Page 1

DPU-30

THERMAL PRINTER

TECHNICAL REFERENCE

U00084936302

Seiko Instruments Inc.

Page 2

DPU-30 TECHNICAL REFERENCE

Document Number U00084936302

First Edition January 2004

Second Edition

Third Edition March 2006

Seiko Instruments Inc. (SII) has prepared this manual for use by SII personnel, licensees, and

customers. The information contained herein is the property of SII and shall not be reproduced in

whole or in part without the prior written approval of SII.

November 2005

Copyright

©2004, 2005, 2006 by Seiko Instruments Inc.

All rights reserved.

SII reserves the right to make changes without notice to the specifications and materials contained

herein and shall not be responsible for any damages (including consequential) caused by reliance

on the materials presented, including but not limited to typographical, arithmetic, or listing errors.

SII is a trademark of Seiko Instruments Inc.

ESC/POS is a trademark of EPSON.

Page 3

Introduction

DPU-30-0B-E is a compact printer unit which is connected to a computer or a host system via a

parallel port (Centronics interface) or serial port (RS-232C) and prints the data input through such

interface in the direct thermal printing.

Features of this printer

• Provides the High-speed and noiseless print according to thermal printing system.

• Because of the direct thermal printing, this printer is very quiet while printing.

• Prints both 16×16 and 24×24 dot size characters clearly.

• Prints the Kanji characters (JIS level 1 non-kanji, level 1 and 2).

• Prints barcodes using the barcode print function. (UPC-E, JAN13, JAN8, CODE39, ITF,

CODABAR, and CODE128).

• Test patterns can be printed.

• Prints the test pattern and dump mode characters.

• Print the various size characters such as enlargement character.

Standard size character

Kanji size character

Enlargement characters (64 times characters size max)

• Defines the line spacing and character spacing arbitrarily.

• Prints the various size characters such as enlargement character.

• Prints the graphic using the Bitimage.

• Registers and prints any font using the downloaded character function and user-defined

character function.

• Feeds paper forward or backward using the paper feed functions.

• Characters to be printed can be inverted from black-on-white to white-on black, or vice versa.

• Characters to be printed can be flipped from top to bottom.

• Provides various functions including the reverse printing, flip or ruler line.

• Changes the print density using print density command.

• ESC/POS compliant command system is adopted.

Structure of this printer

• This printer is compact and thin so that it takes less space than the others.

• Its design is simple so that it can be used with any type of devices.

Functions

• The out-of-paper detection sensor is mounted on this printer.

• The easy-to-use operation function allows to easily replenish paper.

Power supply

• The power is fed via a connector for interface.

Page 4

Page 5

TABLE OF CONTENTS

Section Page

CHAPTER 1 OPERATIONAL PRECAUTION

1.1 SAFETY PRECAUTION............................................................................................... 1-1

1.2 NOTES ON USE .......................................................................................................... 1-2

1.3 NOTES ON TREATMENT OF THERMAL PAPERS.................................................... 1-3

1.4 NOTES ON INSTALLATION........................................................................................ 1-3

CHAPTER 2 TERMS USED IN THIS MANUAL

CHAPTER 3 PREPARATIONS AND OPERATION

3.1 PARTS NAME .............................................................................................................. 3-1

3.2 DIMENSIONS............................................................................................................... 3-2

3.3 INSTALLATION............................................................................................................ 3-4

3.4 SETTINGS OF THE FUNCTIONS............................................................................... 3-6

3.4.1 Test Print..................................................................................................... 3-7

3.4.2 Hex Dump Print........................................................................................... 3-7

3.4.3 Paper Empty (Paper Out) Detection Function............................................. 3-7

3.4.4 Adjustment of Print Density......................................................................... 3-7

3.4.5 Resetting the Printer While Printing ............................................................ 3-8

3.4.6 Memory ....................................................................................................... 3-8

CHAPTER 4 INTERFACE

4.1 CONNECTOR TERMINAL LAYOUT............................................................................ 4-1

4.2 PARALLEL INTERFACE.............................................................................................. 4-3

4.3 SERIAL INTERFACE ................................................................................................... 4-3

CHAPTER 5 COMMAND FUNCTION

5.1 FUNCTION OUTLINE .................................................................................................. 5-1

5.1.1 Mode 1/Mode 2 ........................................................................................... 5-1

5.1.2 Mode 3 ........................................................................................................ 5-2

Page 6

Section Page

5.2 FUNCTION CODES..................................................................................................... 5-5

5.3 CHARACTER CODES................................................................................................. 5-5

5.3.1 1-Byte Character Codes ............................................................................. 5-5

5.3.2 2-Byte Character Codes ............................................................................. 5-5

5.4 FUNCTION CODE DESCRIPTION.............................................................................. 5-6

5.4.1 Function Code Description Format............................................................. 5-6

5.4.2 Mode 1/Mode 2........................................................................................... 5-7

5.4.3 Mode 3........................................................................................................ 5-12

APPENDICES

APPENDIX A. SPECIFICAIONS ............................................................................................ A-1

APPENDIX B. DATA CODE TABLE....................................................................................... B-1

Page 7

FIGURES

Figure Page

2-1 System Configuration.................................................................................................... 2-1

3-1 Front Name of the Printer ............................................................................................. 3-1

3-2 Back Name of the Printer.............................................................................................. 3-1

3-3 Printer Dimensions ....................................................................................................... 3-2

3-4 Fixing Bracket Dimensions ........................................................................................... 3-3

3-5 Installing the Fixing Bracket.......................................................................................... 3-4

3-6 Setting Paper................................................................................................................ 3-5

Page 8

TABLES

Table Page

3-1 DIP Switch Setting........................................................................................................ 3-6

3-2 Communication Method ............................................................................................... 3-6

3-3 Command Mode........................................................................................................... 3-6

4-1 Connector Terminal Assignment.................................................................................. 4-1

4-2 DC Socket Terminal Assignment ................................................................................. 4-2

4-3 I/O Signal Specifications............................................................................................... 4-5

5-1 Status Response Value Table...................................................................................... 5-35

Page 9

CHAPTER 1

OPERATIONAL PRECAUTION

1.1 SAFETY PRECAUTION

Meanings of symbols

The following symbols are used in this Instruction Manual in order to make use of the printer

properly and prevent the printer from being damaged.

Follow the instructions marked with the symbol.

WARNING

CAUTION

Symbol Examples

The symbol indicates caution(including danger and warning).

The example on the left indicates warning or caution.

The symbol indicates prohibition.

The example on the left means prohibition of disassembling.

Do not use a power supply outside of its specified range.

Doing so may cause fire leading to serious accidents.

Do not forcefully bend, or put a heavy matter on, the power cable. Failure to

follow this instruction may damage the power cable, which may result in a fire

or electric shock. Do not use the power cable if it is damaged.

Failure to follow the guidelines marked with this symbol could

result in severe personal injury or death.

Failure to follow the guidelines marked with this symbol could

result in minor personal injury or product and/or peripheral

damage.

WARNING

Never disassemble the printer. Failure to follow this instruction may cause

overheating or burning of the printer which may lead to fires or accidents.

1-1

Page 10

CAUTION

Do not drop any metallic objects or liquids such as water or coffee into the

printer.

Never use the printer in a place of extreme humidity or any place where it

can possibly be splashed by any liquids. If any liquids get into the printer, it

could lead to fire, electric shock, or other serious accidents.

Never touch the thermal head immediately after printing because it

becomes very hot. Make sure that the thermal head is cool before setting

papers or cleaning the thermal head.

Be sure to hold the connector part of the power cable when disconnecting

the cable. Pulling on the cable portion may cause it to fray and break.

Power OFF the printer in any of the following cases:

•

•

•

printer.

Using the printer in any manner other than for which it was designed may

cause accidents or fire.

The printer does not recover from an error.

Smoke, strange noise or smells erupt from the printer.

A piece of metal or any liquid touches the internal parts or slot of the

1.2 NOTES ON USE

• Do not disassemble or repair the printer by yourself.

• Do not drop the printer down on the floor or hit it against the walls.

• Avoid exposure to the water.

• Use the specified type of thermal paper.

• When a trouble such as a paper jam occurs, turn off the power first to fix it.

• The printer does not receive the data in some cases such as a paper out. Monitor the printer

to check if an error occurs and not to stop the system.

• Fix an error if something happens to the printer in order to prevent the whole system from

hanging up. Thus, you need to take an action to prevent the error from affecting the whole

system.

• Immediately turn off the power if the printer fails (for example, you smell something strange,

hear a noise, or smoke rises from the printer). After checking that such failure does not

continue, contact your dealer or us.

1-2

Page 11

1.3 NOTES ON TREATMENT OF THERMAL PAPERS

The surface of thermal paper is specially processed using the chemical agent. And the color rises

through the thermo chemical reaction process. Be aware of the following points.

1) Store the papers in a dry, cool and dark place.

2) Do not rub the papers with hard substance.

3) Keep the papers away from organic solvent.

4) Do not let the papers touched with vinyl chloride film, eraser or adhesive tapes for hours.

5) Do not put the papers on diazo print or wet copy that is just copied

6) Use the water-based glue (for example, starch glue and synthetic glue) when you glue

thermal paper.

7) Adhesive tape may discolor the surface of thermal paper. Put two-sided tape on the back

side of thermal paper if you need to tape it.

8) If you touch thermal paper with sweaty hand, your fingerprint may be left on the surface of

thermal paper and the characters may printed unclearly.

9) If you use this printer to print receipts given to your customers, print the notice which states

that the paper used is thermal paper and the instructions on how to keep it.

10) Use dedicated thermal papers only.

1.4 NOTES ON INSTALLATION

Avoid such places with:

1) Dusty places

2) Unstable places and places that significantly shakes

3) Watery and oily places

4) Places which receive direct sunlight

5) Places where the temperature is 50°C or higher

6) Places where the temperature is 0°C or lower

7) Places where the electromagnetic interference or corrosive gas is generated

8) Places where the relative humidity is over 80%

9) Places where the significant temperature change may result in the formation of any

condensation

1-3

Page 12

1-4

Page 13

Li

CHAPTER 2

TERMS USED IN THIS MANUAL

This chapter describes the terms used in this manual.

Dot A character or graphic im age is c om posed of picture elem ents called dots.

A dot corresponds to one of the thermal head heat elements.

Dot line A line of dots arranged perpendicular to the paper feed direc tion. A dot

line corresponds to a line of thermal head heat elements.

One dot line consists of 384 dots in DPU-30.

Character spacing The space separating contiguous characters on one character line.

Line spacing The space separating character lines.

Input buffer The mem ory for temporarily storing the data (characters and commands)

received from the host device. Data is executed when fetched fr om the

input buffer. The capacity of the input buffer is 4,096 bytes.

Line buffer The memory for storing one line of char acter data fetched from the input

buffer. W hen the line buff er is f illed with character data (i.e. printing of an

entire line) or the printing conditions are m ade valid through a command,

the data in the input buffer is printed.

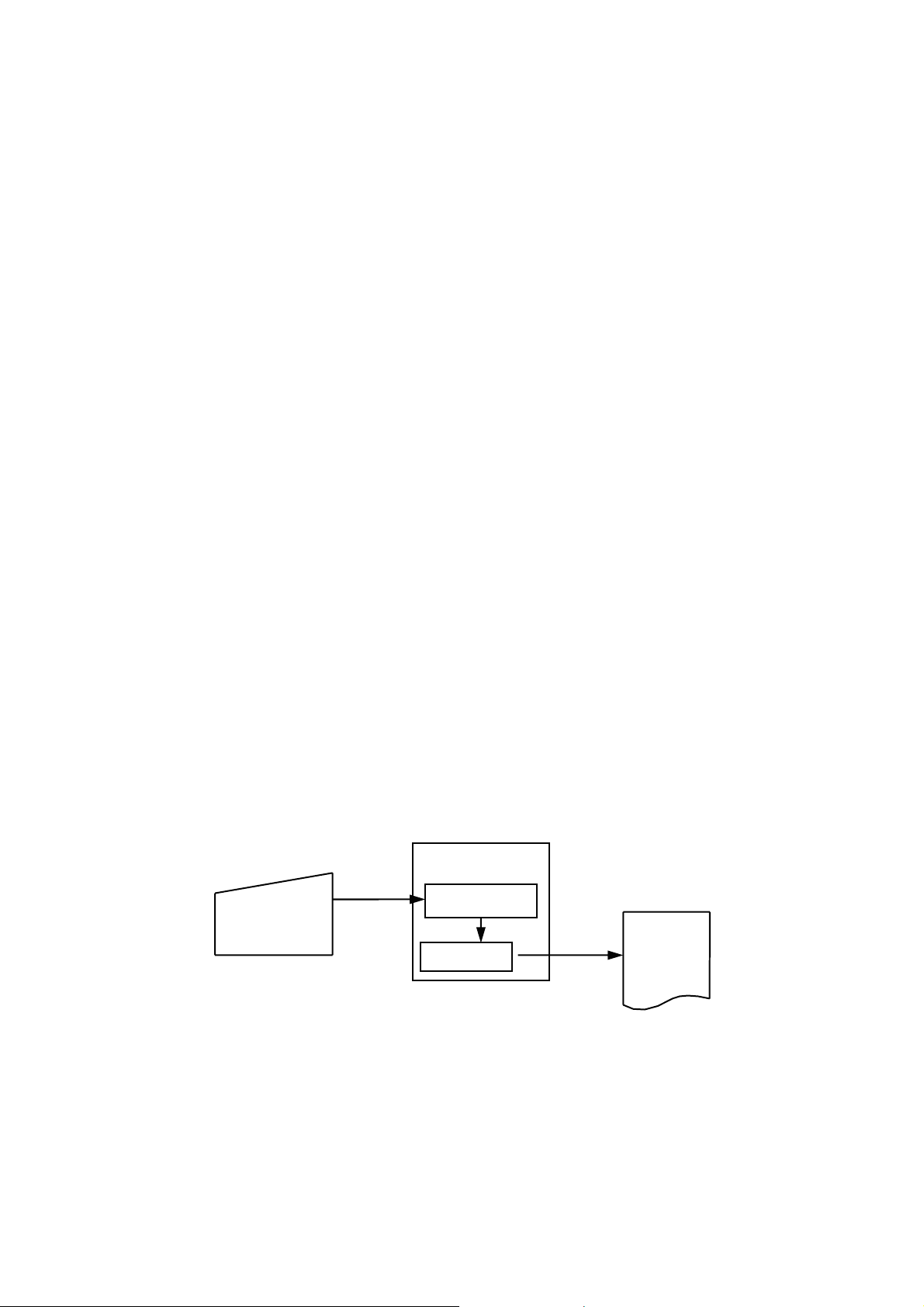

The system configuration is shown in Figure 2-1.

