Page 1

24-pin Dot-matrix Printer

FB-90

OWNER'S MANUAL

0

Page 2

1. No part of this manual may be reproduced in any form.

2. This manual is subject to change without notice.

3. This manual was prepared with the greateset care. If you should find any unclear points,

mistakes, or omissions, please contact us.

4. We will not bear any responsibility for unsatisfactory results from the use of this printer

despite item 3 above.

* EPSON is a registered trademark of S.Epson Corporation.

* LQ-2550 is a registered trademark of S.Epson Corporation.

* IBM is a registered trademark of International Business Machines Corporation.

* IBM 2391 is a registered trademark of International Business Machines Corporation.

* HP is a registered trademark of HEWLETT-PACKARD Company.

* PCL is a registered trademark of HEWLETT-PACKARD Company.

* DeskJet 500 / RuggedWriter 480 are registered trademarks of HEWLETT-PACKARD

Company.

* Windows is a registered trademark of Microsoft Corporation.

Copyright © 1999 SEIKO Precision Inc.

Warning

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can raditae frequency energy and, if not installed and

used in strict accordance with the instructions, may cause harmful interference to radio

communications. However there is no guaratee that interfernce will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television recption, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

— Reorient or relocate the receiving antenna

— Increase the separation between the equipment and receiver.

— Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

— Consult the dealer ro an experienced radio/TV technician for help.

“It is necessary to use shielded interconnect cables to insure compliance with FCC Class

B limits for radio frequency emissions.”

Caution : Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Page 3

1. No part of this manual may be reproduced in any form.

2. This manual is subject to change without notice.

3. This manual was prepared with the greateset care. If you should find any unclear points,

mistakes, or omissions, please contact us.

4. We will not bear any responsibility for unsatisfactory results from the use of this printer

despite item 3 above.

* EPSON is a registered trademark of S.Epson Corporation.

* LQ-2550 is a registered trademark of S.Epson Corporation.

* IBM is a registered trademark of International Business Machines Corporation.

* IBM 2391 is a registered trademark of International Business Machines Corporation.

* HP is a registered trademark of HEWLETT-PACKARD Company.

* PCL is a registered trademark of HEWLETT-PACKARD Company.

* DeskJet 500 / RuggedWriter 480 are registered trademarks of HEWLETT-PACKARD

Company.

* Windows is a registered trademark of Microsoft Corporation.

Copyright © 1996 SEIKO Precision Inc.

Warning

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can raditae frequency energy and, if not installed and

used in strict accordance with the instructions, may cause harmful interference to radio

communications. However there is no guaratee that interfernce will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television recption, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

— Reorient or relocate the receiving antenna

— Increase the separation between the equipment and receiver.

— Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

— Consult the dealer ro an experienced radio/TV technician for help.

“It is necessary to use shielded interconnect cables to insure compliance with FCC Class

B limits for radio frequency emissions.”

Caution: Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Page 4

OWNER'S MANUAL

1999 SEIKO Precision Inc.

C

24-pin Wide-Carriage

Dot Matrix Printer

FB-900

As an ENERGY STAR Partner, SEIKO Precision Inc. has determined that this product meets

the ENERGY STAR guidelines for energy efficiency.

- Outline of the International ENERGY STAR Office Equipment Program -

The International ENERGY STAR Office Equipment Program is an international program

that promotes energy saving through the use of computers and other office equipment. The

program backs the development and dissemination of products with functions that effectively

reduce energy consumption. It is an open system in which business proprietors can participate

voluntarily. The targeted products are office equipment such as computers, displays, printers, facsimiles,

and copiers. Their standards and logos uniform among participating nations.

Page 5

How to use this maunal

This manual describes the operation procedures for the 24-Pin Wide-Carriage Dot

Matrix Printer. Read through this manual before using the printer. Keep this

manual near the printer and refer to it whenever necessary.

Sections 1 and 2 describe the basic procedures, including unpacking, setup and

key operations. Install and setup the printer as described in these sections.

Section 3 and subsequent sections describe the functions and software commands

of the printer. Refer to these sections when necessary.

This manual is organized as shown below.

1. Setting up the printer

2. Control panel operations

3. Setup options

4. Functions

5. Bar code and enlarged character function

6. Troubleshooting

7. Interface specifications

8. Software commands

9. Software setup functions

10. Specifications

11. Character set table

Index

Software command list

Read this manual thoroughly to use the printer properly.

—How to use this manual—

Precautions for use

Organization of this manual

Page 6

Symbols used in this manual

How to use this maunal

A caution symbol

Care should be taken in order to operate the

printer correctly.

This symbol indicates a note that is useful for

operation.

1.

2.

3.

These item numbers show the sequence of

operation. Perform the operations in the

order shown.

The symbols used in this manual have the following meanings.

—How to use this manual—

This symbol indicates that personal injury

may occur if this caution warning is ignored.

!

CAUTION

Caution

Display on the LCD before

the key is pressed

Display on the LCD

1. MULTIPART

2.HEAD ADJUSTMENT

Display on the LCD after the key is pressed

Press the key.

To the next step

Page 7

Contents

Preface

How to use this manual

Cautions for use

Organization of this manual

Symbols used in this manual

● Major functions..................................... i

● Cautions................................................. iv

Safety Cautions............................

iv

Cautions in setting up..................

iv

Cautions in operation...................

iv

● Unpacking the printer......................... v

Unpacking the printer................. vi

● Dimensions........................................... vii

● Components and functions................ viii

Appearance of the printer...........

viii

Components and functions.........

ix

Operation panel explanation 1.. x

Operation panel explanation 2. xi

Options and consumables....... xii

Maintenance............................ xiii

1. Setting up the printer...................... 1-1

● Connecting the printer to

the power source.................. 1-1

● Installing the ribbon cassette........... 1-2

Installing the ribbon cassette..1-2

● Paper path............................................ 1-4

Path of fanfold paper................ 1-4

Path of cut sheet paper............ 1-5

● Selecting the paper path.................... 1-6

● Paper..................................................... 1-8

● Selecting the paper form

..................1-10

● Loading fanfold paper

(Front tractor)

..........................1-12

(Rear tractor)............................ 1-16

● Loading cut sheet paper

(Manual paper feeding)............ 1-19

● Printing using the cut sheet feeder

(Optional)

.............................1-22

● Running the self-test.......................1-27

● Connecting the printer to

the computer...........................1-28

Parallel interface....................1-28

Serial interface.......................1-29

● Input data hexadecimal dump list...1-30

● Link between paper path (PATH)

and paper form (MEMO)..........1-31

2. Control panel

operations

......................... 2-1

● Control panel operations................... 2-1

Control panel............................ 2-1

Fuction keys............................. 2-1

LCD........................................... 2-5

3. Setup options.................................... 3-1

Outline of the

setup modes..... ......3-1

Available function in the

setup modes........... 3-1

Entering the setup

modes.................... 3-1

● Operations on the setup mode...........3-2

Keys for setting......................... 3-2

Setting example in EXTENDED

SETUP MODE.... 3-3

● Setup mode summary (1).................. 3-4

● Setup mode summary (2)

.................. 3-5

● Factory default setting..................... 3-6

#01 Multipart............................................. 3-8

#02 Head adjustment............................... 3-9

#03 TOF adjustment.............................. 3-10

#04 Page length..................................... 3-11

#05 Paper width..................................... 3-12

#06 Top margin..................................... 3-13

#07 Bottom margin............................... 3-14

#08 Left margin..................................... 3-15

#09 Right margin................................... 3-16

#10 Character quality............................ 3-17

#11 Character font................................. 3-18

#12 Character pitch............................... 3-19

#13 Line feed pitch................................ 3-20

#14 Enlarging/Reducing print.............. 3-21

#15 Paper Fastener................................ 3-22

#16 Perforation...................................... 3-22

#17 Fanfold feed.................................... 3-23

#18 Paper Quality.................................... 3-23

#19 Saving data in format memory...... 3-24

#20 Loading data from format

memory................................ 3-24

#20 Emulation........................................ 3-25

#21 Character table (HP)....................... 3-25

#22 Character table (EPSON)............... 3-26

#23 Character table (IBM).................... 3-26

Page 8

#24 National font (EPSON).................. 3-27

#25 Code page...................................... 3-28

#26 Alternate graphics mode (AGM)

(IBM).................................. 3-28

#27 CR code function............................ 3-29

#28 LF code function............................ 3-29

#29 Accent character............................ 3-30

#30 Zero font style................................ 3-30

#31 Horizontal tab................................ 3-31

#32 Locking page length...................... 3-31

#33 Locking font................................... 3-32

#34 Locking character pitch................. 3-32

#35 Locking character quality.............. 3-33

#36 Locking character table.................. 3-33

#37 FF code function / TOF ................. 3-34

#38 Graphic Quality.............................. 3-35

#40

Validity of bar code and

enlarged character

................ 3-36

#41

Bar code type

................................... 3-37

Bar code specifications.........

3-38

#42 Bar code size................................... 3-39

#43 Enlarged character size.................. 3-39

#44 Software setup................................ 3-40

#50 PCL mode (HP).............................. 3-40

#51 Secondary character table (HP).... 3-41

#60 Setting option.................................. 3-41

#61 Paper path....................................... 3-42

#62 Automatic scrolling........................ 3-42

#63 Out-of-paper detection.................... 3-43

#64 Skew detection............................... 3-43

#65 Paper jam detection....................... 3-44

#66 Line feed speed.............................. 3-44

#67 Auto scroll position........................ 3-45

#70 Interface.......................................... 3-46

#71 Printer select command................... 3-47

#72 Parity bit (Serial I/F)................... 3-47

#73 Data length (Serial I/F)............... 3-48

#74 Stop bit (Serial I/F)...................... 3-48

#75 Protocol (Serial I/F)..................... 3-49

#76 Baud rate (Serial I/F)................... 3-49

#77 Serial error (Serial I/F)................ 3-50

#78 CTS signal (Serial I/F)................. 3-50

#79 CD signal (Serial I/F)................... 3-51

#80 DSR signal (Serial I/F)................. 3-51

#81 Input buffer size.............................. 3-52

#82 BUSY/ACK signal timing

(Parallel I/F)....................... 3-53

#83 Data latch timing

(Parallel I/F)....................... 3-53

#84 Error Status (Parallel I/F)............... 3-54

#90 Printing direction........................... 3-55

#91 Display language on LCD............. 3-55

#92 Locking panel keys........................ 3-56

#93 Locking reset key........................... 3-56

#94 Printing panel setting..................... 3-57

#95 Printing setup list........................... 3-57

4. Functions........................................ 4-1

● High speed printing............................. 4-1

● Enhancing the copying capability

for multipart forms................. 4-2

● Setting the printing start position........ 4-2

● Feeding perforation to the cutter

position................................... 4-3

● More stable paper feeding.................. 4-3

● Automatically feeding perforation to the paper

cutter position in the standby condition.. 4-4

● EEPROM initialization ...................... 4-5

● Correcting vertical misalignment........ 4-6

● Using various types of paper............... 4-8

● Executing test printing......................... 4-9

● Key shortcut function........................... 4-9

● Setting the application software......... 4-10

● Connecting the printer in the

HP envioronment................. 4-12

5. Bar code and enlarged

character function

................. 5-1

● Bar code type.......................................5-1

Outline of bar code function

........ 5-1

Makeup of bar code....................... 5-1

Presettable bar code function list.5-2

Bar code command list................. 5-2

(1) Bar code type.......................................... 5-2

(2) Element width........................................ 5-3

(3) Bar code height..................................... 5-3

(4) Setting HRI on and off........................... 5-3

(5) HRI font.................................................. 5-4

(6) Check character.................................... 5-4

Contents

Page 9

(7) Starting the bar code data sequence.... 5-4

(8) Ending the bar code data sequence.... 5-5

(9) Bar code data sequence......................... 5-5

(10) Printing density.................................... 5-5

(11) Guide bar expansion............................ 5-5

(12) Start and stop characters..................... 5-6

(13) Barcode rotational angle...................... 5-6

(14) Disabling HRI of the start

and stop characters................... 5-6

(15) Value input mode.................................. 5-6

(16) Initializing the bar code mode.............. 5-7

Additional explanation of bar code

commands................................. 5-7

◆

Data processing in the bar

code data sequence................... 5-7

◆

Printing bar codes..................................... 5-8

◆

HRI........................................................... 5-9

◆

Error processing...................................... 5-10

◆

Code 128 subset transition rule............. 5-11

◆

UPC-E conversion rule......................... 5-12

◆

Calculating the check character............ 5-12

◆

Other....................................................... 5-14

◆

Element printing.................................... 5-14

● Enlarged character function

........... 5-16

Outline of enlarged character

function................................... 5-16

Enlarged character command list.. 5-16

(1) Executing backspacing......................... 5-17

(2) Executing line feeding.......................... 5-17

(3) Executing form feeding........................ 5-18

(4) Executing carriage return..................... 5-18

(5) Initializing the

enlarged character mode........ 5-18

(6) Arrangement of enlarged characters..... 5-19

(7) Cell magnification for enlarged

characters............................... 5-19

(8) All-character set for enlarged

characters................................ 5-20

(9) Selecting an enlarged character font..... 5-20

(10) Height expansion for enlarged

characters................................ 5-21

(11) HMI for enlarged characters............... 5-21

(12) VMI for enlarged characters............... 5-22

(13) Setting and canceling the enlarged

character mode...................... 5-22

(14) Enlarged character cell offset............ 5-23

(15) Enlarged character pitch.................... 5-23

(16) Enlarged character quality.................... 5-24

(17) Enlarged character rotational angle..... 5-24

(18) Setting and canceling enlarged

character smoothing................. 5-25

(19) Enlarged character top offset............... 5-25

(20) Setting and canceling underlining

of enlarged characters.............. 5-26

(21) Enlarged character widthwise

expansition................................5-26

(22) Horizontal printing position for

enlarged characters.................. 5-27

(23) Vertical printing position for

enlarged characters.................. 5-27

◆

Enlarged character print samples.......... 5-28

6. Troubleshooting............................. 6-1

● Functional error messages

................ 6-1

● Operational error messages.............. 6-2

● Troubleshooting................................. 6-6

7. Interface specifications............... 7-1

● Parallel interface................................. 7-1

Input connector......................... 7-1

Pin configuration...................... 7-1

Timing chart.............................. 7-2

Input/output conditions............. 7-2

Signal explanations................... 7-3

Input signals to the printer........ 7-3

Output signals from the printer...7-4

● Serial interface

.................................... 7-5

Input connector........................ 7-5

Pin configuration...................... 7-5

Timing chart.............................. 7-5

Input signals to the printer........ 7-6

Output signals from the printer.. 7-7

Contents

Page 10

Handshaking protocol................ 7-8

DTR (READY/BUSY)

protocol..................7-8

X-ON/X-OFF (I)/(II) protocol. 7-9

Special notes............................ 7-10

ETX/ACK protocol................. 7-11

Baud rate................................. 7-11

Serial data organization........... 7-11

Automatic serial/parallel

selection.......................... 7-11

8. Software commands..................... 8-1

● EPSON Software command........... 8-1

● IBM Software command................. 8-9

● HP Software command

.................. 8-18

9. Software setup functions.......... 9-1

● Command format............................... 9-1

● Command

............................................ 9-2

10

. Specifications

................................ 10-1

● Printing specifications.......................10-1

● Print mode specifications.................. 10-2

● Graphic printing specifications.......... 10-5

● Throughput......................................10-5

● Paper specifications.......................... 10-6

● Other specifications.......................... 10-6

11. Character set table.................... 11-1

EPSON italic table...................................11-1

EPSON extenced graphic table...................11-1

EPSON international font table..................11-2

IBM character set table 1...........................11-2

IBM character set table 2...........................11-3

IBM all-character set table.........................11-3

Code page 437........................................ 11-4

Code page 850........................................ 11-4

Code page 857 ........................................11-4

Code page 860 .......................................11-4

Code page 863........................................ 11-5

Code page 865........................................ 11-5

ISO-1 (ISO-8859-1)..................................11-5

Code page 858.......................................... 11-5

Code page 861.......................................... 11-6

Code page BRASCII.................................11-6

Code page ABICOMP...............................11-6

ROMAN-8 character set (HP)....................11-7

PC-8 character set (HP).............................11-7

LEGAL character set (HP).........................11-7

MATH 7 character set (HP)........................11-7

LINE DRAW character set (HP).................11-8

International character set (HP) [ISO].........11-8

● Index

● Software command list

Contents

Page 11

i

◆ High-speed printing

Prining mode Pirnt speed Throughput

DRAFT (10 cpi) 603 CPS 206 LPM (132 columns)

