Page 1

---

-

----

-

-------

--------

--

-----......;;

OPERATING

AND

PARTS

BElKO

.

BLIIDSTITCH

INSTRUCTIONS

BOOK

MACHINE

SERIES

CM3-L21

SEIKO

CM3-21

SEMI

S-EWING

TOKYO,

CM3-11

SELF-OILER

MACHINE CO., LTD.

JAPAN

Page 2

STANDARD

#10

Fine knit rayon

:r,

If

who

please write

NEEDLES

you

have any difficulty, do not hesitate

sold

you

this machine.

or

phone

us

If

unable to obtain satisfaction,

direct:-------------

SIZE

#15

#20

#25

#30

#35

#40

to

contact dealer

Fine knit wear

Fine knit jersey

Dresses and light fabrics

For

sportswear

For

heavy, hard material and coats

For

extra hard material

• SEIKO SEWING MACHINE CO., LTD.

11-3,

1-chome,

__

Phone:872-6171/6

Cable

Address: SEIKOSEWMCO

lmado,

Taito-ku,

Tokyo,

TOKYO

Japan

CM3-21

CM3-11

SERIES:

SERIES:

CM3-L21

CM3-P11

SEIKO

SERIES:

SERIES:

BLINDSTITCH

CM3-21L

CM3-11L

CM3-L21L

CM3-P11L

CM3-21M

CM3-11M

CM3-L21M

CM3-P11M

MACHINE

CM3-21H

CM3-11H

CM3-L21H

CM3-P11H

MODELS

CM3-21K(WITH

CM3-11K<NON

CM3-L21K

SKIP

<SKIP

SEMI-SELF

CM3-P11K

<PORTABLE)

SKIP

STITCH)

STITCH)

STITCH

OILER)

&

Page 3

INDEX

INFORMATION

PAGE

Needle Sizes .................................. Inside Cover

Models

Mounting

Oi I ing

Knee

in

our Line.......................... Inside Cover

on

Stand ....................................... .

Instructions ........................................ 1

Lifter Adjustment.................................. 2

Threading Chart ............................................ 2

Rib

Adjusting

to Needle.................................. 3

Stitch Ratio Lever............................................ 3

Testing and Changing Needle........................

How

to Sew.................................................... 5

·4

Stitching ........................................................ 5

Set

Rib

Shaft and

Rib

Connection............ 6 & 7

Needle Stroke ........................................ 6 & 7

Length of Stitch........................................

Adjusting

Looper

.................................... 8 & 9

6 & 7

PARTS

Rib

~--·····

.............................................. 1 0 &

Feed

Frame ........................................ 1 0 &

Main Frame ........................................ 12 &

PAGE

11

11

13

Main Shaft .................................................... 13

Front

Plates ..................................................

Presserfoot Assembly ....................................

Looper

Needle

Regulating

Rocker

Knee

CM3-

Rod

Assembly...................................... 16

Drive

Group........................................ 16

Dial

Group ...........................

Pin

Assembly......................................

~---·····

Lifter Assembly......................................

L21

Self Oiler........................... 19 & 20

11

15

17

17

18

MOUNTING MACHINE

1. Fasten machine to table

2.

screws

a.

b.

c.

The

from

direction

wheel

evenly, turning each a little

When

an

individual motor and clutch

is

employed, it

motor be rated

RPM.

On

all

outside diameter

tended for alteration,

diameter

When the machine

table, a

sible,

should

ING

The

ed for any installation

otherwise specified.

handwheel's direction of rotation

the operator.

pulley,

pulley.

4"

pulley

when

using

be mounted

THE

BELT.

maximum

when

as

looking

shown

using

felt pad. Tighten

at

a time.

is

recommended that the

at

I!J

HP

standard

pulley.

is

should

such

machine speed recommend-

It

by

and 1725/1750

models,

use

mounted

stands, the machine

TO

is

rotates

at

the arrow.

use

On models

a

21f2"

outside

on

be used. If

AVOID

3000

the face of the

a power

CROSS-

RPM,

is

in a clockwise

a Jlf2"

3. Either V-belting or round leather belting

be used.

over-heating and freezing of bearing

wheel.

Excessive

tension

of

belt

will

at

unit

in-

pos-

unless

away

may

cause

hand-

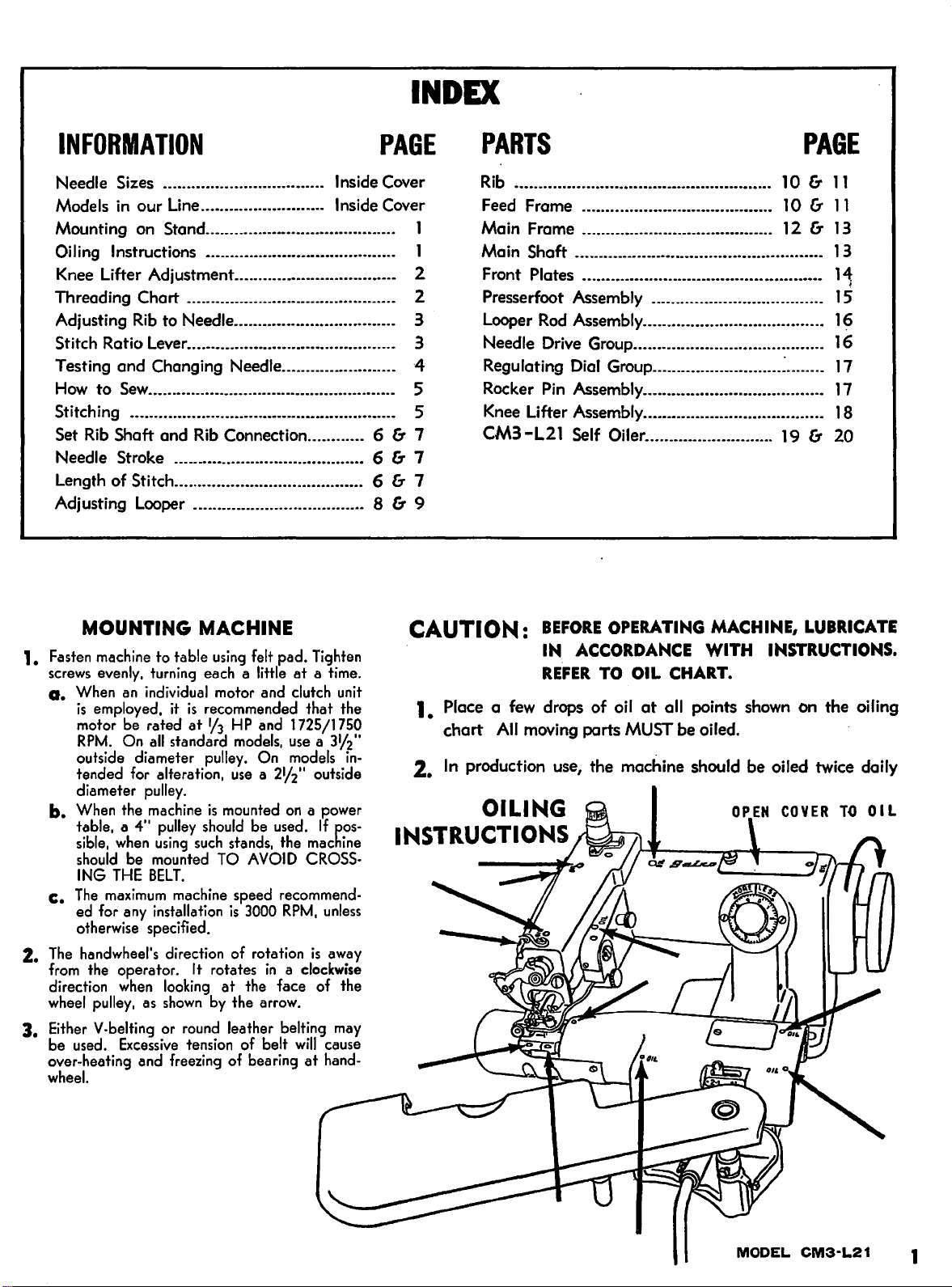

CAUTION:

BEFORE

IN

REFER

1. Place a

chart

2.

