Page 1

1

PARTS CATALOGUE / TECHNICAL GUIDE

Cal. 7N32C

Cal. 7N33C

Cal. 7N39C

[SPECIFICATIONS]

Cal. No.

Item

7N32C

Movement

ø24.0 mm

21.5 mm between 12 o’clock and 6 o’clock sides

21.3 mm between 3 o’clock and 9 o’clock sides

The illustrations refer to Cal. 7N33C.

7N39C

Outside diameter

(x 1.0)

7N33C

ø23.3 mm

21.5 mm between 12 o’clock and 6 o’clock sides

21.3 mm between 3 o’clock and 9 o’clock sides

Casing diameter

Movement size

2.57 mm

Height

Time indication 3 hands

Driving system

Step motor (Load compensated driving pulse type)

Additional mechanism

2.78 mm

Day calendar

Instant setting device

for day calendar

_

_

Loss/gain

Monthly rate at normal temperature range: less than 15 seconds

Regulation system

Nil

Measuring gate by quartz tester

Use 10-second gate.

Battery

SEIKO SR920SW, Maxell SR920SW, Sony SR920SW,

Matsushita SR920SW, Eveready 371

Battery life is approximately 5 years.

Voltage: 1.55V

2 hands

2.57 mm

_

_

_

_

Jewels

1 jewel

Date calendar

Instant setting device for date calendar

Train wheel setting device

Electronic circuit reset switch

Battery life indicator

Page 2

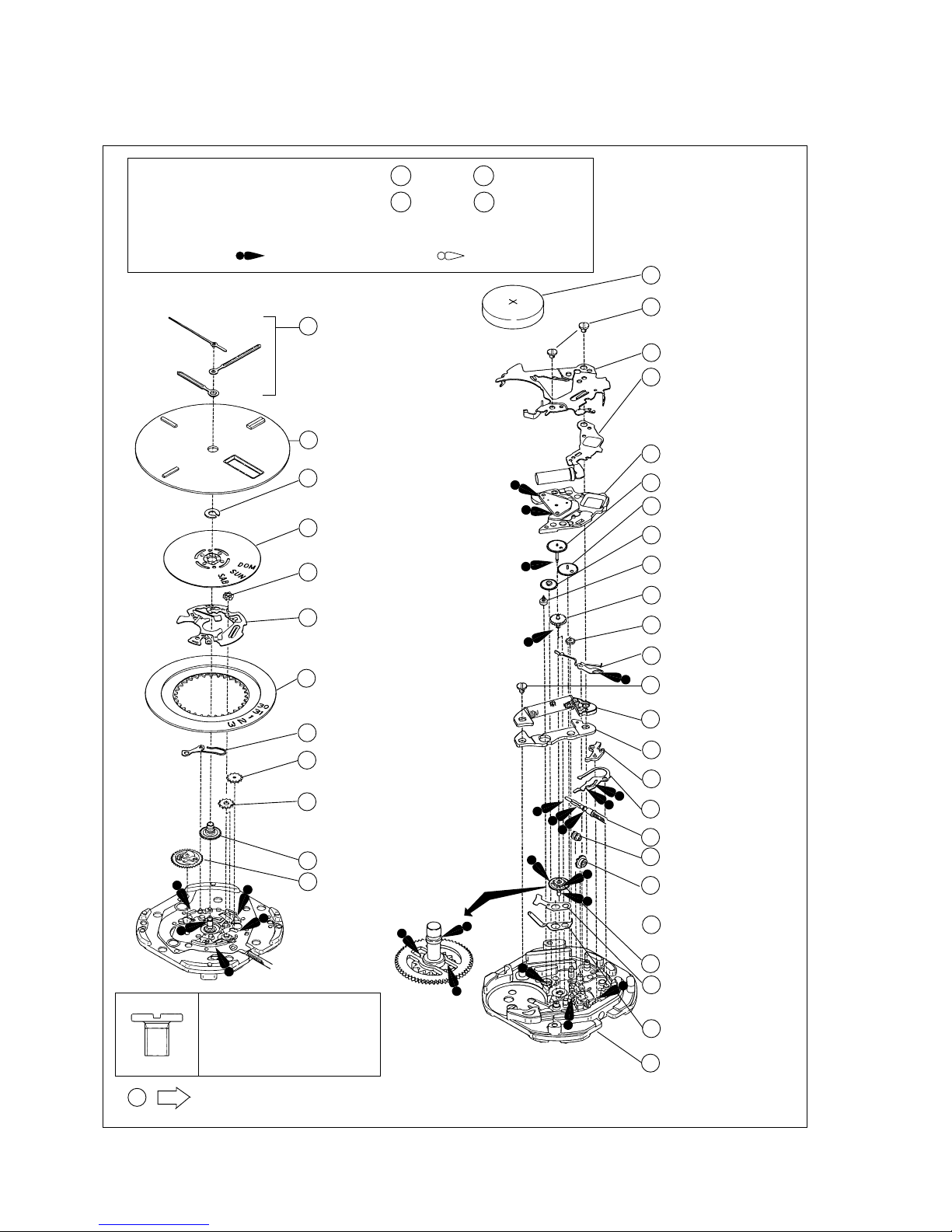

2

Cal. 7N32C, 7N33C, 7N39C

PARTS CATALOGUE

Please see the remarks on the following pages.

