Page 1

PARTS CATALOGUE / TECHNICAL GUIDE

Cal. 6T63A

[SPECIFICATIONS]

Cal. No.

Item

Interval of hands movement

Driving system

Additional function

Loss/gain

Regulation system

Gate time for rate measurement

Power

supply

Battery No.

Battery voltage

Battery life

Number of jewels

1/19

Crown

operation

Normal position

1st click position

2nd click position

Current consumption

Coil resistance

1 second

0 jewel

Stepping motor, 2 pieces

• Stopwatch function

60-minute stopwatch in one second increments.

• Second hand stop function

4002054 (COIL BLOCK A)

1.45 - 1.65 K

Ω

Use 10-second gate.

SEIKO SR936SW

Nil

1.55 V

Approx. 3 years

6T63A

• 3 hands (hour, minute, and

small second hand)

• 24 -hour indicator

• Date indicator

4002055 (COIL BLOCK B)

1.65 - 1.85 K

Ω

Free

Date setting(clockwise)

Time setting, hand position adjustment / resetting the circuit

Monthly rate: Less than 20 seconds (worn on the wrist at the tempera-

ture between 5 and 35)

• Diameter

Outside: Ø 30.8 mm Casing: Ø 29.0 mm

• Height: 5.1 mm

Movement : Less than 2.70 μA

Circuit block: Less than 0.70 μA

Page 2

SPECIFICATIONS

2/19

Cal. 6T63A

Cal. 6T63A has a new structure employing one crown and two buttons. The construction of chronograph

mechanism is based on Cal. 8R28 mechanical chronograph watch by using the one-piece 3 pointed reset

hammer. While other Swiss-made watches are using separate hammers which require an assembly and

adjustment of the hammers, the one-piece hammer design realizes maximum durability and stability of

the component and easier maintenance. It is also equipped with the self-alignment function for all counting

hands to return to zero positions instantaneously.

This is the multi-display analogue watch featuring a stopwatch function.

●

The time is indicated by the 24-hour, hour and minute hands, and a small second hand.

●

The stop watch can measure up to 60 minutes in one second increments. After 60 minutes,

it will stop automatically.

● Measurement performance

Displays the elapsed time with the 2 designated STOPWATCH hands.

Measures up to 60 minutes in one second increments.

● Button operation (Crown position: Normal position)

Button A: START/STOP

Button B: RESET

1. STOPWATCH FUNCTION

Cal . 6T63A

a b c

Hour hand

Minute hand

STOPWATCH 1/5-second hand

STOPWATCH minute

hand

Small second hand

a: Normal position

b: First click

c: Second click

24-hour hand

A

B

CROWN

When pushin g th e re se t bu tton

the HAMMER OPERATING LEVER

B moves automatically to

ke ep ap propr iate bal ance of th e

HAMMER position.

CHRONOGRAPH

COUPLING LEVER

HAMMER OPERATING

LEVER A

HAMMER OPERATING

LEVER B

HAMMER HAMMER

HAMMER OPERATING

LEVER B

FE ATUR ES

START

RESET

Page 3

SPECIFICATIONS

3/19

Cal. 6T63A

After installing the battery, pull out the crown to the second click position. And then follow the

instructions below to correct the hand positions and set the time.

NECESSARY PROCEDURE AFTER BATTERY CHANGE

Pull out to the second click position when the small second hand is at

the 60 seconds position. The small second hand stops on the spot.

Crown

Push back in to the normal position in accordance with a time signal.

Crown

Watch starts moving with 2-second interval for 10 seconds. Wait until it moves with

1-second interval.*

* Do not move the crown before it ends.

Button B

Press Button B for longer than 2 seconds.

The STOPWATCH minute hand turns a full circle.

● Standard measurement

Button A

START

→

Button A

STOP

→

Button B

RESET

● A ccumulated elapsed time measurement

Button A

START

→

Button A

STOP

Button A

STOP

→

Button B

RESET

→

Button A

RESTART

…→

Restart and stop of the stopwatch can be repeated by pressing button A.