Host device

DPU-30

Input buffer

ne buffer

Printer

Figure 2-1 System Configuration

2-1

Page 14

One line full print The printing executed when the data in the line buffer ex ceeds one line.

Character data for one line is stored in the line buffer. When inflowing

data exceeds the number of characters that can be s tor ed in the line buf f er,

the data in the line buffer are printed. The overflowing data is stored at

the beginning of the next line.

Kanji size characters Kanji and user-defined characters.

Standard size Extended graphics characters, katakana, and downloaded characters.

characters

Font The form of a character. A character is composed of a group of dots.

The user can define a font using downloaded fonts, etc.

Font size The size of a character. There are two font sizes, 16-dot font size and

24-dot font size.

The sizes for standard size and Kanji size characters are shown below.

Each size is represented as vertical dots by horizontal dots.

16-dot (height × width)

Standard size characters 16 × 8 24 × 12

Kanji size characters 16 × 16 24 × 24

1-byte characters/ Classification by character codes.

2-byte characters Characters can be specified by 2 types of character codes: 1-byte

character codes and 2-byte character codes.

2-byte character is effective when the situation of kanji mode is specified.

Characters that can be specified by 1-byte character codes include:

• Alphabets, Numbers, and Katakana

• Extended graphics characters

• Downloaded characters

Characters that can be specified by 2-byte character codes include:

• Kanji

• User-defined characters

24-dot (height × width)

2-2

Page 15

CHAPTER 3

PREPARATIONS AND OPERATION

This section describes the information necessary to use the printer connecting to a host device such

as the part names and dimensions of the printer, and how to set the functions.

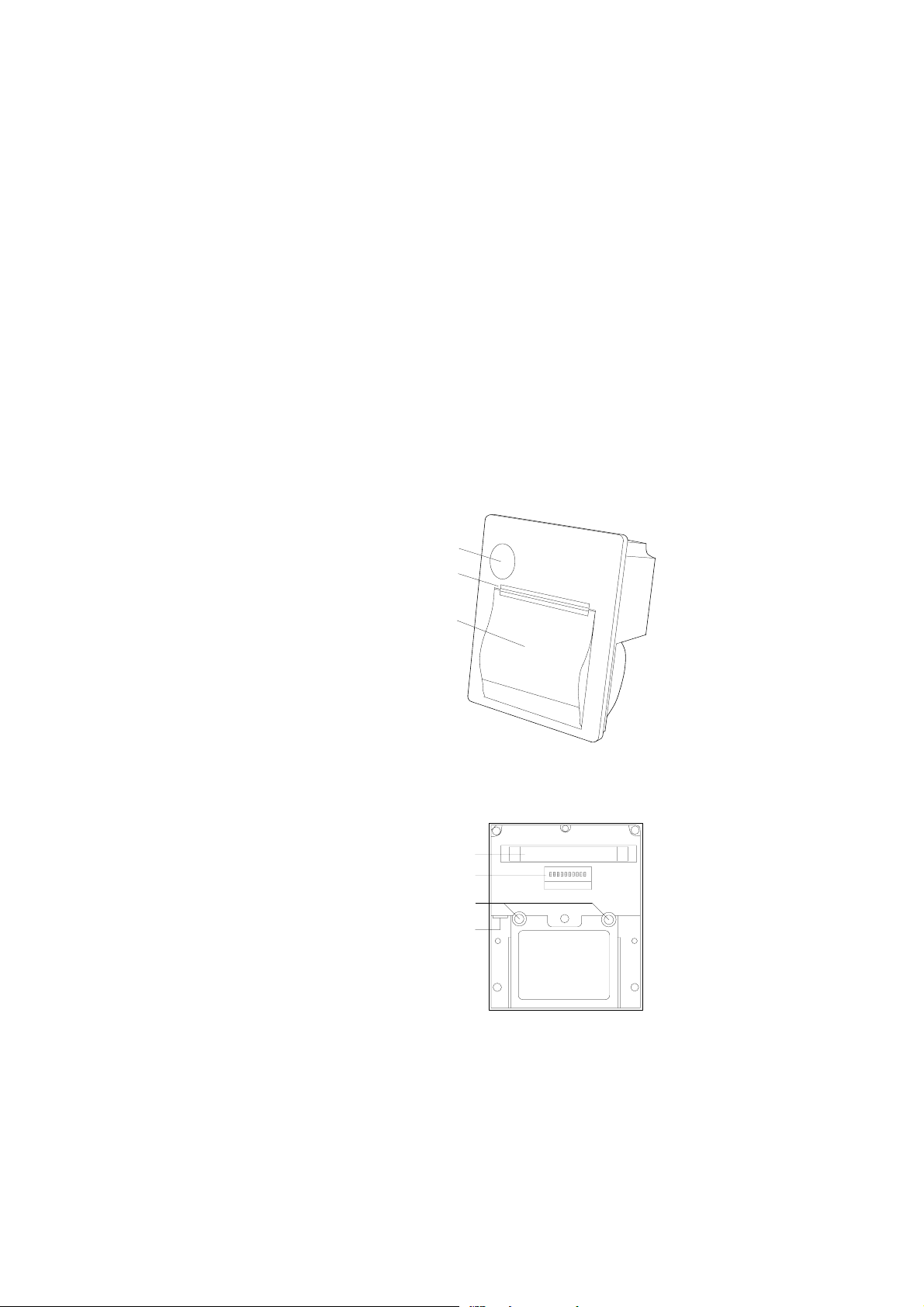

3.1 PARTS NAME

ペーパーカバーオープンボタン

Paper cover open button

ペーパーカッタ

Paper cutter

Paper cover

ペーパーカバー

Figure 3-1 Front Name of the Printer

インターフェース用コネクタ

固定金具用インサートナット

Interface Connector

Dip switches

ディップスイッチ

Insert nut for fitting

DC socket

DCソケット

ON

1

234567

890

Figure 3-2 Back Name of the Printer

3-1

Page 16

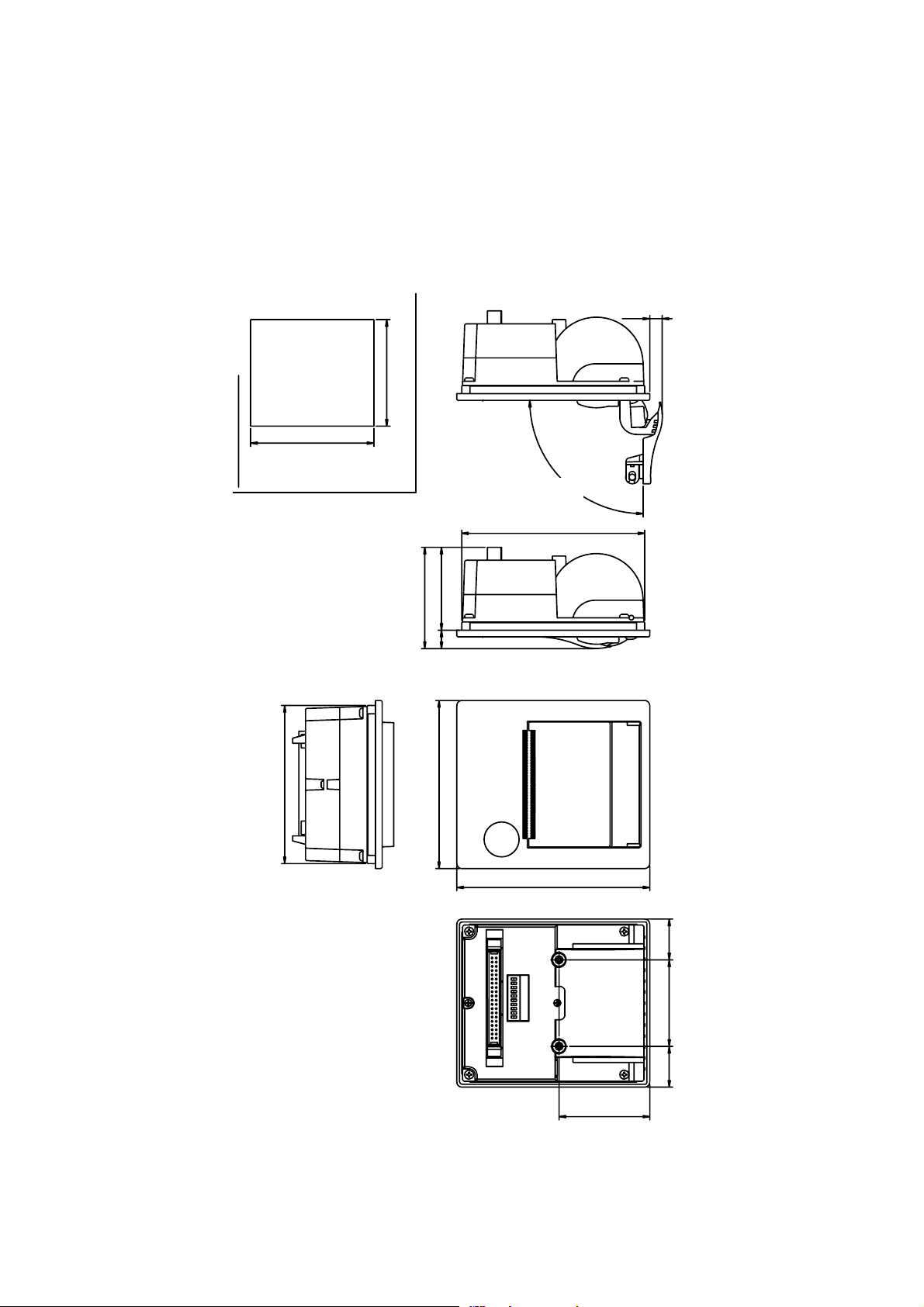

3.2 DIMENSIONS

1. Dimensions of the printer

111.2+0/-0.5

取り付け穴寸法図

Dimensions of the fitting hole

7.5

単位:mm

96+0/-0.5

°

0

約9

Approx. 90º

110

50

61

11

95

Figure 3-3 Printer Dimensions

101

3-2

116

54.5

24.5

52

(24.5)

Unit: mm

Page 17

2. Dimensions of the fixing bracket

固定金具条件

固定金具参考図

24

24

(25)

(25)

2

-

φ

3

2- φ3.6

.

