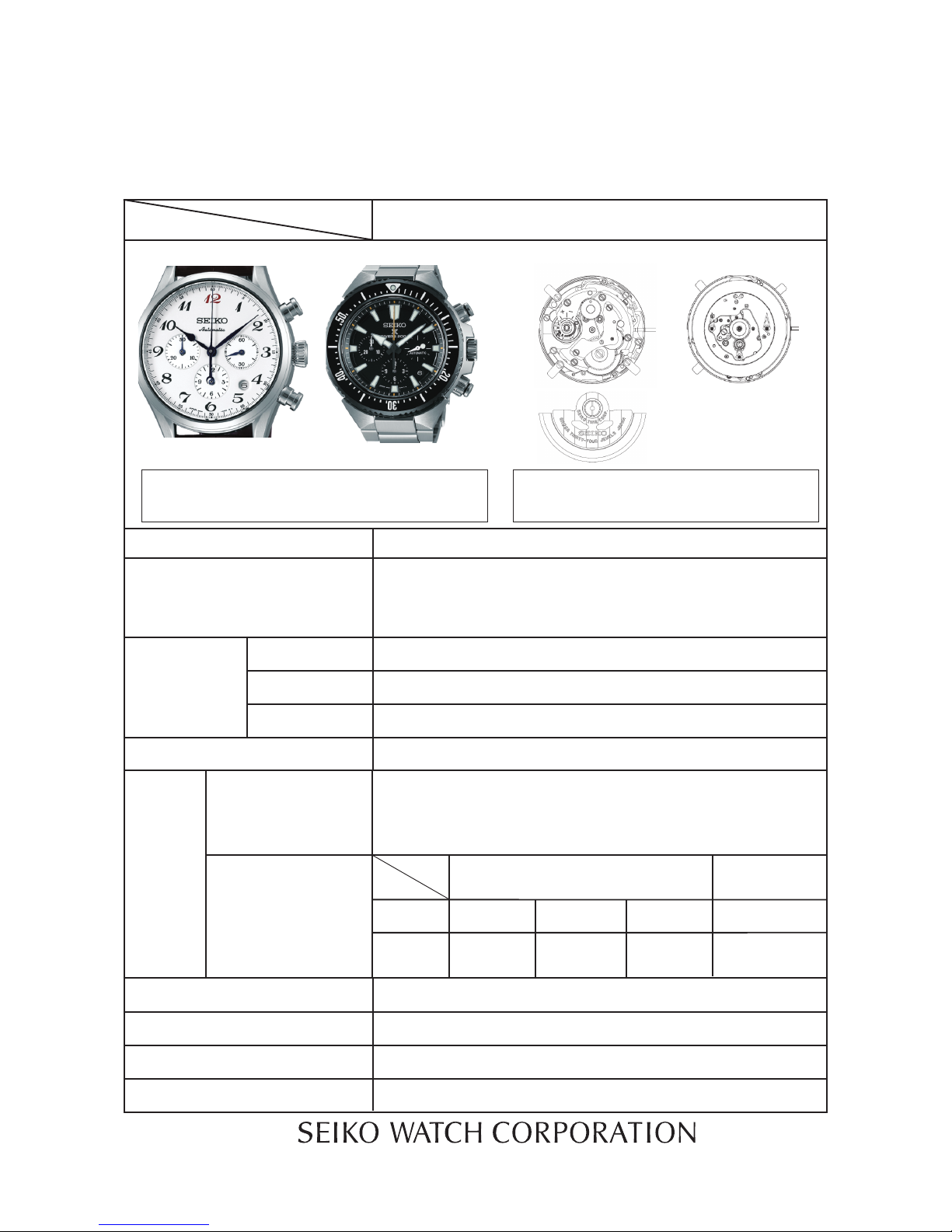

Seiko 8R48A, 8R49A Technical Manual

Movement

[Bridge side] [Calendar side]

Cal. 8R48A Cal. 8R49A

PARTS LIST / TECHNICAL GUIDE

Automatic Chronograph Cal. 8

R48A/8R49A

[SPECIFICATIONS]

1/24

Item

Cal. No.

