Page 1

5.1kW AIR

CONDITIONER

SC-5100AU6A

INSTALLATION

MANUAL

Please read this manual carefully before using, and keep it for future reference.

Page 2

Page 3

CONTENTS

General Safety 4

Selecting Installation Place 5

Installation of Indoor Unit 7

Installation of Outdoor Unit 9

Is the Unit Installed Correctly? 14

Self Diagnosis Functions 15

Specifications 17

Customer Service 20

Page 4

GENERAL SAFETY

Read this manual thoroughly before you start installing the Split system air con.

Store this manual, the completed warranty card, your receipt and the product packaging.

The safety precautions instructions reduces the risk of fire, electric shock and injury when

correctly complied to.

Please follow all instructions and take notice of all warnings.

IMPORTANT INFORMATION

These installation instructions for the Air conditioner are for use by an appropriately

qualified, licensed installer. The appliance mst be installed in accordance with all

applicable regulations. Do not try to install the Air conditioner on your own, doing so will

expose you to danger and void the warranty.

• Before installing this Aircon, make sure your outlet voltage corresponds to the voltage

stated on the power supply rating label.

• The ratings of the fuse installed in the indoor unit is 3.15A/250V,

and outdoor unit is 20A/250V

• DO NOT INSTALL THE UNIT

- In environments where the air could contain gas, oil or sulphur.

- Near sources of heat.

- At a distance of less than 50cm from flammable substances and pressurised containers.

• If the appliance is used in areas without sucient ventilation, precautions must be taken to

prevent any leaks of refrigerant gas from remaining in the environment and creating a fire.

• Make sure that the base of the outdoor unit is firmly fixed.

• Check the air cannot enter the refrigerant system and check for refrigerant leaks

when moving the air con unit.

• Ensure that the mains voltage corresponds to that stamped on the rating plate.

• You must protect the indoor unit with a fuse of suitable capacity for the maximum

input current or with another overload protection device.

• Carry out a test cycle after installing the air con and record the operating data. Make

sure that air cannot enter the refrigerant system and check for any leaks when moving

the air con.

4

Page 5

SELECTING INSTALLATION PLACE

PROTECT YOUR WARRANTY

These installation instructions for the Air conditioner are for use by an appropriately

qualified, licensed installer. Do not try to install the air conditioner on your own; doing so

will expose you to danger and void the warranty. Contact a licensed installer.

INDOOR UNIT

• Install the indoor unit level on a strong wall that is not subject to vibrations.

• The inlet and outlet port should not be obstructed, the air should be able to blow all

over the room.

• Do not install the unit near a source of heat, steam or flammable gas.

• Install the unit near an electric socket or private circuit.

• Do not not install this unit where it will be exposed to direct sunlight.

• Do no install unit in the laundry.

• Install the unit where connection between indoor and outdoor unit is easy.

• Install unit where it is easy to drain condensation water.

• Install unit where the filter can be easily accessed.

5

Page 6

SELECTING INSTALLATION PLACE (Cont.)