LQ (10 cpi) 180 CPS 76 LPM (132 columns)

NLQ (10 cpi) 240 CPS 100 LPM (132 columns)

HQDR (10 cpi) 360CPS 135 LPM (132 columns)

S.D. (12 cpi only) 723 CPS 230 LPM (132 columns)

S.S.D. (15 cpi only) 904 CPS 270 LPM (132 columns)

◆ Original plus 8 multipart forms printing

The printer can print data on an original and up to eight

copies. Copy density can be enhanced by selecting the

DARK 1 (high pressure), DARK 2 (very high pressure) or

AUTO (automatic print pressure adjustment by sensing

the form set thickness). This setting is made in the

MULTIPART function of the SETUP MODE.

✽ : If DARK 1 or DARK 2 is selected, the printing

speed is reduced below the normal print speed

to compensate for the extra energy required

when printing in the high pressure print

modes.

◆ Bar code printing function

A variety of bar codes of this printer may be printed. The

narrow and wide spaces, narrow and wide bars, HRI,

check character, bar code height, and rotation may be

controlled with software commands. Customized bar

codes may also be printed using the element funcion.

Registered bar code formats: Industrial 2 of 5, Interleaved 2

of 5, Matrix 2 of 5, Codabar, Code11, Code 39 , Code 93,

Code 128, EAN-8, EAN-13, UPC-A, UPC-E, and Postnet

◆ Enlarged character printing

Characters can be enlarged (by up to 127 times as large x

127 times as large) using the enlarged character command

unique to this printer. Software commands are used for

control.

●●

Major functions

This printer provides a wide range of print functions, as shown below:

Page 12

ii

●●

Major functions

◆Zooming function (Batch enlargement or reduction printing)

◆ Cut sheet paper manually loading

◆ Skew sensor

A built-in skew sensor detects any cut sheets that are

skewed when loaded and ejects them.

◆ Automatic head adjustment

The printer employs an automatic paper thickness

detection sensor, instead of the conventional paper

thickness adjust lever, for optimum printing on all form

sets.

◆ Automatic loading (For fanfold or cut sheet paper)

◆ Perforation cutting (For fanfold paper)

By pressing the TEAR OFF key, the perforation of fanfold

paper is automatically fed to the paper cutter position.

◆ Paper parking (Switching fanfold paper and cut sheet paper)

If cut sheet paper is selected while fanfold paper is used,

the fanfold paper is automatically fed back to the parking

position (i.e., paper parking).

◆ Load adjustment

The pritning start position may be adjusted within a

range from approximately 0 to 26.7 mm from the top of

the paper. It is recommended that the printing position

be in the center of the paper in the range of 4 mm or less

from the the top of the paper.

◆ MICRO REVERSE LF and MICRO LF keys

These keys are useful for adjusting the printing start

position and paper cutting position.

◆Automatic scroll (For fanfold paper)

If no data input is recived for a preset period (0.5, 1, 5,

10, 15 sec.), the perfpration of the current page of fanfold

paper is fed to the paper cutter position.

Page 13

iii

◆Dual paper parking

If the optional rear tractor is used, two different types of

fanfold paper may be used. Software command or the

PAPER PATH key can be used for selection.

◆ Large 512KB communication buffer

◆ Setup memory for setting various functions on the LCD

◆ Ten resident fonts

◆ Line feed speed adjustment

Standard, 1/2 or 1/3 line feed speed is selectable for

stable paper feeding even when multipart paper is used.

◆ Vertical alignment function

◆ Serial data transfer at a maximum rate of 38.4k bps

◆ Parallel and serial interfaces are standard

Parallel and serial interface are switched automatically.

◆ Printing stops immediately if the printer cover is

inadvertently opened during printing.

◆ Enegy Star

Page 14

iv

●●

Caution

★ Unpack the printer. Make sure that the

printer body and all accessories are

included in the package and no parts are

damaged.

★ Do not use the printer in a location

exposed to direct sunlight or close to a

heater or other heat generating

equipment.

★ Before connecting or disconnecting the

interface cable, be sure to turn off the

printer.

★ Place the printer on a rigid, horizontal

base in a location that is free of vibration.

★ Do not use the printer in a dusty location

or any location subject to sudden

changes in temperature and humidity.

★ Do not connect the printer to a non-

standard power source.

★ Never try to print without a ribbon

cassette installed and paper loaded.

★ Do not turn off the printer during

printing, as this may lead to a

malfunction.

★

Take care not to twist the ribbon while

installing the ribbon cassette.

★

Push the lock levers of both tractors

to the LOCK positions firmly while

loading fanfold paper or single sheet

paper. It is for the purpose of

setting paper path securely.

★

If the case or cover becomes dirty,

clean it with a soft cloth moistened

with a small quantity of neutral

detergent diluted with water. Never

use a hard cloth or volatile solvent

such as alcohol, thinner, or benzine.

★ If any foreign matter gets into the

printer, turn off the printer

immediately and remove the foreign

matter.

Cautions in operation

Safety Cautions

Cautions in setting up

See page 3-1.

★ Use two hands and hold firmly at each

end when lifting the cut sheet feeder.

Personal injury can occur if the CSF unit

is dropped.

★ Do not touch the print head immediately

after printing because it is too hot.

★ Do not put your finger under the tractor

cover while loading fanfold paper.

!

CAUTION

Caution

Caution

Page 15

v

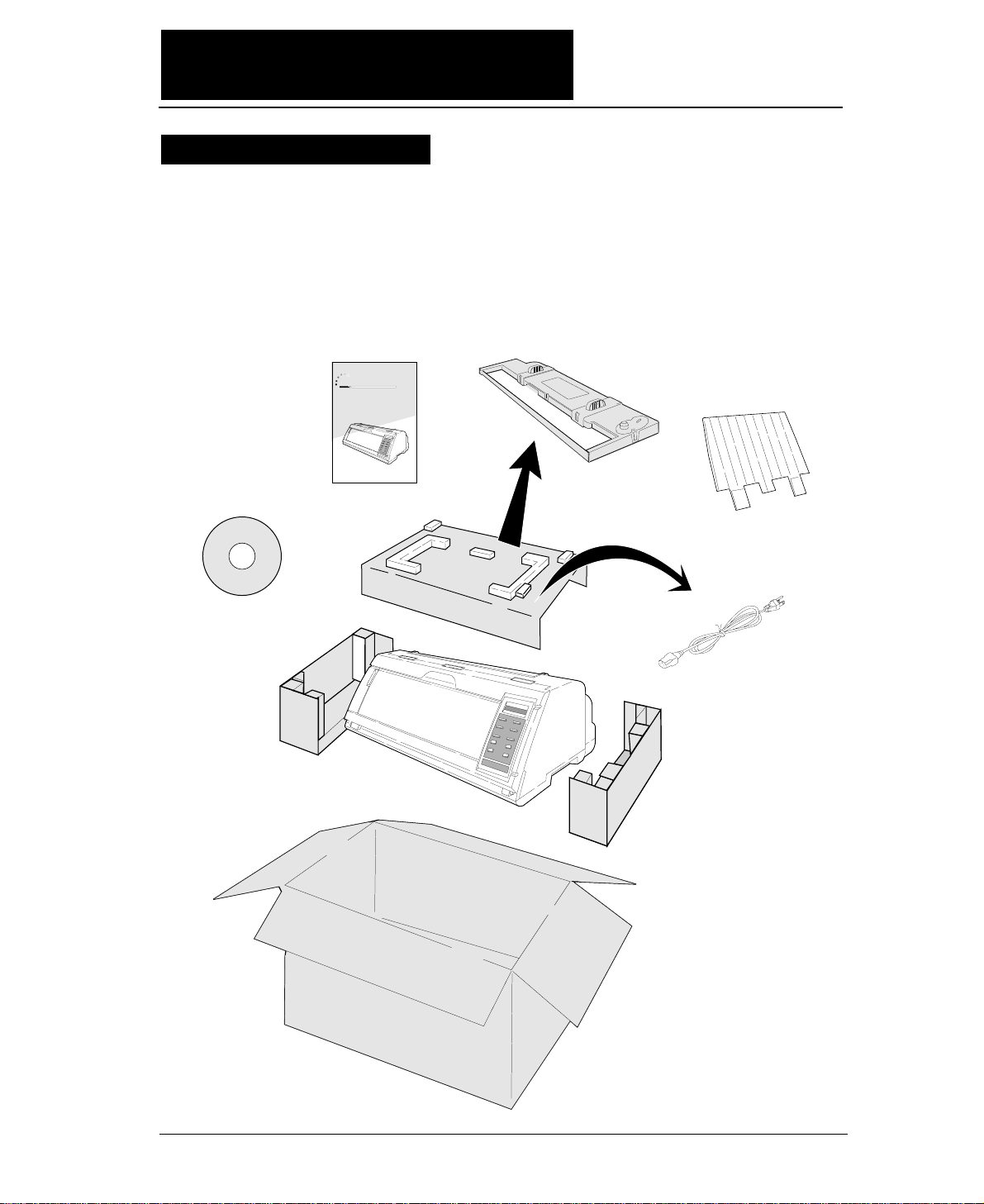

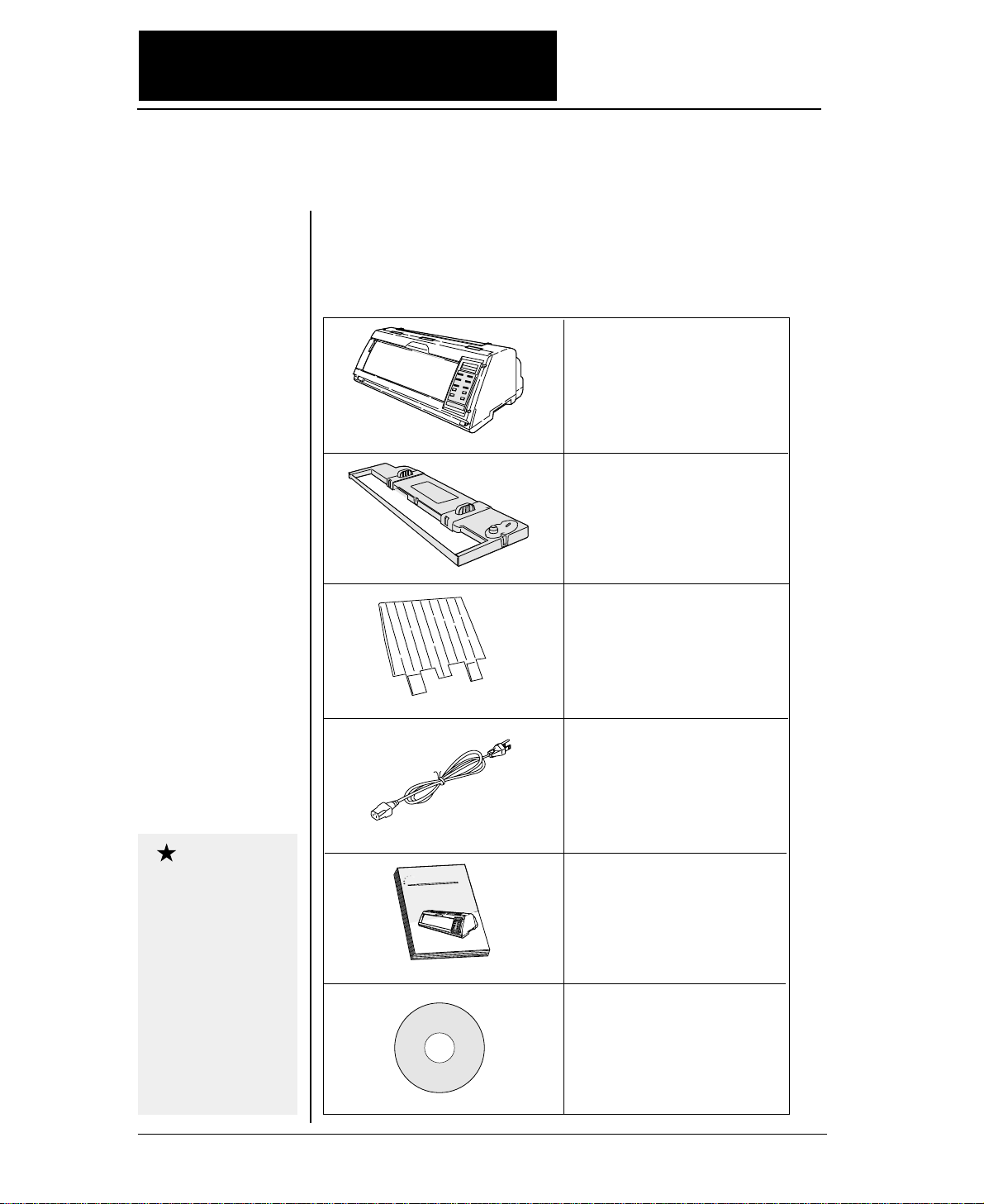

●

The printer body weights approximately 24 kg [52.9 lbs.]. It should be

taken out of the package by two or more persons.