6

44.5 - Panel thickness + 0.5 ±0.3

45.5-板厚+0.5±0.3

52

5225

25

102

102

板厚

44.5 - Panel thickness + 0.5 ±0.2

44.5-板厚+0.5±0.2

44.5

44.5

単位:mm

Unit: mm

Panel thickness

Figure 3-4 Fixing Bracket Dimensions

3-3

Page 18

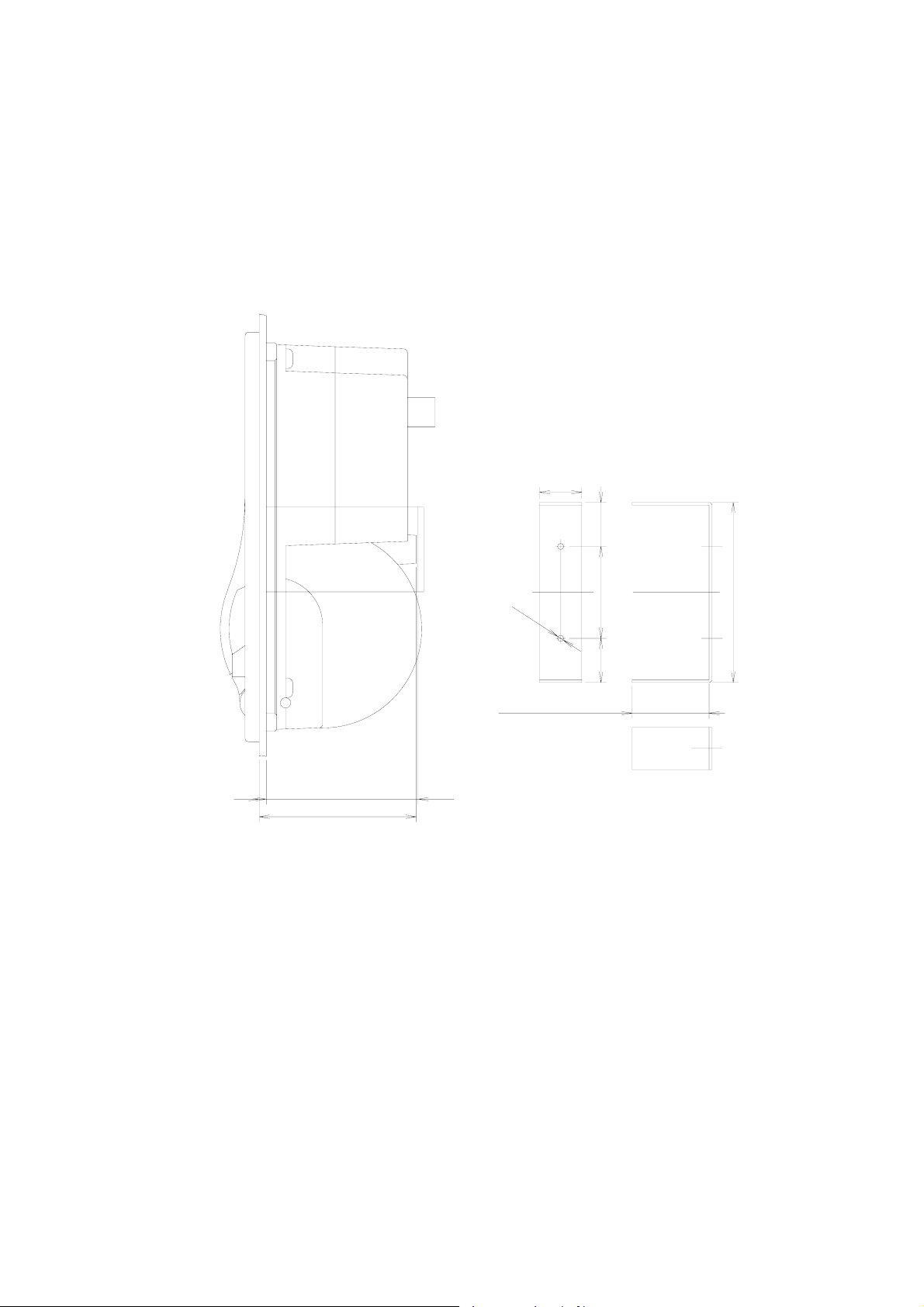

3.3 INSTALLATION

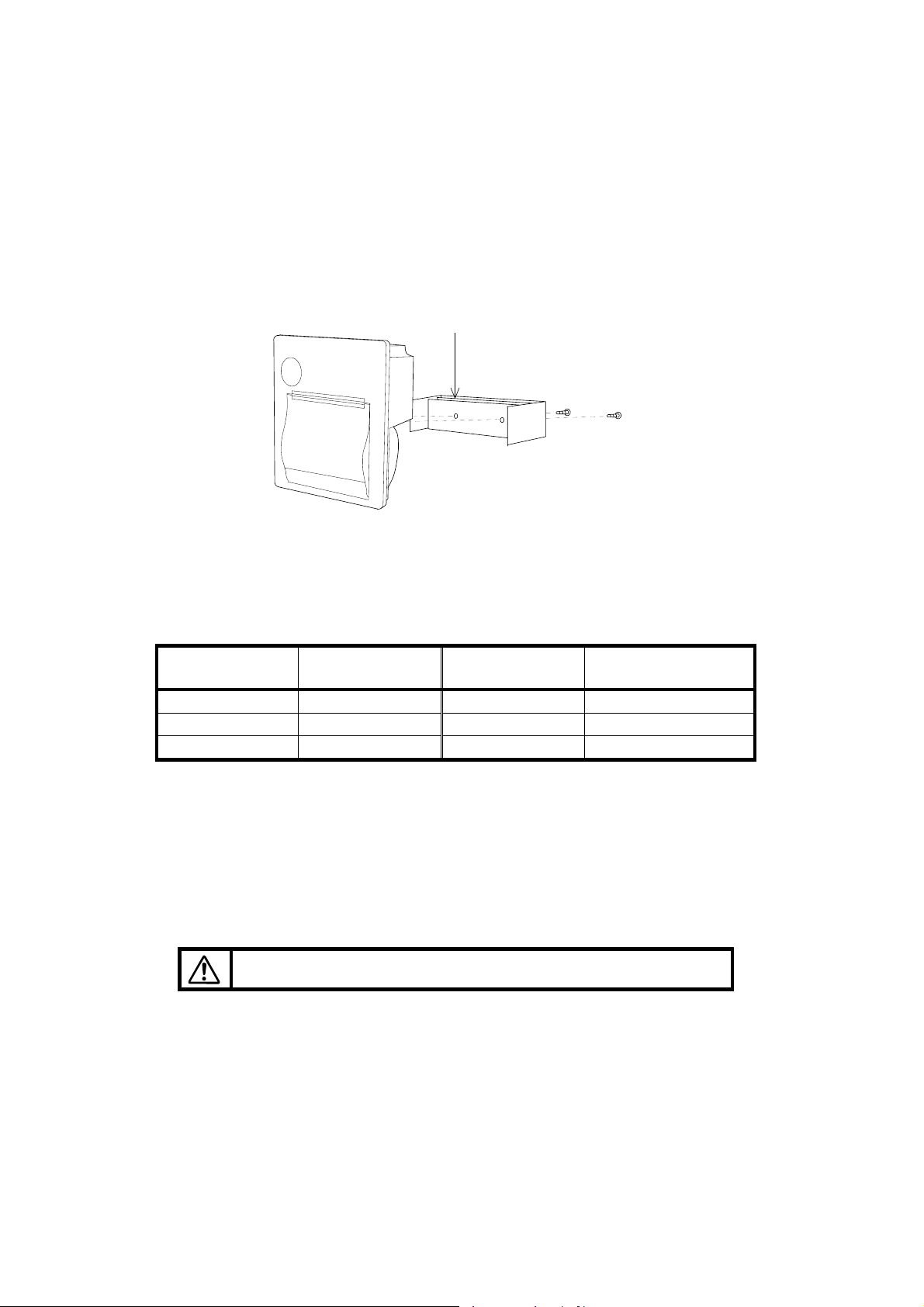

1. How to Install the Fixing Bracket

Use the spacers as much as you need

スペーサーを必要なぶん重ねて使用する。

Figure 3-5 Installing the Fixing Bracket

∗ Use the spacers depending on the fitting panel thickness referring to the next table. If not,

the body may be deformed, and therefore it may be hard to open the paper cover or printing

quality may be deteriorated. (If the fitting panel thickness exceeds 2.2 mm, it may be hard to

tighten the screws.)

Panel thickness

Spacer

thickness

Panel thickness Spacer thickness

1.0 mm None 1.7 to 1.8 mm 0.5 mm and 0.2 mm

1.2 mm 0.2 mm 2.0 mm 1.0 mm

1.5 to 1.6 mm 0.5 mm 2.2 mm 1.0 mm and 0.2 mm

∗ The screw torque is 49 cN m (5 kgf cm).

[Note] Do not touch the end of the DC plug.

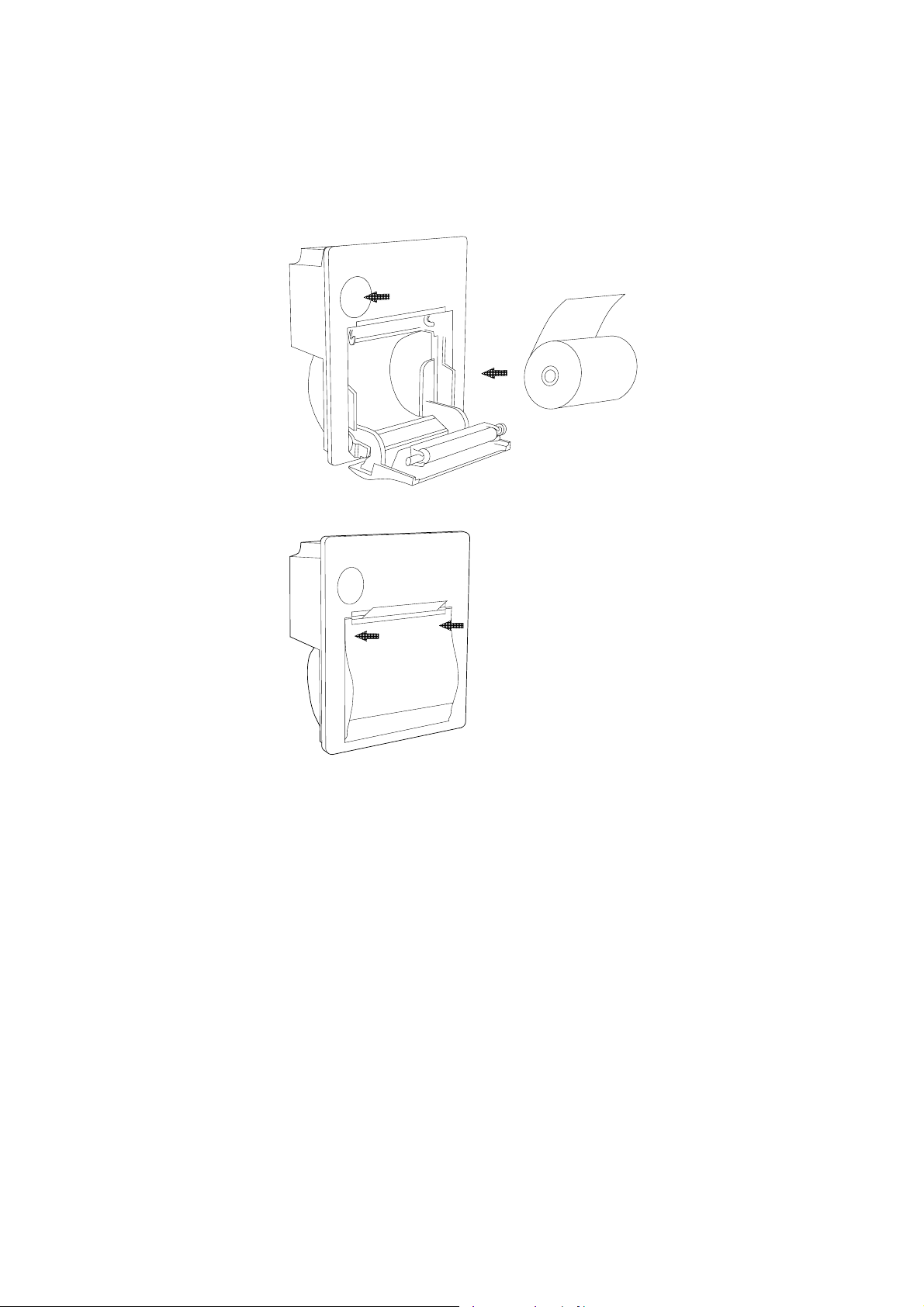

2. Setting Paper

(1) Press the paper cover open button, and open the paper cover.

Handle the paper cutter carefully not to cut your hand.

(2) Set a paper roll as shown in the figure.

(3) Close the paper cover by pressing both ends of the cover so the tip end of the paper will

be emerged from the printer.

3-4

Page 19

①

②

③

③

Figure 3-6 Setting Paper

3-5

Page 20

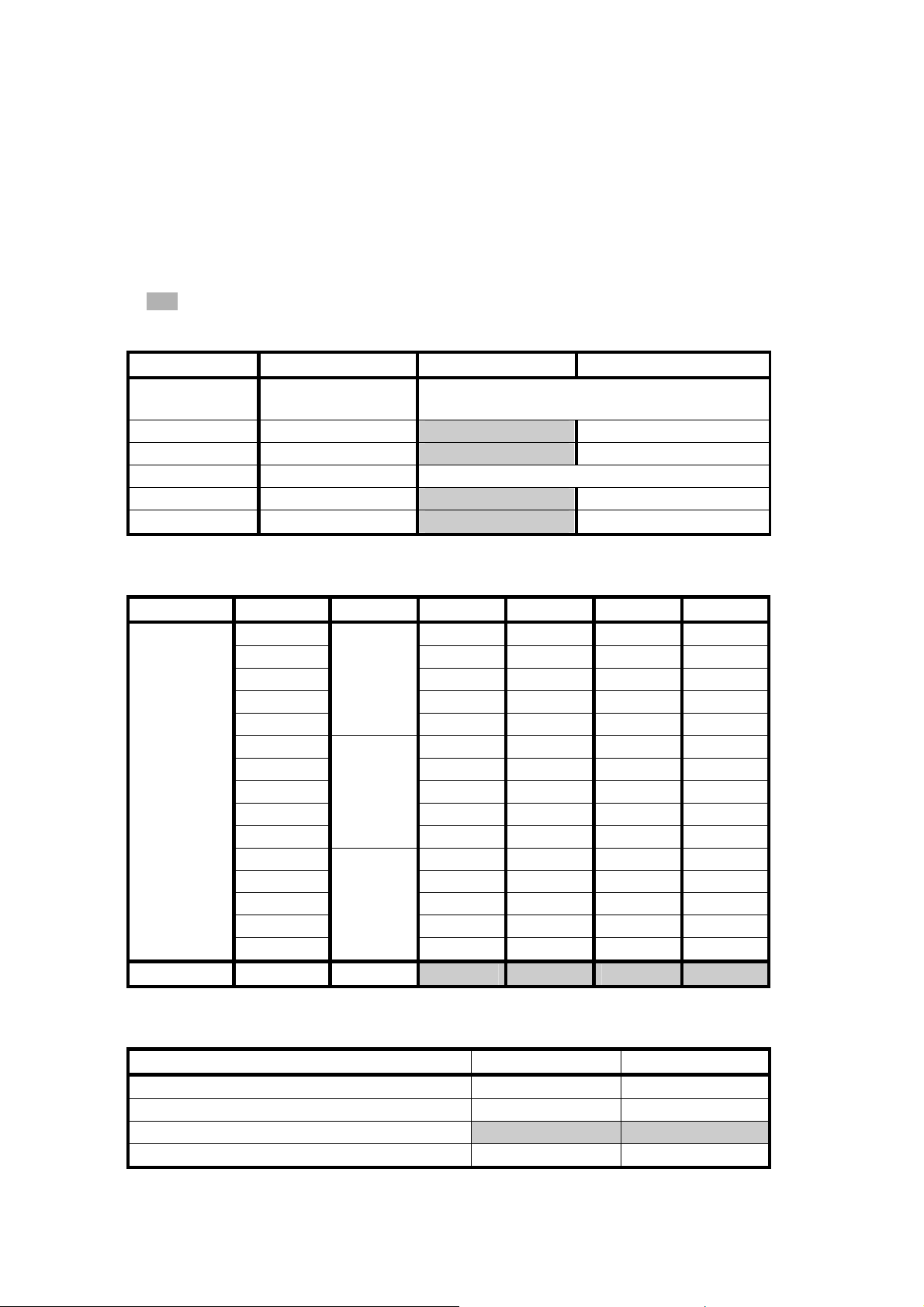

3.4 SETTINGS OF THE FUNCTIONS

Printer functions can be set with the dip switches.

