Page 1

BUSINESS PRINTER

OWNER'S MANUAL

Page 2

This manual and the program samples described in it are copyrighted by SEIKO Precision

Inc. with all rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means, mechanical,

photocopying, recording or otherwise, without the prior written permission of SEIKO

Precision Inc.

* HP is a registered trademark of HEWLETT-PACKARD Company.

* PCL is a registered trademark of HEWLETT-PACKARD Company.

* DeskJet 500/RuggedWriter 480 are a registered trademark of HEWLETT-PACKARD

Company.

* Epson is a registered trademark of Seiko Epson Corporation.

* LQ-2550 is a registered trademark of Seiko Epson Corporation.

* IBM is a registered trademark of International Business Machines Corporation.

* IBM2931 is a registered trademark of International Business Machines

Corporation.

* Windows is a registered trademark of Microsoft Corporation.

Copyright

© 2000 by SEIKO Precision Inc.

Chiba, Japan

Page 3

OWNER'S MANUAL

2000 SEIKO Precision Inc.

C

24-pin wide-carriage

dot matrix printer

As an ENERGY STAR Partner, SEIKO Precision Inc. has determined that this product meets

the ENERGY STAR guidelines for energy efficiency.

- Outline of the International ENERGY STAR Office Equipment Program -

The International ENERGY STAR Office Equipment Program is an international program

that promotes energy saving through the use of computers and other office equipment. The

program backs the development and dissemination of products with functions that effectively

reduce energy consumption. It is an open system in which business proprietors can participate

voluntarily. The tar geted products are office equipment such as computers, displays, printers, facsimiles,

and copiers. Their standards and logos uniform among participating nations.

Page 4

This manual is for the following two models of the printer.

Although these two models, model A and model B, look different,

the difference is only the appearance of the casing areas at the front. The

functions of these models are very much the same.

Refer to the manual of the model A, for the manual of the model B.

Model A

Model B

Page 5

Contents

Caution for use

Unpacking the printer.............. 1

Quick startup.............................. 2

1. Introduction

Features...................................... 3

Options and expendables................. 4

Power code ................................. 5

Printer description......................... 6

Precaution for extra-thick

paper usage ............................ 7

Physical dimension(Model A)........... 8

Physical dimension(Model B)........... 9

2. Setting up

Installing the paper rack ................ 10

Installing the sound seal cover .. ...... 10

Installing the ribbon cassette ........ 11

Connecting the computer ............... 12

Connecting the power cord ............. 12

Loading the paper.......................... 13

Adjusting the print head position....... 15

3. Control panel and operations

Control panel and indicators ......... 16

Control Levers .......................... 19

Paper parking.............................. 20

Printing test pattern ...................... 21

Demonstration print-out ................ 22

Tearing off a form.......................... 22

Power-on operation summary .. ....... 23

4. Basic setup options

About basic setup options ............. 24

Printing multipart paper ......

.......... 26

Selecting page length

for fanfold paper...................... 26

Selecting single sheet

paper size .............................. 27

Selecting font style ...................... 28

Selecting character spacing ........... 29

Enlarging/compressing print ......... 30

Setting top of form position .....

...... 31

Loading user & factory

setup options ............ 31

5. Extended setup options

About extended setup options ........ 33

Extended setup options summary....

.... 34

Print enhancement

10 Emulation................................... 36

11 Character table (HP mode)............... 36

12 Character table (Epson mode)........... 37

13 Character table (IBM mode)............. 37

14 National font style........................ 38

15 Code page................................... 38

16 IBM Alternate graphic mode............ 39

17 Carriage return (CR)....................... 39

1 8 Line feed (LF)............................... 39

19 Line feed spacing.......................... 40

20 Slashed zero................................ 40

21 Set default tab stops...................... 40

22 Lock-in the page length................. 40

23 Print quality ............................... 41

24 Lock-in the font........................... 41

25 Lock-in the character

spacing .................................... 41

26 Lock-in the print quality................. 41

Barcode print enhancement

27 Enable barcode print

and Enlarged character ................ 42

28 Barcode type............................... 42

29 Bar code size................................ 44

30 Enlarged character size................... 44

31 Graphic Print Speed ...................... 45

32 Accent character........................... 45

33 Setting of the FF code at TOF ......... 45

HP mode enhancement

3 8 PCL mode .................................. 46

39 Secondary character table ............ 46

Paper handling enhancement

40 Set the top margin........................ 47

41 Set the bottom margin .................. 47

42 Set the left margi n........................ 47

43 Set the right margin ..................... 48

44 Fanfold paper width ..................... 48

45 Autoscroll delay........................... 48

46 Override bottom margi n ............... 49

47 Label mode................................. 50

48 Setting of "Paper out" detection....... 50

49 Cut sheet feeder type ..................... 50

50 Setting of the auto-scrolling

position ............................ 50

5 1 Line Feed Speed............................ 51

Communication enhancement

60 Interface type............................... 51

6 1 SELECT IN signal......................... 51

62 Parity bit ................................... 51

63 Data length................................. 52

64 Stop bit..................................... 52

65 Communication protocol ............. 52

66 Communication speed .................. 52

67 Serial error check ........................ 53

68 CTS signal................................. 53

69 CD signal .................................. 53

70 DSR signal................................. 53

71 Communication buffer size ........ 54

72 Busy/ACK timing......................... 54

73 Data latch timing.......................... 54

74 Setting of whether ERROR/PE

signals are output or not ...... 54

Miscellaneous

80 Print direction............................. 55

81 LCD display language.................... 55

82 Invert LCD display ...................... 55

Page 6

82 Invert LCD display ...................... 55

83 Software controlled setup ............. 56

84 Lock the RESET key...................... 56

85 Setting ENERGY STAR ................. 56

8 6 Saving user setup options ............. 5 6

87 Printing list of setup options .... ..... 56

6. Setting the application software

About printer driver ...................... 57

Printer driver selection .................. 57

Connecting the BX-900 printer

in the HP environment ............. 5 8

Saving Your Setup ......................... 5 9

7. Troubleshooting

Error messages ............................ 60

Troubleshooting guide .................. 61

Input hexadecimal dump mode . . . . . 62

8.

Maintenance

Cleaning...................................... 6 3

Lubrication.................................. 64

Printer cover removal ................... 6 4

Vertical alignment mode ............... 66

9.

Bar code and enlarged character

Bar code function

Outline of bar code function................. 69

Bar code command list........................ 7 0

(1) Bar code type........................ 70

(2) Element width....................... 71

(3) Bar code height..................... 71

(4) Setting HRI on and off............. 71

(5) HRI font.............................. 7 2

(6) Check character..................... 72

(7)

Starting the bar code data sequence

... 72

(8)

Ending the bar code data sequence

.... 73

(9) Bar code data sequence............. 73

(10) Printing density................... 7 3

(11) Guard bar expansion.............. 7 3

(12) Start and stop characters......... 74

(13) Bar code rotational angle........ 74

(14) Disabling HRI of the start

and stop characters.......... 74

(15) Value input mode.................. 74

(16)

Initializing the bar code mode

.... 75

Data processing in the bar

code data sequence........... 75

Printing bar codes.................... 7 6

HRI...................................... 76

Error processing...................... 7 7

Code 128 subset transition rule

...... 77

UPC-E conversion rule.............. 78

Calculating the check character

...... 78

Other.................................... 80

Element printing..................... 8 0

Element printing example ......... 81

Enlarged

character function

Outline of enlarged

characterfunction............ 8 2

Enlarged character

command list................. 8 2

(1) Executing backspacing............ 83

(2) Executing line feeding............. 83

(3) Executing form feeding............ 84

(4) Executing carriage return.......... 84

(5) Initializing the enlarged

character mode............... 8 4

(6) Arrangemen t of enlarged

characters..................... 8 5

(7) Cell expansion for

enlarged characters.................. 8 5

(8) All-character set for

enlarged characters................... 8 6

(9) Selecting an enlarged

character font......................... 8 6

(10) Height expansion for

enlarged characters.................. 8 7

(11)

HMI for enlarged characters

.......... 87

(12)

VMI for enlarged characters

........... 88

(13)

Setting and canceling the

enlarged character mode

...... 88

(14)

Enlarged character cell offset

..... 89

(15) Enlarged character pitch......... 89

(16) Enlarged character quality....... 9 0

(17)

Enlarged character rotational angle..90

(18)

Setting and canceling enlarged

character smoothing

.. 91

(19)

Enlarged character top offset

...... 91

(20)

Setting and canceling underline

for enlarged characters

... 92

(21) Enlarged character

width expansition ........... 92

(22) Horizontal printing position

for enlarged characters... 9 2

(23)

Vertical printing position for

enlarged characters

.. 93

Enlarged character print samples

..... 94

Page 7

Appendices

A.

Specifications

Printing specifications ............. 95

Parallel interface

specifications ................ 100

Serial interface

specifications ................ 101

Other specifications ......

.......... 102

B. Control code summary

IBM mode ............................. . 103

EPSON mode ........................... 109

PCL mode ........................... ... 115

Setup options control codes ........ 122

C. Character sets........... ...............127

D. Reverse control panel sheet ....... 136

Page 8

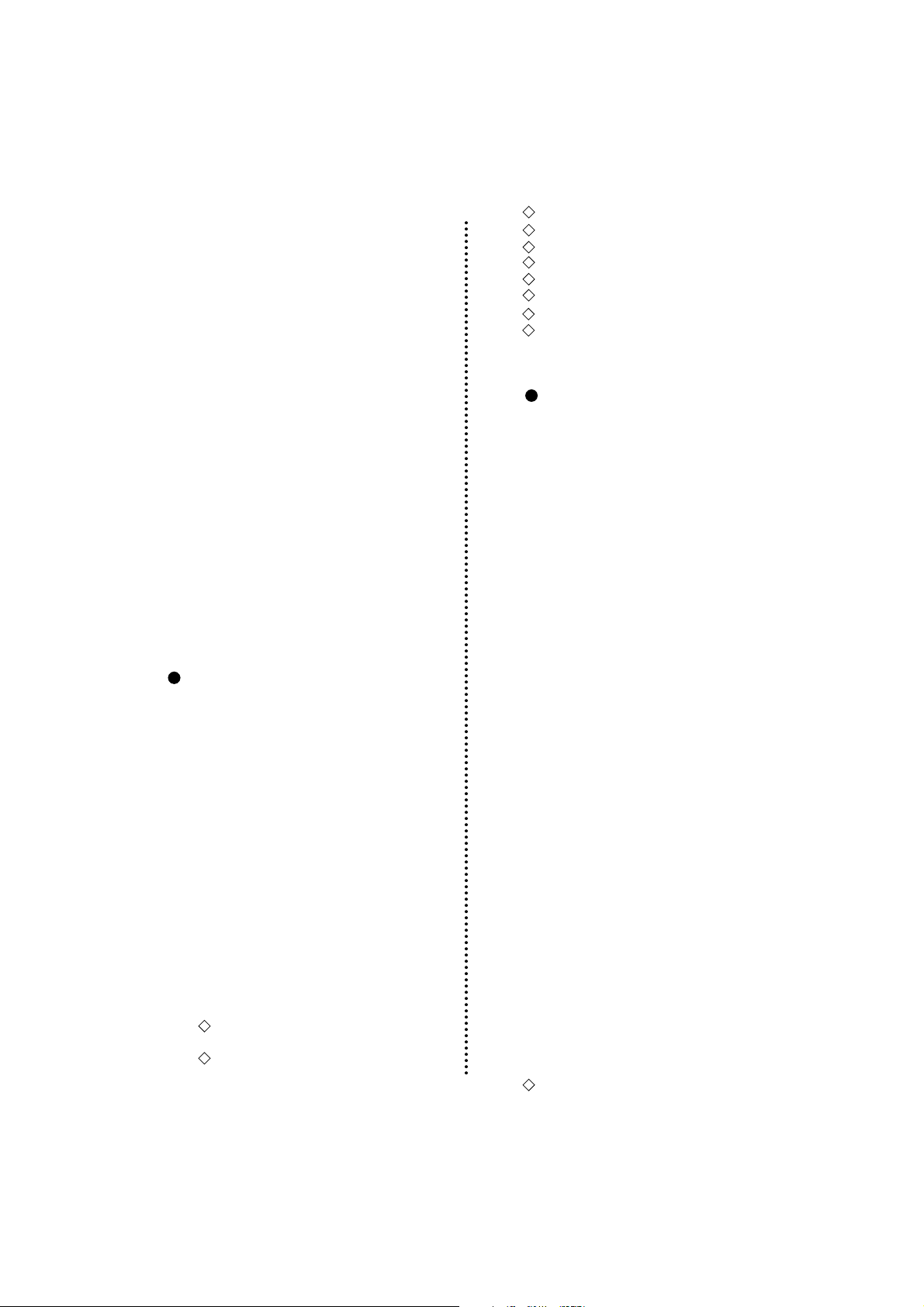

❏Power sourc e

• Be sure to insert the power plug only in a

wall unit of the voltage designated in the

voltage selector and on the rating plate on

the back of the unit.

• Do not place the power cord near heat

sources or place heavy objects on it. Do not

bend or twist the power cord.

❏Foreign matter and water

• Keep your hands and personal items, such as

scarfs and ties, away from the carriage

mechanism while the printer is operating.

The carriage moves with considerable force.

• Keep the printer dry. If you accidentally

spill water on the machine, turn the power

off immediately and wipe it dry. Do not turn

the power on until the machine is

completely dry.

❏Installation environment

• The printer should be used where humidity is

low, where there is little dust, and where the

printer is not in direct sunlight.

• Avoid placing or leaning anything on top of

the printer. If you accidentally drop any

object into the machine, turn the power off

immediately, and disconnect the power code

from the wall outlet, then carefully remove

the object.

• Do not twist the ribbon while installing it.

❏Operating condition

• Wait at least two seconds after turning power

off before turning it back again. The

initialization process may not be performed

correctly if this is not done.

• Do not touch the print head immediately

after printing because it is too hot.

• Never operate the printer without paper nor ribbon properly installed.

If you use paper that is not as wide as the platen, be sure that printing does not exceed paper width.

• Never insert or pull out the interface cable while the power to the printer and computer is on.

• Be sure to turn off the printer before turning off a connected host computer.