●

Measurement functions

Accumulated elapsed time measurement and split time measurement are available.

Page 4

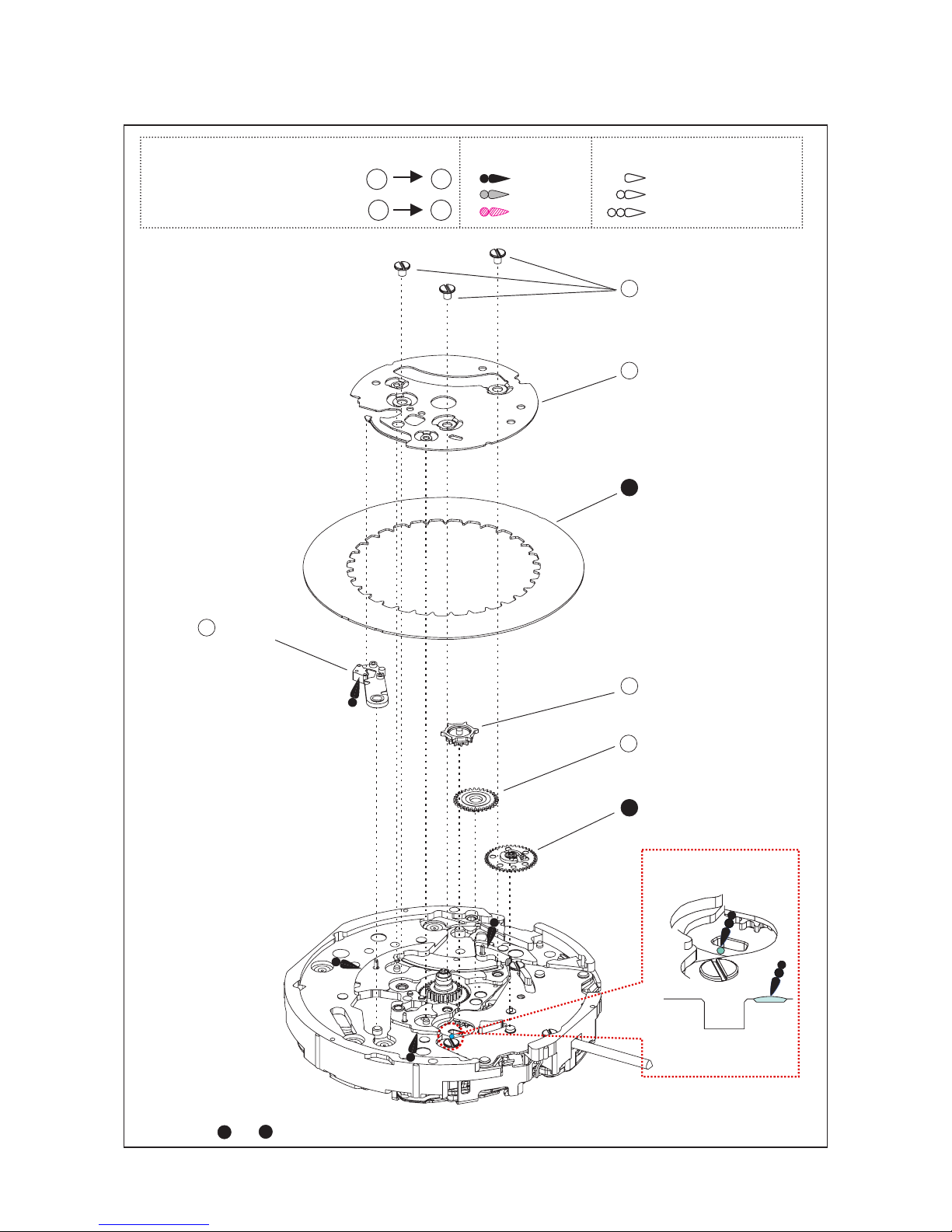

Cal. 6T63A

PARTS LIST

4/19

DAT E I NDI CATOR

MAINTAINING

PL AT E SC REW

0012354

1

2

3

4

5

6

7

DAT E I NDI CATOR

MAINTAINING

PL AT E

0808052

DATE DIAL

0878***

DAT E J UM PER

0810019

DATE CORRECTOR

WHEEL

0806002

INTERMEDIATE

SMALL HOUR HAND WHEEL

AND PINION

0817048

SMALL HOUR HAND WHEEL

0157***

[ Cross section ]

7

3

For parts and , please refer to the page 10.

