Page 1

PARTS CATALOGUE / TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

[SPECIFICATIONS]

Cal. No.

Item

Movement

Movement

size

Time indication 3 hands (hour, minute and second hands) + 24-hour hand

Driving system

Additional mechanism

Outside diameter

Casing diameter

Height

Including the

(

battery portion

ø18.5 x 17.7 (3H - 9H) x

)

• Calendar (Leap year indication, month and date)

• Independent adjustment of hour hand

• Train wheel setting device

•Electronic circuit reset switch

• Battery life indicator

4F56A 8F58A

18.5 (12H - 6H)

17.1 (3H - 9H)

4.8

• Step motor (for 24-hour, hour, minute and second hands)

• Ultrasonic motor (for calendar indication)

Perpetual calendar up to February 28, 2100

8F56A

ø26.4 x 25.6 (3H - 9H) x 25.6 (12H - 6H)

24.8 (3H - 9H) x 24.8 (12H - 6H)

4.8

(x 1.0)The illustrations refer to Cal. 8F56A.

Loss/gain Annual rate within normal temperature range: less than 20 seconds

Regulation system

Measuring gate by quartz tester Use 10-second gate.

Battery

Battery No.

Voltage 3.0 V

Battery life Approx. 5 years

Jewels

Logical regulation (Pattern cutting system: 3 steps)

CR1612

4 jewels

BR2412

Approx. 8 yearsApprox. 10 years

1

Page 2

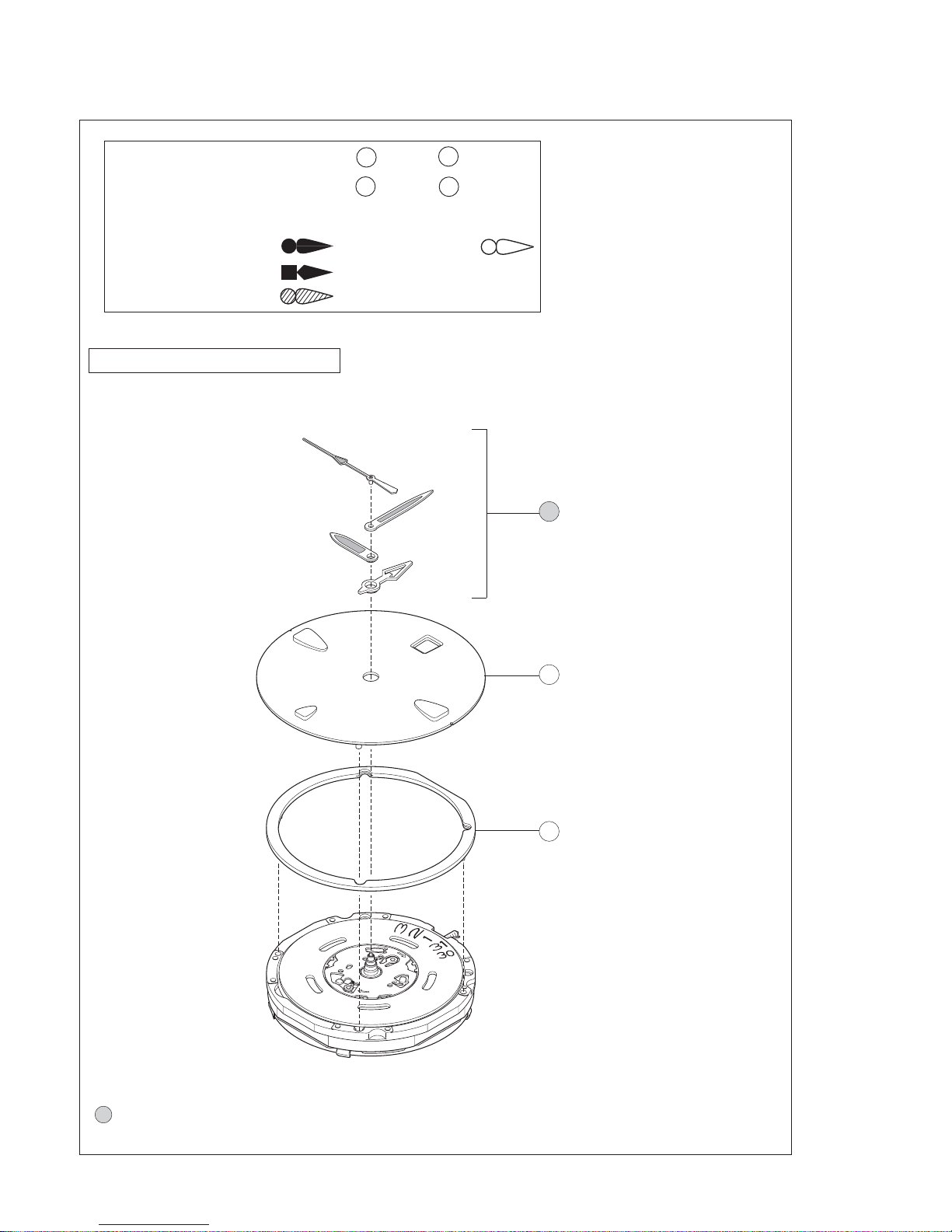

PARTS CATALOGUE

Disassembling procedures Figs.: 1 fi 49

Reassembling procedures Figs.: 49 ‹ 1

Lubricating: Types of oil Oil quantity

Moebius A Normal quantity

Moebius V

Moebius F

Cal. 4F56A, 8F56A & 8F58A

Ex. : Cal. 8F56A

Cal. 4F56A, 8F56A, 8F58A

1 24-hour, Hour, Minute and

second hands

Please see the remarks on the following pages.

