Page 1

FLAT

BED

MACHINES

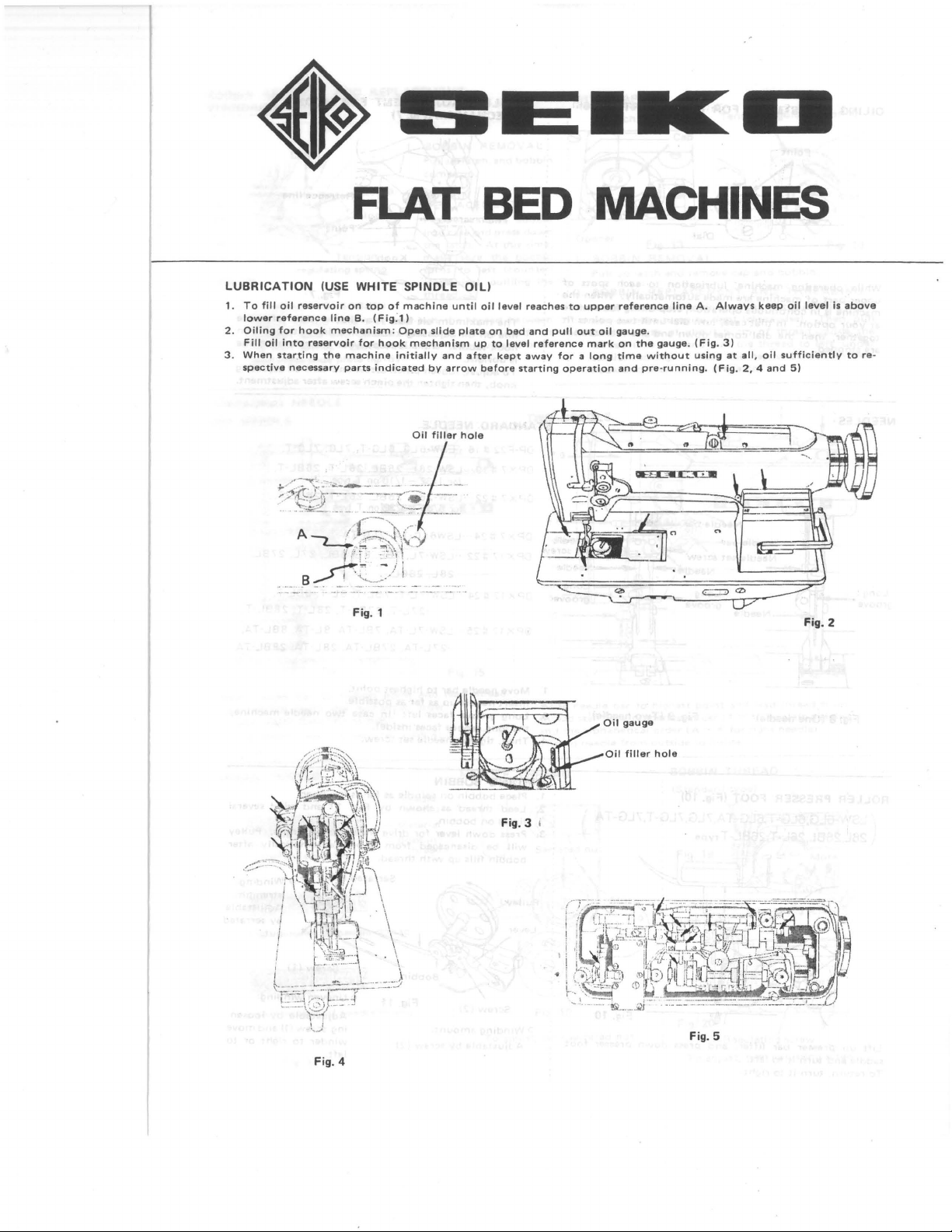

LUBRICATION

1.

To

fill

oil

2.