Disassembling procedures Figs. : 1 61

Reassembling procedures Figs. : 61 1

AO-2

Type of oil Oil quantity mark

NORMAL QUANTITY

AO-3

S-6

LIBERAL QUANTITY

SMALL QUANTIT Y

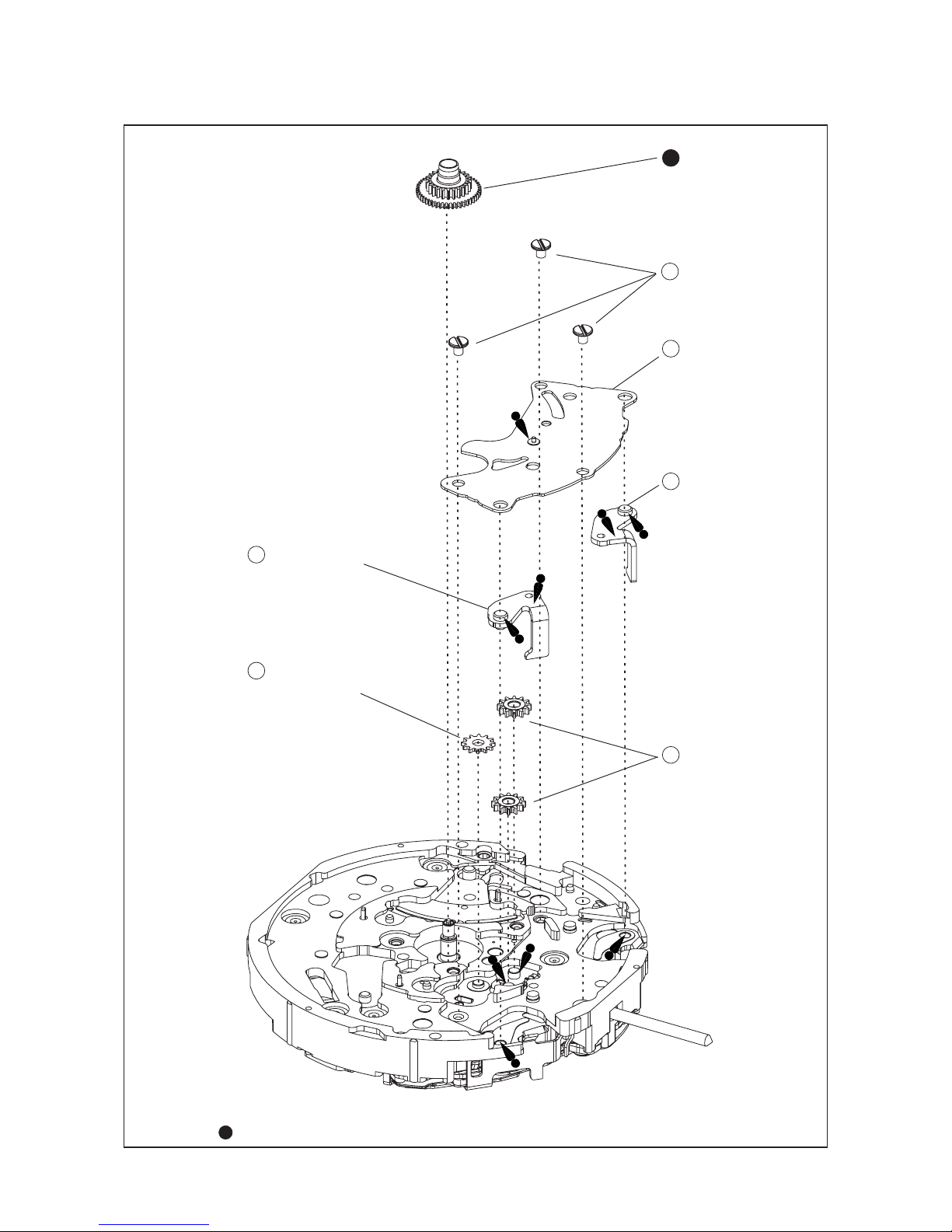

Page 5

Cal. 6T63A

PARTS LIST

5/19

HOUR WHEEL

0273***

8

9

SWITCH LEVER

HOLDER SCREW

012354

10

11

12

14

13

SWITCH LEVER

HOLDER

0837005

SWITCH LEVER A

4450017

SWITCH LEVER B

4450018

DATE CORRECTOR

SETTING

TRANSMISSION

WHEEL B

0962013

DATE CORRECTOR

SETTING TRANSMISSION

WHEEL C

0962891

For parts , please refer to the page 10.

8

Page 6

Cal. 6T63A

PARTS LIST

6/19

*1

*1

*2

*2

15

SWITCH SPRING SCREW

0016121

17

SECOND COUNTING

WHEEL FRICTION

SPRING

0353018

18

CHRONOGRAPH

BRIDGE

0190007

16

SWITCH SPRING

4250***

19

CHRONOGRAPH

COUPLING LEVER

0581007

25

TRAIN WHEEL

STOP LEVER

0894002

26

HAMMER OPERATING

LEVER A

0587004

20

HAMMER OPERATING

LEVER B

0587006

HAMMER

0585013**

15

SWITCH SPRING SCREW

0016121

21

SECOND

COUNTING

WHEEL

0888***

22

POSITIONING

ARBOR

0685002

23

MINUTE

COUNTING

WHEEL

0740***

24

For parts , please refer to the page 10 and 11.

For parts and , please refer to the page 10.

For parts , , , , and , please refer to the page 12 and 13.

22

16

25 26

24

2019 21

Page 7

Cal. 6T63A

PARTS LIST

7/19

For parts , please refer to the page 12 and 13.

27

LOWER PLATE FOR