Make sure that no parts of the printer are damaged.

●●

Unpacking the printer

Printer

Ribbon Cassette

Power Cord

24-pin Dot-matrix Printer

FB-900

Hand book

CD-ROM

Hand book

Top Paper Rack

Unpacking the printer

Page 16

vi

●●

Unpacking the printer

●

Check the carton for the following items:

■

Printer

■

Ribbon cassette

#SBP-1051

■

Power cord

Connect this power cord to an

AC outlet.

If some part is not

included in the package,

contact the dealer where

you purchased the

printer.

Keep the carton and

packaging material.

They are needed for

transporting the printer

or returning it for

service if ever required.

■

Top paper rack

Attach the top paper rack to

eject paper to the top of the

printer. Sheets of paper are

stacked on this rack.

■

Hand book

■

CD-ROM

Driver-CD with Owner's

Manual, printer driver

software.

Caution

FB-90

Hand book

24-pin Dot-matrix Printer

0

Page 17

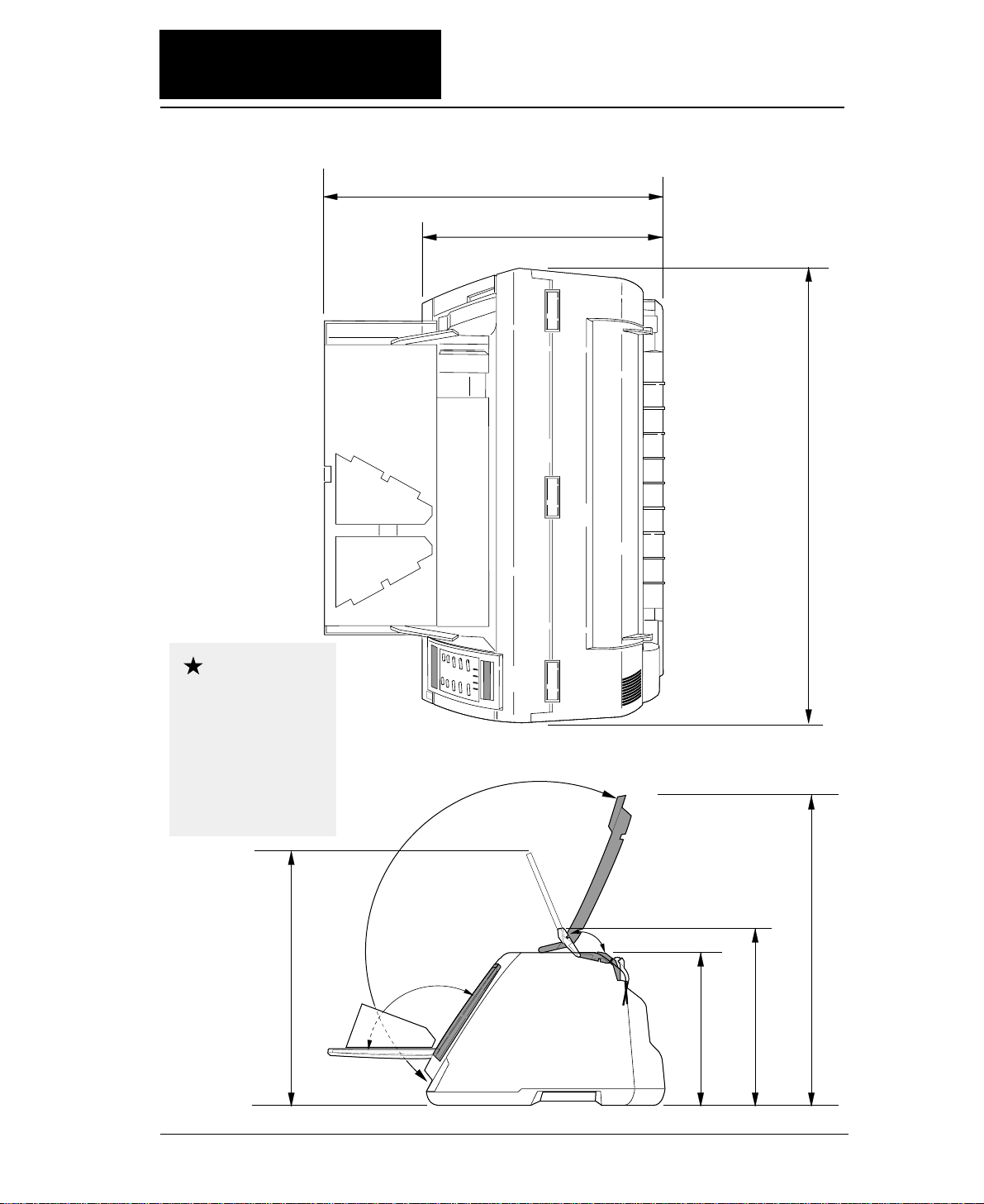

vii

●●

Dimensions

●

The following drawings show the outside dimensions of the printer.

300mm

250mm

520mm 630mm

505mm

395mm

442mm

The weight of the

printer including the

ribbon cassette is

approximately 24 kg

[52.9 lbs.]. Two

persons should carry

the printer.

Caution

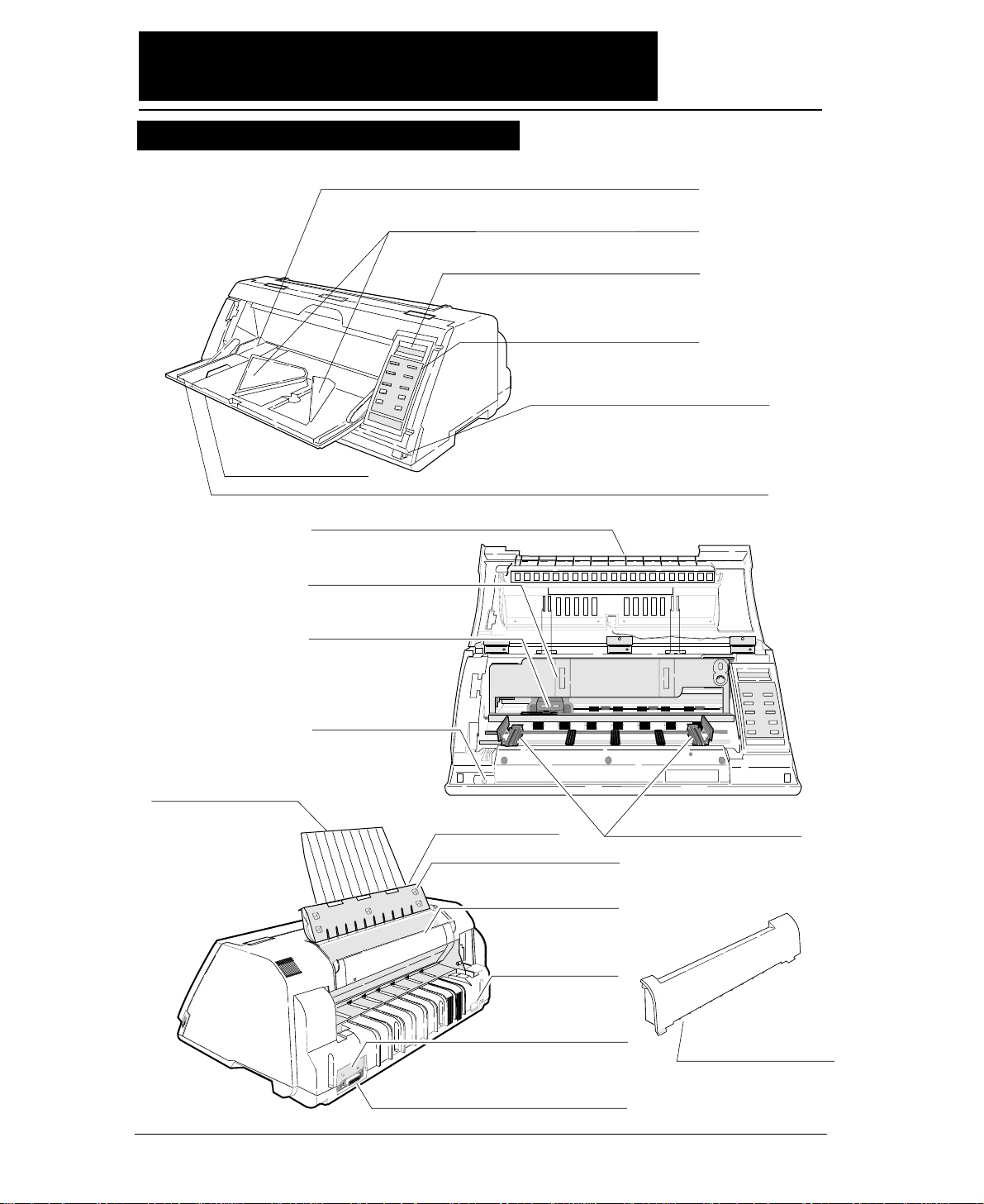

Page 18

viii

●●

Components and functions

1

1. Paper Guide (for Manual Feeding)

2. Paper Stacker (for Cut Sheet Feeder)

3. Liquid Crystal Display (LCD)

4. Control Panel

11. Power Switch

16. AC Receptacle

17. Serial Connector

18. Parallel Connector

12. Tractor

19. Rear Printer Cover

14. Top Cover

LCD: TOP COVER

5. Paper Rack

LCD: PAPER RACK

15. Rear Cover

LCD: REAR COVER

13. Top Paper Rack

8. Front Cover

LCD: FRONT COVER

10. Print Head

9. Ribbon Cassette

6. Paper Support Guide (for Manual Feeding)

20. Paper Cutter

7. Front Cover Lock Release Button

Appearance of the printer

Page 19

ix

The names and functions of the printer components are shown below.

Name (See drawing on left.) Function

1. Paper guide Adjusts the printing position when feeding paper

manually.

2. Paper stacker When the optional CSF is used, sheets of paper

are ejected into this paper stacker. Both sides of

the paper stacker should be set up.

3. Liquid crystal display (LCD) Displays the condition and settings of the printer.

4. Control panel Displays and sets the printer conditions.

5. Paper rack If the “OPEN PAPER RACK” message is

desplayed on the LCD when setting the paper

path, open the paper rack.

6. Paper Support Guide Guide the cut sheet at manuarl feeding.

7. Front Cover Lock release button To open the front cover, push the two buttons

located on the lower corners of the front cover.

8. Front cover To mount fanfold paper on tractors or replace the

ribbon cassette, open the front cover.

9. Ribbon cassette If printed characters vecome pale, replace the

ribbon cassette.

10. Print head Prints characters on paper.

11. Power switch Pressing the power switch toggles the power on

and off.

ON: Switch depressed OFF: Switch released

12. Tractor The tractor pins engage sprocket holes on both

sides of fanfold paper for feeding.

13. Top paper rack Ejected cut sheets are stacked on the top paper

rack.

14. Top cover Eject fanfold paper to the top of the printer. If

the “OPEN TOP COVER” is displayed on the

LCD when setting the paepr path, open the top

cover.

15. Rear cover To eject fanfaold paper to the top of the prieter,

open the rear cover. If the “OPEN REAR

COVER” is displayed on the LCD when setting

the paper path, open the rear cover.

16. AC receptacle

Connect the power to this AC receptacle. The

power is desigated on the rating plate on the back

of the printer.

17. Serial connector

RS-232C interface connector

18. Parallel connector

Parallel interface connector

19. Rear printer cover

When the rear tractor or CSF is used, remove the

rear printer cover.

20. Paper Cutter

Cut the paper after pressing the TEAR OFF key.

●●

Components and functions

Components and functions

Page 20

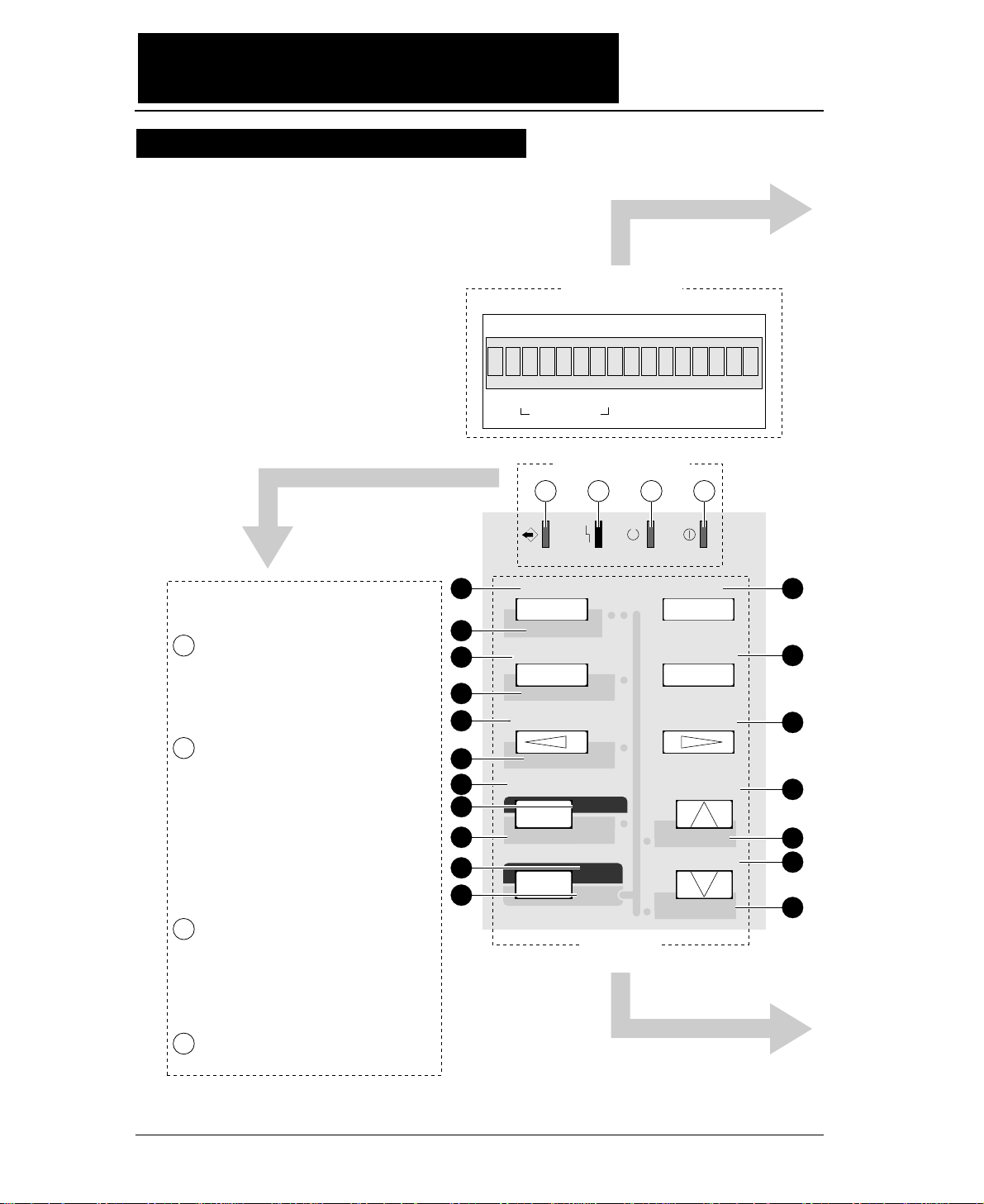

x

●●

Components and functions

Control panel explanation 1

DATA ERROR ONLINE POWER

TEAR OFF

ONLINE

PAPER PATH

FORM FEED

LINE FEED

REVERSE LF

TOF SET

QUALITY

EJECT/LOAD

PAPER FORM

RESET

SET UP

MICRO LF

MICRO RLF

EXIT

EXTENDED

ENTER

ALT

FORM

1.5

x

IN OUT

PAPER PATH

F.TR REAR

1

2

3

4

5

6

11

12

13

14

15

16

17

18

7

9

8

10

1 2 3 4

State display Lamps

State display LCD

Key Panel

Blinks while data is transferred.