2Dial

3 Holding ring for dial

0884 167 (4F56A)

0884 166 (8F56A,8F58A)

2

Page 3

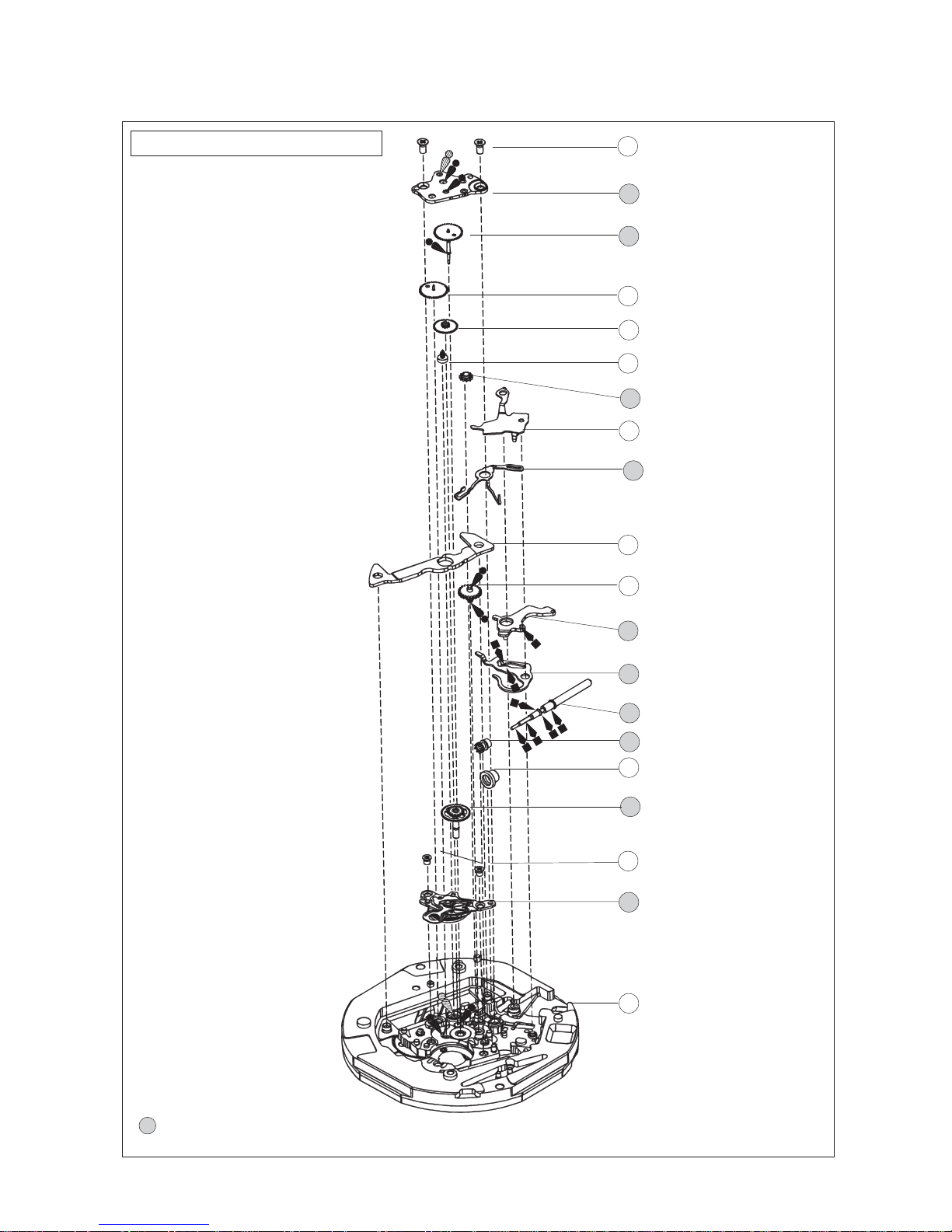

PARTS CATALOGUE

Note Pull out the crown to the first click before starting disassembling or reassembling.

Cal. 4F56A, 8F56A, 8F58A

It is highly recommended that the exclusive

movement holder (S-680) be used for

disassembly or reassembly. Contact SEIKO

SERVICE CENTER to purchase this tool.

4 Battery

For removing or installing the

battery and inputting calendar data,

refer to page 11 to 16.

2 Battery

5 Insulator for battery (A)

A battery with 5 Insulator for

battery (A) (red) may be installed in

some models. Discard this type of

battery after replacing it with a new

battery of the latest model, to which

the insulator for battery (white) is

attached.

Insulator for battery(B) (white)

( + )

( - )

Cal. 4F56A, 8F56A & 8F58A

Ex. : Cal. 8F56A

4 Battery

5Insulator for battery (A)

6 Circuit block cover screw

0016 704

7 Circuit block cover

0016 704

• Circuit block cover screw (4 pcs.)

• Train wheel bridge screw (2 pcs.)

0016 705

• Ultrasonic motor screw (2 pcs.)

Please see the remarks on the following pages.

8 Circuit block

4003 424 (4F56A)

4003 091 (8F56A,8F58A)

9 Date driving

contact point spring

4281 115

10 24-hour contact point spring

4281 119

11 Battery connection (–)

4270 415

12 Insulator for battery (B)

4216 116

13 Coil block

4002 115

3

Page 4

PARTS CATALOGUE

Cal. 4F56A, 8F56A & 8F58A

Ex. : Cal. 8F56A

Note Never remove the 24-hour

wheel and date driving wheel

while working on the date dial

replacement(without

disassembling the train wheel

side), as the date driving

contact point spring and 24hour contact point spring may

drop off.