In

few

drops of

All

moving parts

production use, the machine should be oiled twice daily

OILING

INSTRUCTIONS

OPERATING

ACCORDANCE

TO

OIL

CHART.

oil

at

all points

MUST

be oiled.

MACHINE,

WITH

INSTRUCTIONS.

shown

LUBRICATE

on the oiling

MODEL

CM3-L21

1

Page 4

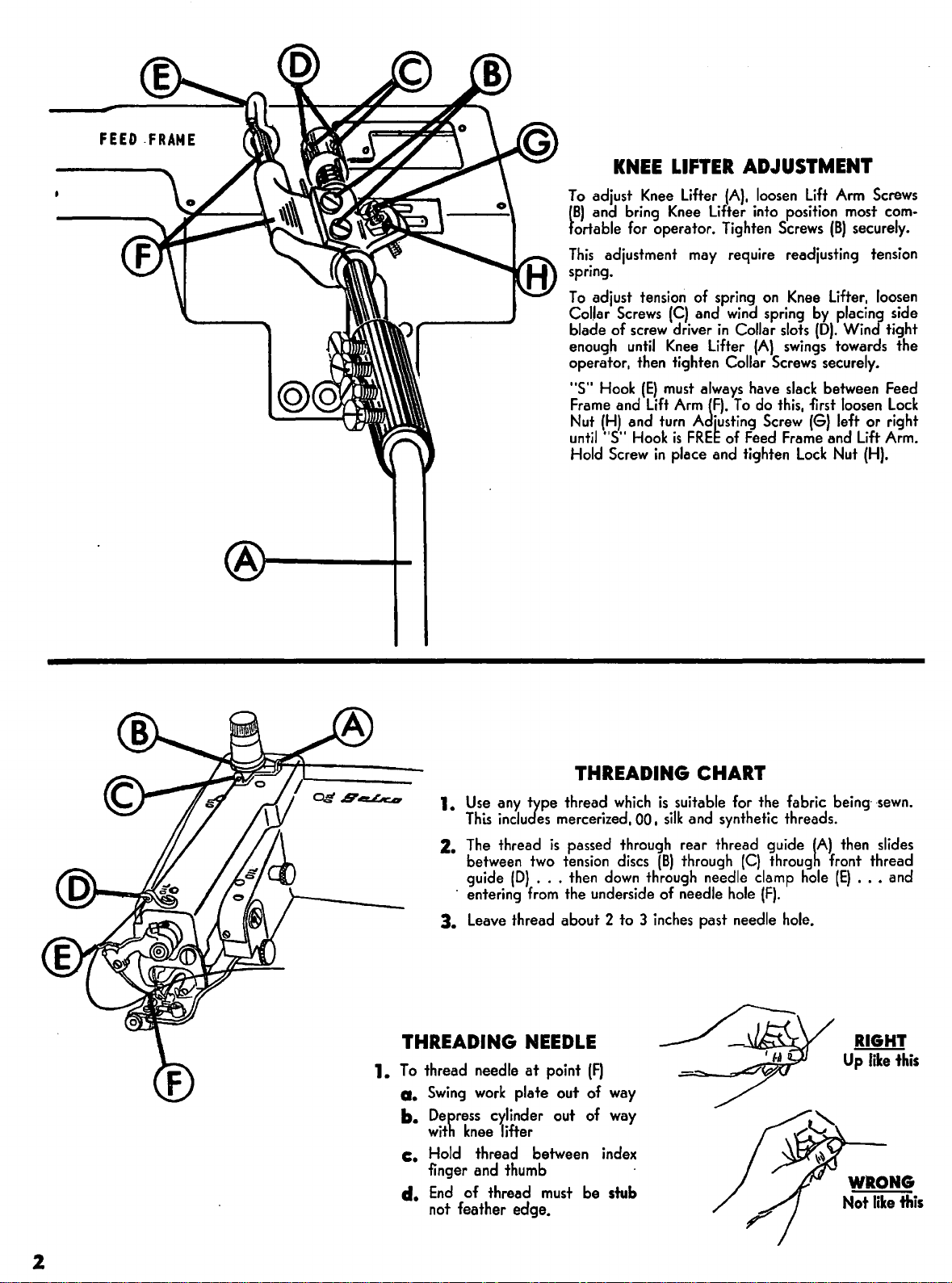

KNEE

To

adjust

(B)

and bring

fortable

This

adjustment

spring.

To

adjust

Col.lar

Screws

blade of

enough

operator, then tighten Collar

"S"

Hook

Frame

and

Nut

(H)

untii"S"

Hold

Screw

LIFTER ADJUSTMENT

Knee

lifter

(A),

Knee

Lifter into position most

for

operator. Tighten

may

require readjusting tension

tension

screw

until

(E)

and

Hook

of spring

(C)

and

wind

driver

in

Knee

Lifter

must

always

Lift

Arm

(F).

turn

Adjusting

is

FREE

of

in

place and tighten

Collar

(A)

have

To

Feed

loosen

Screws

on

spring

slots

swings

Screws

do

this,

Screw

Frame

Lift

Knee

slack

Lock

Arm

(B)

securely.

Lifter,

by

placing side

(D).

Wind tight

towards the

securely.

between

first

loosen

(G)

left or right

and

Nut

Screws

loosen

Lift

(H).

com-

Feed

Lock

Arm.

1.

2.

3.

THREADING

1.

To

thread needle

a.

Swing

b.

Depress

with

c.

Hold

finger and thumb

d.

End

not feather edge.

Use

any

type thread

This

includes

The

thread

between

guide

· entering

Leave

two

(D)

...

from

thread about 2 to 3

NEEDLE

at

work

plate out of

cylinder out of

knee

lifter

thread between

of thread

THREADING CHART

which

is

suitable for the fabric

mercerized, 00,

is

passed through rear thread guide

tension

then

down

the underside of needle

point

(F)

way

way

index

must

be stub

silk

and synthetic threads.

discs

(B)

through

through needle clamp

inches

past needle

(C)

hole

being·

·sewn.

(A}

then

slides

through front thread

hole

(E)

..•

(F).

hole.