Lights while data is processed except

during communication or when the

input buffer contains data. Goes out

in other conditions.

ON : Paper is not detected some

other operational error has

occurred.

OFF : Paper is detected.

Blinking : A functional error (such

as home sense error,

internal RAM error,

paper path switching error,

head adjustment error,

park error and skew error)

ON : Printing is enabled.

OFF : Printing is disabled.

Blinking : The cover is open, or

the printer is in the head

temperature protect

condition.

On when printer power is turned on.

State display lamps

1

2

3

4

115

Page 21

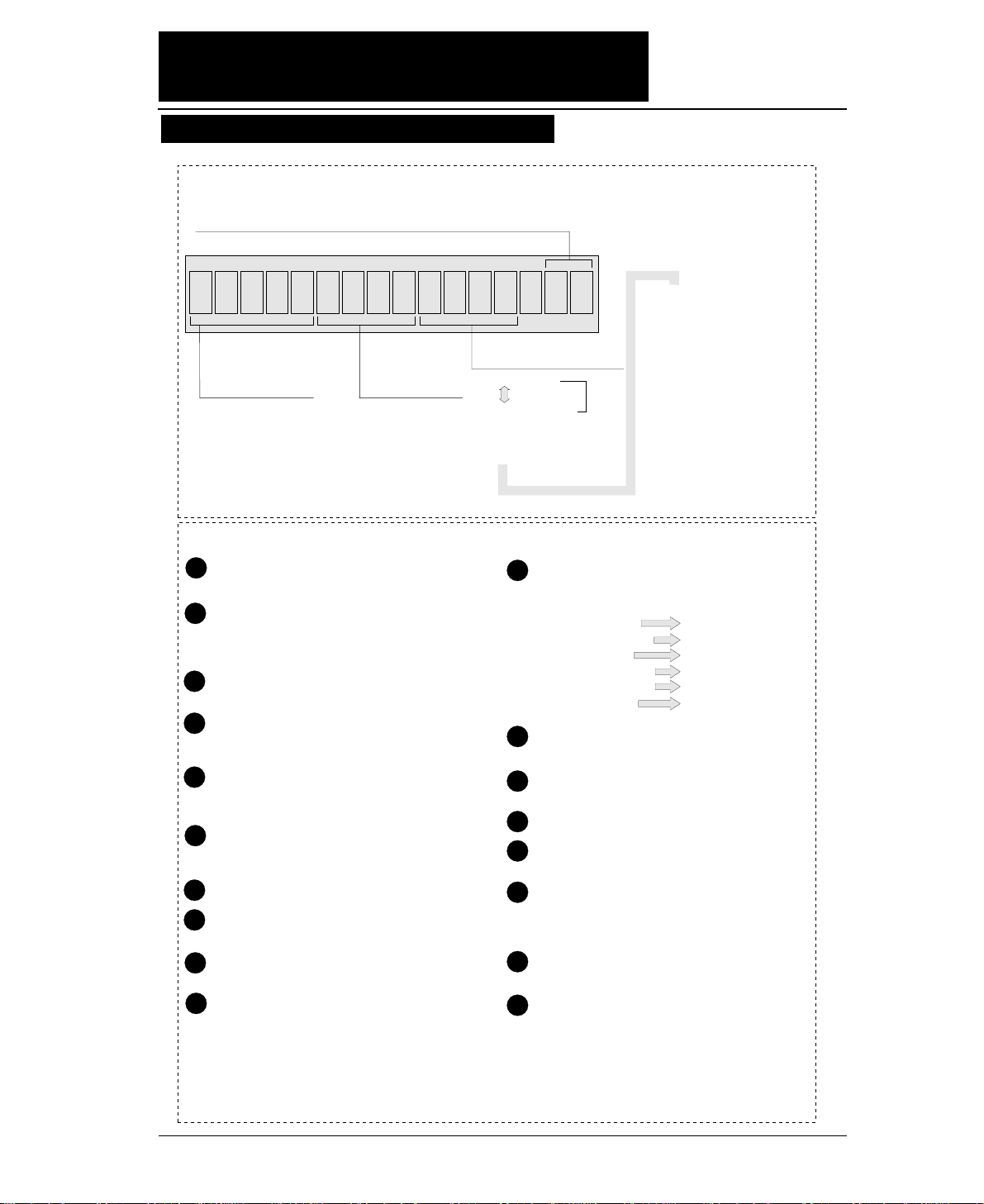

xi

●●

Components and functions

.5x15F . TR REAR1

F. TR

R. TR

MAN

CSF

: Front Tractor

: Rear Tractor

: Manual

: Cut Sheet Feeder

REAR

TOP

FRNT

: Rear

: Top

: Front

1inch=25.4mm

Paper In

Paper Out

15: 15 inches 12: 12 inches 10: 10 inches 5: 5 inches

Paper Width (Fanfold Paper)

2

16.5

A3

A4

A5

Page Length (Fanfold Paper)

Paper Size (Cut Sheet Paper)

: 2 inches

: 16.5 inches

: A3

: A4

: A5

LT

HLT

LG

EX

GLT

GLG

LD

F4

PC

C6

C10

MN

DL

C5

: LETTER

: HALF LETTER

: LEGAL

: EXECUTIVE

: GOVERNMENT LETTER

:

GOVERNMENT LEGAL

: LEDGER

: F4 SIZE

: POST CARD

: COMMERCIAL-6

: COMMERCIAL-10

: MONARCH

: DL Envelope

: C5 Envelope

Feeds the perforation of fanfold paper to the paper

cutter poistion. (For fanfold paper only)

(ALT + TEAR OFF keys)

Press these keys for two seconds or more. Release

the keys when "INITIAL" is displayed on the LCD.

The printer will be reset.

Changes the paper path display. To select the

displayed paper path, press the ENTER key.

(ALT + PAPER PATH keys)

When paper is loaded, the current printing position is

considered as the TOF position.

Loads paper or feed back paper to the parking

position when fanfold paper is used. Loads or

and ejects paper when cut sheet paper is uesd.

(ALT + EJECT/LOAD keys)

Changes the printing quality display. To select

the displayed mode, press the ENTER key.

Enters the SETUP MODE.

Quits the SETUP MODE or EXTENDED

SETUP MODE.

(ALT + SETUP keys)

Enters the EXTENDED SETUP MODE.

Selects an item displayed in the SETUP MODE,

the EXTENDED SETUP MODE, setting the

paper path, setting the paper form or setting the

printing quality.

1

2

3

4

5

6

10

11

12

13

14

15

16

17

7

9

8

When pressing the corresponding key while you

press the ALT key, one of the following

functions is executed.

Changes the printing enable (online) state and

printing disable (offline) state.

Changes the paper form display. To select the

displayed paper form, press the ENTER key.

Feeds one page.

Feeds one line in the forward direction at a pitch

of 1/6 inch.

(ALT + LINE FEED keys)

Feeds one line in the forward direction at a pitch

of 1/360 inch.

(Micro line feed)

Feeds one line in the reverse direction at a pitch

of 1/6 inch.

(ALT + REVERSE LF keys)

Feeds one line in the reverse direction at a pitch

of 1/360 inch.

(Micro reverse line feed)

18

State display LCD

Keys on the panel

LINE FEED

REVERSE LF

SET UP

EJECT/LOAD

PAPER PATH

TEAR OFF

MICRO LF

MICRO RLF

EXTENDED SETUP

QUALITY

TOF SET

RESET

1

Orientation (Cut Sheet Paper)

p: Portrait l: Landscape

Page

Length

Control panel explanation 2

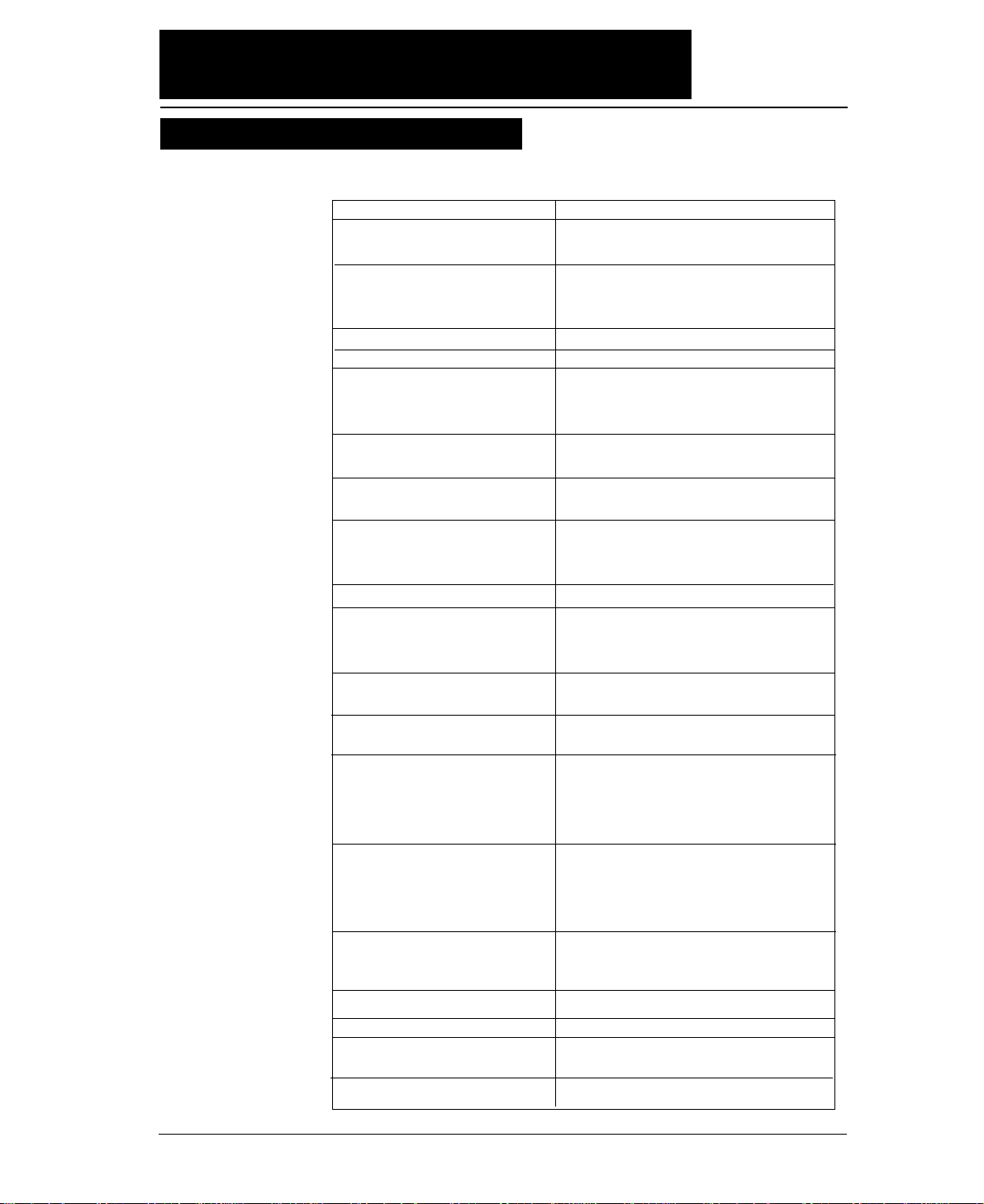

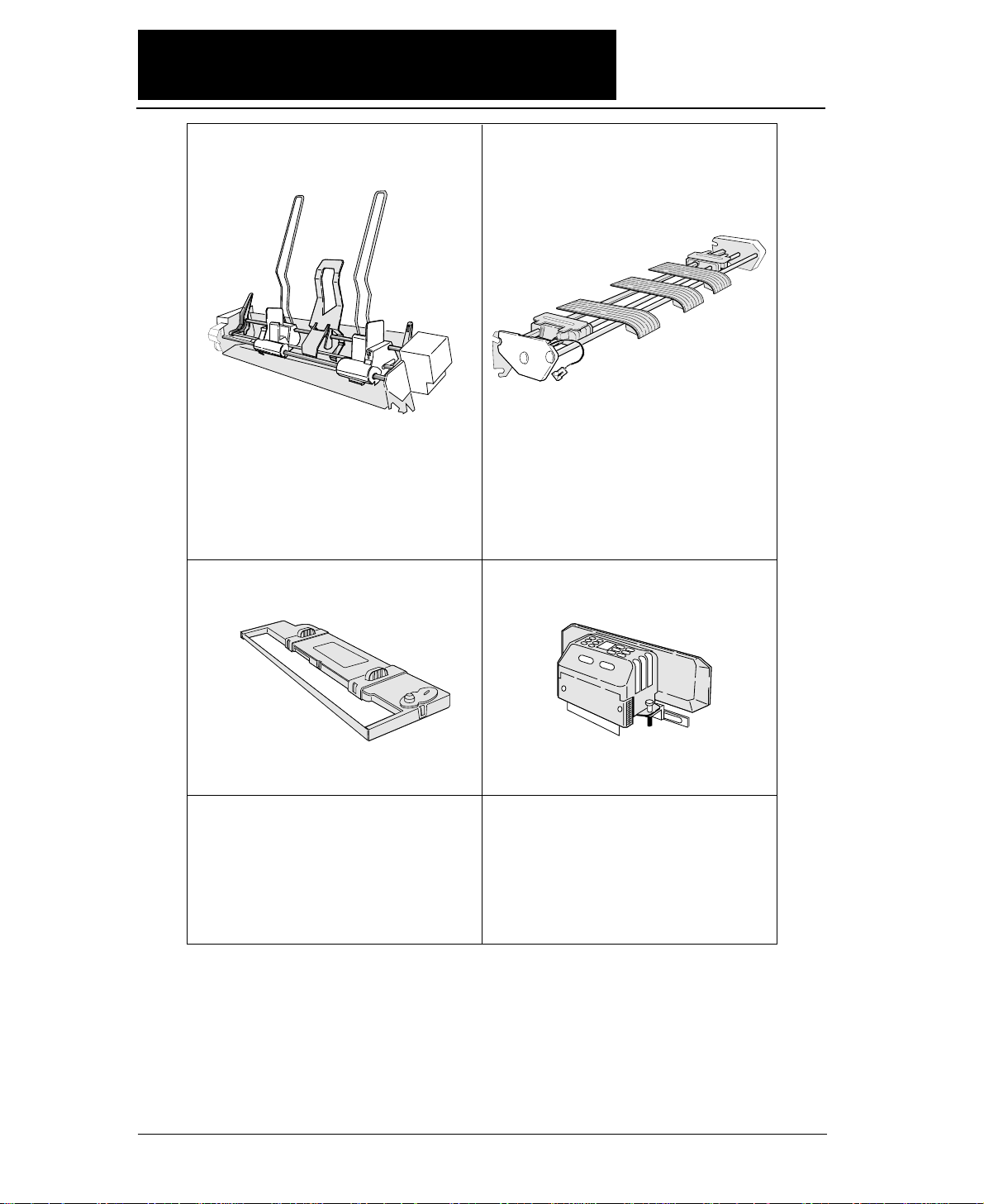

Page 22

xii

#FB-84008

Cut sheet feeder Rear tractor

For attaching the cut sheet feeder,

see pages 1-22 to 1-26.

