Page 1

DPU-414

SERIAL THERMAL PRINTER

SERVICE MANUAL

U00100139501

Seiko Instruments Inc.

Page 2

DPU-414 SERVICE MANUAL

Document Number U00100139501

First Edition December 1996

Second Edition January 2006

Copyright 1996,2006 by Seiko Instruments Inc.

All rights reserved.

Seiko Instruments Inc. (SII) has prepared this manual for use by Sll personnel,

Iicensees, and customers. The information contained herein is the property of Sll and

shall not be reproduced in whole or in part without the prior written approval of SII.

Sll reserves the right to make changes without notice to the specifications and

materi-als contained herein and shall not be responsible for any damages (including

consequential) caused by reliance on the materials presented, including but not

limited to typographical, arithmetic, o r l i s t i n g e r r o r s .

Sll is a trademark of Seiko Instruments Inc.

ii

Page 3

TABLE OF CONTENTS

Section Page

CHAPTER 1

GENERAL SPECIFICATIONS...................................1-1

1.1 PRINTER SPECIFICATIONS ............................................................1-1

1.2 THERMAL PAPER SPECIFICATIONS ........................................... 1-2

1.3 BATTERY PACK (OPTION) SPECIFICATIONS ............................. 1-3

1.4 AC ADAPTER (OPTION) SPECIFICATIONS ........ ............................1-3

CHAPTER 2

DISASSEMBLY..............................................2-1

CHAPTER 3

ADJUSTMENT...............................................3-1

3.1 ADJUSTING THE APPLIED ENERGY FOR THE THERMAL HEAD .3-1

3.2 ADJUSTING THE CHARGING TIME FOR THE BATTERY ............ 3-4

CHAPTER 4

TROUBLESHOOTING.........................................4-1

CHAPTER 5

CIRCUIT DIAGRAM ..........................................5-1

5.1 MAIN BOARD CIRCUIT DIAGRAM ...................................................5-2

5.2 SWITCH BOARD CIRCUIT DIAGRAM ........................................... 5-5

CHAPTER 6

BOARD DIMENSIONS ........................................6-1

6.1 MAIN BOARD DIMENSION ............................................................ 6-2

6.2 SWITCH BOARD DIMENSION ....................................................... 6-3

CHAPTER 7

PARTS LIST ................................................7-1

CHAPTER 8

PACKING SPECIFICATIONS...................................8-1

iii

Page 4

TABLES

Table Page

1-1 Printer Specifications ...................................................................... 1-2

1-2 Thermal Paper Specifications ......................................................... 1-3

1-3 Battery Pack (OPTION) Specifications ........................................... 1-3

1-4 AC Adapter (OPTION) Specifications ...............................................1-3

7-1 Parts List ...........................................................................................7-3

8-1 Packing List ....................................................................................... 8-3

FIGURES

Figure Page

2-1 Remaining the Screws of the Upper Cover.........................................2-1

3-1 Head Rank Mark ............................................................................... 3-1

5-1 Main Board Circuit Diagram (1/3) ......... .. .. ... .. .. .. .......................... .. ... . 5-2

5-2 Main Board Circuit Diagram (2/3) ........ .. .. .. .. ... .. .......................... .. .. .. .. 5-3

5-3 Main Board Circuit Diagram (3/3) ......... .. .. ... .. .. .. .......................... .. .. 5-4

5-4 Switch Board Circuit Diagram ...........................................................5-5

6-1 Main Board Wiring Pattern (Heads side) ......................................... 6-2

6-2 Main Board Wiring Pattern (Tails side) ............................................ 6-2

6-3 Main Board Parts Layout (Heads side) ................. ... ....................... 6-3

6-4 Main Board Parts Layout (Tails side) ......................... .. .. .. .. ... .. .. .. .. .. 6-3

6-5 Switch Board Dimensions ............................................................... 6-4

7-1 Parts Developments .......................................................................... 7-2

8-1 Packing Materials Developments ...................................................... 8-2

