i

PW, LPW

OPERATOR'S

GUIDE

PW-6,6B,7,7B,8,8B,8M,8BM,26,26B,27,27B,28.28B

LPW-6.6B,7,7B.8,8B.8M,8BM,26,26B.27,27B.28,28B

LPW-6L.6BL,7L,7BL,8L.8BL,26L,26BL,27L,27BL,28L,28BL

LUBRICATION (PW

type)

Use

white

spindle oil. When starting

the

machine initially

and

after

kept

away

for

a long

time

without

usingatall, oil

sufficiently to respective necessary parts before starting operation and pre-running. ( i ...• oiling point)

Fig.

3

Model PW, LPW-8M, 8BM

Fig.4

Fig.

5

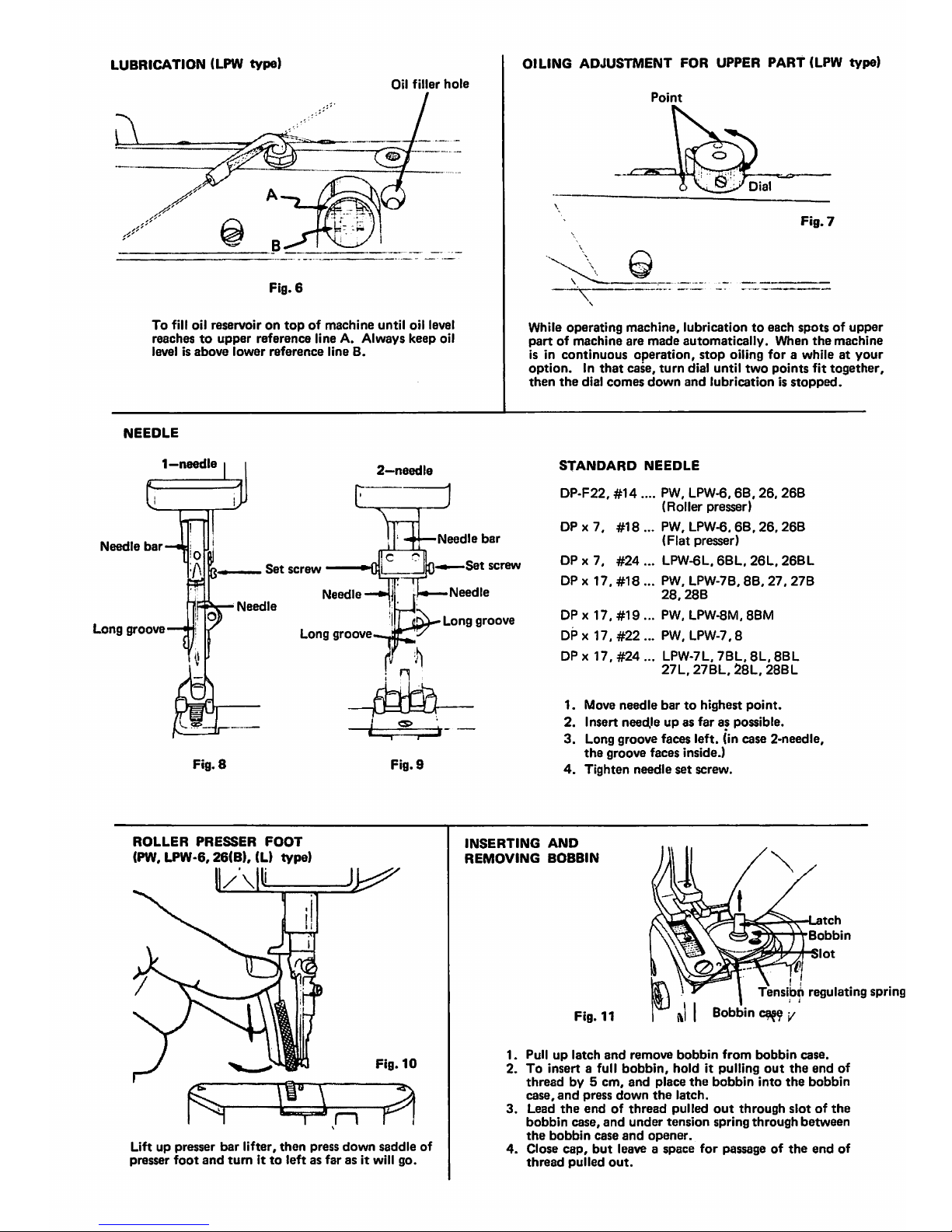

LUBRICATION (LPW

type)

Oil

filler

hole

OILING ADJUSTMENT FOR UPPER PART (LPW type)

Point

Fig.

6

To

fill

oil

reservoirontopofmachine

until

oil

level

reachestoupper

reference

lineA.Always

keep

oil

levelisabove

lower

reference

line

8.

NEEDLE

1—needle

2—needle

L J

_ J

J L

['

)

Fig.

7

"V

While

operating

machine,

lubricationtoeach

spotsofupper

partofmachine

are

made

automatically.

When

the

machine

is in

continuous

operation,

stop

oiling

forawhileatyour

option.

In

that

case,

turn

dial

until

two

points

fit

together,

then

the

dial

comes

down

and

lubricationisstopped.

STANDARD

NEEDLE

..

PW,

LPW-6.6B,26,

26B

(Roller

presser)

Needle

bar

Needle

bar

DP-F22,#14.