For attaching the rear tractor, see pages 1-16 to 1-18.

Print head

#FB-90090

For mounting the print head, refer to the manual

supplied with the print head.

Ribbon cassette

#SBP-1051

For attaching the ribbon cassette,

see pages 1-2 and 1-3.

Current loop interface unit

RS-422A interface unit

#FB-84011#FB-84010

#FB-84009

This unit enables data to be transferred through

an RS-422A interface. This is a built-in unit

that is installed by the dealer. If the RS-422A

interface unit is installed, the RS-232C

interface cannot be used.

This unit converts serial data into 20 mA

current loop signals. This is a built-in unit that

is installed by the dealer. If the current loop

interface unit is installed, the RS-232C

interface cannot be used.

The cut sheet feeder feeds cut sheets automatically

and continuously. A maximum of 150 sheets of

paper (55 kg paper) may be set in the holder of the

cut sheet feeder.

Dual paper parking is available when the rear

tractor is used. Two different types of paper may

be set onto the front and rear tractors and may be

selected by issuing software commands or

pressing the PAPER PATH key to change the

paper paths.

●●

Options and consumables

Page 23

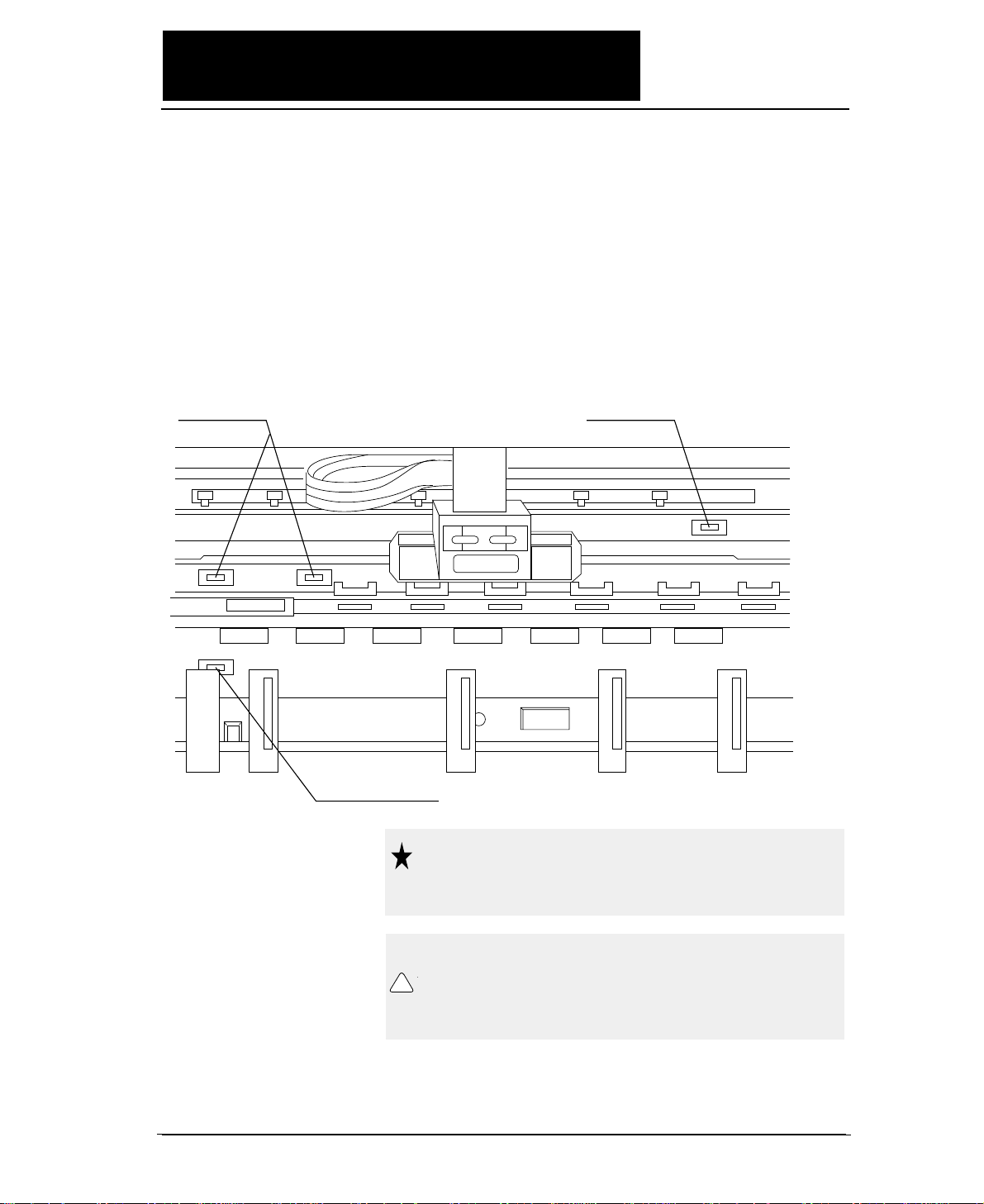

xiii

●●

Maintenance

Periodic maintenance and inspection is recommended to keep

the printer in good condition.

●

Remove paper particles or dust adhered to

the detection sensor cover upper surfaces

(three locations) inside the printer and to the

paper jam sensor surface (one location), by

wiping with a soft clth or a cotton bud. The

paper particles or dust on the sensor

surfaces may cause faulty operation.

Detection sensor Detection sensor

Paper jam sensor

Do not use a hard brush to clean the

sensor cover and the sensor surface.

The brush may scratch the surface.

When opening the front cover just

after the printer has been in operation,

do not touch the printer heard which

is hot and may cause burns.

Caution

!

Caution

Page 24

1-1

—

1. Setting up the printer

—

1. Setting up the printer

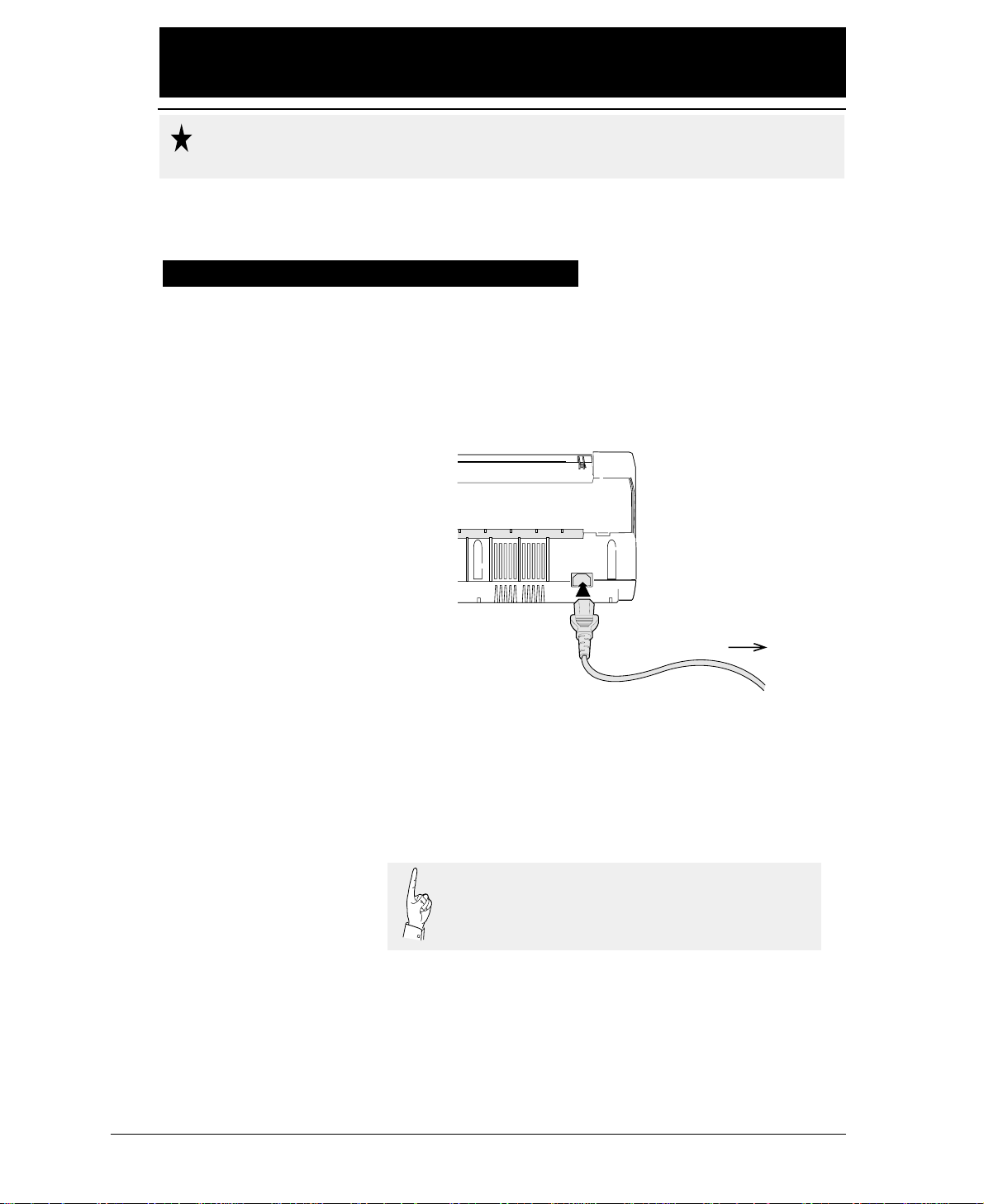

●

Make sure that the power switch is set to off.

Connect the printer with the supplied power

cord to an AC outlet.

●

The AC outlet shall be installed near the

printer and shall be easily accessible.

To AC outlet

Connect the AC power plug to an AC outlet of the voltage

designated on the rating plate on the back of the pirnter.

Once the printer is turned off, wait for three seconds or

more before turning it on again. If the printer is turned

on again within three seconds after turning it off, it

may malfunction due to an initializtion failure.