The indicates the factory default setting.

Table 3-1 DIP Switch Setting

No Function OFF ON

1 to 4 Communication

See Table 3-2.

method

5 Bit length 8BIT 7BIT

6 Flow RTS/CTS Xon/Xoff

7 to 8 Command mode See Table 3-3.

9 Direction Upright Invert

0 Test pin Normal mode Prohibited

Table 3-2 Communication Method

Method Baud Parity DP1 DP2 DP3 DP4

Serial

38400 OFF OFF OFF OFF

None

19200 ON OFF OFF OFF

9600 OFF ON OFF OFF

4800 ON ON OFF OFF

2400

38400 ON OFF ON OFF

Odd

OFF OFF ON OFF

19200 OFF ON ON OFF

9600 ON ON ON OFF

4800 OFF OFF OFF ON

2400

38400 OFF ON OFF ON

Even

ON OFF OFF ON

19200 ON ON OFF ON

9600 OFF OFF ON ON

4800 ON OFF ON ON

2400

OFF ON ON ON

Parallel − − ON ON ON ON

Table 3-3 Command Mode

Mode DP7 DP8

Mode 1 (20 digit DPU-20-20CF compatible) ON ON

Mode 2 (24 digit DPU-20-24CF compatible) OFF ON

Mode 3 (32 digit ESC/POS compliant) OFF OFF

HEX dump mode ON OFF

3-6

Page 21

3.4.1 Test Print

The detail of the setting by dip switches is confirmed by test printing.

In the test print mode, characters (ANK, Kanji) and barcode are printed.

Turning power ON with the !FEED_IN signal kept low starts the test print.

3.4.2 Hex Dump Print

In the hex dump mode, the printer prints data input from the computer with hexadecimal numbers

and characters.

Set the dip switch No.7 ON, No.8 OFF, and turn the power on to enter the HEX dump mode.

• If the input data exceeds a line long, such data will be printed as follows. If the input data

does not exceeds a line log, set the !FEED_IN signal to Low. The rest of the data will be

printed.

• Turn off the power to finish the HEX dump mode.

[ HEX DUMP MODE ]

00 01 02 03 04 05 06 07 ........

08 09 0A 0B 0C 0D 0E 0F ........

10 11 12 13 14 15 16 17 ........

18 19 1A 1B 1C 1D 1E 1F

20 21 22 23 24 25 26 27

28 29 2A 2B 2C 2D 2E 2F ()∗+,-./

0D 0A 20 20 0D 0A

.. ..

........

!″ #$%&′

3.4.3 Paper Empty (Paper Out) Detection Function

Detects the existence of paper using the photo interrupter.

Use the specified type of paper.

3.4.4 Adjustment of Print Density

The print density is automatically adjusted by the head resistance, the number of dots, the head

temperature, and the head voltage.

The commands are also able to correct the print density.

It can be adjusted in the range from 0% to 255% of the rated energy.

3-7

Page 22

3.4.5 Resetting the Printer While Printing

When the data with a lot of dots is printed, the print data may be missing and then, the printing may

often continue in the state that each setting by the commands is reset.

This is because too many print dots decrease the voltage, which results in the activation of the reset

circuit of the printer.

The commands which tend to increase the number of print dots are:

• Underline

• Reverse

• Ruled line (in case that the number of dots is many)

• Bitimage

Case that a horizontal line is printed when printing a full line of “H” characters without spaces

between the characters.

The print density set command (case that the print density is set at over 100%) expands the length

of strobe, which very often resets the settings, although this command does not increase the

number of print dots. Be aware of these points when using the printer.

3.4.6 Memory

1. Input buffer memory

An input buffer memory (RAM) with the capacity of 4,096 bytes is built in the printer.

2. User memory

A user memory (RAM) with the capacity of 16,384 can be used when setting the printer in Mode 3.

The data registered in this memory are cleared when turning off the power.

This memory is used when using the downloaded characters, the user-defined characters, and

the downloaded Bitimages.

The memory used by the downloaded characters and user-defined character is restricted as

follows. The remaining is used for the downloaded Bitimages. However, it can release the

memory of the downloaded character and use-defined character so that ensuring the capacity

for Downloaded Bitimage.

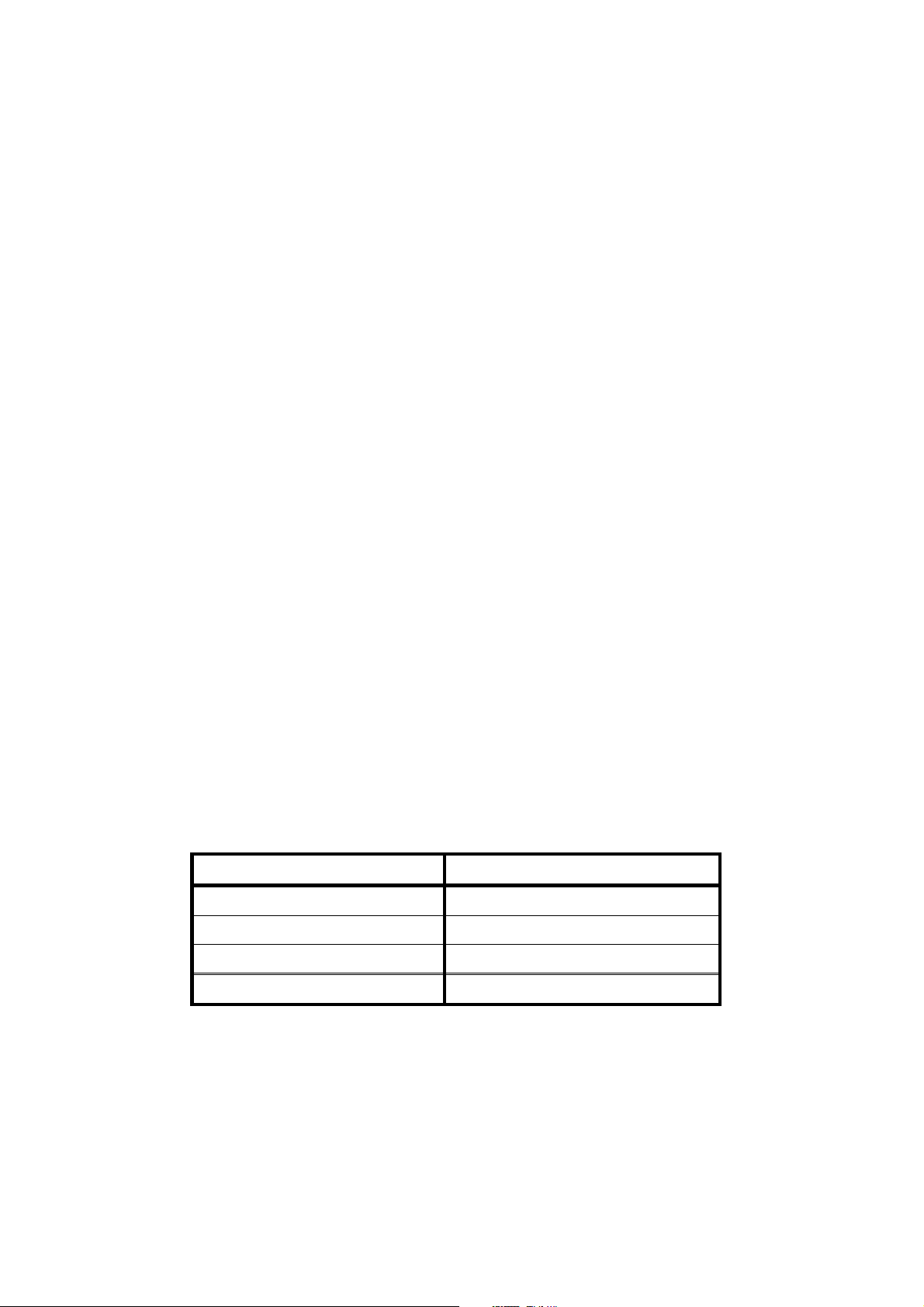

The memory capacity immediately after the initialization

Application Capacity (in byte)

Downloaded character 4,560

User-defined character 1,080

Downloaded Bitimage 10,744

Total 16,384

The capacity for the downloaded characters and the user-defined characters is readily ensured

at the initialization.

This area can be released by a command to use the area for the downloaded Bitimages.

When registering the downloaded Bitimages, calculate the remaining capacity of the memory

before registering them.

Be sure that the data with the larger capacity than the remaining capacity is ignored even if you

trying to register such data.

3-8

Page 23

CHAPTER 4

INTERFACE

This chapter describes inform ation that is requir ed when using the printer connected to a hos t, such

as the serial and parallel interface specifications.

4.1 CONNECTOR TERMINAL LAYOUT

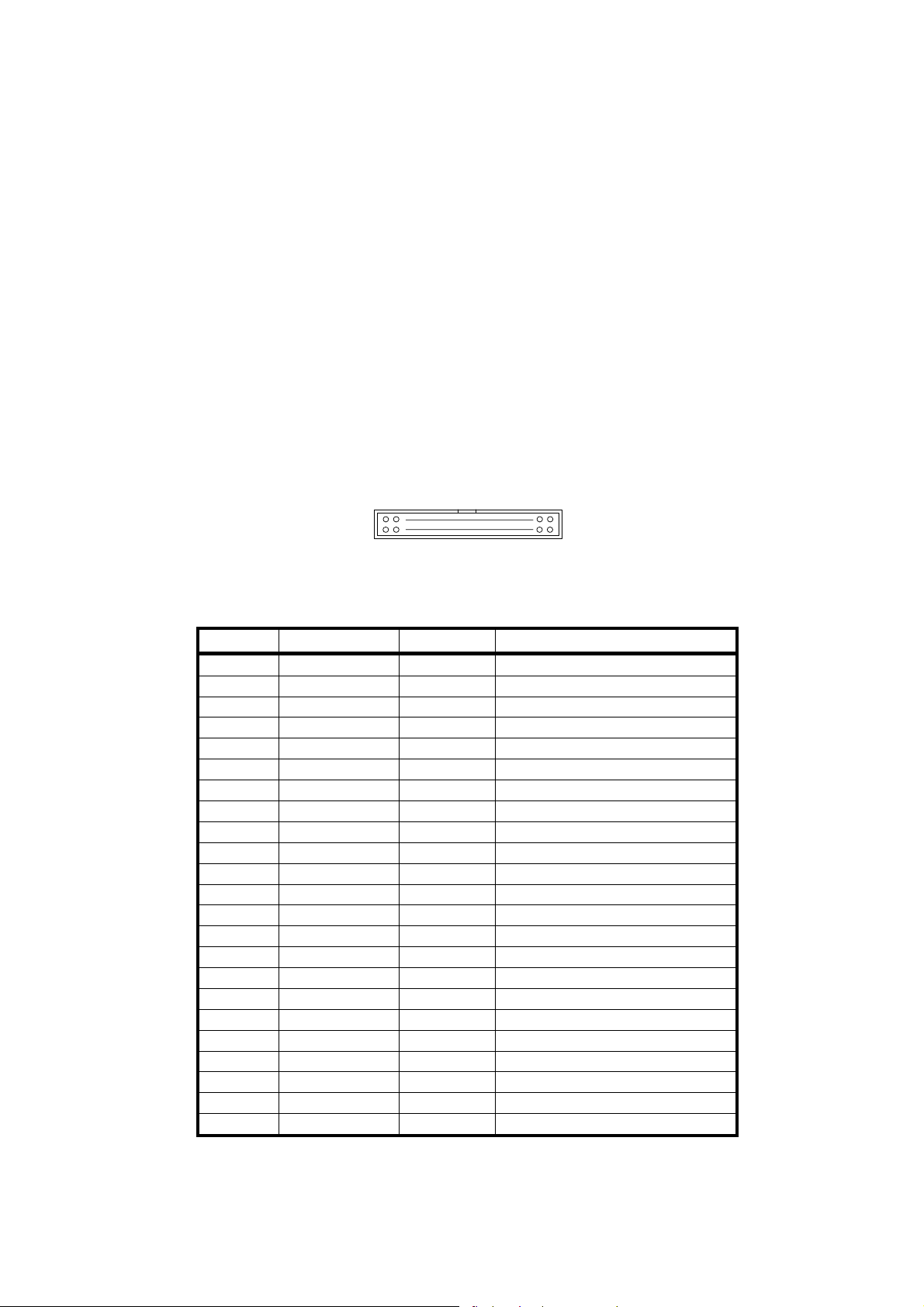

1. Interface and power connector terminal layout

Connector (plug) : XG4A-4032(Omron)

Connector signal layout

39

40

1

2

(!signal name indicates Active Low.)

Table 4-1 Connector Terminal Assignment

No. Signal name Direction Description

1 !STROBE In Parallel data input

2 to 9 DATA0 to 7 In High:1, Low:0

10 !ACK Out Acknowledge

11 BUSY Out Busy to read

12 PE Out Paper empty

13 SEL OUT Out Online High

14 !ERROR Out Error

15 !RESET In Reset (Valid in Low 20ms)

16 TxD Out Serial data ouput

17 RxD In Serial data input

18 RTS Out RS-232C Request to send

19 CTS In RS-232C Clear to send

20 NEAR_A Out Paper near end ⋅ A (+)

21 NEAR_C In Paper near end ⋅ C (+)

22 NEAR_K − Paper near end ⋅ K (−)

23 NEAR_E − Paper near end ⋅ E (−)

24 NEAR_OUT Out Paper near end signal

25 !FEED_IN In Feed signal

26 GND − Ground

27 SEL_LED+ Out SEL LED on (+)

28 SEL_LED- Out SEL LED on (−)

29 to 34 V+ − Power (+)

35 to 40 V− − Power (−)

∗ Connect to all the No.29 to 34 and No.35 to 40 terminal when supplying the power

4-1

Page 24

into V+ and V-pins. (To avoid voltage drops.)