Caution for use

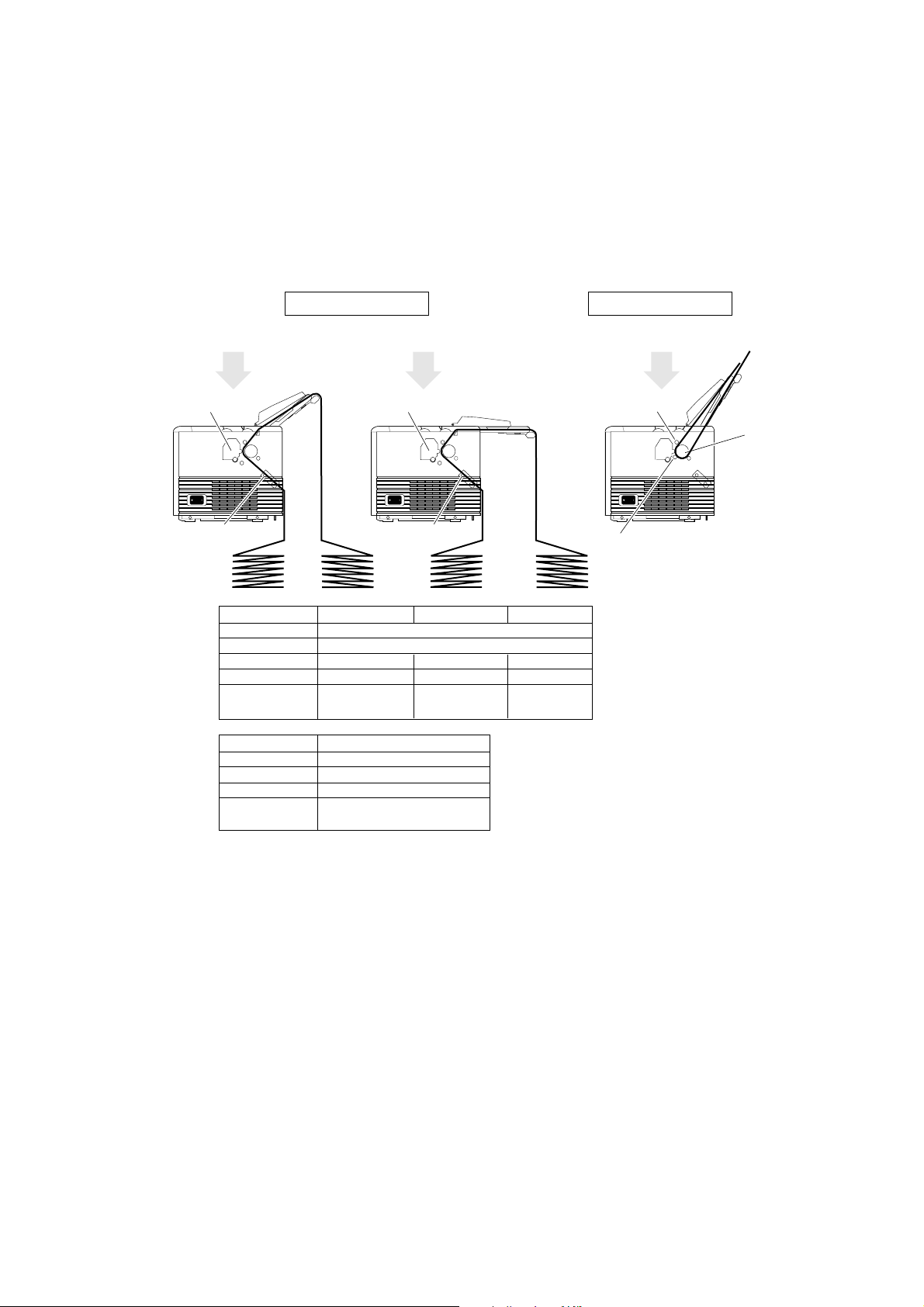

Page 9

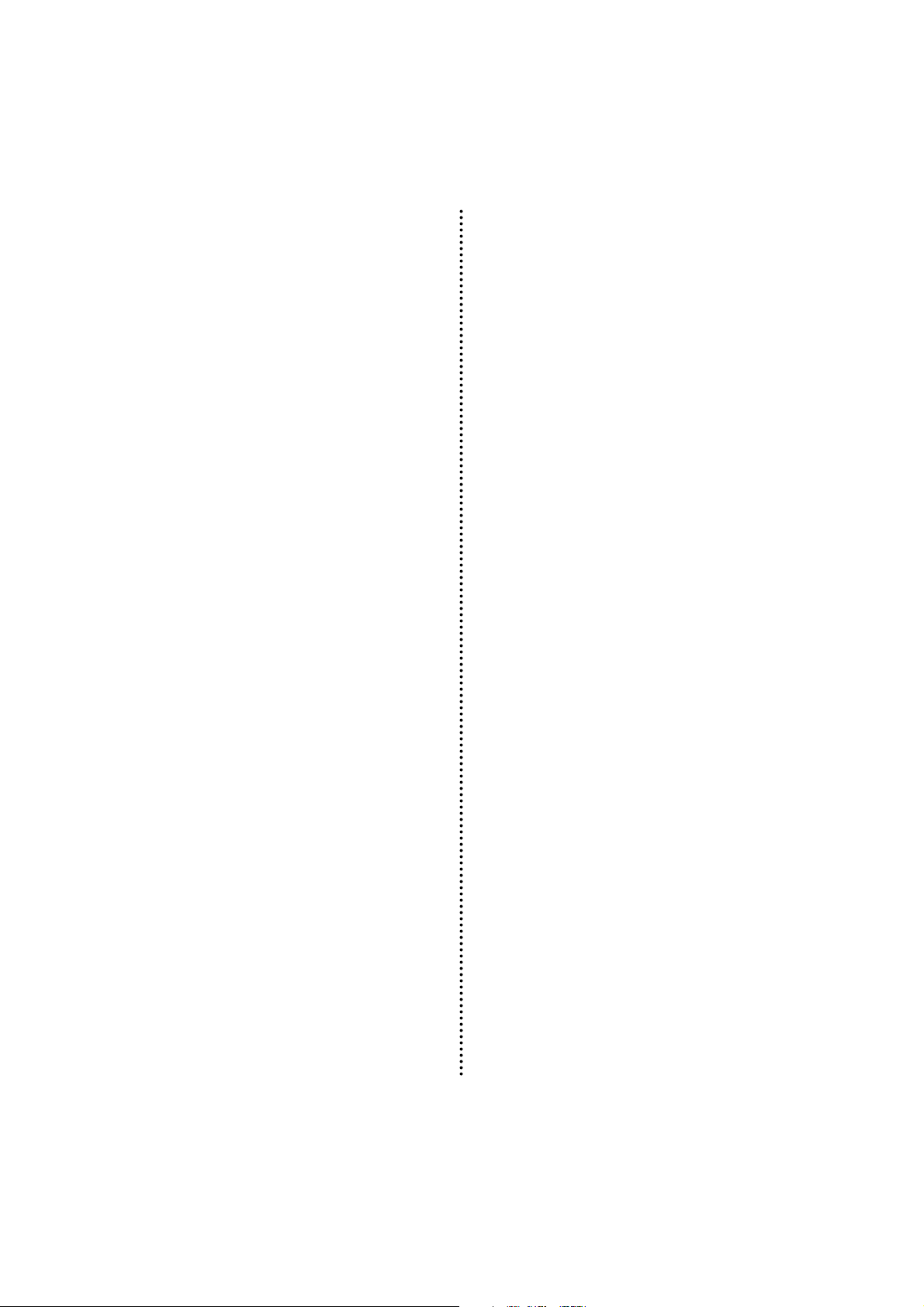

Check the cartons for the following items:

Paper Rack

(See page 10)

Power Cord

(See page 12)

Sound Seal Cover

(See page 10)

Ribbon Cassette

(#SBP-3051)

(See page 11)

Printer

Handbook

Reverse Control Panel

(See page 55, 136)

CD-ROM

(Driver-CD with Owner’s

Manual, printer driver software)

BUSINESS PRINTER

OWNER’S MANUAL

TOF SET

BIN

PARK

ENTER

ALT

SETUP

M.RLF

LF M.LFFF

TEAR

OFF RLFON LINE

P.OUT

ON

LINE

POWER

EXIT

QUALITY

L C D

RESET

Handbook

1

Unpacking the printer

Unpacking the printer

Page 10

To make your first print, follow the procedure below . For more detailed instructions on setting your

printer, please refer to the page indicated.

Self Test

Self Test

?

?

?

?

?

?

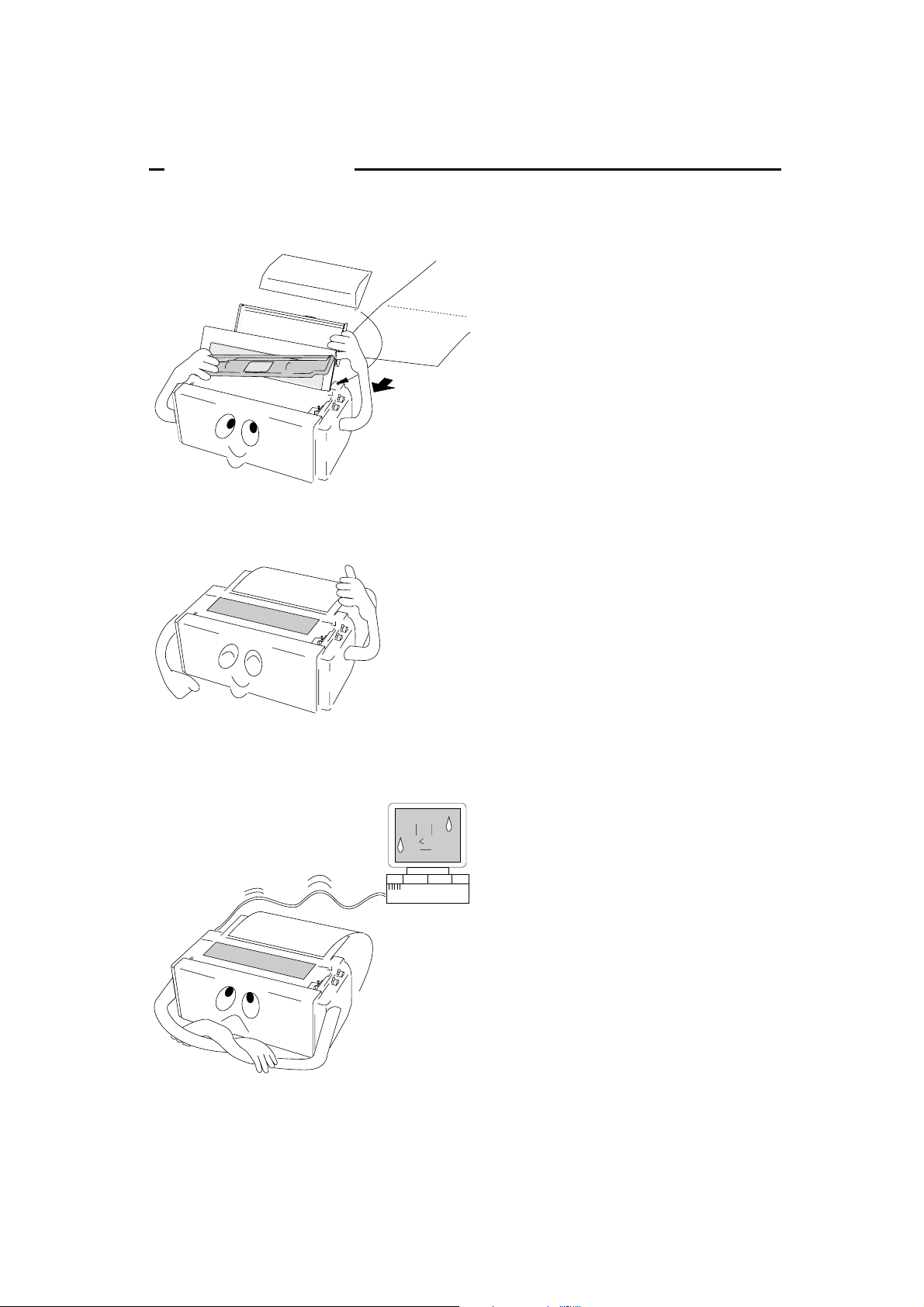

❏ To set up the printer

1. Install the paper rack, the sound seal cover,

and the ribbon cassette — Pages 10 and 11.

2. Load the single cut sheet paper or fanfold

paper. Press the FF key to load the paper —

Pages 13 and 14.

❏ To make a test print

1. Set the paper size of the printer in the setup

options — Pages 26 and 27.

2. Press the LF key and hold while initializing

the printer by the RESET key. Hold the LF

key until the self test starts — Page 21.

❏ To connect your computer

1. With all equipment turned off, connect the

printer to your computer. Interface cable is

purchased separately — Page 12.

2. Use the extended setup options (emulation

type and communication enhancement

section) to match the specification needs

between the printer and your computer —

Pages 33 to 56.

3. Select the printer driver from your

application software — Page 57.

2

Quick startup

Quick startup

Page 11

Features

❏ Barcode Print available

• 13 resident barcode type

Industrial 2/5, Interleave 2/5, Codabar, Matrix 2/5, Code 11, Code 39,

Code 93, Code 128, EAN-8, EAN-13, UPC-A, UPC-E, Postnet

❏ Enlarged character printing

Characters can be enlarged (by up to 127 times as large x 127 times as

large) using the enlarged character command unique to this printer.

Software commands are used for control.

❏ Contain the 3 kind of emulations

Compatible to major printer emulations, Epson, IBM and Hewlett Packard printers.

• EPSON LQ-2550 compatible

• IBM 2391 compatible

• Hewlett Packard Rugged Writer 480 (PCL3) compatible

❏ Wide selection of paper size

• Single cut sheet papers A3, A4, B4, B5, Letter, Legal

• Fanfold continuous paper 5 - 16 inch wide and 2 - 16.5 inch long paper

• Multi-part paper Original plus 5 copies

• Labeling paper Label peel-proof capability

❏ Full option of font types and variation of character spacings

• 10 resident fonts Courier, Prestige, Script, OCR-A, OCR-B, Gothic, Orator, Orator-S,

Roman, and Sans Serif

• 8 character spacings 10, 12, 15, 16.7, 17.1, 20, 24 characters per inch (CPI), and

proportional and 1/2 proportional characters

❏ Enlarge/reduce your layout to fit in any paper size

• you can print the same layout of the document in different paper size.

❏ Easy operation

• Multiple display language for international use.

• Upside down display enables operation from the back of the printer.

❏ Superb compatibility and connectability

• Communication protocols adjustable to any computer.

• Interface connections provided for parallel, RS-232C.

• Parallel and serial interface are switchted automatically when "AUTO" setting is selected.

• Parallel interface complies with IEEE1284 Nibble mode.

3

1. Introduction

1. Introduction

Page 12

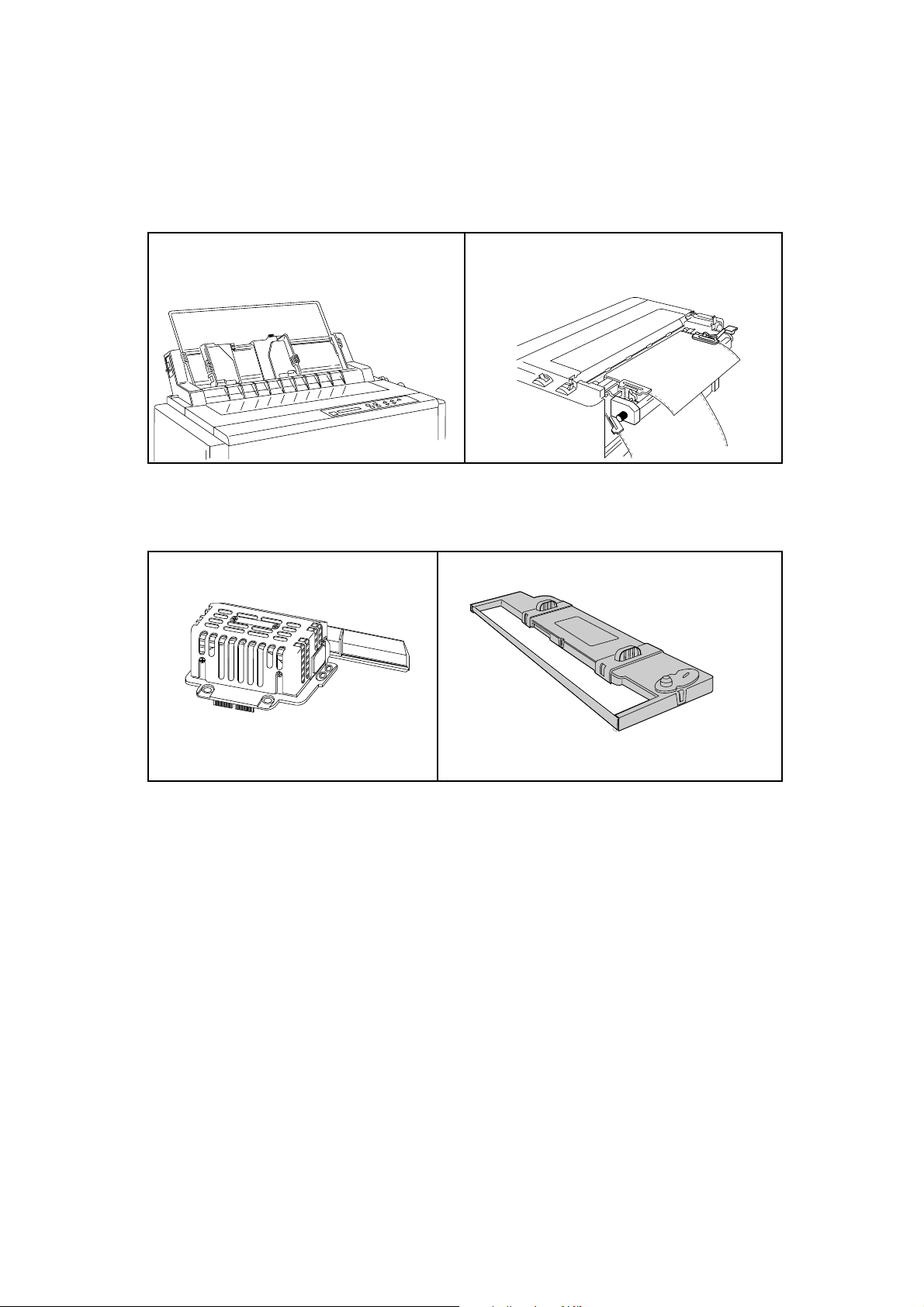

Options and expendables

Cut Sheet Feeder Pull Tractor (#BP-57008)

1 Bin (#BP-78009)

2 Bin (#BP-78009E)

Matrix Print Head Ribbon Cassette (#SBP-3051)

The Cut Sheet Feeder greatly enhances the speed and

efficiency of document printing by feeding of up to 80 single

sheets of paper without reloading.

Paper dimensions

Length: 14.5"~7.0"

Width : 15.0"~5.7"

Weight : 15~21 lbs.

The Pull Tractor is recommended for applications using

extra thick forms.

4

1. Introduction

Page 13

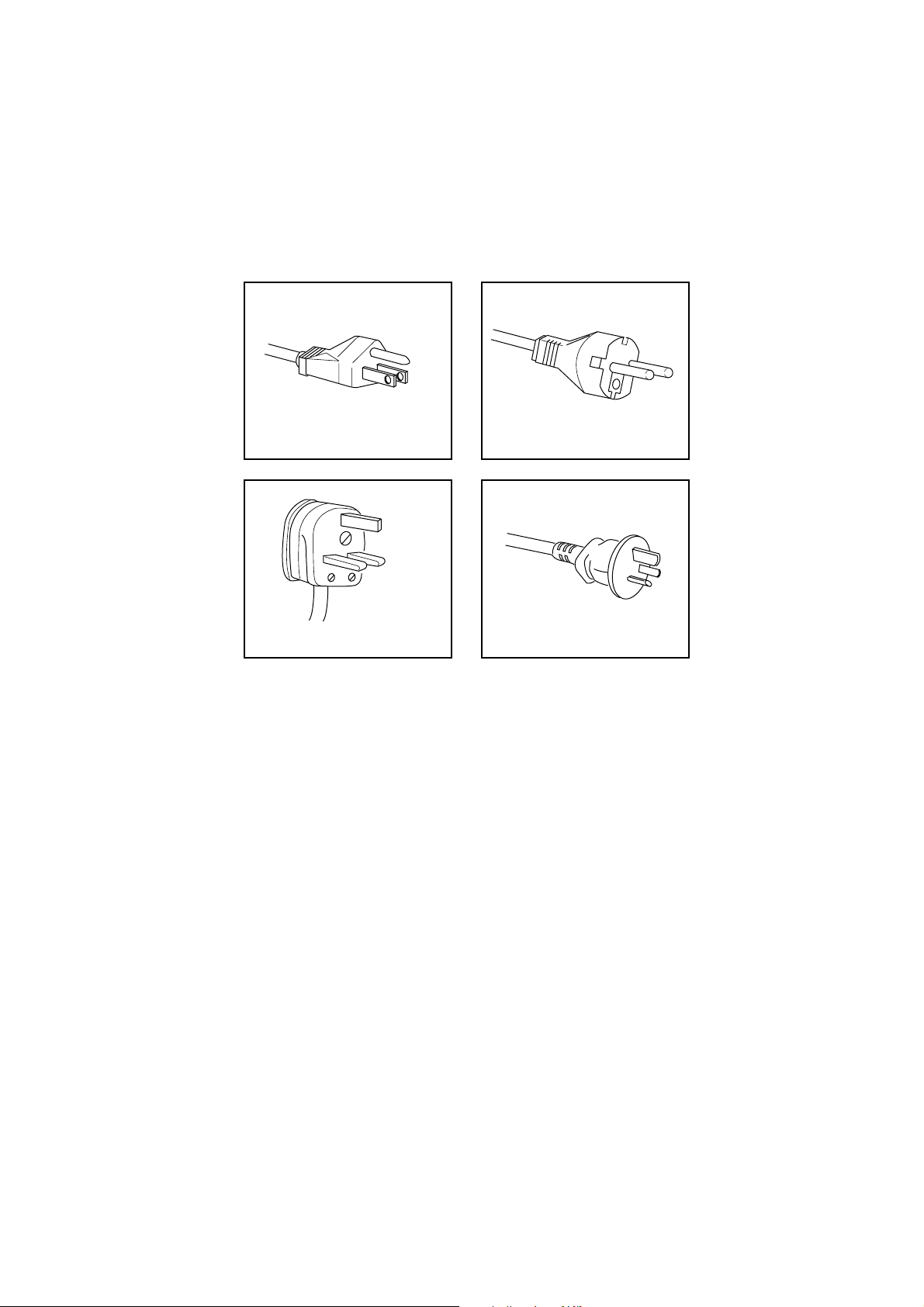

Power cord

One of the following plug types is supplied. See "Connecting the power cord" on page 12.