●●

Connecting the printer to Power

Caution

Page 25

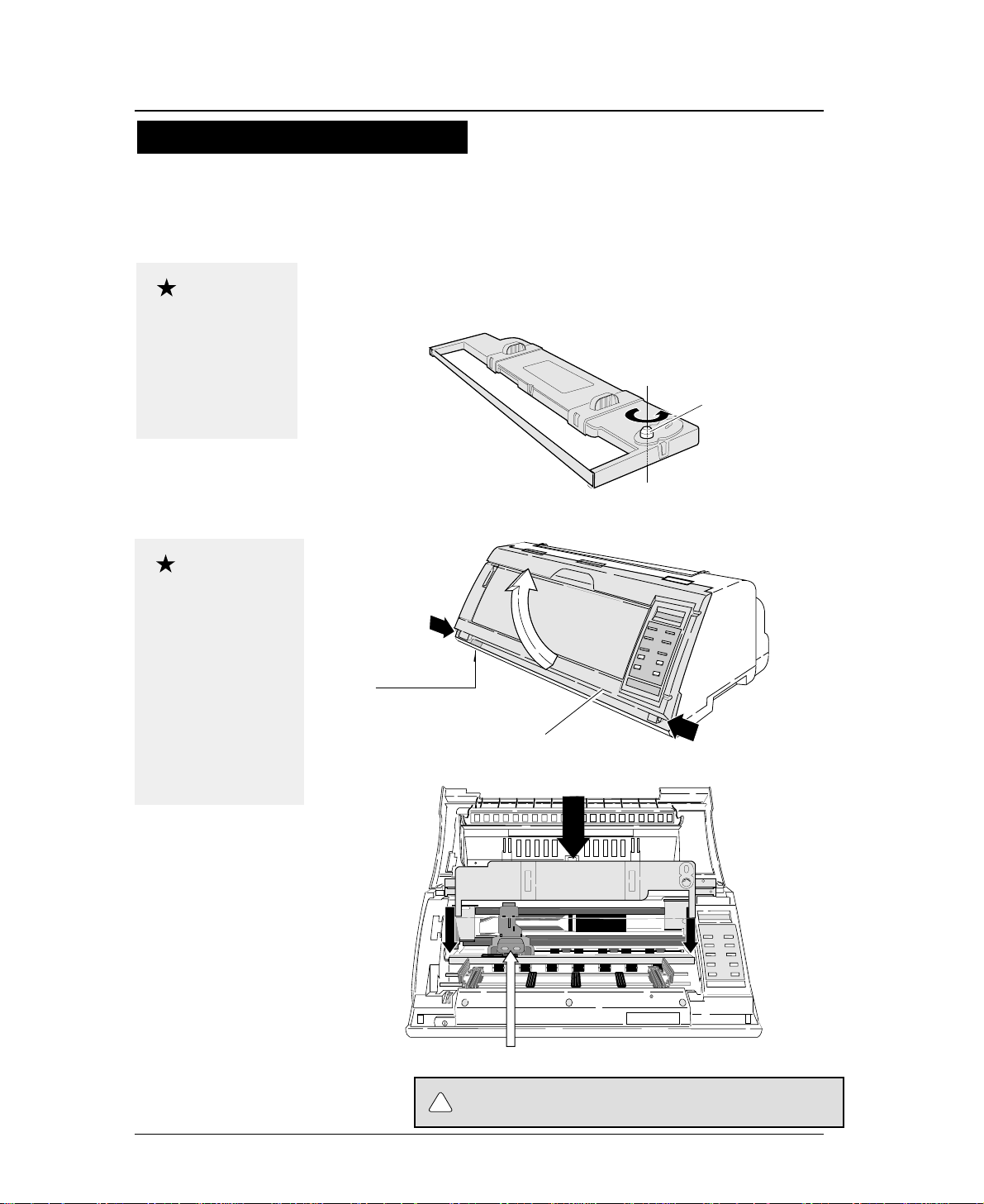

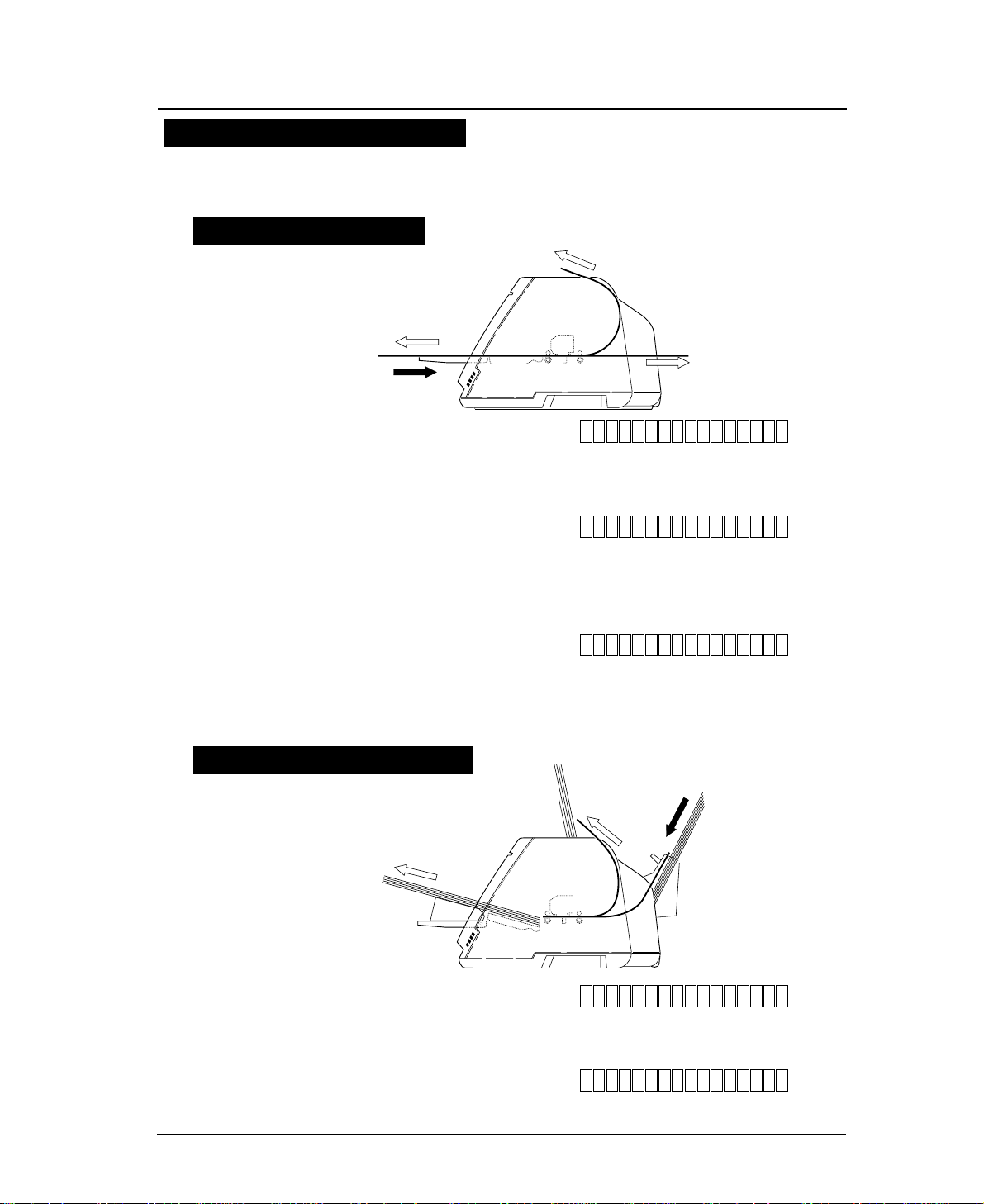

1. Turn the ribbon feed knob on the ribbon

cassette counterclockwise to stretch the

ribbon tight.

2. Turn off the power. Open the front cover.

3. Attach the ribbon cassette as shown below.

1-2

Do not touch the print head immediately

after printing becouse it is too hot.

Use the specified

ribbon cassette .

When power is turned

off, data in the buffer

is lost. Output all data

before turning off the

printer.

Open the front cover by

pressing both side locks

with both hands. Hold

both sides with both

hands to raise it upward

slowly. When closing

the front cover, hold

both sides with both

hands to pull it down

slowly. Press the front

cover to lock it.

Stretch the ribbon

Ribbon feed knob

Installing the ribbon cassette

Approximately 15 seconds after the printer is rutned on, the print head will move to

the left.

Print head position

Front cover

Power switch

Every press of the power

switch turns the power on

or off.

—

1. Setting up the printer

—

●

Installing the ribbon cassette

Caution

Caution

!

CAUTION

Page 26

1-3

●

Installing the ribbon cassette

—

1. Setting up the printer

—

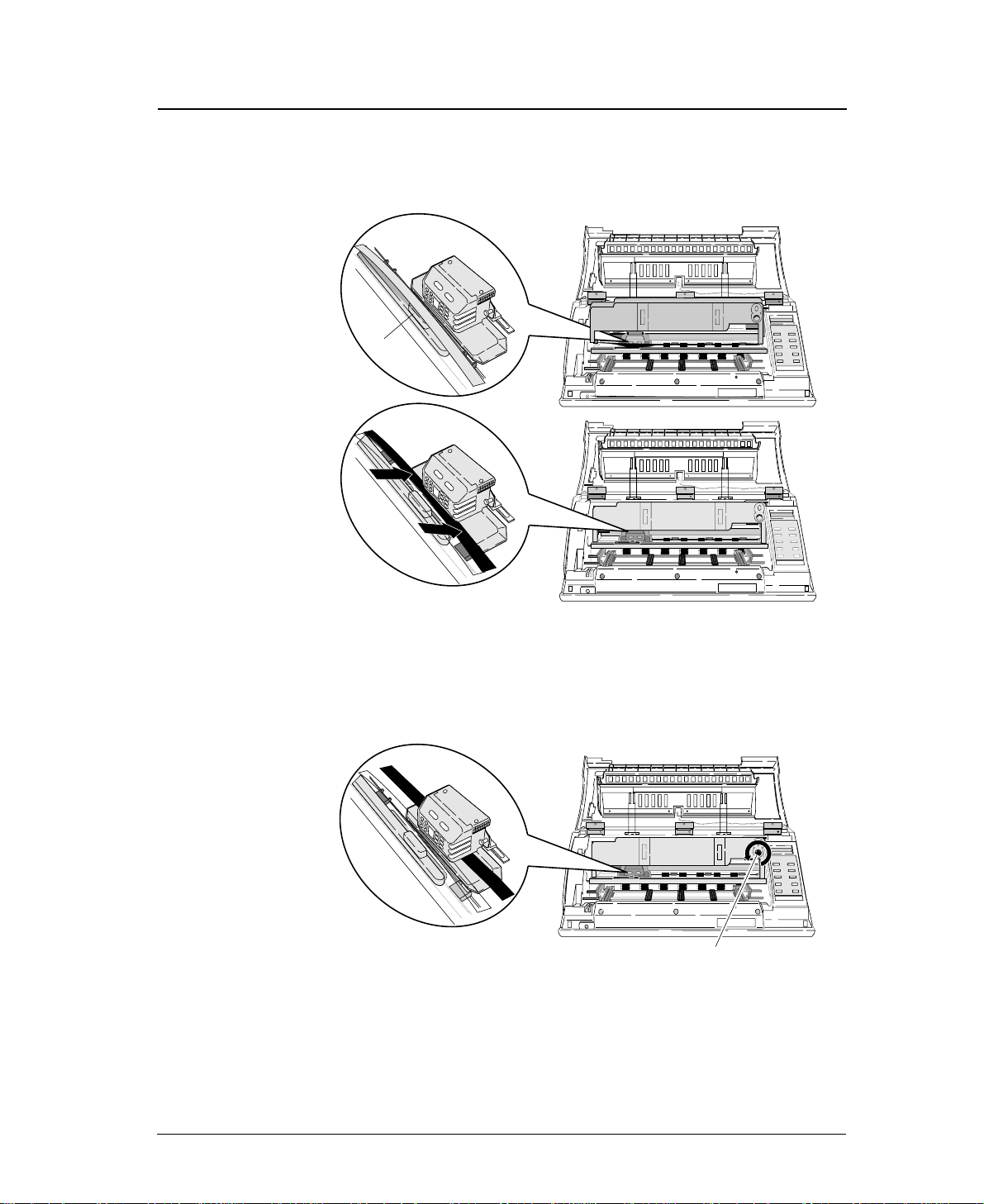

4. Slide the ribbon toward the print head so

that the ribbon is lightly in contact with the

projection of the print head.

5. Attach the cassette firmly to the mounting

plate. Turn the ribbon feed knob

counterclockwise.

Fit the right and left projections on the mounting plate to the holes in

the bottom of the ribbon cassette.

6. Close the front cover.

Pull down the front cover slowly toward you with both hands from

both sides to close it.

Push down on both sides at the bottom of the front cover to close it

firmy. Two hands are required to engage and lockthe front cover on

both sides.

Slide

Slide

Projection

Ribbon feed knob

Page 27

1-4

—

1. Setting up the printer

—

●

Paper path

1

2

Paper loading direction

Rear tractor

(Optional)

Paper loading

direction

3

Paper rack

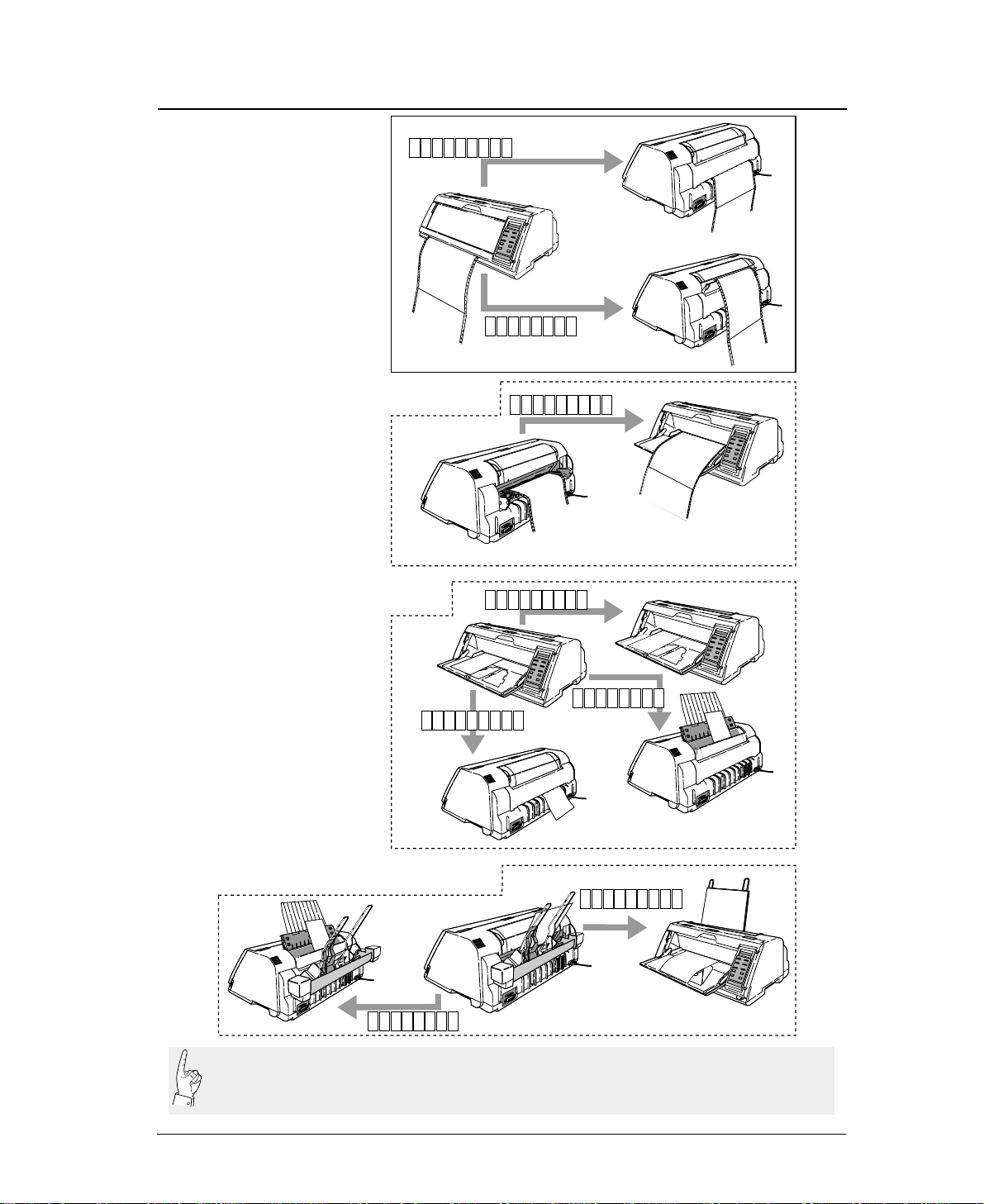

2. Front loading, top ejection

This paper path applies a smaller load to the paper.

This is recommended for printing on thick paper

(such as multipart paper or label sheets).

1. Front loading, rear ejection

This paper path is recommended if fanfold paper is

cut along the perforation frequently.

The perforation is automatically fed to the paper

cutter of the top cover by pressing the TEAR OFF

key so that the paper may be torn off easily.

To cut the paper, hold the upper cover firmly with

one hand and tear the paper towards you.

3. Rear loading, front ejection

Dual paper parking is available when the optional

rear tractor is used. Two types of fanfold paper of

different size and thickness may be used and

selected from the control panel or by issuing a

software command (ESC EM or software setup*)

from the computer.

* Software setup commands

The software setup commands are unique to this

printer. Most functions available on the SETUP

MODE and EXTENDED SETUP MODE can may

11x 5F.TR REAR

11x 5FTRTOP

11x 5R.TR FR T N

Liquid crystal display

Inside of the printer viewed

from the right.

✩

Inside of the printer viewed

from the right.

✩

.

1

1

1

Path of fanfold paper

The three fanfold paper paths shown below are available. For selecting a paper

path, See pages 1-6 and 1-7.

