Seiko BBW Instruction Manual

INSTRUCTION

MANUAL

BBW

Series

SEIKO SEWING

MACHINE

CO.,

LTD.

Thank

the safety instructions

With

parts

you

very

industrial

suchasthe

much

sewing

needle

for

buyingaSEIKO

below

and the explanations

machines,itis

and

^read

that can be causedbythese parts,-

regarding

correctly.

safe

and

correct

operkion

sewing

machine.

normaltocarry

take—up

Follow

before

lever,

the instructions

operating

Before

given

inthe instruction

out

work

and

consequently

from

the

machine

using

while

training

sothat

your

new

manual.

positioned

machine,

directlyinfrontofmoving

please

read

thereisalwaysadangerofinjury

personnel

you

will

and

instructions

know

howtouse

it

1.

Safety

This

indications

instruction

manual

inorder to ensure safe

people.

Indications

The

meaningsofthese

A CAUTION

Symbols

0

...

SAFETY

and

their

meanings

and

the

indications,

operation

This

symbol

cates

the

(Forexample,the

This

symbol

This

symbol

of

the

thing

(For

example,

ofthis

indications and symbols are given below.

The

instructions

could

cause

ings.

(A)

natureofthe

(0)

(•)

that

the

and

machine

which

injury

when

indicates

symbolatleft

indicates

indicates

mustbedone.

something

caution

something

something

symbolatleft

INSTRUCTIONS

symbols

andto preventaccidents and

follow

that

means "bewareof

means

that are

this

using

term

the

machineorphysical

that

you

mustbetaken.

that

you

that

you

"you

used

onthe

indicate

situations

- .

shouldbecareful

injury".)

must

not

do.

must

do.The

must

make

the

picture

ground

machine

itself

are

irijurytoyourself

where

failuretofollow

damagetoequipment

of.

The

picture

inside

inside

the

circle

indicates

connection".)

provided

or other

the

instmctions

and

surround

the

triangle

the

indi

nature

2.

o

o

Notes

a

o

on

safety

A CAUTION

Environmental

•

Use

the

sewing

fromsourcesofstrongelectricalnoise such ^

frequency welders.

Sources of strong electrical noise maycause prob

lems

with

•

Any

fluctuations inthe powersupplyvoltageshould

within

be

chine.

Voltage

cause

• The

the requirements lorthe sewing machine's electri

cal consumption.

Insufficient

lems withcorrect operation.

• Thepneumatic

than the requirements lor the sewing machine's total

air consumption.

Insufficient

problems with correct operation.

fluctuations

problems withcorrect operation.

power

machine

correct

±10%

operation.

ofthe rated voltage lor the ma

supply

power

supply

delivery

pneumaticdeliverycapability maycause

in art

area

which

are

greater

capacity

should

begreaterthan

capacitymaycause prob

capability

shouldbe greater

whichisfree

than

this

higli-

may

requirements

•,

The^amblenl

^of

§*Cto95*C

Temperatures

maycause problems

•

The

relative

o

o

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation

lion.

•

Avoid

Exposuretodirect

withcorrect operation.

•Inthe

and disconnect the powercord

Lightning

tion.

may

exposuretodirect

event

may

temperature

during

use.

which

are

with

humidity

ofan

shouldbewithin

cause

problems

sunlight

electrical

cause

problems

shouldbewithin

lowerorhigher

correctoperation.

the

with

correct

sunlight

may

storm,

during

cause

turn

from

with

off

the

wall

correct

the

range

than

this

range

of

opera-

use.

problems

the

power

outlet.

opera

A

CAUTION

Installation

Q

O

0

Q

O

0

• Machineinstallation shouldonlybe carriedout by

a qualified technician.

•

Contact

cian

done.

• The

installation

people.

• Do not connect the powercord

your

for

any

sewing

SEIKO

dealerorqualified

electriacal

machine

shouldbecarried

work

weighs

that

more

out

until

eloctri-

may

needtobe

than52kg.

by two or

installation is

"Hie

more

complete, otherwise the machine mayoperate

the treadle is depressed by mistake,

result in injury.

• Be

sure

to connect the ground.Ifthe ground con

nection is notsecure, you runa high

inga serious

rect operation may also occur.

• All

cords

from

any

electric

shouldbesecuredatleast25mm

moving parts. Furthermore, do not ex

shock,

and

cessively bend the cords orsecure themtoo

vkrith

staples, otherwisethere is the danger that fire

or

electric

shocks

could

occur.

which

riskofreppiv-

problems

with

could

cor

away

finnly

Sewing

• install

• Ifusing a worktable which has casters, the casters

o

•

A

the

belt

guards

motor.

should

besecured insuch a wayso that

not

move.

Use

both

hands

tilting

itback orreturningittoits

only

one

hand is

to the

machine

to hojd

the

machine

original

used,

the weight of the machine

head may cause your hand to slip, and

may get caught.

head

they

head

position.

your

and

can

when

If

hand

if

• Be

sure

0

to wear protective goggles

handling

ydiir

tion

Furthermore, do not drink the oilunderanycircum

stances,asthey

Keep

eyes or

can

result

the

the

lubricating oil,sothat

onto

your

skin,

can

cause

oilout of

the

reach

othenwise

vomiting

of children.

and

gloves

when

no oilgets into

inflamma

and

diarrhoea.

0

0

A

• This sewing machineshould only be used by op

erators

in

• The

applications

• Turn off the power switch at the

otherwise the machine may operate ifthe treadle

is

jury.

•

•

• Wheri not using the machine and when leaving

• When using a clutch motor, the motor

• Ifusing a work table which

shouldbesecuredinsuchawaysothat

not

who

have

safe

sewing

use

received

beforehand.

machine

other

than

should

sewing.

the

necessary

training

notbe usedfof'any

following

depressed

When

When

the

machine

turning even after the power is switched off

resultofthe

stops

move.

by mistake, which could result in in-

threading

replacing

fully

unattended

motor's

before

the

needle

the

bobbin

inertia.

starting work.

has

and

needle

Wait

casters,

until

the

the

will

casters

they

times,

keep

as

motor

can

• Attach all safety,

A

A

A

O

a

o

machine.Ifthe

vices attached, injury

• Do not touch

objects

may

chine.

•

Use

tiltingit back or returning itto its original position. If

only

head

may get caught.

• Ifan error occurs in

mal noises or smells

offthe power switch. Then contact your nearest

SEIKO dealer or a qualified technician.

• If

nearest

against

resuitinpersonal

both

one

hand is

may

the

machine

SEIKO

devices

machineisiised

anyofthe

the

before using the sewing

may

result.

moving

machine

partsorpress

while sewing,asthis

injuryordamagetothe'

handstohold

cause

develops

dealerora qualified technician.

the

machine

used,

the weight of the machine

your hand to slip,

machine

are

operation,or ifabhoi~

noticed, immediatelyturn

a ploblem,

without

and

contact

head

your

these

your

de

any

ma

when

hand

A

Q

A

CAUTION

Cleaning

Turn

off

tfiepowerswitchbefore carrying outclean

ing, otherwise the machine may operate ifthe

treadle is pressed by

injury.

* When using a clutchmotor, the motor

turningeven after the poweris switched

resultofthe

stops

fully

before

KIfusinga worktable which has casters, the casters

shouldbesecuredInsuch

not

move.

motor's

mistal<e,

inertia.

starting

work.

a waysothat they

which

Wait

until

couldresult in

4,;.

will

Keep

offasa

the

motor

can

A

0

Use

both

handstohold

tilting

itback or returning ittoKsoriginal

onlyone hand is used, the weight of the machine

head may

may get caught. ' '

Besure to wear protectivegogglesand gloveswhen

handling the lubncating oil,so that no oilgets into

your

tion

Furthemnore, do not drink the oil under any circum

stances,asthey

Keep

eyesor

can

result.

the

cause

onto

can

oil out of

the

machine

head

when

position.

your hand to slip, and yourhand

your

skin,

cause

the

otherwise

vomitingand diarrhoea.

reach

of children.

infl^mfha-

If

A

A

A

Maintenance

• I^Aaintenance

shouldonlybe carried out by a qualified technician.

• Askyour

carry out anymaintenance andinspection ofthe

electrical

• Tum off

cord

from

. erwiise

depressed

•

When

•i'

*

When

. turning

resultofthe

...

stops

•

Disconnect

waitfor

to

'O'

and

repair of any parts, which

equipment. ^ .

• if the power switch and air

carrying out

fulto observe allsafety precautions. ^ -

and

inspection of

SEIKO

dealeror a

system.

the

power switch

the

wall outletatthe

the

machine

by mistake, which could result in injury.

carrying out inspection, adjustment

may

usingaciutch

even

after

the

motor's

fullybefore starting work.

the

air

the

needleonthe

before

hoses

carrying

some

adjustment, be extremely

the

sewing machine

qualified

and

operateifthe

motor,

power is switched offasa

inertia.

from thie air

pressure

out

inspection,

need

eloctrician to

disconnect the

following times, oth-

the

motor

Wait

until

supply

gaugetodrop

adjustment

use

the pneumatic

to be lefton when

treadle

will

the

power

and

keep

motor

and

care

and

is

Inspection

• Ifusing a work table which

o

A

O

Q

0

. shouldbesecuredinsuch

not

•

Use

tilting

>only

headmay

may

•

When

touch moving parts

and needle

- them with other objects, otherwise injury or darn-

age tothe machine may

•

-Use

fied by SEIKO '

• Ifany safety devices

solutely

sitions

fore using

• Any problems in machirie operation which result

from

not be covered by

move.

both

handstohold

itbackor

one

hand is

cause

get

caught

checking

only

the

sure

and

the

unauthorized

has

casters, the ciasters

a waysothat they

the

returning

used,

your hand to slip;

•

the

rotary hook lubrication, do not

suchasthe rotary hook, needle

bar

with your finger or

pepper

replacement

to re-install them to their original po

check

that

machine.

modificationstothe

the

machine

ittoits

the

weight of the machine

result.

.

v.;

have

been

they

operate

warranty.

head

original

' : .

positiOni

and

your hand

paper

nor push

•

partsas

speci

removed, be ab

correctly be

machine

can

.yvhen

If

will

★

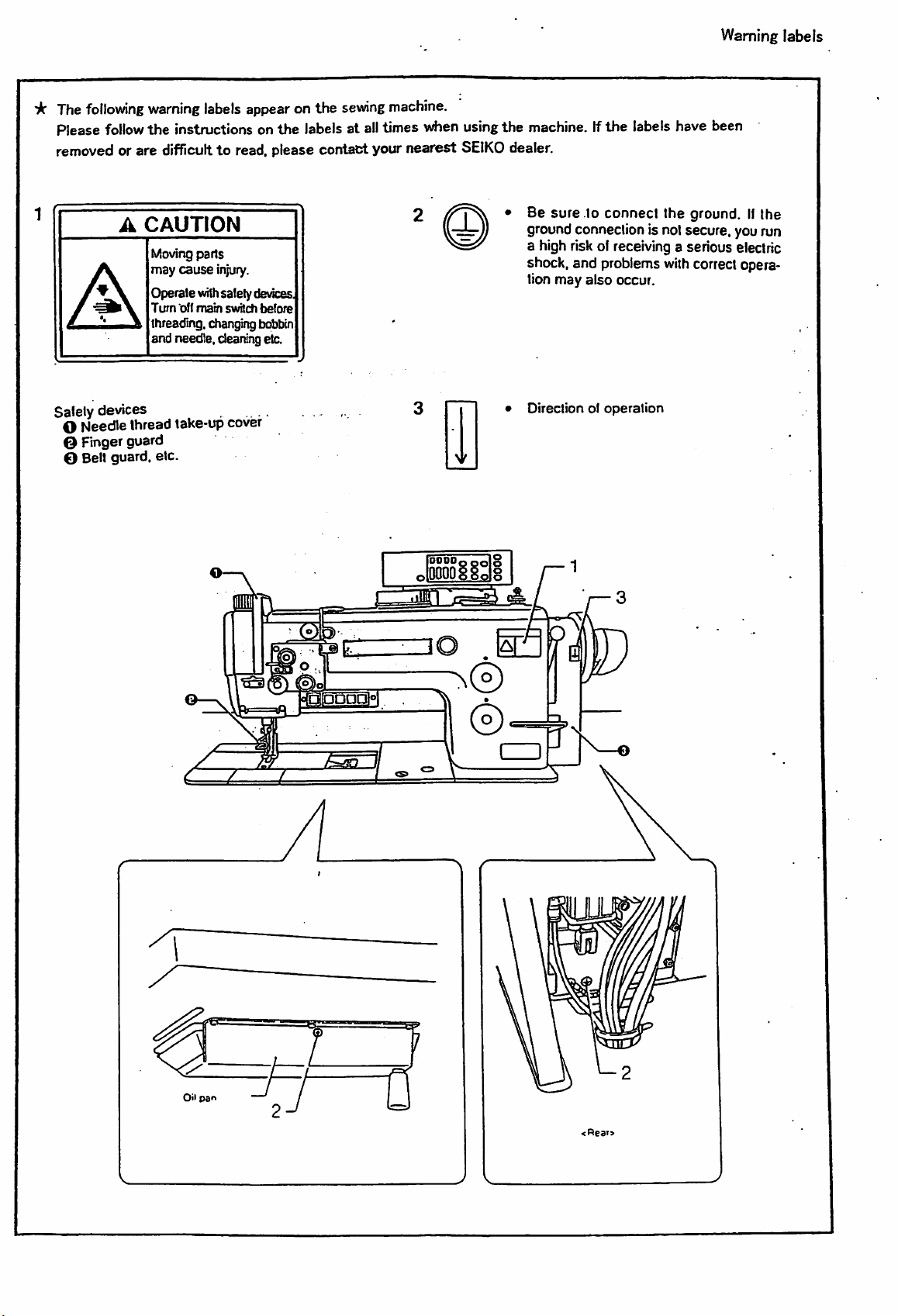

The

following

Please

follow

warning

the

labels

instructions on

appearon the

the

labels at alltimes when using

sewing

machine.

removed or are difficultto read, please contact your nearest

CAUTION

A

t^oving parts

may

cause

injury.