Please see the rating plate on the back of your printer for appropriate input voltage and consult your

dealer for a specific type of power cord, if necessary.

120V For USA

240V For U.K.

240V For Australia

220-240V For Asia and Europe

5

1. Introduction

Page 14

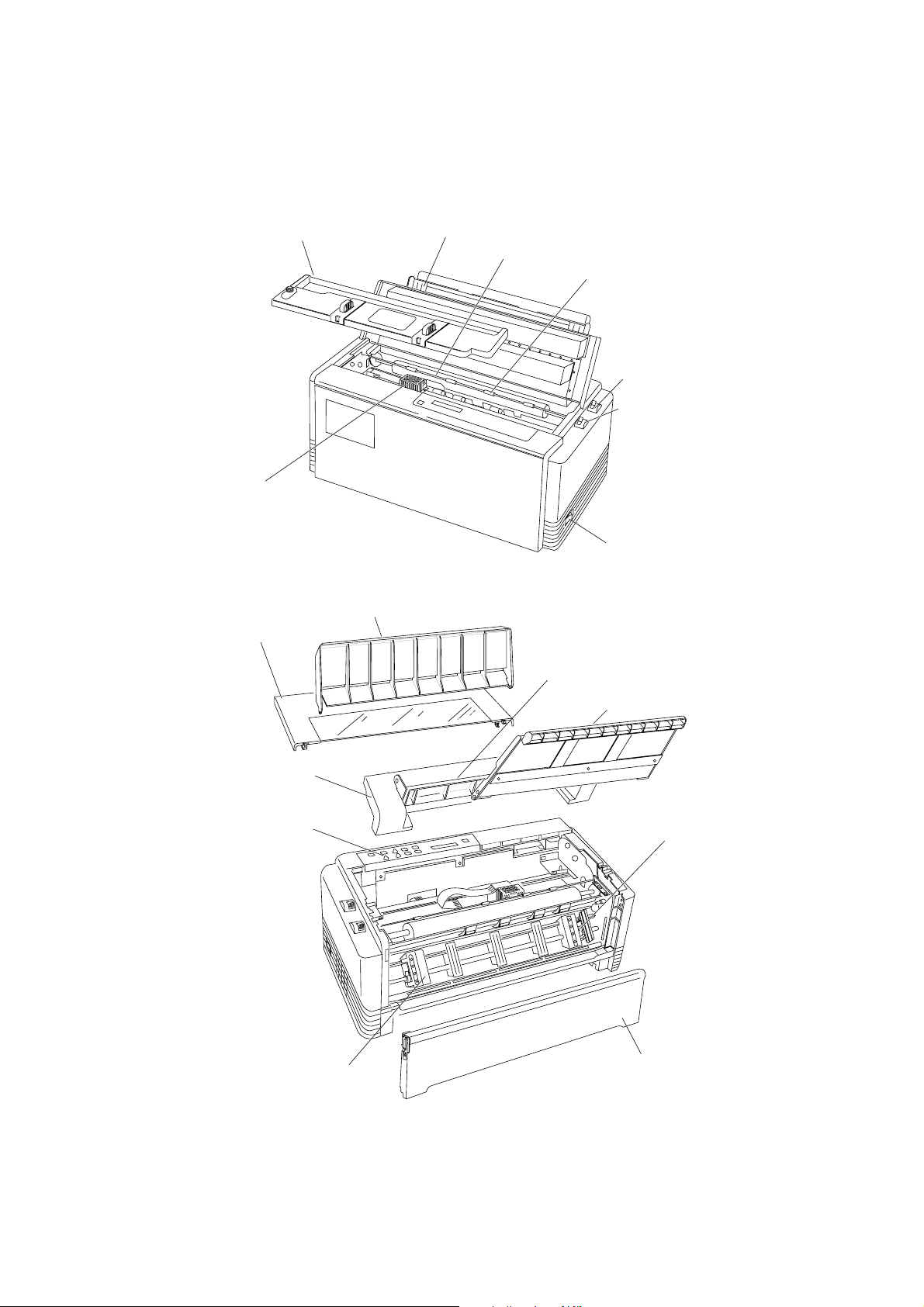

6

1. Introduction

Printer description

Paper Guide

Ribbon Cassette

Platen

Power Switch

Paper Select Lever

(Friction Lever)

Head Adjustment Lever

Printhead

Paper Bail

Sound Seal Cover

Paper Rack

Paper Cutter

Top Rear Cover

Operator Panel

Tractor Cover

Tractor Lock Lever

Printer Cover

Rear Cover

Page 15

Precaution for extra-thick paper usage

Label fanfold paper may get jammed in the printer due to its stiffness and inflexibility. When using

such paper, set the paper rack in the slant position shown in the figure.

Tractor

Platen

Print Head

Print Head

Friction Roller

Print Head

Tractor

Description

Paper width

Paper length

Ply

Total thickness

Paper weight

Single-ply

single

0.065~0.12mm

14lbs.~28lbs.

53g/m ~105g/m

2

2

Multiple Copies

Original+5 max.

0.35mm max.

non-carbon

Label Paper

single

0.12mm max.

125Kg max.

• Label Fanfold Paper

Description

Paper size

Ply

Total thickness

Paper weight

Single-ply

A3, A4, B4, B5 Letter, Legal

single

0.08~0.12mm

17lbs.~28lbs.

64g/m ~105g/m

2

2

Fanfold Paper

Single Sheet Paper

Push Tractor Method Friction Feed Method

• Single ply Fanfold Paper

• Multiple Fanfold Paper

• Single Sheet Paper

5~16 inch

2~16.5 inch

7

1. Introduction

Page 16

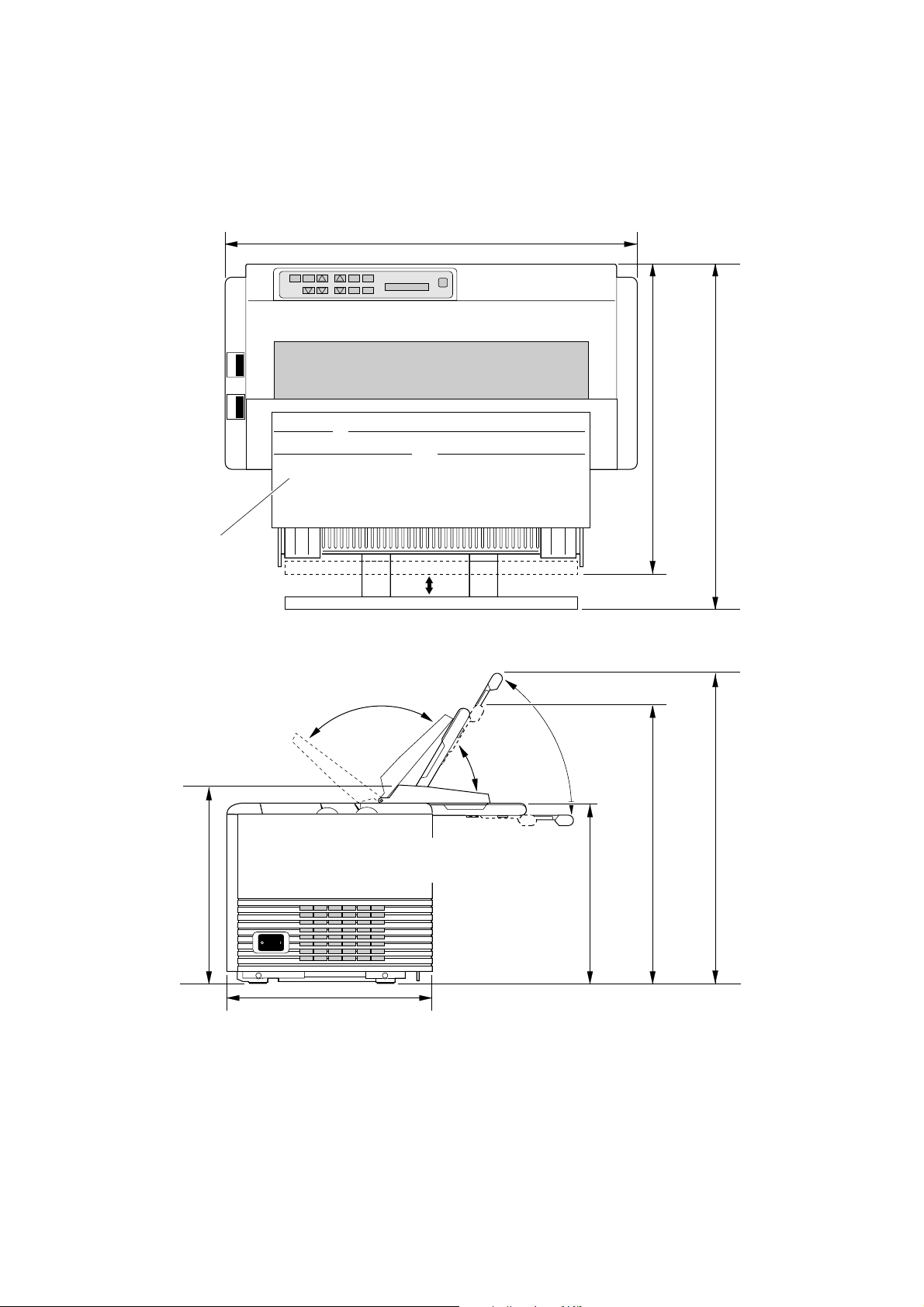

Physical dimension(Model A)

Weight: 44.1 lbs. (20 kg)

17.9"

(455mm)

19.9"

(505mm)

24 .4" (620mm)

15.4"

(390mm)

17.1"

(435mm)

10.2"

(260mm)

12.0"

(305mm)

Sound Seal Cover

11.6"

(295mm)

✽Paper Rack in flat position

(Continuous paper setting)

✽Paper Rack in upright position

(Single sheet setting)

✽Paper Rack in flat position

(Continuous paper setting)

1. Introduction

8

Page 17

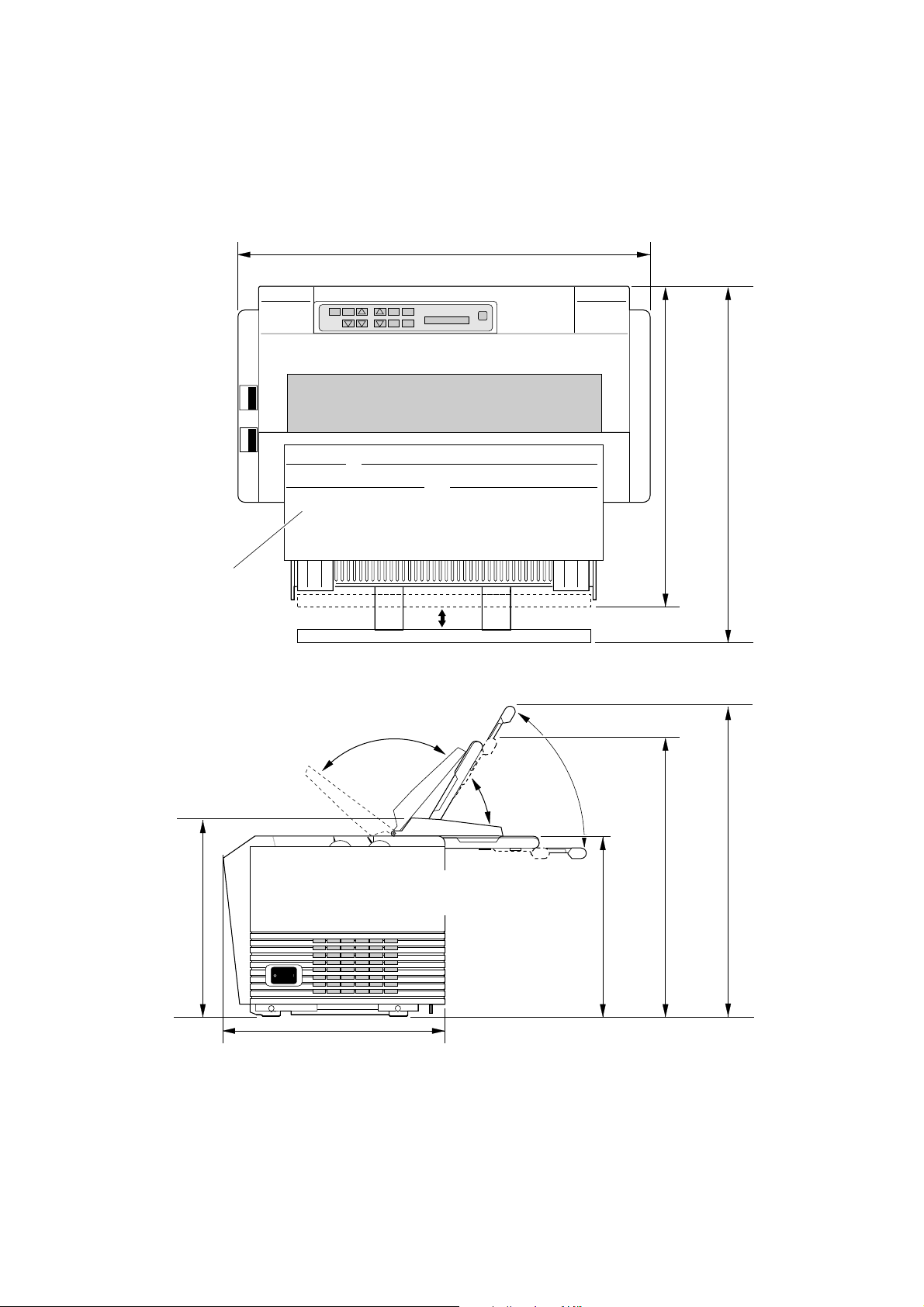

9

Physical dimension(Model B)

Weight: 44.1 lbs. (20 kg)

1. Introduction

18.9"

(480mm)

20.9"

(530mm)

24.4" (620mm)

15.4"

(390mm)

17.1"

(435mm)

10 .2"

(260mm)

13.0"

(330mm)

Sound Seal Cover

11.6"

(295mm)

✽Paper Rack in flat position

(Continuous paper setting)

✽Paper Rack in upright position

(Single sheet setting)

✽Paper Rack in flat position

(Continuous paper setting)