8R48A/8R49A

34 jewels

Automatic winding with manual winding mechanism

+ 25 / - 15 seconds at normal temperature range

(Between 5°C and 35°C )

• Stopwatch function

Measures up to 12 hours

• Semi-instantaneous date change mechanism

• Second hand stop function

Date setting (counterclockwise only)

Time setting (Hour and minute)

Manual winding (clockwise only)

• Diameter Outside : Ø 28.6 mm

Casing: Ø 28.0 mm

• Height:

7.6 2 mm

• 3 hands (hour and minute hands, and small sec ond hand at

3 o'clock position)

• C alendar (Date: Da te disk)

28,800 (8 beats per second)

Testing

positions

± 10 s/d

Measurement

(daily rate in

seconds:s/d)

Dial upward

+ 20 s/d

– 10 s/d

ETACHRON system

From fully wound to stoppage: Approximately 45 hours

Movement size

52 °

6 o’clock

at the top up

Dial upward

9 o’clock

at the top up

Isochronous fault

Instantaneous rate at T0

(Fully wound condition)

+ 15 s/d

– 5 s/d

+ 20 s/d

– 10 s/d

Driving system

Additional function

Crown operation

Daily Date

Regulation system

Number of jewels

Normal position

1st click position

2nd click position

Lift angle of the escapment

Vibration per hour

Coutinuous operating time

Standard rate

for movement

Loss/Gain

SPECIFICATIONS

2/24

Cal. 8R48A/8R49A

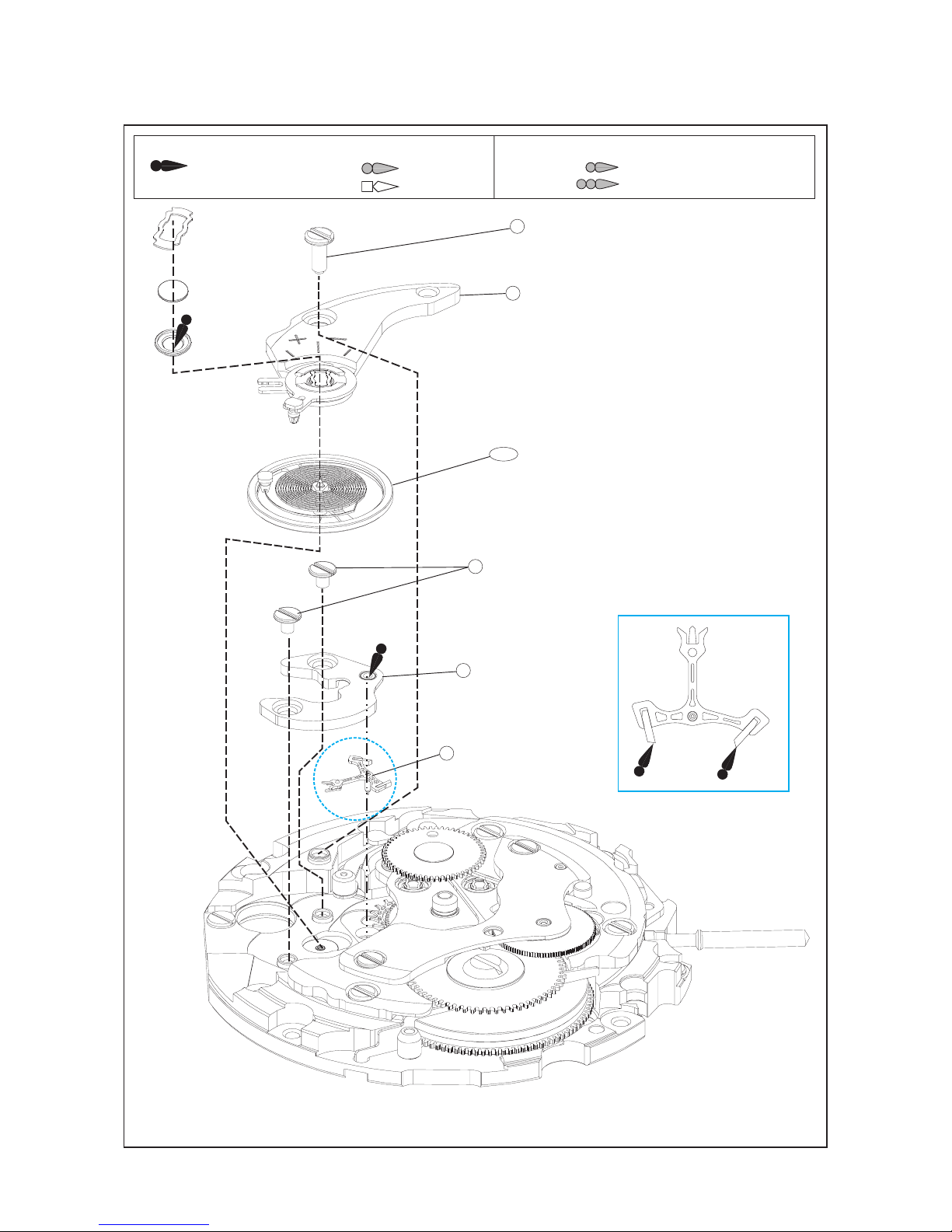

Disassembling procedures figs. 1

93

Reassembling procedures Figs. 93 1

Types of oil Oil quantity mark

AO-3 (Moebius A) NORMAL QUANTITY

S-6

S-4 SUFFICIENT QUANTITY

[ NOTE ]

Please press button A to START the chronograph function before disassembly.

If it is at RESET position 41 Chronograph coupling lever A and 42 Chronograph coupling lever B are

under 47 Second counting intermediate wheel; it makes disassembly difficult.

Button B

Chronograph RESET

Button A