Operate

wifti

oft

main

safetydeuces.

switch

before

tx}bbin

A

Salety devices

Turn

threading,changing

and needle, deaning etc.

O Needle thread take-up cover

© Finger guard

0 Belt guard, etc.

SEIKO

the

machine. If

the

labels have been

dealer.

Be

suretoconnect

ground connection is notsecure, yourun

a high

risir

ol receiving a serious electric

shock, and problems

tion may also occur.

•

Directionotoperation

the ground.IIthe

with

correctopera

Warning labels

I

Oil

Pd^

<He3f>

1.

NAMES

2.

MACHINE

3.

WORK

4.

MOTOR

5.

INSTALLATION

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

TABLE

Rubber

Oil pan

Machine

V-belt

Belt

Operation

for

Air

for

5-7-1.

5-7—2.Adjusting

5-8.

Cotton

5-9.

Knee

5-10.

Knee

5-11.

Ground

for

3.

LUBRICATION

7.

CHECKING

ROTATING

3.

ADJUSTING

POSITION

7.

PREPARATION

9-1. Installing

9-2.

Removing

9-3.

Winding

9-4.

Installing

9-5.

Threading

9-6.

Adjusting

9-7.

Adjusting

9-8.

Alternating

9-9.

Using

9-10.

Using

10.

SEWING

10-1. Sewing

10-2. Backtacking

OF

MAJOR

SPECIFICATIONS

AND

cushion

PARTS

V-BELT

head

guard

panel

8BLC/28BLC-BTFL-CD-DS

unit

8BLO/28BLC-BTFL-CD-DS

Installation

the

air

pressure

stand

lifter

switch

vdre

connection

8BLC/28BLC-BTFL-CD-DS

THE

MACHINE

DIRECTION

THE

NEEDLE

BEFORE

the

needle

the

bobbin

the

lower

the

bobbin

the

upper thread

the

stitch

the

stitch length

for

8BLC/28BLC-BTFL-CD-DS

presser

the

manual

for

8BLC/28BLC-BTFL-CD-DS

the

knee

for

8BLC/28BLC-BTFL-CD-DS

SEWING

thread

length for 8BLy28BL

foot movement amount

switches

swKch

PULLEY

STOP

CONTENTS

11. THREAD TENSION 29

11-1. Adjusting

11~2.

11-3. Adjusting the traiiinglength afterthread

12. CLEANING 32

12-1. Dailycleaning

5

6

6

7

7

8

10

10

10

11

12

13

13

14

15

17

18

19

19

20

21

22

23

24

24

25

25

27

28

28

12-2.

13. STANDARD ADJUSTMENTS 35

13-1.

13~1~L

13-1-2.

13-1-3.

13-1-4.

13-1-5. Adjusting

13-1-6.

13-1—7.

13-1-8.

13-H9.; Adjusting

13—1—10.

13-2.

13-2-1. Adjusting

13-2-2. Adjusting

13-2-3.

13-2—4.

13-2—5.

13-2—6.

13-2-7.

13-2-8.

13-3. Adjusting

13-4. Replacing

14.

REPLACING

(CHANGING

15. INSTALLING THE CONVERSION PARTS

SET(SINGLE NEEDLE TO TWIN

NEEDLE)

16. SAFETY EQUIPMENT 66

17. TROUBLESHOOTING 67

17-1.

17-2. Thread timming

the

thread

tension 29

Adjusting

trimirong

Cle^aning

the presserfoot pressure 30

for

8BLC/28BLC-BTFL-CD-DS

procedures

the

oilfilter

31

32

(carry out once a month) 34

Afjjusting

. hook timing

Adjusting

28BLO-BTFL-CI^DS

Machine

for

the

machine head 36

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

the thread tension

spring

36

the feed dog height 37

the needle bar height 37

the needleand rotary

38

the

needle guard position 39

the

needle

and

feed

mechanisim timing 30

Adjusting

Adjusting

movement

Acljusttng

Adjusting

Adjusting

Adjusting

position

Adjusting

position

Adjusting

Adjusting

the

opener position 40

the presserfoot height 42

the

aHematingpresser foot

amount

the

the

presserfoot

thread

trimmer

timing

for

BBLO/

'

the

fixed knife position 46

the

knifetimingposition 46

the

driving

knife

height 47

the drtvingknife stop position 48

the

driving

knifeoperating

the thread

the thread

the

the

rotary hook lubrication amount 52

the

timing belt 53

GAUGE

THE

NEEDLE

head

tension

PARTS

holding

spring

trimming

release

GAUGE)

timing

amount

43

45

46

49

50

50

51

erros

8BLC/28BLC-BTFL-CD-DS

57

60

67

72

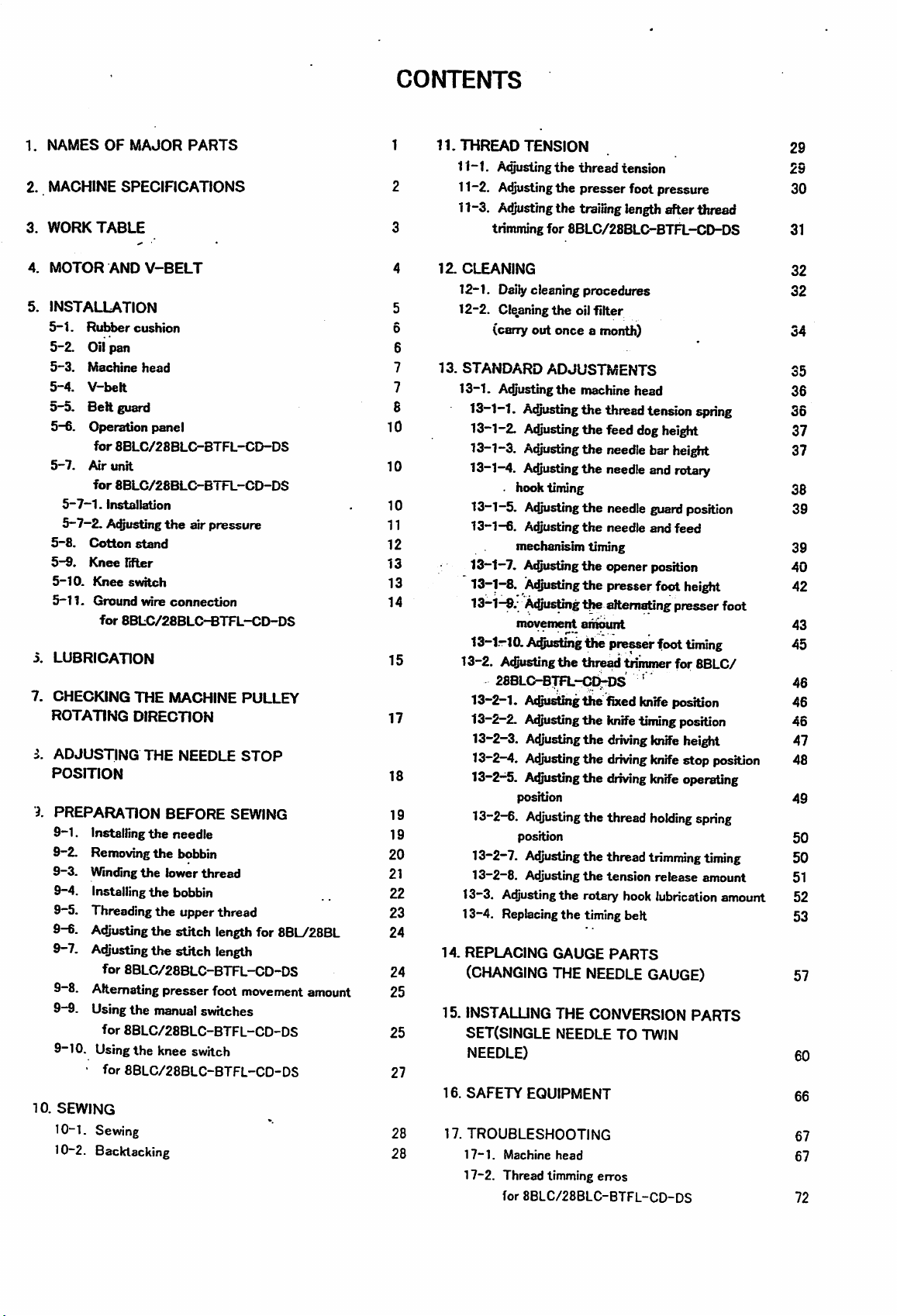

1.

NAMES

OF MAJOR PARTS

1.

NAMES

OF

MAJOR

PATS

)0

*

_ g

V-.

O

O Allernaling

dial

presser

O Machine pulley

O

Feed

adjustment dial

® Outei presser loot

Salely

devices

® Fingei guard

loot movement

© Operation

©

Presser

O

Manual

®

Feed

dog

(D

Thread

panel

lifter

bar

switch

taKe-up

cover

Bobbin

O

Reverse

O Inner

© Safety

0

Bell

winder

lever

presser

clutch

guard

toot

mechanism

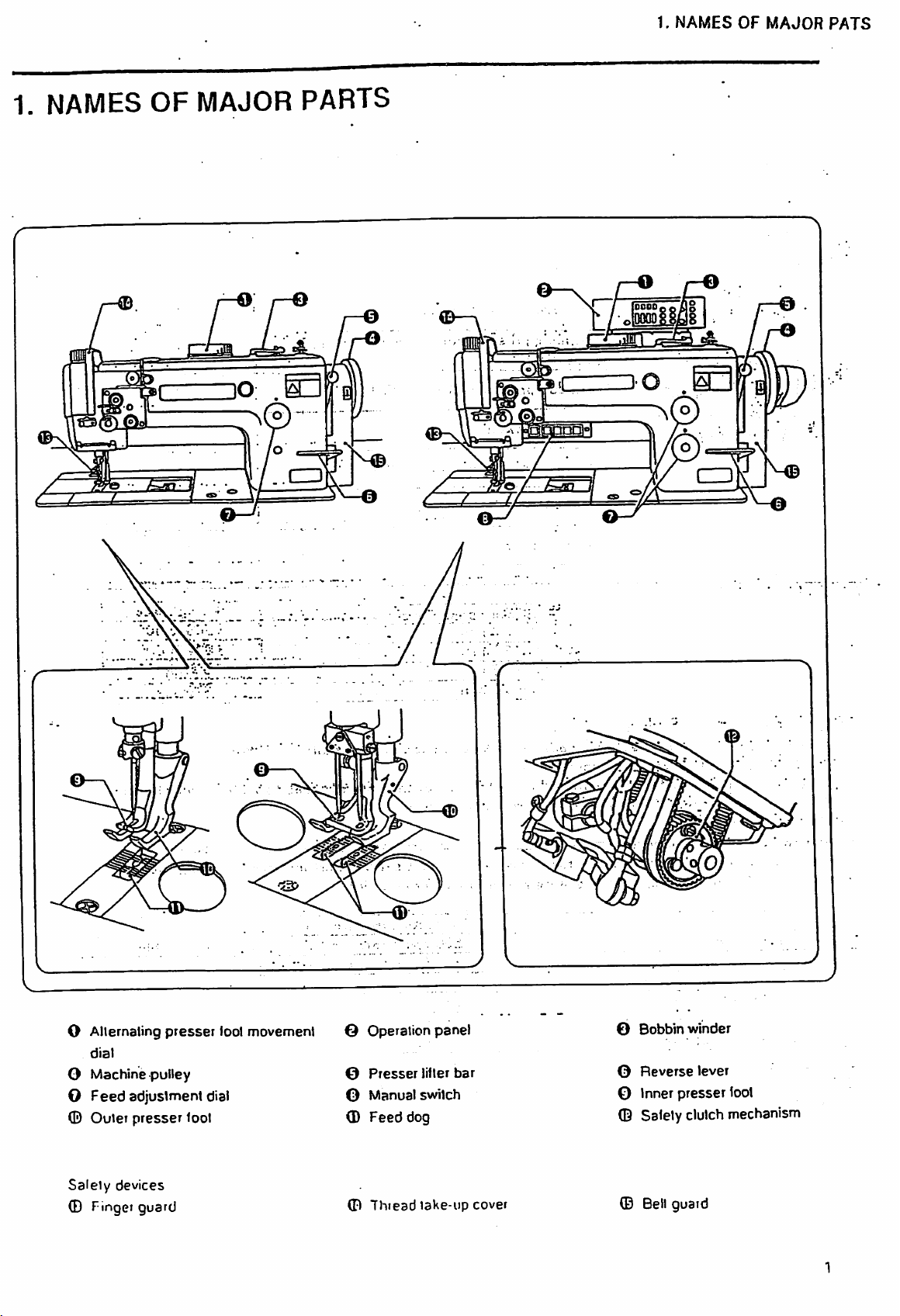

2. MACHINE

2.