Page 18

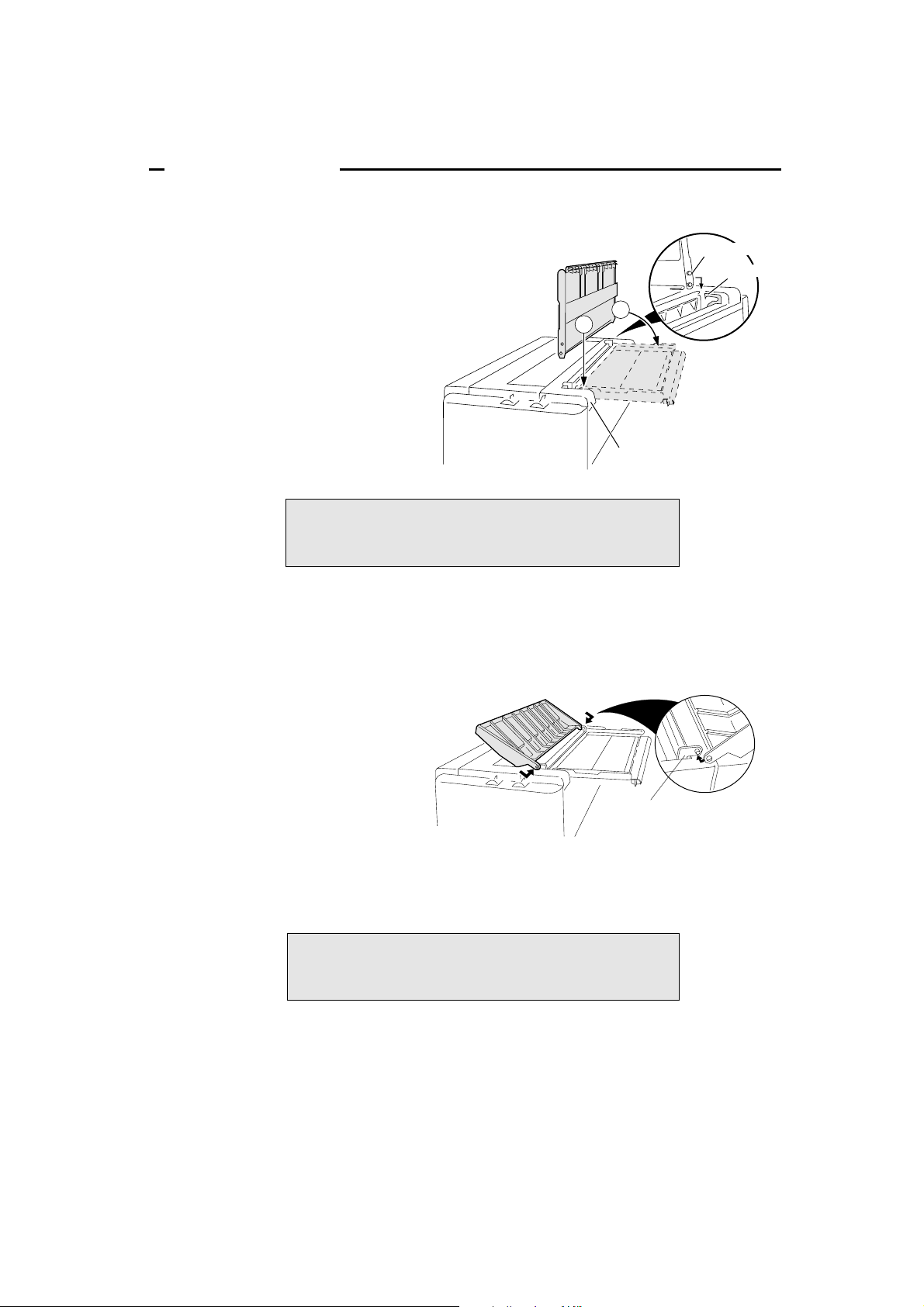

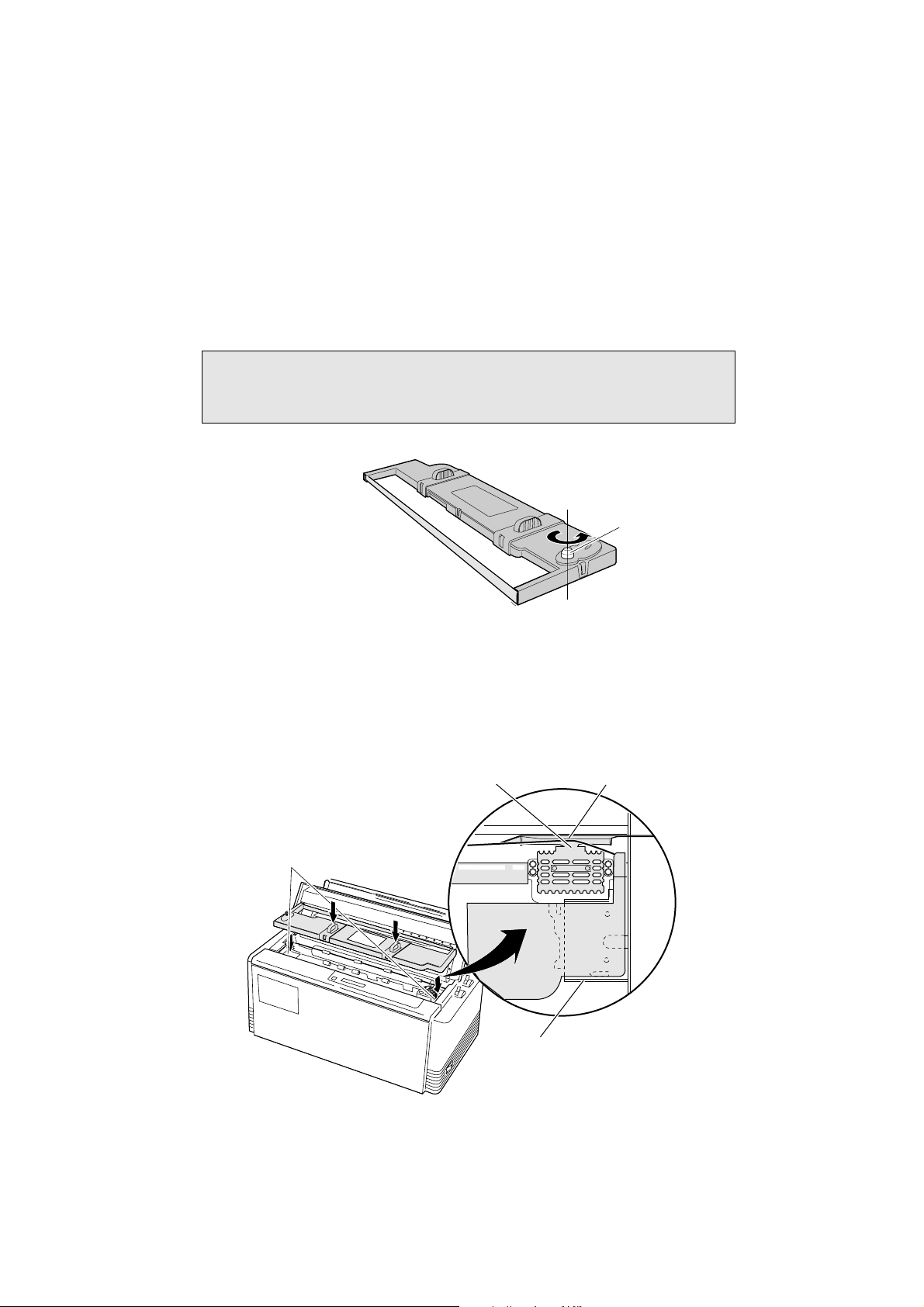

Installing the paper rack

1. Slide both paper guides to the

extreme left and right edges of the

paper rack.

2. With the two small pivots on either

side of the paper rack downward, fit

the pivots in the groove on the rear

top cover.

3. Place the paper rack in upright

position for single cut sheet paper

and lay it down for fanfold

continuous paper.

Installing the sound seal cover

1. Lay the sound seal cover upside

down on the printer.

2. Fit one of the holes of the cover to

the stud of the L-angle hinge on one

side of the printer.

3. Fit the other hole to the other stud

by pressing the L-angle hinge

inward then out through the hole.

Note

The paper guides should be placed to the outside edges during

the installation or removal of the paper rack.

Note

Make sure that both studs are out through the hole completely,

otherwise, the sound seal cover will be stuck in place.

10

2. Setting up

2. Setting up

Pivots

Groove

2

1

Rear Top Cover

L-angle Hinge

Page 19

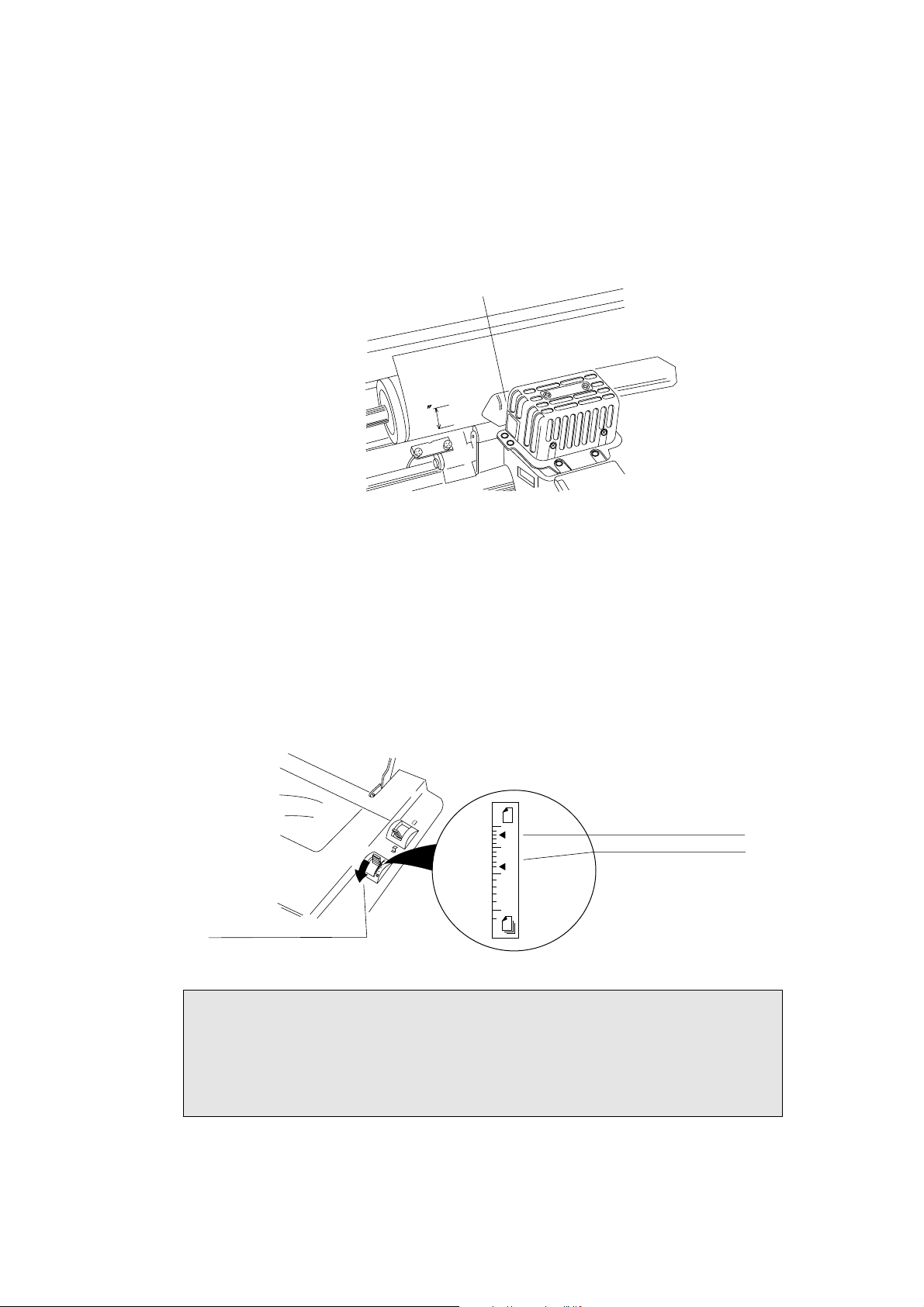

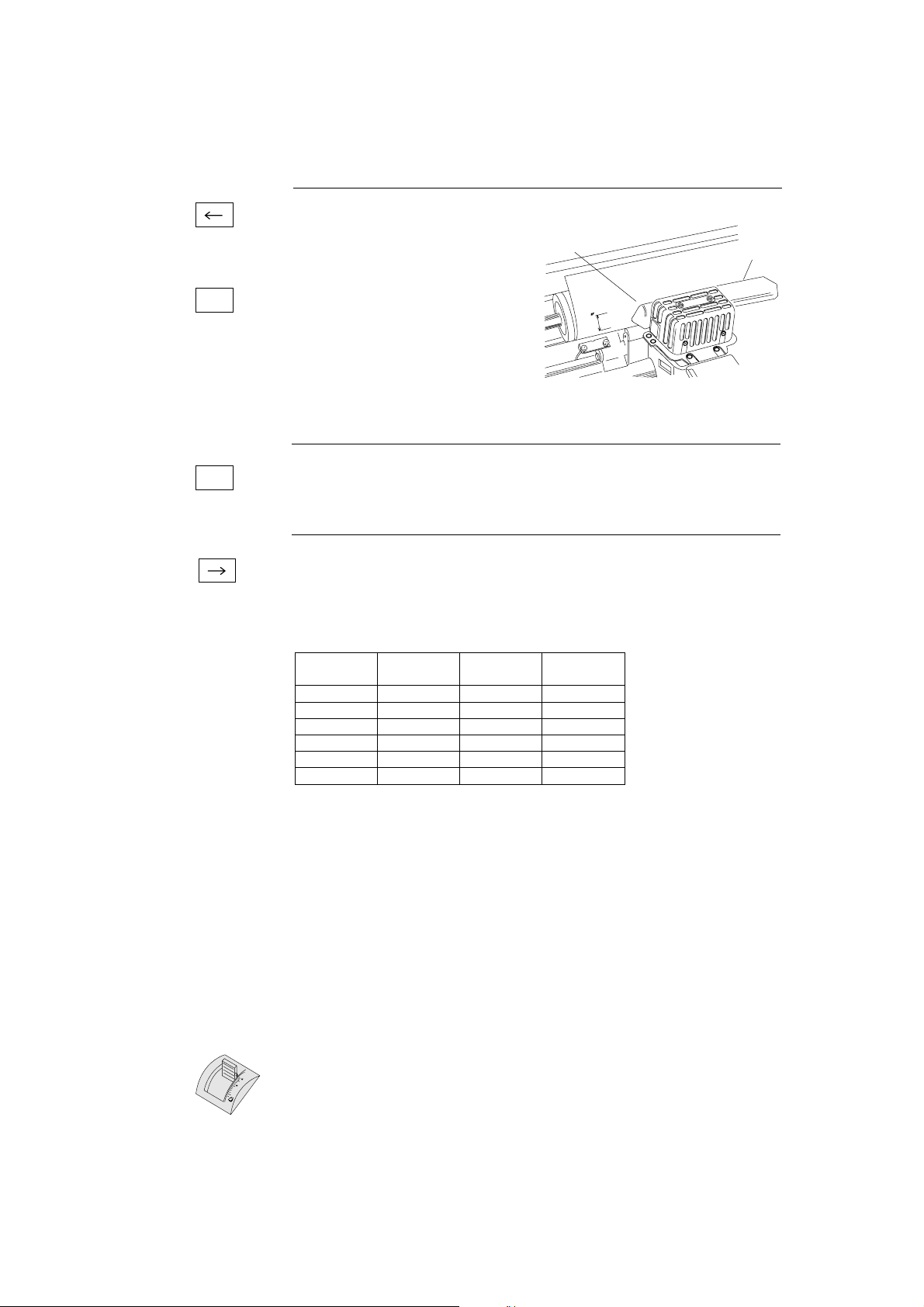

Installing the ribbon cassette

Turn OFF the printer's power and remove the used ribbon cassette, if necessary, by pulling straight

upward.

1. Open the printer cover.

2. Manually move the print head to the extreme right side of the printer for easy installation of the

ribbon. Do not try to move the print head if the power is on.

3. Turn the ribbon feed knob in the direction of the arrow on the knob to remove any slack in the

ribbon.

4. Place the ribbon cassette on the left and right cassette holders, such that the ribbon rests on the

ribbon guide. Check to be sure that the ribbon drive shaft on the left cassette holder is inserted in the

hole on the bottom of the ribbon cassette.

5. Turn the ribbon feed knob in the direction of the arrow on the knob to remove any slack in the

ribbon.

6. Replace the front printer cover and set the head adjustment lever to the proper position for the best

print quality.

CAUTION

Do not touch the print head if the printer has been running for a long time. Wait until

the print head is cooled off.

11

2. Setting up

Remove any slack from ribbon

Ribbon Feed Knob

Ribbon Guide

Cassette Holders

Cassette Holder

Ribbon Mask

Page 20

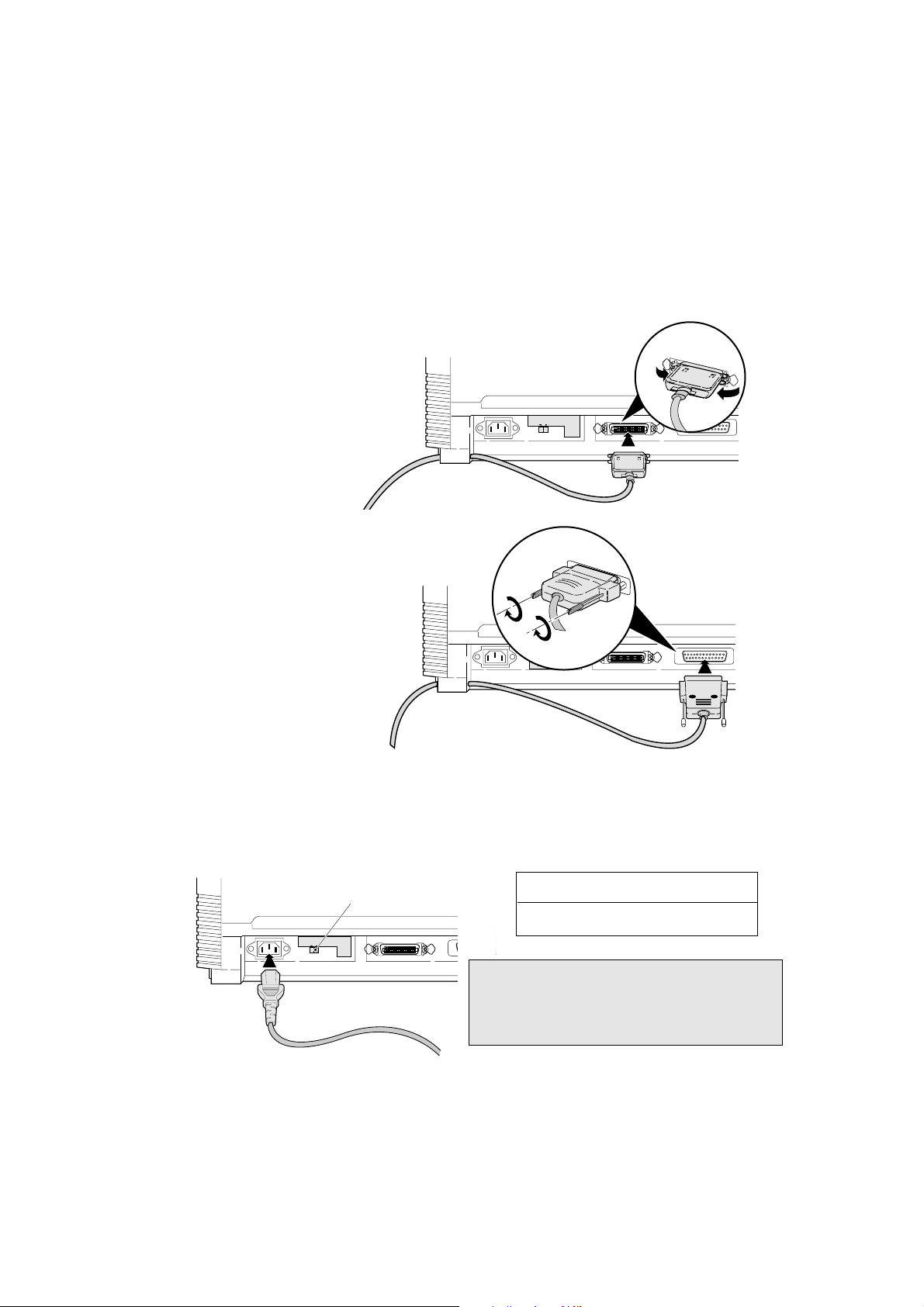

Connecting the computer

The printer has a parallel interface connector (Centronics) and a serial interface connector (RS232C).

Before you connect an interface cable to your computer, you need to know what type of printer

driver is supported by your software applications and what type of connector is needed to attach the

printer to the computer.

❏ Parallel Interface

36-pin plug

❏ Serial Interface

25-pin plug

Connecting the power cord

Check the power requirement printed on the rating plate on the rear of the printer before attaching

the power cord and turning on the printer. Both POWER and P.OUT lamps light up when the

printer is switched on correctly. The voltage selector should be set correctly as follows.

