the operator reverses during that

period (e.g. pressure detection).

Procedure for Enabling the TOP Soft-Mode

Remove the jumper „KRAFT/PRESSURE“ before starting the

learning cycels and leave it removed until the learning cycles are

completed - the TOP Soft-Mode then is enabled.

After the learning cycles the Jumper „Kraft/Pressure“ fulfills its‘

normal function („Normal Force/Higher Force during CLOSING

Soft-Stop“ as to page 10) and can be replaced.

TIP: should you decide to remove the jumper, then plug it

back onto one pin only - so it remains available on the P.C.B.

for later use.

Quick Reference „Programming the BOTTOM Soft-Mode“

1.) During the first learning

cycle in CLOSING direction

Keep the LERN/LEARN button

pressed during the first run in

CLOSING direction and keep it

pressed -the operator increases

speed

2.) The operator is running

in CLOSING direction with

increased speed

Release the LERN/LEARN button

at the position where the softstop shall start in future.

If the LEARN button is kept

pressed until the door is

completely shut, then the

soft-stop will be disabled.

3.) The operator reaches the CLOSED position. It will proceed

with the learning-cycle (two more runs) before finishing the programming. The CLOSING Soft-Stop will then be set as to your

adjustments.

Quick Reference „Enabling the TOP Soft-Mode“

1.) Remove the Jumper KRAFT/PRESSURE before starting the

learning cycles

2.) Start the learning cycle

3.) After the learning cycles are completed the jumper can be

replaced (dependant on the required function, as to page 10)

TOP soft-mode

BOTTOM soft-mode

Special Functions

Page 14

HF-MODUL/RECEIVER CARD

KRAFT/

PRESSURE

LERN/LEARN

TEST/RUN

Vp

TEST/

FUNK

8k2/

DIAG

MO910-V2

Präge.

Uext

HF-MODUL/RECEIVER CARD

Ant

KRAFT/

PRESSURE

LERN/LEARN

TEST/RUN

24 V

H

F

-

M

O

D

U

L

/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

HF-MODUL/RECEIVER CARD

KRAFT/

PRESSURE

LERN/LEARN

TEST/RUN

Vp

TEST/

FUNK

8k2/

DIAG

1

2

3

4

5

6

7

8

0 - 55

56 - 75

76 - 95

96 -115

116 -170

8

7

6

5

4

14

Enhanced Adjustments

Reducing the Closing Speed

When using the standard programming procedure, then the closing speed is automatically set to maximum; for most

CE compliant garage doors no changes are necessary.

Why reduce the Closing Speed?

Reducing the closing speed will also reduce the forces and the

time for reversion which appear when the garage door hits an

obstacle.

The greater the weight of a garage door, the higher the mass that

needs to be moved, stopped and reversed in case of detection of

an obstacle. Especially on heavy doors this momentum may result

in a short peak force, leading to higher forces on the leading edge

. The lower the closing speed, the lower the momentum of force

and the peak forces.

When to reduce the Closing Speed?

The table besides provides information on suggested closing

speeds for different door weights. For new, CE-compliant doors

you should find the doors weight either labelled on the door or in

the instructions. Adjust the closing speed according to this information, as far as a change is required.

When automating an older, non CE-compliant garage door, we

strongly recommend to use speed level 4 or lower (please also

refer to page 3).

Programming the Closing Speed

The programming of the closing speed must be made before

running the learning cycle. If, however, the learning cycle was

already completed, it must be run again after changing the closing

speed.

1.) The operator is switched on

2.) Press the red LEARN-button and keep it pressed. Press the

black TEST-button in addition and keep both buttons pressed for

approx. 3 seconds.

3.) The operators light starts blinking and the red LED „Diag“

blinks in intervalls; the buttons can now be released.

4.) The LED „Diag“ is blinking in intervalls (8 blinks followed by a

short break) - indicating the factory pre-set speed level 8.

5.) Each press of the TEST-button will reduce the closing speed by

one level, each press of the LEARN-button will increase the speed.

After readjusting the speed, wait for the short break between the

intervalls and count the number of blinks from there to check the

entirely adjusted speed level.

6.) Once you reached the wanted closing speed level, press the

LEARN-button and in addition the TEST-button and keep both

pressed for approx. 1 second.

7.) The closing speed is now adjusted and the operator is now

in the ordinary learning mode (the operators light and the LED

„Diag“ are blinking constantly). If the limit-switches were adjusted

already, you can now start the learning cycle by shortly pressing

the red LEARN-button.