iv

Page 5

CHAPTER 1

GENERAL SPECIFICATIONS

1.1 PRINTER SPECIFICATIONS

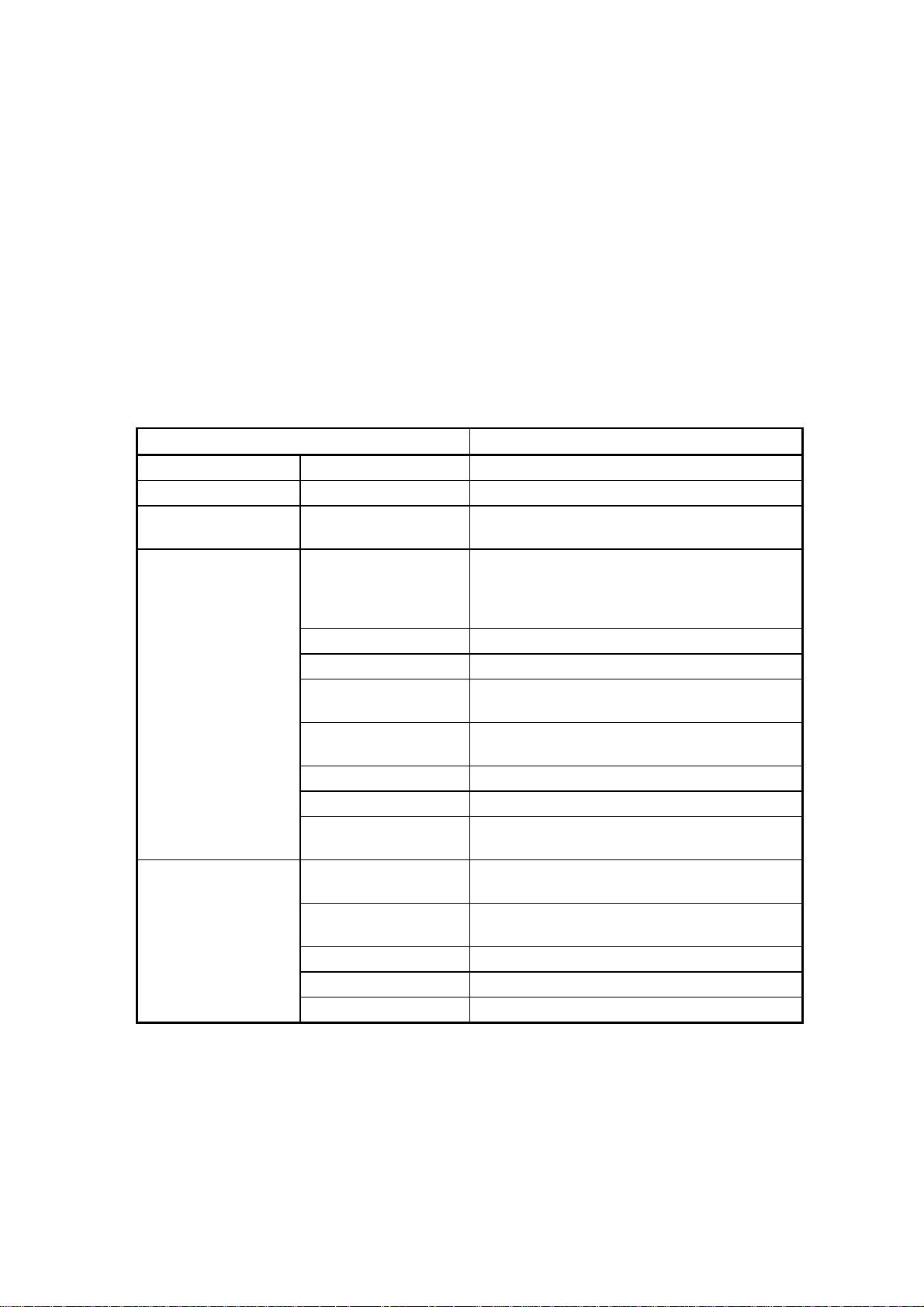

Table 1-1 Printer Specifications

Item Specification

Model number DPU-414-30B -E

Print method Thermal serial dot method

Image mode selection Swichable to character mode or bit-image

graphic mode through program.

JIS special patterns: 222 kinds

International (Country) characters: 28 kinds

Special characters: 6 kinds

Total: 256 kinds

2.47 x I .88 mm: at 40 column (normal)

2.47 x 0.94 mm: at 80 column (condensed)

40 column (normal)

80 column (condensed)

Max. 52.5 cps (normal)

Max. 80 cps (condensed)

8 x 320 dots / Iine (single density)

8 x 640 dots / Iine (double density)

0.28 mm (single density)

0.14 mm (double density)

Character mode

specifications

Bit-image graphics

mode specifications

Fonts

Total number of dots 9 x 320 dots / Iine

Character matrix 9 dot high x 7 dot wide

Character dimension

Columns

Line space Programable (default: 6 dots)

Printing direction Unidirectional or bidirectional logical seek

Printing speed

Total number of dots

Horizontal dot pitch

Vertical dot pitch 0.28 mm

Printing width 89.6 mm

Printing direction Unidirectional logical seek

1-1

Page 6

Table 1-1 Printer Specifications (Continued)

Item Specification

Life 500 thousand lines or over

(“8” 40 digit continuous printing)

Interface 8-bit parallel and RS-232C serial

External dimensions 160 mm x 170 mm x 66.5 mm

Mass

Operating

temperature

Environmental

conditions

Chargeable

battery

Connectors

(printer side)

Input buffer 28 Kbytes

Strage

temperature

Operating

humidity

Strage humidity 5 to 90 '% RH (non-condens ing)

Charging time

Battery life approx. 3,000 Iines in character printing.

Serial interface RDED-9SE-LN (Hirose) or equivalent

Parallel interface 57LE-40360-7700 (D29) (DDK) or equivalent

Power

(AC adapter)

approx. 580 g

(excluding the battery pack and thermal roll pape r)

0 to 40 °C (32 to 104 °F)

-20 to +60 °C (-4 to 140 °F)

30 to 80 % RH (non-co ndensing)

approx. 10 hours through the AC adapter at power

OFF the printer.