Cal. 4F56A, 8F56A, 8F58A

14 Date dial guard 0808 127

15 24-hour clutch wheel

0273 113

16 Dial Washer

0491 016

17 Date dial

18 Hour wheel

0273 114

19 Intermediate 24-hour driving

wheel and pinion

0817 117

20 Third intermediate wheel for

hour corrector

0168 014

21 Date jumper screw

0012 354

0012 354

Date jumper screw ( 4 pcs. )

Please see the remarks on the following pages.

22 Date jumper

0810 116

23 Calender Plate

0195 014

24 Second intermediate wheel for

hour corrector

0168 013

25 Intermediate date driving wheel

and pinion

0817 118

26 Bush for second intermediate wheel

for hour corrector guide

4247 018

27 Ultrasonic rotor

4062 117

28 24-hour wheel

1019 114

29 Date driving wheel

0802 116

4

Page 5

PARTS CATALOGUE

Cal. 4F56A, 8F56A, 8F58A

Cal. 4F56A, 8F56A & 8F58A

Ex. : Cal. 8F56A

30 Train wheel bridge screw

0016 704

31 Train wheel bridge

0125 254

32 Fourth wheel and pinion

33 Third wheel and pinion

0231 116

34 Fifth wheel and pinion

0701 116

35 Rotor

4146 116

36 Setting wheel

0281 115

37 Yoke guard

0388 116

38 Train wheel setting lever

0391 115

39 Stator

4239 115

40 Minute wheel and pinion

0261 048 (4F56,8F56A)

0261 049 (8F58A)

41 Setting lever

0383 115 (4F56A)

0383 116 (8F56A,8F58A)

42 Yoke

0384 116

Please see the remarks on the following pages.

43 Setting stem

44 Clutch wheel

0282 117

45 First intermediate wheel for hour

corrector

0168 011

46 Center wheel and pinion

47 Ultrasonic stator unit screw

0016 705

48 Ultrasonic stator unit

4234 115

49 Main plate

0100 148 (4F56A)

0100 138 (8F56A,8F58A)

5

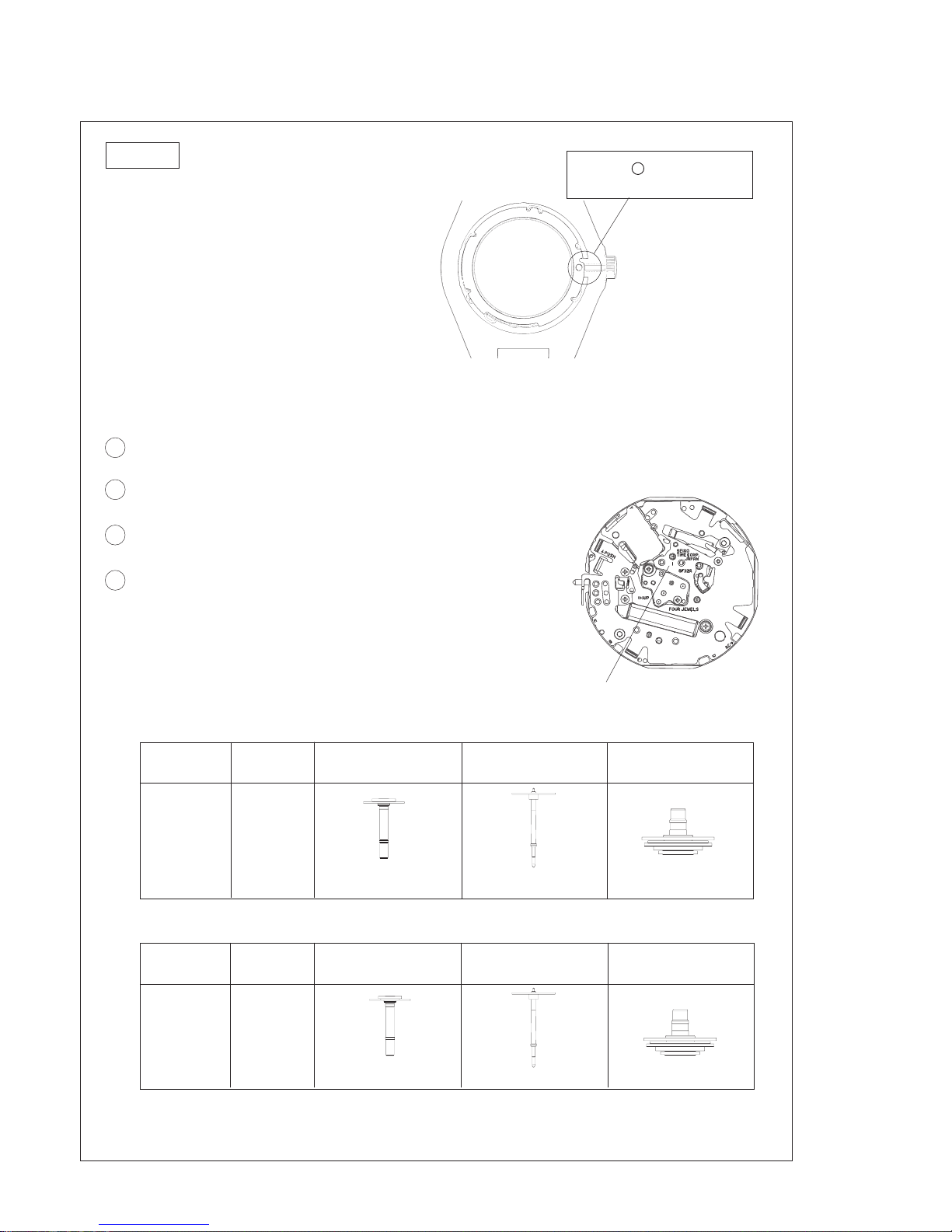

Page 6

PARTS CATALOGUE

Cal. 4F56A, 8F56A, 8F58A

Remarks

● Back plate

For some models which use the back plate, refer

to the illustration at the right to mount it.

