Page 1

m

SSH-8BLD-25

High

Lockstitch

For

Speed,

Heavy

Vertical

Needle,

Reverse

Single Needle,

Machine

Weight

Rotary

Large

Upper & Lower

Feed,

Operator's Guide

25

Material,

Hook,

inch

Feed,

Long

Arm

Page 2

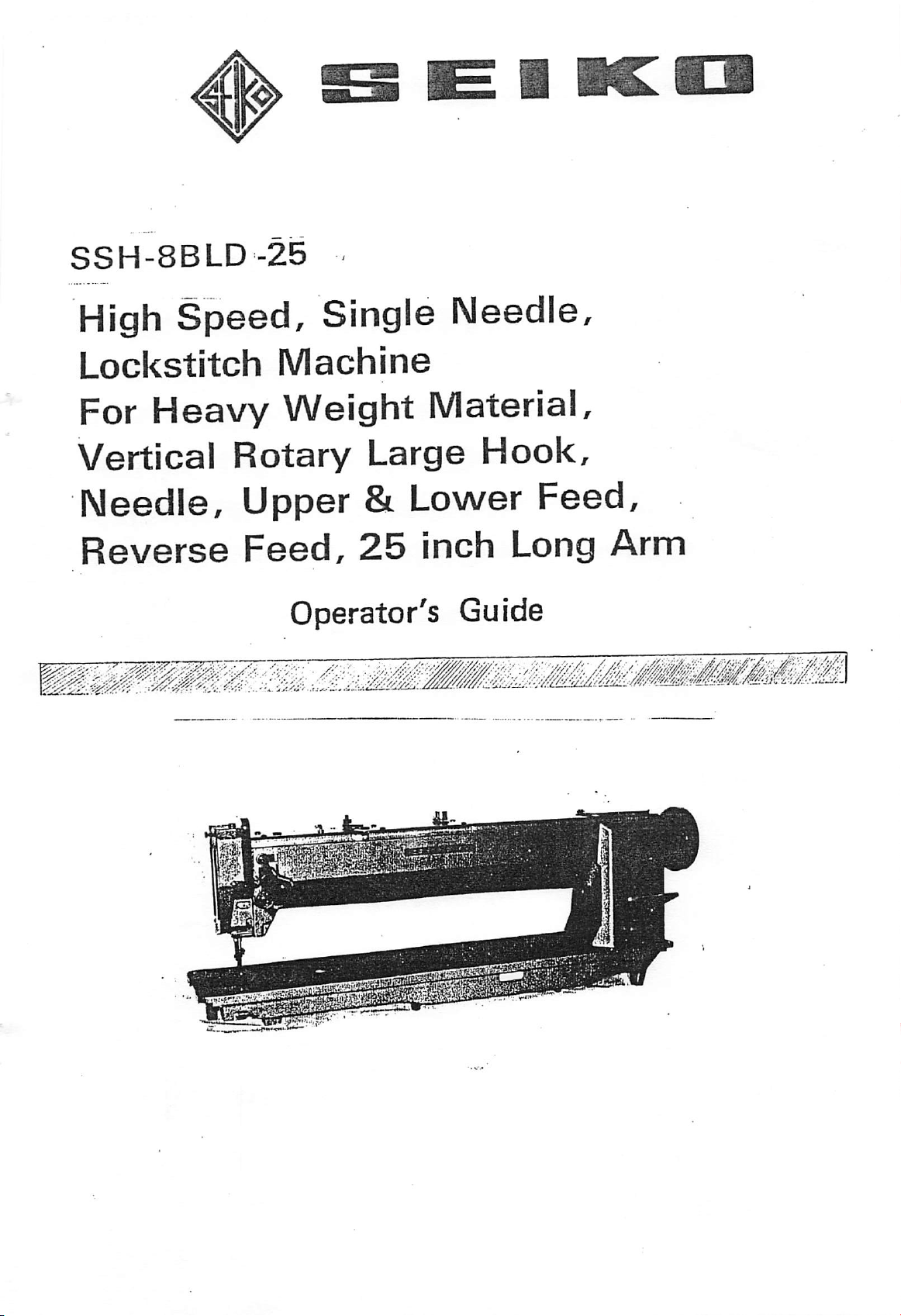

1.OILING

Wbea

•for

s-tartixag

a long

time

^rrtspeotive

by allows

Fig

5) .