Otherwise you can now adjust the limit-switches (please refer to

pages 10 and 11) and then start the learning cycle.

Quick Reference „Ajusting the Closing Speed“

1.) First press LEARN button,

then in addition TEST-button,

keep both pressed for 3 sec.

The operators light begins blinking

when the buttons are pressed

2.) Red LED „Diag“ begins to

blink in intervalls

Release both buttons when the LED

„Diag“ starts blinking

Factory pre-set: 8 blinks followed by

a short break (= max. speed)

3.) Reduction of speed by

pressing the TEST button

Each press on the TEST button

reduces the closing speed by one

level (pressing the LERN button will

increase the speed).

Wait for the break and count the

number of blinks from there to

check the entire adjustment.

4.) First press LEARN button,

then in addition TEST-button

and release both

The operator is now in the ordinary

learning mode; the operators light

and the LED „Diag“ are now blinking simultaneousely.

5.) Adjust the limit-switches and start the learning-cycle.

If changes to the soft modes are necessary, then please refer to page

11.

If the limit-switches had been adjusted previousely, the learning-cycle

can be started instantly by shortly pressing the LERN button.

Speed Level (No. of blinks of

the LED „Diag“)

Closing Speed (cm/sec.)

1 6 cm/sec.

2 6,5 cm/sec.

3 7,5 cm/sec.

4 9,5 cm/sec.

5 10,5 cm/sec.

6 11,5 cm/sec.

7 12,5 cm/sec.

8 14,5 cm/sec.

Speed Level

Door

Weight

in kg

Printed Circuit Board: Adjustments and Connections

Page 15

D

C

24V

24V

24 V

24 V

N.C.

8,2 kW

C

D

8,2 kW

MO910-V2

Prä ge.

Uext

HF-MODUL/RECEIVER CARD

Ant

KRAFT/

PRESSURE

LERN/LEARN

TEST/RUN

A B

C D

24 V

15

External Connections

Printed Circuit Board: Adjustments and Connections

Component Connector Function

Push Button and

Key Switch

A + B Floating connector for push button and key switch:no electricity to come into contact

with these connectors!

When using an external receiver the impulse wires are connected to this terminal.

Photo-Cell

C + D

(with 8,2 kOhm

resistor)

Function

OPENING direction: when releasing the CLOSING limit-switch the connector is checked for 3

seconds (= hatch door closed or opened). Impulses coming in later during the OPENING cycle will

be ignored.

CLOSING direction: the connector is being checked throughout the whole CLOSING cycle. If an

obstacle is recognized (by the security-beam) the operator will reverse

Hatch-Door Switch

A hatch-door within the garage door can be secured with a switch - when the switch is not activated (e.g. the hatch-door stands open) the operator will not work.

ATTENTION: when a photo-cell AND a hatch-door switch are connected at the same time,

then they must be connected in a row (not parallel)!

Please also take into consideration, that the hatch-door switch may not be sensitive to

the shaking of the garage door during the movement - otherwise it may come to unwan-

ted stops and reversions during the closing procedure!

24V AC Supply 24V 24V AC power supply for external components (external receiver, photo-cell), a maxi-

mum of 200 mAmp. is allowed.

Receiver-Module HF-Modul /

Receiver-Card

Plug for Seip remote-receiver cards.

Transmitter

Receiver

Page 16

MO910-V2

Prä ge.

Gnd

8k2

Uext

24Vac

Gnd

BT

Uext

HF-MODUL/RECEIVER CARD

Ant

KRAFT/

PRESSURE

LERN/LEARN

TEST/RUN

24 V

16

LED-Lamps

Printed Circuit Board: Adjustments and Connections

LED Function ON OFF

LED “TEST“ (green)

Turns on when:

1.) a device connected to A+B (push-button, key-switch) gives an

impulse

2.) the P.C.B.’s TEST-button is pressed

3.) a signal from a registered hand-transmitter is received

4.) the operator is in programming-mode

This LED also is being used for the programming of special

functions (pre-warning, time internal light)

Incoming impulse No incoming im-

pulse

LED “Diag“ (red)

Turns on when:

1.) a safety-device recognizes an obstacle

2.) a short-cut is detected in the wiring of a security device

3.) a safety-device is not working properly

This LED also is being used for the programming of special

functions (pre-warning, time internal light)

Incoming impulse

from a programmed

hand-transmitter

No incoming impulse from a handtransmitter

LED “Vp“ (yellow)

“ON“ when mains power supply is o.k.