CHRONOGRAPH BRIDGE SCREW

0016121

28

LOWER PLATE FOR

CHRONOGRAPH BRIDGE

0186002

29

CIRCUIT BLOCK SPACER

44 0814 9

30

CIRCUIT BLOCK

4004253

31

BATTERY CONNECTION (-)

4270336

35

SECOND COUNTER

INTERMEDIATE WHEEL

AND PINION

0885003

38

COIL BLOCK SCREW

0012354

39

COIL BLOCK A

4002054

40

STEP ROTOR

4146063

41

STAT OR A

4239063

34

MINUTE COUNTER

INTERMEDIATE WHEEL

AND PINION B

0886006

36

COUNTER

INTERMEDIATE WHEEL

AND PINION

0886004

37

MINUTE COUNTER

INTERMEDIATE WHEEL

AND PINION A

0886005

42

FIFTH WHEEL AND

PINION

0701015

32

TRAIN WHEEL BRIDGE

0125316

33

MINUTE COUNTER

INTERMEDIATE WHEEL

AND PINION

0886007

*1

28

Page 8

Cal. 6T63A

PARTS LIST

8/19

43

RESET LEVER

4455006

50

TRAIN WHEEL

SETTING LEVER

0391028

51

COIL BLOCK SCREW

0012354

52

COIL BLOCK B

4002055

53

STEP ROTOR

4146063

54

STAT OR B

4239064

57

SETTING

LEVER

0383891

58

YOKE

0384024

60

CLUTCH

WHEEL

0282452

61

DATE CORRECTOR

SETTING

TRANSMISSION

WHEEL A

0962012

59

WINDING STEM

0351177

44

THIRD WHEEL

AND PINION

0231043

45

FOURTH WHEEL

AND PINION

0144 002

46

MINUTE WHEEL

AND PINION

0261026

47

SETTING WHEEL

0016121

48

CENTER WHEEL AND

PINION BRIDGE

0016121

49

CENTER WHEEL

AND PINION

0221***

55

FIFTH WHEEL

AND PINION

0701015

56

SECOND WHEEL

0240***

*1

*1

49 56 59

For parts , and , please refer to the page 10.

