Operating

Instructions

For

CH

Series

CH-2B

CH-2B/DF

CH-6B

CH-7B

CH-8B

CH-2-RF

<f

h

SEIKO

SEWING

MACHINE

CO.,

LTD.

TOKYO•JAPAN

Specifications

of

CH

Types

Sewing

speed;

Needle

type:

Number

of

needle:

Sewing

type:

Hook:

Bobbin:

Thread:

Feed

system:

Stitch

length:

Presser

foot:

Presser

lift:

Thread

take-up:

Thread

take-up

stroke:

Needle

bar

stroke:

Bed

shape:

Bed

size:

Working

space:

Net

weight

(head

only)

JIS

classifications:

Motor:

Motor

pulley:

V

Belt:

Applications:

Max. 800

s.p.m.

(Max.

sewing

speed

willbechanged

by

the

models

and

applications.)

DD X 1

#24-25,

standard

#24

(Needle

type

may

differ

from

the

above

types

according

to

the

threadstobe

used

and

the

materials

being

sewn.)

Single

needle

Lockstitch

Oscillating

large

hook

CH

Type

(240 x 30.3

width)

Cottonorsynthetic

fiber

(SB) Needle,

upper&lower

feed,

reverse

feed

(7B)

Needle,

Lower

feed,

reverse

feed

(6B)

Lower

feed,

reverse

feed

(2B)

Upper&lower

feed,

reverse

feed

(2B/DF)

Upper&lower

feed,

reverse

feed

(Capableofintermediate

shirring)

Max.

10mm

(SB) Alternating

foot

(walking

foot&presser

foot)

(7B)

Flat

foot

(6B)

Roller

footorflat

foot

(2B) Alternating

foot

(walking

foot&presser

foot)

(2B/DF)

-

ditto

-

20mm

by

knee

lifter

(10mmbylever)

Cam

type

90.5mm

51mm

Cylinder

bed

(tubular

type

820)

820X600mm

200mm

x

400mm

65Kg

LS3

400W.

4P

clutch

motor

6O0(5OHZ)

5O0(6OHZ)

M62

Suitable for

sewingofshoes,

bags, satchels, sport-goods,

luggages,

ultra

heavy

materials.

Contents

1 Lubrication 1

2 Needle 1

3 Thread 1

4 Insertion

and

Removal 2

5 Winding the Bobbin Thread 3

6 Upper Threading 3

7 Tension of Bobbin Thread and Needle Thread 4

Adjusting Needle Thread Tension 4

Adjusting Bobbin Thread Tension 4

8 Pressure of Presser Foot 5

9 Adjustmentof Stitch Length 5

10 Timing of Thread Tension Releasing Mechanism 6

11

Removal of Shuttle Race Body 6

12 Adjusting on

the

Each Points 7

(A)

Adjusting Needle Position Against Needle Hole of 7

the

Feed

Dog

{7B & 8B

Types)

(B)

Adjusting of Feed Dog Height 7

(C)

Adjusting theForward and Backward Position of q

Needle

BarFrame

(D)

Timing of Needle and Hook 8

Positioning of

needle

and

tip of

the

hook 9

Adjusting

the

height of needle bar 9

Adjusting

the

position of

the

tip of hook 9

Clearance between needle

and

tip of hook 9

Each timing for up/down strokes of

presser

10

foot

(2B & SB

Types

only)