HEC0470-01 -630 (Hosiden) or equivalent

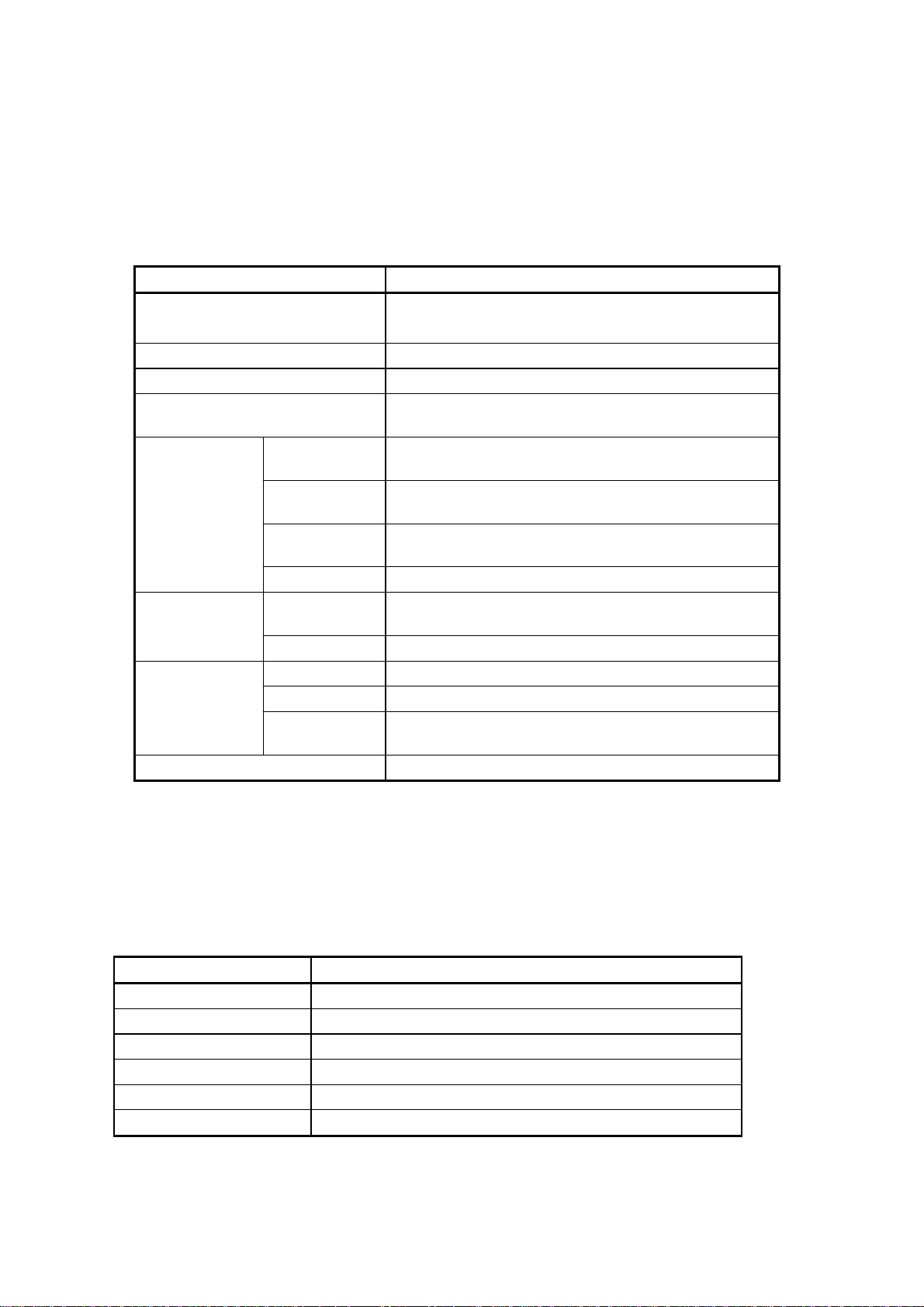

1.2 THERMAL PAPER SPECIFICATIONS

Table 1-2 Thermal Paper Specifi cations

Specification

Item

Product No. TP411 -28CL (TP-411 L)

Type Normal thermal paper

Paper width 112 mm

Roll external diameter 48 mm (maximum)

Paper length approx. 28 m

Paper thickness 64 ± 4 µm

1-2

Page 7

CHAPTER 1 GENERAL SPECIFICATIONS

1.3 BATTERY PACK (OPTION) SPECIFICATIONS

Table 1-3 Batter y Pack (OPTION) Specifications

Item Specification

Product No. BP-4005-E

Battery type Ni-MH battery

Output voltage 4.8 V

Weight approx. 0.26 lbs (approx. 120 g)

1.4 AC ADAPTER (OPTION) SPECIFICATIONS

Table 1-4 AC Adapter (OPTION) Specificatio ns

Item Specification

Model number PW-4007-U1-E PW-4007-E1-E

External dimensions

(W × D × H)

