Seiko SK-6, SK-6F, SKM-26 Instruction Manual

OPERATING

MODELS

INSTRUCTIONS

S^^-6/W-6F

SKM-26

SEIKO

SEWING

TOKYO,

MACHINE

JAPAN

CO.,

LTD

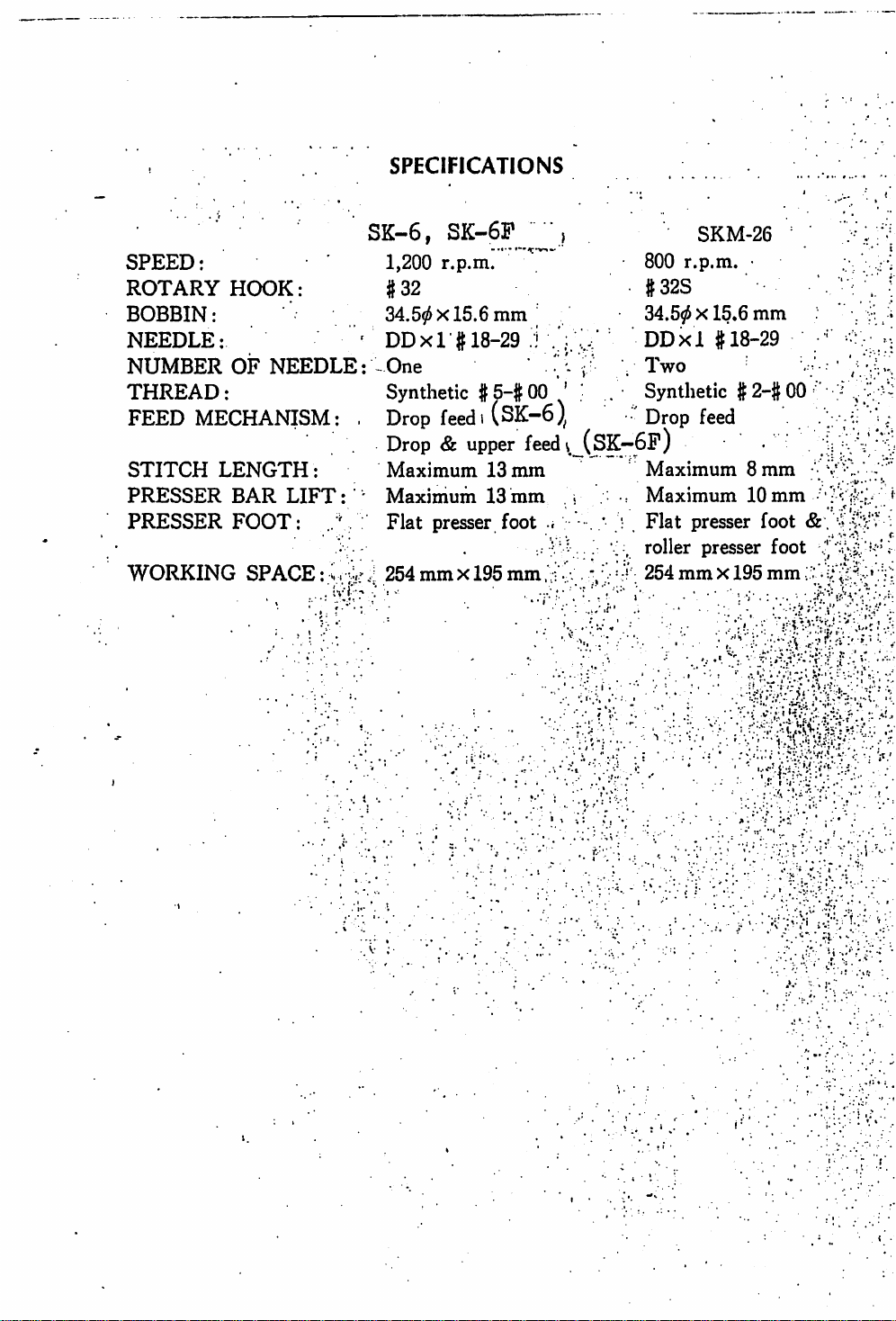

SPECIFICATIONS

SPEED:

ROTARY

BOBBIN:

NEEDLE:

NUMBER

THREAD:

FEED

STITCH

PRESSER

PRESSER

WORKING

MECHANISM:

HOOK:

OF

NEEDLE

LENGTH

BAR

FOOT:

SPACE:;.v

:

LIFT:

SK-6,

1,200

#32

34.50x15.6

DDxl #

SK-6P

r.p.m.

18-29

: One •/

Synthetic

.