0-iTirs

l™..;

screw(2,Fig.

in

adiustzieni:

ts:

fas

machine

without using

parts^and

Fig

1,2,3

to

<l»'o5l

5)

counter

IT ?

each

& 4.

hook:

mechanism:

flow,

clockivvise.

of

N

at

the

aim

all,

«»

oil

place

suj-^icienul/

inaicated

oU. oOSttotuig

by

-t

cri-5

Fig.

1

Fig.

4

Fig.

5

Page 3

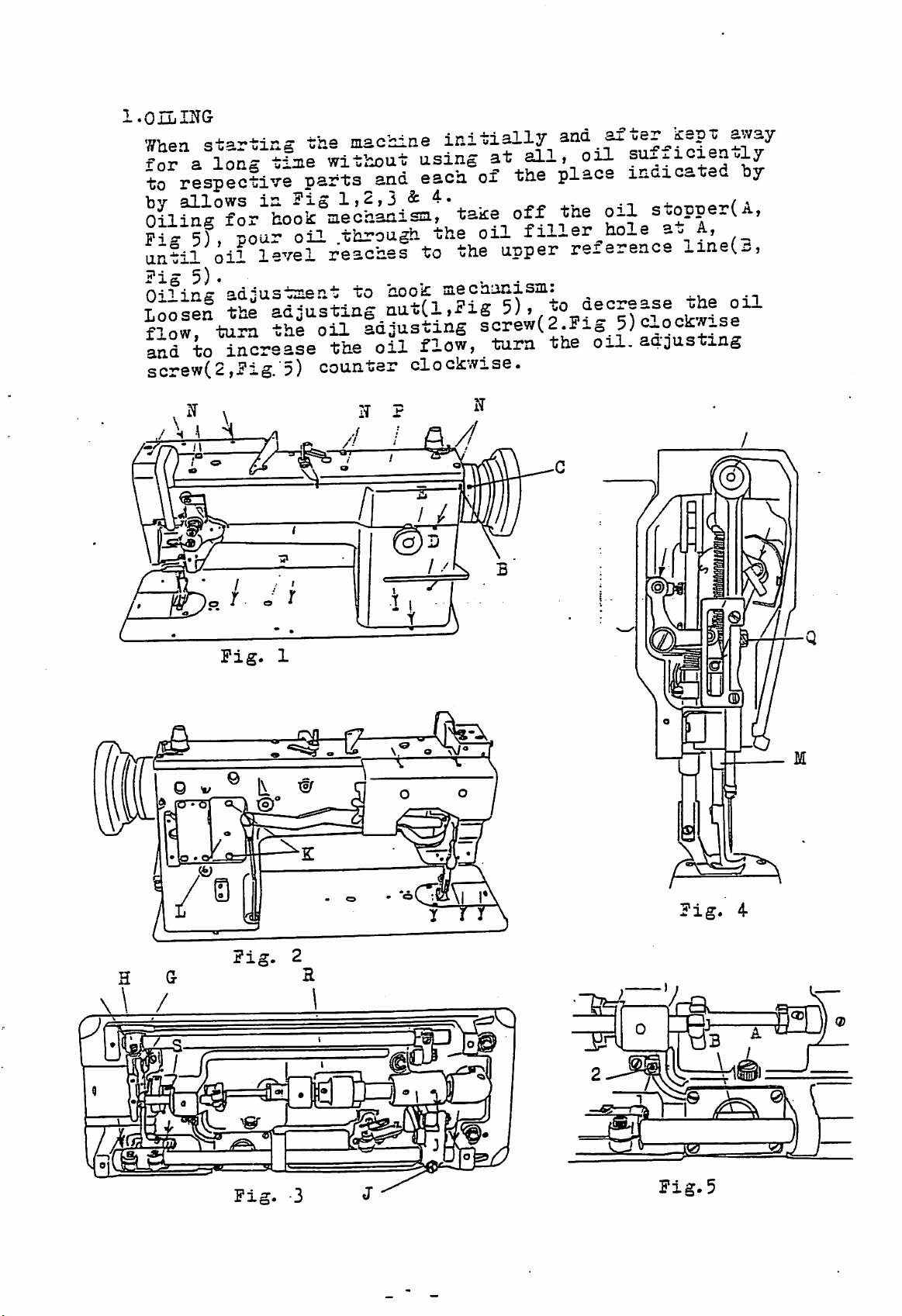

2.