MACHINE

SPECIFICATIONS

SPECIFICATIONS

r

Sewing

BBW-8BLC-BTFL-CD-

DS

SEIKO

MACHINE

>

ONE

BBW-28BLC-BTFL- ^

, SBKO

MACHINECOLTD

TWO

speed

SEWING

CO

NEEDLE

CD-OS

SEWING

NEEDUE

table

LTD

^

J

J

Thread

Quick

Alternating

switch

Automatic

Half

Stitch

trimmer

reverse

(do)

sthch

length

pres^r

presser

switch

Aiito backtack

Operation

p^el

Alternating

1.0-2.4

2.5-3.9

4.0-4.7

4.8-7.0

(C)

switch (BT)

foot

foot

change

select

presser

mm

mm

mm

mm

switch

switch

movement

lifter (PL)

(DS)

foot

movement

change

amount

(2)8BL

-

-

-

- V

- •;

-

CO-DS

o

o

(2)8BLC

o

o • - ;

o

p

o

o

Sewing

3,500.

3.000

2500.

2.000

speed

0

-

-

-

-

-

<-(2)8BLC-BTFL-CD-DS

The

sowing

speediscontrolled

SPECinCAT10NS>

automatically

to the

attemating presser foot movement amountsetting.

*

However,ifsewing

the motoror onthe

<-{2)8BL

Setthe

accordance

stitch

Use

Maximum Sewing

Maximum

Presser

Aitemating

Peed

Needle

Ann

Standard needle gauge

SPECIRG^ONS> ;

sewing

with

length

dog

pocket

of6

strtch

foot height

presser

height

size

withastitch

operation

speedbothe

the

alternating

mmormore,

speed

ienjrt

h

Presser

Knee

Automatic

foot

movement

(-28BL/-28BLC-BTFL-CD-DS)

value

bar

lifter

length

panel

before

whichisequal

presser

set the

sewing

lifter

presser

amount

of6

mmormore,

canying

foot

movement

speedto2,000

foot

lifter

values

to or

showninthe

set

out

sewing

less

amount

than

the

the

setting.

rpmorless.

Car

seats,

furniture,

3500 spm (Refer to

9 mm (both forward and

9

mm

16

mm

16

mm

1-7

mm

0.5

mm

DP X 17 (#22)

300

mm

3

mm

4

mm

6

mm

8

10

12

tableinaccordance

sewing

speedto2,000

value

showninthe

Furthermore,ifsewing

bags.

etc.

the

"Sewing Speed Table*'0

reverse)

mm

mm

mm

with

rpmorless

table

in

with

the

on

a

3.

WORK

TABLE

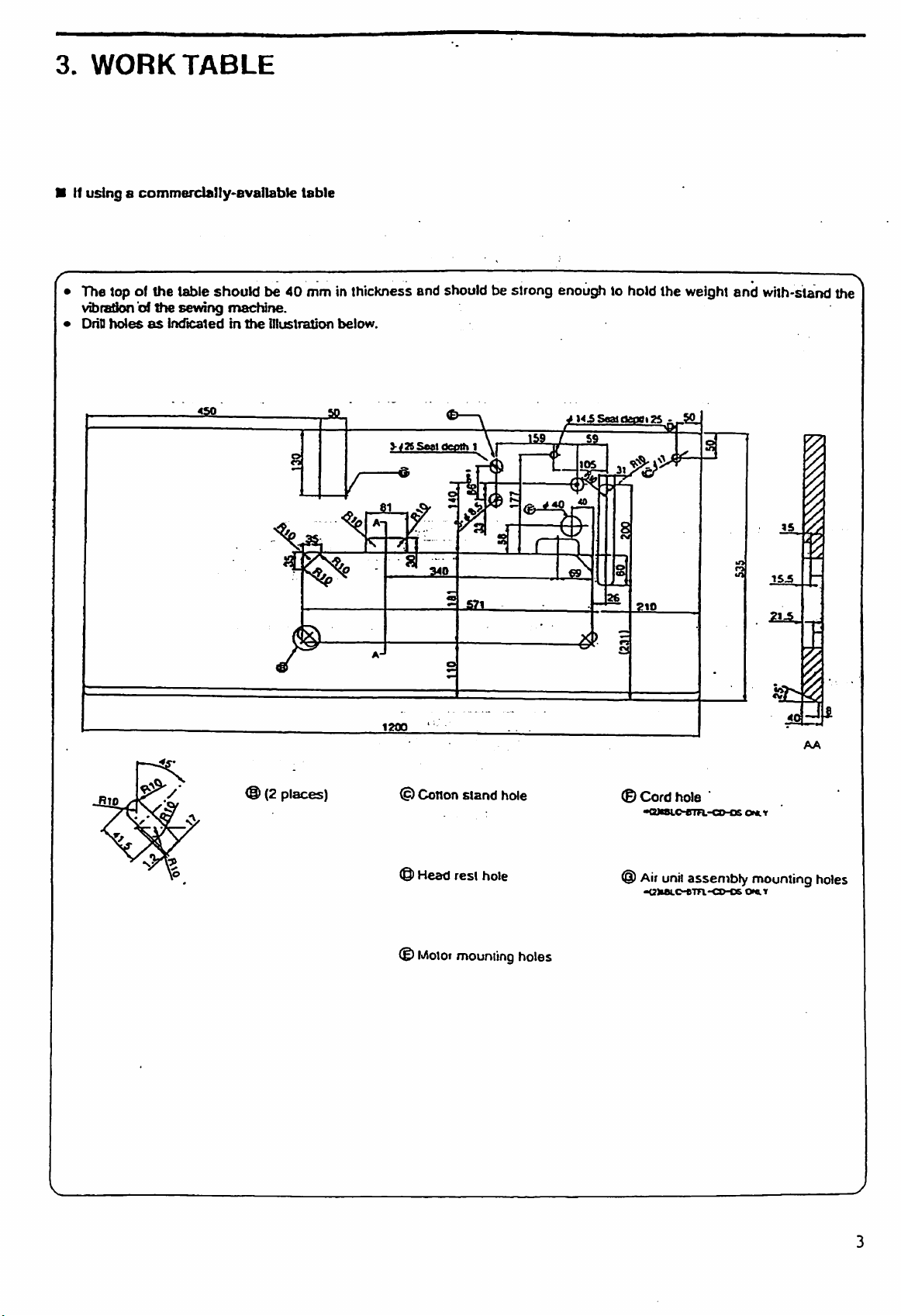

• IIusing a commerdally-Bvallabte

• The top of the table

vibrafim of

• DriD

holes

the

as

should

sewing

indicatedinthe

macNne.

4S0

be 40 mm in thickness and should be strong enough to hold the weight

illustration

table

below.

50

and

with-stand the

.^l4SScaiOeodi25

1S9

/

L_105

440«

sT

rU^-

8

depth

1

r—hK

81

<&

J

340

JSZl.

CT

26

glO

1S.5

213

(§>

(2 places)

1200

© Gotton

(§)

©

Head

Molot

stand

rest

hole

mounting

hole

holes

-t=^ rjj

©Cord

•ca>8).c-eTn.-Go-os

(§)

Air

unit

-OMLC-eTFl-CD-OS

hole

assembly

dn

ONLY

mounting

0»«.Y

—4

AA

holes

0

4. MOTOR AND

4.

MOTOR

•

All

cords

be

parts. Furthermore, do not excessively

cordsorsecure

wise there is the

could

which

securedatleast

occur.

V-BELT

AND

are

connected

25 mm away from any moving

them

too firmly with

danger

V-BELT

to

that fire or electric shocks

the

staples,

A

motor

CAUTION

should

bend

the

other

Install the correct belt guard which

the motor being

used.

corresponds

to

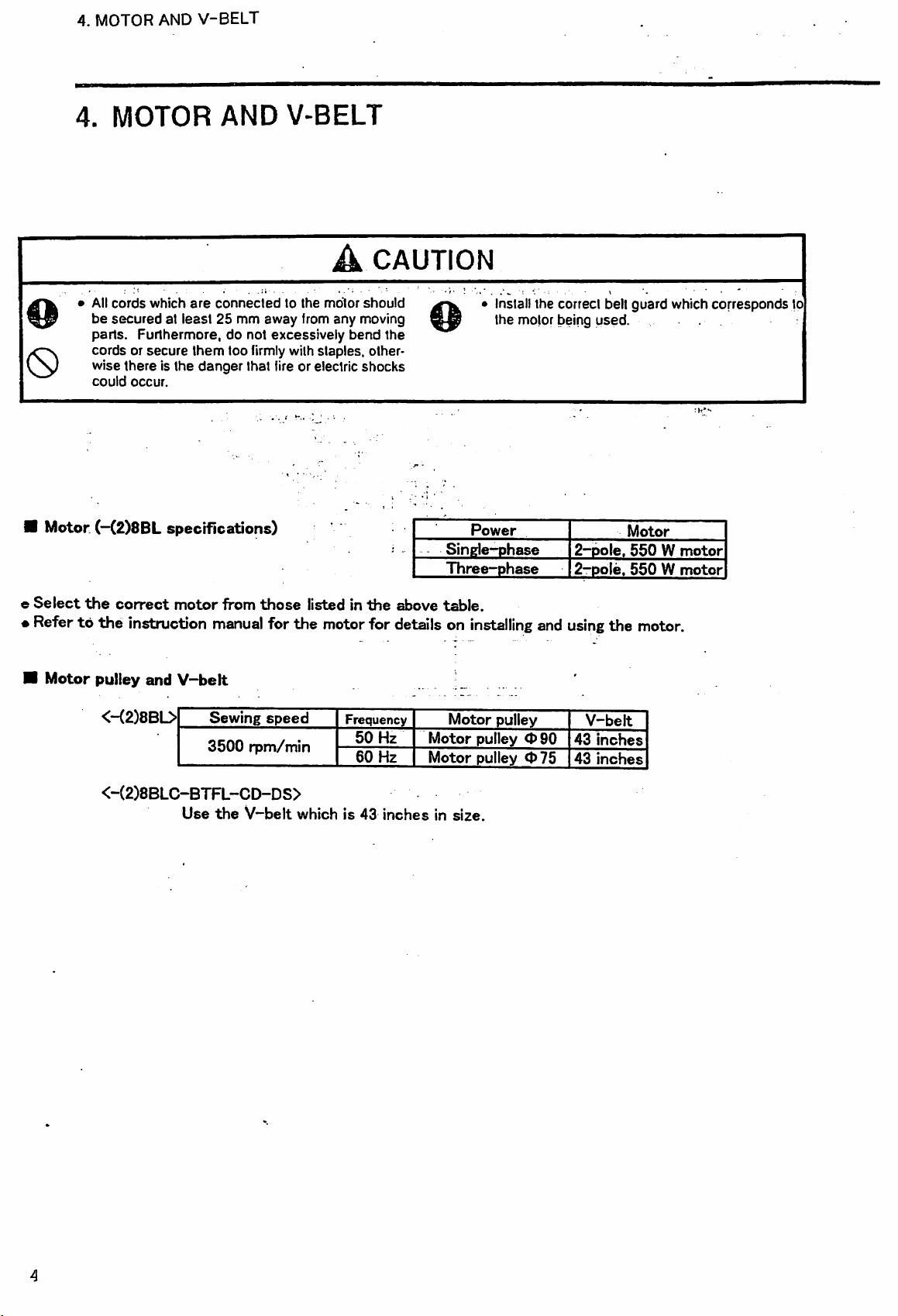

Motor (-(2)8BL specifications)

e

Select

• Refertothe

Motor

the

correct

pulley

<-(2)8BL>

motor

instruction

and

V-belt

manual

Sewing

3500

<-(2)8BLC-BTFL-CD-DS>

Use

the

Power

from

those

listed in

Ihe

above

Single-phase

Three-phase

table.