3.

lower

Oiling

Fill

When

spective

reference

for

oil

into

starting

reservoir

hook

necessary

(USE

WHITE

on

top

line

B.

mechanism: Open

reservoir

the

for

machine

parts

Fig. 1

SPINDLE

of

machine

(Fig:l)

hook

initially

indicated

until

slide

mechanism

and

by

arrow

Oil

filler

OIL)

plate

after

hole

oil

up

before

on

to

level

bed

level

kept

reaches

and

reference

away

starting

to

upper

pull

out

mark

for a long

operation

oil

Oil

reference

gauge

.

on

the

time

without

and

pre-running.

gauge

line

A.

gauge. (Fig.

using

Always

3)

at

(Fig.

keep

all,

oil

2, 4 and

oil

level

sufficiently

5)

Fig. 2

is

above

to

re-

Fig. 4

Fig. 3 1

Oil

filler

hole

Fig. 5

Page 2

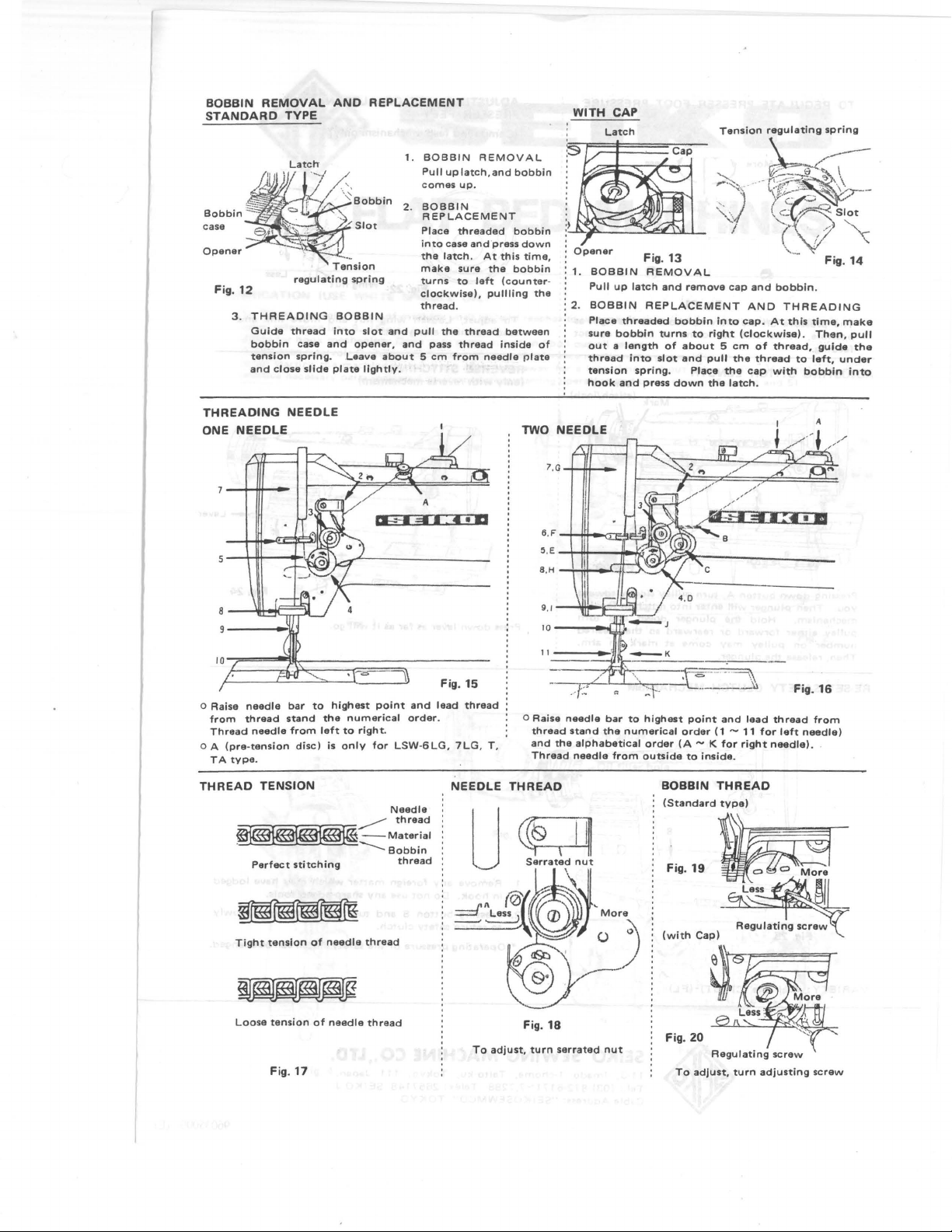

BOBBIN

STANDARD

Bobbin

case

Opener

Fig.