Weight approx. 690g approx. 1000g

Cable length approx.1.9m approx.1.9m, 1.9m

Input power voltage AC 120 V AC 230 V

Frequency 60 Hz 50 Hz

Rated output voltage DC 6.5 V DC 6.5 V

Rated output current 2.0 A 2.0 A

Safety regulation UL, CSA CE

100 mm × 58mm × 49 mm 1 14 mm × 74 mm × 61 mm

1-3

Page 8

1-4

Page 9

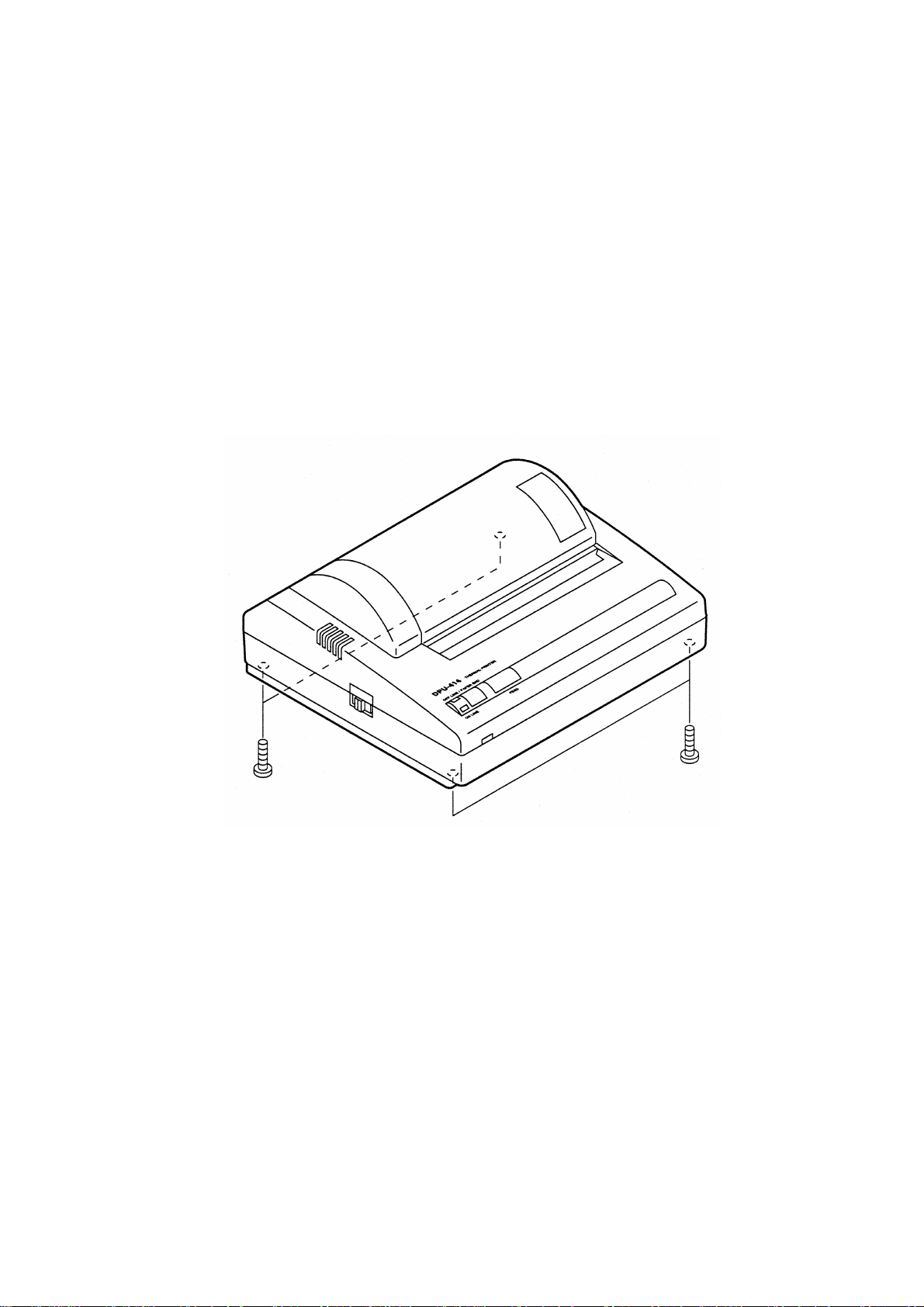

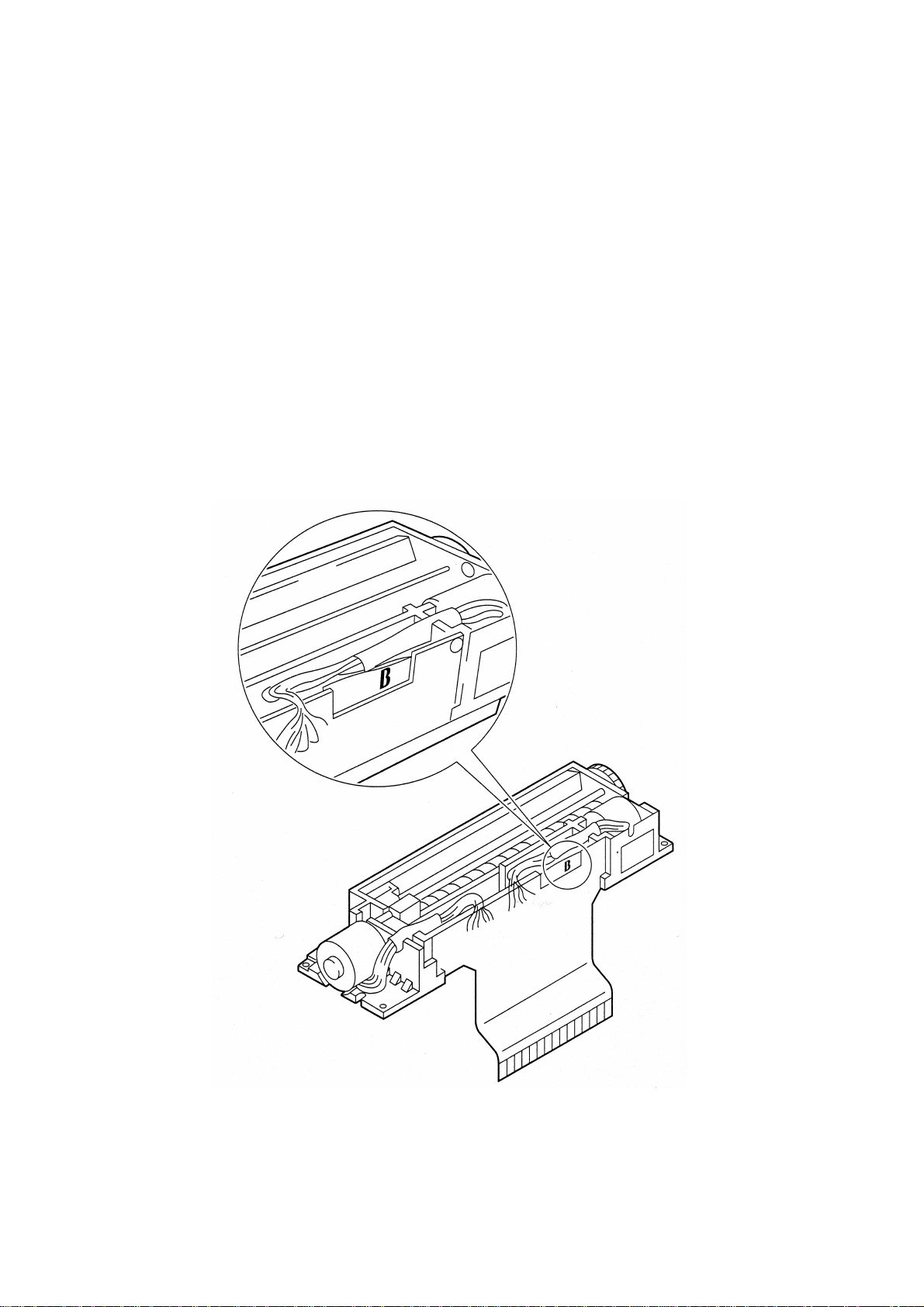

CHAPTER 2

DISASSEMBLY

How to disassembly the DPU-414 Serial Thermal Printer is given in this chapter.