15 Battery connection (+)

18 Fourth wheel and pinion

0022 247

• Battery connection (+)

screw (2 pcs.)

• Coil block screw (1 pc.)

Disassembling procedure Figs. : 1 → 36

Reassembling procedure Figs. : 36 → 1

Lubricating: Types of oil Oil quantity

Moebius A Normal quantity

Ex. : Cal. 7N33C

1 Hour, minute and

second hands

(Cal. 7N32C, 7N33C)

Hour and minute hands

(Cal. 7N39C)

2 Dial

3 0963 230 (Cal. 7N33C)

Snap for day star

with dial disk

4 0150 515 (Cal. 7N33C)

Day star with dial disk

5 0989 890 (Cal. 7N33C)

Intermediate wheel

for day correction

13 Battery

(See the front page.)

14 0022 247

Battery connection (+)

screw

17 0125 923

Train wheel bridge

16 4000 634

(Cal. 7N32C, 7N33C)

4000 633 (Cal. 7N39C)

Circuit block

19 0231 904

Third wheel and pinion

20 0701 904

Fifth wheel and pinion

21 4146 886

Step rotor

22 0261 904

Minute wheel

23 0281 904

Setting wheel

24 0391 890

Train wheel setting lever

26 4002 923

Coil block

33 Center wheel and pinion

35 4270 904

Battery connection (-)

34 4216 904

Insulator for battery

connection C

32 0806 890

(Cal. 7N32C, 7N39C)

Date corrector wheel

32 0962 890 (Cal. 7N33C)

First intermediate wheel

for calendar correction

31 0282 890

Clutch wheel

29 0384 890

Yoke

28 0383 891

Setting lever

27 4239 892

Rotor stator

30 Winding stem

8 0810 890

Date jumper

9 0737 891 (Cal. 7N33C)

Date corrector setting

wheel

10 0962 891 (Cal. 7N33C)

Second intermediate

wheel for calendar

correction

7 0878 579 (Cal. 7N32C)

0878 643 (Cal. 7N33C)

0878 633 (Cal. 7N39C)

Date dial

25 0022 247

Coil block screw

36 Main plate

6 0808 890 (Cal. 7N33C)

0808 891

(Cal. 7N32C, 7N39C)

Date dial guard

11 Hour wheel

12 0802 890 (Cal. 7N33C)

0802 891

(Cal. 7N32C, 7N39C)

Date driving wheel

Page 3

3

Cal. 7N32C, 7N33C, 7N39C

PARTS CATALOGUE

Remarks:

11 Hour wheel

18 Fourth wheel and pinion

33 Center wheel and pinion

36 Main plate

• Discrimination of the hand installation heights

Cal. 7N Series watches have numerals printed on the dial and the movement to indicate the hand

installation heights. When repairing, refer to the table below.

Discrimi-

nation

Printed on Dial Movement

Numeral for

discrimination

Height Short type

1

Standard type

2

Ex) Standard type

Ex) Standard type

Printed position

The numeral is printed at

the right end.

The numeral is printed

below the calibre number.

Combination:

* The hand installation heights can be discerned from the shape of the following parts. Refer to the table

below.

[Cal. 7N32C]

Numeral for

discrimination

1

2

Center wheel

and pinion

0271 929

Hour wheel

0221 904 0241 904 0271 942 0100 942

Main plate

(Center pipe)

Fourth wheel

and pinion

0100 941

0241 929

0221 929

JAPAN 7N33-5A00 R2

Page 4

4

Cal. 7N32C, 7N33C, 7N39C

PARTS CATALOGUE

[Cal. 7N33C]

Numeral for

discrimination

2

Center wheel

and pinion

0271 934

Hour wheel

Main plate

(Center pipe)

Fourth wheel

and pinion

0100 943

0241 934

0221 934

[Cal. 7N39C]

Numeral for

discrimination

1

2

Center wheel

and pinion

0271 929

Hour wheel

0221 904 0241 941 0271 942 0100 942

Main plate

(Center pipe)

Fourth wheel

and pinion

0100 9410241 940

0221 929

15 Battery connection (+) 4268 620

Note: The battery connection (+) we are supplying has no calibre number nor numeral printed on it for

discriminating the hand installation height.

30 Winding stem 0351 892

The type of winding stem is determined based on the design of cases.

Check the case number and refer to “SEIKO Casing Parts Catalogue” to choose a corresponding winding

stem.