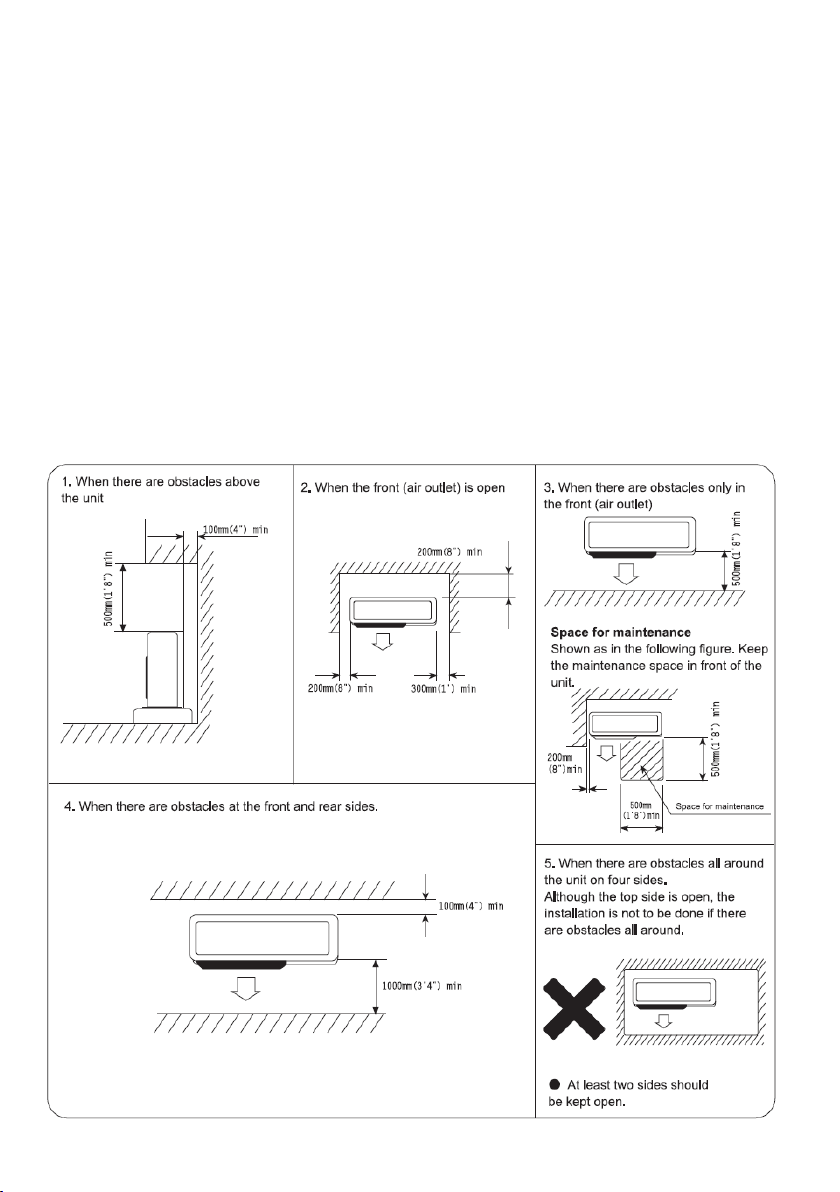

OUTDOOR UNIT

• DO NOT INSTALL THE UNIT

Near heat sources, steam or flammable gas.

Exposure to high winds or dust.

• Avoid installing in direct sunlight.

• Where the air discharge and sound level will not disturb neighbours.

• Leave minimum clearences around the unit for free air circulation.

• If the outdoor unit is vibrating, place rubber gaskets on the feet of the unit.

• The method of fixing is not to depend on the use of adhesives since they are not

considered to be a reliable fixing means.

MINIMUM DISTANCES FOR INSTALLATION

6

Page 7

INSTALLATION OF INDOOR UNIT

1. Installation of Wall Mounting Plate

• Make sure the plate is completely level by using a spirit level, if mounting plate is

slanted it can hinder the smooth discharge of the condensed water.

• Mark and drill mounting holes corresponding with the mounting holes in the

mounting plate.

• Fix the wall mounting plate firmly on the wall with screws.

The method of fixing is not to depend on the use of adhesives since they are not considered

to be a reliable fixing means. *(Mounting hardware not supplied)

2. ACCESS TO PIPING

• Drill holes at places slightly below the wall mounting plate corresponding with where the

piping and drain outlet exit the indoor unit with hole diameter of 65mm starting from the

inside wall, and make the outside wall 5-10mm lower so the water can smoothly flow out.

• Cut the wall penetrating pipe to correct length according to the thickness of the wall and

add 5mm extra length longer then the wall thickness and insert the pipe as indicated.

3. INSTALLATION OF DRAIN PIPE

• Install the piplines of the indoor unit in accordance with the wall hole.

• Wrap tightly the drain pipe and the pipelines with trap, Make sure the drain pipe is

underneath the pipelines of indoor unit.

7

Page 8

INSTALLATION OF INDOOR UNIT (Cont.)

4. INSTALLATION OF INDOOR UNIT

• Pass the connection wires, connecting pipelines and drain pipe through the wall hole.

• Hang the indoor unit on the hook of the top of the wall mounting plate so that the

hooks at the bottom of the indoor unit match the hook of the wall mounting plate.

5. INSPECTIONS

• Check if the hooks on the mounting plate and unit at the top or bottom are firmly fixed.

• Check that the indoor unit is properly level.

• The drain pipe should not curve upward (refer to picture below).

• The drain pipe should be at the lower part of the wall pipes. (refer to below).

8

Page 9

INSTALLATION OF OUTDOOR UNIT

• Use caution when hoisting cables to lift the unit as the centre of balance is not at the

installation centre.