Page 9

Cal. 6T63A

PARTS LIST

9/19

●

Tools and consumables required for disassembling/reassembling

• Movement holder

UNIVERSAL MOVEMENT HOLDER (S-682)

• Watch oils

SEIKO watch oil AO-3 (or Moebius A) and AO-2 (or Moebius F)

AO-3

AO-2

S-6

Page 10

TECHNICAL GUIDE

Cal. 6T63A

10/19

●

How to find the correct parts, if not determined by 4 digit caliber number

Following par ts are determined based on the design of watches, such as hands height, dial

color, and design of cases. Please refer to the SEIKO WATCH PARTS CATALOGUE in order to

choose corresponding parts.

3

DATE DIAL 0878***

59

WINDING STEM 0351177

* For screw down crown models, the stem is assembled to the crown and is not available

separatelly

7

SMALL HOUR HAND WHEEL

8

HOUR WHEEL

16

SWITHCH SPRING

22

SECOND COUNTING WHEEL

24

MINUTE COUNTING WHEEL

49

CENTER WHEEL AND PINION

56

SECOND WHEEL

Please refer to the following table in order to find the correct part number of each wheel

according to the hand installation height. The numeral 2 or 4 is printed on the DIAL.

7 SMALL

HOUR HAND

WHEEL

8 HOUR

WHEEL

16 SWITHCH

SPRING

22 SECOND

COUNTING

WHEEL

24 MINUTE

COUNTING

WHEEL

49 CENTER

WHEEL AND

PINION

56 SECOND

WHEEL

2

0157012 0273038 4250035 0888017 0740002 0221087 0240018

4

0157013 0273042 4250054 0888019 0740003 0221092 0240019

Page 11

TECHNICAL GUIDE

Cal. 6T63A

11/19

Push the "A" on the SETTING LEVER

gently(refer to the pic ture on the

right) in order to disengage it from

the SETTING STEM. Then pul out

the crown with the stem completely.

FOR UNIT'S DIGIT properly.

REMARKS ON DISASSEMBLING AND REASSEMBLING THE MOVEMENT

●

How to remove the SETTING STEM before dismantling the movement

Crown position: normal (=0) position.

A

●

How to remove or install the battery

1) Remove the hook of the switch spring's battery clamp.

2) Insert the battery sideways, and have the hook of the switch spring's battery clamp catch the

main plate.

Battery clamp

Main plate

1) When Removing

2) When Installing

16 Switch spring

●

Remarks on installing the battery

1) Af ter t he bat t er y is re plac e d

battery is reinstalled following

the repairing procedures, be

sure to touch the AC terminal

of circuit block and the switch

spring with conductive tweezers

to reset the circuit as illustrated.

Tweezers

Page 12

TECHNICAL GUIDE

Cal. 6T63A

12/19

●

Remarks for the lubrication

Hammer

21

There must be oil within the range of the arrow.

Lower plate for chronograph bridge

28

Note

*1: Oiling should be done on the

pointed spot of marked place.

*1

*1

*1 *1

Switch spring

*Oiling spot and spring set ting position.

16

*2

*3

*3

*2

Chronograph coupling lever

19

Setting position

Switch spring

16

*Oiling should be done on the contact spot of the spring and the pin.

Hammer operating lever B

20

AO-2

Type of oil

Oil quantity mark

NORMAL QUANTITY

AO-3

S-6

LIBERAL QUANTITY

SMALL QUANTIT Y

Page 13

TECHNICAL GUIDE

Cal. 6T63A

13/19

●

Remarks for setting position of the spring of chronograph function

Lower plate for

chronograph bridge

28

Hammer operating

lever A

26

Train wheel stop lever

25

Chronograph coupling

lever

19

Hammer operating

lever B

20

Hammer

21

*2

*3

*4

*1

*1

*2

*3

*4

Setting position

●

Remarks for setting position of the SWITCH LEVER A and B

*1 *2

Chronograph

coupling lever

Hammer operating

lever A

Switch spring

Switch lever B

Switch lever A

Switch spring

*2

*1

Enlarged view

Switch lever B is set between the switch

spring and hammer operating lever A .