● Case ring

The type of case ring is determined based on the

case design.

Check the case number and refer to “SEIKO

Casing Parts Catalogue” to choose the appropriate

case ring.

7 Circuit block cover

32 Fourth wheel and pinion

46 Center wheel and pinion

18 Hour wheel

Align the indicator to the

setting stem.

• Discrimination of the hand installation height

Cal. 4F and 8F Series watches have numerals printed on

movement to indicate the hand installation height. When

repairing, refer to the table below.

4F56A

Numeral for

discrimination

2

Circuit

block cover

4461 034

Center wheel and

pinion

0221 122

8F56A

Numeral for

discrimination

2

Circuit

block cover

4461 026

Center wheel and

pinion

0221 122

Numeral for discrimination

Fourth wheel and

pinion

0241 167

Fourth wheel and

pinion

0241 167

Hour wheel

0273 114

Hour wheel

0273 114

6

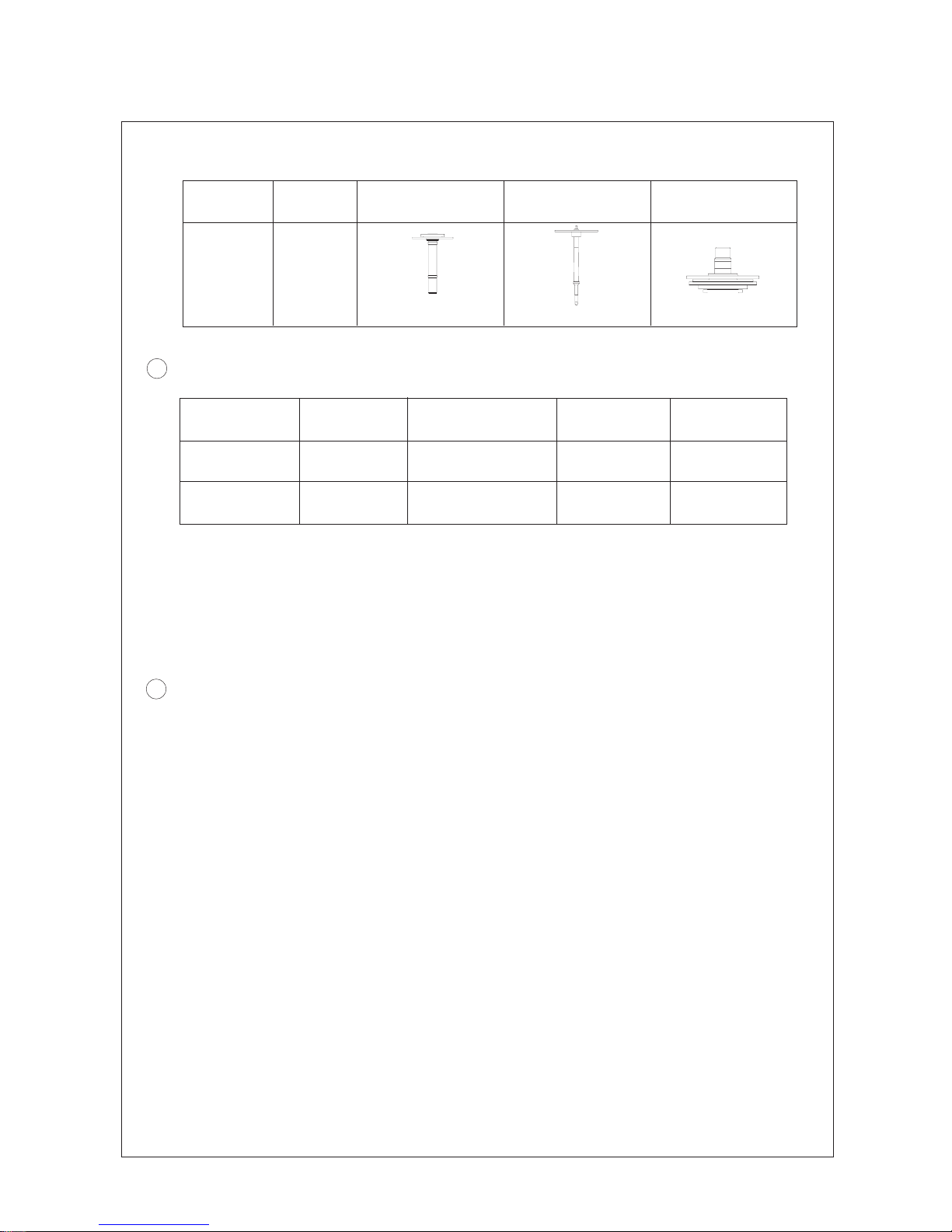

Page 7

PARTS CATALOGUE

8F58A

Cal. 4F56A, 8F56A, 8F58A

Numeral for

discrimination

2

17 Date dial

Cal. No.

4F56A

8F56A

8F58A

The type of date dial is determined based on the case design.