Drop

feed1(SK~6)^

Drop&upper

Maximum

Maximum

Flat

presser foot i

.

254mmX195mm.:

-vi:-

mm

#5-#

13

13

J

00

feedv,

mm

mm

800

•

#32S

34.50X15.6

^

DDxl

V

Two

Synthetic

•

Drop

(SK—6P)

Maximum

Maximum

Flat

roller presser foot

254

SKM-26 \

r.p.m.

• ; /

mm

#18-29 '

#2-#00

'

feed

8 mm

10

presser foot & . :

mm

X195

mm

mm

VV

-

••••

:•

"f^

[

i

• I :

!

..

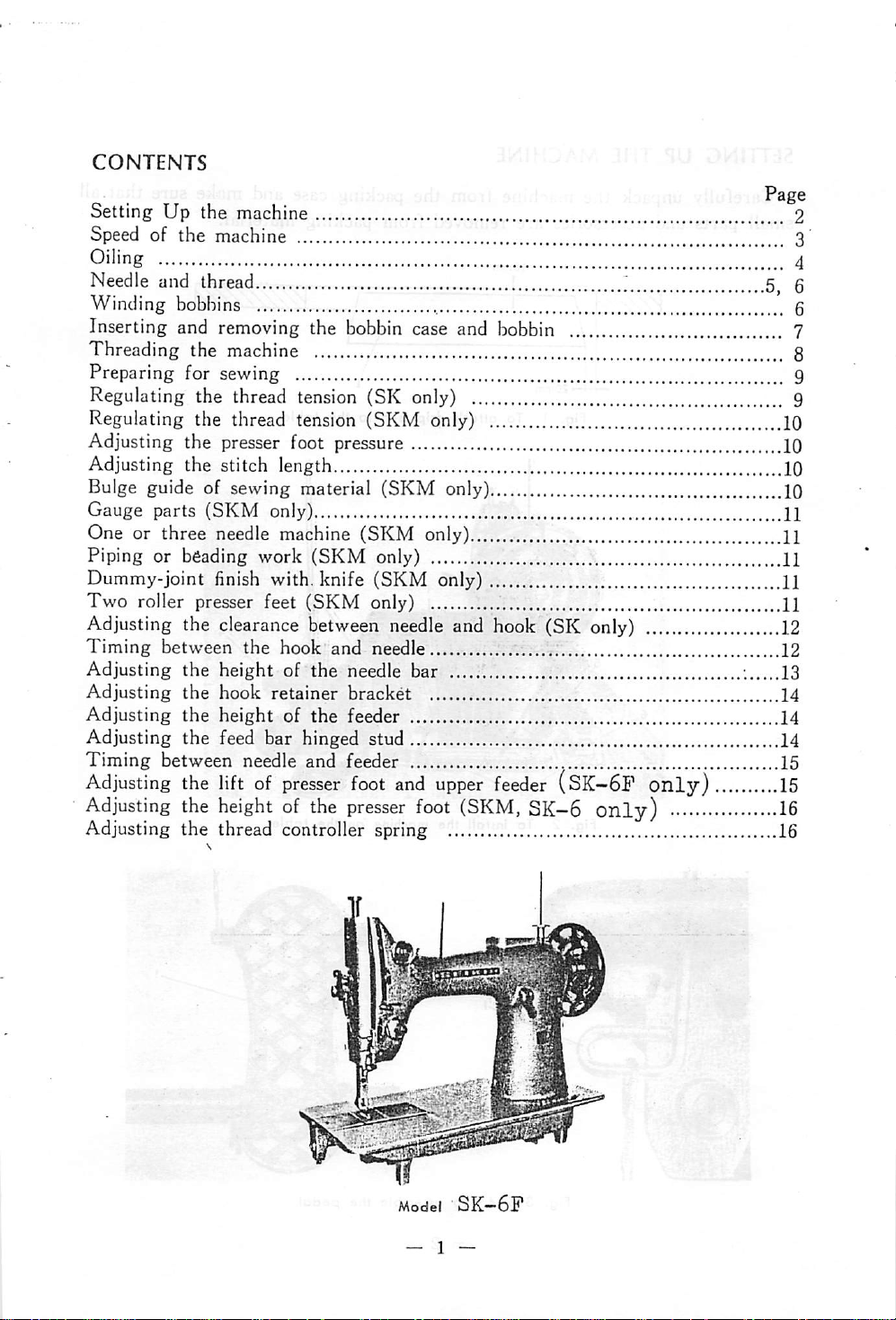

CONTENTS

Page

Setting Up the machine 2

Speed

of the machine 3

Oiling 4

Needle

Winding bobbins g

Inserting and removing the bobbin case and bobbin 7

Threading the machine 8

Preparing for sewing 9

Regulating the thread tension (SK only) 9

Regulating the thread tension (SKM only) 10

Adjusting the presser foot pressure 10

Adjusting the stitch length 10

Bulge guide of sewing material