When supplying the power through the DC socket, be sure to leave V+

and V- unconnected. Never supply the power into V+ and V- terminals,

and never short V+ and V- terminals.

∗ Use terminal numbers 22, 23 or 26 as the signal ground for RS-232C.

∗ Short terminal numbers 25 and 26 to feed the paper.

∗ SEL LED lights up at the time on-line by connecting it to terminal numbers 27 and 28.

∗ Paper near end sensor:

This printer does not have the paper near end function. However, this function can be

built in by mounting a device such as a photo sensor.

NEAR_A: Pull up it with +4.75 to +5.1 V through the current limit resistance.

NEAR_OUT: The logic of NEAR_C is inversed and output.

Example:

The following diagram describes how a device such as a photo sensor is mounted to

use.

フォトセンサ等

5V

220 Ω

NEARA

CN2

20

Photo sensor, etc

CN2

21

NEARC

NEARK

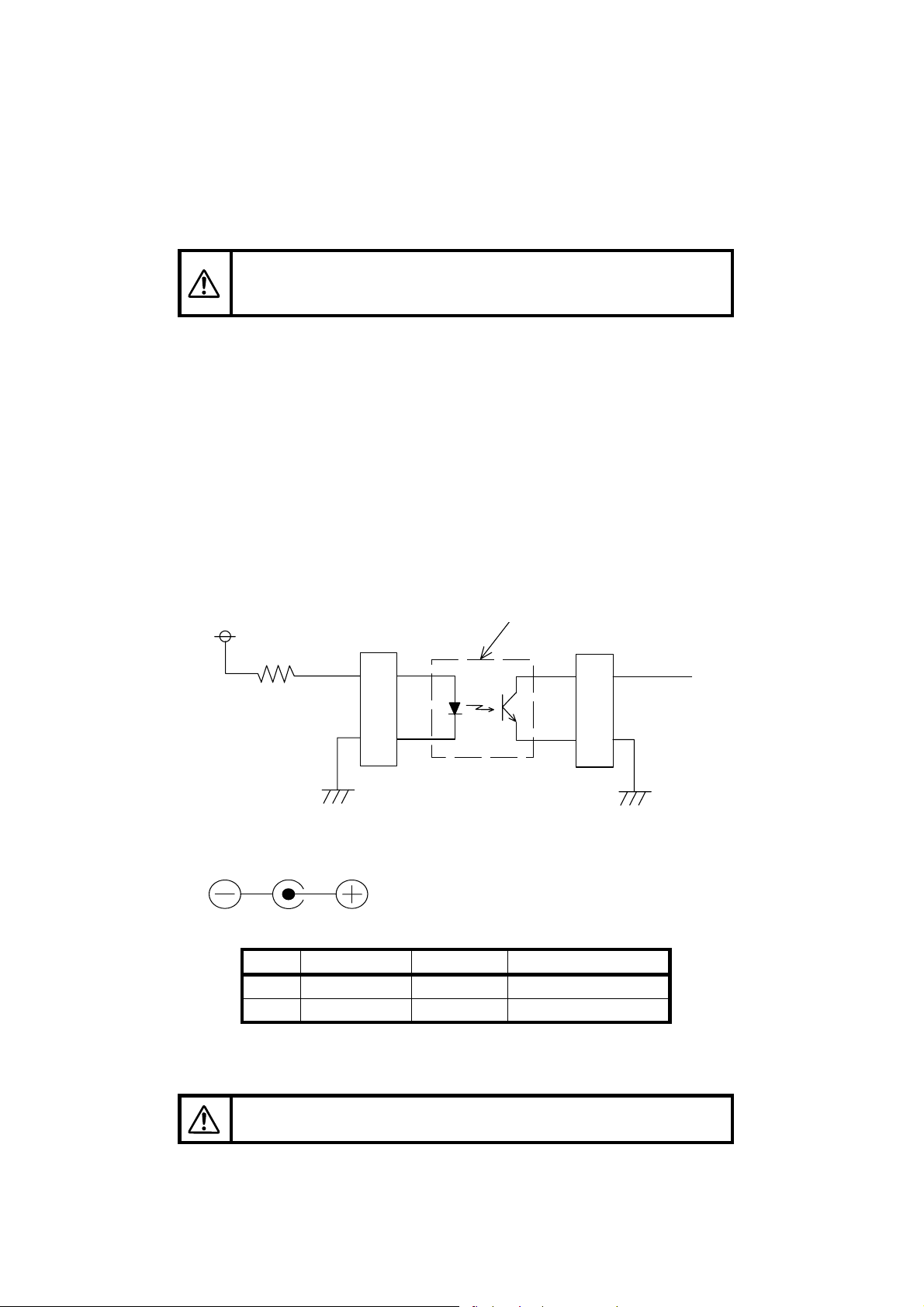

2. DC socket terminal layout

22

24

NEARE

Connector (Socket) : HEC0470-01-630 (Hosiden)

Polarity:

(Center plus)

Table 4-2 DC Socket Terminal Assignment

No. Signal name Direction Function

1 DC+8.7V − Power input

2 GND − Ground

∗ Supply of the power through the interface connector terminals is available, instead of the DC

socket terminal.

When supplying the power through the interface and power connector

terminals, do not connect the DC socket.

4-2

Page 25

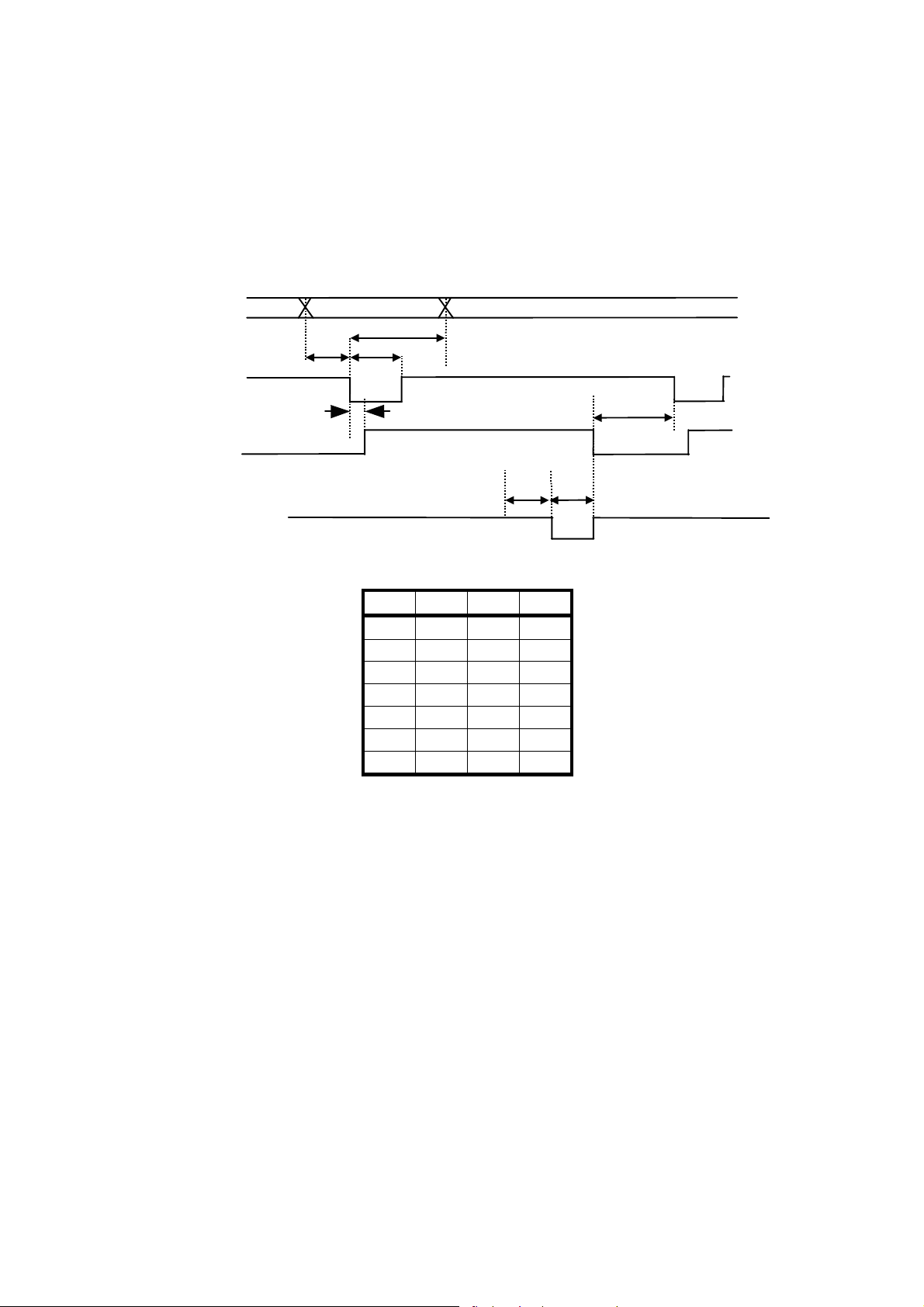

4.2 PARALLEL INTERFACE

A

1. Data input timing

DATA0 to 7

STROBE

T3

T2T1

BUSY

CK

T4

T6

T7

T5

Min. Max. Unit

T1 0.1 − µs

T2 0.5 − µs

T3 0.5 − µs

T4 − 0.5 µs

T5 0 − µs

T6 0.5 − µs

T7 − 1.0 µs

4.3 SERIAL INTERFACE

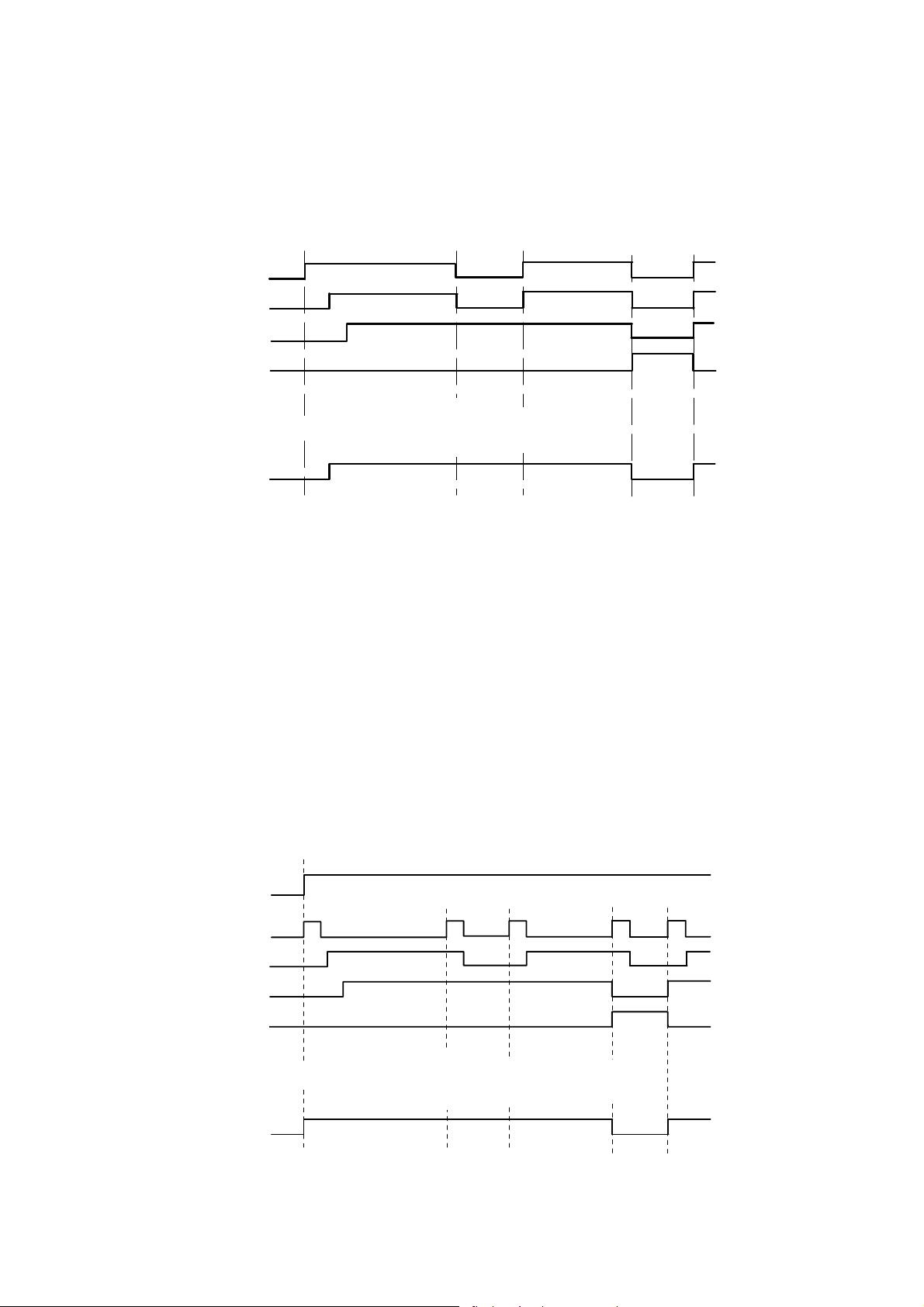

1. Hardware control

The RTS signal (Low or High) controls the transmission of the data from a host computer.

When the data st ored in the input buf f er of the pr inter ex c eeds 4,046 bytes, the RTS s ignal turns

Low.

Once the RTS signal turns Low, the host computer stops to transmit the data.

If the data stored in the input buffer of the printer falls below 3,995 bytes, the RTS signal turns

High.

Once the RTS signal turns High, the host computer resumes transmitting the rest of the data.

∗ When the printer fails (for example, paper-out), the RTS signal also turns Low.

And then, after the printer gets back to normal, the RTS signal turns High.