12

3 .

THREADING

Guide

bobbin

tension

and

REMOVAL

TYPE

Latch

regulating

thread

case

spring.

close

slide

AND

REPLACEMENT

Bobbin

Slot

Tension

spring

BOBBIN

into

slot

and

opener,

Leave

plate

lightly.

1.

BOBBIN

Pull

comes

2.

BOBBIN

REPLACEMENT

Place

into

the

make

turns

clockwise),

thread

and

pull

and

pass

about 5 em

up

threaded

case

latch.

sure

to

.

the

thread

from

REMOVAL

latch,

up.

and

left

thread

and

·press

At

this

the

(counter

pullling

between

inside

needle

bobbin

bobbin

down

time,

bobbin

the

plate

of

·

WITH

;

Opener

:

1.

BOBBIN

Pull

:

2.

BOBBIN

Place

sura

out a length

thread

tension

hook

CAP

Latch

up

threaded

bobbin

and

latch

into

spring.

Fig.

13

REMOVAL

and

remove

REPLACEMENT

bobbin

turns

to

right

of

about 5 em

slot

and

pull

Place

press

down

the

Tension

~

'.~)

,

I

regulating

~

spring

----

~-

~

~Slot

c·\

/:/'

_v

~

Fig.

cap

and

bobbin.

AND

Into

the

the

latch.

THREADING

cap.

At

of

thread

cap

this

thread,

with

(clockwise).

to

bobbin

time,

Then,

guide

left,

make

under

14

pull

the

into

THREADING

ONE

NEEDLE

o Raise

from

Thread

o A

(pre-tension

TA

tVPe.