Gauge parts (SKM only) H

One or three needle machine (SKM only) 11

Piping or beading

Dummy-joint finish with, knife

Two

Adjusting the clearance between

Timing

Adjusting

Adjusting

Adjusting

Adjusting the feed bar hinged stud 14

Timing

Adjusting

Adjusting

Adjusting the thread controller spring 16

and

thread

(SKM

work

(SKM

roller presser feet (SKM only) 11

only) 11

(SKM

needle

between

the

the

the

between

the

the

the

hook and needle 12

height of

hook

height

needle

lift

of

the

retainer

of

the

and

presser

heightofthe

needle

bracket

feeder 14

feeder

foot

presser

only) 10

only) 11

and hook (SK only) 12

bar

and

upper

foot

feeder

(SKM,

(SK-6P

SK—6

only)

only)

5^

; 13

14

15

15

16

g

Model

SK—6P

- 1 —

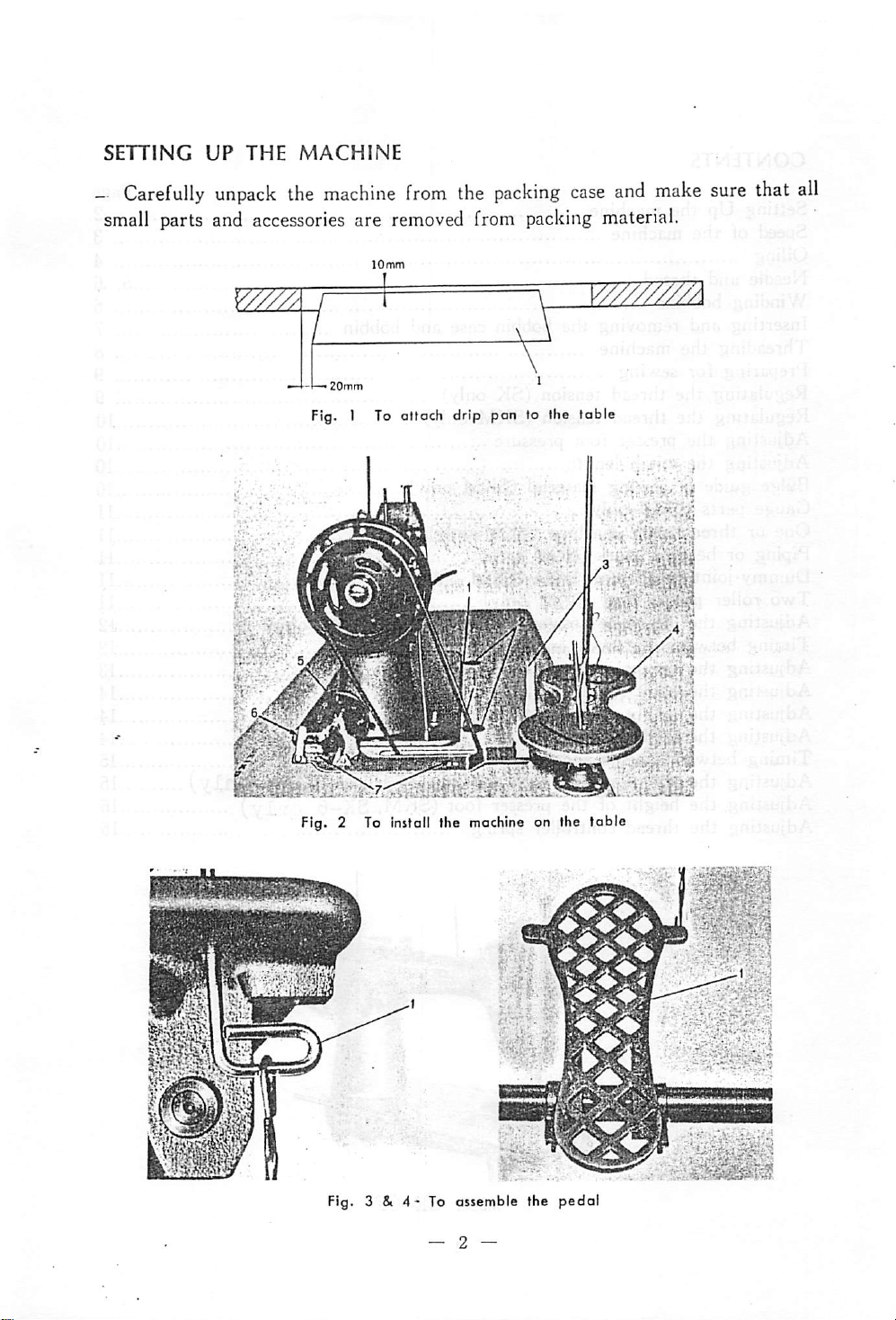

ase

and

ma

ig material.