13

25

1

14

CAUTION

220-240V 120V

13

25

1

14

CAUTION

220-240V 120V

T5A 250V

T2.5A 250V(For European)

13

25

1

CAUTION

220-240V 120V

Voltage Selector

12

2. Setting up

120V : USA, Canada

230V :

Europe, Asia, Oceania

Note

For continued protection against risk of fire and

destruction of Power PCB Assembly, switch the

voltage selector according to using voltage.

Page 21

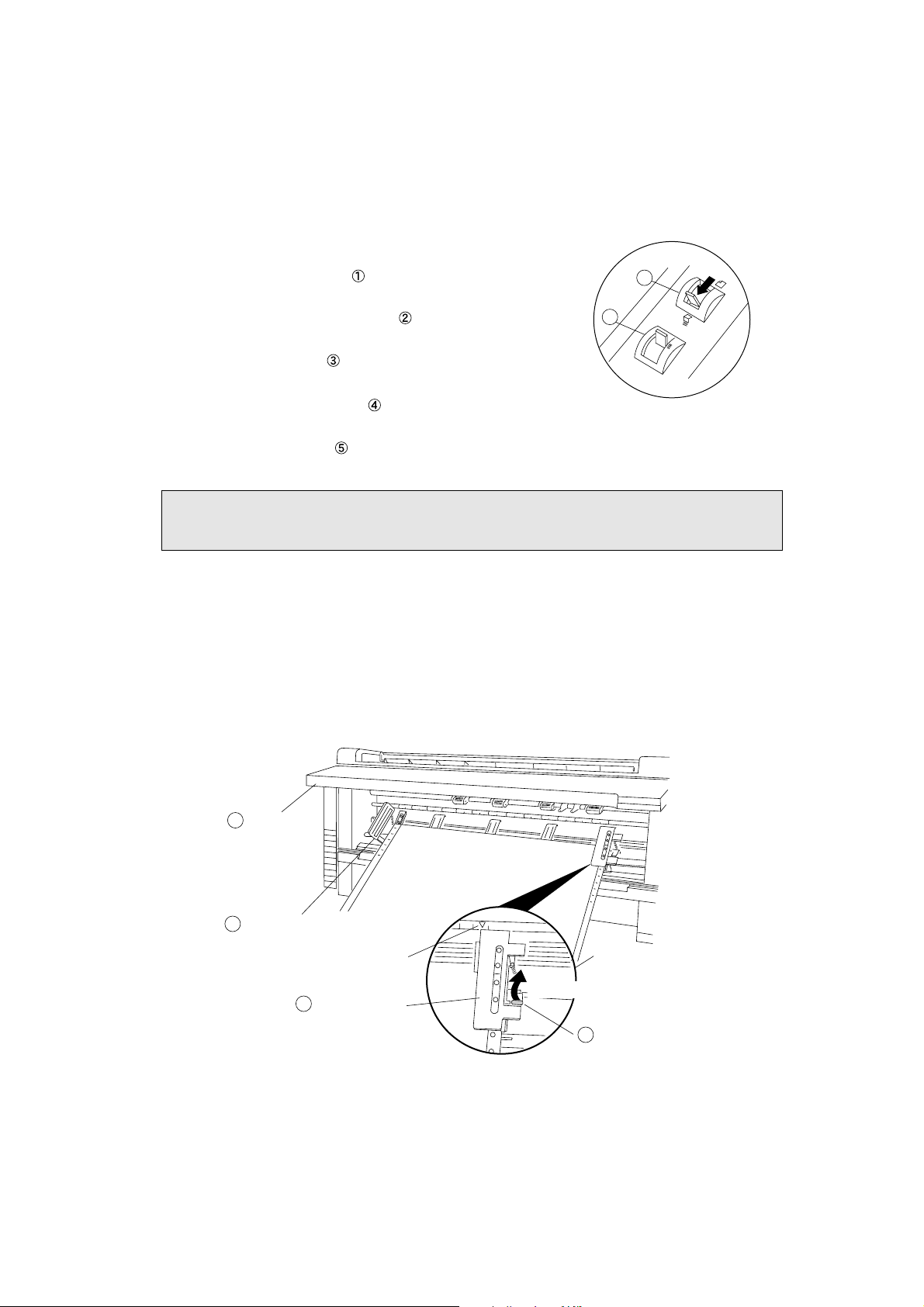

Loading the paper

❏ Fanfold continuous paper

1. Move the paper select lever toward the front of the printer to set

the fanfold paper setting.

2. Set the print head adjustment lever . In general, position 1 is

used for one-part paper. (See page 15)

3. Remove the rear cover of the printer or open the rear cover to

lock the cover in the open position.

4. Release the tractor lock levers (upward), and move the right tractor to

the marked position as shown in the figure, and lock it in place.

5. Open both tractor covers and place the fanfold paper so that the tractor pins are aligned with the

holes in the paper. Carefully close both tractor covers.

6. After the paper is properly installed, re-adjust the left tractor to a position to keep the paper taut (but

not too taut) between the left and right tractors.

7. To load the paper, press the FF key on the front panel. The fanfold paper is fed to the top-of-form

position 14/60 inch (6mm) below the top edge of the paper. The top-of-form position can be

adjusted from 0/60 inch to 480/60 inches (8 inches = 203mm) in the basic setup options on page 31.

8. The paper bail automatically lowers to press the paper against the platen when the leading edge of

the paper feeds more than one inch onto the platen.

1

2

13

2. Setting up

CAUTION

Be careful not to catch your finger when closing the tractor covers.

3

Rear Cover

Not Too Taut !!

5

Left Tractor Cover

Left Margin Marker

Right Tractor

Releasing direction

5

Tractor Cover

4

Tractor Lock Lever

Page 22

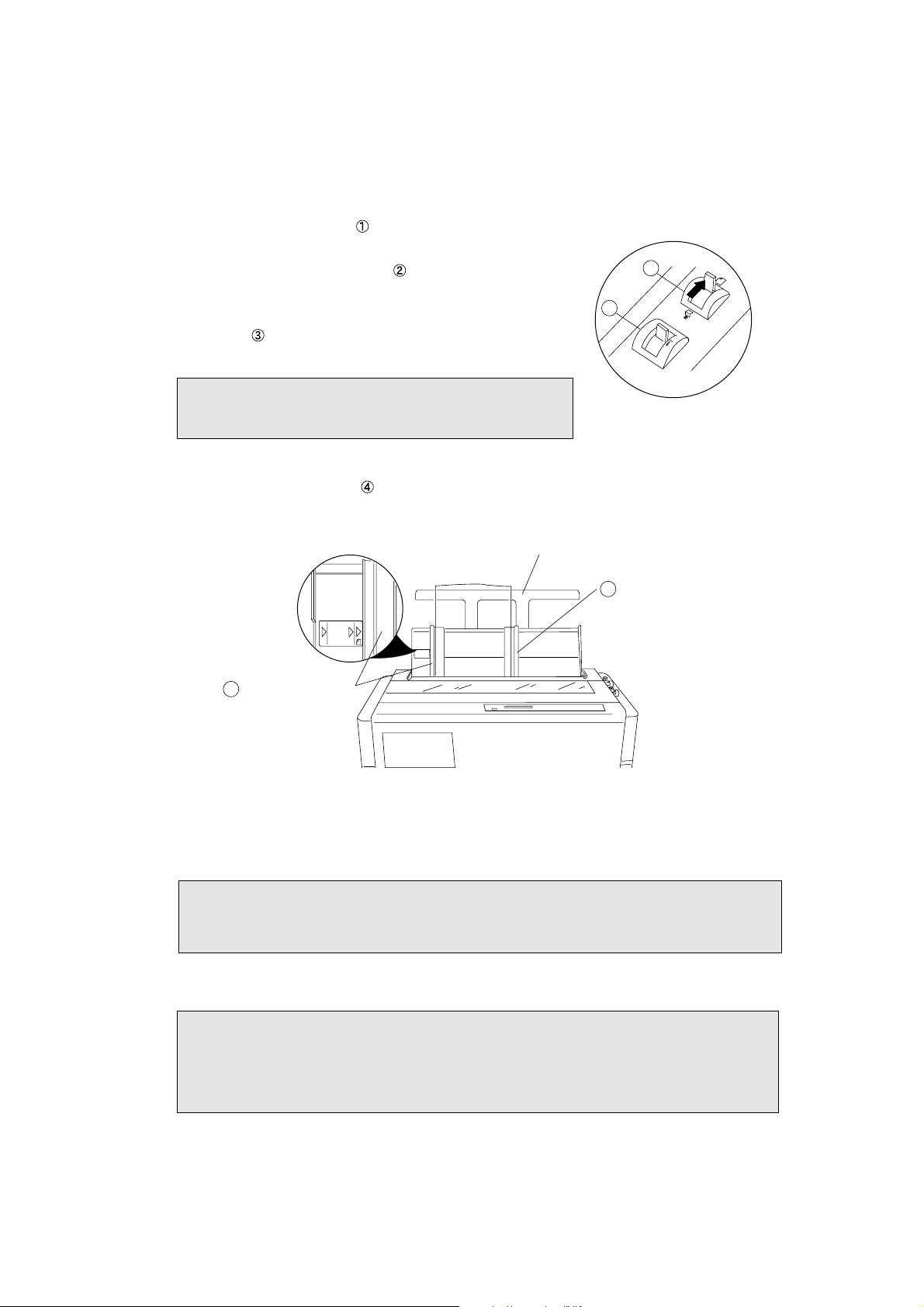

❏ Single sheet paper

1. Move the paper select lever toward the rear of the printer to the single

sheet setting.

2. Set the print head adjustment lever . In general, position 1 is used

for one-part paper. See page 15.

3. Raise the paper rack to the vertical position and adjust the left

paper guide to the proper position for the size of the paper being

used.

4. Place single sheet paper against the paper rack and let it slide behind the platen.

5. Adjust the right paper guide so that it comfortably holds the paper in between the two paper

guides.

6. Press the FF key to load the single sheet paper to the top-of-form position 14/60 inch (6mm) below

the top edge of the paper. The top-of-form position can be adjusted from 0/60 inch to 480/60 inches

(8 inches = 203mm) by using the front panel controls in the basic setup options on page 31.

7. The paper bail automatically lowers to press the paper against the platen when the leading edge of

the paper feeds more than one inch onto the platen.

Note

If the paper is not loaded on the proper mark, the printer may

not detect the paper and will display PAPER ERROR.

Note

If the paper is not completely fed in, slightly push the paper downward. If it is still not fed in,

look in the TROUBLESHOOTING section.

Notes

1. Extension Arm

The extension arm is used to keep large size (Legal, B4) single sheets from falling behind the

paper rack. When using the extension arm, pull the arm until it clicks and locks in place.

2. TEAR OFF key is invalid with single sheet paper.

1

2

14

2. Setting up

Paper Size Marker

3

Left Paper Guide

A3

B4

Extension Arm

4

Right Paper Guide

Page 23

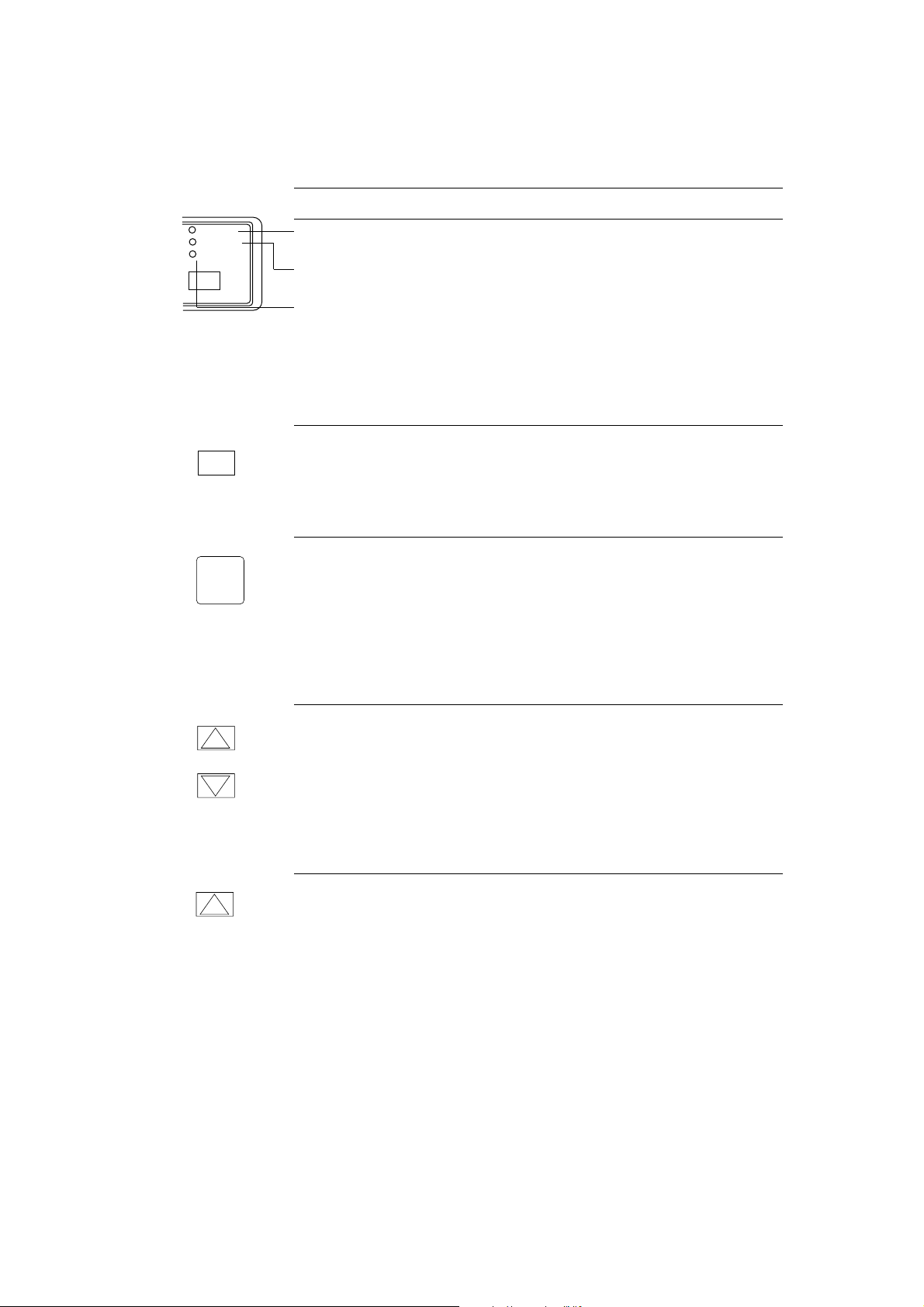

❏ Paper alignment

Current print line location

The current printing line (DDD...) is the third line down from the top of the ribbon guide (line

spacing is 1/6 line: 6 LPI).

Adjusting the print head position

The head adjustment is used to obtain the best print quality possible for the specific paper

being used. The print head position can be adjusted to accommodate printing on single and

multipart forms. When using multipart forms, move the print head adjustment lever toward the

front of the printer to widen the gap between the print head and the platen.

In general, position 1 is used for one-part paper. Moving the head adjustment lever one notch

adjusts the print head gap an amount corresponding to the addition of one more paper part.

Re-adjustment of the lever may be required depending on the quality of the actual printout:

• If the ribbon smears on the paper, the gap is too narrow.

• If the printed image is too light to read, the gap is too wide.

Ribbon Guide

D

A

A

A

A

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

0.5

Head Adjustment Lever:

Move toward the front of

the printer for thicker paper

1 part-paper: 2nd click

6 part-paper: 9th click

(This scale is the suggested

number of sheets

for non-carbon part-paper.)

1

6

1

5

9

Notes

1.The print head adjustment lever should be set before loading the paper to avoid paper

jams.

2.If the printed image on the last copy of a multipart form is too light to read, set the

MULTIPART mode in the basic setup options (see page 26). This will increase the

striking intensity on multipart forms.