2-pole.

2-pole.

for the motorfor details on installing and usingthe motor.

speed

rpm/min

V—belt

which

Frequency

50

Hz

60

Hz

is 43

inchesInsize.

Motor

Motor

Motor

pulley

pulley

pulley

075

90

43

43

Motor

550Wmotor

550Wmotor

V-belt

inches

inches

5.

INSTALLATION

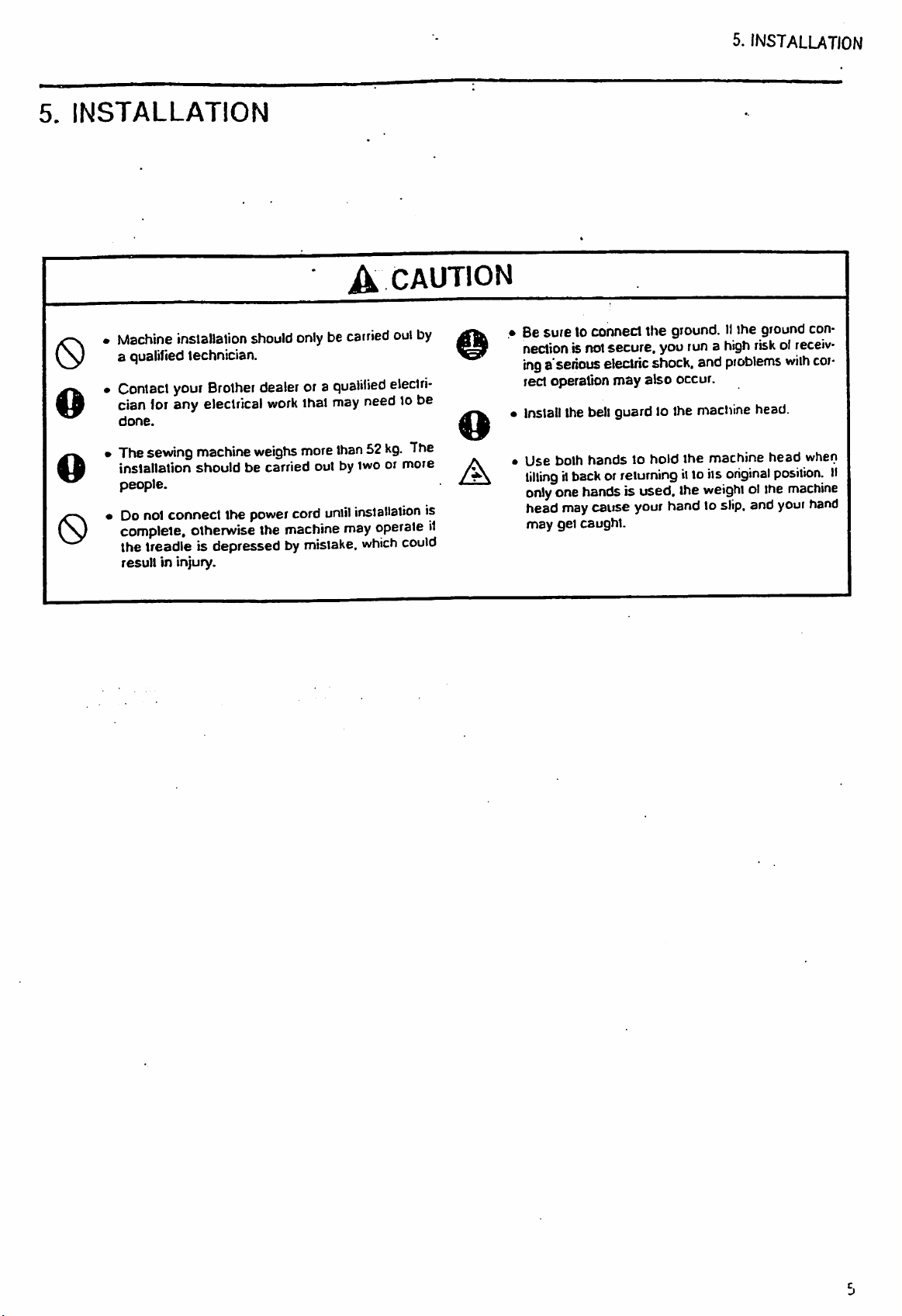

Machineinslallalion shouldonlybe carriedoutby

Q

a qualified technician.

Contact

cian

O

O

0

for

done.

The

sewing

installation

people.

Do

not

connectthe

complete,

the treadle is depressed by

result in injury.

your

Brother

any

electrical

machine

shouldbecarried

otherwise

dealer

work

weighs

power

the

A

ora

qualified

that

may

more

than52kg.

outbytwoormore

cord

until

machine

mistake,

irrslatlation

may

CAUTION

electri

need

tobe

The

operate

which

is

it

could

o

A

5.

INSTALUTION

Be

sure

to connect

nectionis notsecure, you run a

ing

a'senous

rect operation

Installthe belt guard to the macltine head.

Use

both

handstohold

tillinghbackorreturningittoits

only

one

head

may

handsisused,

may

cause your hand to

get

caught.

electric

may

the

ground.11the ground con

high

risk

shock,

and

problems

also

occur.

the

machine

original

the

weightolIhe

slip,

and

head

position.

ofreceiv

with

cor

wheri

machine

your

hand

II

5.

INSTALLATION

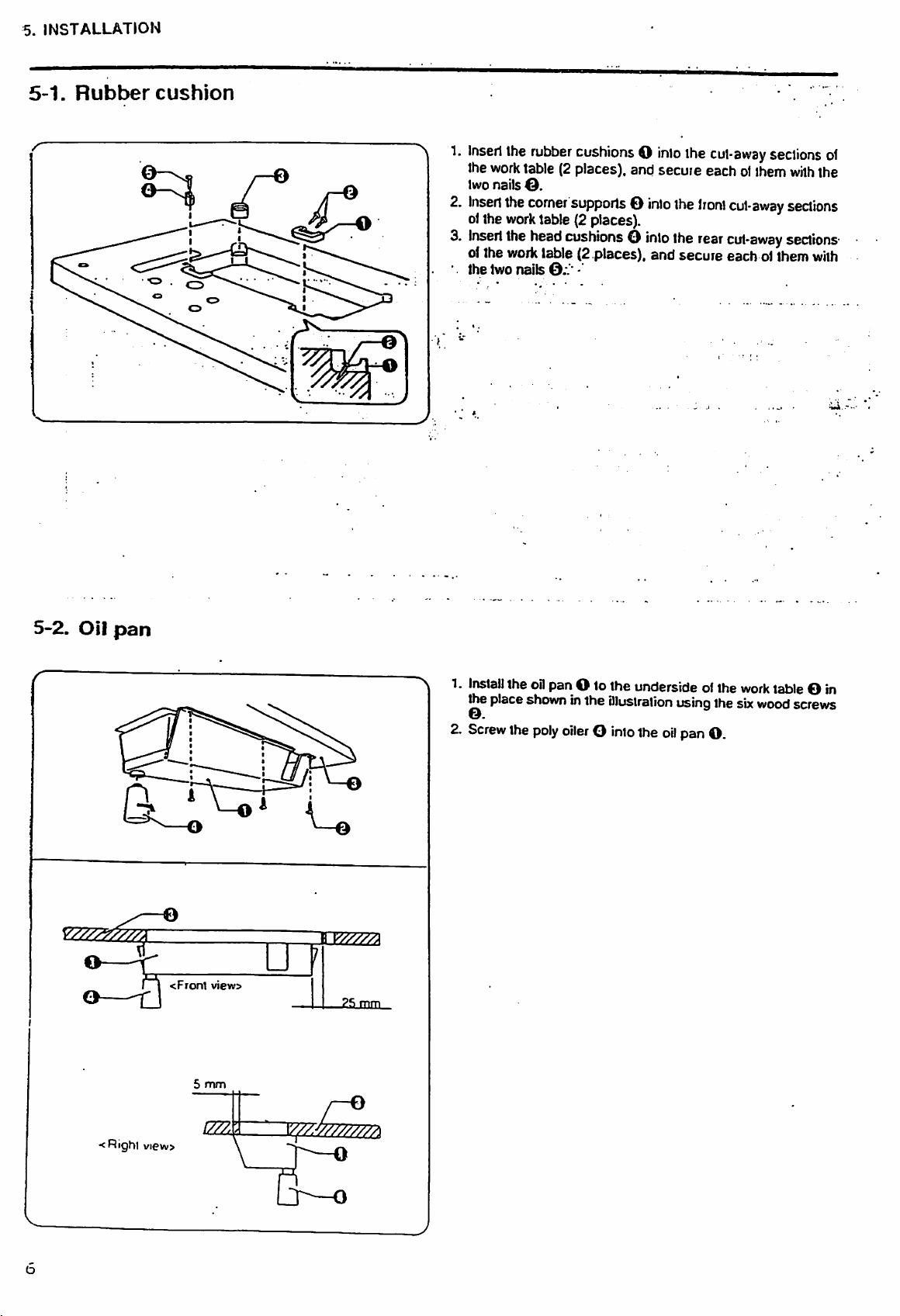

5-1.

Rubber

cushion

R

1.

insert

the

rubber

cushionsOinlo

Ihe

work

table (2 places), and secuie each ofthem

Iwo nails

2.

Insert

i

of

3.

Insert

ofthe worktable (2 places), and secure each of them

'

the

the

two

Q.

the

corner

work

table (2places).

the

head

nails

supportsOinlo

cushionsOinto

the

the

the

front

rear

cut-swey

cut-away

cut-away

seclions

with

sections

sections*

of

the

with

u..-.

5-2.

Oil

pan

O—Y

<Fronl

view>

V////A

-25

mm.

1.

2.

Install

the

place

©.

Screw

the

oil

panO tothe

showninthe

the

poly

illustration

oilerGinlo

underside

using

the

oil

pan O.

ofthe

the

work

six

table

wood

O in

screws

5

mm

:Righl

vievi/>

IZ2Z.

V

y

5.

INSTALLATION

5-3.

5-4.