Mains power supply

o.k.

No mains power

Page 17

H

F

-

M

O

D

U

L/

R

E

C

E

I

V

E

R

C

A

R

D

K

R

A

F

T

/

P

R

E

S

S

U

R

E

L

E

R

N

/

L

E

A

R

N

T

E

S

T

/

R

U

N

V

p

T

E

S

T

/

F

U

N

K

8

k

2

/

D

I

A

G

17

Programming the Hand Transmitters

Remote Control

Quick reference: programming the first hand transmitter

1.) Keep the LERN/LEARN

button pressed for approx.

3 sec.

The operators‘ light will start

blinking

2.) Press the hand transmitter button you want to use

The operators‘ light stops

blinking - the transmitter was

succesfully programmed

Quick reference: Programming additional hand transmitters from a distance

Remark: additional hand transmitters can be programmed

either like the first transmitter or from a distance as explained

below:

1.) Open the garage door

for approx. 50 cm and close

it again

After the garage door is closed

you have got 10 seconds to proceede to step 2)

2.) Press buttons 1+2

simultaneousely on any

registered transmitter for

3 sec.

The operators‘ begins blinking

- release the hand transmitters‘

buttons

3.) Take the new hand

transmitter and press the

button you want to use

shortly

The operators‘ light stops

blinking - the hand transmitter

was successfully programmed

Basics

As a standard the operator is equipped with a 433 MHz AM

remote control set. The coding is done via rolling code - the code

is changed after each impulse; receiver and transmitter agree completely automatic about the next code to be used. New codes will

be chosen out of a pool of billions of possible codes.

Your operator is equipped with our standard remote control set

when you hand transmitters looks like the one shown on the right

hand side. The 4-channel MIDI transmitter is standard equipment,

the 2-channel MINI transmitter is available as an optional.

If your operator is equipped with another remote control set,

please refer to the manufacturers instructions for programming.

Programming Transmitter and Receiver

To use a hand transmitter it must first be registered (programmed)

by the receiver. Only one hand transmitter button can be used for

one receiver.

Registering the first hand transmitter

The first hand transmitter (e.g. no hand transmitter has been

registered for the receiver, yet) must be learned directly via the

operators‘ main electronic:

1. Press the LERN/LEARN button on the main electronic for approx.

3 seconds until the operator’s light starts blinking and release the

LERN/LEARN button.

2. Press the hand transmitter button you want to register to the

receiver - the operators’ light stops blinking when the transmitters’ signal was received. The transmitter is now registered.

Registering additional hand transmitters

When at least one hand transmitter has been registered by the

receiver you may program additional hand transmitters from a

distance:

1. The garage door must be closed

2. Open the garage door approx. 50 cm and close it again.

3. After the garage door is closed you have got 10 seconds to

press the buttons 1+2 simultaneously on the registered hand

transmitter - the operator’s light then starts blinking.

4. The light will keep blinking for another 10 seconds - during that

period of time you must press the button on the new hand transmitter which you want to use with the operator. Once the new

transmitter is registered the operator’s light stops blinking.

The procedure must be repeated for each new hand transmitter.

Clearing the receivers‘ memory

Keep the LERN/LEARN button pressed for approx. 15 sec.. The

operators‘ light and the red LED „Diag“ will start blinking after 3

seconds. After another 10 seconds the red LED „DIAG“ will glow

constantly. You can then release the LERN/LEARN button.

All previousely programmed hand transmitters are now

cleared from the receivers‘ memory.

Page 18

1

2

4

3

A23S

12V

18

Remote Control

Additional Information

4-Channel MIDI transmitter,

433 MHz, rolling code

Battery

Usable types of batteries: A23, 23A, 23L, EL12, VR 22 and

MN 21

Voltage: 12V

Used batteries must be disposed of according to national

laws!

Criterias influencing the range

The RP operators are equipped with a high quality remote

control set as a standard!

Nevertheless the remote control is the part of the operator which

might be influenced by circumstances in the surroundings of the

garage. With our standard remote control you might reach a

range of more than 100 meters. In areas with high disturbancies

the range will still be approx. 50 meters.

The range might be influenced by:

- old batteries in the hand transmitter - if you should experience

a problem with the range, please change the batteries first. The

lower the batteries run the lower the range will be.

- Building materials of the garage

In a garage made of concrete and steel you might reach a lower

range than in an ordinary garage build of stone. The more steel

was used for the walls the shorter the range of your remote-control.