15

2. Setting up

Page 24

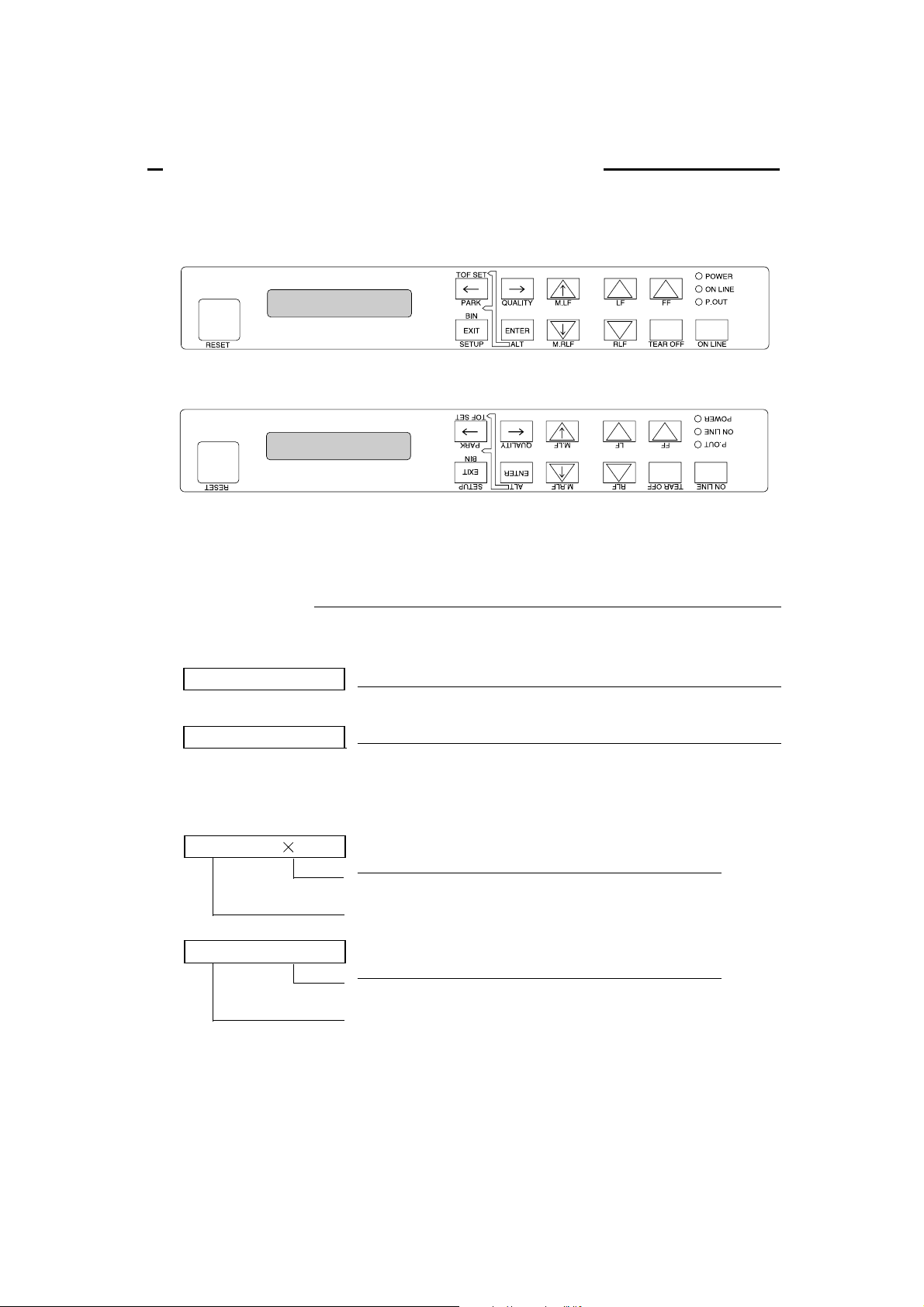

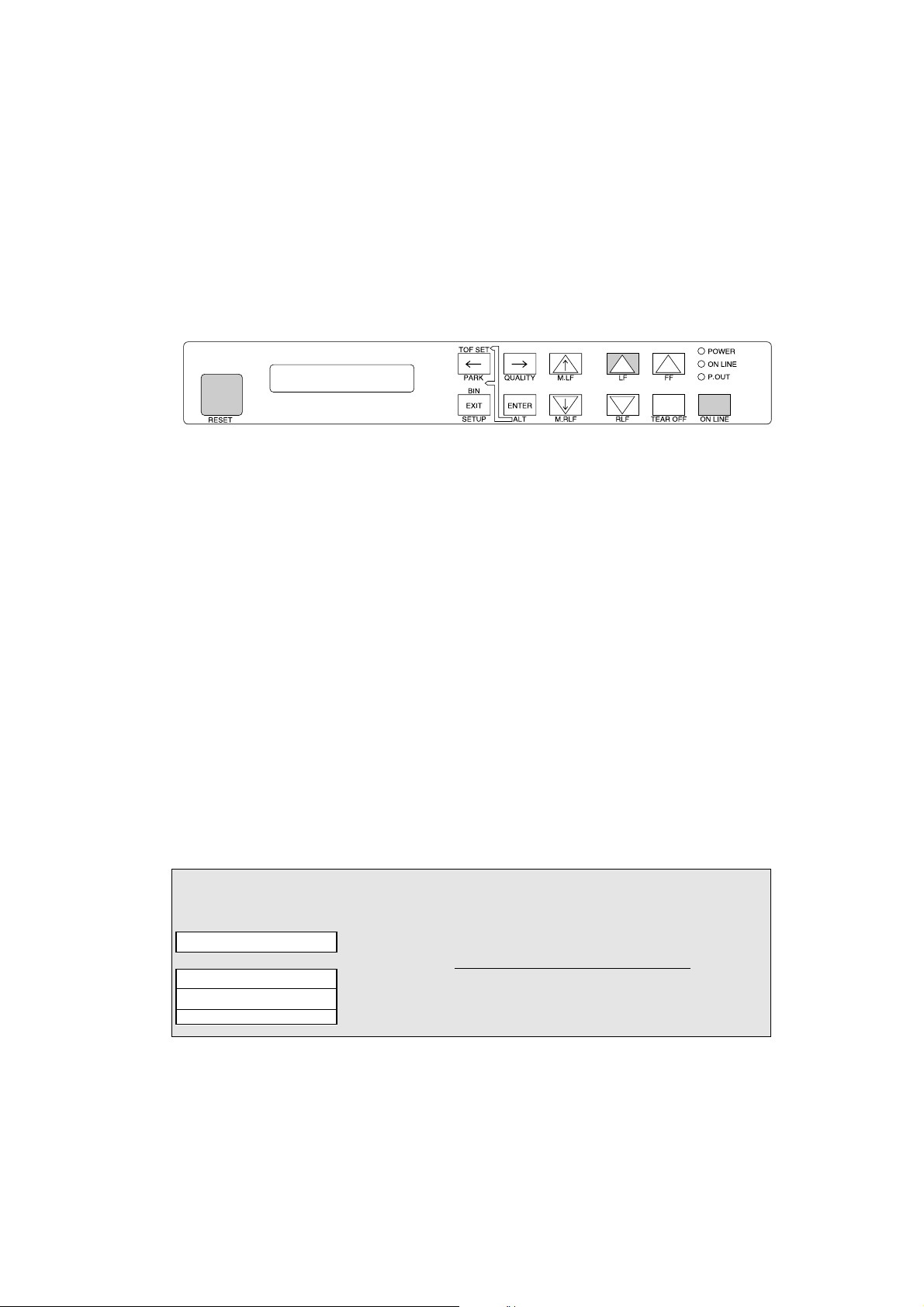

Control panel and indicators

Standard Panel

Alternate up-side down reverse panel

Note: The alternate reverse panel installation instruction is described in Appendix D.

❏ Indicators

• Display window Liquid Crystal Display (LCD)

Displays status and errors during operation and menus in the setup options.

LCD

LCD

The followings are some examples of the display messages.

If the printer is in the offline mode, the following appears on the display.

Status message

This indicates that the printer is in offline and paper out status.

P.OUT FANFOLD

Warning message

This indicates that the printer cover is open. Close the cover to

resume the operation .

COVER OPEN

Status message for fanfold continuous paper

This column indicates the page length; and the paper widlh.

This indicates the type of paper selected is fanfold continuous

paper.

FANFOLD 11 15

Status message for single sheets paper

This indicates a paper size; B5 through A3 depending on the

designated paper size (default A4) selected in the setup options.

This indicates the type of paper selected is single sheet paper.

MANUAL, BIN 1, BIN 2, BIN 1+2

MANUAL: A4 P

16

3. Control panel and operations

3. Control panel and operations

Page 25

• Indicator lamps

❏ Function Keys

• ON LINE

Pressing this key places the printer offline so that the printer can perform

some functions independent from the host system. In the offline mode, data

is not received. When the printer is offline, pressing the key places the

printer online and ready to receive data from the host system.

• RESET

When the RESET key is pressed, the printer immediately enters the reset

state and prepares for the initialize operation, which is nearly the same

initialize operation as when the power is turned on.

The following keys are active only in the offline mode:

• LF/RLF (Line feed and reverse line feed)

When the LF/RLF key is pressed, paper is fed per the line spacing at the 6

line per inch forward or backward, respectively.

While this key is pressed and held, the paper is continuously fed forward or

backward, respectively.

• FF (Form feed)

Pressing this key feeds the paper to the next top of form position when the

paper is already loaded. Single sheet paper is fed to eject. Pressing this key

loads the paper when the paper is not loaded.

Lamp On Off Blinking

POWER Power On Power Off —

(green)

ON LINE Online Offline Cover open, or Head overheat

(green) protection activating

P.OUT Out-of-paper Paper-in Home sensor error, RAM error,

(umber) or paper error.

ON LINE

P

.OUT

ON

LINE

POWER

ON LINE

RLF

LF

FF

RESET

17

3. Control panel and operations

Page 26

• M.LF/M.RLF (Micro line feed/micro reverse line feed)

When the M.LF/M.RLF key is pressed, the paper is fed 1/360 inch forward

or backward, respectively. This key is used to set the paper position.

To set the TOF SET (top-of-form set) function, press the FF key and then

simply advance the loaded paper forward or reverse to your desired print

position using the M.LF/M.RLF keys. Hereafter until you reload paper, the

first print position of the form is always fed at the same place.

• TEAR OFF [Used only for fanfold paper]

Pressing this key advances the perforation of the form to the paper cutter so

that the leading form can be torn off from the rest.

If this key is pressed after the form is torn off, the paper is fed backwards

and the mode is returned to offline. If the ON LINE key is pressed instead

of the TEAR OFF key, the paper is fed backwards and the mode is changed

to the online mode.

• PARK (Paper parking)

Pressing this key unloads the paper if the paper is already loaded.

Fanfold continuous paper (paper select lever in fanfold setting)

The paper is moved to the park station in the back of the printer by pressing

this key.

Single sheet paper (paper select lever in single sheet setting)

The paper in the print station will be ejected.

• BIN (ALT+SETUP keys)

This key is for selecting the active paper tray of the cut sheet feeder or the

paper feed type:MANUAL, BIN1, BIN2 or BIN1+2. BIN1, BIN2, BIN1+2

appears only when the cut sheet feeder (CSF) option is set.

+

TEAR OFF

TOF SET

PARK

M.RLF

M.LF

18

3. Control panel and operations

BIN

EXIT

SETUP

ENTER

ALT

Note

The paper select lever must be switched to the single sheet setting.

Page 27

19

3. Control panel and operations

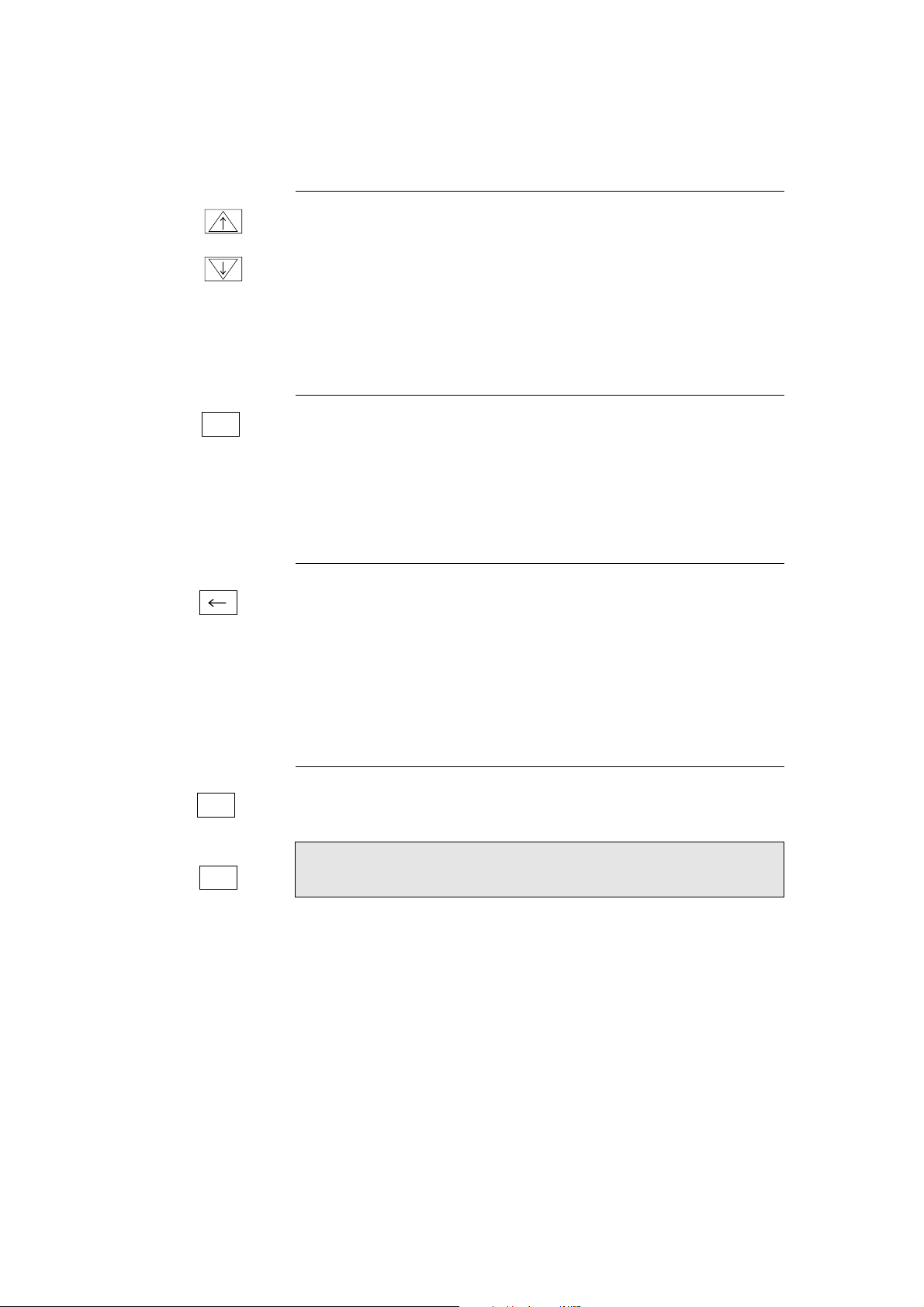

• TOF SET (ALT+PARK keys)

The TOF SET key is valid only when paper is loaded. When the TOF SET

key is pressed in the offline state, the TOF position is set to the top of the

ribbon guide, and the buzzer

sounds.

+ After two seconds, the paper is

fed backward so that the TOF

position is at the current

printing position.

When the TOF position is set,

the setting of “7 TOF ADJUST”

is changed to this set automatically.

*TOF:Top of form

• SETUP

When the SETUP key is pressed the printer enters the setup options. The

setup options are explained later in the "Basic setup options" section.

• QUALITY

This key is for selecting the print quality: LQ, NLQ, HQDR (high quality

draft), DRAFT, SD (speed draft), or SSD (super speed draft). To set your

desired print quality simply scroll and stop where your selection is

displayed. The printer beeps once for an acknowledgment.

Software commands can override the print quality setting of this key.

However, "#26 Quality Lock" option described on page 41 can lock-in the

selection by this key and disable software commands.

This key also selects the graphic print speed.

*The graphic print speed is selected only by “31 GRAPHIC QUALITY”

in the extended setup options.

• Others

The ←, →, ↓, ↑ EXIT and ENTER keys become effective only in the setup options entered by

pressing the SETUP key. For more information refer to "Basic setup options."

Control Levers

• Head adjustment Lever

This lever adjusts the gap between the print head and the platen. The correct

gap adjustment for a different paper thickness is required to obtain optimum

print quality. See also page 15.

BIN

EXIT

SETUP

QUALITY

1

6

TOF SET

PARK

ENTER

ALT

LCD

Graphic print speed

LQ

NLQ

HQDR

DRAFT

S.D.

S.S.D.

LQ

NLQ

LQ

LQ

S.D.

S.S.D.

Draft

Draft

HQDR

Draft

S.D.

S.S.D.

Normal✽

High speed 1

High speed 2

High speed 2

High speed 2

High speed 2

ESC x 1

LQ is selected

ESC x 0

Draft is selected

TOF Position

D

A

A

A

A

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

0.5

Ribbon Guide

Page 28

• Paper Select Lever

The paper select lever serves to switch between the fanfold continuous paper

setting and the single sheet paper setting (or CSF setting when CSF

installed).

Note: Switching this lever to continuous paper setting will mechanically

release the pressure roller for single sheets and engage gear trains for

continuous paper.

Paper parking

This function moves fanfold paper back to the push tractor position (park station) so that single

sheet paper can be used. Specifically it is useful when switching from fanfold paper to single

sheet paper.

• Pressing the PARK key removes the fanfold paper from the print station so that single sheet

paper can be used.

• Switching of the paper select lever is required for the actual mechanical switching of the paper

select.

• Pressing the FF key when the printer is in the paper-out state loads the selected paper (fanfold

or single sheet) to the top-of-form position.

The following table explains the paper handling of the FF and the PARK key in the offline

state:

Notes

1. Make sure that the setting of the paper select lever corresponds to the type of paper being

used.

2. The paper park function causes PAPER ERROR in the following situations:

a) when the fanfold paper is not set in the park station (at the push tractors) after moving

more than 22 inches backward.

b) when the paper (fanfold or single sheet) is not autoloaded to the print station after

feeding more than 8 inches. (At this time, the printer tries to sense the paper in the

printer.)

c) when single sheet paper is not ejected from the printer after advancing more than 22

inches.

20

3. Control panel and operations

Friction Lever P.OUT Lamp Function Key Action

Continuous

ON FF Autoload the paper

Paper

PARK Ignore the key

OFF

FF Feed to the next TOF

PARK Park the paper in the push tractor

Single Sheets

ON

FF Autoload the paper

PARK Ignore the key

OFF

FF Eject the paper

PARK Eject the paper

Page 29

Printing test pattern

Before performing the printer's self test, be sure the ribbon cassette and paper are properly

installed in the printer. The self test prints a continuous pattern of printable characters (ASCII

character pattern) in either draft or letter quality (LQ).

While test printing is executed, the ON LINE lamp blinks and the LCD indicates “SELF TEST”.

❏ To run the draft self test

Press the LF key while turning ON the printer's power. If the printer is already turned ON, the

draft self test may be performed by pressing the LF key together with the RESET key.

Keep pressing the LF key until the self test begins.

❏ To run the LQ self test

Press both the LF and ON LINE keys simultaneously while turning ON the printer. If the

printer is already turned ON, the LQ self test may be performed by pressing both the LF and

ON LINE keys simultaneously together with the RESET key.

Keep pressing the LF and ON LINE keys until the self test begins.

❏ To stop the self test temporarily

Press the ON LINE key to stop printing.

❏ To resume the self test

Press the ON LINE key again to restart printing.

❏ To terminate this function

Press the RESET key or turn off the power.

SELF TEST DRAFT

Note

Before initiating the self test, make sure that the width of the paper, especially fanfold paper

loaded in the printer corresponds to the setting selected in the extended setup options.