* Not all the types of date dial are shown in the table above.

Check the case number and refer to “SEIKO Casing Parts Catalogue” to choose the appropriate date dial.

Circuit

block cover

4461 035

Part code

0878 320

0878 356

Center wheel and

pinion

0221 124

Position of crown and

calendar frame

3 o'clock

3 o'clock

Fourth wheel and

pinion

0241 167

Color of figure

Black

Black

Hour wheel

0273 114

Color of

background

White

White

43 Setting stem 0351 196

The type of setting stem is determined based on the case design.

Check the case number and refer to “SEIKO Casing Parts Catalogue” to choose the appropriate setting

stem.

7

Page 8

Cal. 4F56A, 8F56A, 8F58A

TECHNICAL GUIDE

• The explanation here is only for the particular points of Cal. 4F56A, 8F56A and 8F58A.

• For repairing, checking or measuring procedures, refer to the “TECHNICAL GUIDE, GENERAL

INSTRUCTIONS”.

I. STRUCTURE OF THE CIRCUIT BLOCK

[ Cal. 4F56A ]

“M” terminal (for month setting)

“ø” terminal

(for resetting the date dial)

[ Cal. 8F56A, 8F58A ]

“ø” terminal

(for resetting

the date dial)

“M” terminal (for month setting)

“Y” terminal (for year setting)

AC terminal

“D” terminal

(for date setting)

“Y” terminal

(for year setting)

Input terminal (+)

C-MOS-IC

Crystal unit

C-MOS-IC

Input terminal (+)

Coil block output terminal

Input terminal (–)

Coil block output terminal

“D” terminal

(for date setting)

AC terminal

8

Crystal unit

Input terminal (–)

Page 9

TECHNICAL GUIDE

II. REMARKS ON DISASSEMBLING AND REASSEMBLING

It is highly recommended that the exclusive movement holder (S-680) be used to disassemble or

reassemble the watch.

Use of other movement holders may make unreliable the screw pins (the gold part) of the main plate.

Be careful not to press the main plate too hard when screwing or unscrewing the pins.

To prevent deformation of the main plate, never use the movement holder which is designed to hold

the movement with only two side guides.

◆ How to use the exclusive movement holder

[ Cal. 4F Series ]

Setting stem guide

Cal. 4F56A, 8F56A, 8F58A

A portion

Disassembling/reassembling procedures :

[ Cal. 8F Series]

A portion

Disassembling/reassembling procedures :

«

1

29

«

29

1

B portion

Disassembling/reassembling procedures :

Setting stem guide

B portion

Disassembling/reassembling procedures :

30

30

«

49

«

49

9

Page 10

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

1 24-hour, hour, minute and second hands

Always set the hands with the battery installed.

Set the movement to the A portion of the exclusive movement holder.

If any other movement holder is used, be certain to place the movement on a secure, flat plate. Pay special

attention not to damage the hooking portion.

Hooking portion

◆ How to set the hands

1. Set 4 Battery. (Refer to page 12.)

2. Set 3 Holding ring for dial.

3. Set 2 Dial.

4. Go to "Necessary procedure after a battery change".

*Refer to page 12 for details.

5. Input the calendar data.

*Refer to page 13 to 16 for details.

Installation of the hands

Turn the crown clockwise until the date changes, then set the hands to point at the 12 o’clock position.

To set the hands more accurately,

1) Turn the crown clockwise until the date changes.

2) Give the crown four counterclockwise turns until the previous date appears.

3) Slowly turn the crown clockwise until the date changes again.

4) Set the hands to point at the 12 o’clock position.

Battery

10

Page 11

TECHNICAL GUIDE

4 Battery

It is highly recommended that the exclusive tool (S-912) be used for removing or

installing the battery, resetting the built-in IC or inputting the calendar data.

Contact SEIKO SERVICE CENTER to purchase this exclusive tool.

S-912

◆ How to remove the battery

1. Insert the tip of the tweezers into the gap between the battery and the circuit block cover at the insertion

point 1 in the illustrations below to gently lift up the battery.

2. Insert the tip of the tweezers into the gap between the battery and the circuit block cover at the insertion

point 2 in the illustrations below to gently lift up the battery.

3. Remove the battery with due care not to damage the coil.

The illustrations below show the new battery installed. (The battery is a new model with the new white

battery insulator.) (In a case where the red insulator is installed, insert the tweezers between the red insulator

and the circuit block cover in the order of the numbers illustrated below.) Take care not to insert the tweezers

too deep into the gap as this may damage the coil.

Cal. 4F56A, 8F56A, 8F58A

[ Cal. 4F56A ]

Insertion point 2

Insertion point 1

[ Cal. 8F56A, 8F58A ]

Insertion point 1

Insertion point 2

11

Page 12

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

◆ How to install the battery

1. In a case where a red battery insulator is installed, remove and discard it.

2. To install a new battery with a battery insulator, align the tip of the arrow mark on the seal attached

to the battery with the crown. Then press it towards the portion for a battery check. Be careful not to deform

the portion for battery check.

*Make sure that the battery is securely fixed by the four hooking portions.

3. After the battery is installed, turn to the "Necessary procedure after a battery change".

4. After completing the "Necessary procedure after a battery change", turn to “How to input the calendar

data.”

Grounding portion

Portion for battery check

◆ Necessary procedure after a battery change

1. After the battery is replaced with a new one, push the crown back to its normal position.

2. Contact the “AC” terminal of the circuit block and the (+) surface of the battery with a S-912 tool or

conductive tweezers for more than three seconds to reactivate the built-in IC.