Switch lever A is set between the switch

spring and chronograph coupling lever.

Page 14

TECHNICAL GUIDE

Cal. 6T63A

14/19

REMARKS ON INSPECTION AND MEASUREMENT

1. To measure the current consumption for the whole move-

ment, connect the ( -) probe to the battery connection ( -)

and (+) probe to the other metal part of the movement,

such as battery clamp or circuit block cover.

* When measuring the current consumption using the

SEIKO digital multi-tester (S-860), use the range of 40 μ

A of SUPPLY V (= 1.55 V) & GATE TIME (2 S).

2. Connect the AC component to the positive terminal for 2

seconds until a short circuit occurs to reset the integrated

circuit.

3. After the integrated circuit is reset, wait approximately for

10 seconds until a stable measurement is obtained, and

then read the measurement.

4. Make sure the read value is less than 2.7 μ A.

●

How to measure the current consumption for the whole movement

●

How to measure the current consumption for the CIRCUIT BLOCK alone

1. To measure the current consumption for the CIRCUIT

BLOCK alone, connect each probe to the appropriate

positive (+) or negative (- ) input terminal of the CIRCUIT BLOCK (please refer to “Structure of the CIRCUIT

BLOCK” below) .

* When measuring the current consumption using the SEI-

KO Multi-Tester S-860, use the range of 4 μ A of SUPPLY

V (= 1.55 V) & GATE TIME (2 S).

2. Repeat the same procedures as 2. and 3. of measuring

current consumption for the whole movement above.

* When measuring the current consumption for the circuit

block alone, be careful not to damage or deform the pattern of the circuit block.

3. Make sure the read value is less than 0.7 μ A.

Page 15

TECHNICAL GUIDE

Cal. 6T63A

15/19

●

Value checking – coil resistance (coil blocks)

Check the resistance of each coil block if they are within the range in the following table.

1.45 KΩ ~ 1.65 K

Ω

1.65 KΩ ~ 1.85 K

Ω

COIL BLOCK (A)

COIL BLOCK (B)

4002054

4002055

[Structure of the CIRCUIT BLOCK]

Input terminal (+)

Input terminal (-)

Output terminal(hand moving)

Crystal unit

Output terminal(CG)

C=MOS=IC

Page 16

TECHNICAL GUIDE

Cal. 6T63A

16/19

Operation

Function

Checkpoint

Pull out the crown

to the 2nd click

and push it back

in to the normal

position. Repeat

the same several

times.

Setting mechanism

- switching the

function of the time

setting

Make sure that it

has a click at each

position and the

stem is not pulled

off.

Pull out the

crown to the 1st

click, then turn it

clockwise.

Hands installation

Make sure that the

hour and minute

h a n d s m o v e

smoothly (without

touching each other

of touching the

surface of the dial or

inside of the glass).

Make sure that

the day changes

smoothly.

Calendar mechanism

- correcting the day

Make sure that the

date changes when

the hour and minute

hands pass around

midnight.

Calendar mechanism

- date change

●

Function check

Press button A

to start the stopwatch.

Press button A

again to stop the

stopwatch.

Press button B

to reset the stopwatch.

Stopwatch

mechanism

Make sure that the

Stopwatch hands

start/stop smoothly.

Make sure that the

Stopwatch hands

are reset to the

“0” position.

Pull out the crown

to the 2nd click,

then turn it.

Setting mechanism

- hour and minute

hand setting

A

B

A A B

Start Stop Reset

Page 17

TECHNICAL GUIDE

Cal. 6T63A

17/19

●

Water resistance test

Check the water resistance according to the designated specification of the watch.