44 PAPER WIDTH

WIDTH: 15 IN

WIDTH: 10 IN

WIDTH: 5 IN

Maximum printable columns at 10cpi

.................... 136 columns

.................... 80 columns

.................... 36 columns

21

3. Control panel and operations

Page 30

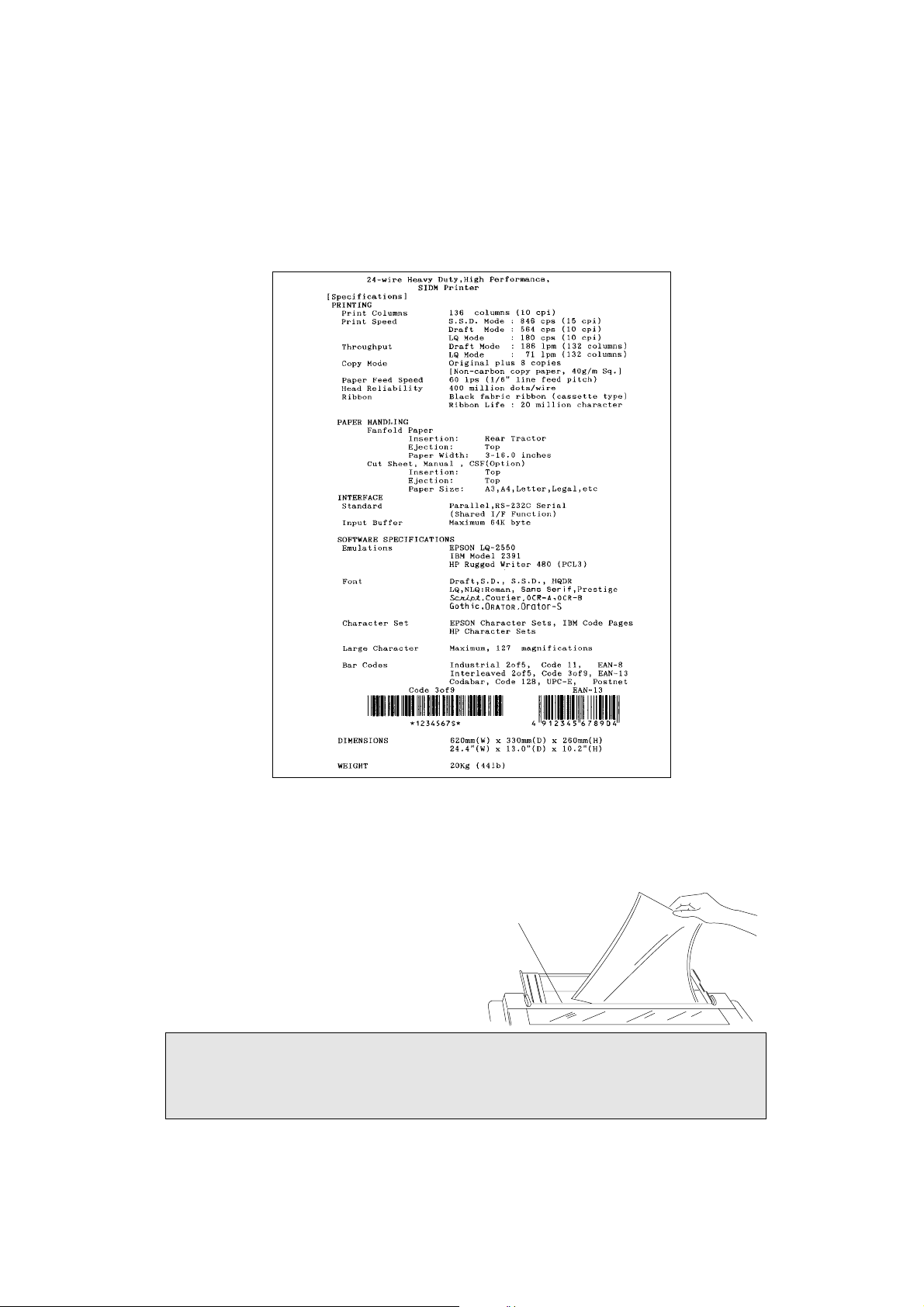

Demonstration print-out

To see what this printer can do, you may run this demonstration print-out (Letter or A4 paper

size) for checking the printer's performance. Press and hold the RLF and the M.RLF keys

while turning on the printer's power.

Tearing off a form

(Used only with fanfold continuous paper)

This function is activated by the TEAR OFF key and feeds fanfold paper so that the

perforation is aligned with the paper cutter located at the top rear of the printer, thus enabling

simple paper tearing. During the tear off

operation, the M.LF, and M.RLF keys are

used to correctly align the paper to the paper

cutter.

After tearing off the form, pressing the

TEAR OFF key a second time reversely

feeds the paper to the top of the next

available form.

Note

Pressing the TEAR OFF key (or the ONLINE key) the second time may return the paper to

the original print position when the top edge of the form does not pass above the paper

location prior to the first TEAR OFF operation.

22

3. Control panel and operations

Paper Cutter

Page 31

Power-on operation summary

Operation (reference page)

Self test, draft (P21)

Self test,LQ (P21)

Hex dump, draft (P62)

Hex dump,LQ (P62)

Extended setup options (P33)

Demo printout (P22)

Loading MEMO 1 (P31)

Loading MEMO 2 (P31)

Loading MEMO 3 (P31)

Vertical alignment (P66)

EEPROM initialize 1

EEPROM initialize 2

LF

FF

ON LINE

PARK

QUALITY

M. LF

M. RLF

RLF

TEAR OFF

SETUP

ALT

RESET

POWER

Notes

1. Use either the RESET key or power switch when the circle is in both the RESET and

POWER columns.

2. EEPROM initialize 2 operation requires the vertical alignment operation after the

execution of the EEPROM initialize 2.

23

3. Control panel and operations

Page 32

About basic setup options

The setup options serve to define various initial states of the printer that are executed when the

power is turned on or when the RESET key is pressed. In addition, this mode serves to

redefine the font type, character spacing, and other parameters for the printer's current

operating conditions. The parameters set in the setup options are stored in the memory of the

printer and used as the default values in initialize operations.

❏ To set this option

When the SETUP key is pressed in the offline mode, the printer enters the function setup

option, where various functions can be set. The keys used in the function setup mode are

described below.

← and → [Alternate to the PARK and QUALITY]

These keys are used to go over menus in the display, but cannot be used to select

a menu item.

↓ and ↑ [Alternate to the M.LF/M.RLF]

These keys are used to go over items within a menu in the display, but cannot be

used to set an item parameter.

ENTER [Alternate to the ALT]

When this key is pressed, an asterisk (*) indicating that the item is the currently

selected parameter is added at the end of the item.

EXIT [Alternate to the SETUP]

When this key is pressed, the content of the item is stored in the memory of the

printer. Then, the printer exits from the setup options and enters the offline

mode.

ONLINE

This key's function is similar to the EXIT key in that the printer saves the

selected item and exits from the setup options. At that time, if no errors or

irregular conditions exist, the printer enters the online mode.

Select functionSelect menu

Choose selected function

Exit setup to offline

Exit setup to online

POWER

ON LINE

P.OUT

RESET

TOF SET

MAIN SETUP

PARK

BIN

EXIT ENTER

SETUP ALT

QUALITY

M.RLF

M.LF

RLFLFTEAR OFF ON LINE

FF

24

4. Basic setup options

4. Basic setup options

Page 33

❏ Selection procedure example

The following example illustrates the correct procedure to select a letter-portrait paper size

from the front panel:

1. Press the ON LINE key to enter the offline state. The ON LINE lamp is put out:

2. Press the SETUP key to enter the SETUP options. The LCD displays:

3. Press the Right Arrow (→) key to select the menu and to display:

4. Press the Down Arrow ( ↓ ) key to step down the function items, and to display:

5. Press the ENTER key to select letter-size portrait as the desired PAPER SIZE. The LCD

briefly displays the paper size with an asterisk at the end.

6. Press the EXIT key to store the selection, terminate the setup options, and return to the offline

state or press the ON LINE key to return to the on line state.

❏ Setup Memory

Current memory

The printer contains one current memory for automatically storing the preset setup states and

three user memories for storing data that is designated by the user.

The current memory automatically stores the configuration when the setup options are

terminated. When the power is turned on or when the RESET key is pressed, the printer

automatically sets the configuration per the current memory. Thus, when entering the setup

options, the contents of the current memory can be altered.

User memory

The user memories can store three different configurations. The user can set and recall the

contents of the memory to configure the printer. When the power is turned on or when the

RESET key is pressed, the contents stored in the user memories are not used as the initial

values. To use the contents of the user memories as the initial values, it is necessary to select

one of the user memories, MEMO 1 to MEMO 3, in the setup options and evoke the contents as

the preset condition.

To use the contents of the user memory as the current setup, it is necessary to display the “8

SELECT SETUP” on the menu and select one of the user memories. Exiting from the setup

options with a user memory selected will cause the contents of the user memory to be stored in

the current memory which then becomes the printer initial values.

To store a configuration in a user memory, display the “86 SAVE SETUP” selection in the

extended setup options and select one of the user memories. The current setup content is stored

in the specified memory when exiting the setup options.

SIZE: LETTERp

SIZE: LETTERp*

1 MULTIPART

3 PAGE SINGLE

25

4. Basic setup options

Page 34

Printing multipart paper

The multipart mode increases the print intensity on multipart forms.

Selecting page length for fanfold paper

The page length selection varies from 2 inches to 16.5 inches with a 0.5 inch increment. The

page length is the same as the distance between two perforations.

The page length can be changed by software commands, but when the "Page Lock" option in

the extended setup options is set enabled, this page length selection becomes the fixed length

and software commands are ignored.

1 MULTIPART

COPY: NORMAL

COPY: DARK 1

COPY: DARK 2

2 PAGE FANFOLD

PAGE: 2 IN

PAGE: ...

PAGE: 11 IN

PAGE: ...

PAGE: 16.5IN

........... With one pass printing, normal speed

........... With one pass printing, reduced speed

........... With two pass printing

Default page length is 11 inches

Printable area

Printable area

Perforation

2 - 16.5 Inch

Page length for fanfold paper

TOF(Top Of Form)

26

4. Basic setup options (1-2)

Page 35

Selecting single sheet paper size

This function sets a paper size (page length, the right and left margins) of single sheet paper.

The "Page Lock" option in the extended options can lock-in the character spacing selected in

this option and ignores the related software command.

3 PAGE SINGLE

SIZE: B5 p

SIZE: B5 l

SIZE: A4 p

SIZE: A4 l

SIZE: B4 p

SIZE: B4 l

SIZE: LETTERp

SIZE: LETTERl

SIZE: LEGAL p

SIZE: LEGAL l

SIZE: A3 p

SIZE: A3 l

CONDITIONS

• Character Pitch: 10 CPI

• Line Feed Pitch: 6 LPI

• Page Length(in Epson/IBM) : = Paper form length - 0mm (top margin) - 17mm (bottom margin) - 2mm (tolerance)

• Page Length and Number of Lines in HP depend on the TOF position and override function.

• Right and Left Margin: correspond to the scale on the paper bail. (The unit is the number of characters).

Note

A3 landscape can not be used with CSF.

B5 Portrait

B5 Landscape

A4 Portrait

A4 Landscape

B4 Portrait

B4 Landscape

Letter Portrait

Letter Landscape

Legal Portrait

Legal Landscape

A3 Portrait

A3 Landscape

1

1

1

1

1

1

1

1

1

1

1

1

68

98

80

114

98

136

82

108

82

136

114

136

68

98

80

114

98

136

82

108

82

136

114

136

238

163

278

191

345

238

261

197

337

197

401

278

257

182

297

210

364

257

11"

8.5"

14"

8.5"

420

297

EPSON/IBM

HP

56

38

65

45

81

56

61

46

79

46

94

65

55

37

64

43

80

55

60

45

78

45

93

64

Override OFF

58

40

67

47

83

58

63

48

81

48

96

67

56

39

66

45

82

56

62

47

80

47

95

66

Override ON

56

38

65

45

81

56

61

46

79

46

94

65

55

37

64

43

80

55

60

45

78

45

93

64

Override OFF

60

43

70

49

86

60

66

51

84

51

99

70

59

41

69

48

84

59

64

49

82

49

98

69

Override ON

Left Margin (chr.)

Right Margin (chr.)

Recommended

Number of Columns

(chr./line)

Recommended

printing area

(length in mm)

Maximum length

of page (mm)

TOF Adj. TOF Adj. TOF Adj.

0/60" 14/60"

TOF Adj.

Paper Size

item

0/60" 14/60" 0/60" 14/60" 0/60" 14/60"

Number of Lines / Page

27

4. Basic setup options (3)

........... "P" denotes portrait.

........... "I" denotes landscape

........... Default page size is A4 portrait.

Page 36

Selecting font style

This selection is effective only in the LQ or NLQ print mode. There are 10 resident fonts

provided.

When the OCR-A or OCR-B font is selected, either 10 cpi or 12 cpi character spacing can be

selected. The "Font Lock" option in the extended options can lock-in the font selected in this

option and ignores the related software command.

4 FONT SELECT

FONT: ROMAN

FONT: S.SERIF

FONT: COURIER

FONT: PRESTIGE

FONT: SCRIPT

FONT: OCR-B

FONT: OCR-A

FONT: GOTHIC

FONT: ORATOR

FONT: ORATORs

........... Default font is Roman.

........... Sans Serif

Note:

1. If the current 'QUALITY' selection is SD, SSD, DRAFT, or

HQDR, the font selection depends on the EMULATION

currently selected:

HP mode — FONT SELECT selection is accepted and

QUALITY is automatically changed to LQ.

EPSON or IBM mode — FONT SELECT selection will not

take effect until QUALITY selection is changed to either

NLQ or LQ.

2. If the current 'CHAR PITCH' is set to 15, 16, 17.1, 20, or

24 and OCR-A or OCR-B is selected, the ROMAN font

will be automatically substituted.

28

4. Basic setup options (4)

FONT

ROMAN

SANS SERIF

COURIER

PRESTIGE

SCRIPT

OCR-B

OCR-A

GOTHIC

ORATOR

ORATOR-S

PRINT SAMPLE

Page 37

Selecting character spacing

This function selects one of the fixed spaced characters and proportional spaced characters.

The "Pitch Lock" option in the extended setup options can lock-in the character spacing

selected in this option and ignores the related software command.

When SD (speed draft) or SSD (super speed draft) is set the character spacing automatically

changes to 12 cpi or 15 cpi, respectively.

When OCR-A or OCR-B font is selected, either 10 cpi or 12 cpi can be selected.

5 CHAR PITCH

PITCH: 10 CPI

PITCH: 12 CPI

PITCH: 15 CPI

PITCH: 16.7 CPI

PITCH: 17 CPI

PITCH: 20 CPI

PITCH: 24 CPI

PITCH: PROP.

PITCH: 1/2PROP.

........... Default character spacing is 10 cpi printing

The Proportional character width is twice the 1/2 Proportional width. In the Epson mode,

the print quality is changed to the high quality one. In the IBM or HP mode, print quality

does not change the print quality.

10 CPI

12 CPI

15 CPI (HP/ IBM)

15 CPI (EPSON )

16.7 CPI

17.1 CPI

20 CPI

24 CPI(EPSON )

24 CPI (HP/ IBM)

Character Picth

Print Sample

Proportional

1/2 Proportional

10 cpi

12 cpi

15 cpi (EPSON)

15 cpi (HP/IBM)

16.7 cpi

17 cpi

20 cpi

24 cpi (EPSON)

24 cpi (HP/IBM)

Proportional

1/2 Proportional

24 X 36

24 X 30

16 X 24

24 X 36(+12)

24 X 36(+7)

24 X 36(+6)

24 X 30(+6)

16 X 24(+6)

24 X 24(+6)

24 X N

24 X N

1/180 X 1/360

1/180 X 1/360

1/180 X 1/360

1/180 X 1/720

1/180 X 1/720

1/180 X 1/720

1/180 X 1/720

1/180 X 1/720

1/180 X 1/720

1/180 X 1/360

1/180 X 1/720

Character pitch

Dot-spacing (V x H) Character structure (V x H)

Letter Quality

29

4. Basic setup options (5)

Page 38

Enlarging/compressing print

Enlarges or compresses the text size.

Any setting other than 100% will cancel the double height printing mode. The relationships

between the paper sizes with their enlargement and compressing ratio are described below.

Note: The expansion displayed on the LCD has some allowance. Enlarged or reduced

characters are printed in a different font from the specified font.

6 ZOOM IN/OUT

ZOOM OUT: 66 %

ZOOM OUT: 79 %

ZOOM OUT: 83 %

ZOOM OUT: 91 %

NO ZOOM: 100 %

ZOOM IN: 116 %

ZOOM IN: 120 %

ZOOM IN: 141 %

ZOOM IN: 200 %

ZOOM IN: 400 %

ZOOM IN: 600 %

ZOOM IN: 800 %

ZOOM IN: 1000 %

ZOOM IN: 1200 %

ZOOM IN: 1400 %

ZOOM IN: 1600 %

100%

91%

79%

66%

116%

120%

141%

200%

400%

600%

800%

1000%

1200%

1400%

1600%

83%

4 point character size

66%

83%

79%

116%

120%

141%

B4 B5

A3 A4

B4 A4

A4 B5

A3 B4

B5 A4

B4 A3

A4 B4 A4 A3

ZOOM OUT

ZOOM IN

Note: This sample illustrates only a scale image.

30

4. Basic setup options (6)

Page 39

Setting top of form position

The top-of-form (TOF) can be set using this function, anywhere from a minimum of 0 inch to a

maximum of 480/60 inches (8 inches = 203mm) by increments of 1/60 inch.

Press the Up or Down arrow keys to increase or decrease the TOF setting, respectively. Press

the ENTER key to select the desired setting.

Note: Any improper setting of TOF position will set it back to the default value. The top of

form differs from the top margin in that the top of form determines the first line of the print

station where the top margin can be moved anywhere between the top of the form and the

bottom margin. See "40 TOP MARGIN" on page 47.

Loading user & factory setup options

Loads one of three user designed setup options to the current active memory. This will erase

and replace setup contents in the current memory. The printer has three setup storage areas that

can store different setups. If you need to save the current setups before replacement, it is

necessary to select the “86 SAVE SETUP” item in the extended setup options on page 56.

Note: When this setting is executed, the printer will be initialized.