Procedure:

1. Remove the 4 screws in the bottom of the printer.

2. Lift the upper cover straight up to remove.

Figure 2-1 Remaining the Screws of the Upper Cover

2-1

Page 10

2-2

Page 11

CHAPTER 3

ADJUSTMENT

How to adjust the applied

given in this

chapter.

energy for the thermal head and the charging time for the battery are

3.1 ADJUSTING THE APPLIED ENERGY FOR THE THERMAL HEAD

Procedure:

1. Check the head rank mark (A, B or C) displayed on the FPC of the printer mechanism

Figure 3-1 Head Rank Mark

3-1

Page 12

2. Initialize the dipswitches with the following procedure:

1. Remove the AC adapter from the power plug.

2. Connect the AC adapter to the power plug.

3. Power ON the printer while pressing the ONLINE and PAPER FEED buttons on the printer.

4. Release the ONLINE and PAPER FEED buttons after the ONLINE and OFFLINE Iamps blink.

It takes approx. 30 seconds.

3. Initialize the applied energy for the thermal head with the following procedure:

1. Prepare a parallel interface communication between the printer and the computer.

2. Send the following command from the computer:

ESC + "!" + FF

+ FF16

16

4. Set the head rank and the dipswitches with the following procedure:

1. Prepare a parallel interface communication between the printer and the computer.

2. 2. Send one of the following commands from the computer according to the head rank used:

Head rank

A ESC + "." + EB

B ESC + "." + EB

C ESC + ". " + EB

Command

+ FF16+ FF16+ 7316

16

+ FF16+ FF16+ 7216

16

+ FF16+ FF16+ 7116

16

5. Make sure that the printing density is OK by printing a test print.

3-2

Page 13

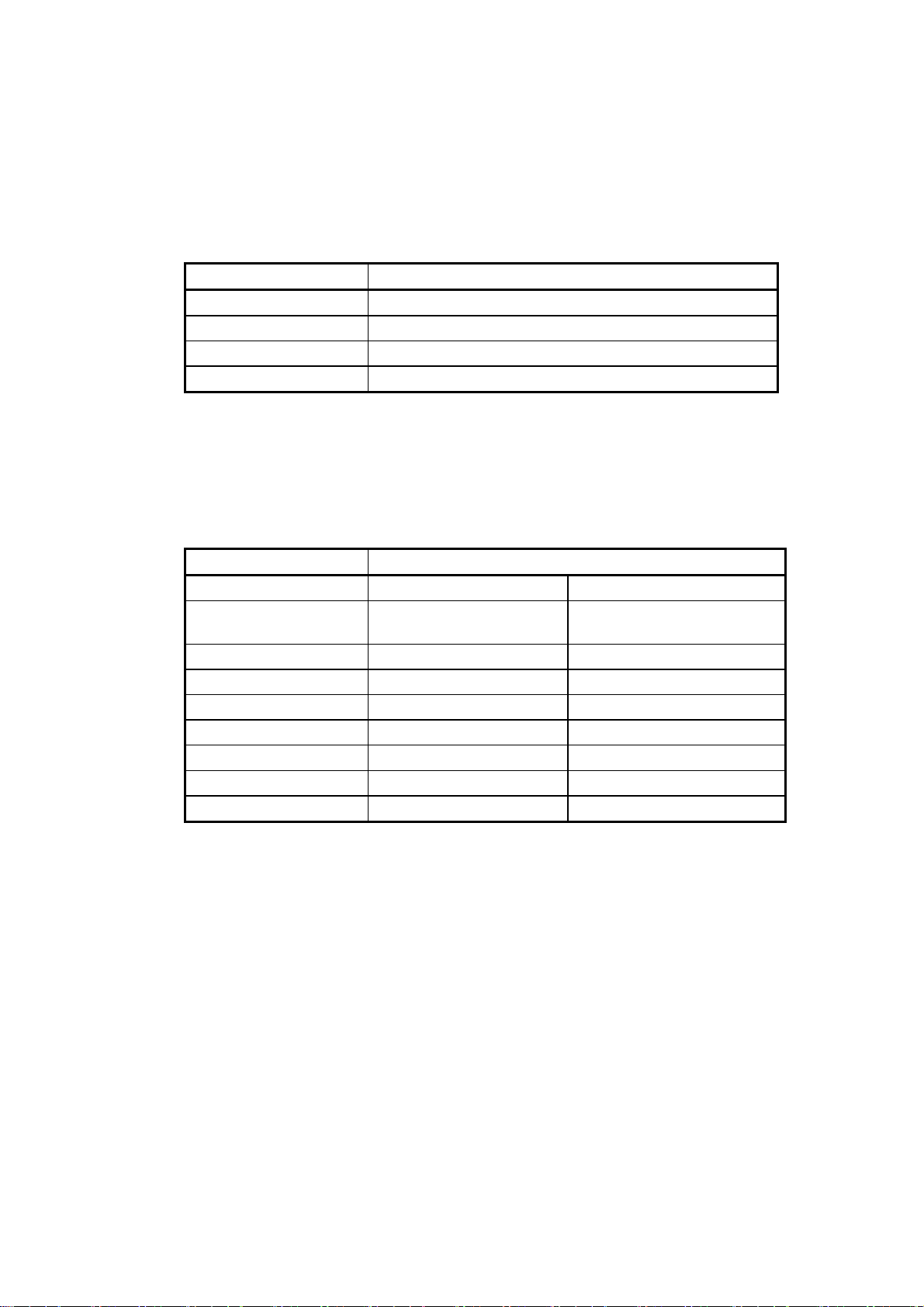

[Reference:]