4-3

Page 26

Data timing for hardware control

RTS

RTS

RxD

RxD

Print

プリント

Paper out

紙無し

ON-LINE

ON‑LINE

OFF‑LINE

OFF-LINE

Power ON

電源ON

4046バイト以 上 3995バイト 以 下

Buffer

バッファ

4,046 bytes

or more

Buffer

バッファ

3,995 bytes or less

2. Xon/Xoff control

The data transmission from a host computer is controlled through the exchange of Xon(11

command and Xoff(13

When the data stored in the input buff er of the pr inter ex ceeds 4,046 bytes, the printer sends the

Xoff command to the host computer.

Upon the reception of the Xoff command, the host computer stops to send the data.

If the data stored in the input buffer of the printer falls below 3,995 bytes, the printer sends the

Xon command to the host computer.

Upon the reception of the Xon com mand, the host computer resum es sending the rest of the

data.

∗ When the printer fails (for exam ple, paper-out), the printer sends the Xoff c ommand to the

host computer.

And then, after the printer gets back to normal, the printer sends the X on command to the

host computer.

Data timing for Xon/Xoff control

) command between the printer and the host computer.

16

)

16

RTS

RTS

RxD

TxD

RxD

RxD

Print

プリント

紙無し

Paper out

ON‑LINE

ON-LINE

OFF‑LINE

OFF-LINE

Xon

Xon

電源ON

Power ON

4046バイト 以 上 3995バイト以 下

Xoff

Xoff

Buffer

バッファ バッファ

4,046 bytes

or more

4-4

Xon

Buffer

3,995 bytes or less

Xoff

Xoff Xon Xon

Xon

Page 27

3. Input / Output signal specifications

Table 4-3 I/O Signal Specifications

Item Condition

High input voltage !RESET 1.76 − 5.5 V

Low input voltage !RESET 0 − 1.44 V

High input voltage

Low input voltage

High input voltage RXD, CTS +2.8 − +15 V

Low input voltage RXD, CTS −15 − −2.8 V

High output voltage

Low output voltage

High output voltage

Low output voltage

DATA0 to 7, !STROBE,

!FEED_IN, NEAR_C

DATA0 to 7, !STROBE,

!FEED_IN, NEAR_C

BUSY, !ACK, !ERROR,

SEL OUT, PE, NEAR_OUT

BUSY, !ACK, !ERROR,

SEL OUT, PE, NEAR_OUT

TXD, RTS

( RL = 3 KΩ)

TXD, RTS

( RL = 3 KΩ)

Rate Value

Min Typ. Max

3.15

0

4.75 − 5.1 V

0 − 0.5 V

+5

−15

−

−

+9 +15 V

−9 −5 V

5.5 V

1.35 V

Unit

4-5

Page 28

4-6

Page 29

CHAPTER 5

COMMAND FUNCTION

This chapter describes the functions of the commands processed by the printer.

5.1 FUNCTION OUTLINE

DPU-30 has two sets of commands: Mode 1/Mode 2 and Mode 3. The commands are as listed

below:

5.1.1 Mode 1/Mode 2

1. Basic commands (DPU-20-20CF/24CF compatible commands)

Command Function See page

CR Line Feed 5-7

LF Carriage Return 5-7

SO Double–Width Printing Mode Specify 5-7

SI Double–Width Printing Mode Clear 5-8

CAN Cancel 5-8

ESC S Bitimage Graphic 5-8

ESC c Special Character Specify 5-9

ESC R International Character Specify 5-9

2. Extension commands

Command Function See page

ESC @ Initialization 5-10

DC2 > Print Drive Mode Select 5-10

DC2 % Print Drive User Define 5-11

DC2 ~ Print Density Set 5-11

5-1

Page 30

5.1.2 Mode 3

1. Paper feed commands

Command Function See page

CR Carriage Return 5-12

LF Line Feed 5-12

FF Page Length Print 5-12

ESC J Print and Feed Forward 5-13

ESC j Print and Feed Backward 5-13

ESC d Print and Continuous Line Feed 5-13

ESC C Page Length Set 5-14

2. Tab commands

Command Function See page

HT Horizontal Tab 5-15

ESC D Horizontal Tab Set 5-15

3. Form commands

Command Function See page

ESC 2 Default Amount of Line Spacing Specify 5-16

ESC 3 Amount of Line Spacing Set 5-16

ESC SP Standard Size Character Right Spacing

Set

5-16

GS L Left Margin Set 5-17

GS W Width of Printing Area Set 5-17

ESC $ Absolute Position of Printing Area Specify 5-18

ESC a Position Align 5-18

4. Character decoration commands

Command Function See page

ESC ! Decorated Characters Collectively Specify 5-19

ESC G

ESC E

Bold Characters Specify and Clear

5-20

ESC { Inversion (Flip) Specify and Clear 5-20

ESC - Underline Specify and Clear 5-21

GS ! Character Size Set 5-21

GS B Reverse Character Specify and Clear 5-22

5-2

Page 31

5. Character selection commands

Command Function See page

ESC M Font Select 5-23

ESC R International Character Select 5-24

ESC & Downloaded Character Register 5-25

ESC ? Downloaded Character Delete 5-25

ESC % Downloaded Character Specify and Clear 5-26

6. Barcode commands

Command Function See page

GS H HRI Character Printing Set 5-27

GS w Width of Barcode Set 5-27

GS h Height of Barcode Set 5-28

GS k Barcode Print 5-29

7. Ruled line control commands

Command Function See page

DC3 A Ruled Line Buffer A Select 5-30

DC3 B Ruled Line Buffer B Select 5-30

DC3 C Ruled Line Buffer Clear 5-30

DC3 D Write in Position Specified by Dot in Ruled

Line Buffer

DC3 L Write in Position Specified by Line in

Ruled Line Buffer

DC3 + Print Mode of Ruled Line Approve 5-32

DC3 − Print Mode of Ruled Line Prohibit 5-32

DC3 P 1 Dot Line of Ruled Line Print 5-32

8. Response commands (only for serial mode)

Command Function See page

GS a Validity / Invalidity of Automatic Status

Transmission and Real Time Command

Select

GS r Status Transmit 5-34

DLE EOT Status Transmit in Real Time 5-35

DLE ENQ Major Buffers Clear in Real Time 5-36

5-31

5-31

5-33

5-3

Page 32

9. Bitimage commands

Command Function See page

ESC ∗ Bitimage Select 5-37

GS ∗ Downloaded Bitimage Register 5-38

GS / Downloaded Bitimage Print 5-39

10. Kanji commands

Command Function See page

FS & Kanji Mode Specify 5-40

FS . Kanji Mode Clear 5-40

FS C Kanji Code System Select 5-40

FS S Character Spacing for Kanji Set 5-41

FS ! Print Mode for Kanji Collectively Specify 5-42

FS − Underline of Kanji Specify and Clear 5-43

FS W Double-Width and Double-Height Kanji

Set and Clear

5-43

FS 2 User-Defined Character Register 5-44

11. Function and setting commands

Command Function See page

ESC @ Initialization 5-46

CAN Print Buffer Clear 5-46

DC2 D Registration Area of Downloaded

Character Ensure and Release

DC2 G Registration Area of User-Defined

Character Ensure and Release

5-47

5-47

DC2 > Print Drive Mode Select 5-48

DC2 % Print Drive User-Define 5-49

DC2 ~ Print Density Set 5-49

5-4

Page 33

5.2 FUNCTION CODES

All commands start with one of the following control codes (called function codes hereinafter):

LF (0A

FS (1C

), CR (0D16), SO (0E16), SI (0F16), DC2 (1216), DC3 (1316), CAN (1816), ESC (1B16),

16

), DEL (7F16)

16

Some function codes form a command by itself and others are followed by parameters and/or image

data.

The number of bytes configuring a command differs from command to command. The shortest

commands consist of 1-byte and the longest, some hundred bytes.

5.3 CHARACTER CODES

This section describes the character codes in detail.

The character codes are classified into two groups: 1-byte character codes and 2-byte character

codes. The 1-byte character codes are used to print standard-size characters, whereas the 2-byte

character codes print Kanji, user-defined characters.

In Mode 1 and Mode 2, the printer uses only the 1-byte character codes.

The following subsections describe the 1-byte and 2-byte character codes individually.

5.3.1 1-Byte Character Codes

Used for standard size character printing.

The hexadecimal codes valid as the 1-byte character codes are as shown below:

• 20

to FF16 (Some character tables make codes 7F16 and FF16 invalid.)

16

5.3.2 2-Byte Character Codes

The 2-byte character codes are invalid in mode 1 and 2. The 2-byte character codes are used to

print Kanji, and user-defined characters when in the Kanji mode.

• The first byte

through 2016: Function codes are processed as function codes (See 5.2 FUNCTION

00

16

CONDES). All the other codes are ignored.

If the second-byte code is received along with a Kanji mode clear

command, the next received data is processed as a 1-byte character

code.

through 7E16: First byte of a JIS Kanji code.

21

16

through FF16: Ignored.

7F

16

5-5

Page 34

• The second byte

through 1F16: The first byte already entered is ignored. Function codes are processed

00

16

as function codes. All the other codes are ignored along with the first

byte. If the following code accompanies a Kanji mode clear command,

the next received data is processed as a 1-byte character code.

: Ignored along with the first byte.

20

16

through 7E16: Print Kanji or user-defined characters if the first byte is one of 2116

21

16

through 7E

: Ignored along with the first byte.

7F

16

through FE16: Ignored along with the first byte unless the first byte is 0016.

80

16

: Ignored along with the first byte.

FF

16

.

16

For the correspondence between the 2-byte codes and the printed characters, refer to “Kanji Code

Table” (as per JIS C 6226-1983).

5.4 FUNCTION CODE DESCRIPTION

This chapter describes the commands in each function by the mode.

5.4.1 Function Code Description Format

Each function code is described in the format below.

The same format is used for both Mode 1/Mode 2 and Mode 3.

X X

Indicates

X X X X

the command. Indicates the command name.

Code Indicates command part and parameter past.

X

indicates hexadecimal code.

16

Function Indicates the functions of the commands.

Details Explains detailed printer operation when inputting commands.

5-6

Page 35

5.4.2 Mode 1/Mode 2

1. Basic command

CR Carriage Return

Code

Function

Details

0D

16

Prints the data stored in the print buffer, and then starts a new line according to the

defined amount of paper feed for one line.

• After executing this command, a head of a line is set as a starting position of

printing.

• LF command received immediately following CR is ignored.

• The amount of paper feed for one line is fixed at 24-dot pitch.

LF Line Feed

Code

Function

Details

0A

16

Prints the data stored in the print buffer, and then starts a new line according to the

defined amount of paper feed for one line.

• After executing this command, a head of a line is set as a starting position of

printing.

• LF command received immediately following CR is ignored.

• The amount of paper feed for one line is fixed at 24-dot pitch.

SO Double–Width Printing Mode Specify

Code

Function

Details

0E

16

Specifies the double−width printing. Hereafter, the width of characters to be printed

is doubled.

• This command is not cancelled until either ESC @ or SI command is entered.

5-7

Page 36

SI Double–Width Printing Mode Clear

Code

Function

0F

16

Clears the double−width printing.

CAN Cancel

Code

Function

18

16

Clears the print buffer.

Details

• After executing this command, a head of a line is set as a starting position of

printing.

ESC S n1 n2 n3 n4 Bitimage Graphic

Code

Domain of

function

Function

+ 5316 + n1 + n2 + n3 + n4 + [DATA]

1B

16

≤ n1, n2, n3, n4 ≤ 3916

30

16

“0001” ≤ “n1 n2 n3 n4” ≤ “1023”

0 ≤ d ≤ 255 (graphic data)

The number of data specified in ASCII code n1, n2, n3 and n4 are specified as a

Bitimage.

Example: Case that 192 Bitimages are specified

1B

+ 5316 + “0192” + . . . . . . . . .

16

[192 DATA]

Details

• The code outside the domain of function processes the data as the 1-byte data

thereafter.

• If the dots are specified outside the printing area, the data is ignored.

• The data deployment position is set in accordance with the predefined starting

position of the data deployment.

• This command is affected by the inverse printing.

• If the next Bitimage Specify command is received at the occurrence of the line

overflow, the data of the previous line stored in the print buffer is printed. The line

overflow is determined according to the number of dots described below.

− Mode 1: Determined as the line overflow if the number of dots exceeds 276.

− Mode 2: Determined as the line overflow if the number of dots exceeds 332.

• Refer to the figure shown below for how the data is deployed.

5-8

Page 37

(Input i mage) (Deploy ment imag e)

d1 d2 d3

MSB

d1 d2 d3

LSB

ESC c Special Character Specify

Code

Function

+ 6316

1B

16

Replaces the character code table from F9

to FD16 as follows.

16

Category F916 FA16 FB16 FC16 FD16

1 (default value) 市 区 町 村 人

2 Σ μ Ω π δ

Details

• The operation is executed as a toggle operation.

• The table is changed when this command is executed.

ESC R n International Character Specify

Code

Domain of

1B

+ 5216 + n

16

0 ≤ n ≤ 6

function

Function

Selects a set of characters of each country described below.

The characters are replaced with only the characters of a country of specified

corresponding code according to the katakana – compliant character code table

(refer to “APPENDIX B. DATA CODE TABLE.”).

Details

• The data beyond the defined domain of function is ignored.

• In default, n = 0.

5-9

Page 38

2. Extension commands

ESC @ Initialization

Code

Function

+ 4016

1B

16

Initializes the printer.

Details

• The allocation of the user memory is initialized.

• The receive buffer is retained.

• The print buffer is cleared.

• The settings of each command are initialized.

• ROM SW is reread.

DC2 > n Print Drive Mode Select

Code

Domain of

+ 3E16 + n

12

16

0 ≤ n ≤ 2

function

Function

Sets the print drive mode.

n Print drive mode Feature

0 High speed mode The printer is driven at high speed and high

electric power.

1 Medium speed mode 1 The printer is driven at medium speed and low

electric power.