8 SELECT SETUP

SETUP: MEMO 1

SETUP: MEMO 2

SETUP: MEMO 3

SET.: FACTORY

7 TOF ADJUST

TOF: + 0/60IN

TOF: +nnn/60IN

TOF: +480/60IN

Equivalent short cut operation can be performed when:

........... pressing the PARK key with the RESET key,

........... pressing the QUALITY key with the RESET key,

........... pressing the M.LF key with the RESET key.

........... Defaults to 14/60 inch

Note

When using settings less then 14/60", the printer is more susceptible to a paper jam,

depending on forms type being used.

31

4. Basic setup options (7-8)

Page 40

Factory Default Setting

Option Menu Factory Default

<Basic options>

1 MULTIPART NORMAL

2 PAGE FANFOLD 11"

3 PAGE SINGLE A4 PORTRAIT

4 FONT SELECT ROMAN

5 CHAR PITCH 10 CPI

6 ZOOM IN/OUT 100%

7 TOF ADJUST 14/60 INCH

<Extended options>

10 EMULATION EPSON

11 CHR TB HP ROMAN-8

12 CHR TB EPSON ITALIC

13 CHR TB IBM SET 1

14 NATIONAL FONT USA

15 CODE PAGE 437(USA)

16 AGM IBM NO

17 CR SETTING CR ONLY

18 LF SETTING LF+CR

19 LF PITCH 6 LPI

20 ZERO STYLE NO-SLASHED

21 TABULATION 8 CHAR.

22 PAGE LOCK NO

23 QUALITY LQ

24 FONT LOCK NO

25 PITCH LOCK NO

26 QLTY LOCK NO

27 BC/L.CHR MODE 1

28 BC TYPE CODE39

29 BC SIZE 1

30 LARGE CH.SIZE 8

31 GR QLTY MODE 2

32 ACCENT CHR SIMPLE

33 FF CODE/TOF YES

Option Menu Factory Default

38 PCL MODE PC L3+

39 CHR TB2 HP LINE-DRAW

40 TOP MARGIN 0 LINE

41 BOTTOM MARGIN 0 LINE

42 LEFT M. 0 COLUMN

43 RIGHT M. 0 COLUMN

44 PAPER WIDTH 15 INCH

45 AUTO SCROLL NO SCROLL

46 OVERRIDE BM YES

47 LABEL MODE NO

48 P.OUT DTCT ANY POS

49 CSF OPTION NOT INSTALLED

50 SCROLL POS ANY POS

51 LF SPEED NORMAL

60 INTERFACE PARALLEL

61 SLCT IN CMD NO

62 PARITY BIT NON

63 DATA LENGTH 8 BITS

64 STOP BIT 1 BIT

65 PROTOCOL D TR

66 BAUD RT 9600 BPS

67 SERIAL ERROR PRINT *

68 CTS ENABLE NO

69 CD ENABLE NO

70 DSR ENABLE NO

71 BUFFER SIZE 64 KB

72 BUSY/ACK TYPE 2

73 DATA LATCH TYPE F

74 ERROR STATUS YES

80 PRINT DIR BI-DIRECTION

81 DISPLAY LANG ENGLISH

82 INVERT DISP NO

83 SOFTWARE SET YES

84 RESET LOCK NO

85 SLEEP MODE YES

Option Menu CURRENT MEMO1 MEMO2 MEMO3

<Basic options>

4 FONT SELECT ROMAN COURIER COURIER COURIER

<Extended options>

10 EMULATION EPSON HP HP IBM

18 LF SETTING LF+CR LF ONLY LF ONLY LF ONLY

32 ACCENT CHR. SIMPLE COMPO. COMPO. SIMPLE

38 PCL MODE PCL3+ PCL3+ PCL3 PCL3+

61 SLCT IN ENBL NO NO NO YES

32

4. Basic setup options (8)

Page 41

About extended setup options

The extended setup options contain various setup options which are used less frequently than

the basic setup options. The function in these options are categorized to four functional blocks:

• Items numbering in 10's through 30's are for "Print enhancement" which defines the emulation

type or character tables.

• Items numbering in 40's and 50's are for "Paper handling enhancement" which defines the paper

characteristics or print area.

• Items numbering in 60's and 70's are for "Communication enhancement" which defines the

interface control parameters.

• Items numbering in 80's are for other functional items to "Miscellaneous".

For the overview of the extended setup options, refer to the extended setup options summary on

page 34 and 35.

Note: You may have noticed that some option numbers are skipped in the display. Those

skipped item numbers are reserved for special use and they do not affect regular operation of

this printer.

❏ To set this option

By pressing and holding the SETUP key when the RESET key is pressed, the printer enters the

extended setup options, where various functions including the basic setup options can be set.

The keys and operation method in the extended setup options are the same as those in the basic

setup options. However, when exiting from the extended setup options, the initialization of the

printer will be conducted by printing the RESET key.

Select functionSelect menu

Store selected function

Exit setup to offline

Enter extended setup options

POWER

ON LINE

P.OUT

RESET

TOF SET

EXTENDED SETUP

PARK

BIN

EXIT ENTER

SETUP ALT

QUALITY

M.RLF

M.LF

RLFLFTEAR OFF ON LINE

FF

33

5. Extended setup options

5. Extended setup options

Page 42

34

5. Extended setup options

B5 PORT

B5 LAND

A4 PORT *

A4 LAND

B4 PORT

B4 LAND

LETTER PORT

LETTER LAND

LEGAL PORT

LEGAL LAND

A3 PORT

A3 LAND

ROMAN *

SANS SERIF

COURIER

PRESTIGE

SCRIPT

OCR-B

OCR-A

GOTHIC

ORATOR

ORATOR-S

10 CPI *

12 CPI

15 CPI

16.7CPI

17.1CPI

20 CPI

24 CPI

PROPORTIONAL

1/2 PROPORTIONAL

66 %

79 %

83 %

91 %

100 % *

116 %

120 %

141 %

200 %

400 %

600 %

800 %

1000 %

1200 %

1400 %

1600 %

2

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

8.5

9

9.5

10

10.5

11*

11.5

12

12.5

13

13.5

14

14.5

15

15.5

16

16.5

NORMAL *

DARK 1

DARK 2

1

2

3

4

5

6

MEMO 1

MEMO 2

MEMO 3

FACTORY

TOP OF FORM

+ n/60 inches

0 ≤ n ≤ 480

Default: n=14

7

8

CR SETTING

CR SETTING

CR ONLY *

CR+LF

AUTOFEED

17

LF SETTING

LF SETTING

LF ONLY

LF+CR *

18

LF PITCH

PITCH

6 LPI *

8 LPI

9 LPI

3 LPI

4 LPI

19

ZERO STYLE

ZERO STYLE

NO-SLASHED *

SLASHED

20

PAGE LENGTH

LOCK

PAGE LOCK

NO *

YES

22

PITCH LOCK

NO *

YES

25

PITCH LOCK

QUALITY LOCK

NO *

YES

26

QUALITY LOCK

27

BARCODE/

ENLARGED

CHARACTER

BC/L.CHR

IGNORED

MODE1 *

MODE2

Next page

MULTIPART

PAGE LENGTH

(FANFOLD)

PAGE LENGTH

(SINGLE)

FONT SELECT

CHARACTER

PITCH

ZOOM IN/OUT

TOF

ADJUSTMENT

SELECT SETUP

MEMORY

The asterisk (*) indicates

the factory default setting.

●Basic setup options #1-#8 ●Extended setup options #1-#87

Press both the SETUP and RESET keys to enter the extended setup options.

EMULATION

EMULATION MODE

EPSON *

IBM

HP

10

CHARACTER

TABLE (EPSON)

CHARACTER

TABLE (IBM)

CHARA.TABLE

ITALIC *

GRAPHICS

DOWNLOAD

CODE PAGE

CHARA. TABLE

CHAR.SET1 *

CHAR.SET2

12

13

BARCODE

TYPE

28

BARCODE TYPE

INDSTRIAL 20F5

INTERLEAVED 20F5

MATRIX 20F5

CODABAR

CODE11

CODE39*

CODE93

CODE128

EAN8

EAN13

UPC-A

UPC-E

POSTNET

ELEMENT

FONT LOCK

24

FONT LOCK

NO *

YES

QUALITY TYPE

LQ *

NLQ

HQDR

23

QUALITY

TABULATION

TABULATION

2 CHAR.

4 CHAR.

6 CHAR.

8 CHAR.*

10 CHAR.

12 CHAR.

21

CODE PAGE

CODE PAGE

437:USA *

850:MULTILINGUAL

857:TURKEY

858

860:PORTUGAL

861

15

AGM

(IBM)

ALTERNATE GRAPHIC

NO *

YES

16

NATIONAL

FONT

SPAIN

JAPAN

NORWAY

DENMARK2SPAIN 2

LATIN AMERICA

KOREA

TURKEY

LEGAL

NATIONAL FONT

USA *

FRANCE

GERMANY

U.K.

DENMARK

SWEDEN

ITALY

14

CHARACTER

TABLE (HP)

EMULATION MODE

11

ROMAN-8 *

CODE PG

PC-8D/N

ECMA

LEGAL

SWEDEN1

SWEDEN2

SPAIN

FRANCE

GERMAN

U.K.

PORTUGAL

NORWAY1

NORWAY2

IRV

ITALY

FRANC2

GERMAN2

SPAIN2

SPAIN3

JAPAN

PORTUGAL2

32

ACCENT CHAR

PRINT METHOD

SIMPLE*

COMPO

GRAPHIC PRINT

MODE

PRINT SPEED

MODE1

MODE2*

MODE3

31

ENLARGED CHAR

SIZE

30

1

2

4

8*

12

16

24

32

BARCODE

SIZE

1*

1.5

2

2.5

29

DRAFT

S.D

S.S.D.

863:CANADIAN-FRENCH

865:NORWAY

BRASCII

ABICOMP

ISO-8859-1

Exte nde d s e t u p o p t i o n s summary

Page 43

35

5. Extended setup options

3434

FF CODE

AT TOF

VALID

YES*

NO

33

3736

LABEL MODE

LABEL MODE

NO *

YES

47

P.OUT

DETECTION

DETECTION

ANY POS*

PAGE END

48

INTERFACE

INTERFACE

PARALLEL*

SERIAL

AUTO

60

STOP BIT

STOP BIT

1 BIT *

2 BITS

64

62

SELECT IN

CMD

SELECT IN COMMAND

YES

NO *

I/F

61

PARITY BIT

PARITY

NONE *

EVEN

ODD

63

DATA LENGTH

LENGTH

8 BITS *

7 BITS

BUSY /ACK

TIMING

TIMING

TYPE 1

TYPE 2 *

TYPE 3

72

BAUD RATE

BAUD RATE

38400 BPS

19200 BPS

9600 BPS *

4800 BPS

2400 BPS

1200 BPS

600 BPS

300 BPS

66

67

SERIAL ERROR

ERROR

PRINT *

IGNORED

68

CTS ENABLE

CTS SIGNAL

NO *

YES

70

DSR ENABLE

DSR SIGNAL

NO *

YES

CD ENABLE

CD SIGNAL

NO *

YES

69

INVERT

DISPLAY MODE

INVERT

NO *

YES

82

RESET KEY

LOCK

RESET KEY LOCK

NO *

YES

84

SLEEP MODE

SLEEP

YES*

NO

85

SAVE SETUP

SAVE

MEMO 1

MEMO 2

MEMO 3

86

SOFT WARE

SETUP

SOFTWARE

COMMAND

NO

YES *

83

SETUP MENU

LIST

LIST

MAIN *

EXTENDED

ALL SETUP

FACTORY

87

40

TOP MARGIN

TOP MARGIN

+ n LINE

0 n 15

DEFAULT: n=0

42

LEFT MARGIN

LEFT MARGIN

+ n COLUMN

0 n 63

DEFAULT: n=0

FANFOLD

PAPER WIDTH

WIDTH

15 INCH *

10 INCH

5 INCH

44

RIGHT MARGIN

43

RIGHT MARGIN

+ n COLUMN

0 n 63

DEFAULT: n=0

Previous page

3535

OVERRIDE BM

46

OVERRIDE

NO

YES *

AUTO SCROLL

NO SCROLL *

0.5 SEC

1 SEC

5 SEC

10 SEC

15 SEC

45

AUTO SCROLL

DATA LATCH

TIMING

STROBE

TYPE F.*

TYPE R.

73

ERROR

STATUS

STATUS SIGNAL

YES*

NO

74

PRINT

DIRECTION

80

DIRECTION

PRE-DIRECTION

UNI-DIRECTION

BI-DIRECTION *

DISPLAY

LANGUAGE

LCD LANGUAGE

ENGLISH *

DEUTSCH

FRANCAIS

ESPANOL

ITALIANO

81

CHR TB2 HP

LINE DRAW *

MATH-7

39

2ND CHARACTER TABLE

PROTOCOL

65

PROTOCOL

DTR *

XON/XOFF 1

XON/XOFF 2

ETX/ACK

71

BUFFER SIZE

BUFFER

64KB *

8KB

128B

41

BOTTOM MARGIN

BOTTOM MARGIN

+ n LINE

0 n 15

DEFAULT: n=0

PCL MODE

38

PCL MODE

PCL3+ *

PCL3

PCL3+D

50

AUTO SCROLL

VALID POSITION

ANY POS *

TOF ONLY

51

LF SPEED

LF SPEED

NORMAL*

1/2

CSF OPTIONS

CSF TYPE

NOT INSTALLED *

SINGLE

DOUBLE

49

Page 44

Print enhancement

Emulation

The desired emulation mode of the printer can be selected using this function.

Character table (HP mode)

This function selects one of character sets provided in the HP emulation.

10 EMULATION

EML: EPSON

EML: IBM

EML: HP

........... Epson LQ-2550 compatible

........... IBM 2391 compatible

........... RuggedWriter 480 compatible

(HP SET,1U)

(ISO-25,0F)

(HP SET,OG)

(HP SET,1S)

(ISO-85,6S)

(ISO-84,5S)

Setup menu #15 CODE PAGE:

CODE PAGE 437 PC-8(10U)

CODE PAGE 850 PC-850(12U)

CODE PAGE 857 TURKEY

CODE PAGE 858 EURO SYMBOL

CODE PAGE 860 PORTUGAL

CODE PAGE 861 ICELANDIC

CODE PAGE 863 CANADIAN-FRENCH

CODE PAGE 865 NORDIC

CODE PAGE BRASCII

CODE PAGE ABICOMP

ISO-8859-1

ROMAN-8 (8U)

CODE PAGE

PC-8 (11U)

(ISO 8859-1,0N)

(ISO-10,0S)

(ISO-11,3S)

(ISO-17,2S)

(ISO-69,1F)

(ISO-21,1G)

(ISO-4,1E)

(ISO-16,4S)

(ISO-60,0D)

(ISO-61,1D)

(ISO-2,2U)

(ISO-15,0I)

(ISO-14,0K)

PCL3, PCL3+, PCL3+D mode

TBL: ROMAN-8

TBL: CODE PG

TBL: PC-8D/N

TBL: ECMA

TBL: LEGAL

TBL: SWEDEN1

TBL: SWEDEN2

TBL: SPAIN1

TBL: FRANC1

TBL: GERMAN

TBL: U.K.

TBL: PORTU1

TBL: NORWAY1

TBL: NORWAY2

TBL: IRV

TBL: ITALY

TBL: FRANC2

TBL: GERMN2

TBL: SPAIN2

TBL: SPAIN3

TBL: JAPAN

TBL: PORTU2

See page 38

11 CHR TB HP

36

5. Extended setup options (10-11)

Page 45

Character table (Epson mode)

This function selects one of character sets provided in the Epson emulation.

Character table (IBM mode)

This function selects between the IBM character set 1 and set 2.

Refer to the character set tables in Appendix C.

12 CHR TB EPSON

TBL: ITALIC

TBL: GRAPHIC

TBL: DOWN LD

TBL: CODE PG

13 CHR TB IBM

TBL: SET 1

TBL: SET 2

........... Sets italic table (see page 127)

........... Sets graphic table (see page 127)

........... Sets user defined download table

........... This selection replaces the ASCII character area 80h-FFh

with the code page selected in "15 CODE PAGE"

........... Sets IBM character set 1 table (see page 128)

........... Sets IBM character set 2 table (see page 129)

37

5. Extended setup options (12-13)

Page 46

National font style

One of the following 16 national fonts can be selected.

Code page

The default code page can be selected using this function. Refer to the code page table in

Appendix C.

15 CODE PAGE

C.P.: 437

C.P.: 850

C.P.: 857

C.P.: 858

C.P.: 860

C.P.: 861

C.P.: 863

C.P.: 865

C.P.:

BRASCII

C.P.:

ABICOMP

C.T.: ISO-1

........... USA (see page 133)

........... Multilingual (see page 133)

........... Turkey (see page 133)

........... Multilingual Euro symbol(see page 134)

........... Portugal (see page 134)

........... Icelandic (see page 134)

........... Canadian-French (see page 134)

........... Norway (see page 135)

........... BRASCII (see page 135)

........... ABICOMP (see page 135)

........... ISO-8859-1(see page 135)

14 NATIONAL FONT

CNTRY: USA

CNTRY: FRANCE

CNTRY: GERMANY

CNTRY: U.K.

CNTRY: DENMRK

CNTRY: SWEDEN

CNTRY: ITALY

CNTRY: SPAIN

CNTRY: JAPAN

CNTRY: NORWAY

CNTRY: DNMRK 2

CNTRY: SPAIN 2

CNTRY: LATN AM

CNTRY: KOREA

CNTRY: TURKEY

CNTRY: LEGAL

ASCII HEXADECIMAL

23 24 40 5B 5C 5D 5E 60 7B 7C 7D 7E

38

5. Extended setup options (14-15)

Page 47

IBM Alternate graphic mode (AGM) (Valid in IBM mode)

This function enables the IBM emulation to work similar to the Epson emulation in high

density graphics. The table below describes the differences in their related control codes.

Carriage return (CR)

A carriage return (ASCII code 0Dh or 13) causes data in the buffer to be printed and the

carriage to be moved to the left most print position at the same line. The following option can

be selected when issuing a carriage return. Refer to the specification of your application for

correct selection.

Note: Autofeed is effective for the system using parallel interface with AUTO FEED signal to

control the the carriage return with or without a line feed. The autofeed signal must be low