Head Pulse Width:

[Condition:]

CAPTER 3 ADJUSTMENT

• 2-2 phase

• High speed print mode

• Print density: 100%

• Non-s im ulatio n of st rage he at

=Th

R×7.1

2

)25.0-Vp(

T-24

×2.1+1(×

op

10

Th: Head pulse width (ms)

Vp: Head applied voltage (V)

R: Head resistance (Ω)

Head rank

Resistance

A 17.9

B 16.3

C 14.7

Top: Ambient temperature (°C)

M: Correction factor according to the number of common activated dots

Number of dots

m

0 to 3 1.000

4 to 6 1.125

7 to 9 1.250

n: Correction factor according to the activation history

n×m×)

Activation history

000 7 / 7

100 6 / 7

010 5 / 7

110 5 / 7

001 4 / 7

101 4 / 7

011 4 / 7

111 4 / 7

n

3-3

Page 14

3.2 ADJUSTING THE CHARGING TIME FOR THE BATTERY

Procedure:

1. Initialize the dipswitches with the following procedure:

1. Remove the AC adapter from the power plug.

2. 2. Connect the AC adapter to the power plug.

3. Power ON the printer during pressing ONLINE and PAPER FEED button on the printer.

4. Relea se ONLINE and PAPER FEED buttons after the ONLINE and OFFLINE lamps blink. It

takes approx. 30 seconds.

2. Initialize the charging time for the battery with the following procedure:

1. Prepare a parallel interface communication between the printer and the computer.

2. Send the following command from the computer:

ESC + "#" + FF

3. Set the head rank and the dipswitches with the following procedure:

1. Prepare a parallel interface communication between the printer and the computer.

2. Send one of the following commands according to the head rank used from the computer:

16

Head rank

Command

A ESC + "." + EB

B ESC + "." + EB

C ESC + "." + EB

+ FF16 + FF16 + 7316

16

+ FF16 + FF16 + 7216

16

+ FF16 + FF16 + 7116

16

3-4

Page 15

CHAPTER 4

TROUBLESHOOTING

In this chapter, possible causes, the method for the ir diagnosis, and suggested recovery procedures for

problems that may occur when using the DPU-414 Serial thermal Printer are given.

Below is a listing of the items covered in this chapter, along with the number of the page where they can

be found.

No. Problem Page number

(1) No power. (with the AC adapter) 4-2

(1’) No power. (without the AC adapter) 4-2

(2) Battery is not charged. 4-2

(3) No interface Communication. 4-3

(4) Paper can not be fed. 4-3

(5) Abnormal sound is emitted. 4-3

(6) ERROR LED lights. 4-4

(7) The printer is not initialized. 4-4

(8) Nothing is printed. 4-4

(9) Dots are missing. 4-5

(10) Shortened printing in horizontal direction. 4-5

(11) Defective printing density. 4-5

(12) Uneven printing 4-6

(13) Shortened paper feed pitch. 4-6

4-1

Page 16

(1) No power. (with the AC adapter)

[Condition] The printer operates, but LEDs do not lights.

Possible cause Diagnostic method

Flat ribbon cable

disconnected

Defective soldering for LED or

defective LED

Defective mainboard

Check the continuity of the flat ribbon cable

with a tester.

Check the continuity of the LED with a

tester.

Measure the voltage of the LED with a

tester.

[Condition] The printer does not operate.

Possible cause Diagnostic method

AC adapter disconnected Measure the output voltage with a tester. 8.5 ± 2.0V Replace the AC adapter.

Defective main board

Measure the system clock for the main

board with an oscilloscope.

(1') No power. (without the AC adapter)

[Condition] The printer does not operate.

Possible cause Diagnostic method

The battery is not charged

Disconnected connector

Measure the output voltage of the battery

with a tester.

Visually inspect the connection of the

connector.

(2) Battery is not charged.

[Condition] The charging time is too short or long.

Judgement

and rating

Short Replace the flat ribbon cable.

Diode resistance Replace the switch board.

2.0 ± 0.5 V Replace the main board.

Judgement

and rating

4.19 MHz Replace the main board.

Judgement

and rating

5.6 ± 1.2V

Charge the battery with the

AC adapter.

-

Insert the connector

correctly.

Recovery

Recovery

Recovery

Possible cause Diagnostic method

Charging time setting error Measure the charging time.

Judgement

and rating

Approx. 10

hours

Set the charging time

correctly.

Recovery

[Condition] The charge of the battery is not started.

Possible cause Diagnostic method

Defective voltage of the

battery

Defective AC adapter

Measure the output voltage of the battery

with a tester.

Measure the output voltage of the AC

adapter with a tester.

Judgement

and rating

0.5 to 6.8 V Replace the battery pack.

8.5 ± 2.0 V Replace the AC adapter.

Recovery

4-2

Page 17

(3) No interface communication.

[Condition] The parallel communication does not operate.

CHAPTER 4 TROUBLESHOOTING

Possible cause Diagnostic method

Dipswitch setting error

Defective main board

Check the setting of the dipswitch

through the test print.

Check the l/O signals with an

oscilloscope.

[Condition] The serial communication does not operate.