THREAD

~~~==~~~~=~

~--Material

needle

thread

needle

TENSION

Perfect

NEEDLE

bar

to

stand

the

from

left

disc)

is

stitching

highest

numerical

to

right.

only

for

---_Bobbin

point

LSW·6LG,

Needle

thread

thread

and

order

Fig.

lead

.

7LG,

NEEDLE

15

thread

T,

TWO

7.G+-IH---

6

F'

'

5, E

0

Raise

thread

and

Thread

THREAD

NEEDLE

-t-#1r-"<iJ~IE!;!j

-4~1--·-+tJ

needle

stand

the

alphabetical

needle

bar

the

from

~'-'

·

to

highest

numerical

order

outside

/1..-1."\\

point

order

(A-K for

to

BOBBIN

(Standard

and

( 1

~

inside.

THREAD

type)

Fig. 19

lead

11

right

for

needle)

Fig.

thread

left

16

from

needle)

.

Tight

tension

of

needle

thread

Loose

tension

of

needle

Fig.

thread

To

17

adjust,

Fig.

turn

18

serrated

nut

More

Fig.

20

....s...:~:::.........

Regulating

To

adjust,

-

-

-f:O;:;.:"

screw

turn

adjusting

screw

Page 3

OILING

While

upper

machine

at

your

together,

are

stopped.

ADJUSTMENT

Point

operating

part

of

machine

is

in

continuous

option.

then

In

the

machine,

are

that

dial

FOR UPPER

lubrication

made

automatically.

operation,

case,

turn

comes

down

stop

dial

until

and

PART

to

each

oiling

the

(Fig.

Fig. 6

spots

When

for a while

two

points

lubrications

61

of

the

fit

OILING

MECHANISM

The

maximum

line

on

oil

hook

saddle. While

is

upright.

To

adjust,

knob,

then

ADJUSTMENT

(fig.

7)

oil

flow

adjusting

loosen

tighten

it

pinch

the

knob

stops

pinch

is

available

is in a

screw

FOR

when

and

screw

HOOK

when

line

the

turn

after

reference

with

point

reference

oil

adjusting

adjustment

on

line

.

NEEDLES

Long

groove

Fig. 8 (One needle)

ROLLER

PRESSER FOOT (Fig. 10)

Fig. 9

Jfoii~~--Long

(Two

LSW-6LG,6LG-T,6LG-TA,7LG,7LG-T,7LG-TA )

(

26L,26BL,26L-T,26BL-T

type

l+o---Needle

groove

needle)

STANDARD

DP·F22 # 16

OPX7 # 19

OPX7

OPX7

OPX 17

OPX

17

OPX 17

1.

Move

Insert

Long

the

Then,

long

needle

needle

groove

tighten

2.

3.

4.

WINDING

1.

Place

Lead

times

Press

will

bobbin

bobbin

thread

on

down

be

2.

3.

NEEDLE

..

·LS

..

·LSW·26L. 26BL.

for

#22

..

·LSW·26L,

for

5/64' -3/32' on T type

#24

..

·LSW6LG·TA.

#22

..

·LSW·7L,

28L,

#24

..

·LSW·7L·T.

#25

..

·LSW·7

·

27L·TA, 27BL

bar

up

faces

groove

faces

needle

BOBBIN

on

as

bobbin

.

lever

disengaged

fills

up

with

W·6LG. 6LG·T.

1/32'-1/16'on T type

26BL.

78L, BL.

28BL

·27L·T.

L·TA, 7BL·TA, BL·TA.

to

highest

as

far

as

possible

left

(In

inside)

set

screw

spindle

as

shown

by

for

drive

from

thread.

7LG

.

7BL·T,

27BL·T.

point.

case

.

far

Fig.

then

V·belt

7LG.

26L·T.

26L·T,

·TA

BBL.

BL·T,

·TA.

.

two

.

as

it

11

start

automatically

7LG·T,

26BL·T

26BL

·T.

27L,

27BL.

BBL·T

,

28L·T.

28BL·T

BBL·TA.

28L

·TA,

28BL·TA

needle

machine,

will go.

and

wind

machine. Pulley

0

Winding

strength

Adjustable

by

nut.

.

.

several

after

:

serrated

Fig.

10

o

Lift

saddle

To

return,

up

presser

and

turn

turn

bar

lifter,

and

press

down

presser

it

to

left.

It

to

right.

foot

Winding

Adjustable

Screw

(2)

amount

by

:

screw

Fig.

(2)

11

o

Uneven

Adjustable

ing

screw

winder

left

.

winding:

by

(1)

and

to

right

loosen

move

or

·

to

Page 4

TO

REGULATE

PRESSER

FOOT

PRESSURE

ADJUSTING

PRESSER

(Compound

LIFT

FEEl'

feed

OF

ALTERNATING

mechanism

only)

More

"

_;.~

::-o_-

:

::·.-~=-

~

·

...

.

:_l=~~::-.-::

The

pressure

·.

o~

. 'i>osslble, '

f~eding.

'

ADJU~TI!'IG

Pressing

you.

mechanism. Hold

pulley

number

Then,

down

Then

either

on

release

while

·

STITCH

button

plunger

forward

pulley

the

plunger

the

still

~1?

..

~-

~-:;:L~_

-_

f

'r'

.

~-:

~ ~~-:-

.

Fig. 21

material

sufficient

LENGTH

A,

turn

enter

or

.

pulley

Into

plunger

rearward

come

will

the

may

)

-

should

to

down

at

Less

insure

slowly

notch

so ·that

mark

be

as

in

feeding

and

on

light

correct

toward

turn

desired

arm

as

.

To

adjust, Loosen

stud

assembly

REVERSE

(only

with

Pr

ess

down

along

STITCHING

reverse

mechanism)

lever

as

far

wing

slot

as

nut

.

it

will go .

and

move

link

and

RE

-SE:r

SAFETY

Fig

;

25

'

VARIETY: Available

CLUTCH

(C)•(BT)•(FL)

MECHANISM

. ' .

SEIKO

11 Tel.: (03)

Cable

1.

Remove

in

2.

Pressing

to

•

Operating

any

hook. Do

button B and

return

safety

pressure

•

SEWING MACHINE CO.,LTD.

3,

lmado 1-chome,

872-6171-7,7288

Address: "SEIKOSEWMCO" TOKYO

Taito-ku,

Telex: 2657148

Tokyo,

foreign

not

use

clutch.

of

111

matter

any

sharp-edged

turn

the

safety

Japan.

SEIKO

which

pulley

clutch

J

may

have

tools

rearward

can

.

be

lodged

slowly

changed

.

96035000- (E)

Loading...

Loading...