➔

Be careful not to damage the circuit block. (To prevent any damage to the circuit block, it is highly

recommended the exclusive tool S-912 be used .)

Battery

AC Terminal

Reactivate the built-in IC by contacting the AC

terminal and the side face of the battery with the

tip of the tool.

2

[ Position of AC terminal of

Cal. 8F (Gent's) Series ]

B

1

R

4

2

AC Terminal

[ Position of AC terminal of

Cal. 4F (Ladies') Series ]

Circuit Block

AC Terminal

12

Page 13

TECHNICAL GUIDE

◆How to input the calendar data

A How to check the calendar data (after battery change)

■

1. Pull out the crown to the first (or the second) click, then

immediately push it back to its original position.

Gently support the battery with fingers and securely hold

the movement.

➟

2

2. Check the movement of the second hand and follow the flowchart below.

Five-second interval movement

➟

One-second interval movement :

The data is retained securely.

Go to C. How to check the calendar data.

Cal. 4F56A, 8F56A, 8F58A

Five-second interval movement :

The data has been erased.

Go to B. How to input the calendar data.

One-second

interval

movement

Five-second

interval

movement

If the second hand shows neither one-second interval movement nor five-second interval movement,

return to the "Necessary procedure after a battery change" followed by A. How to check the calendar data

(after battery change).

C.

How to check

the Calendar

Data

The data is correct.

Complete.

The data is wrong.

B.

How to input

the calendar

data

13

Page 14

TECHNICAL GUIDE

B How to input the calendar data

■

To input the calendar data, activate the circuit by

contacting each terminal and the side face of the battery

repeatedly with tweezers. Be careful not to damage the

circuit block.

Cal. 4F56A, 8F56A, 8F58A

Battery

Circuit Block

Year

Month

Ø

[ Position of the terminals of Cal. 8F (Gent's) Series ]

• Input each calendar data item in the following order.

2

B

1

R

4

2

AC

Date

Ø Y M D

Resetting

the date dial position

Set the date dial to “1”.

Year setting

Set the date dial to

the current year.

Year

Month

Ø

[ Position of the terminals of Cal. 4F (Ladies') Series ]

Month setting

Set the date dial to

the current month.

AC

C

R

1

6

1

2

Date setting

Set the date dial to

the current date.

Date

1. Pull out the crown to the second click.

[8F]

1

Ø

[4F]

Ø

2. Contact the “Ø “ terminal with the tip of tweezers until “1” appears

14

in the calendar frame.

Page 15

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

2

[Ex. : July]

7

[Ex. : 12th.]

12

[8F]

[4F]

[8F]

[4F]

[8F]

[4F]

3. Contact the “Y” terminal with the tip of tweezers until the year

Y

Y

number representing the current year appears in the calendar frame.

(Refer to the table below for the year number.)

4. Contact the “M” terminal with the tip of tweezers until the current

month appears in the calendar frame.

M

M

5. Contact the “D” terminal with the tip of tweezers until the current

date appears in the calendar frame.

D

D

[8F]

6. Contact the “Ø “ terminal with the tip of tweezers once to check if “1”

appears in the calendar frame.

If “1” does not appear in the calendar frame, redo the whole

1

Ø

[4F]

Ø

procedures from 1 to 6 once again.

7. Push the crown back to its original position.

For the year number which represent the current year in the calendar frame, refer to the table below.

Year number in the calendar frame

1 234

One year since

the last leap year

Year

2001

2005

2009

•

•

Two years since

the last leap year

2002

2006

2010

•

•

Three years since

the last leap year

2003

2007

2011

•

•

Leap year

2004

2008

2012

•

•

15

Page 16

Cal. 4F56A, 8F56A, 8F58A

TECHNICAL GUIDE

C How to check the calendar data (After inputting the data)

■

Ex.: July 12, 2002

Pull out the crown to the first click, then immediately push it back to its original position. Gently support the

battery with fingers to securely hold the movement.

Each calendar data item will be shown in the following order.

Year

Month

Date

Ex.: July

Ex.: 12th.

The number of times that the second hand moves in five-second

intervals indicates the number of the year which has passed since

the last leap year.

Ex. Year 2002:

The year number 2 ; the second hand moves twice in five-second

intervals.

The current month will be displayed for a while in the calendar

frame.

7

Subsequently the current date will be displayed in the calendar

frame.

12

If all the data items are correct, proceed to the time setting.

When setting the time, make sure that AM/PM is properly set.

Note

This watch does not feature an Automatic Calendar Function.

Date is interlocked to the movement of the hands.

Be certain that AM/PM is properly set when setting the time to prevent the wrong date from appearing.

If any data item is not correct, return to B. How to input the calendar data and repeat the whole procedures

once again.

16

Page 17

TECHNICAL GUIDE

Note Pull out the crown to the first click before starting disassembling or reassembling.

7 Circuit block cover

Reassembling :

When setting the circuit block cover, take care not to deform the terminal for battery check.

[ Cal. 4F56A ] [ Cal. 8F56A, 8F58A ]

Cal. 4F56A, 8F56A, 8F58A

Terminal for battery check

8 Circuit block

Disassembling :

Insert tweezers from the positions indicated in the illustration below to remove the circuit block.

Reassembling :

Locate the circuit block using the guide pin A on the coil side. Then gently press down the guide pin B

under the 24-hour wheel to fix the circuit block.

When mounting the circuit block, make sure that the date driving contact point spring and 24-hour contact

point spring are correctly mounted and that the tip of the reset lever is positioned at the center of the

eyehole as shown in the illustration below.