13

CH-2B/DF

11

a. Use of

the

Differential Feed Mechanism 10

b. Adjusting Upper Feed Length Against Lower Feed 11

Length

14

CH-2-DF

Adfusting

Upper

Feed

Length

11

Adfudting

Lower

Feed

Length 12

Positioning

Upper

Feed

Dog 13

Adjustment

14

Adjusting

Up/Down

Amount

of

Upper

Feed

14

Positioning

presser

Bar

15

1

Lubrication

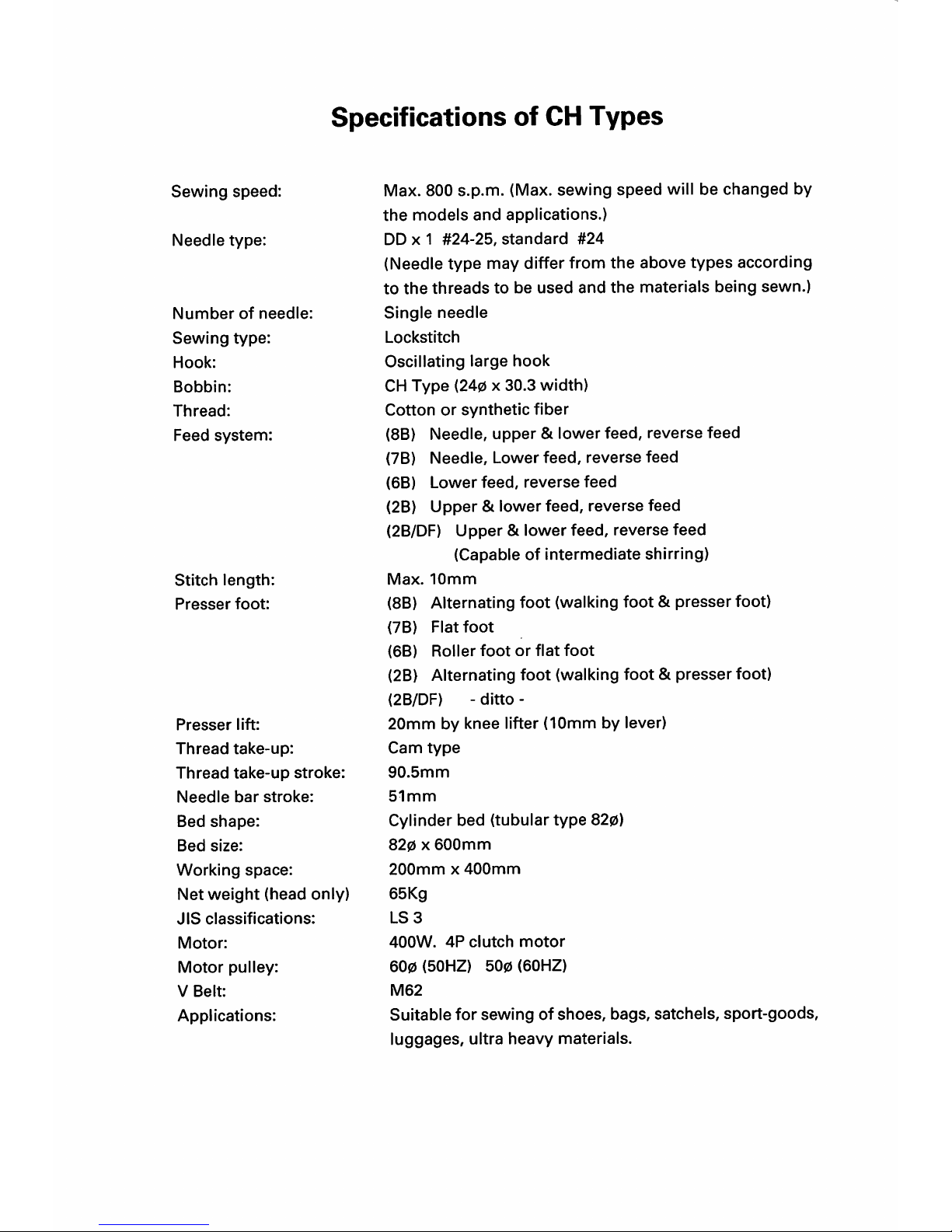

Lubricate all points indicated by arrows in figure.