Remote-control activity in the area

Radio and television transmitters close to your garage might

reduce the range.

Older baby-phones

Especially older baby-phones might influence the range of the

remote control severely. These devices send strong signals via the

houses internal power supply net. These signals also intrude other

devices via the wall plug, as eg the operator.

It is extreemely unlikely that the range will drop to an unacceptable distance. If, however, problems should occure we will like to

be helpful.

Please avoid to drop the hand transmitter - parts could

be damaged inside the transmitter. That might lead to

malfunctions!

Use with a HomeLink© System

The standard remote control SKR433-1 supplied with the

TS-series is compatible with HomeLink© systems Software

Revision 6 or higher. Older Software Revisions are not

supported. Information on the Software Revision in your car and

programming information can be obtained from the cars

documentations (programming information is also available on

the internet: www.eurohomelink.com).

Programming procedure:

1. Original hand-transmitter must be programmed into the

HomeLink© Modul

2. Garage Door Operator must be put into learning mode

(page 18 “Programming additional hand transmitters from a

distance”)

3. A signal must be sent from the HomeLink© Module to the

operator

1-Channel Wall Transmitter

433 MHz, rolling code

Usable types of batteries: A23, 23A, 23L, EL12, VR 22 and

MN 21

Voltage: 12V

Used batteries must be disposed of according to national

laws!

Battery

Page 19

A B

C D

24 V

19

Technical Data

Technical Information

Wiring

Internal Wiring

1 Blue, mains supply, 230V

2 Brown, mains supply, 230V

3 Black, transformer, 230V

4 Black, transformer, 230V

5 Brown, Lighting, 230V

6 Blue, Lighting, 230V

7 White, transformer, 24V

8 White, transformer, 24V

9 MOTOR Connector for the plug from the motor

PE Earthing from the printed circuit board to the

base plate

Earthing of

the mains

supply

The earthing of the mains supply (green/yellow)

is connected to the base plate with a screw (the

screw is marked with a earthing symbol)

External connections

(Explained on pages 12 + 13)

A + B Floating connector for push-button, key-switch

and the impulse cables of an external receiver

C + D Floating connector with a 8,2kOhm resistor for

impulse cables from a photo-cell receiver

24V 24V AC for a photo cell transmitter when a

self test before every movement of the door is

required

Others

HF-Modul/Receiver

Card

Plug for receiver module, 433 MHz

FUSE Fuse T1,6A 250V

Devices for adjustments

Button

„Test/Run“

Runs the operator - OPEN-STOP-CLOSE

Button

„Lern/Learn“

For automatic force setting and registration

of hand transmitters

Jumper

“FORCE/

PRESSURE”

Setting of lower or higher force

RP 60 A

Maximum Pulling Force (adjustable) 60 kg (+/- 4%)

Force-Setting for Operation automatic

Motor 24V DC, low-noise

Running Speed 14 cm/sec.

Speed in Soft Mode 8 cm/sec.

Lighting 230V AC, max. 40 watts

Lighting Durance (adjustable) 10 to 300 seconds

Duty Cycle 80%

Power Consumption in Stand By 2,3 watts

Power Supply 190-250V AC

Transformer 230V AC, 24V DC

Pre-Warning Light adjustable

Soft-Stop in Closing Direction adjustable

Nett Running Length 2.640 mm

Max. Running Length with Extension 4.050 mm

Overall Length mm

Height Motor Head mm

Length Motor Head mm

Width Motor Head mm

Minimum Space above the door 35 mm

Weight including packaging kg

Emissions

≤ 60 dB(A)

Page 20

20

Technichal Information

Troubleshooting

Error Messages

The RP 60 is equipped with a system of error messages via the

internal lighting and the LED “Diag“.

Error messages via the operator‘s light

2 x blinking

Running-time error - the operator did not reach the runninglength block within the programmed distance. Check the blocks

and try reprogramming the P.C.B. (e.g. start the learning-cycles)

4 x blinking

The microprocessor has lost data - try to run the learning cycle.

When this does not work, the motor-head needs to be replaced.

5 x blinking

The microprocessor cannot save data - the P.C.B. shuts down

and stops all operations. The motor-head needs to be replaced.

6 x blinking

Damaged relays - the electronics need to be exchanged

7x blinking

The Hall-Sensor in the motor is damaged OR there is a loose

connection between the motor and the electronics OR there is

an error on the motors plug

If... then...