Machine

V-belt

head

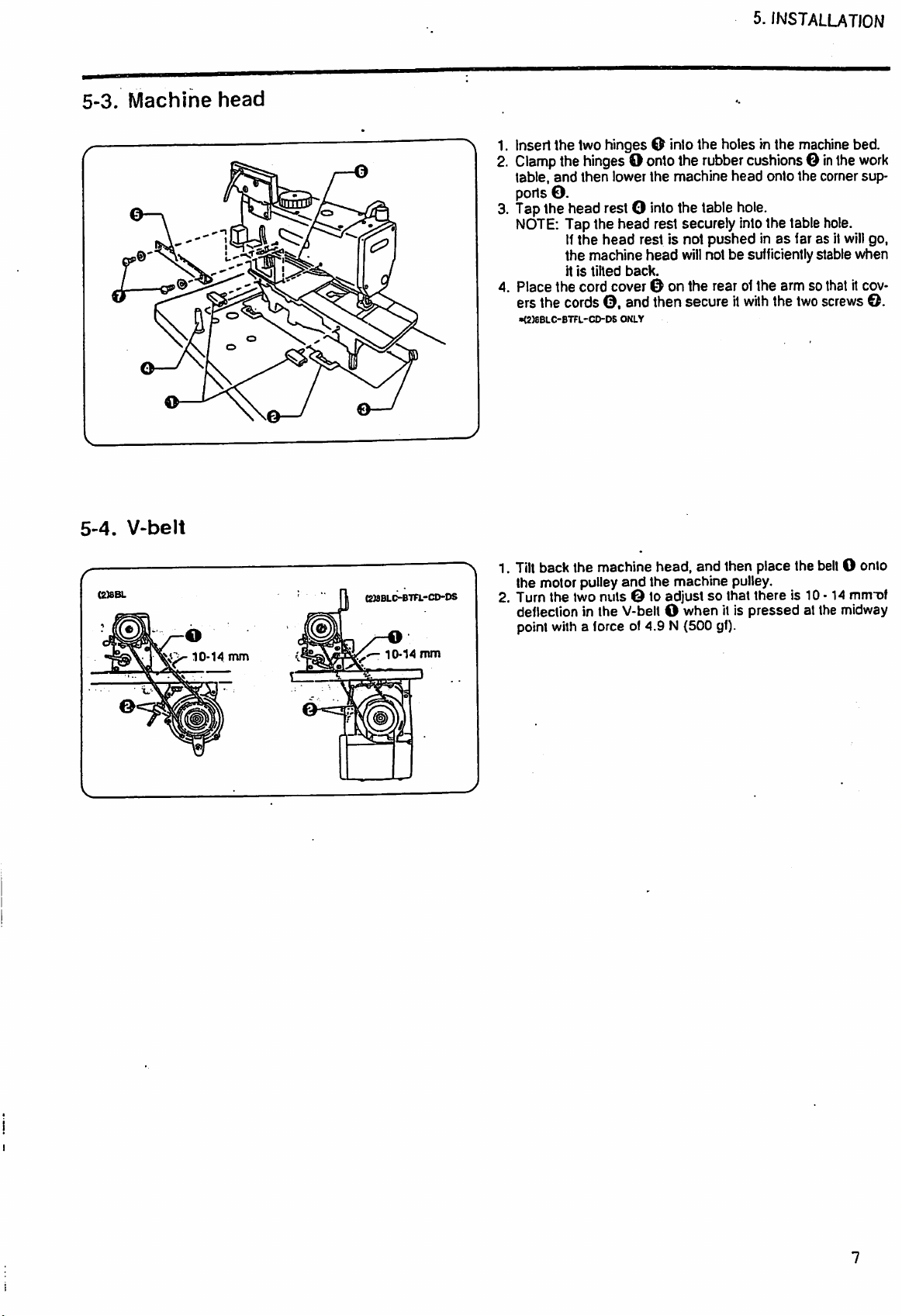

1. Insertthe two hinges © inlothe holes in the

2.

Clamp

the

hinges

table,

and

then lower

ports

O.

3. Tapthe head rest O

O ontothe

the

into

rubber

machine

the table

cushions Ointhe

head

hole.

machine

onto the comer

NOTE: Tap the head rest securely intothe table hole.

Ifthe

head

rest is not

4.

Place

the machine

itistilted

the cord

head

back.

cover©on

ers the cords ©, and then secure it

•(2)8BLC-BTFL-CD-DS OKLY

pushedinas

will

not be sufficiently stable when

the

rear of

with

tar as it

the

arm so that it cov

the

two

bed

work

sup

will

go,

screwsG.

(2)BBL

10-14

mm

eJ8BLC-BTFL-CD-DS

10-14

mm

1.

Tilt

back the machine head, and then place the

the motor pulley

2. Turn the two nuts O to adjust so that there is 10

deflection in

point with a force ot 4.9 N (500 gf).

the

and

the machine pulley.

V-belt O

when

it is

pressed

at the midway

belt

-14

O onto

mm-of

5.

INSTALLATION

5-5. Belt

guard

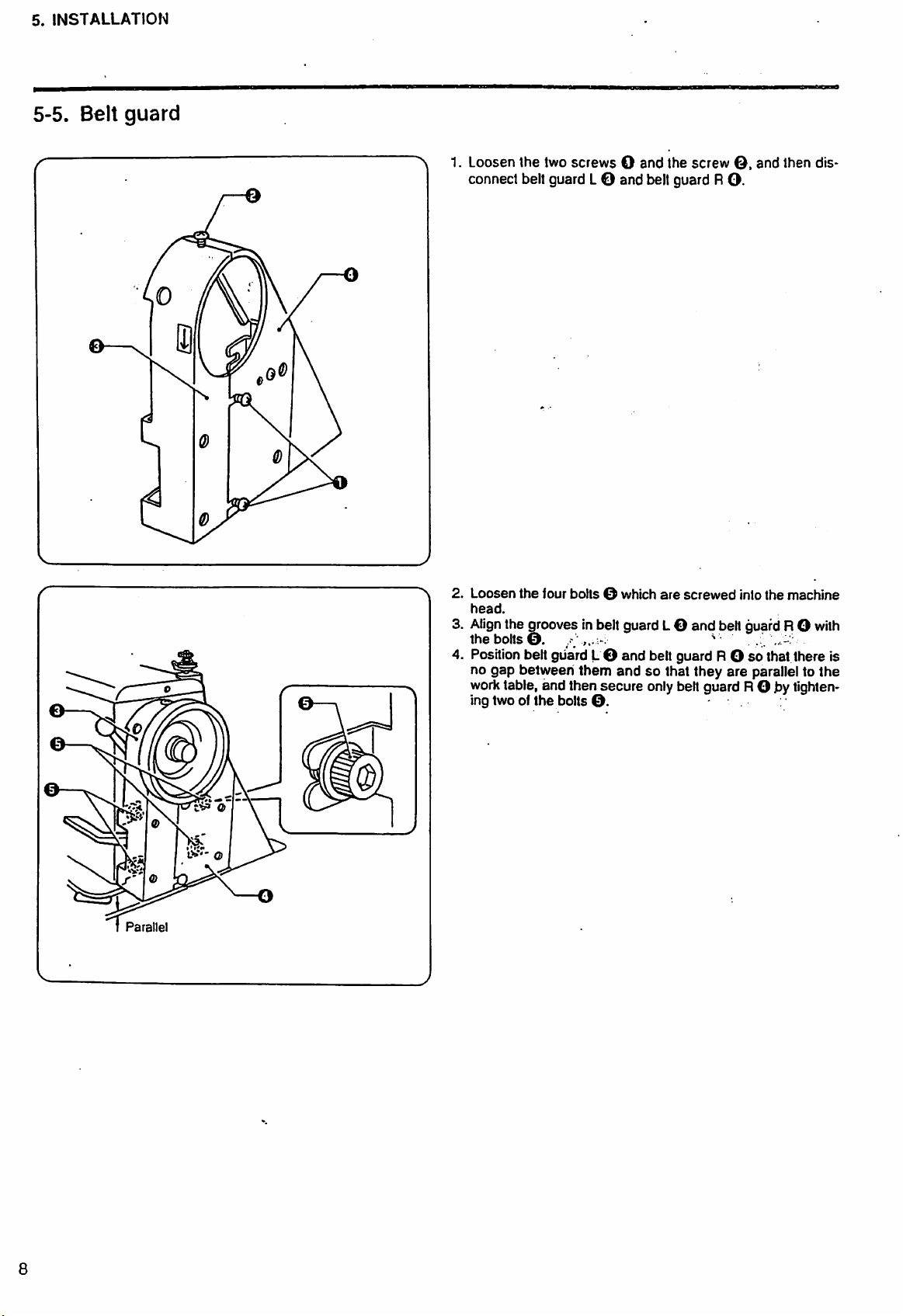

1. Loosen

the

two

screwsOand

the

screwG,and then dis

connect belt guard LO and belt guard R O.

Parallel

9

2.

3.

Loosen

head.

Align

the

the

four

boltsewhich

are

screwed

into

the

the grooves in belt guard LO and belt guardR O

bolts©.

^

machine

with

4. Position beltguard L© and bell guard R O so that there is

no gap between them and so that they

are

parallel to the

worktable, and then secure onlybelt guard R O by tighten

ing two of

the

bolts

©.

050

5.

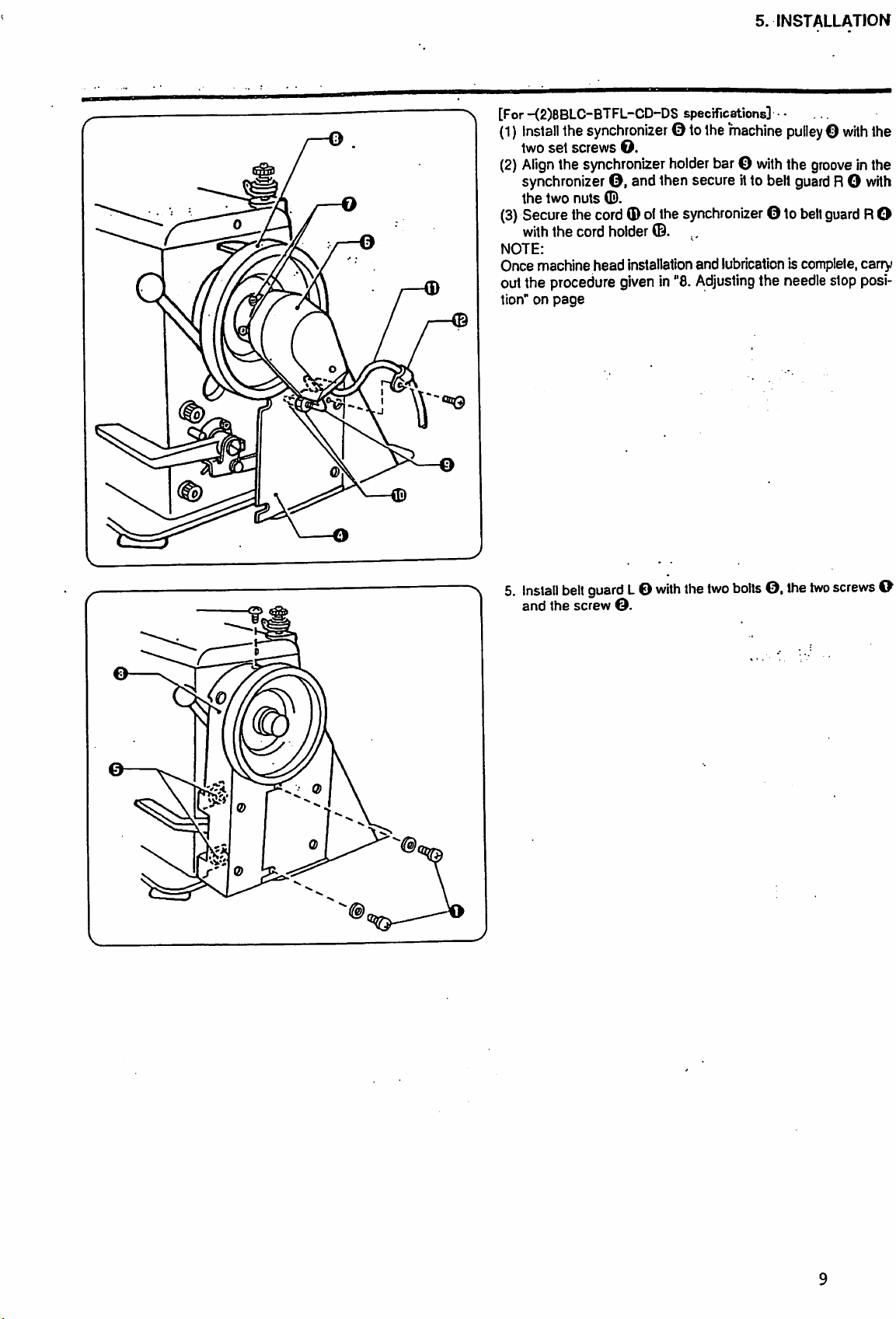

[For-(2)BBLC-BTFL-CD-DS specifications] ••

(1)

Install

the

(2)

two

Align

set

screws

the

synchronizer

synchronizer

O.

© to

holder

the

bar©

machine

with

synchronizer ©, andthen secure itto belt

the

two

nuts

QD.

(3)

Secure

with

NOTE:

Once machine

outthe procedure

tion"onpage

the

the

cord holder

cord©of

head

the

synchronizer

©.

installationand lubricationIscomplele,carry

given

in"8.

Adjusting

© to

the needlestop posi

INSTALLATION

pulley©with

the

groove

guard

belt

RO

guard

the

inthe

with

RO

5.