2

Needle

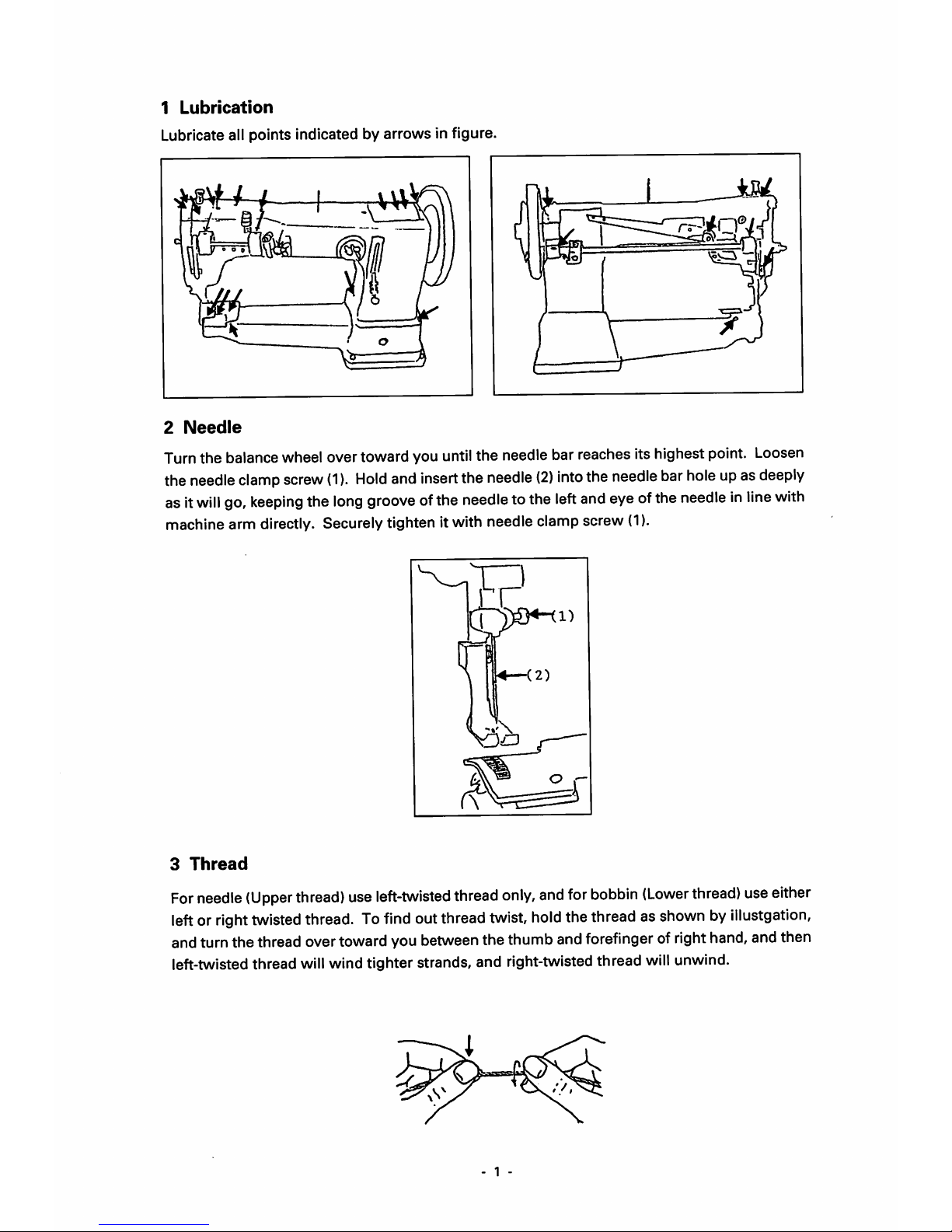

Turnthe balance wheel over toward you untilthe needle bar reaches its highest point. Loosen

the

needle

clamp

screw

(1).

Hold

and

insert

the

needle

(2)

into

the

needle

bar

holeupas

deeply

asit

will

go,

keeping

the

long

groove

ofthe

needle

tothe

left

and

eyeofthe

needleinline

with

machine arm directly. Securelytighten itwith needle clamp screw

(1).

3

Thread

For

needle

(Upper

thread)

use

left-twisted

thread

only,

and

for

bobbin

(Lower

thread)

use

either

leftorright

twisted

thread.Tofind

out

thread

twist,

hold

the

threadasshownbyillustgation,

andturnthe thread overtowardyoubetweenthe thumb andforefinger of

right

hand,andthen

left-twistedthread

will

wind tighter strands, and right-twistedthread

will

unwind.