2 Medium speed mode 2 The printer is driven at our recommended electric

power. The speed of printing in this mode is slower

than that in the medium speed mode 1.

Details

• Even if our recommended electric power is adopted in the high speed mode, the

print speed may slow depending on the print ratio.

• In default, n = 2.

5-10

Page 39

DC2 % n Print Drive User Define

Code

Domain of

+ 2516 + n

12

16

1 ≤ n ≤ 16

function

Function

Executes the printing according to the print drive defined by a user.

n = 1: The amount of 1 × 8 dots

n = 16: The amount of 16 × 8 dots

Details

• When one line is printed, the number of division is calculated every n × 8 dots.

Example: Suppose that the number of dots printed = 128 dots, and n = 1

128 ÷ (1 × 8) = 16 (one line printed is divided into 16 parts)

• The smaller the value of n, the lower the required electric power. And the bigger

the value of n, the faster the speed of printing.

DC2 ~ n Print Density Set

Code

Domain of

+ 7E16 + n

12

16

0 ≤ n ≤ 255

function

Function

Sets the print density.

Details

• n means n%.

• When adjusting the print density double for low heat sensitive paper, set n=200.

• The print density cannot be set for each character. The print density can be set

for each line.

• In default, n = 100.

5-11

Page 40

5.4.3 Mode 3

A

1. Paper feed commands

CR Carriage Return

Code

Function

Details

0D

16

Prints the data stored in the print buffer, and then starts a new line according to the

defined amount of paper feed for one line.

• After executing this command, a head of a line is set as a starting position of

printing.

• LF command received immediately following CR is ignored.

LF Line Feed

Code

Function

0A

16

Provides the same function as CR.

Details

fter executing this command, a head of a line is set as a next starting position of

•

printing.

• LF command received immediately following CR is ignored.

FF Page Length Print

Code

Function

0C

16

Feeds paper based on the setting of page length.

Details

• After executing this command, a head of a line is set as a next starting position of

printing.

5-12

Page 41

ESC J n Print and Feed Forward

A

A

Code

Domain of

+ 4A16 + n

1B

16

0 ≤ n ≤ 255

function

Function

Prints the data stored in the print buffer, and then feeds paper n × dot pitch forward.

Details

• After executing this command, a head of a line is set as a next starting position of

printing.

• This function is not affected by the setting of the amount of line spacing.

ESC j n Print and Feed Backward

Code

Domain of

+ 6A16 + n

1B

16

0 ≤ n ≤ 255

function

Function

Details

Prints the data stored in the print buffer, and then feeds paper n × dot pitch

backward.

fter executing this command, a head of a line is set as a next starting position of

•

printing.

• This function is not affected by the setting of the amount of line spacing.

ESC d n Print and Continuous Line Feed

Code

Domain of

+ 6416 + n

1B

16

0 ≤ n ≤ 255

function

Function

Prints the data stored in the print buffer, and then feeds paper n lines forward.

Details

fter executing this command, a head of a line is set as a next starting position of

•

printing.

5-13

Page 42

ESC C n Page Length Set

Code

Domain of

+ 4316 + n

1B

16

1 ≤ n ≤ 255

function

Function

Sets the amount of page feed.

Details

• The page feed is executed using the FF command.

5-14

Page 43

2. Tab commands

HT Horizontal Tab

Code

Function

09

16

Moves the printing position to the position of the next horizontal tab.

Details

• If the position of the horizontal tab is not set, this command is ignored.

• If the position of the horizontal tab is out of the printing area, it is set at the head

of the next line.

• The position of the horizontal tab is set using the ESC D command.

• The default value of the horizontal tab is 8 character pitches.

ESC D n1...nk NUL Horizontal Tab Set

Code

Domain of

function

Function

+ 4416 + n1...nk + 0016

1B

16

1 ≤ n ≤ 255

0 ≤ k ≤ 32

Sets the position of the horizontal tab.

n describes the number of characters from the head of a line to the position at

which the horizontal tab is set.

k describes the number of data to be set.

Details

• The position of the horizontal tab to be set is [character width × n].

→ The character width includes the right space and the horizontal scaling factor.

• All the values previously set are cleared.

• The maximum number of horizontal tab positions settable is 32. If the number

exceeds the limit, the rest of the data is processed as normal data.

• The positions are set in ascending order. And the final value is NUL code.

• If the smaller value is set than previously set value, such value is recognized as

NUL code.

• Even if changing the width of character after setting, the position of tab set is not

changed.

5-15

Page 44

3. Form commands

ESC 2 Default Amount of Line Spacing Specify

Code

Function

+ 3216

1B

16

Restores the amount of paper feed for one line to its default value.

ESC 3 n Amount of Line Spacing Set

Code

Domain of

+ 3316 + n

1B

16

0 ≤ n ≤ 255

function

Function

Sets the amount of paper feed for one line at [n × dot pitch].

Details

• The default amount of paper feed for one line, n = 28.

ESC SP n Standard Size Character Right Spacing Set

Code

Domain of

+ 2016 + n

1B

16

0 ≤ n ≤ 127

function

Function

Sets the character spacing for standard size character at [n × dot pitch].

Details

• The right character spacing increases depending on the horizontal scaling factor.

• This command does not affect kanji.

• In default, n = 0.

5-16

Page 45

GS L nl nh Left Margin Set

Code

Domain of

function

Function

+ 4C16 + nl + nh

1D

16

0 ≤ nl ≤ 255

0 ≤ nh ≤ 255

Sets the left margin at [(nh × 256 + nl) × dot pitch].

Details

• This setting is only valid at a head of a line.

• The maximum settable left margin corresponds to the horizontally printable area.

• When a setting value exceeds maximum value, the setting value is replaced

within printable maximum area.

• In default, nh and nl = 0.

GS W nl nh Width of Printing Area Set

Code

Domain of

function

Function

+ 5716 + nl + nh

1D

16

0 ≤ nl ≤ 255

0 ≤ nh ≤ 255

Sets the width of the printing area at [(nh × 256 + nl) × dot pitch]

Details

• This setting is only valid at a head of a line.

• The settable printing area corresponds to the horizontally printable area except

for the left margin. If printable range is exceeded, it replaces to the horizontally

printable maximum area except the left margin.

• In default, nh × 256 + nl = 384.

5-17

Page 46

ESC $ nl nh Absolute Position of Printing Area Specify

Code

Domain of

function

Function

Details

+ 2416 + nl + nh

1B

16

0≤ nl ≤ 255

0 ≤ nh ≤ 255

0 ≤ nh × 256 + nl ≤ 127

Sets the printing area at the absolute position based on the left margin. The setting

range is [(nh × 256 + nl) × dot pitch].

• This setting is only valid at a head of a line.

• The value of setting exceeding the maximum value of nh or nl invalidates this

command.

ESC a n Position Align

Code

Domain of

+ 6116 + n

1B

16

0 ≤ n ≤ 2

function

Function

Aligns one line of data to be printed in the specified position.

n = 0: left – aligned

n = 1: center – aligned

n = 2: right – aligned

Details

• This function makes an alignment within the predefined printing area.

• In default, n = 0.

5-18

Page 47

4. Character decoration commands

ESC ! n Decorated Characters Collectively Specify

Code

Domain of

+ 2116 + n

1B

16

0 ≤ n ≤ 255

function

Function Collectively specifies the printing modes.

Bit Description

Function

0 1

0 Font 24 dot type 16 dot type

1 Undefined − −

2 Undefined − −

3 Bold character clear specify

4 Double–height character clear specify

5 Double–width character clear specify

6 Undefined − −

7 Underline clear specify

Details

• When specifing both Bit 4 and Bit 5 described in the table above, the

double-height and double-width size characters are printed.

• The dot pitch of underline is 2 dot pitch. However, if the several underlines with

the different thicknesses exist in one line, the thickness of those underlines will be

brought into line with the thickest underline.

• Each setting is not related to the previous settings.

• The settings of the characters except for the bold characters and the font are

valid only for the standard size characters.

• In default, n = 0.

5-19

Page 48

ESC G n

ESC E n Bold Characters Specify and Clear

Code

Domain of

+ 4716 + n

1B

16

1B

+ 4516 + n

16

0 ≤ n ≤ 255

function

Function

Specifies and clears the bold characters.

n = <xxxxxxx0>B: The bold characters are cleared.

n = <xxxxxxx1>B: The bold characters are specified.

Details

• n is valid only for the least significant bit.

• In default, n = 0.

ESC { n Inversion (Flip) Specify and Clear

Code

Domain of

+ 7B16 + n

1B

16

0 ≤ n ≤ 255

function

Function

Specifies and clears the inversion.

n = <xxxxxxx0>B: The inversion is cleared.

n = <xxxxxxx1>B: The inversion is specified.

Details

• n is valid only for the least significant bit.

• This setting is valid only at a head of a line.

• In default, n = 0.

5-20

Page 49

ESC – n Underline Specify and Clear

Code

Domain of

+ 2D16 + n

1B

16

0 ≤ n ≤ 255

function

Function

Specifies and clears the underline.

n = <xxxxx000>B: underline 0 dot pitch

n = <xxxxx111>B: underline 7 dot pitch

Details

• n is valid only for the low 3 bits.

• This setting is valid only for the standard size characters.

• The underline is added to the width of character and the character spacing.

• This function is not affected by the setting of the amount of line specing.

• If the several underlines with the different thicknesses exist in one line, the

thickness of those underlines will be brought into line with the thickest underline.

• In default, n = 0.

GS ! n Character Size Set

Code

Domain of

+ 2116 + n

1D

16

0 ≤ n ≤ 255

function

Function

Specifies the character size.

n = <xxxx0000>B: scaling factor in the vertical direction : × 1 <minimum>

n = <xxxx0111>B: scaling factor in the vertical direction : × 8 <maximum>

n = <0000xxxx>B: scaling factor in the horizontal direction : × 1 <minimum>

n = <0111xxxx>B: scaling factor in the horizontal direction : × 8 <maximum>

Details

• This setting is valid for any type of characters other than HRI characters.

• n is valid only for 0 to 2 bits and 4 to 6 bits.

• In default, n = 0.

5-21

Page 50

GS B n Reverse Character Specify and Clear

Code

Domain of

+ 4216 + n

1D

16

0 ≤ n ≤ 255

function

Function

Specifies and clears the reverse characters.

n = <xxxxxxx0>B: The reverse characters are cleared.

n = <xxxxxxx1>B: The reverse characters are specified.

Details

• n is valid only for the least significant bit.

• In default, n = 0.

5-22

Page 51

5. Character selection commands

ESC M n Font Select

Code

Domain of

+ 4D16 + n

1B

16

0 ≤ n ≤ 255

function

Function

Selects the character font.

n = <xxxxxxx0>B: character font (12 × 24 and 24 × 24)

n = <xxxxxxx1>B: character font (8 × 16 and 16 × 16)

Details

• n is valid only for the least significant bit.

• This setting is also valid for Kanji.

• The character font can be set by ESC ! command but the setting by the command

which has been processed at last becomes valid.

• In default, n = 0.

5-23

Page 52

ESC R n International Character Select

Code

Domain of

+ 5216 + n

1B

16

0 ≤ n ≤ 7

function

Function

Details

Selects a set of characters of each country described below.

When selecting JAPAN, the set of characters corresponds to the katakana –

compliant character code table (refer to APPENDIX B. DATA CODE TABLE.).

When selecting a set of characters other than JAPAN, the characters are replaced

with only the characters of a country of specified corresponding code according to

PC 437 code table (refer to APPENDIX B. DATA CODE TABLE.).

• The data beyond the defined domain of function is ignored.

• In default, n = 0.

5-24

Page 53

ESC & y c1 c2 [x1 d1...d(y×x1)]...[xk d1...d(y×xk)] Downloaded Character Register

Code

Domain of

function

+ 2616 + y + c1 + c2 [x1 d1...d (y × x1)]...[xk d1...d (y × xk)]

1B

16

y = 3

20

≤ c1 ≤ c2 ≤ 7E16

16

0 ≤ x ≤ 12 (When font (12 × 24) is selected)

0 ≤ x ≤ 9 (When font (8 × 16) is selected)

0 ≤ d1…d (y × xk) ≤ 255

Function

Defines the downloaded pattern for the specified character code.

y : The number of bytes in the vertical direction

x : The number of bits in the horizontal direction

c1 : Start code of character definition

c2 : End code of character definition

Details

• When defining only one character, c1 is equal to c2.

• d means the graphic data of the downloaded characters,

• The residual right space generated by specifying x is processed as blank.

• The code previously registered is overwritten.

• When making the registered font valid, set ESC %.

• The maximum output for 16 bit type fonts is 8 dots (width) × 16 dots (height).

ESC ? n Downloaded Character Delete

Code

Domain of

1B

16

20

16

+ 3F16 + n

≤ n ≤ 7E16

function

Function

Deletes the downloaded characters of the specified code.

Details

• n means the defined character code. After deleting the downloaded characters,

the internal characters are printed.

• If the specified character code is undefined, this command is ignored.

5-25

Page 54

ESC % n Downloaded Character Specify and Clear

Code

Domain of

+ 2516 + n

1B

16

0 ≤ n ≤ 255

function

Function

Specifies and clears the downloaded character set.

n = <xxxxxxx0>B: The downloaded character set is cleared.

n = <xxxxxxx1>B: The downloaded character set is specified.

Details

• n is valid only for the least significant bit.

• When clearing the downloaded character set, specify the internal character set.

• When specifying the downloaded character set, specify the downloaded

characters for the defined code and the internal characters for the undefined

code.

• In default, n = 0.