Possible cause Diagnostic method

Dipswitch setting error

Defective main board Check the l/O signals with an oscilloscope. - Replace the main board.

Check the setting of the dipswitch through

the test print.

(4) Paper can not be fed.

[Condition] The paper feed motor does not operate.

Possible cause Diagnostic method

Defective drive voltage of the

paper feed motor

Attachment of alien

substances to the gears of the

paper feed motor

Measure the voltage between motor

common and each phase with an

oscilloscope.

Visually inspect for substances around the

gears.

(5) Abnormal sound is emmited.

[Condition] There is an abnormal sound when the thermal head is scanned.

Judgement

and rating

-

- Replace the main board.

Judgement

and rating

- Set the dipswitch correctly.

Judgement

and rating

4.88 ± 0.5 V Replace the main board.

- Remove alien substances.

Set the dipswitch

correctly.

Recovery

Recovery

Recovery

Possible cause Diagnostic method

Attachment of alien

substances around the head

carrier

Awry FPC for head

Visually inspect around the head carrier for

alien substances.

Visually inspect the FPC for head for alien

substances.

Judgement

and rating

- Remove alien substances.

- Set the FPC correctly.

Recovery

[Condition] There is an abnormal sound when the paper is fed.

Possible cause Diagnostic method

Attachment of alien

substances to gears

concerned with the paper feed

Visually inspect the gear around for alien

substances.

4-3

Judgement

and rating

- Remove alien substances.

Recovery

Page 18

(6) ERROR LED Iights.

[Condition] The printer does not operate.

Possible cause Diagnostic method

Paper jams and the head does

not scan

Visually inspect the paper jam. - Remove the paper jam.

(7) The printer is not initialized.

[Condition] The head scaning motor starts and stop immediately.

Possible cause Diagnostic method

Defective timing switch

Check ON/OFF of the home switch with a

tester.

(8) Nothing is printed.

[Condition] The head operates correctly, but nothing is printed.

Possible cause Diagnostic method

Disconnected FPC for the head

Disconnection of the connector

of the FPC for the head

Burned thermal head

Reverse setting of the thermal

paper

Paper used is not a thermal

paper

Measure the resistance of the FPC for the

head with a tester.

Visually inspect the connection of the FPC

connector.

Measure the resistance of the FPC for the

head with a tester.

Visually inspect the surface of the thermal

paper.

Visually inspect the paper itself. -

[Condition] The printer does not operate.

Judgement

and rating

Judgement

and rating

- Replace the printer unit.

Judgement

and rating

16.3 ±: 3.0 Ω Replace the printer unit.

- Insert the connector correctly.

16.3 ± 3.0 Ω Replace the printer unit.

-

Set the thermal paper

correctly.

Use the specified thermal

paper.

Recovery

Recovery

Recover y

Possible cause Diagnostic method

Disconnection of the connector

of the head scaning motor

Disconnected load wire for the

head scaning motor

Defective main board

Visually inspect the connection of the head

scanning motor connector.

Check the continuity of the lead wire. Short Replace the printer unit.

Measure the drive voltage of the head

scaning motor with an oscilloscope.

Judgement

and rating

4.88 ±: 0.5 V Replace the main board.

- Insert the connector correctly.

Recovery

4-4

Page 19

(9) Dots are missing.

[Condition] Only certain dots are not printed.

CHAPTER 4 TROUBLESHOOTING

Possible cause Diagnostic method

Disconnected FPC for the

head

Defective contact between the

FPC for the head and the

connector on the board

Burned thermal head

Measure the resistance of the FPC for the

head with a tester.

Measure the resistance of the connector on

the board with a tester. 16.3 ± 3.0 Ω

Measure the resistance of the FPC for the

head with a tester.

(10) Shortened printing in horizontal direction.

[Condition] Stack of dots.

Possible cause Diagnostic method

Step-out of the head scaning

motor (Abnormality of the drive

voltage of the head scaning

motor)

Step-out of the head scaning

motor (Attachment of alien

substances around the head

carrier)

Measure the voltage between motor

common and each phase with an

oscilloscope.

Visually check alien substances around the

head carrier.

(11) Defective printing density.

[Condition] All dots are blurred or too light

Judgement

and rating

16.3 ± 3.0 Ω

16.3 ±: 3.0 Ω

Judgement

and rating

4.88 ± 0.5 V

-

Recovery

Replace the printer unit.

Insert the FPC to the

connector correctly again.

Replace the printer unit.

Replace the main board.

Remove alien substances.

Recovery

Possible cause Diagnostic method

Defective thermal head

resistance

Defective contact between the

FPC and the connector

Use of unspecified paper Visually inspect the paper used.

Error of the dipswitch setting

Error of the head rank or

applied energy setting

Measure the resistance at the FPC

terminals with a tester.

Measure the resistance at the connector

terminals with a tester.

Execute the test print and check the

printing density.

Measure the applied pulse width and

voltage with an oscilloscope.

Judgement

and rating

16.3 ± 3.0 Ω

16.3 ± 3.0 Ω

-

-

-

Replace the printer unit.

Insert the FPC to the

connector correctly again .

Use the recommended

thermal paper.

Set the dipswitch correctly.

Adjust the applied pulse

width correctly.

Recovery

4-5

Page 20

[Condition] Certain dots are blurred or too light.

Possible cause Diagnostic method

Flaw and dent of the platen

surface

Defective rocking of the platen Visually inspect alien substances around

Increase of the resistance of the

certain dots of the thermal head

Attachment of alien

substances to the platen

Visually inspect the surface of the platen

(rubber of the platen).

the platen supporter.

Measure the resistance at the FPC

terminals with a tester.

Visually inspect the surface of the platen

(rubber of the platen).

(12) Uneven printing.

[Condition] The start point of printing is uneven.