ITSSI)I5

1.

Turn,

bar

2.

Insert

deeply

the"needle

3.

Tighten

the

moves

the

as

machine

up

needle

it

faces

the

to

will

needle

pull07

its

up

go,

the

highest

into

left.

set

o

toward

with

screw

—ITeedle

Set

Screw

point.

the

the

you

needle

long

securely.

until

bar

groove

needle

as

of

3.

WIlfDESG THi:

Place

thread

bobbin.

machine.

bobbin

as

Push

stopped

with

1.

ADJUSTMZJTT OP THE THHEAD

thread.

Loosen

turn

proper

se

the

volume.

cu''^ely.

2. ADJUS-l^fT

To

increase

nut

turn

8

cloclcwise

the

shown

The

at

the

the

adjusting

serrated

LOVTEH

on

lever(

lever

original

set

After

OP

THE

thje

Groove

r

THaSlH

spindle

by

Pig.7

5i^'ig.7)

will

screw.6

collar

WIOTIHG

winding

and

nut

^

'\f

ON

of

the

and

automatically

position

"ffHrDIHG

for

7

adjustment,

STHEHGTH

strength,

to

decrease

8

counter

'THE

wind

to

the

and

bobbin

several

left

and

after.bobbin

TDLULIE

adjusting

adjust

tighten

turn

the

clockwise.

winder

then

be

so

the

winding

and

times

start

released

fills

collar

as

to

the

screw

serrated

strenth,

lead

on

7

wind

the

and

up

and

6

rig

-

7

d.