Fig. 2 To Install the

Fig. 3 &

4'

To assemble the pedal

machine

A

on the table

ti.'v30''~40

ii'

s.

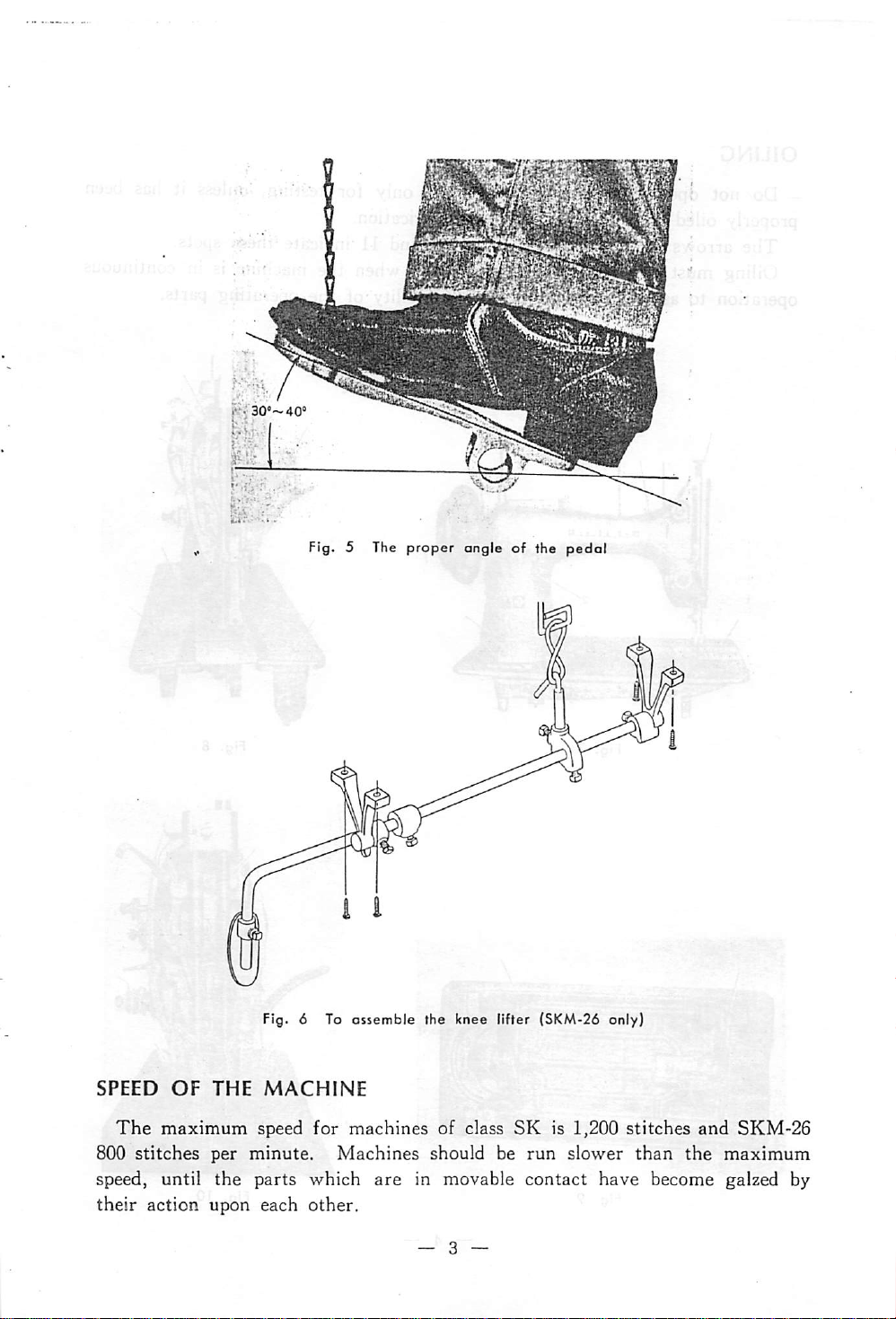

Fig. 5 The

proper

angle of the

pedal

i

Fig. 6 To ossemble the knee lifter (SKM-26 only)

SPEED

The

800

OF

maximum

stitches

THE

per

MACHINE

speed

minute.

for

machines

Machines

of class

should be

SK

run

is 1,200

slower

stitches

than

and

the

SKM-26

maximum

speed, until the parts which are in movable contact have become galzed by

their

action upon each

other.