Rear tractor (Option)

Front tractor

Page 28

1-5

—

1. Setting up the printer

—

●

Paper path

Path of cut sheet paper

The five cut sheet paper paths shown below are available.

1. Front loading, front ejection

This paper path applies a lighter load on feeding paper. This

is recommended for printing on thick paper (such as

multipart paper, postcards, and envelopes).

3. Front loading, top ejection

This paper path enables face-down stacking.

1

3

2

Paper loading

direction

4. CSF loading, front ejection

This paper path is suitable for thick paper (such as multipart

paper, postcards and so on). Sheets of paper are stacked face-up.

5. CSF loading, top ejection

This paper path enables face-down stacking.

Paper loading

direction

4

5

A4 pMAN F RN T

A4 pMAN REAR

A4 pMAN TOP

A4 pCSF FR

A4 pCSF TOP

Inside of the printer

viewed from the right.

✩

✩

This paper path applies a lighter load on feeding paper. It is

recommended for printing on thick paper (such as multipart

paper, postcards, and envelopes).

NT

2. Front loading, rear ejection

Inside of the printer

viewed from the right.

Manual paper feeding

Cut sheet paper (Option)

●Sheets of paper are loaded manually one at a time.

Page 29

1-6

—

1. Setting up the printer

—

●

Selecting the Paper path

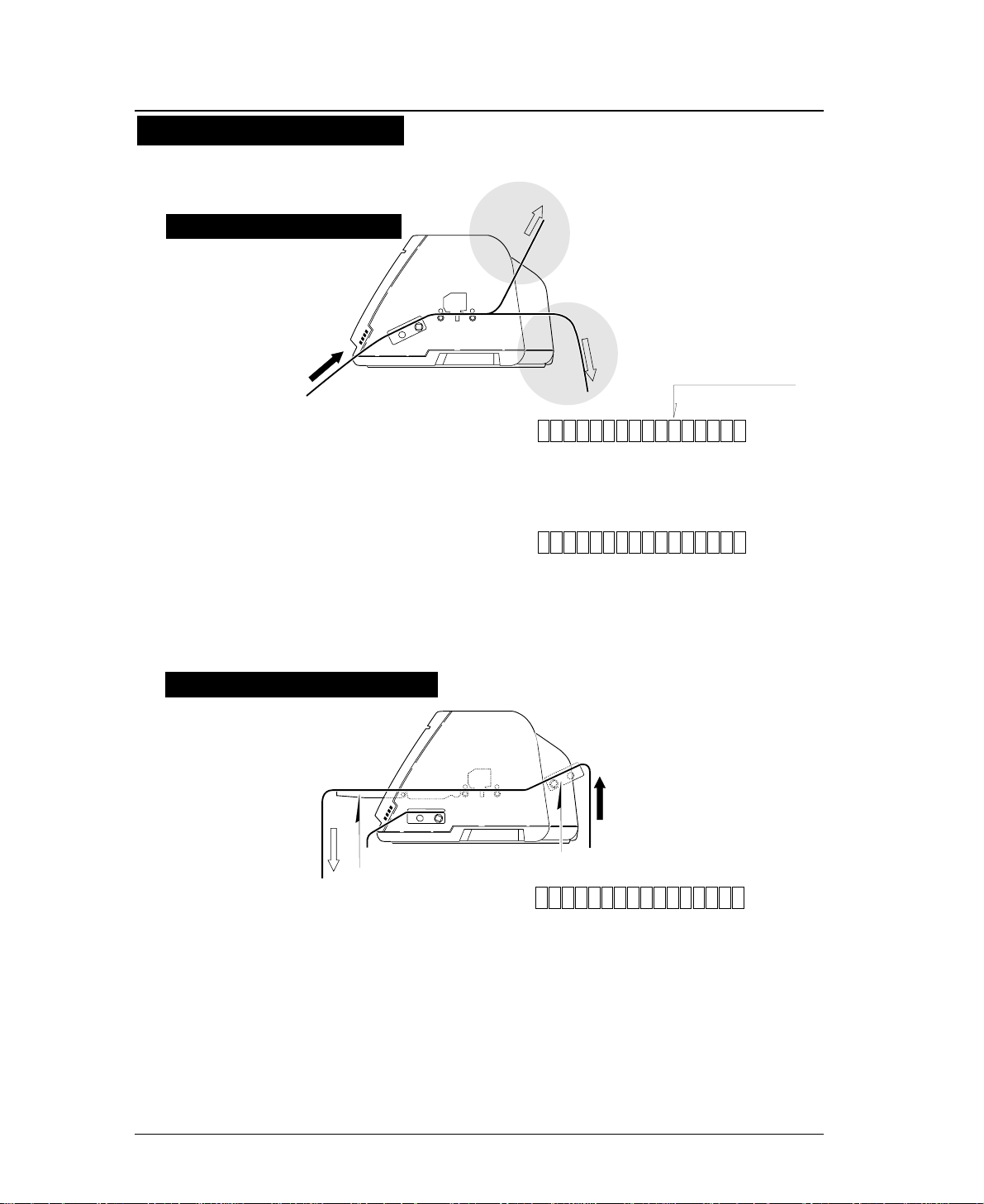

1. Press the PAPER PATH key.

The paper path currently selected is displayed.

2. Continue to press the PAPER PARH key until

“PATH: F. TR. -> TOP ” is displayed. Press

the ENTER key.

Selecting the paper path

The following shows an example of changing the paper path for reference. The

example shown below changes front tractor loading and rear ejection to the front

tractor loading and top ejection.

11x 5

F .

TR EA

IN

OUT

FORM

PAPER PATH

>

RE

T

F

-APH

.T

RA

PAPER PATH

R

.:

1RR

PAPER PATH

ENTER

IN

OUT

PAPER PATH

FORM

11x 5F.RT

IN

OUT

PAPER PATH

FORM

IN

OUT

PAPER PATH

FORM

1

MEM 1F

. R->R ATERO

MEM 1F

. R->T PTO

->T PO

O

Page 30

1-7

—

1. Setting up the printer

—

●

Selecting the paper path

1

1

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

1

1

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

◆Cut sheet paper (Manual feeding)

◆Fanfold paper

1

1

◆Cut sheet paper (Optional cut sheet feeder)

1

◆Fanfold paper (Optional rear tractor)

LOAD

EJECTION

LOAD

EJEC-

TI

ON

EJEC-

TIO

N

LOAD

EJECTION

EJECTION

EJECTION

LOAD

EJECTION

EJEC TION

F.TR REA

F.TR TOP

R.TR FRN

MAN F RN

MAN R EA

MAN TOP

CSF TOP

CSF FRN

EJEC-

TION

R

T

T

R

T

AAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAA

AAAAAAAAAAAAAAAA

The optional CSF and rear tractor cannot be used together. If the optional CSF or rear tractor is

installed, enable it by using the EXTENDED SETUP MODE (#60 option). If the option is not

enabled on the EXTENDED SETUP MODE, the paper path cannot be selected.

Page 31

1-8

—

1. Setting up the printer

—

●

Paper

16 mm or more

0/60 inch - 63/60 inches

(#3 TOF ADJUSTMENT on SETUP

MODE)

2 mm

Printing area

Printing area

5, 10, 15 inches

(#5 PAPER WIDTH on SETUP MODE)

Perforation

2.5 - 16.5 Inches

(#4 PAGE LENGTH on SETUP MODE)

0/6 inch - 15/6 inches

(#6 TOP MARGIN on SETUP

MODE)

0/6 inch - 15/6 inches

(#7 BOTTOM MARGIN on

SETUP MODE)

Last page

Paper form

Multipart

form

Rear tractor 3 ~ 16.5 inches (76 ~ 420mm)

1

9 or less

1

0.08

~ 0.12mm

55 ~ 90kg 34kg x 9P

0.12

~ 0.59mm

0.12

~ 0.18mm

125kg or less

Front tractor 3 ~ 16 inches (76 ~ 406mm)

Paper width

Number of sheets

Thickness

Paper weight

16 mm or more

Label

form

Single

Paper quality Wood-free paper

22 holes

Page length

0.5 inch × 22 = 11 inches

0.5 inch

30 holes

Page width

0.5 inch × 30 = 15 inches

Page length

Paper width

Sprocket holes are made on both sides

of fanfold paper at an interval of 0.5

inch, which can be used to calculate

the page length and width.

The page length can be determined by

multiplying the number of sprocket

holes per page by 0.5 inch.

To find the paper width, use another

sheet of fanfold paper and count the

number of sprocket holes.

Printing area on fanfold paper

Calculating sizes of fanfold paper

Sizes of fanfold paper are

generally shown in inches.

One inch is 25.4 mm.

When fanfold paper is used, set the page length (#4 PAGE LENGTH) and paper

width (#5 PAPER WIDTH) on the SETUP MODE. For setting, see page 1-12.

Page 32

1-9

A4, LETTER, LEGAL, A3, etc

(#4 PAGE LENGTH on SETUP MODE)

0/60 inch - 63/60 inches

(#3 TOF ADJUSTMENT on SETUP

MODE)

4mm

Printing area

2 mm or more2 mm or more

Horizontally loaded

size A5 sheets and

postcards cannot be

ejected upward.

Standard-size form

Multipart paper

Glued portion

Approx. 0.5 mm

The thickness of the bound

portion is the sum of the

paper thickness and 0.25 mm

or less.

Use wood-free paper. Cut sheet paper can be

loaded manually or by using the CSF.

Paper form

Paper quality

Number of sheets

Thickness (mm)

Paper weight

Single

0.08 ~ 0.12

55 ~ 90kg 34kg x 9P

0.12 ~ 0.59 0.08 ~ 0.8

0.5 or less

Wood-free

paper

Wood-free paper

0.08 ~ 0.11

55 ~ 78Kg 34kg x 6P

0.12 ~ 0.39 0.08 ~ 0.22

Manual paper feeding CSF paper feeing

Available standards-size forms

Envelopes and horizontally set post cards

cannot be printed by using the CSF.

Non-carbon, middle carbon

and back carbon multipart

paper can be used.

Multipart

form

1

9 or less

11

Card Envelope

Carbon or

non-carbon

Paper form

Paper quality

Number of sheets

Thickness (mm)

Paper weight

Paper length

Single

Wood-free

paper

1

Multipart

form

6 or less

Non-carbon

140mm and over

Card

Wood-free

paper

1

39 ~ 78kg 55 ~ 165kg

Paper Size

Manual Feeding CSF Feeding

A3

A4

A5

Letter

Half Letter

Legal

Executive

Government Legal

Government Letter

Ledger

F4

Post card

Commercial -6

Commercial -10

Monarch

DL

C5

Portrait Landscape Landscape

(297mm X 420mm)

(210mm X 297mm)

(148mm X 210mm)

(8.5" X 11")

(5.5" X 8.5")

(8.5" X 14")

(7.25" X 10.5")

(8.5" X 13")

(8" X 10.5")

(11" X 17")

(210mm X 330mm)

(100mm X 148mm)

(6 1/2" X 3 5/8")

(9 1/2" X 4 1/8")

(3 7/8" X 7 1/2")

(110mm X 220mm)

(162mm X 229mm)

❈1 Paper length 150mm (5.9inch) or less can not be ejected to the top.

❈2 A3 (portrait) or Ledger (portrait) can not be stacked on the top paper rack.

Regular size formEnvelope

Portrait

—

1. Setting up the printer

—

●

Paper

Printing area on cut sheet paper

Specify the paper size of cut sheet paper using #4 PAGE

LENGTH on the SETUP MODE. For setting, see page 1-19.

Page 33

1-10

—

1. Setting up the printer

—

●

Selecting the paper form

Paper form selection 1

15

12:

10:

5:

15 inches

12 inches

10 inches

5 inches

Paper Width

(Fanfold Paper)

2

16.5

A3

A4

A5

LT

HLT

LG

LD

EX

: 2 inches

: 16.5 inches

: A3

: A4

: A5

: LETTER

: HALF LETTER

: LEGAL

: LEDGER

: EXECUTIVE

Page Length (Fanfold Paper)

Paper Size (Cut Sheet Paper)

GLT

GLG

F4

PC

C6

C10

MN

DL

C5

: GOVERNMENT LETTER

: GOVERNMENT LEGAL

: F4 SIZE

: POST CARD

: COMMERCIAL-6

: COMMERCIAL-10

: MONARCH

: DL Envelop

: C5 Envelop

F

1.5x 5

.TR

REAR

1

p:l:Portrait

Landscape

Orientation

(Cut Sheet Paper)

Page

Length

1

11x 5F.TR REAR

IN

OUT

FORM

PAPER PATH

PAPER FORM

4Ap4

PAPER FORM

PAPER FORM

PAPER FORM

PAPER FORM

PAPER FORM

PAPER FORM

PAPER FORM

111 I x 15

IN

1

211 I x 15

NIN

311 I x 15

IN

5Ap4

6Ap4

N

N

Factory default setting

Liquid crystal display

If the EEPROM is

initialized, preset form

sizes are replaced by the

factory default settings.

Sizes of up to six frequently-used forms may be stored in MEMO 1 to MEMO 6 in the internal memory.

Any of the stored sizes may be read out of the memory with the PAPER FORM key whenever necessary.

See page 1-31.

Page 34

1-11

—

1. Setting up the printer

—

1. Press the PAPER FORM key.

The paper size currently selected is displayed.

2. Continue to press the PAPER FORM key to

select MEMO 3 as shown below.

3. Specify the intended form size as shown

below.

4. The A5 portrait form is set in MEMO 3.

●

Selecting the paper form

Paper form selection 2

The following shows an example of setting form size for reference. The example below

shows how to change the size stored in MEMO 3 ( page length: 11 inches, paper width:

15 inches) to an A5 portrait form.

Specifying form size

11 5xF.TR RE

I

IN

OUT

PAPER FORM

PAPER PATH

IN

OUT

PAPER PATH

PAPER FORM

PAPER FORM

N1xIA1R11

N

51

SET UP

F.TR REAR 11 x 15

1. MULTIPART

4. PAGE LENGTH

SIZE: A5 p

PAGE:11 INCH

1. MULTIPART

SIZE: A5 p*

ENTER

SIZE: A5 p

EXIT

SAVE?: YES

ENTER

SAVE?: YES

F.TR REAR A5 p

4. PAGE LENGTH

4. PAGE LENGTH

PAPER PATH

ENTER

IN

OUT

PAPER PATH

FORM

11x 5F.RT

IN

OUT

PAPER PATH

FORM

IN

OUT

PAPER PATH

FORM

1

MEM 1F

. R->R ATERO

MEM 1F

. R->T PTO

->T PO

O

Page 35

1-12

1. Check the rating of the fanfold paper to be

used that is marked on the side of the

package.

2. Press the PAPER PATH key to select the

desired paper path.