DP

X

7.

#18

DPx

7.

#24

DPx

17,

#18

DPx

17.

#19

DPx

17,

#22

DPx

17.

#24

..

PW,

LPW-6,

68,

26,268

(Flat

presser)

..

LPW-6L.6BL,26L,26BL

..

PW.

LPW-7B.

88.

27.

278

28.288

..

PW.

LPW-8M,

88M

..

PW,

LPW-7,8

Set

screw

Needle

F

Needle

Long

groove

Long

groove

Fig.

8

ROLLER

PRESSER

FOOT

(PW,

LPW-6,26(B),

(L)

type)

k:^

Qm Set screw

Needle

Long

groove

LPW-7L.78L.8L,88L

27L,278L,28L.

288L

Fig.

9

1.

Move

needle

bartohighest

point.

2.

Insert

needileupas

faraspossible.

3. Long groove faces left, (in case 2-needle,

the

groove faces inside.)

4.

Tighten

needle

set

screw.

Fig.

10

INSERTING

AND

REMOVING

BOBBIN

Fig.

11

3.

Tensibh regulating spring

Bobbin

c^^

y

Latch

Bobbin

Slot

Liftuppresser

bar

lifter,

then

press

down

saddle

of

presser

foot

and

tumitto

leftasfar

as it will

go.

Pulluplatch

and

remove

bobbin

from

bobbin

case.

To

insertafull

bobbin,

holditpulling

out

the

end

of

threadby5

cm,

and

place

the

bobbin

into

the

bobbin

case,

and

press

down

the

latch.

Lead

the

endofthread

pulled

out

through

slotofthe

bobbin

case,

and

under

tension

spring

through

between

the

bobbin

case

and

opener.

Close

cap,

but

leaveaspace

for

passageofthe

end

of

thread

pulled

out.

WINDING

BOBBIN

1. Placea bobbin on the bobbin winder spindle as far as possible.

2.

Lead

threadasshownbyFig.12

and

wind

several

timesonbobbin.

3. Press down lever for drive then start machine. Pulley will be

disengaged

from

V-belt

automatically

after

bobbin

fillsupwith

thread.

o Winding

strength:

Adjustablebyserrated

nut.

Serrated

nut

THREADING

NEEDLE

1-NEEDLE

II

Pulley

Lever

'>1 '..•cTN

Screw

(2)

o

Winding

amount:

Adjustablebyscrew

(2).

LPW

Screw

(1)

o

Uneven

winding:

Adjustablebyloosen

screw

(1)

and

move

windertorightorto

left

•

Fig.

12

PW

Fig.

15

Fig.

13

o Raise needle

bartohighest

point

and

lead

thread

from

thread

stand

the

following numerical

order

1(A)~11(K).

oTHREAD

NEEDLE

1—needle

from

lefttoright

2—needle

from

insidetooutside

THREAD

TENSION

Needle

^ thread

ataiatatate'

^Material

Bobbin

Perfect

stitching

thread

Tight

terisionofneedle

thread

Loose

tensionofneedle

thread

Fig.

16

NEEDLE

THREAD

Less

Serrated

nut

Fig.

17

To

adjust,

turn

serrated

nut

BOBBIN

THREAD

' \

Tension

regulating

screw

h V ,

it'More'^

Fig.

18

To

adjust,

turn

adjusting

screw

TO

REGULATE

PRESSER

FOOT

PRESSURE

ADJUSTING

LIFT

OF

ALTERNATING

PRESSER

FEET

(Comiwund

feed

with

walking

foot

machina

only)

PW

type

LPW

type

More

Less

Wing

nut

Fig.

19

To

adjust,

loosen

wing

nut

and

move

link,

and

stud

assembly

along

slot.

ADJUSTING

STITCH

LENGTH

Number

(stitches/inch)

Fig.

22

Pressing

down

buttonA,turn

pulley

slowly

toward

you.

Then

plunger

will

enter

into

notchinfeeding

mechanism.

Hold

the

plunger-down

and

turn

pulley

either

forward

or

rearward so

that'desired

number

on pulley may come at

markonarm.

Then,

release

the

plunger.

RE-ENGAGE

SAFETY

CLUTCH

MECHANISM

(except

PW.

LPW-6,6B,

26,26B)

m

Fig.

24

1.

Remove

any

foreign

matter

which

may

have lodged

in

hook.

Do

not

use

any

sharp-edged

tools.

2. Pressing

buttonBand

turn

pulley rearward slowly

to

re-engage

safety

clutch.

Fig.

20

More

^ i 1

^

Less

A

© I

i @

The

pressureonthe

material

shouldbeas

lightaspossible,

while

still

sufficienttoinsure

correct

feeding.

REVERSE

STITCHING

(only

wHh reverse

stitch

mechanism.)

iff

Lever

evT—

Fig.

23

To

reverse

stitching,

press

down

the

lever ps

far

as it will

go.

TRIMMER

(8M,BBM

type)

Lever

Fig.

26

Fig.

21

Screw

Fig.

26

When

replacementofknife,

loosen

two

screws.

SEIKO

SEWING

MACHINE

CO.,LTD.

11-3,

imado

1-chome,

Taito-ku,

Tokyo

111-6534,

Japan

Tel:81-3-3872-6173--4{Ovsiseas Group) Fax:81-3-3873-6596

Loading...

Loading...