• Use expansion bolts to fix the mounting supports on the wall.

• Use bolts and nuts to fix the outdoor unit firmly on the supports and keep on the

same level.

• If the unit is installed on the wall or rooftop, the supports have to be firmly fixed so it

can resist strong weather conditions.

ORDINARY PIPELINE CONNECTIONS AND AIR PURGING

No dust, foreign objects, air or moisture should be allowed to enter the air conditioning

system. Careful attention should be paid when the pipeline connection to the outdoor unit

is made. Try to avoid curves as much as possible, as hardening or cracks may occur to the

copper pipes. Suitable wrenches should be used when the pipeline connection is done, so

as to ensure appropriate torque (refer to torque table below). Excessive torque may damage

the joints, while too little torque may lead to leakage.

TORQUE BASED UPON THE WRENCH TO BE USED

9

Page 10

INSTALLATION OF OUTDOOR UNIT (Cont.)

1. Check that the pipeline connections have

been properly connected. Remove the

charging port cap, then connect the

manifold gauge and the vacuum pump to

the charging valve by the service hoses,

(shown in drawing).

2.Open the valve on the low pressure side

of the manifold gauge, then run the

vacuum pump. Vacuum the indoor unit

and the connecting pipes until the

pressure in them lowers to below

1.5mmGH (the operation time for this

should be about 10 minutes).

When the desired vacuum level is reached,

close the low pressure valve on the

manifold, then stop the vacuum pump.

3.Disconnect the service hoses, then fit

the cap to the charging valve.

4.Remove the blank caps, then fully open

the spindles on the 2-way and 3-way

valves with a service valve wrench.

5. Tighten the blank caps on the 2-way

and 3-way valves, according to the

previous torque Table 1.

ADDING REFRIGERANT

Refrigerant must be added if the piping measures more than 5 metres (16’5”) in length. This

operation can only be performed by a professional technician. For the refrigerant amount,

please refer to the table below.

Additional Refrigerant Amount

Liquid pipe diameter Ø6.35 (1/4”) Liquid pipe diameter Ø9.52 (3/8”)

(piping length-5)mx30g

or (piping length-16)ftx0.3oz

10

(piping length-5)mx65g

or (piping length-16)ftx0.7oz

Page 11

INSTALLATION OF OUTDOOR UNIT (Cont.)

GAS LEAKAGE INSPECTION

After the pipeline connections are done, use a leakage inspection device or soap

suds to carefully check if there is any leakage at any joints. This is an important step to

ensure the quality of the installation. Once a leakage is detected, proper treatment should

be taken immediately.

PIPELINE CONNECTIONS FOR SPLIT TYPE QUICK COUPLER

If you purchase the unit for split type quick couple model, please follow these pipeline

connection procedures:

1. Remove the dust caps from the indoor and

outdoor units, and the connecting pipe.

2. Align the joint counter of the connecting

pipe with the proper indoor and outdoor

joint conic surfaces, tightening the

connecting nut manually. Then make is

secure with a wrench (as shown in drawing),

according to the torque Table on page 10.

3. Remove the two valve core caps from the

outdoor unit.

4. Turn the high and low pressure valve cores

with a socket wrench, then tighten the two

valve core caps of the outdoor unit (Fig 8).

5. Finally, wrap hot insulating cotton around

the joints of the indoor and outdoor units.

1. See the connecting pipe bending minimum radius parameters.

2. Quick coupler assembly and disassembly limit: the assembly and disassembly

times are inadvisably more than 7.

Normal Diameter (mm) Minimum Bending Radius (mm) Cooling Capacity

DN10-12(1/2”) 100 (4”) 2500 ~ 5100W

(9000-18000BTU)

11

Page 12

INSTALLATION OF OUTDOOR UNIT (Cont.)

CONNECTION OF POWER CABLE

1. Remove the connection panel of the outdoor unit.

2. Non-quick Coupler: Connect the indoor power

and control wires with the matching outdoor wires

in accordance with the electric schematic diagram

on each unit, making sure that the connection

is secure.

Quick Coupler: Directly connect the quick cable

couplers with indoor and outdoor quick cable

couplers after the disassebly of the outdoor unit.

3. Use a press plate to fix the wires firmly into

place, then reinstall the connection panel.

4. Option steps: If present in the unit, you should

connect the indoor wire connector with the outdoor

probe wire connector for defrosting.