Chronograph START / STOP

1 0509 ***

Oscillating weight with ball bearing

*Refer to page 10 for the parts code

*1

*1

PARTS CATALOGUE

Cal. 8R48A/8R49A

3/24

*1

2 0016 709

Hour wheel guard screw

*3

3 0376 178

Hour wheel guard

4 0491 184

Dial washer A

5 0273 277

Hour wheel

7 0016 709

Date indicator maintaining plate screw

8 0808 178

Date indicator maintaining plate

10 0810 177

Date jumper

13 0595 177

Date corrector lever

14 0732 177

Date corrector cam

17 0012 092

Chronograph bridge screw

18 0190 ***

Chronograph bridge

* Refer to page 15 for the oiling

position.

* Refer to page 10 for the parts

code

17 0012 092

Chronograph bridge screw

16 0353 177

Second counting sheel spring

15 0012 092

Second counting wheel spring screw

12 0817 179

Intermediate date wheel and pinion

11 0802 178

Date indicator driving wheel

9 Date dial

6 0270 443

Center wheel

Intermediate date wheel

and pinion setting position

*5

*2

*4

*5

*2

*3

*1

Types of oil

AO-3 (Moebius A)

Oil quantity mark

NORMAL QUANTITY

SUFFICIENT QUANTITY

S-6

S-4

Oiling position

Second counting wheel spring

Second counting wheel

*4

Cal. 8R48A/8R49A

PARTS CATALOGUE

4/24

19 0491 182

Dial washer C

22 0886 183

Minute counter intermediate

wheel and pinion B

24 0902 ***

Minute counting wheel

* Refer to page 11 for

location of jewels.

20 0491 181

Dial washer B

Note:

Refer to the page 19 for distinguishing

the dial washers B, C and D.

21 0491 183

Dial washer D

23 0886 182

Minute counter intermediate

wheel and pinion A

25 0902 ***

Hour counting wheel

* Refer to page 11 for location of

jewels.

27 0894 177

Wheel stop lever

28 0587 179

Hammer operating lever B

26 0743 179

Hour chronograph coupling lever

* Refer to page 12 for the oiling

position.