—

Page 4

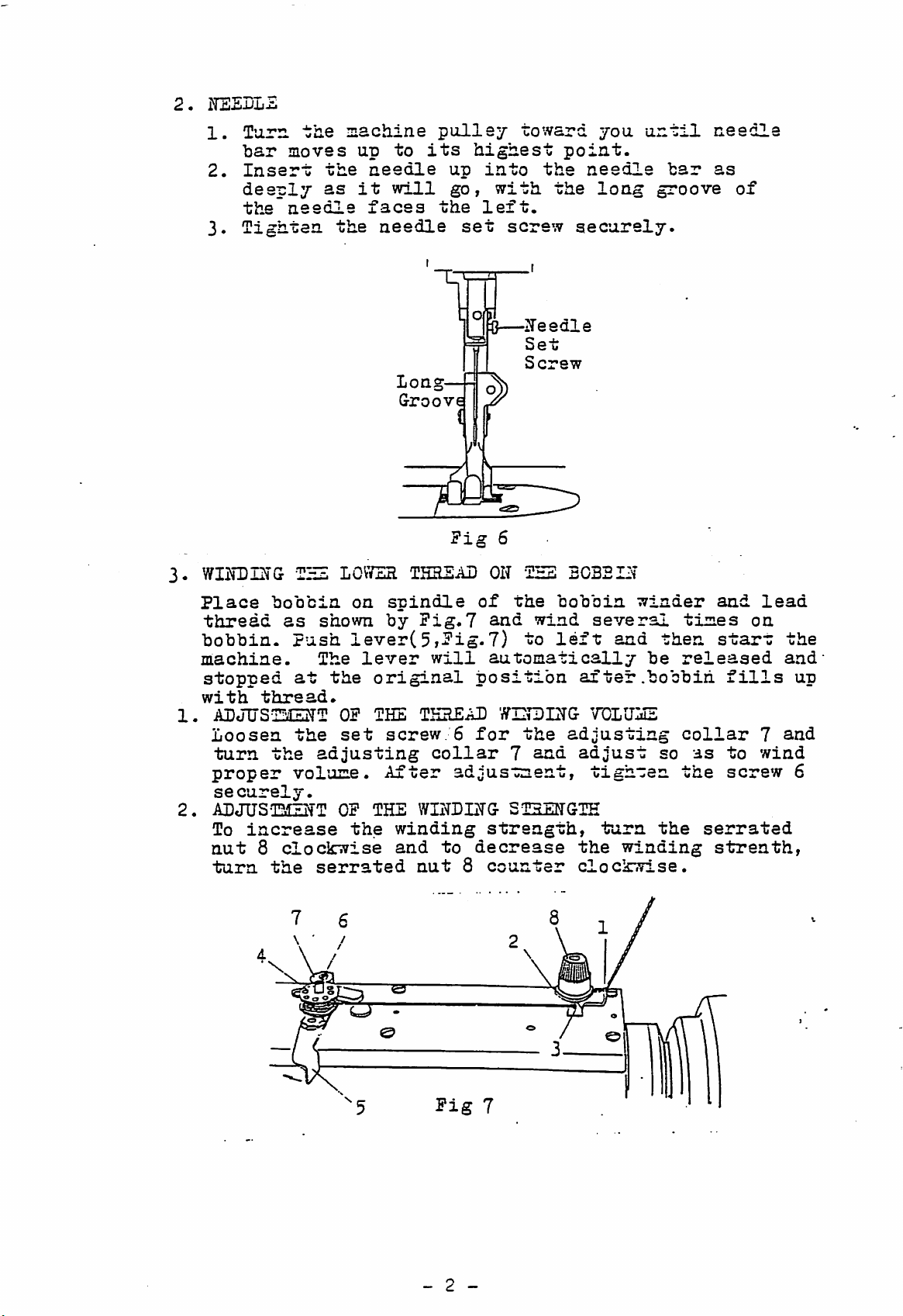

IITiZHTIilTG

4.

1.

2.

3-

4.

MD

^ign

(C.Pig.l).

Pull

remove

Hold

thumb

and

guide

the

up

the

and

place the threaded bobbin into

the

HEMOVIKG

arm-mark:(B

the

latch(l,Pig.8)

the

bobbin

threaded

forefinger

thread

BOBBIIT

_ _

.Pig.l)

,

case.

bobbin

of

into

and hook cap between

your hands as

the

slot(2,Pig

trie thread under the tension

into

Pull-out

the bobbin

go.

the

delivery

a

length

into

eye(4,Pig9).

of

5cm

the

hook

of

shaft

with

of

the

the

bobbin

hook

spring(2,?ig

the

thread

as

far

puiley-mark

case

shown

9)

-i'

cap.

and

PiS'9

1

lead

9)

and

and

...

and

inser.

as

it

will

and

the

lead

5.

Lead

thrsabiitg

the

eye

from

about

5cm

9.7

needle

thread

left

lengtho

to

as

right

fi

shown

Fig.lO

and

then

Pig.9

and

pull

thread

into

out the thread

needle

Pig

10

Page 5

6-

RSGULATIiS'G THHRAD

TSRiSIONS

7.

EEGOLATIIf(J

To

adjust

on

and

tension.

tension

turn

g|gaiG3ig3tfais—

PERFECT

TIGHT

TENSION

LOOSE

TENSION

TENSION

tension,

device

it(l,Figl2)

STITCHING

Fig

clockr.vise

OF

OF

NEEDLE

material

BOBBIN

NEEDLE

NEEDLE

THREAD

THREAD

THREAD

THREAD

11

0?

THE

UPPER

turn

the

counter-clockwise

(NEEDLE)

serrated

to

increase

THREAD

nut(l,Figl2)

tension

to

decrease

8.

regulating

The

lower

(l,Pig

the

thread

will

decrease

13).

TENisION

thread

Turning

tension,

it.

Fig

OF

tension

this

while

Fig

12

LOWER(BOBBIN)

is

controlled

screw

turning

1

13

clockwise

it

counter-clockwise

THREAD

by

the

will

screw

increase

- A -

Page 6

9.