1 -

4

Insertion

and

Removal

of

Bobbin

§

RemovalofBobbin

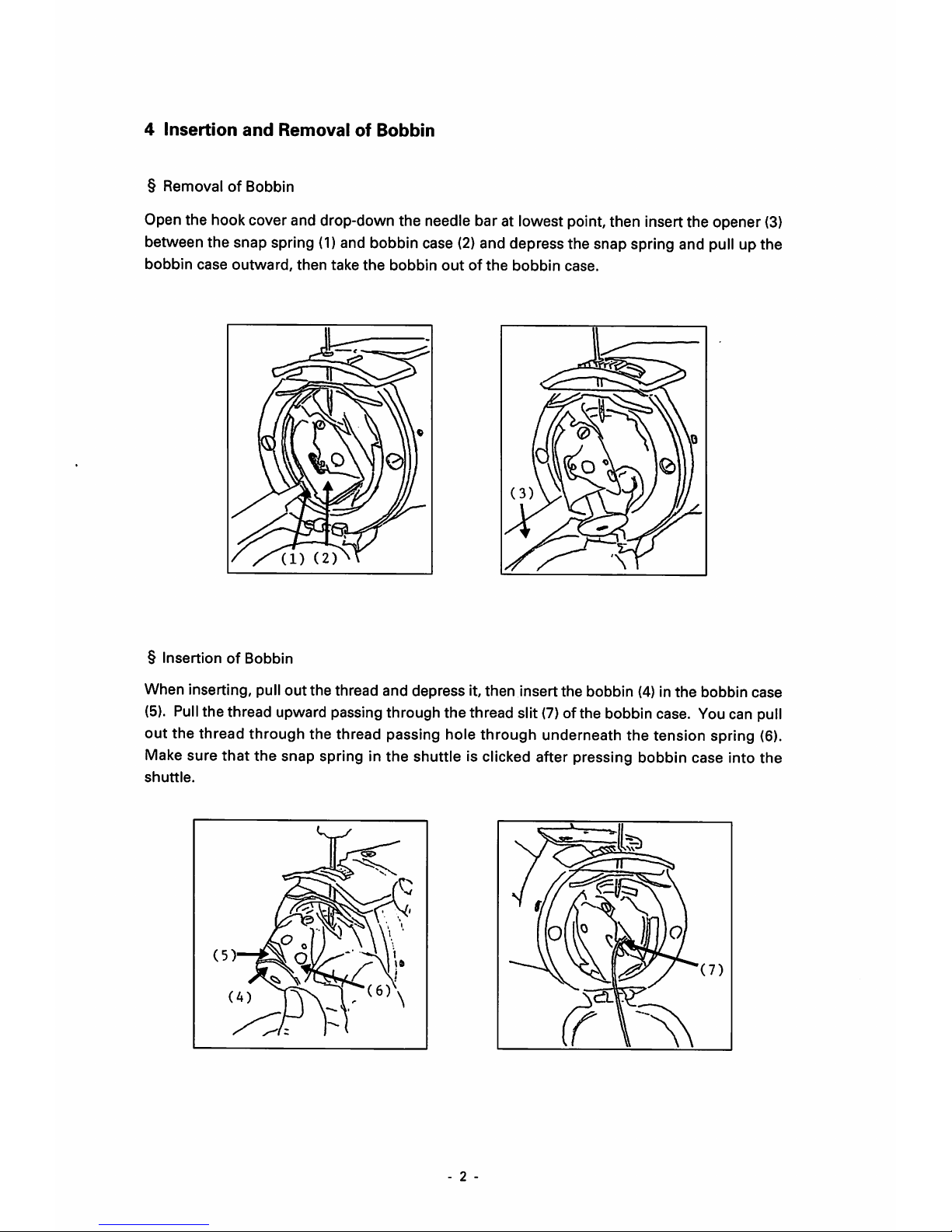

Open the hook cover and drop-down the needle bar at lowest point, then insert the opener (3)

between the snap spring

(1)

and bobbin case

(2)

and depress the snap spring and pull up the

bobbin

case

outward,

then

take

the

bobbin

outofthe

bobbin

case.

§

InsertionofBobbin

When inserting, pull

out

the

thread

and

depress

it,

then

insert

the

bobbin (4) in

the

bobbin

case

(5).

Pull

the thread upward passing through the thread slit

(7)

of the bobbin case. Youcan pull

out the thread through the thread passing hole through underneath the tension spring (6).

Make sure

that

the snap spring in the shuttle is clicked after pressing bobbin case into the

shuttle.

2 -

5

Winding

the

Bobbin

Thread

Bobbin winding should be made by the following order.

(l)Spool pin—

(2)

Thread guide

(arm)—(3)

Needle

thread tension thread guide — passing

through the clearance betweentwo tension discs —(4)

Needle

thread tension thread guide

(5)Bobbin (winding several times) — (6)Move

the

bobbin winding lever.

A

Winding

volume

shouldbeadjusted

bythe

screw

(7)

and

positioning

ofthe

moving

lever

(6).

6

Upper

Threading

Upper threading should be made by the following order.

(I)

Spool

pin

—(2)

Thread

guide

ofthread

tension

—(3)

Clearanceoftwo

tension

discs

—(4)

thread guideofthreadtension

—(5)

Thread

controller-*^disc

wind

a time—

(6)

Thread

guide

(7)

Tensionspring —

(8)

Thread take-up —(9)Thread guide, face plat —(10) Needlecramp

(II)

Needle

\|1^(1)

- 3 -

Loading...

Loading...