Install

and

belt

guardL0with

the

screw

the

two

bolts©.the

0.

two

screws

O

^^fe!^llllATION

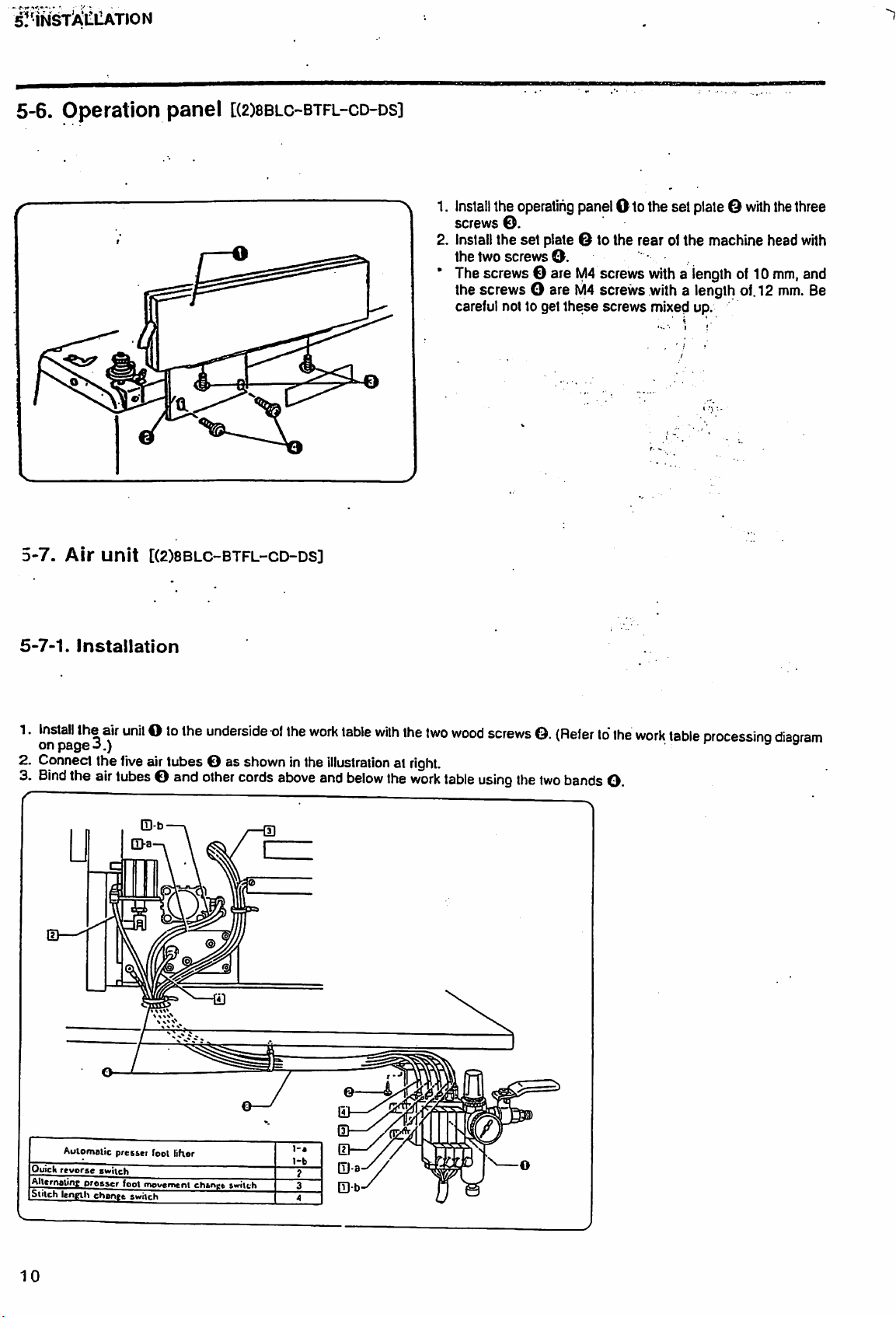

5-6. Operation

5-7.

Air

unit

panel

[(2)8blc-btfl-cd-ds]

[(2)8BLc-btfl-cd-ds]

1.

Install

the

operating

2.

screws

Install

the

0.

the set plate 0 to the rear ol the machine head

two

screws

* Thescrews© are

panel

O.

iyi4

thescrews O areM4screws

careful not to get

these

Oto

screws

screws

the set plateG

withalength

with

a lengthof.12

mixed up.

with

of10

thethree

with

mm,

and

mm.

Be

5-7-1.

1.

Install

on

2.

Connect

3.

Bind

Installation

the

page•3.)

the

the air

air

unitOto

five

tubes

the

undersideolthe

airtubes O as

O and

other

showninthe

cords

above

work

table

with

illustrationatright.

and

below

the

the

work

two

wood

screws0.(Refertothe

table

using

the

two

bands

O.

work

table

processing

» »

diagram

Automalic prcsser foot litior

Uinck

reverse

Stitch

length

10

switch

change

switch

1-e

1-b

?

3

4

5.

INSTALLAION

5-7-2.

Adjusting

©If

the

air

pressure

the

power switch and air need to be left on when carrying

be extremely carefultoobserve all

CAUTION

safety

precautions.

The air pressure shouldbe set to0.49 MPa (5

use.

1.

Pull

air

2. After adjusting,

'

When

knob O by turning it in the direction of the arrow.

up the

pressure.

releasing

knob

push

out

G ofthe air

the knob G

the

air.

close

some adjustment,

kgf/cm')

unitO,and

back

the

turnitto

in.

cock0and

before

adjust

the

loosen the

11

5.

INSTALLAION

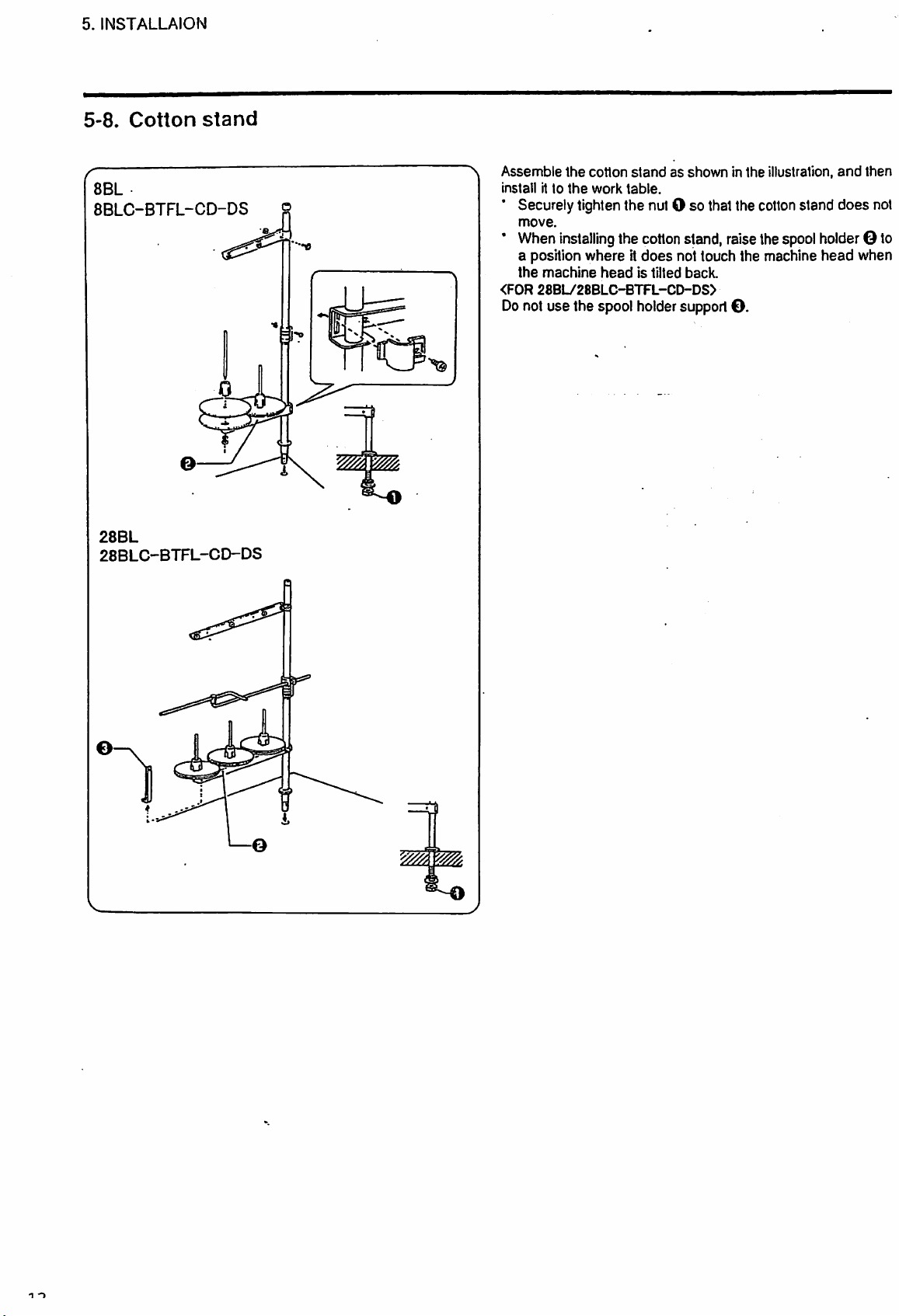

5-8.

Cotton

stand

8BL

8BLC-BTFL-CD-DS

28BL

28BLC-BTFL-CD-DS

Assemble

Installitto

»

* Securely tighten the nut O so that the

move.

* When

a position where it

the

<FOR

Do

the

cotton

standasshowninthe

the

work

table.

installing

machine

28BL/28BLC-BTFL-CD-DS>

the

cotton

does

headistilted

stand, raisethe

not touch the machine

back.

not use the spool holdersupport G.

illustration,

cotton

stand does not

spool

and

holder

head

then

G to

when

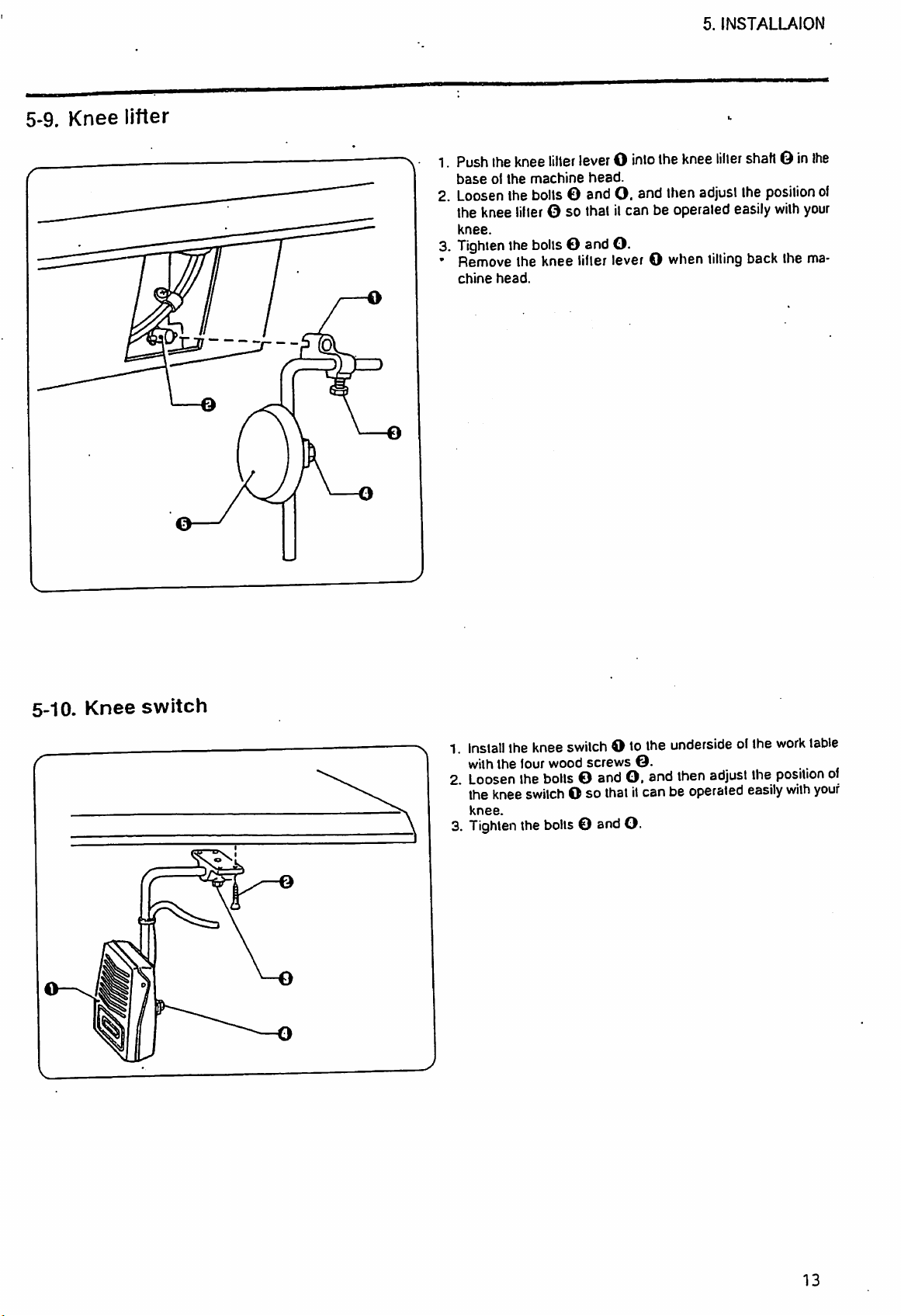

5-9.