WARNING

• Do not connect the wires the wrong way around, otherwise malfunction or damaging the

unit can occur.

• The appliance shall be installed in accordance with national wiring regulations.

• If the supply cord is damaged, it must be replaced by the manufacturer or a qualified

service agent in order to avoid hazard.

12

Page 13

INSTALLATION OF OUTDOOR UNIT (Cont.)

FINAL TOUCHES

• Wrap the pipelines tightly with ethylene tape.

• Fix the wrapped pipelines to the exterior walls with clamps.

• Fill in any gaps left over from the pipeline holes in the wall to prevent rain water

from entering and from air drafts.

TEST RUNNING

• Connect units to power, then check that the function selection keys on the remote

control are working correctly.

• Check that the room temperature adjustments and timer settings are working correctly.

• Check that the drainage system is smooth and operational.

• Check for any abnormal noises, vibrations or smells.

• Check for any leakage of refrigerant.

13

Page 14

IS THE UNIT INSTALLED CORRECTLY?

SUITABLE INSTALLATION POSITION

• Is there anything that prevents ventilation, or obstructs operation and eective air flow

in front of the indoor unit?

• Do not install in locations where flammable gases may leak or oil splashes often.

• In seaside districts where sea breezes will be encountered by the unit, the high

salt content in the air often leads to early corrosion. Please monitor the unit over time.

• The air-conditioner should be at least 1 metre away from TVs or radios.

• The dehumidified water should be drained into a location that drains water well.

OPERATION NOISE

• When installaing the unit, choose a location that can stand the weight of the unit, that

will not increase the operation noise or vibration. If the vibrations are transmitted to

the house itself, place the unit with vibration-proof pads (not supplied) between the

unit and the fittings.

• Choose the place where hot air and operation noise from the outlet of the outdoor

unit does not annoy neighbours.

• Things left near the outlet and inlet of the outdoor unit may cause malfunction or

increased operation noise.

• If irregular sound is heard during operation, contact our customer support centre.

INSPECTION AND MAINTENANCE

• According to operating environments the inside of the air conditioner will become dirty

after a few years (3-5) of service, which will result in decreased operating performance.

Inspection and maintenance are recommended in addition to the usual cleaning.

• Only use qualified air conditioner technicians to inspect and perform maintenance checks

on your air conditioner and commenced during the o-season period when aircon is not

in use.

• Ensure all indoor and outdoor units have been switch o from the power source before

any inspection or cleaning is carried out.

14

Page 15

SELF DIAGNOSIS FUNCTIONS

The air-conditioner has sensors and a self diagnosis system which will display error codes

when an issue is detected.

Self Check Information Indicator Behaviour Error Code Behaviour

Defrost Indication 1 flash per second “dF” or a Heating icon

Room Temperature Sensor

Fault

Coil Temperature Sensor 1 flash per 8 seconds E3

External Feedback Fault 7 flashes per 8 seconds E7

Outdoor Tube Temperature

Sensor Faults

(EEPROM) Communication

failures

Outside Temperature

exceeds operational range

1 flash per second E2

4 flashes per 8 seconds E1

6 flashes per 8 seconds E6

1 flash per second

FF

15

Page 16

SPECIFICATIONS

COOLING 5100W (5.1kW)

Capacity

HEATING 5200W (5.2kW)

COOLING 7.0 A

Max. Current Input

HEATING 6.8 A

COOLING 1504 W

Max. Power Input

HEATING 1480 W

Room Size Suitability

Rated Voltage and Frequency

Ingress Protection

Net Weight

Max. Pressure

Refrigerant Type

Noise Level

Dimensions

28-32 m²

220-240V AC / 50Hz

OUTDOOR UNIT IP24

INDOOR UNIT

OUTDOOR UNIT 40 kg

DISCHARGE 4.2 MPa

SUCTION 1.3 MPa

TYPE R410A

QUANTITY 1420 g

INDOOR UNIT 42-46 dB(A)

OUTDOOR UNIT 55 dB(A)

INDOOR UNIT (mm) 296 (h) x 900 (w) x 222 (d)

OUTDOOR UNIT (mm) 605 (h) x 850 (w) x 295 (d)

14 kg

16

Page 17

171819

Page 18

Page 19

Page 20

CUSTOMER HELPLINE:

1300 296 699

DISTRIBUTED BY:

AYONZ PTY LTD

Loading...

Loading...