ADJUSTMENT

Of

THE

THREAD

CONTROLLER.SPRING

Normally,

should

needle

pause

the

1

FOR

Loosen

(3»Fig

(For

s c r s w

2

TO

Loosen

(5,

Turn

lighten

turn

Tighten

adjustment.

hold

reaches

while

upper

MORE

the

14)to

less

AD^ST

the

Fig

the

it

the

thread

CONTROLLER

action,

THE

thread

slack:

to

raising

stop

screw(2,Fig

the

TENSION

serrated

of

the

of

through

ACTION

right

move

nut(4,

14).

tension

the

tension(to

stud(6.

counter-dockv/ise)

the

screw

and

controller

the

upper

materials,

the

needle

the

ON

for

more

it

to

OF

THE

Pig

Fig

strengthen

with

nut

upon

spring(l,Pig

thread

and

and

bobbin

THE

14),

THREAD:

move

action.

left).

SPRING:

14)

14)clockwise

and

the

screw

completion

until

it

should

passing

case.

the

Tighten

the

tension,

driver.

14)

the

of

stop

the

screw

to

of

10.

ADJUSTIVIENT

The

pressure

the

screw

To

increase

and

turn

OP

THE

of

in

the

the

it

counter-clockwise

PRESSURE

the

presser

hole(A,

pressure,

Pig

turn

ON

feet

15)

Fig

THE

the

to

14

MATERIAL

is

adjusted

with

screw

decrease

screw

clockwise

by

driver,

it.

Fig

15

- 5 -

Page 7

11.

REYEHSE

To

reverse

as

far

bTITCHING

stitching,

as

it

will.go.

press

down

the

lever(D,Pig

1)

12.

13.

adjustment

Turn

by

then

the

stitch

pressing

set

the:desired

ADJUSTMENT

FEET

Loosen

and

the

foot.

the

stud

feeding

Tighten

assembly

op

stitch

down

OP

THE

wing

presser

wing

length

the

LIPT

nut(l.

along

foot

nut

length

adjustable

lever(D,Pig

dial

OP

Pig.

the

and

upon

number

THE

16)

slot

push

completion

dial(E,Pig

1)

slightly,

just

ALTERNATING

and

-

Pig

16

move

move

down

above.

up

to

of

l),

PRESSER

the

link

to

lower

adjustment.

and

raise

this

14.

HOW

The

a

safety

If

clutch,

1.

2.

3.

4.

TO

RE-SET

sewing

clutch.

it

should

the

Depress

the

machine

a

safety

Hold

turning

make

the

an

then,

(3,

Pig

To

increase

(4,

Pig

stop

After

screw(4.

button(P,

turning

clutch

THE

hook

the

and

become

following

button(P,

and

clutch

clutch(Left,l,Pig

the

machine

half

stop

17)

17)

rotation

screw(4,Pig

of

the

clockwise

Pig

completion

Pig

1)

the

machine

mechanism

SaPETY

its

necessary

adjustments

turning

will

the

clutch(Left,l,

spring

17)

of

in

will

CLUTCH MECHiiNISM

mechanism

Pig

the

be

disengaged.

pulley

of

the

17)

tension,

and

1)

17)

to

are

to

re-engage

are

in

the

machine

by

by

your

clutch(Right,2,Pig

is

visible

turn

decrease

counter-clockwise.

the

adjustment,

the

bed

pulley

normally

plate

by

your

be

protected

the

req^uired.

bed

pulley

your

hand

plate

finger,

so

in

Pig

17).

the

it,

depress

of

the

hand,

re-engaged.

by

safety

of

stron^y,

"as

to

the

hole

stop

screw

turn

the

machine,

a

safety

17),

the

Pig

- 6 -

17

Page 8

15.

ADJUSTMZiJT

OP

THE

HEIGHT

OF

TRti

FEED

DOG

The maxinuiii

surface

To

adjust

Turn

needle

Loosen

adjust

or

lowering

Securely

of

adjustment.

the

of

machine

to

the

the

tighten

K

height

the

this

its

hell

height

the

needle

height:

lowest

crank

hell

VISMUVH-

of

pulley

of

the

the

feed

plate

so

point.

screw(G.

the

feeder

crank(H,

screw

1mm

is

as

upon

dog

from

normally

to

lower

Fig

Fig

hy

3)

raising

3).

completion

Fig

18

the

1mm.

the

and

16.