RIGHT

Up

like

and

this

2

Page 5

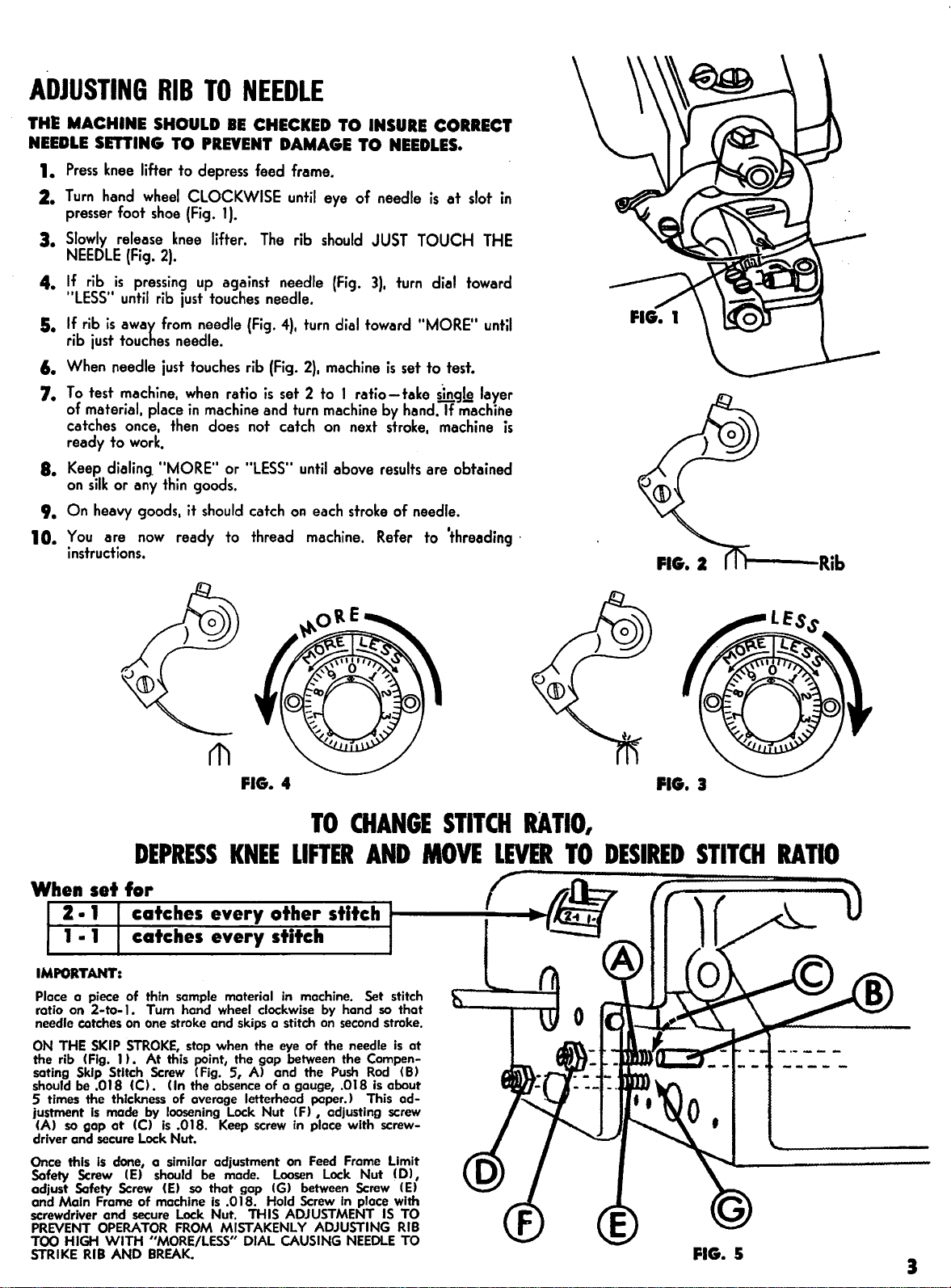

ADJUSTING

RIB

TO

NEEDLE

THE MACHINE SHOULD

NEEDLE

1.

2.

3.

4. If

5.

6.

7.

8.

9.

10.

SmiNG

Press

knee

lifter to depress feed frame.

Turn

hand

presser foot

Slowly

NEEDLE

rib

"LESS"

If

rib

rib

just

When

To

test

wheel

shoe

release

(Fig.

2).

is

pressing

until

rib

is

away

from

touches needle.

needle

just

machine,

of material, place

catches once,

ready to

Keep

dialing.

on

silk

or

On

heavy

You

are

then

work.

"MORE'' or

any

thin

goods, it

now

TO

PREVENT

CLOCKWISE

(Fig. 1 ).

knee

lifter.

up

just

touches needle.

needle

touches

when

in

machine

does not catch

goods.

should

ready to thread

instructions.

IE

CHECKED TO

DAMAGE TO

until

The

rib

against needle

(Fig.

4),

turn

rib

(Fig.

2),

ratio

is

set 2 to 1

and

turn

"LESS

..

until

catch

oR

each

machine.

INSURE

NEEDLES.

eye of needle

should

(Fig.

dial

toward

machine

JUST

3),

turn

is

set to test.

ratio-take

machine

on

above

next

stroke

by

hand.

stroke,

results

of needle.

Refer

CORRECT

is

at

slot

in

TOUCH

dial

..

MORE"

toward

sing!.§

If

machihe

THE

until

layer

machine

are obtained

to 'threading ·

is

FIG.

4

IMPORTANT:

Place a piece of thin sample material

ratio on

needle catches on one stroke

ON

the rib (Fig. 1 ) • At this point, the

sating Skip Stitch Screw (Fig.

should be

S times the thickness of average letterhead paper.> This

justment

(A) so

driver and secure Lock Nut.

Once this

Safety Screw

adjust Safety Screw

and

screwdriver

PREVENT

TOO

STRIKE

2-to-

1. Turn hand wheel clockwise by hand so

THE

SKIP

STROKE,

.018

(C).

Is

made by loosening Lock Nut

gap

at

(C)

Is

done, a similar adjustment on Feed Frame Limit

(E)

Main Frame of machine

and

secure Lock Nut. THIS ADJUSTMENT

OPERATOR

HIGH

WITH "MORE/LESS"

RIB

AND

stop when the eye of the needle

Un

the absence of a gauge, .018

is

.018. Keep screw

should be made. Loosen

(E)

so

FROM

BREAK.

and

5,

that

is

.0

MISTAKENLY

in

machine. Set stitch

skips a stitch

gap

A>

gap

(G) between Screw

18. Hold Screw

DIAL

on

between the Compen-

and the Push

(f)

, adjusting screw

in

place with screw-

ADJUSTING

CAUSING

second stroke.

Rod

is

Lock

Nut (D),

in

place with

NEEDLE

that

is

(B)

about

ad-

(E)

IS

TO

RIB

TO

at

FIG.