Positions to insert tweezers

Guide pin A

Terminal for battery check

Tip of the reset lever terminal

(Center of the eyehole)

Guide pin B

Eyehole

17

Page 18

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

9 Date driving contact point spring

10 24-hour contact point spring

• Setting position

Date driving contact point spring 24-hour contact point spring

Note The date driving contact spring and the 24-hour contact point spring contact with the circuit block to

drive and control the ultrasonic motor. Failure of this electric contact will cause a malfunction of the

ultrasonic motor or defective calendar display. To guard against this problem, carefully handle the

contact point springs not to bend or straighten them.

To prevent a problem caused by deformation of the springs, it is recommended that the springs be

replaced with new ones at the time of disassembling or reassembling.

14 Date dial guard

Unlike conventional movements, the date dial guard is not fixed

with screws. It is set to the main plate with the three protrusions,

which are caught under the main plate by turning the guard.

Then, it is fixed by the two guide pins.

• How to remove

1. Gently lift up the A portion of the date dial guard with

tweezers to clear it from the guide pin, and then, move it in

the clockwise direction until it gets on the guide pin.

2. Release the B portion of the date dial guard in the same

manner as you release the A portion, and then, move it in

the clockwise direction until it gets on the guide pin.

3. Check that all the three protrusions of the date dial guard

have come off the main plate. Then, remove the date dial

guard.

Note Take care not to deform the date dial guard, as it is

softly built.

D portion

B portion

A portion

Guide pin

Date dial guard

C portion

18

Date dial guard

E portion

Date dial guard

Guide pin

Page 19

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

• How to install

1. Put the date dial guard on the main plate so that the

A and B portions are over the guide pins, as shown

in the illustrations at the right.

2. Move protrusion D of the date dial guard in the

counterclockwise direction so that it is caught under

the main plate.

3. Slightly move protrusions C and E in the

counterclockwise direction alternately to set them

under the main plate. While doing so, set the A and

B portions of the date dial guard to the guide pins.

Note Take care not to press down the ultrasonic rotor

pinion while installing the date dial guard.

Ultrasonic rotor pinion

Protrusion D

B portion

Protrusion C

A portion

Protrusion E

18 Hour wheel

Refer to the illustration below for lubricating.

Lubricating hole

Caution must be taken not to

spill oil over the wheel.

Caution must be taken not to

spill oil inside.

19

Page 20

TECHNICAL GUIDE

25 Intermediate date driving wheel and pinion

27 Ultrasonic rotor

Cal. 4F56A, 8F56A, 8F58A

28 24-hour wheel

29 Date driving wheel

• Setting position

Refer to the illustration at the right.

Intermediate date driving

24-hour wheel

Ultrasonic rotor

wheel and pinion

Date driving wheel

Note The pinions of the ultrasonic rotor and date driving wheel are made of plastic. Be careful not

to damage or deform them while working on reassembling or disassembling.

27 Ultrasonic rotor 48 Ultrasonic stator unit

Note When holding the ultrasonic rotor and ultrasonic stator unit with tweezers, be sure to catch the

portions illustrated below. Failure to do so may adversely affect their functions.

Ultrasonic rotor

Ultrasonic stator unit

Do not touch here.

Tweezers

Tweezers

Keep this side away from dust or dirt.

20

Page 21

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

31 Train wheel bridge

• Setting position of the wheels

36 Setting wheel

Make sure that the top face is up.

Train wheel bridge side

Main plate side

38 Train wheel setting lever

41 Setting lever

Step rotor

Fifth wheel and pinion

Setting wheel

Minute wheel and pinion

Fourth wheel and pinion

Third wheel and pinion

42 Yoke

• Setting position

Train wheel

setting lever

Setting lever

Yoke

Make sure that the spring of the yoke is

appropriately fit into the frame of the

main plate.

Note Handle with care not to deform the spring of the york.

When the circuit block cover is missing, do not pull out or push back the

crown.

44 Clutch wheel

To mount the clutch wheel, set the smaller face width of the wheel toward the center of the

setting wheel.

Setting wheel

Clutch wheel

setting stem

Yoke

21

Page 22

TECHNICAL GUIDE

Cal. 4F56A, 8F56A, 8F58A

III. VALUE CHECKING

● Coil block resistance

3.6 KW ~ 4.0 KW

Measuring the coil block resistance

1. Measure the resistance with the coil block installed on the main plate.

2. Apply the red and black probes of the tester to the patterns of the coil lead terminal. While doing so,

take care not to touch the end portion of the coil lead terminal, as this will break the coil wire.

Coil board pattern

● Current consumption

For the whole movement : Less than 1.3 mA (with voltage of 3.0 V supplied from a battery)

For the circuit block alone : Less than 0.9 mA (with voltage of 3.0 V supplied from a battery)

Measuring the current consumption for the whole movement

1. Check that the crown is in the normal (pushed in) position.

Black probe

Red probe

2. Apply the red and black probes of the tester to the circuit block cover and the pattern of the (–) terminal

of the circuit block, respectively.

3. After connecting the tester, contact the “AC” terminal of the circuit block and the circuit block cover

with conductive tweezers. Then, after approximately 20 seconds, start measurement, checking that

a stable measurement is obtained.

Measuring the current consumption for the circuit block alone

1. Connect the tester to the input terminals (+) and (–), and contact the “AC” and (+) terminals with

conductive tweezers. Then, after approximately 10 seconds, start the measurement, checking that

a stable measurement is obtained.