RELATIVE

PLATE

1.

Set

2.

Turn

feed

3*

Loosen

4.

Adjust

needle

hole

5.

Securely

POSITION

the

stitch

the

machine

dog

to

the

to

plate

on

the

tighten

its

screw(J.

he

32.1mm

to

feed

OF THE FEEDER TO THE NEEDLE

length

pulley

highest

the

dog.

the

32.1mii

to

Fig

from

center

screw.

minimum.

so

as

point.

3).

the

of

Fig

to

edge

the

19

raise

of

needle

the

the

- 7 -

Page 9

17.

THE

POSITION

HOLE OP THE PEEDER

1.

Loosen

cover(L,

2.

Loosen

3.

Holding

frameCM,

needle

on

the

Pi g

20).

4. Tighten

cover{L,

the

Pig

the

the

Pig

to

feed

the

Pig

OP

THE

screw(K,

^)•

screw(l,

hottom

4) move

the

dog and

screw(K,

2).

•s

NEEDLE

center

Pig

Pig

of

the

it

of

tighten

Pig

AIO

THE

NEEDLE

4) and remove

^

20;.

needle

so

as

the

needle

the

2) and

bar

to

put

screw(l,

close

hole

the

rock

the

the

18.

TIMING

It

on

is

mainted

When

reaches

dog

When

THE

is

important

its

downward

the

scarf

the

must

start.

adjustment

procedure to

21):

1.

Loosen

top cover(P,

2.

Normally

the

the

3. Turn

Imm

reverse

"turn,

both

the

camC3,

arm

the

up

from

the

the

NEEDLE

that

stroke

at

all

of

top

surface

is

change

screw(N,

Pig

put

shaft.

machine

stitching

Pig

its

cam(

needle

the

3,

WITH PEED

the

timing

and

times.

the

needle

of

required,

the

position-of

Pig

1).

reference

21) on

pulley

lowest

leverXD,

Pig

and_the

the

point

21)

Pig

DOG

the

the

1)

to

and

feeder

20

between

feed

on

the

feed

use

and

the

remove

line(2,

7

ditch(l,

place

and moving

Pig

1)

set

rest.

the

dog

movement

downward

dog,

following

the

cam(3,

Pig

Pig

the

needle

up

and

this

at

the

the

« \

21;

needle

_

stroke

feed

arm

or

21)

the

down,

the

?ig

x-

of

at

point

B

Pig

- 8 -

21

Page 10

19.

ADJUSTMENT

CONNECTION

OP

AND

THE

PEED

CLEAEANCE

PORK

COLLAR

BETWEEN

PEED

POfiKED

20.

1.

2.

Incorrect

of

feed

Pig

21)

overheating,

To

adjust

1.

To

increase

(6,

clockwise.

To

decrease

(7>

counter-clockwise.

2.

This

the

clearance.

TIMING

Set

the

pulley

about

should

At

hook

2mm

this

point

be'2.4mm,

point

to

If

and

0.1mm.

the

loosen

Turn

the

set

hook.

To

and

Pig

as

Please

the

Therefore,

adjustment.

the

center

screws

adjust

the

3) and. move

may

V

clearance

forked

will

this;

Pig

21)

Pig

machine

between

toward

be

ditch

21)

adjustment

stitch

from

at

time,

and

further

the

sewing

the

three

hook

of

and

the

needle

require.

note

keep

between

connection

bring

etc.

and

and

the

the

irregular

clearance,

turn

clearance,

turn

the

the

should

pulley

THE HOOK AND THE

length

you

and

its

the

center

normally,

upper

the

needle

hook

set

shaft

the

toward

to

when

lowest

of

the

end

clearance

hollow.should

should

screw(R,

to

align

needle.

re-check

clearance

hollow,

the

one

of

of

hook

the

Re-tighten

hook

the

shaft.

screw

loosen

two

the

the

and

stitch

loosen

screw(7,

loosen

screw(6.