3

FIG. S

Page 6

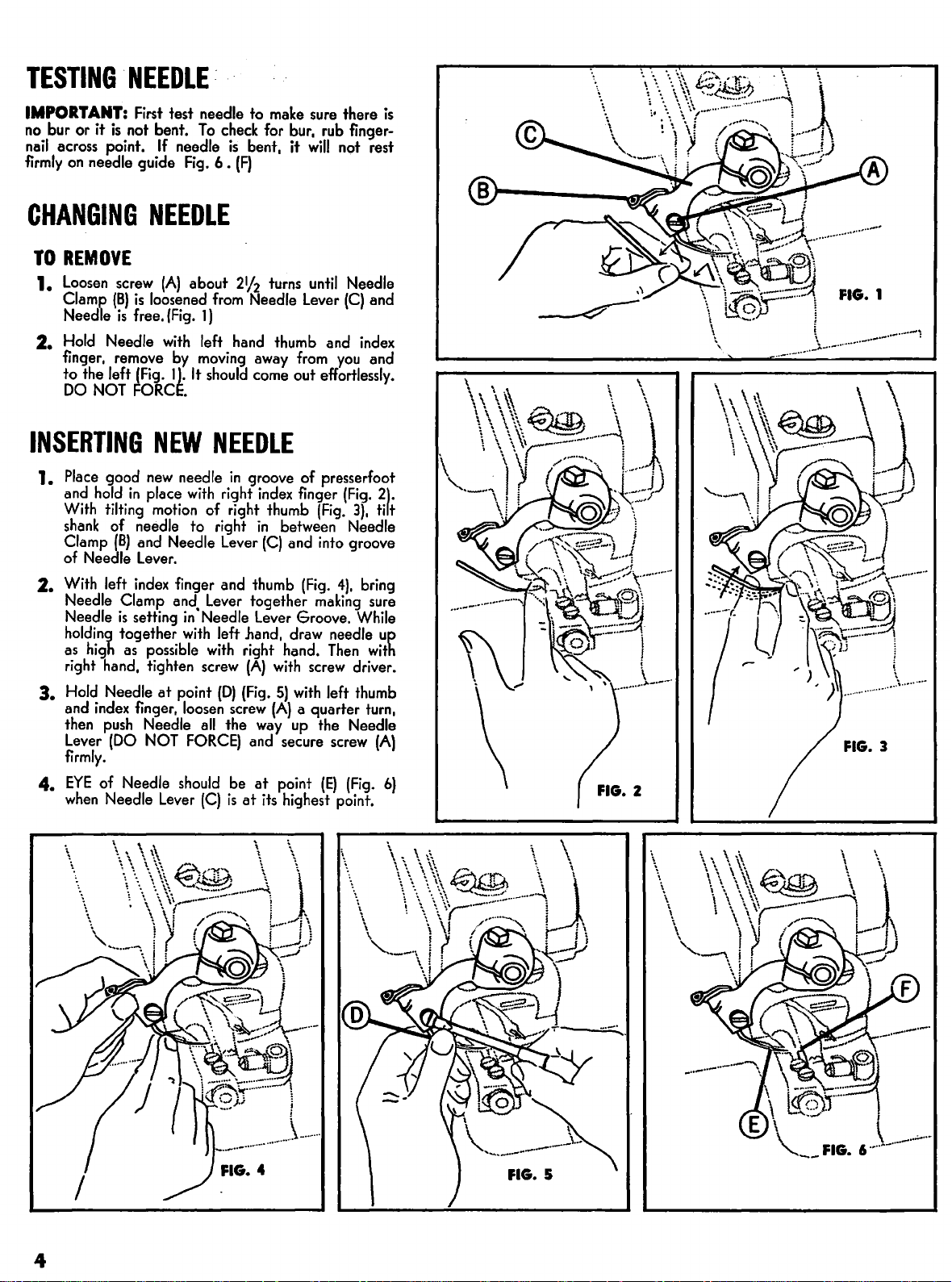

TESTING

'NEEDLE:

IMPORTANT:

no

bur or it

nail

across point.

firmly

on

CHANGING

TO

REMOVE

1.

Loosen

Clamp

Needle

2.

Hold

finger,

to the

DO

INSERTING

1.

Place

and

With

shank

Clamp

Needle

of

2.

With

Needle Clamp

Needle

holding

as

right

3.

Hold

and

then

Lever

firmly.

4.

EYE

when

First

is

not bent.

needle guide

If

NEEDLE

screw

(A)

(B)

is

loosened

is

free.

(Fig.

Needle

left

NOT

with

remove

(Fig. 1 ).

FORCE.

NEW

good

hold

high

index

new

in

place

tilting

motion

of needle to right

(B)

and Needle

Lever.

left

index

is

setting

together

as

possible

hand,

tighten

Needle

push

(DO

of Needle

Needle

at

finger,

Needle

NOT

Lever

test needle to

To

check

needle

by

Fig.

about

from

1)

left

moving

It

should

6 •

is

bent, it

(F)

21f2

Needle

hand

come

away

NEEDLE

needle

finger and

and

point

should

in

with

in·

with

loosen

FORCE)

groove of presserfoot

right

of right thumb

Lever

thumb

Lever

together

Needle

screw

all

(C)

left

with

(D)

screw

the

be

is

Lever

.hand,

right hand.

(A)

(Fig.

and

at

at

make

sure

for

bur,

rub

will

turns

until

Lever

thumb and

from

out

effortlessly.

index

finger

(Fig.

in

between Needle

(C)

and

into

(Fig.

making

Groove.

draw needle

Then

with

screw

5)

with

left

(A)

a quarter

way

up

the Needle

secure

point

its

highest point.

screw

(E)

there

finger-

not rest

Needle

(C)

and

index

you

and

(Fig.

2\.

3),

tirt

groove

4),

bring

sure

While

up

with

driver.

thumb

turn,

(A)

(Fig.

is

FIG. 1

~·--··-·-··-·.,._.,-~

FIG. 3

6)

\.

\

\

\.

\

~

\\

\\\

~

\

......