Marking on the case back Tes t met hod Applied pressure

WATER RESISTANT (WATER RESIST) 3 BAR

WATER RESIST 5BAR 5 BAR

WATER RESIST 10BAR 10 BAR

WATER RESIST 15BAR 15 BAR

WATER RESIST 20BAR 20 BAR

SCUBA DIVER'S (AIR DIVER'S) 150 m

18.75 BAR = 150 (m) times 0.125

SCUBA DIVER'S (AIR DIVER'S) 200 m 25 BAR = 200 (m) times 0.125

He-GAS DIVER'S 300 m 37.5 BAR = 300 (m) times 0.125

He-GAS DIVER'S 600 m 75 BAR = 600 (m) times 0.125

He-GAS DIVER'S 1000 m 125 BAR = 1000 (m) times 0.125

Air leak test

Condensation test

Condensation test

Water pressure test

Water pressure test

Condensation test

Page 18

TECHNICAL GUIDE

Cal. 6T63A

18/19

Movement

TROUBLESHOOTING

The watch stops operating. The battery has been depleted.

Measure the bat tery voltage.

Replace the battery with a new

one.

The hour wheel and the pinion of

the minute wheel are not properly

engaged. (Or the teeth of the hour

wheel and/or minute wheel have

been broken.)

Check the relevant parts, and

replace the damaged parts with

new ones.

The hooking por tions of the

circuit block cover are not

properly engaged, resulting in

poor conductivity.

Securely attach the hooks of the

circuit block cover to the main

plate.

The coil is broken.

Measure the coil block resistance.

Replace the coil with a new one.

One or more wheels have been

contaminated with dir t, dust or

other particles.

An excessive amount of oil in the

movement has caused adhesive

forces among the parts. (wringing)

Remove dir t or dust and clean the

contaminated wheels. Be careful

so as not to damage the teeth of

the plas tic par ts while cleaning.

The current consumption

for the whole movement

exceeds the standard

value.

Dirt, dust or foreign particles are

adhered to the movement.

Remove dir t, dus t or foreign

particles and clean the movement.

The driving pulse is generated in

order to compensate the excessive

load applied to the wheels. (The

oil has deteriorated, leaked or run

out.)

If the current consumption for

the circuit block alone is within

the standard value range,

overhaul and clean the movement parts, and then make the

measurement again.

The current consumption

for the circuit block alone

exceeds the standard

value.

The light from outside the

movement is affecting the

measurement.

Shut out the light, and make the

measurement again.

There is a defec t in the IC

(integrated circuit).

Replace the circuit block with a

new one.

Symptom Possible causes Solutions

Page 19

TECHNICAL GUIDE

Cal. 6T63A

19/19

ST OP WATC H

One or more STOP-

WATCH hands have

stopped moving or show

an abnormal movement.

The relevant coil is broken.

Measure the coil block resistance.

Replace the coil with a new one if

nece ss ar y.

An excessive load is being

applied to the chronograph

wheels due to dust or foreign

particles adhering to them or

oil starvation.

Clean the relevant parts and

lubricate with an adequate

amount of oil.

The step motor shows an

abnormal movement

.

There is a crack on the circuit

block switch pattern.

Replace the circuit block with a

new one.

The but tons do not operate

normally.

The amount of oil around the

buttons is insufficient.

Clean the buttons and lubricate

appropriately.

The circuit block pat tern has

been broken or bent.

Adjust the circuit block pattern

or replace the circuit block with a

new one.

The crown falls off.

The winding stem is not securely

installed. (The setting lever and

yoke are disengaged.)

Check the main plate, winding

stem, setting lever and yoke.

Replace the defective parts with

new ones.

The current consumption

exceeds the standard value.

An excessive load is being

applied due to friction among

the hour, minute and STOP-

WATCH hands.

Small amount of water/

blur inside of the glass

persists.

Water resistance is deteriorated.

The watch has been subjected to

water pressure that exceeds the

guaranteed degree.

Investigate the causes to take

necessary measures, while

cleaning inside of the watch.

Replace the stator with a new

one.

Adjust or remount the relevant

hands.

Symptom

Possible causes

Solutions

Exterior

parts

The step motor has been deformed.

Copyright©2012 by

Loading...

Loading...