* While measuring current consumption, be sure to protect the circuit block from light with black

cloth or the like, as the light may increase the current consumption, resulting in an inaccurate

measurement.

Note When the current consumption for the whole movement exceeds the standard value while the

current consumption for the circuit block alone is within the standard value range, a driving pulse

may be generated to compensate for the heavy load applied on the gear train, etc. In that case,

overhaul and clean the movement parts, and then, measure the current consumption for the

whole movement again.

22

Page 23

4F56A, 8F56A, 8F58A

Page 24

【Supplement】 Time accuracy adjustment by crown operation

(Only recommended to the Service Centers of SEIKO Affiliates and Distributors)

Although time accuracy is normally adjusted by pattern cutting (P.21), in case it cannot be adjusted within the

standard accuracy by this method, please adjust by the crown operation which is shown below:

2) Push back the

crown to the first click

from the second click.

The second hand

starts to move at the

same time.

3) Leave this 2) condition for 5 seconds and then

pull the crown out to the second click again.

(note: The second hand starts to move by the

operation 2), after 5 seconds by the second

hand, then pull the crown out to the second

click.)

1) Pull out the

crown to the

second click.

After you push back the crown to the original position (0 click), the calendar returns to the current date

and the second hand starts to move. (During the time when you are adjusting the accuracy, the watch

has been stopped and the time setting is necessary after the adjustment has finished.)

4) According to the above operations, the calendar

automatically moves as follows:

① The calendar will move to 8 from the current

date and stops initially.

② Then it automatically moves from 8 to 1 in order.

③ Then it automatically moves from 1 to 15 in order, each date takes 3 seconds to change to the next date.

The dates 1 to 15 correspond to the adjustable seconds in the following table.

Therefore, you have to decide beforehand how many seconds are necessary to adjust.

.

after 5 seconds

Note: Regarding the adjustable

seconds, this is based on

accuracy before adjustment.

The adjustable amount is upto

–0.056, and you cannot increase

it beyond the limit by repeating

the above operations.

④ You choose the date according to the adjustable seconds and push the

crown to the original (0 click) position while the target date is displayed.

eg.) present accuracy: 0.100 seconds/day

When adjusted to be –0.056 seconds/day

Push the crown at the moment when the calendar shows “15”. The accuracy after

the adjustment is about 0.044 seconds/day. If you have not pushed back the crown

at the date which should be done, the calendar changes to 16 after 15 and returns to

the current date.

3 seconds

3 seconds 3 seconds 3 seconds

*

*

21

(supplement)

Cal. 4F56A, 8F56A, 8F58A

Page 25

Tips on repairing the perpetual calendar (4F,8F Series)

• Be aware that incorrectly-input calendar data will cause a wrong calendar display.

• For troubleshooting problems with the calendar, refer to the table below.

Symptoms

• The calendar does

not work.

• The second hand

moves at a fivesecond interval.

Problems

• The battery is running low.

• The insulator for the battery is out of

alignment and the battery has

shorted.

• The battery is not securely set to the

battery holder of the circuit block

cover.

• Problems with parts of the date dial

or the date dial guard, or the date dial

or the date dial guard is incorrectly

mounted.

• The date driving contact point spring

or 24-hour contact point spring is not

contacted with the circuit block.

• The calendar data is incorrectly input.

• The calendar data is incorrectly input.

• The insulator for battery is out of

alignment and the battery is shorted

out.

Solutions

• Replace the battery.

• Set correctly the insulator for the battery.

• Use a new battery with the battery insulator.

• Securely set the battery to the battery

holder of the circuit block cover.

• Check the parts of the date dial or the date

dial guard and replace them with new ones

as necessary or remount them correctly.

• Remove all dust or dirt on contact points of

the date driving contact point spring, 24hour contact point spring or the circuit

block.

• Replace the date driving contact point spring

or 24-hour contact point spring with new

ones.

• Refer to the technical guide to correctly

input the calendar data.

• Refer to the technical guide to correctly

input the calendar data.

• Set correctly the insulator for battery.

• Use a new battery with battery insulator.

Reference

p.11,12

p.3

p.11,12

p.18,19

p.18

p.13-16

p.13-16

p.3

• The calendar

display is wrong.

•A character(s) of

the calendar is out

of the calendar

frame.

• The calendar data is incorrectly input.

• The date driving contact point spring,

24-hour contact point spring or the

circuit block are dirty.

• The date dial or the date dial guard is

incorrectly mounted.

• The date dial or the date dial guard is

deformed or deteriorated.

• The train wheel setting lever is out of

alignment.

• The portion for battery check of the

circuit block cover is deformed.

• Problems with parts of the date dial

or the date dial guard, or the date dial

or the date dial guard is incorrectly

mounted.

• Refer to the technical guide to correctly

input the calendar data.

• Remove all dust or dirt on the contact points

of the date driving contact point spring, 24hour contact point spring or the circuit block.

• Refer to the technical guide to correctly

remount them.

• Replace the date driving contact point spring

or 24-hour contact point spring with new

ones.

• Check if the train wheel setting lever

operates normally or remount it as

necessary. Note that it must be mounted

with the crown at the first click position.

• Reshape the deformed part. Replace the

circuit block cover with a new one as

necessary.

• Check the parts of the date dial or the date

dial guard and replace them with new ones

as necessary or remount them correctly.

* For troubleshooting of the general defects of conventional quarts watches, refer to the “TECHNICAL

GUIDE, GENERAL INSTRUCTIONS”.

p.13-16

p.18

p.18

p.18

p.21

p.17

p.18,19

23

Page 26

24

2004-02-01

Loading...

Loading...