30 0587 181

Hammer operating lever A

29 0782 177

Click spring

* Refer to page 12 for the oiling

position.

31 0585 177

Hammer

* Refer to page 14 for

the oiling position.

Note:

For the setting position of the spring

and lever etc., refer to page 16.

*2

*1*1

*2

*1

Types of oil

AO-3 (Moebius A)

Oil quantity mark

NORMAL QUANTITY

SUFFICIENT QUANTITY

S-6

S-4

34 0575 177

Operating lever spring

35 0571 179

Operating lever B

40 0837 178

Chronograph coupling lever holder

41 0581 179

Chronograph coupling lever A

PARTS CATALOGUE

Cal. 8R48A/8R49A

5/24

*1

*2

*1

*2

Note:

For the setting position of the spring

and lever etc., refer to page 16.

44 0240 ***

Second wheel

* Refer to page 10 for the parts

code.

42 0581 180

Chronograph coupling lever B

32 0571 177

Operating lever A

33 0012 092

Operating lever spring screw

45 0012 201

Operating cam screw

46 0576 180

Operating cam

* Refer to page 14 for the oiling

position.

47 0885 192

Second counter intermediate

wheel

36 0012 092

Operating cam jumper screw

37 1024 177

Operating cam jumper

38 0012 092

Chronograph coupling lever

spring screw

39 0584 178

Chronograph coupling

lever spring

43 0888 181

Second counting wheel

Types of oil

AO-3 (Moebius A)

Oil quantity mark

NORMAL QUANTITY

SUFFICIENT QUANTITY

S-6

S-4

Cal. 8R48A/8R49A

PARTS CATALOGUE

6/24

*1

48 0186 192

Chronograph main plate

* Refer to page 15 for the

oiling position.

49 0012 354

Unit intermeidate spacer

screw

50 4408 181

Unit intermediate spacer

51 0962 023

Date corrector setting

transmission wheel D

52 0962 023

Date corrector setting

transmission wheel C

53 0962 190

Date corrector setting

transmission wheel B

54 0817 180

Time setting transmission

wheel and pinion

55 0505 181

Second transmission wheel

* Refer to page 17 for the

setting position.

56 0505 182

Minutes transmission wheel

* Refer to page 14 for the

oiling position.

* Refer to page 17 for the

setting position.

57 Main plate

58 0012 092

Main plate screw

58 0012 092

Main plate screw

Types of oil

AO-3 (Moebius A)

Oil quantity mark

NORMAL QUANTITY

SUFFICIENT QUANTITY

S-6

S-4

*1

59 0012 420

Balance bridge screw

60 0171 349

Balance cock

60-1

0310 ***

Balance complete with stud

* Refer to page 10 for the parts code.

61 0012 354

Pallet bridge screw

62 0161 310

Pallet bridge

63 0301 315

Pallet fork

PARTS CATALOGUE

Cal. 8R48A/8R49A

7/24

*1

*1

Types of oil

AO-3 (Moebius A)

Oil quantity mark

NORMAL QUANTITY

SUFFICIENT QUANTITY

S-6

S-4

Cal. 8R48A/8R49A

PARTS CATALOGUE

8/24

64 0012 354

Automatic train bridge screw

65 0191 064

Automatic train bridge

66 0514 183

Second reduction whell and pinion

67 0012 919

Ratchet wheel screw

68 0285 051

Ratchet wheel

74 0511 010

First reduction whell and arbor

73 0831 183

Pawl lever

72 0836 002

Reduction wheel holder

69 0012 420

Barrel and train wheel

bridge screw

71 0363 184

Ratchet sliding wheel

spring

76 0436 166

Lower plate for barrel

and train wheel bridge

75 0012 354

Lower plate for barrel

and train wheel bridge

screw

70 0114 177

Barrel and train wheel bridge

* Refer to page 13 for the

oiling position.

Types of oil

AO-3 (Moebius A)

Oil quantity mark

NORMAL QUANTITY

SUFFICIENT QUANTITY

S-6

S-4

Loading...

Loading...