\

~

~~~_

·-v.•, \

......

\

~

\

4

Page 7

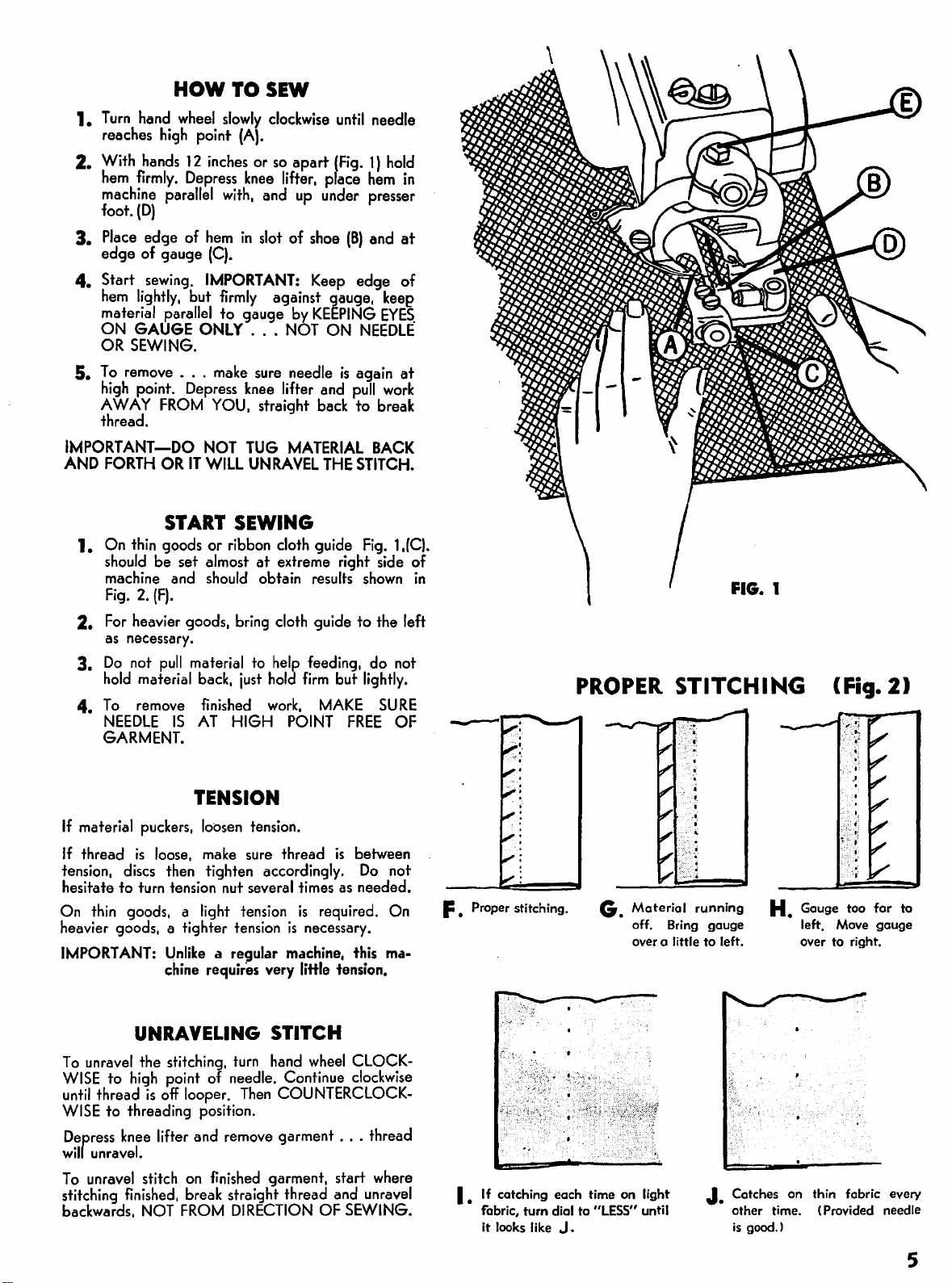

HOW

1.

Turn

hand

reaches

2. With

hem

machine

foot.

3.

Place

edge of gauge

4. Start

hem

material

ON

OR

SEWING.

5.

To

remove

high

AWAY

thread.

IMPORTANT-DO

AND

FORTH

wheel

high

hands

firmly.

parallel

(D)

edge of

sewing.

lightly,

parallel

GAUGE

...

point.

FROM

OR

START SEWING

1.

On

thin

goods or

should

machine

Fig.

2.

For

as

3.

Do

hold

4.

To

NEEDLE

GARMENT.

be set almost

and

2.

(F).

heavier goods,

necessary.

not

pull

material

remove

IS

TO

slowly

point

(A).

12

inches

or

Depress

but

Depress

IT

material

knee

with,

hem

in

(C).

IMPORTANT:

firmly

to gauge

ONLY

back,

finished

AT

make

YOU,

NOT

WILL

ribbon

should

HIGH

...

sure

knee

TUG

UNRAVEL

at

bring

to

just

SEW

clockwise

so

lifter,

and

slot

of

against gauge,

NOT

needle

lifter and

straight

MATERIAL

cloth

extreme right side of

obtain

cloth

help

hold

work,

POINT

until

needle

apart

(Fig.

1)

pface

hem

up

under presser

shoe

(B)

and

Keep

edge of

by

KEEPING

ON

NEEDLE

is

again

pull

back

to break

BACK

THE

STITCH.

guide

Fig.

results

guide to the left

feeding, do not

firm

but

MAKE

FREE

shown

lightly.

SURE

hold

in

at

keep

EYES.

at

work

l.(C).

in

OF

PROPER

FIG.

1

STITCHING (Fig. 2J

TENSION

If

material

If

thread

tension,

hesitate to

On

thin

heavier goods, a tighter

IMPORT

puckers,

is

loose,

discs

turn

goods, a

ANT:

chine

loosen

then

tension

light

l)nlike

tension.

make

sure

tighten accordingly.

nut

several

tension

tension

a regular

requires

thread

times

is

is

necessary.

machine,

very

little tension.

is

between

Do

as

needed.

required.

this

not

On

ma-

F • Proper stitching.

UNRAVELING STITCH

To

unravel

WISE

until

WISE

Defress

wil

unravel.

To

unravel

stitching

backwards,

the stitching,

to

high

point

of

thread

is

off

looper.

to threading position.

knee

lifter and

stitch

finished,

NOT

on

finished

break

FROM

remove

turn

hand

needle. Continue

Then

straight thread

DIRECTION

wheel

COU

NTERCLOCK-

garment

garment, start

OF

CLOCKclockwise

...

thread

where

and

unravel

SEWING.

I.

If

catching each time on light

f'obric, turn dial to

it looks like J .

G.

Material

off. Bring gouge

over

"LESS" until

o little

running

to

left.

J.

H.

Gouge too for

left. Move gouge

over to right.

Catches on thin fabric every

other time. (Provided needle

is

good.)

to

5

Page 8

PROPER

Turn

Handwheel clockwise until Needle

hand

edge

of

Needle Guide

SETTING

"A"

(Fig.

FOR

is

o.n

1),

RIB

the

DOWN stroke.

Rib

"B"

CONNECTION

When

should STOP

Needle reaches right

and

SHOULD NOT

MOVE

OPENING

If Rib does move,

Needle Point bock

screwdriver in place. Move Com

position, holding Needle in Position with handwheel while performing this operation. Tighten

Screw

If still

forward

sure to TIGHTEN

When

to

UNTIL

"B".

not

or

needle

desired position. Secure Screw. (See page 9 for closer detail

NEEDLE

"C".

make

Test

accuracy

correct, readjust by loosening screw

backward

is

in

POINT

the

following

to

right

hand

of

adjustment by repeating operation outlined in first paragraph.

as

needed

BOTH

some position

SCREWS

PASSES

edge

(R-1062) forward

and

"A" & "8"

TO

as

OVER

adjustment:

of

Needle Guide. Then loosen .screw

retighten Screw

SET

in

RIB

Fig. 1, loosen Screw (R-1117)

RIB

TO OTHER

First loosen Screw

or

backward until

"8"

again, change angle

11

•

"B

When adjusted satisfactorily,

before putting machine into operation.

SHAFT

of

SIDE

"A

in

Rib

OF

PRESSERFOOT

11

(Fig.

Rib

is

of

Fig.

3,

Shaft

if needed.)

2).

Bring

"B",

keeping

at

the

STOP

Com slightly

be

and

turn Rib

NEEDLE

Turn Handwheel clockwise, bringing Needle

the

Needle tip should be

To

attain

until Needle reaches desired position.

Loosen Screw

Indicator Notch

smaller

OR

POSITION

this, loosen Eccentric Ball Screw R-1118 (Fig.

R-1

072

in

the

number by

SHORTER, CHECK

OF

FEEDER

5/8"

to

11/16"

REGULATING

(fig.

5)

in

Stitch Regulating Collar

R-1

014.

The

larger

the

notch,

FEEDER

WHEN CHANGING

the

shorter

WITH

from the right side of Presserfoot opening (Fig.

LENGTH

the

LOOPER

STROKE

to

end

of

stroke

Pumber by

the

stitch. WHEN MAKING STITCH

AND

LENGTH

at

the

5)

and

turn

OF

STITCH

and

turn until desired number

the

notch,

PRESSERFOOT

OF

STITCH

right side.

Eccentric Ball (

the

longer

At

this point,

the

stitch.

AS

IT CHANGES

4J.

R-1

086)

is

by

The

LONGER

6

Page 9

FIG.S

t-1091

REGULATING

orR-1092

COLLAR

NOTCH

R-1014

IN

.,

Page 10

ADJUSTING

LOOPER

1. (FIG.

2.

To

Looper Rod (C)

3. (FIG.

Chain-Off

o

from

4.

Should Looper touch needle

wide

turn

counterclockwise.

5.

prong)

6.

prong

turn

at

7.

raise

1)

Loosen screw (A)

put

Looper in,

2)

Pin

sheet

of

paper

the

needle when needle

blade

of

Eccentric Block clockwise. If Looper

(FIG.

3)

If Looper touches