5-26

Page 55

⋅⋅⋅

⋅⋅⋅

⋅⋅⋅

⋅⋅⋅

⋅⋅⋅

⋅⋅⋅

Image of registration

Font 12 × 24

d1

d2

d5

d3 d36

d6

Font 12 × 24

d1

d2

d5

⋅ ⋅ ⋅

⋅ ⋅ ⋅

⋅ ⋅ ⋅

⋅ ⋅ ⋅

⋅ ⋅ ⋅

d34d4

d35

Character output range

d34d4

d35

Font 8 × 16

d1

d2

d5

d3 d27

d6

Font 8 × 16

d1

d2

d5

d25 d4

d26

d22 d4

d23

MSB

LSB

d3 d36

d6

⋅ ⋅ ⋅

5-27

Page 56

6. Barcode commands

GS H n HRI Character Printing Set

Code

Domain of

+ 4816 + n

1D

16

0 ≤ n ≤ 255

function

Function

Specifies the printing position of the HRI characters when printing a Barcode.

n = <xxxxxx00>B: HRI characters are not printed.

n = <xxxxxx01>B: HRI characters are printed on top of the Barcode.

n = <xxxxxx10>B: HRI characters are printed below the Barcode.

n = <xxxxxx11>B: HRI characters are printed on top of and below the Barcode.

Details

• n is valid only for the low 2 bits.

• In default, n = 0.

GS w n Width of Barcode Set

Code

Domain of

+ 7716 + n

1D

16

1 ≤ n ≤ 4

function

Function Sets the width of Barcode.

Module width of

n

JAN/UPCE

Module width of ITF, CODE39, and CODABAR

Narrow bar Wide bar

1 2 dot pitch 1 dot pitch 3 dot pitch

2 3 dot pitch 2 dot pitch 5 dot pitch

3 4 dot pitch 3 dot pitch 8 dot pitch

4 5 dot pitch 4 dot pitch 10 dot pitch

Details

• For CODE128, the width of a Barcode cannot be set (the module width is fixed at

2 dot pitch).

• In default, n = 2.

5-28

Page 57

GS h n Height of Barcode Set

Code

Domain of

+ 6816 + n

1D

16

1 ≤ n ≤ 255

function

Function

Sets the height of Barcode.

Details

• In default, n = 162.

5-29

Page 58

GS k m d1...dk NUL Barcode Print

Code

Domain of

function

Function

+ 6B16 + m + d1...dk + NUL

1D

16

1 ≤ m ≤ 7

The values of d1 to dk depend on a type of Barcode.

Selects a type of Barcode and prints the Barcode.

m Type of Barcode

1 UPC-E

2 JAN13

3 JAN8

4 CODE39

5 ITF

6 CODABAR

7 CODE128

Details

• This command is finished by a NUL code.

• UPC−E is the 7-byte Barcode data and internally adds a check digit.

• JAN13 is the 12-byte Barcode data and internally adds a check digit.

• JAN8 is the 7-byte Barcode data and internally adds a check digit.

• CODE39 automatically adds the start and stop modules.

• ITF is the even number-byte Barcode data and automatically adds the start and

stop modules.

• CODE128 transmits the start module and the Barcode data. And the check digit

and the stop module are automatically added.

If the special characters are included in the data, specify them at 2 bytes as

follows.

SHIFT → 7B

CODE A → 7B

CODE B → 7B

CODE C → 7B

FNC 1 → 7B

FNC 2 → 7B

FNC 3 → 7B

FNC 4 → 7B

’{’ → 7B

, 5316 ({S)

16

, 4116 ({A)

16

, 4216 ({B)

16

, 4316 ({C)

16

, 3116 ({1)

16

, 3216 ({2)

16

, 3316 ({3)

16

, 3416 ({4)

16

, 7B16 ({{)

16

Example) When printing Start Code C, Fnc 1, and 0012, (where n = 7),

send 1D

, 6B16, 0716, 6916, 7B16, 3116, 3016, 3016, 3116, 3216, 0016

16

in this order.

5-30

Page 59

7. Ruled line control commands

DC3 A Ruled Line Buffer A Select

Code

Function

+ 4116

13

16

Selects the ruled line buffer A.

Details

• This function selects the ruled line buffer A.

• There are 2 independent buffers (A and B) as the ruled line buffer.

• The ruled line buffer A is selected as the default.

DC3 B Ruled Line Buffer B Select

Code

Function

+ 4216

13

16

Selects the ruled line buffer B.

Details

• This function selects the ruled line buffer B.

• The ruled line buffer A is selected as the default.

DC3 C Ruled Line Buffer Clear

Code

Function

+ 4316

13

16

Clears the contents of the selected ruled line buffer.

Details

• The whole data is cleared to 0.

5-31

Page 60

DC3 D nl nh Write in Position Specified by Dot in Ruled Line Buffer

Code

Domain of

function

Function

Details

+ 4416 + nl + nh

13

16

0 ≤ nl ≤ 255

0 ≤ nh ≤ 3

Writes 1 in the specified position in the ruled line buffer.

The position is set at [(nh × 256 + nl) × dot pitch].

• Regardless of the printable area, this function writes 1 in the selected ruled line

buffer.

• nh is valid only for the low 2 bits.

DC3 L nl nh ml mh Write in Position Specified by Line in Ruled Line Buffer

Code

Domain of

function

+ 4C16 + nl + nh + ml + mh

13

16

0 ≤ nl ≤ 255

0 ≤ nh ≤ 3

0 ≤ ml ≤ 255

0 ≤ mh ≤ 3

Function

Writes 1 in the range from nhnl to mhml in the ruled line buffer.

0 ≤ nhnl ≤ mhml ≤ 1023

nhnl = (nh × 256 + nl) × dot pitch

mhml = (mh × 256 + ml) × dot pitch

Details

• Regardless of the printable area, this function writes 1 in the selected ruled line

buffer.

• nh and mh are valid only for the low 2 bits.

5-32

Page 61

DC3 + Print Mode of Ruled Line Approve

Code

Function

+ 2B16

13

16

Approves the print mode of the data stored in the ruled line buffer.

Details

• When a printing command (CR, LF, etc.) is executed after the approval, the data

stored in the selected ruled line buffer is always included in the data to be printed.

• This command is not affected by the printing area commands such as GS L, and

GS W.

• In default, the print mode of the data stored in the ruled line buffer is prohibited.

DC3 – Print Mode of Ruled Line Prohibit

Code

Function

+ 2D16

13

16

Prohibits the print mode of the data stored in the ruled line buffer.

Details

• After the print mode of the ruled line is cancelled, the data stored in the ruled line

buffer is not printed.

DC3 P 1 Dot Line of Ruled Line Print

Code

Function

Details

+ 5016

13

16

Prints the data stored in the print buffer and 1 dot line of the data in the selected

ruled line buffer.

• Even if no data exists in the print buffer, 1 dot line of the data in the selected ruled

line buffer is printed.

• If the print mode of the data stored in the ruled line buffer is prohibited, none of

the data is printed.

5-33

Page 62

8. Response commands (only for serial mode)

GS a n Validity / Invalidity of Automatic Status Transmission and Real Time Command Select

Code

Domain of

+ 6116 + n

1D

16

0 ≤ n ≤ 3

function

Function

Specifies the validity or invalidity of the automatic status response which is one of

the printer statuses.

Specifies the validity or invalidity of the real time command.

n = 0: The automatic status response becomes invalid.

n = 1: The automatic status response becomes valid. And the current status is

returned.

n = 2: The real time command becomes invalid.

n = 3: The real time command becomes valid

Details

• The automatic status response automatically returns a response depending on

the change in status.

• The real time command is executed at the reception.

• For the status values, refer to Table 5-1 Status Response Value Table.

• This command is executed at the deployment of the receive buffer so that the

execution of the command may be delayed depending on the conditions of the

receive buffer.

• When a value is returned, the conditions of the host computer are not checked.

• In default, both the automatic status response and the real time command are

invalid.

5-34

Page 63

GS r n Status Transmit

Code

Domain of

+ 7216 + n

1D

16

0 ≤ n ≤ 255

function

Function

Details

Returns the current printer status.

n = <xxxxxxx1>B : The status is returned

• n is valid only for the least significant bit.

• Regardless of the validity of the automatic status response, this function returns

the current status.

• For the status values, refer to Table 5-1 Status Response Value Table.

• This command is executed at the deployment of the receive buffer so that the

execution of the command may be delayed depending on the conditions of the

receive buffer.

• When a value is returned, the conditions of the host machine are not checked.

5-35

Page 64

DLE EOT n Status Transmit in Real Time

Code

Domain of

10

n = 1

16

+ 0416 + n

function

Function

Details

Returns the current printer status in real time.

• Regardless of the validity of the automatic status response, this function returns

the current status.

• For the status values, refer to Table 5-1 Status Response Value Table.

• This command is executed at the reception.

• When the real time command is invalid, this command is ignored.

• Users should be aware that even if this command is valid and consistent with

DLE ENQ 1 in the image data, this command will be executed.

Table 5-1 Status Response Value Table

Response value

Printer status

(1 byte)

Bit 0 Out-of-paper error no error error

Bit 1 Cover open error no error error

Bit 2 Voltage error no error error

Bit 3 Temperature error no error error

Bit 4 Printer operation standby operating

Bit 5 Fixed to 1 − fixed

Bit 6 Fixed to 1 − fixed

Bit 7 Fixed to 0 fixed −

* :This bit is valid only for DLE EOT. The value is fixed at 0 for the other commands.

Description

0 1

5-36

Page 65

DLE ENQ n Major Buffers Clear in Real Time

Code

Domain of

10

n = 1

16

+ 0516 + n

function

Function

Details

Clears the major buffers in real time while off line.

n = 1: The major buffers are cleared.

• This command is valid while off line.

• This command is executed at the reception.

• When the real time command is invalid, this command is ignored.

• Users should be aware that even if this command is valid and consistent with

DLE ENQ 1 in the image data, this command will be executed. (however, this

note is not necesary while on line)

• The buffers cleared are:

• Receive buffer

• Print buffer

• Command edit mode

5-37

Page 66

9. Bitimage commands

ESC ∗ m nl nh [d1...dk] Bitimage Select

Code

Domain of

function

+ 2A16 + m + nl + nh + [d1...dk]

1B

16

m = 0,1,32,33

0 ≤ nl ≤ 255

0 ≤ nh ≤ 3

0 ≤ d ≤ 255

Function

Specifies the Bitimages with the number of dots specified as nl and nh in Mode m.

m Mode

The number

of dots in

the vertical

direction

The number of

dots in the

horizontal

direction

(1 line)

0 8 dot single density 8 192 nh × 256 + nl

1 8 dot double density 8 384 nh × 256 + nl

32 24 dot single density 24 192 (nh × 256 + nl) × 3

33 24 dot double density 24 384 (nh × 256 + nl) × 3

Details

• If m is out of the domain of function, the data after nl is processed as the normal

data.

• nl and nh mean the number of dots in the horizontal direction of the Bitimage to

be printed.

• If the dot is specified beyond the printable area, the data is deleted.

• The data deployment position corresponds to the deployment start position.

• This command is affected by the inverse print but the others such as dual print,

bold print and reverse print.

• Refer to the diagram for how to deploy the data.

The number of

data (k)

5-38

Page 67

8-dot bitimage

d1 d2 d3

d1 d2 d3

MSB

24-dot bitimage

d1

d4

d7

LSB

d1 - - - - - - - - - - d9

MSB

d2

d5

d8

Double

densit y

d3

d6

d9

LSB

GS ∗ x y [d1...d(x × y × 8)] Downloaded Bitimage Register

Code

Domain of

function

+ 2A16 + x + y + [d1...d (x × y × 8)]

1D

16

1 ≤ x ≤ 255

1 ≤ y ≤ 48

0 ≤ d ≤ 255

(x × y × 8) ≤ Empty space of user memory

Single

density

Function

Details

Defines the downloaded Bitimage with the number of dots specified as x and y.

x: The number of dots in the horizontal direction (x × 8) is specified.

y: The number of dots in the vertical direction (y × 8) is specified.

• If the number of dots is specified beyond the defined domain of function, this

command is ignored.

• Check the user memory for the empty space.

• Refer to the diagram for how to deploy the data.

5-39

Page 68

GS / m Downloaded Bitimage Print

Code

Domain of

+ 2F16 + m

1D

16

0 ≤ m ≤ 3

function

Function

Prints the downloaded Bitimage in the specified Mode m.

m Print mode Description

0 Normal mode Prints the normal size characters

1 Double width mode Prints the double-width characters

2 Double height mode Prints the double-height characters

3 Double height and width

mode

Details

• If the downloaded Bitimage is not defined, this command is ignored.

• If the data is stored in the print buffer, both such data and the downloaded

Bitimage are printed.

• No print mode but inversion affects this command.

• As for unprintable area, the fractional images are printed per rightward bytes to

the unprintable area.

Structure of downloaded Bitimage

ダウンロードビットイメージの構成

d1

d1

dy + 1

dy+1

Prints the double-height and double−width

characters

X × 8 dots

x×8ドット

・・・・・・

MSB

MSB

dy + 2

dy+2

d2

×

Y × 8 dots

y

8ドット

d2

・・・

dy×2 dy×x×8

dy

dy × 2

dy

・・・・・・

・・・

・・・・・・

dy × x × 8

LSB

LSB

5-40

Page 69

10. Kanji commands

FS & Kanji Mode Specify

Code

Function

+ 2616

1C

16

Specifies the kanji mode.

Details

• The Kanji Mode Specify is valid only when the JIS code is selected.

• If the kanji mode is selected, each and every character code is processed as 2

byte kanji code.

• In default, the kanji mode is cleared.

FS . Kanji Mode Clear

Code

1C

+ 2E16

16

Function

Clears the kanji mode.

Details

• The Kanji Mode Clear is valid only when the JIS code is selected.

• If the kanji mode is cleared, each and every character code is processed as

ASCII code.

• In default, the kanji mode is cleared.

FS C Kanji Code System Select

Code

Domain of

+ 4316 + n

1C

16

0 ≤ n ≤ 255

function

Function

Selects the kanji code system.

n = <xxxxxxx0>B: JIS code

n = <xxxxxxx1>B: Shift JIS code

Details

In default, n = 0.

5-41

Page 70

FS S nl nr Character Spacing for Kanji Set

Code

Domain of

function

Function