Page 5

5

Cal. 7N32C, 7N33C, 7N39C

TECHNICAL GUIDE

• The explanation here is only for the particular points of Cal. 7N32C, 7N33C and 7N39C.

• For the repairing, checking and measuring procedures, refer to the “TECHNICAL GUIDE, GENERAL

INSTRUCTIONS”.

I. STRUCTURE OF THE CIRCUIT BLOCK

Note:

Though Cal. 7N32C, 7N33C and 7N39C have the

same circuit block pattern, Cal. 7N39C is not

provided with the battery indicator function. The

circuit block of Cal. 7N39C has an identification

mark as shown below to distinguish it from the

circuit blocks of Cal. 7N32C and 7N33C.

Identification mark

II. REMARKS ON DISASSEMBLING AND REASSEMBLING

Use the universal movement holder for disassembling and reassembling.

1 Hands

• How to install

When installing the hands, remove the battery and

place the movement directly on a flat metal plate or

the like.

Coil output terminal

Input terminal (+)

Input terminal (-)

Crystal unit

C-MOS-IC

Metal plate

Page 6

6

Cal. 7N32C, 7N33C, 7N39C

TECHNICAL GUIDE

5 Intermediate wheel for day correction (only for Cal. 7N33C)

Set the intermediate wheel for day correction in the direction as

shown in the illustration at right.

Tweezers

Guide pin

Date dial guard

6 Date dial guard

Unlike conventional movements, the date dial guard is not fixed with screws. It is set to the main plate

with the three protrusions, which are caught under the main plate by turning the guard. Then, it is fixed

by the two guide pins.

• How to remove

1) Lightly lift the A portion of the date dial guard

with tweezers to release it from the guide pin,

and then move it in the counterclockwise

direction until it gets on the guide pin.

2) Release the B portion of the date dial guard in

the same way as described above, and then

move it in the counterclockwise direction until

it gets on the guide pin.

3) Check that all the three protrusions of the date

dial guard have come off from the main plate,

and then remove the date dial guard.

• How to install

1) Put the date dial guard on the main plate so

that the A and B portions are over the guide

pins, as shown in the illustrations at right.

2) Move the protrusion D of the date dial guard

in the clockwise direction so that it is caught

under the main plate.

3) Slightly move the protrusions C and E in the

clockwise direction alternately to set them

under the main plate. Then, set the A and B

portions of the date dial guard to the guide

pins.

4) Check that the date dial guard is fixed securely

to the main plate.

Protrusion C

Protrusion E

A portion

B portion

Protrusion D

B portion

Protrusion

A portion

Dial side

Main plate side

Page 7

7

Cal. 7N32C, 7N33C, 7N39C

TECHNICAL GUIDE

13 Battery

• How to install

Insert the battery aslant from the direction shown by the

arrow.

Fasten the screw on the crystal unit side while holding down

the edge of the crystal unit.

15 Battery connection (+)

• How to install

Have the hooking portion (2 places) catch the main plate.

In disassembling and reassembling, take care not to deform

the hooking portions.

After installing the battery connection (+), check that the two

hooking portions securely catch the main plate.

17 Train wheel bridge

• Setting position

Refer to the illustrations below.

Setting wheel

Minute wheel

Fifth wheel and pinion

Step rotor

Third wheel and pinion

Setting wheel

Fourth wheel and pinion

Note: Take care not to damage the wheels made of plastics in disassembling and reassembling.

14 Battery connection (+) screw

Center wheel and

pinion

Third wheel

and pinion

Fourth wheel

and pinion

Step rotor

Fifth wheel

and pinion

Minute wheel

Page 8

8

Cal. 7N32C, 7N33C, 7N39C

TECHNICAL GUIDE

Refer to the illustration at right.

24 Train wheel setting lever

28 Setting lever

29 Yoke

• Setting position

Setting lever

Yoke

Train wheel setting lever

Note: Take care not to deform the spring portion of the yoke.

30 Winding stem

The first intermediate wheel for calendar correction (Cal.

7N33C) or the date corrector wheel (Cal. 7N32C and 7N39C)

has some elasticity in the contact with the winding stem

so that it can be easily fixed.

Push in the winding stem straight toward the center of

the main plate.

Winding stemClutch wheel

First intermediate wheel for calendar

correction (Cal. 7N33C)/

Date corrector wheel (Cal. 7N32C, 7N39C)

III. VALUE CHECKING

• Coil block resistance

1.18KΩ ~ 1.58KΩ

• Current consumption

For the whole movement : less than 1.20µ A

For the circuit block alone : less than 0.28µ A

Remarks: When the current consumption exceeds the standard value for the whole movement but within

the standard value range for the circuit block alone, the watch is generating the driving pulse

for compensating for the heavy load that may be applied to the gear train, etc.

In this case, overhaul and clean the movement parts and then measure current consumption

for the whole movement again.

95-3 Printed in Japan

Loading...

Loading...