Knee

litter

5.

INSTALLAION

V.

1. Pushiheknee

baseolthe

2. Loosen the bolts © andO.and then adjust the position

the knee lilterO so that itcan be operated easily

knee.

3.

Tighten

• Remove the

chine

head.

the

lilter

machine

bolls

O and O.

knee

leverOinlo

head.

lifter lever O when tilling back the ma

Iheknee

liller

shaft

G in

with

your

the

of

5-10.

Knee

switch

1.

Install

with

2.

Loosen

the knee

knee.

3.

Tighten

the knee switch O to the underside ofthe

the

tour

wood

screws

thebolls © and O. and then

switch

O so thatilcan be operated easily

the

bolts

© andO.

©. .. <

adjust

the

work

table

position

with

of

your

13

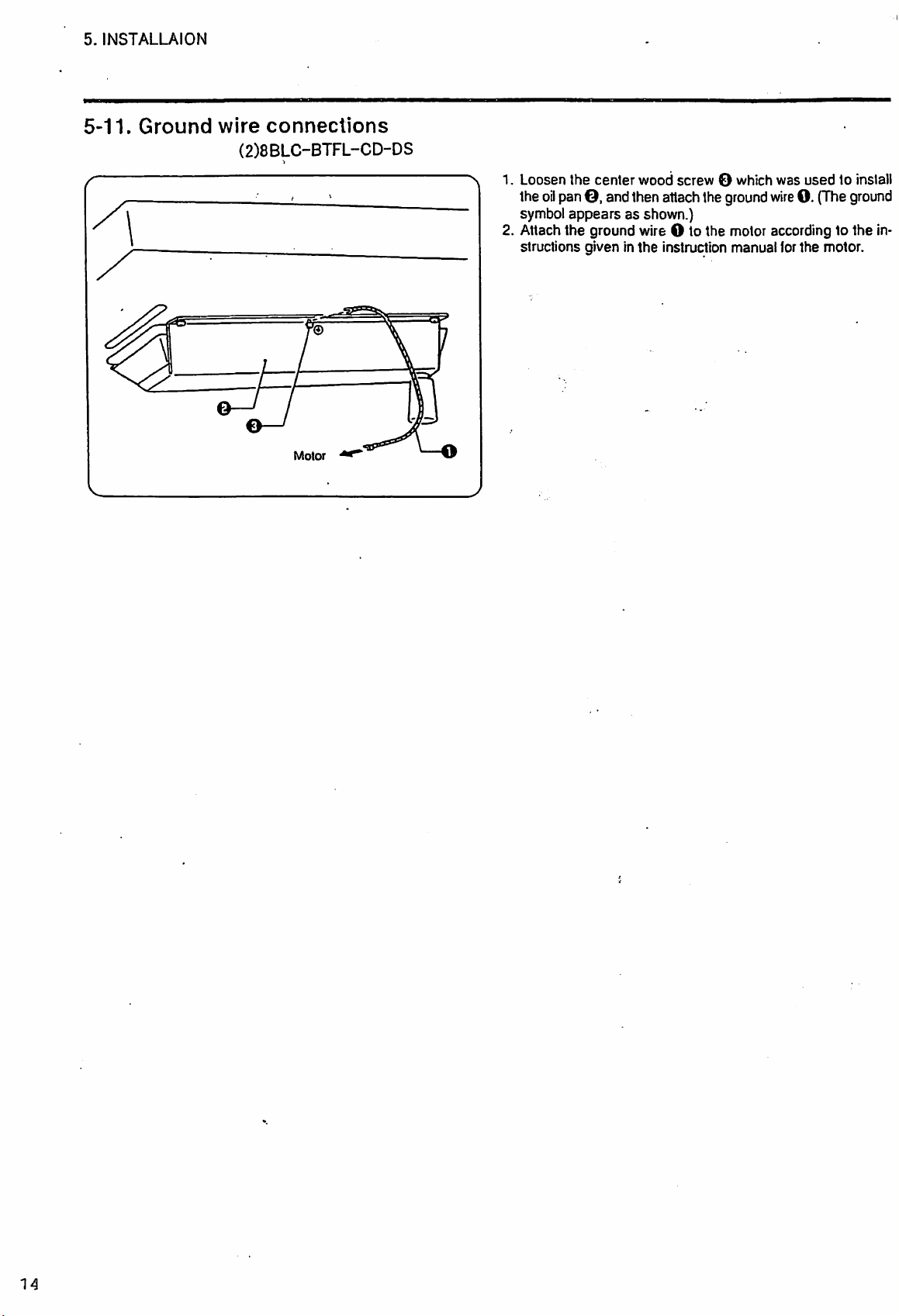

5.

INSTALLAION

5-11.

Ground

wire

connections

(2)8BLC-BTFL-CD-DS

Motor

Loosen

the

symbol

the

center

oil

pan©, andthen

appears

wood

screw

attach

as shown.)

0 which

the

ground

was

used

wireO.(The

to install

ground

Attachthe ground wire O to the motor according to the In

structions given In

the

instruction manual forthe motor.

14

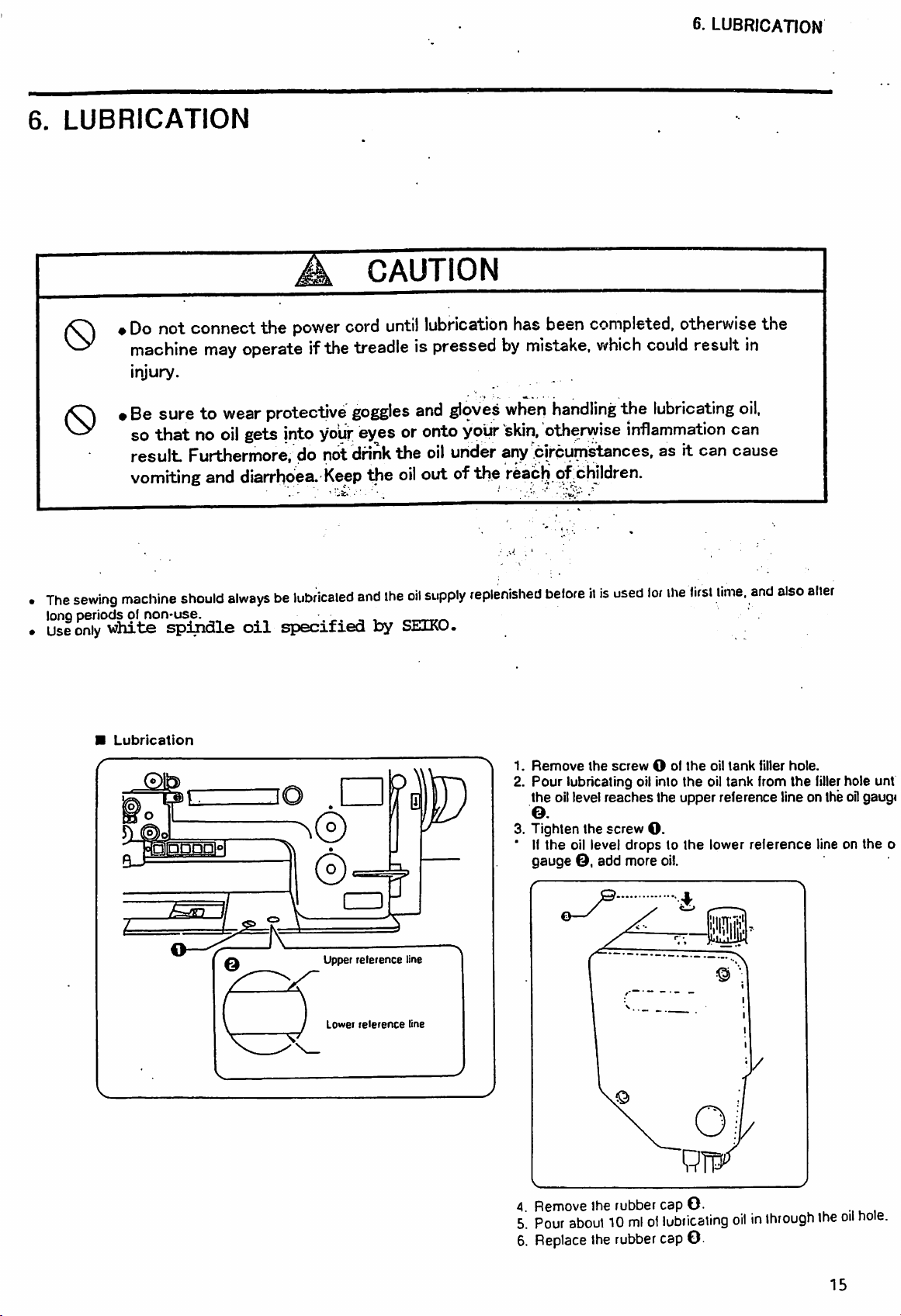

6.

LUBRICATION

CAUTION

6.

LUBRICATION

.

•

#Donot connect the

Q

• Be sure to

Q

The

long

Use

sewing

only

machine

periodsolnon-use.

white

Lubrication

machine

injury.

so that no

result

Furthermore,donot

vomiting

should

spindle

power

may

operate ifthe treadle is pressedbymistake,

wear

protective

oil

gets

into

and

diarrhoea.

alwaysbelubricaled

oil

specified

cord

your

Keep

. ^

until

goggles

eyesor

drink

the

the

oil

and

the

by

lubrication has been

and

onto

oil

gloves

under

your

when

skin,

any

outofthe

oil

supply

replenished

SEIKO.

completed,

v^hich

handling

otherwise

the

inflammation

^circumstances,

rSachofcWldren.

beforeitis

1.

Remove

2.

Pour

lubricating oil into

the

oillevel

e.

3. Tighten the screw

'IIthe

gauge0,add more

used

the

screw

reaches

oil level drops to

otherwise the

could

result

lubricating

in

oil.

can

as it can cause

lor

the

lirst

lime,

and

also

alter

O ol

the

oil

tank

liller

hole.

the

oil tank from

the upper reference line on the oilgaugi

O.

the

lower

oil.

the

reierence

filler

hole unt

line on the o

I'

upper

Lower

reference

reierence

line

line

4. Remove the rubber cap

5.

Pour

about10mlollubiicating

6.

Replace

the

rubber

cap

©

O.

O.

oilinthrough

the

15

oil

hole.

6.

LUBRICATION

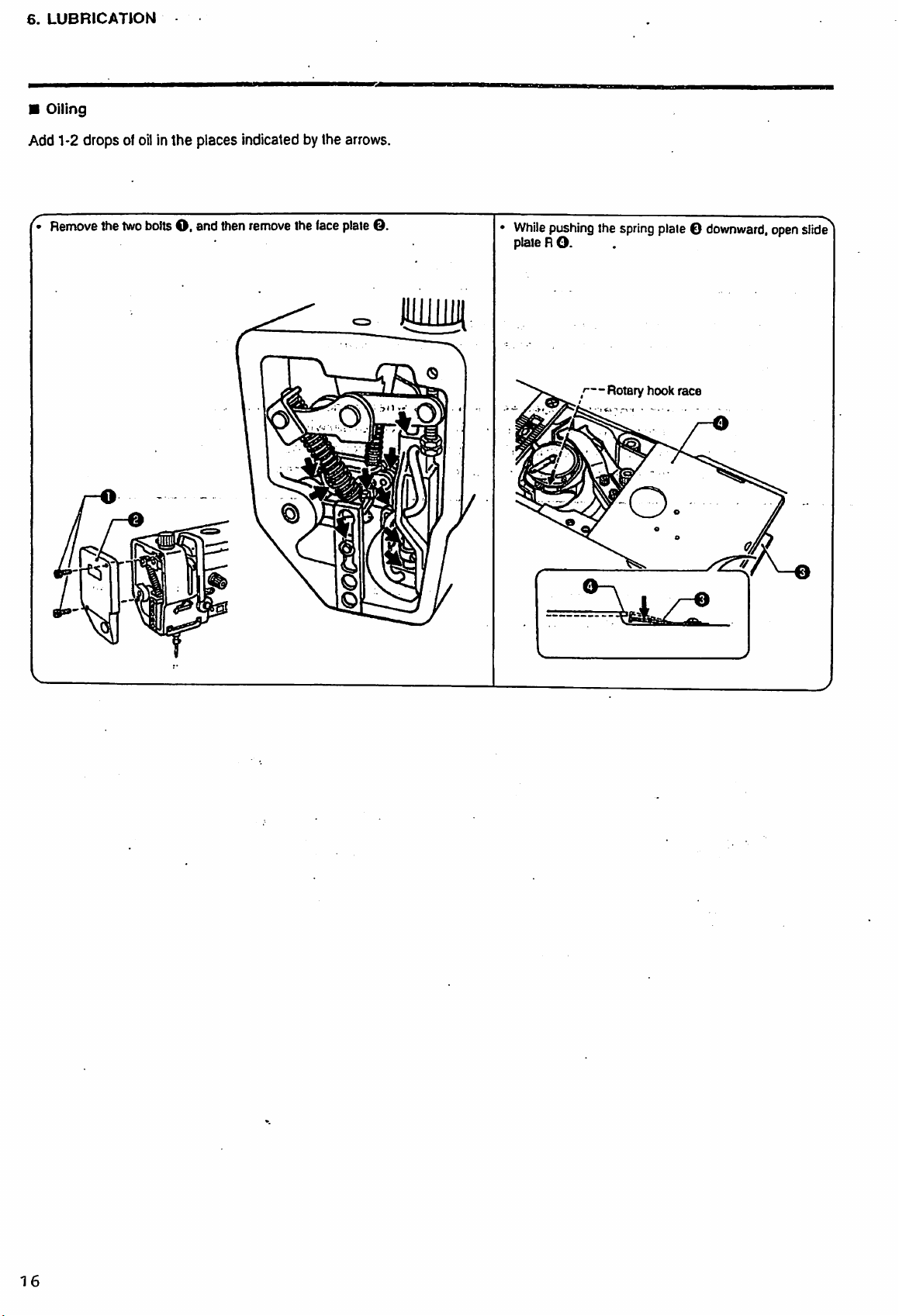

• Oiling

Add 1-2 drops ol

Remove the twoboltsO,and then remove the face plate G.

oil

inthe places indicated by the arrows.

lUHlUlt

•

While

plate R

pushing

O.

the

spring

'—Rotary

hook race

o

plate©

downward,

open

slide

Q

J

16

7.