of

Looper

(FIG. 3 & FIG. 1) Should Looper be

of

Looper

Leaper

point (L)

(FIG. 2 & FIG.

or

lower your Loeper

be

at

point

Turn

Handwheel by

(E)

and

at

point

screwdriver

at

at

point

Rod

at

point (C) downwards, which

and

raise

3)

By

sure

you

(D).

clear

(G).

in

point

(L),

(L),

the

Looper

turning Eccentric Block

at

to

toke

out

Looper (B) - (Port

put

Looper in until shoulder

hand,

needle, being just above

The

is

at

the

or

Presser Foot

slot

of

Pres~er

turn

then

at

points (K)

carefully

long prong

limit

Eccentric Block

Foot or needle

Eccentric Block clockwise.

touching

you

must

point

and

of

stroke.

is

(K).

of

at

point

too

at

loosen

will

(J)

(L).

far

of

and

slowly. Looper

the

needle

the

Looper should

(G),

loosen screws (H)

at

(J)

. If Looper

obove needle,

at

point (

point (

K)

nut

(M)

clear

the

clockwise

#R-2200).

Looper touches shoulder

must

clear

about

the

thickness

be

about

is

hitting needle,

turn

Eccentric Block

K>

and

upper

and

needle touching

and

screws

short

prong

of

or

counterclockwise, it will

3/32"

and

part

Uong

short

(N).

Then

your Looper

of

the

of

use

With

ECCENTRIC

TURNING

8.

(FIG. 3 & FIG.

Eccentric Block

give you

9.

(FIG. 1 & FIG.

against

re-tightening screws (H) .

10. (FIG.

and

put

into

undercut

tightening

Needle Guide Screw

11. (FIG.

o

hair

(FIG.

BE

DOUBLY

LOOPER

the

desired clearance.

Looper Rod Carrier (T)

4)

When

in o new one. NOTE:

firmly, push Needle Guide securely towards screw, hold in position

5)

Feeder should

less

at

4).

BE

SURE

BLOCK,

ROD, you

2)

For Looper

U)

can

2)

If this

Needle Guide (U) (port

neck

of

(V).

point

(X).

SURE

LOOPER

FEEDER

you

RAISE

RAISE

To

be moved from left

is

necessary,

and

When

screw

(V).

be

below Presser Foot o

CLEARS

SCREWS

or

LOWER

one

side

clear

Chain-Off

to

be

sure

does

not have

#R-1238)

replacing Needle Guide, slide

Hold

together

FEEDER

<Z>.

ARE

Looper on BOTH

and

you

LOWER

Pin

(Q)

right by loosening screws

that

Looper Rod.Carrier Pin (S)

any

play

becomes grooved or broken, remove

and

screw on Presser Foot.

maximum

AT

POINT

SECURED

of

FIRMLY.

and

left

3/32"

(Y).

SIDES.

the

.other

Presser Foot

or

"U"

at

side.

(H).

right. Secure by

of

Needle Guide

Just

and

point

at

This will

is

flush

before

tighten

<W)

and

fR),

8

Page 11

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4--

32

FIG.

\ "

1

''10

4

-

1

1

1

1

1

1

1

1

1

ftG. 2

fiG· 1

Page 12

RIB

FOR

VARIOUS

MODELS AS INDICATED

Model

CM3-21L

CM3-11L

CM3-L21

CM3-P11L

I

R-6036

L

Rib

FEED

GROUP

R-1205 Window Plate

R-1

030

R-1

087

R-1

088

R-1

069

R-1159 Screw - Spring Link Lock

R-11

R-1146 Nut - Feed Frame Limit Screw Lock

GROUP

R-1

029

R-11

R-1202 Skip Regulating

R-1

028

R-1203 Stud - Skip Regulating Lever

R-1332 Screw -

Model

CM3-21M I

CM3-llM

CM3-l21M

CM3-P11M

FRAME

I

Screw - Window Plate

Rib Shaft Bushing - Left

Rib

Shaft Bushing - Right

Set Screw - Platten Bracket Pivot Stud

04

Screw - Feed Frame Limit

2

Nut

- Skip Stitch Compensating

05

Screw - Skip Stitch Compensating

Spring

Washer

Skip Regulating Lever Stud-Lock

Rib

CM3-21H l

R-6010

(CM3·21)

- Skip Regulating Lever Stud

CM3-11H

CM3-L21H

CM3-Pl1H

Model

Rib

R-6015

Model

CM3-21K l

CM3-11

CM3-l21K

CM3-P11K

K

R-6032

Rib

GROUP

RIB

R-

R~

R-1164 Stud R-1161

R-1

R-1162

GROUP

R-1166

R-2451

R-2450

R-2400

R-2401

R-1244

R-1167

R-1168

R-1114

R-1171

R-1021

GROUP

R-1212 Cylinder

R-11

3

-See

1163 Crank -

1117 Screw -

Rib

076

Screw -

Rib

R-1

076

Screw -

4

Stud-

Platten Bracket - Left

Platten

Platten - Left

Platten.- Right

Screw Nut

Nut

Screw - Platten Bracket Limit

Spring - Platten Bracket

Spacer - Platten Bracket

5

01

Screw- Cylinder

Chart

Shaft Collar - Left

Shaft Collar - Right

- Platten to Bracket Attaching Screw

- Platten Bracket Limit Screw-Lock

Top

of

Page

Rib

Shaft

Rib

Shaft Crank - Clamp

Rib

Shaft Crank

Rib

Shaft

Collar-Clamp

Rib

Shaft Collar-Clamp

Platten Bracket Pivot

Bracket-

Platten

Right

to

Bracket - Attaching

For

Seiko

Models

Use

same

CM3-21,

IMPORTANT

Semi-Self-Oiler

CM3-

part

but

L21

numbers

add

Series

prefix

as

''L'·

10

Page 13

R-1212

I

GRouP

sl

Rl

8 -

TOP

OF

SEE

PAGE

.J

,.

\ : I

\ :

.,

CHART

! i R-1117

10 ; i R

j

,.,

L,

_,

•,

\

GROUP

31

I

1163

-

~

R-11 1

6

R-1166

0)

P.-110 1 I

R-2400 R-2401

R-1167®·~~

----

----

R-1171"-

._

~

R-2451 R-1·114

~a-~~~

R-1244~~

• ------

·~R-1168

• R-1171 -

I

GROUP

41

4

2

~OR-1167

~

-~

• R-1168

~

I

I

I

i

I

-®---1

R-1021

~

R-1114

FEED

CM3-21

IMPORTANT

Ordinarily, machines have this narrow

cylinder, but thicker

as

illustrated above

without any

additional charge.

R-1101

~',~.

R-2455

cylinder No.

is

installed on order

~~F="'::'-=-=~=-=-

R-2456

R-1211

""-.....;a,...--

FRAME

SERIES

----

FEED

GROUP

NARROW

R-1166

R-2455

R-2456

R-241 0

R-2409

R-1244

R-1167