The operator does not react on the transmitter or on the push-button switch

Power failure? Disconnect and connect the operator. Is the door stuck

because of snow and ice? Check the lines and the connections of the

push-button switch. Is there water in the push-button switch or in the key

operated switch? Disconnect alle external components and try running the

operator via the TEST/RUN button.

The operator reacts on the transmitter but not on the push-button

switch

Check the line of the push-button switch. Does the push-button switch

work, when the remote receiver is disconnected? If so, the remote transmitter or receiver might be defective.

The operator reacts on the push-button but not on the transmitter

Check the accordance of the transmitter and the receiver code. Displace

the antenna of the receiver. Avoid each metal contact (reduces the range).

Check the battery of the transmitter

The operator neither reacts on the push-button nor on the

transmitter

Disconnect the receiver or remove the transmitter battery. Use your pushbutton switch only. If this solves the problem, your transmitter may be

defective. Disconnect the push-button switch and use your transmitter

only. If this solves the problem, the push-button switch or the line of the

push-button switch may be defective.

The door doesn’t open completely

Is the limit switch „OPEN” correctly set? Is the door jamming while

opening? Unlock the carriage manually (make the door running well).

Lubrificate and oil the pivotal points of the door. Increase the power.

The door doesn’t close completely and opens again

Is the limit switch „CLOSE” set correctly? Is the door jamming while

closing? Unlock the carriage manually (make the door running well).

Lubricate and oil the pivotal points of the door. Run through the automatic

learning cycle.

The emergency release doesn’t work

Is the limit switch „CLOSE” correctly set? If not, your opener switches off

under pressure. In this case the chain is under tension and therefore the

emergency release can hardly be unlocked. Make sure that the limit switch

is correctly set.

The light doesn’t work

Replace the bulb (230 V, max. 40 Watt)

The operator isn’t running smooth

Unlock the carriage of the opener. Move the door manually and make sure

that the door is well balanced (must come to a stop at each position).

The spring tension is too high or there is even a spring fracture.

The motor is buzzing but the door doesn’t move

The door is jamming.

The operator works, but the door doesn’t move

The carriage is unlocked. If you want to lock it, open the door, but not

completely, and let the opener run. The carriage locks in automatically.

The operator doesn’t work because of a power failure

Unlock the carriage with the help of the emergency release and open

the door manually. (If you have a garage where you can only enter from

outside: Unlock the door with the key and turn the door-handle, then your

opener will be unlocked. If you have a garage where you can also enter

from inside: pull at the Bowden cable hanging from the carriage.)

Additional messages only via the LED “Diag“

3 x blinking

Photo cell - either an obstacle was recognised by the photo

cell/hatch-door switch or one of the devices is damaged. Please

also check the wiring.

Page 21

Grombacher Straße 83

75045 Walzbachtal-Jöhlingen

Germany

www.seip.com

Myke Seip, Walzbachtal-Jöhlingen, 02.05.2009

TECHNIK

ANTRIEBSANTRIEBS

GmbH

We,

Wir,

Seip Antriebstechnik GmbH

Grombacher Straße 83, 75045 Walzbachtal-Jöhlingen, Deutschland

hereby declare, that the following products comply to the mentioned EC-regulations.

erklären hiermit, daß die nachfolgenden genannten Produkte den unten angegebenen

EG-Richtlinien entsprechen.

Type of Product / Produktart Garage Door Operator / Torantrieb

Product Name / Modell RP60A

Approved according to 2006/95/EC and 2004/108/EC / Geprüft nach 2006/95/EC und 2004/108/EC

Referring EC-regulations: / Angewandte harmonisierte Normen:

Electromagnetic Compatibility /

Elektromagnetische Verträglichkeit

EN 61000-3-2

Limits for harmonic current emissions /

Grenzwerte für Oberschwingströme

EN 61000-3-3

Limitation of voltage changes, voltage fluctuations and flicker in publik low-voltage supply systems /

Grenzwerte für Spannungsschwankungen und Flicker

EN 61000-6-3

Emission standard for residential, commercial and light-industrial environments /

Störaussendung für Wohnbereich, Geschäfts- und Gewerbereiche sowie Kleinbetriebe

EN 61000-6-2

Generic standards - Immunity for industrial environments

Fachgrundnorm - Störfestigkeit - Industriebereich

Low-Voltage Directive /

Niederspannungsrichtlinie

EN 60335-2

Particular requirements for drives for vertically moving garage doors for residential use /

Anforderungen für Antriebe von Garagentoren mit Senkrechtbewegung zur Verwendung im Wohnbereich