—

1. Setting up the printer

—

●

Loading fanfold paper (Front tractor)

Fanfold paper setting procedures 1

This section describes how to set fanfold paper for front loading and rear ejection

or front loading and top ejection. Before setting fanfold paper, it is necessary to

specify the page length, paper width, etc. on the SETUP MODE.

Rating

10 X 11 - 1P

Page lengthPaper width

Fanfold paper rating marked on side of package (Example)

Multipart paper

(Number of sheets)

Paper loading direction

Paper loading direction

F.TR REAR 11 x 15 F.TR TOP 11 x 15

1

1

Page 36

3. Specify the page length using #4 PAGE

LENGTH on the SETUP MODE as shown

below.

4. Then specify the paepr width using #5

PAPER WIDTH on the SETUP MODE as

shown below.

1-13

—

1. Setting up the printer

—

●

Loading fanfold paper (Front tractor)

Fanfold paper setting procedures 2

SET UP

1. MULTIPART

4. PAGE LENGTH

1. MULTIPART

ENTER

4. PAGE LENGTH

F.TR REAR A5 p

PAGE: 11 INCH

SIZE: A5 p*

PAGE: 11 INCH

PAGE: 11 INCH*

4.PAGE LENGTH

ENTER

5.PAPER WIDTH

SAVE?: YES

F.TR REAR 11 x 10

WIDTH: 10 INCH

WIDTH: 15 INCH*

WIDTH: 10 INCH*

ENTER

WIDTH: 10 INCH

EXIT

SAVE?: YES

5.PAPER WIDTH

Page 37

1-14

5. Open the front cover.

6. Lift to release the tractor lock lever. Move

the left tractor to the triangle mark. Then

push down on the lever.

—

1. Setting up the printer

—

●

Loading fanfold paper (Front tractor)

Fanfold paper setting procedures 3

Do not put your finger under the tractor cover.

Open the front cover by

pressing both side locks

with both hands. Hold

both sides with both

hands to raise it upward

slowly. When closing

the front cover, hold

both sides with both

hands to pull it down

slowly. Press the front

cover to lock it.

Push the lock levers of

both tractors to the

LOCK positions firmly.

If the lock levers

protrude from the

tractor covers, paper

will not be fed properly,

resulting in paper

jamming.

In order to load

less than 5 inch

width fanfold

paper, remove one

or two tractor

guides.

Caution

Caution

Release

Lock

Release

!

CAUTION

Tractor guide

Triangle mark

Lock

Lock lever

Page 38

1-15

7. Open the tractor covers on both sides. Fit

the sprocket holes on both sides of the

fanfold paper to the tractor pins. Then close

the tractor covers. Push down the lock lever

of the right tractor.

8. Close the front cover.

Hold both sides of the front cover with both

hands and pull down the front cover slowly.

Press the front cover to lock it.

—

1. Setting up the printer

—

●

Loading fanfold paper (Front tractor)

Fanfold paper setting procedures 4

By default, paper is

fed to the 14/60

inch (approximately

6 mm) position

from the top. This position

may be freely adjusted on

the SETUP MODE

between 0/60 inch (0 mm)

and 63/60 inches

(approximately 26.7 mm)

from the top of paper or the

perforation at a pitch of

1/60 inch.

The TOF position can be set from 0/60 inch (0

mm). However, if this position is set to 0/60 to

9/60 inch, paper may jam, depending on the paper condition. Normally,

it is recommended that the TOF position be adjusted to the 14/60 inch

(approximately 6 mm) position from the top of the paper.

when setting the paper on the tracter, Take care

not to over tighten or allow too much slack. Over

tightening deforms the guide holes and the paper may become

disconnected from the tracter during printing. Too much slack may

cause the paper to become clogged when it is inserted.

Caution

Caution

Page 39

1-16

—

1. Setting up the printer

—

●

Loading fanfold paper (Rear tractor)

1. Detach the rear printer cover from the

printer.

2. Install the rear tractor, and plug in the

connector.

Dual paper parking is available if the optional rear tractor is used. This funcion

enables two types of fanfold paper of different formats to be set together and

selected with the PAPER PATH key on the printer or by issuing a setup command

from the computer.

1

Leg

Leg

1

Paper setting procedures usig rear tarctor 1

Pull the upper

part of the rear

printer cover to

the front to

detach it from the printer.

When attaching the rear

printer cover, insert

the two legs into the

printer and then press

the rear printer cover

to lock it.

Page 40

1-17

—

1. Setting up the printer

—

3. Adjust the tractor guides so that they are

located at almost the same interval. Lift and

release the tractor lock levers. Move the left

tractor to the triangle mark, then push down

the lever.

4. Set fanfold paper onto the rear tractor. Push

down the lock lever of the right rear tractor.

●

Loading fanfold paper (Rear tractor)

Triangle mark

1

Tractor guide

Lock

Release

1

Paper setting procedures usig rear tarctor 2

Push the lock levers of

both tractors to the

LOCK positions firmly.

Do not put your

finger under the

tractor cover.

In order to load

less than 8 inch

width fanfold

paper, remove

one or two tractor

guides.

Caution

!

CAUTION

Page 41

1-18

5. Enter the EXTENDED SETUP MODE. Select

the rear tractor on this menu so that the

printer recognizes that the rear tractor is in

use.

6. Press the PAPER PATH key to select REAR

Tr FRONT.

7. “OPEN PAPER RACK” will be displayed. Open

the paper rack.

—

1. Setting up the printer

—

●

Loading fanfold paper (Rear tractor)

SET UP

F.TR REAR 11 x 10

20. EMULATION

60. OPTION

NOT INSTALL*

60. OPTION

ENTER

EXIT

F.TR REAR 11 x 10

ALT

60. OPTION

INITIAL

INITIAL

OPTION: REAR Tr.*

OPTION: REAR Tr.

OPTION: REAR Tr.

Paper setting procedures usig rear tarctor 3

Page 42

1. Check the rating of the cut sheet paper to be

used that is marked on the side of the

package.

2. Press the PAPER PAHTH key to select

MANUAL FRONT or MANUAL TOP, or MANUAL

REAR .

3. Specify the form size correctly on the

SETUP MODE (#4 PAGE LENGTH).

1-19

—

1. Setting up the printer

—

●

Loading cut paper

(manual paper feeding)

Select Manual feeding procedures 1

This section describes how to load cut sheet paper, showing an example of using

an A5 portrait form. Before loading a cut sheet, it is necessary to specify the

paper size on the SETUP MODE. Be sure to load cut sheet paper one sheet at a

Rating

A5 (Wood-Free / 70kg)

Wood-free paper

Form size

Cut sheet paper rating marked on side of

package (Example)

Paper weight

1. MULTIPART

4. PAGE LENGTH

SIZE: A5 p

SIZE: A4 p*

4. PAGE LENGTH

SIZE: A5 p *

ENTER

SIZE: A5 p

ENTER

SET UP

MAN FRNT A4 p

1. MULTIPART

SAVE? : YES*

EXIT

4. PAGE LENGTHSAVE? : YES

MAN FRNT A5 p

Page 43

1-20

4. Adjust the edge of the paper guide to

approximately 2 mm left of the triangle mark.

Refer to page 1-21 regarding use of the paper rack guide.

●

Loading cut paper

(manual paper feeding)

—

1. Setting up the printer

—

Select Manual feeding procedures 2

Mark

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAA

1

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

LOAD

EJECTION

EJEC TION

MAN F

MAN

REA

TOP

1

EJECTION

R

RN

T

MAN

The triangle mark shows the printing start

position at the left of the printer.

Page 44

1-21

5. Insert a sheet of paper straight along the

paper guide.

If paper is inserted at a skewed angle, the skew sensor detects

and the paper is ejected.

—

1. Setting up the printer

—

●

Loading cut paper

(manual paper feeding)

Insert sheets of paper one at a time along the paper

guide. Only one sheet at a time can be set on the

paper rack.

Select Manual feeding procedures 3

To alternate manual printing and printing with the

optional rear tractor or CSF, be sure to move the

paper guide to the left end after completion of

manual printing. Further, return the paper guide of the paper rack

to the left end. If printing is performed using the rear tractor or

CSF with the paper guide left in the manual feeding position,

paper loaded form the back will hit the paper guide, resulting in

paper jamming.

Move the Paper Guide and the Paper Support Guide to the left end.

When using wide paper, insert

the paper using the paper

support guide attached to the

left end of the paper rack.

Caution

Caution

Page 45

1-22

1. Press the EJECT/LOAD key to move back

the fanfold paper.

2. Enter the EXTENDED SETUP MODE

according to the proceures shown below

and select #60 OPTION on the menu. Select

CSF (cut sheet feeder).

3. Detach the rear printer cover from the

printer.

—

1. Setting up the printer

—

●

Printing using the cut sheet feeder (Option)

Printing procedures using CSF 1

An optional cut sheet feeder is available for this printer. The cut sheet feeder is

useful for continuous printing on cut sheets.

The paper holder of the cut sheet feeder accommodates a maximum of 150 sheets

(of 55 kg paper). Normal paper and multipart paper can be used.

SET UP

F.TR REAR 11 x 10

20. EMULATION

60. OPTION

OPTION: CSF

NOT INSTALL*

60. OPTION

OPTION: CSF*

ENTER

EXIT

F.TR REAR 11 x 10

ALT

60. OPTION

INITIAL

INITIAL

OPTION: CSF

1

Leg

Leg

Pull the upper

part of the rear

printer cover to

the front to

detach it from the printer.

When attaching the rear

printer cover, insert the

two legs into the printer

and then press the rear

printer cover to lock it.

Page 46

1-23

4. Attach the hoppers and center support to

the cut sheet feeder.

5. Attach the cut sheet feeder to the back of

the printer.

—

1. Setting up the printer

—

●

Printing using the cut sheet feeder (Option)

Printing procedures using CSF 2

1

CSF

1

Hopper

Center support

Use two hands and hold

firmly at each end when

lifting the cut sheet

feeder. Personal injury

can occur if the CSF unit

is dropped.

!

CAUTION

Page 47

1-24

6. Shuffle the paper as show below.

7. Turn the CSF release levers to the front to

release the paper bins.

—

1. Setting up the printer

—

●

Printing using the cut sheet feeder (Option)

Printing procedures using CSF 3

Be sure to shuffle sheets sufficiently before setting

them. Otherwise, several sheets of paper may be fed

at the same time resulting in a paper jam.

CSF release lever

Caution

Page 48

1-25

8. Turn the paper guide lock levers to the

RELEASE positions to adjust the paper

width.

9. Turn the paper guide lock levers to the

LOCK positions.

—

1. Setting up the printer

—

●

Printing using the cut sheet feeder (Option)

1

Mark

Adjust the edge of the paper guide to

appriximately 2mm left (outside) of the

triangle mark.

CARD

Paper guide lock lever

Postcard changeover lever

When printing on postcards,

turn this lever down.

Release

Lock

Printing procedures using CSF 4

The triangle mark shows the printing start

position at the left of the paper.

Adjust the paper guide

to remove the gap

between the paper and

the paper guide, ensuring

that the paper does not press

too tightly against the paper

guide to avoide faulty

feeding.

Page 49

1-26

—

1. Setting up the printer

—

●

Printing using the cut sheet feeder (Option)

10. Move the CSF release levers to the back to

fix the paper bins.

11. Press the PAPER PATH key to select CSF

FRONT or CSF TOP.

12. Press the ENTER key to select the displayed

paper path.

CSF TOP A4 p

CSF FRNT A4 p

Printing procedures using CSF 5

Page 50

1-27

—

1. Setting up the printer

—

1. Turn on the printer power while keeping the

LINE FEED key, or LINE FEED and ONLINE

keys depressed.

After initialization, the printer enters the self-test mode and starts the

self-test.

During printing, the ONLINE lamp blinks at an interval of 0.5 second.

The following message is displayed on the LCD.

The draft or LQ self-test prints the ASCII character in a rolling pattern.

2. To pause the self-test, press the ONLINE

key.

To terminate the self-test, keep the ALT and

RESET keys depressed for two seconds or

more, or turn the power switch to off.

●

Running self-test

It is recommended that a self-test of the printer be performed before connecting

the printer to the computer. The printer can execute the self-test by itself to check

on printing quality, printing pressure, and any printer troubles.

Draft self-test printing: Turn on power while pressing the

LINE FEED key.

LQ self-test printing: Turn on power while pressing the LINE

FEED and ONLINE keys.

Draft self-test printing “SELF TEST DRAFT”

LQ self-test printing “SELF TEST LQ”

Page 51

1-28

—

1. Setting up the printer

—

1. Make sure that the power switch is turned to

off. Connect the signal cable to the printer

and computer.

2. Specify the following parallel interface

parameters on the EXTENDED SETUP

MODE.

●

Connecting the printer to the computer

13

25

1

14

Close the latches to secure

the connector.

Latches

Parallel Interface

The printer has a Centronics parallel interface and an RS-232S serial interface

as standard features.

Select the appropriate interface according to the computer and application

software to be used.

Connecting the priter to the computer

The printer has been set to the normal parallel

interface setting before shipment. If the default

setting does not provide proper communication,

recheck the interface setting shown below.

EXTENDED SETUP MODE Default setting page

#70. INTERFACE Parallel 3-46

#71. SELECT IN ENABLE 0 3-47

#81. BUFFER SIZE 512 KB 3-52

#82. BUSY/ACK TIMING TYPE 2 3-53

#83. DATA LATCH TIMING TYPE F. 3-53

#84. ERROR STATUS YES 3-54

Page 52

1-29

—

1. Setting up the printer

—

1. Make sure that the power switch is turned to

off. Connect the signal cable to the printer

and computer.

2. Specify the following serial interface

parameters on the EXTENDED SETUP

MODE.

●

Connecting the printer to the computer

Serial Interface

13

25

1

14

Tighten the screws on both

sides of the connector.

Specify the following serial interface parameters on

the EXTENDED SETUP MODE.

EXTENDED SETUP MODE Default setting Page

#70. INTERFACE Parallel 3-46

#

71. SELECT IN ENABLE 0

3-47

#

72. PARITY BIT Non

3-47

#

73. DATA LENGTH 8 bits

3-48

#

74. STOP BIT 1 bit

3-48

#

75. PROTOCOL DTR

3-49

#

76. BAUD RATE 9600 bps

3-49

#

77. SERIAL ERROR Print

3-50

#

78. CTS ENABLE No

3-50

#

79. CD ENABLE No

3-51

#

80. DSR ENABLE No

3-51

#81. BUFFER SIZE 512 KB 3-52

Page 53

1-30

—

1. Setting up the printer

—

1. Turn on the printer power while keeping the

FORM FEED key or FORM FEED and ONLINE

keys depressed.

While printing the hexadecimal dump list, the following message is

displayed.

2. Output data from the computer to the

printer.

The printer will begin to print the hexadecimal dump list.