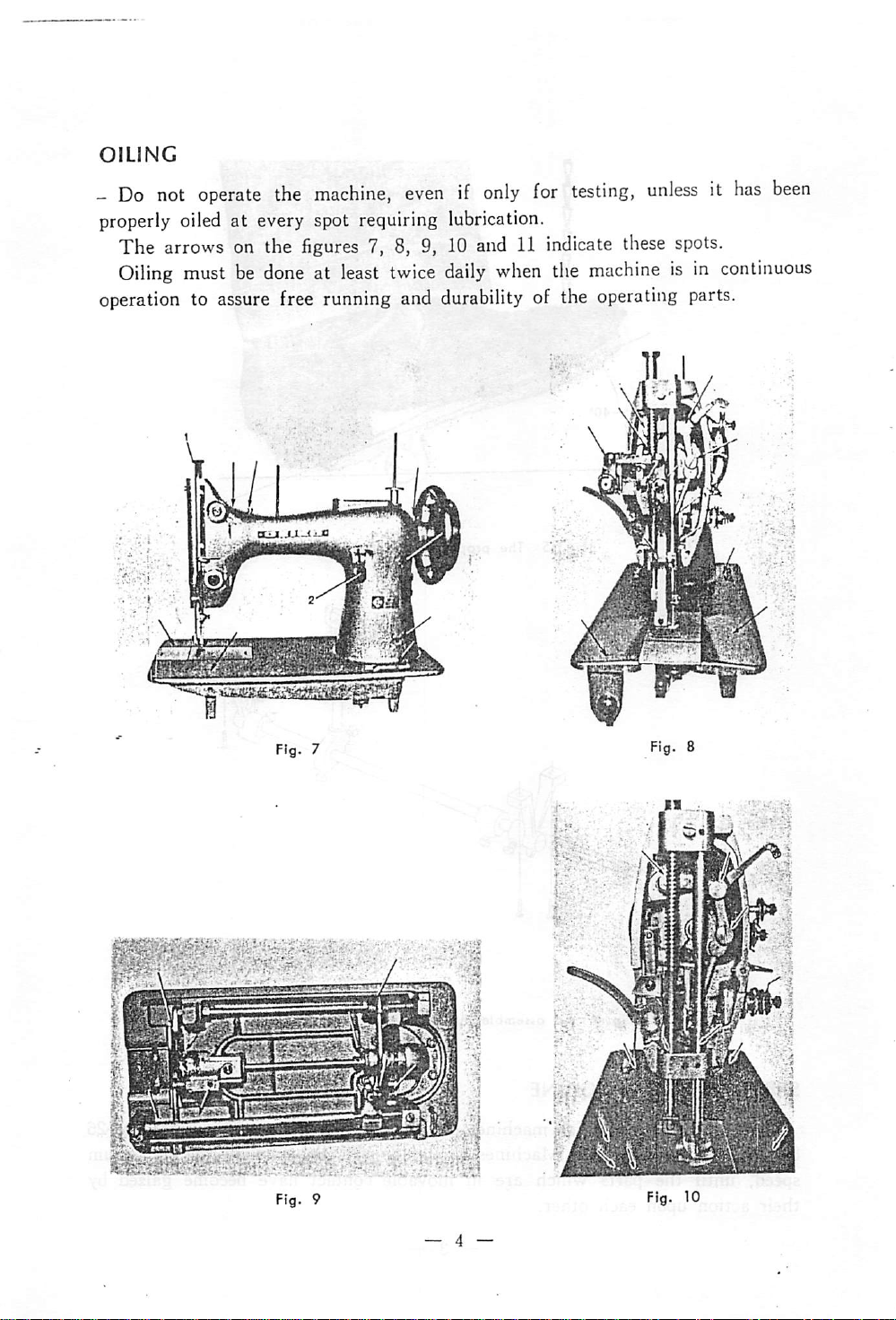

OILING

-

Do

not

operate

properly oiled at every spot requiring lubrication.

The arrows on the

Oiling

operation

must

to

assure

the

figures

be

doneatleast

free

machine,

7, 8, 9, 10 and

running

evenifonly

twice

and

daily

durability

11

when

for

testing,

indicate

the

of the

unlessithas

these

spots.

machineisin

operating

parts.

ir I

i

rV....

mESp

been

continuous

lol

n

®!5

Loading...

Loading...