EN 60335-1

Safety of household and similar electrical appliances /

Sicherheit elektrischer Geräte für den Hausgebrauch

Safety in Use /

Nutzungssicherheit

EN 12453

Safety in use of power operated doors, requirements /

Nutzungssicherheit kraftbetätigter Tore, Anforderungen

EN 12445

Safety in use of power operated doors, Test methods /

Nutzungssicherheit kraftbetätigter Tore, Prüfverfahren

Forces

Betriebskräfte

EN 13241-1

Tested for Up-and-Over Doors and Sectionaldoors up to 4m wide and 2,50m high

Geprüft für Kipp- und Sektionaltore bis zu 4m Breite und 2,50m Höhe

EC Declaration of Confirmity

As to European Directives

Low-Voltage Directive 2006/95/EC

Electro-Magnetical Compatibility 2004/108/EC

EG-Konformitätserklärung

im Sinne der EG-Richtlinien

Niederspannungsrichtlinie 2006/95/EC

Elektromagnetische Verträglichkeit 2004/108/EC

Document No. AN-02052009

Dokument Nr. AN-02052009

21

Page 22

EC Declaration of Confirmity

in accordance with the Radio and Telecommunications

Terminal Equipment Act (FTEG) and Directive 1999/5/EC

(R&TTE Directive)

EG-Konformitätserklärung

gemäß dem Gesetz über Funkanlagen und Telekomm

unikationsendeinrichtungen (FTEG) und der Richtlinie

1999/5/EG (R&TTE)

Grombacher Straße 83

75045 Walzbachtal-Jöhlingen

Germany

www.seip.com

TECHNIK

ANTRIEBSANTRIEBS

GmbH

We, Wi r,

Seip Antriebstechnik GmbH

Grombacher Straße 83, 75045 Walzbachtal-Jöhlingen, Deutschland

declare that the product

erklären, daß das Produkt

SKR 433-1

Code B43A023004-1

Hand Transmitter as remote control for garage door operators

Handsender als Fernbedienung für Garagentorantriebe

(Short Range Device)

(Funkgerät geringer Reichweite (SRD))

complies with the essential requirements of §3 and the other relevant provisions of the FTEG (Article 3 of the R&TTE Directive),

when used for its intended purpose.

bei bestimmungsgemäßer Verwendung den grundlegenden Anforderungen des §3 und den übrigen einschlägigen

Bestimmungen des FTEG (Artikel 3 der R&TTE) entspricht.

§3(1)1, (Article 3(1)a)) does not refer to this type of product.

§3(1)1, Artikel 3(1)a) bezieht sich nicht auf diesen Produkttyp, es gibt hierzu keine Norm

Protection requirement concerning electromagnetic compatibility §3(1)(2), (Article 3(1)(b))

Schutzanforderungen in Bezug auf die elektromagnetische Verträglichkeit §3(1)2, Artikel 3(1)b))

EN 300 220-1/1997

EN 300 683/1997

EMV / EMC Directive 89/336/EEC;92/31/EEC;93/68/EEC

Myke Seip, Walzbachtal-Jöhlingen, 09.03.2010

Document No. FU-009032010

Dokument Nr. FU-009032010

and/und

SKR1W433

Code B43A623001

Wall Transmitter as remote control for garage door operators

Wandsender als Fernbedienung für Garagentorantriebe

(Short Range Device)

(Funkgerät geringer Reichweite (SRD))

complies with the essential requirements of §3 and the other relevant provisions of the FTEG (Article 3 of the R&TTE Directive),

when used for its intended purpose.

bei bestimmungsgemäßer Verwendung den grundlegenden Anforderungen des §3 und den übrigen einschlägigen

Bestimmungen des FTEG (Artikel 3 der R&TTE) entspricht.

§3(1)1, (Article 3(1)a)) does not refer to this type of product.

§3(1)1, Artikel 3(1)a) bezieht sich nicht auf diesen Produkttyp, es gibt hierzu keine Norm

Protection requirement concerning electromagnetic compatibility §3(1)(2), (Article 3(1)(b))

Schutzanforderungen in Bezug auf die elektromagnetische Verträglichkeit §3(1)2, Artikel 3(1)b))

EN 300 220-1 V2.1.1

EN 300 220-2 V2.1.2

EN 301 489-1 V1.6.1

EN 301 489-3 V1.4.1

EN 60950-1:2006

EMV / EMC Directive 2006/95/EC;2004/108/EC; 99/5/EC

22

Page 23

23

Loading...

Loading...