R-1172

R-1021

R-1056

R-1055

R-1132

R-1262

R-1212

R-11

R-1069

CYLINDER

CM3-21

Stud-

Platten - Left

Platten - Right

Screw

Nut

Spring - Platten Bracket

SpacerSpring Post

Stop Post

Screw Nut

Cylinder

01

Screws - Cylinder

Set

Platten Bracket Pivot

Platten Bracket - Left

Platten

Bracket-

Platten

- Platten

Platten Bracket

Platten Bracket-Limit

- Platten Bracket Limit-Screw Lock

Screw-

MACHINES

SERIES

Right

to

Bracket

to

Bracket Screw

Platten Bracket Pivot Stud

11

Page 14

MAIN

R-1010~

R-1011.

FRAME

GROUP

For

Seiko

Models

Use

·same

CM3-21,

IMPORTANT

Semi-Self-Oiler

CM3-

part

but

L21

numbers

add

prefix

Series

as

"L "

I

GROUP

31

R-5001

R-108~

R-10098

R-1083

R-1084

~

_

R-5002

__,

S E

I

GROUP

IIICIDI

21

R-1096

T

I

\

.

R-1081

R-I0

68R

l

---~

R-ll20R

~

R-12

R-124~

R-10

66

R.-l02::i

I

89

I

GRO

UP 1 I

12

Page 15

·~----MAIN

GROUP

R-1

R-1

R-1

RM-1

RM- 1

R-1

R-1120R Set

R-1

R-1096

R-1240

R-1094

R-1289

GROUP

R-5002

R-1084

R-1082

R-1083

R-1009

R-1085

R-1

R-1010

R-1080

R-1070

066

093

025

088

087

068R

081

2

011

1

ShaftSet

Pin - Regulating Fork-Pivot

Main

Main

Belt Guard

Cover

Screw - Cover Plate

Eccentric Pin

Screw - Eccentric Pin Set

Screw-

Tension Assembly,

Thread

Tension Post

Tension Discs

Cover

Spring

Ratchet

Nut

Front

Screw-

·FRAME

Feed Frame Rocker

Screw - Feed Frame

Shaft

Shaft

Screw-

Plate

Eccentric Block

Guide

Thread

Front

GROUP

Bushing - Right

Bushing -

Belt Guard

Complete

Guide

Thread

Guide

Shaft

left

MAIN

GROUP

R-1044

R-1129

R-1069

GROUP

RT-5003 Group 2, Fitted &

R-1

R-1071

R-1062

R-1120

GROUP

R-1043

R-1121

R-1069

GROUP

RT-5004

R-1014

R-1331

R-1331A

R-1013

R-1086

R-1072

1

Main

GearScrew - Skip Stitch Drive Gear

2

015

Rib

Connection Lever

Screw - Rib

Rib

Connection .Eccentric

Screw-

3

Handwheel

Screw - Handwheel Set

Screw - Handwheel

4

Group

Needle

Set

Screw - (Cone Point) Feed Eccentric

ScrewNeedle

Eccentric

Screw - Needle Connection

SHAFT

Shaft

Skip Stitch Drive

Connecting Lever

Rib Lever Eccentric

4,

Fitted

and

Feed Eccentric

(Flat) Eccentric

Shaft

and

Ball Stud

GROUP

lapped

Set

and

Lapped

Feed Connection

(CM3-21)

(Cone Point)

Set-lock

Set

Clamp

GROUP

I

GROUP

RT-5004

3

R-5001

R-5019

Side

Screw - Side Cover

~tl

FITTED-LAPPED

R-1072

I B

i

_!..-

Cover

COHPLETE

I

GRouP

--~1

.

R-1134

R-1014

sl

R-1132

-~J

MAIN

I

SHAFT

GROUP

1 I

GROUP

R-1134

R-1132

5

GROUP

Eccentric

Screw-

Eccentric Ball Guard

Ball Guard

RT-5003

FOR

CM3-21

SERIES

I

GROUP

31

13

Page 16

~ALL

EXCEPT

R-1200

MODELS CM3-21

"K"

R-1051

I

GROUP

1 I

THESE

PARTS

SWING

BRACKET

FOR

ALL

PLATES

COMPLETE

BRACKET

FOR

ALL

USE

PLATE

ASSEMBLY

CM3·21

No.

1·5180

AND

MODELS

FRONT

GROUP

R-5180 Complete Plate

R-5180-6 Complete Plate

R-1200 SwingPiate

R-1200-6 Swing Plate (618-6 Series)

R-5015 Support Shaft

R-1051

R-1228

R-1052

R-1053

R-1227

R-1230

R-1229

R-1103

R-1230

R-1229

R-11

R-1225

R-1048

R-1226

R-1049

R-1

051

PLATE

1

Screw- Pivot Pin-Lock

Bracket - Swing Plate-Support

Screw - Stop

Washer

Stop

Washers (Flat) -Swing Plate Support Bracket Screw

Washers (Lock) -Swing

Screw - Swing

Washer

Washer

03

Screw- Swing

Pin - Swing

Retaining Ring - Swing

Collar - Swing Plate Pivot Pin

Set Screw- Swing

Screw - Swing Plate Pivot Pin-Lock

GROUP

(618and808)

Plate

- Stop Plate Screw

Plate

(Flat) -Swing Plate Support Bracket Screw

(Lock) -Swing Plate Support Bracket Screw

Plate Pivot

AND

and

Bracket Assembly (618

and

Bracket Assembly (618-6 Series)

Assembly

Plate Support Bracket

Plate Support Bracket

Plate Pivot Pin Collar

SUPPORT

Plate Support Bracket Screw

Plate Pivot Pin

14

BRACKETS

and

808)

~

R-1051

R-1103

Page 17

SPECIAL

THAT

GUIDE

IS

HARD

R-2600NT

FOR

618NT -618NT -808NT

COMPLETE

CLOTH

ASSEMBLY

AND

TO

GUIDE

GAUGE

KEEP

UNCURLED,

I

GROUP

WHERE

31

NECESSARY

SUCH

AS

NYLON

FOR

MATERIAL

TRICOT.

PRESSERFOOT

®R-1054

GROUP

Model

L

M

H

K

Presser

completefassy.

44A

44C

44C

44C

foot

Rib

6036

6010

6015 2506

6032

Shoe

498

49C

49C

Cloth

2600

2600

2600

2600

guide

Cylinder

1212

1212

NON

1212

15

Page 18

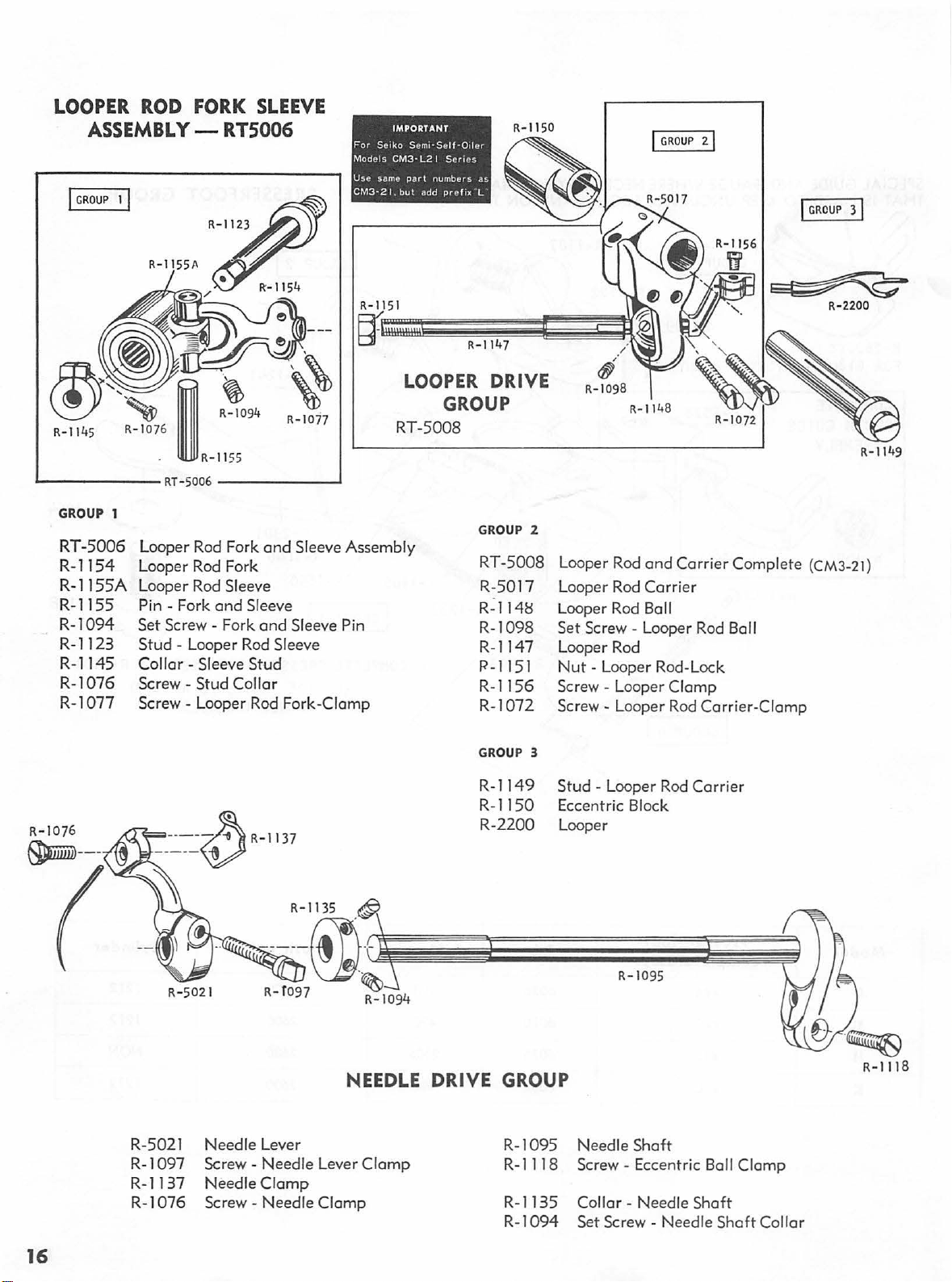

LOOPER ROD FORK

ASSEMBLY-

I

GROUP

RT5006

SLEEVE

For

Sc1ko

Models

Use

same

CM3-21.

IMPORTANT

Sem•·Self·Oder

CM3-

L21

part

numbers

but

add

Seroes

pre

lox L

as

I

GROUP

21

I

GROUP

31

'-------

GROUP 1

RT-5006

R-1154

R-11

R-1155

R-1

R-1123

R-1145

R-1076

R-1 077

55A

094

RT-5006

Looper Rod Fork

Loo

per

Lo

ope

- F

Pin

Set Screw - Fork

Stud -Lo

Collar

-----....J

and Sleeve

Rod Fork

r Rod Sleeve

ork and Sleeve

and

ope

r Rod Sleeve

- Sleeve

Stud

Screw - Stud Collar

Screw -Loo

per

Rod F

R-10

77

Assembly

Sleeve Pin

ork

-Clamp

LOOPER

GROUP

RT-5008

R

-114

7

DRIVE

GROUP 2

RT

-5008

R-50

R-114H

R-1098

R-114

R-1151

R-1156

R-1072

GROUP 3

17

7

R-1

098

48

R-11

Looper Rod

L

ooper

Looper Rod

Set

Screw-Looper Rod Ball