Possible cause Diagnostic method

Step-out of the head scaning

(out of range of printing)

(Defective drive voltage of the

head scaning motor)

Step-out of the head scaning

motor

(out of range of printing)

(Attachment of alien substances

around the head carrier)

Defective timing switch Check the switch timing with an

Measure the voltage between motor

common and each phase with an

oscilloscope.

Visually inspect alien substances around

the head carrier.

oscilloscope.

(13) Shortened paper feed switch.

[Condition] There is a stack of the line space.

Judgement

and rating

-

-

16.3 ± 3.0 Ω

-

Judgement

and rating

4.88 ± 0.5 V

-

-

Recovery

Replace the printer unit.

Remove alien substances

with a cotton swab.

Replace the printer unit.

Remove alien substances

with a cotton swab.

Replace the main board.

Remove alien substances.

Replace the printer unit.

Recovery

Possible cause Diagnostic method

Step-out of the paper feed

motor

(Defective drive voltage of

Measure the voltage between motor

common and each phase with an

oscilloscope.

Judgement

and rating

4.88 ± 0.5 V

Recovery

Replace the main board.

the paper feed motor)

Step-out of the paper feed

motor (Attachment of alien

substances to gears

Visually inspect around the gears.

-

Remove alien

substances.

concerned with the paper

feed)

Too much paper load

Visually inspect the set condition of

the paper.

-

Set the paper correctly

again.

4-6

Page 21

CHAPTER 5

CIRCUIT DIAGRAM

Diagrams of the circuit board are given in this chapter.

5-1

Page 22

5.1 MAIN BOARD CIRCUIT DIAGRAM

2SA1931

S-812C52AUA

NV73A1JTTE20

Figure 5-1 Main Board Circuit Diagram (1/3)

5-2

Page 23

CHAPTER 5 CIRCUIT DIAGRAM

S-808

uPD780053GC

S-93C46BD0I

36CNUA

NJL5165KB

Figure 5-2 Main Board Circuit diagram (2/3)

5-3

Page 24

uPD780053GC

22-02-3253

Figure 5-3 Main Board Circuit Diagram (3/3)

5-4

Page 25

5.2 SWITCH BOARD CIRCUIT DIAGRAM

PG7351KY

CHAPTER 5 CIRCUIT DIAGRAM

Figure 5-4 Switch Board Circuit Diagram

5-5

Page 26

5-6

Page 27

CHAPTER 6

BOARD DIMENSIONS

Dimensions of the board are given in this chapter.

6-1

Page 28

6.1 MAIN BOARD DIMENSION

4.26 (108.4)

6.06 (154)

Figure 6-1 Main Board Wiring Pattern (Heads side)

6.06 (154)

Figure 6-2 Main Board Wiring Pattern (Tails side)

Unit: inches (mm)

6-2

Page 29

CHAPTER 6 BOARD DIMENSIONS

Figure 6-3 Main Board Parts Layout (Heads side)

Figure 6-4 Main Board Parts Layout (Tails side)

6-3

Page 30

6.2 SWITCH BOARD DIMENSION

2.36 (60)

0.94 (24)

Figure 6-5 Switch Board Dimensions

6-4

Unit: inches (mm)

Page 31

CHAPTER 7

PARTS LIST

Diagrams and list of the DPU-414 Serial thermal Printer parts are given in this chapter.

7-1

Page 32

Figure 7-1 Parts Developments

7-2

Page 33

CHAPTER 7 PARTS LIST

Table 7-1 Parts List

No. Part No. Part name Qty. Comments

U000092913X3

1

2

3

4

5

6

7

8

9

10

11

U000093374X2

U000952806X0

U000955855X0

U000955866X0

U000094421X1

U000093600X1

U000095038X0

U000095084X0

U000094948X0

U000076116X0

UPPER CASE 1 With paper cutter

BOTTOM CASE 1 With rubber foot

PRINTER MECHANISM BLOCK 1

MAIN PCB BLOCK 1 With ribbon wire

SWITCH PCB BLOCK 1

PAPER COVER 1

BATTERY LID 1

POWER SW SLIDER 1

ALTERNATE SW BUTTON 1

FEED BUTTON 1

GROUNDING TERMINAL A 1

U00009793100

12

U00099961700

13

U00095504500

14

U00009794200

15

U00009803200

16

Pan head tap tight screw (B tight),NIP,

2.0 x 6

Pan head tap tight screw (B tight) ,NIP,

2.6 x 18

Pan head tap tight screw (B tight) ,NIP,

3.0 x 6

Pan head tap tight screw (B tight) ,NIP,

3.0 x 10

Sems screw (T) ,NIP,

M3.0 x 8

For attaching PRINTER

4

MECHANISM BLOCK

For attaching UPPER

4

CASE and BOTTOM

CASE

For attaching MAIN PCB

BLOCK and SWITCH PCB

3

BLOCK

For attaching

GROUNDING TERMINAL

1

A

1 For attaching terminal

7-3

Page 34

7-4

Page 35

CHAPTER 8

PACKING SPECIFICATIONS

The packing list and diagrams for the DPU-414 Serial Thermal Printer are given in this chapter.

8-1

Page 36

1

3 (cushion)

2

3 (vinyl bag)

Figure 8-1 Packing Materials developments

3 (inner box)

3 (outer box)

8-2

Page 37

CHAPTER 8 PACKING SPECIFICATIONS

Table 8-1 Packing List

No. Part No. Part name Qty. Comments

1

2

3

U000448558X6

U000765854X0

U000086185X0

USER'S GUIDE

THERMAL ROLL PAPER 1

Individual Packing Box Set 1

1

Outer box, inner box,

cushion and vinyl bag

8-3

Loading...

Loading...