be

done

you

minimum,

the

point,

needle.

measurement

of

the

not

the

Re-tighten

the

timing

between

to

the

screws

on

V

screws.

fork(4,

feed

to

NEEDLE

needle

the

needle

between

be

Pig

the

the

right

ditch

fork

length

with

get

turn

be

timed

3).

hook

of

two

is

Pig

the

Pig

the

Pig

turning

correct

the

bar

hook

between

eye

the

about

correctly,

point

the

the

hook

screws(S,

or

placed

during

21)

collar(5>

or

screw

21)

screw

21)

machine

raises

point

should

hook,

0.05

with

three

sewing

point

to

left

on

2.4mm

2mm

Pig

o

22

- S -

0.05-0.1mm

Pig

23

Page 11

21.

ABJUSTfiEEIi'I?OfBOBBIN

The

bobbin case opener

of the needle thread loop by

the bobbin case holder

movement of same. This

instant

opens

a clearance

on the bobbin case holder

retainer permitting the

(iT'^wn

1.

CLiAHifflCE

HOOE

1,

2

3. Tighten the screw(l,

2

POSITION

Place the

by "S" on V

3.

ADJUSTMENT

1.

2.

easilv

Loosen

Adlust

and

the opener by

releasing

or to the

clearance

shown

Turn

fig

the

through

BErffEEN

the

screw(l,

the

clearance

shaft

left

between

26 , „ o^n n

Of

TTTE

opener

one

of screw(3,

ditch

Of

OPERATION:

machine

THE

bushing(2,

as

of the

the pfoj'ection of

its

travel.

Press

make

the

the

opener to

right

side

on the bobbin case holder(6,

of

the

hook

retainer(5»

CASE

facilitates

creating

movement

the

OPENEH

,,

r,- ^

Pig

means

may

the

CAM:

pulley

hook:(4,-

the

clear^ce

OPENjiH

the

passage

slightly

a slighu

nudging

rotating

at

gap

and

needle

gap

•

AHE

2A>

between

between

the tab of the

thread

FHOJECTIOH

• . „

projection

notch

loop

of +

J?ig

be required.

two

parts

fig

24)

fig

hook:

until

24)

is

securely.

24)

which

shaft.

the

to the

The

standard

O.omm

is indicated

opener

fig.25) .extremely

« ^

projection

between

Fig

fig

25)

of hook and

25)

and

0.2mm

as

,

to

be

OP

ox

hooK

as

,

presses

on

the tao

shown

I'ig

3

24

This

screwCT,

adiustment

fig

can be done by

25).

Pig

0,2mm

25

loosening

0.8mm

Pig

the

26

-

10

-

Page 12

22.

TIMING

OF

THE

VIBHaTING

PllESSER

FOOT

This

pulley

foot,

the

feeder

to,

and

presoer

needle

To

adjust

and

adjust the rotating position of the

27)

and

tighten

is

the

normal

toward you,

the

vibrating

ealier

when

foot

point

this,

faster

the

timing

after

presoer

than the needle

the needle

should

has

leave

loft

loosen the

or

slower as

screws.

when

lowering the

foot

raines,

the

feeder

the

feeder.

two

may

turn

the

machine

presoer

should

point

tlie

reach

comes

vibrating

afber

the

sorews(l, Fig 2?)

carar2,

be

desired,

Fig

27

-

11

-

Page 13

SEIKO

Head

Office

Show

4

Osaka

Room

Branch

SEWING

:11-3,

Imado1-chome,

Telex:

2657148

:21-7,

:5-10,

Asakusa

Terada-cho

1-chome,

-i_-

MACHINE

Taito-ku,

SEIKOJTelefax:

2-chome,

n

Tokyo

Taito-ku,

TennojI-ku,

111,

Japan.

03-873-6596

Tokyo

111,

Osaka

OeaUa

CO.,

Cable:

Japan.

543,

Tel:

03-872-6173-4

SEIKOSEWMCO

Tel:

Japan.

JSDSn.

LTD.

03-872-6493

Tel:

06-779-7578

Tfil?

06-779-V578

(Export

TOKYO

Dept.)

Loading...

Loading...