CHECKING

7.

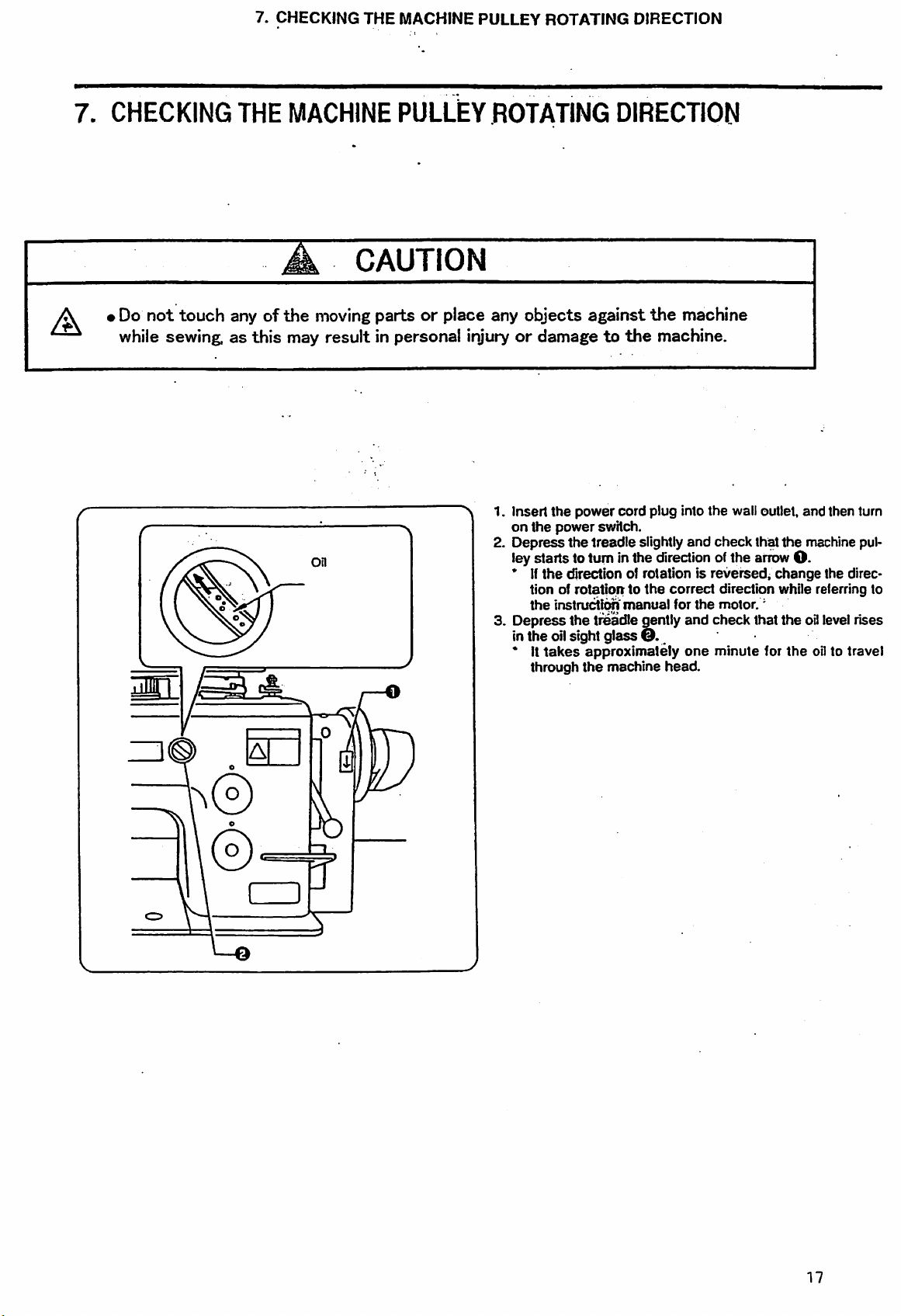

CHECKING THE MACHINE PULLEY ROTATING DIRECTION

THE

MACHINE

PULLEY

ROTATING

DIRECTION

CAUTION

• Do

not

touch

while sewing,asthis

any of

the

moving

partsorplace any

objects

against

may result in personal injuryordamagetothe

the

machine

machine.

1. Insert

2.

on

the

Depress

the

power

powerswitch.

the

cord plug into

treadle

slightly

the

wall outlet, and then turn

and

check

leystarts to turn inthe direction of the arrow

* If

the

direction of rotation is reversed^

tion of rotatiprrto

the

instructlrm

3.

Depress

the

inthe oilsight glass

* it

takes

through

approximately

the

traadle

the

manual

gently

O.

machine

correct

for

and

one

head.

direction while referring to

the

motor.'

check

minute

that

that

for

the

machine pul

O.

change

the

oillevel rises

the

the direc

oil to travel

17

8.

ADJUSTING

THE

NEEDLE

A

8.

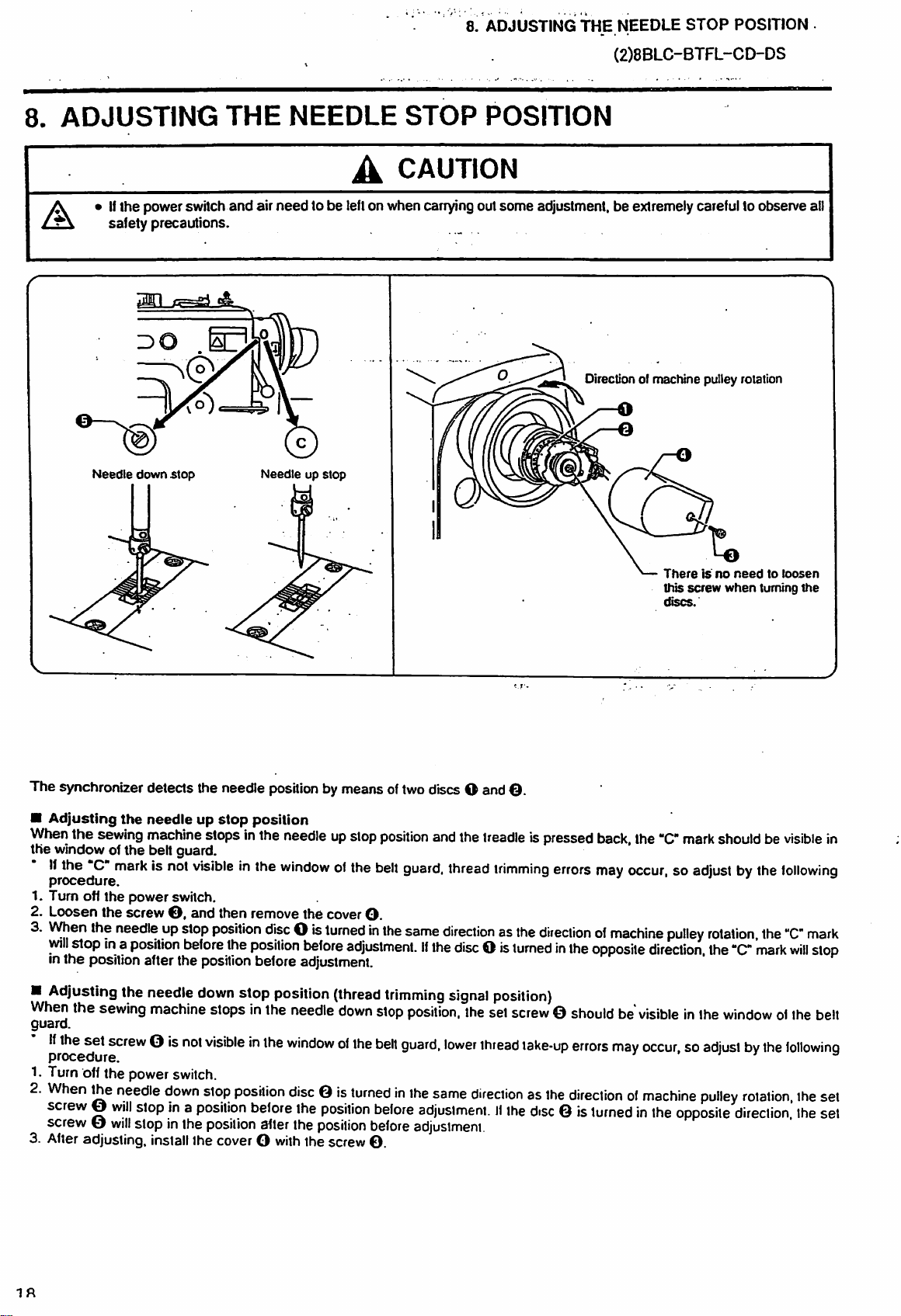

ADJUSTING

STOP

POSITION

CAUTION

THE

NEEDLE

(2)8BLC-BTFL-CD-DS

STOP

POSITION

A*

If

the

power

safety precautions.

s=gi

Needle

down

£top

switch

and

cS.

air

needtobe

Needleupslop

leftonwhen

carrying

out

some

adjustment,

be

extremely

Direction of machine pulley rotation

carefultoobserve

Thereisno

this

screw

discs.

needtoloosen

when

turning

all

the

The synchronizer detects the needle positionby means oftwo discs O and ©.

•

Adjusting

When

the

the

window of

If

the C

procedure.

1. Turn off the power switch.

2.

Loosen

3.

\Vhen

will

stopina

inthe position after the position before adjustment.

•

Adjusting

When

the

guard.

If

the

1. Turn off the powerswitch.

2.

When

screw©will

screw0

3. Afteradjusting, installthe cover O

the

sewing

the

mark

the

screw©,and

the

needleupstop

position

the

sewing

set

screwOis

the

needle

slopina

will

stopinthe

needleupstop

machine

belt guard.

is not

stopsinthe

visible

then remove the cover

position

before

the

needle

down

machine

not

down

stopsinthe

visibleinthe

stop

position

position

position

position

inthe

discOis

position

stop

before

after

needleupslop

window

ofthe

turnedinthe

before

position

needle

(thread

down

windowofthe

disc©is

the

position

the

position

with

the screw O.

position

belt

O.

and

guard,

same

adjustment.Ifthe

trimming

stop

position,

belt

guard,

turnedinthe

before

before

same

adjustment.Ifthe

adjustment.

the

treadleispressed

thread

trimming

directionasthe

discOis

signal

lower

turnedinthe

position)

the

set

screw©shouldbevisibleinthe

thread

directionasthe

back,

errors

may

occursoadjust

directionofmachine

opposite

take-up

errors

may

directionofmachine

disc©is

turnedinthe

the

"C"

mark

shouldbevisible

bythe

pulley

direction,

rotation,

the

"C"

mark

windowofthe

occur,soadjustbythe

pulley

rotation,

opposite

direction

following

the

"C"

will

following

the

the

in

mark

slop

belt

set

set

1R

Loading...

Loading...