and

Carrier Complete

Rod Carri er

Ba

ll

Looper Rod

Nut-

Looper Rod-Lock

Loop

er Clamp

er

Rod

Screw - Loop

Screw-

R-1072

Car

rier-Cl

~

(CM3-21)

amp

R-2200

R

-114

9

R-1076

~-

--

R- 5

R-5021

-10

97

R

R-1

137

R-1

076

-,

021

Needle Leve r

Screw -

Needle

Screw-

Needle

Cla

Needle

R-1149

R-

115

R-2200

R-1135

---ft1\~ES

~

-

;;;;;e::::==:~~

~;"''J

R-f097 R-1094

Stud-Looper

0

E

ccentric Block

Loop

er

R-

Rod

1095

NEEDLE DRIVE GROUP

mp

Lever

Clamp

Clamp

R-1095

R-1118

R-

1135

R-1

Need

Screw-

Collar - Needle

094

Set

le

Shaft

Eccentric Ball

Screw - Needle

Carrier

Shaft

Shaft

Clamp

Collar

16

Page 19

R-5039

I

r---

I

!'

0 -

I

GRouP

GROUP

R-1181

~

5

GROUP 1

R-1183

R-1185

RR-1

R-1094

R-1180

R-1179

R-1

GROUP 2

R-5013

R-1201

R-1069

GROUP

REGULATING GROUP

41

R-50

11

R-1022

~I

I I R-1

'-·

1025

026

069

R-1193

'

~

024

--

--R

Support Arm - Com Roller

Regulating Fork

Pin - Regulating F

Pin - Roller Support

Screw - Roller Support Arm Pivot Pin-Set

Com Roller

Pin - Com Roller Support

Screw-

Skip

Ecc

Pin - Skip

Screw-

R-1

o23

-

5012__j

ork

-Piv

Arm-Pivot

Com

Roller Support

entric

Gear

Assembly ICM3-2 1 Series)

Eccentric

Skip Eccentric Gear

Gear

~~-

R>-----!··0

R-

'1

195 I

- CM3-21 Series

ot

Pin-Set

a0:

~--

R-I09

GROUP

GROUP

21

··

4

R- 1201

1

R-1069

GROUP 3

R-5018

R-

1223

R-1222

R-5010

R-

110

9

R-5039

R-1

039

GROUP 4

R-5011

R- 1

193

R- 1

022

R-1 18 1

GROUP 5

R-5012

R-1195

R:1023

R-1024

Reg

ulating

Dial Assembly

Regulating Dial

Regulating Dial Screw

P

late

Face

Screw

- Regulating Dial Assembly

Di

al

and

Screw - Dial

Push Rod Assembly

Push Rod I

Cotter Pin

Spring - Push Rod (

Push Rod Assembly

Push Rod I

Cotter

Pin

Spring - Push

Shoe

and

Guide Pin Asse mbly

Ratchet Assembly

and

Ratchet Assembly-Lock

V4

"I

3fa

" )

Rod ( 3;8")

V4

")

R-5016(CMJ-71)

FITTED t

-1

R

LAPPE~

072

RT

-5 111

FEED

::~;

-2100

·2101

1\ \

~-~~:it:::

·-···-·

:,

~

I········

~~

;

&_R-1076

£~~

R-

111

9

~----~-=,.,

!

R-1145

'

'·

R-1138

R-

1138

R-

109

1

R-1092

R-1072

R-5016

R-

I 14 5 Collar - Rocker Pin

R-

1076

R-21

00

R-2 101

R-

1119

-59138

RT

DRIVE GROUP

F

eed

Lever

Stitch Regulating Collar

Stitch Regulating Collar F

Screw-Stitch Regulati ng Collar-Clamp

ocker

Pin Assembly

R

Screw - Rocker Pin Collar Feed

Dog

Feed

Dog Fine, 20Te

Sc;ew - F

( 1

091

eed

Dog

& I 1381

eth

Fitted

or

all

"'K•

Clamp

to Inch.

and

Lapped (CM3-21)

17

Page 20

GROUP

R-1060R

R-5060

R-1120

R-1008

R-1035 Screw- Lift Arm Adjustment

R-1

R-1059

R-1036

R-1334

R-1060C

R-10600

GROUP

061

1

Knee Lifter

Lift Arm

Screw

Nut

SpringCollar

Set Screw

Feed Frome

Knee Lifter

Knee Lifter

l

Rod

Shaft

- Lift Arm Clamp

-·Lift Arm Adjusting Screw-Lock

Knee Lifter Rod-Return

- Knee Lifter

- Knee Lifter

"S"

Rod

Rod

Rod

Rod

Hook

Sleeve

Sleeve Screws

Collar

.,

,,

II

II

,,

,,

,,

,,

R-5060

R-10608

R-1208

R-1037

GROUP

R-5020

R-1191

R-1177

R-1184

R-1169

Knee Lifter

Knee Pad

Knee Pod Screw

3

Spring

Main Spring

Screw - Main

Nut-

Main Spring Adjusting

Nut-

Spring Link Assembly-Retaining

Rod

Link Assembly

Spring Link

GROUP

KNEE

GROUP

GROUP

R-1060R

1

LIFTER

2

R-10608

GROUP

3

SPRING

GROUP

18

LINK·

@@)

t

~

R-1169

FEED

FRAME

R-1037

'

Page 21

SEIKO

SEMI-

SELF-OILER

MODELS

CM3-L21

SERIES

IMPORTANT

For

SEIKO

Models

Use

with

add

r·--------

CM3-L21

same

CM3-21

p r e f i x

Semi-Self

part

models

"L

''

---,

I

I

I

I

I

I

Series.

numbers

but

Oiler

as

I

I

I

I

I

I

L-------

-------------

.J

~l-~2

~L-~3

1

ll-~4

19

Page 22

IMPORT

ANT-

Use

same

For

part

SEIKO

numbers

Semi-Self-Oiler

as

with

CM3-21

models,

Models-

but

add

prefix "L".

CM3-L21

·sERIES

L-800

L-801

L-802

L-803

L-804

L-805

L-806

L-807

L-808

L-809

L-810

L-81

L-810B Screw -

L-811

L-812

L-813 Wick

Felt

PadBaseNippleHolder -

Screws Spring

Oil

Bottle

Cover - Main Frame

Gasket - Cover

Screws -

Oil

Vibrator

OA

Spring - Oil Vibrator

Screws - Splasher

Wire Loop

E

xamp

PARTS

ON

Base

Machine

Base

Oil

Bottle

Holder

Clamp - Bottle Holder

Cover

Oi

I Vibrator

Holder - Wick L-813

-Bushing

Needleshaft

1

e:

Needleshaft(CM3-L21

LISTED

SEIKO

(CM3-21

models}

models)

BELOW

ARE

USED

SEMI-SELF-OILERS

Part

No.

Part No.

R-1

LR-1

095

095

EXCLUSIVELY

(CM3·L21 MODELS).

Loop

L-814

L-815

L-816

L-817

L-818

L-819

L-820

L-821

L-822

L-824

L-825

L-826

L-827

L-828

L-829

Wire

Wick Wire

Wick - Skip Eccentric Gear

Wire

Wick - Skip Stitch Gear Drive

Wire

Screws- Wire

Nipple-

WickWire

Wick - Looper

Glass -

Wire

Wick-

Holder- Wick L-815

Rib

Connection Lever

Loop

Holder- Wick L-817

Loop

Holder- Wick L-819

Holder- Wicks

Loop

Wick L-824

Main Shaft

Loop

Holder - Wick L-826

Oi

I Gauge

Loop

Holder - Wick

Drain From Side Cover To Base

Rod

Holders

Carrier

829

20

.·,

~-.

. '

:.

Page 23

Printed

in

Japan

--:--

Loading...

Loading...