Page 1

Securitron Magnalock Corp. www.securitron.com ASSA ABLOY, the global leader

Tel 800.624.5625 techsupport@securitron.com

in door opening solutions

SHEAR ALIGNING MAGNALOCK MODEL SAM2-24

INSTALLATION AND OPERATING INSTRUCTIONS

1 INTRODUCTION

Securitron’s Shear Aligning Magnalock “SAM2-24” is a smaller, 24 Volt (only) version of the

original “SAM” Magnalock and is intended for installations where concealed mounting in the door

and frame is desired. As with the original SAM, the operating fe atures allo w self-alignment while

securing the door when it closes. The SAM2 is designed to operate with one-way swing, bidirectional swing or sliding type doors. On swing type doors the lock installs horiz ontally in the

top or bottom of the door frame or may be installe d vertically in the door frame side. For slider

type door applications the lock must be installed horizontally for proper operation. These units

have also been designed to unlock even if a preload is applied to the door.

2 SPECIFICATIONS

MODEL SAM2-24

Holding Force

Dimensions: Length

Height

Depth

Voltage

Current @ 24 VDC

600 Lbs [272kg]

7.2" [183mm]

1.15" [29mm]

0.94" [24mm]

24 Volts DC

62mA

3 PRODUCT OVERVIEW

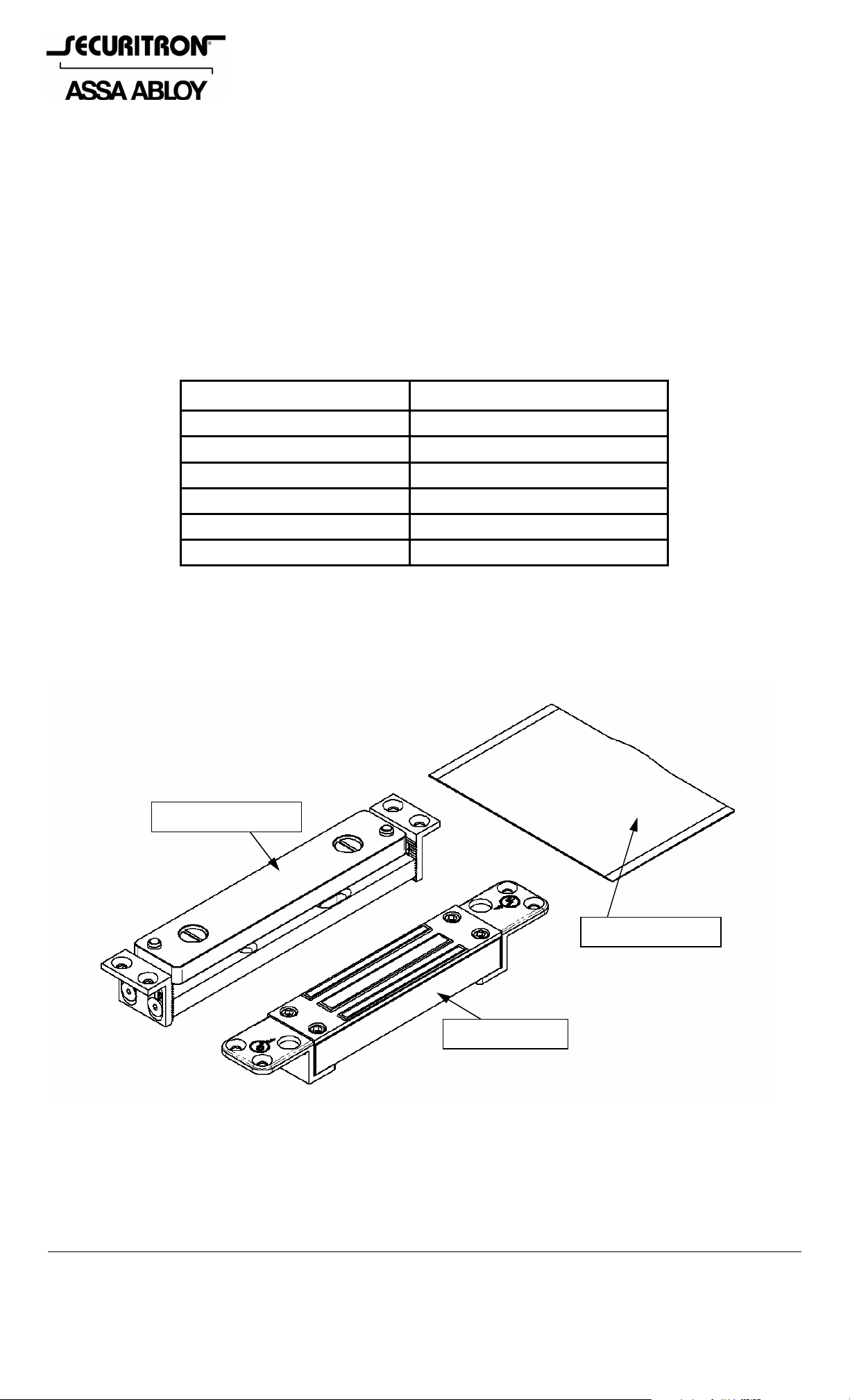

Upon unpacking this product, an inventory should be made to ensure that all the required

components and hardware have been included. Along with these instructions and the

installation template, each product should include the following items:

Strike Assembly

Hardware Pack

Magnalock

Figure 1 – SAM2-24 Magnalock

© Copyright, 2012, all rights reserved PN# 500-10450

Page 1 Rev. B, 02/12

Page 2

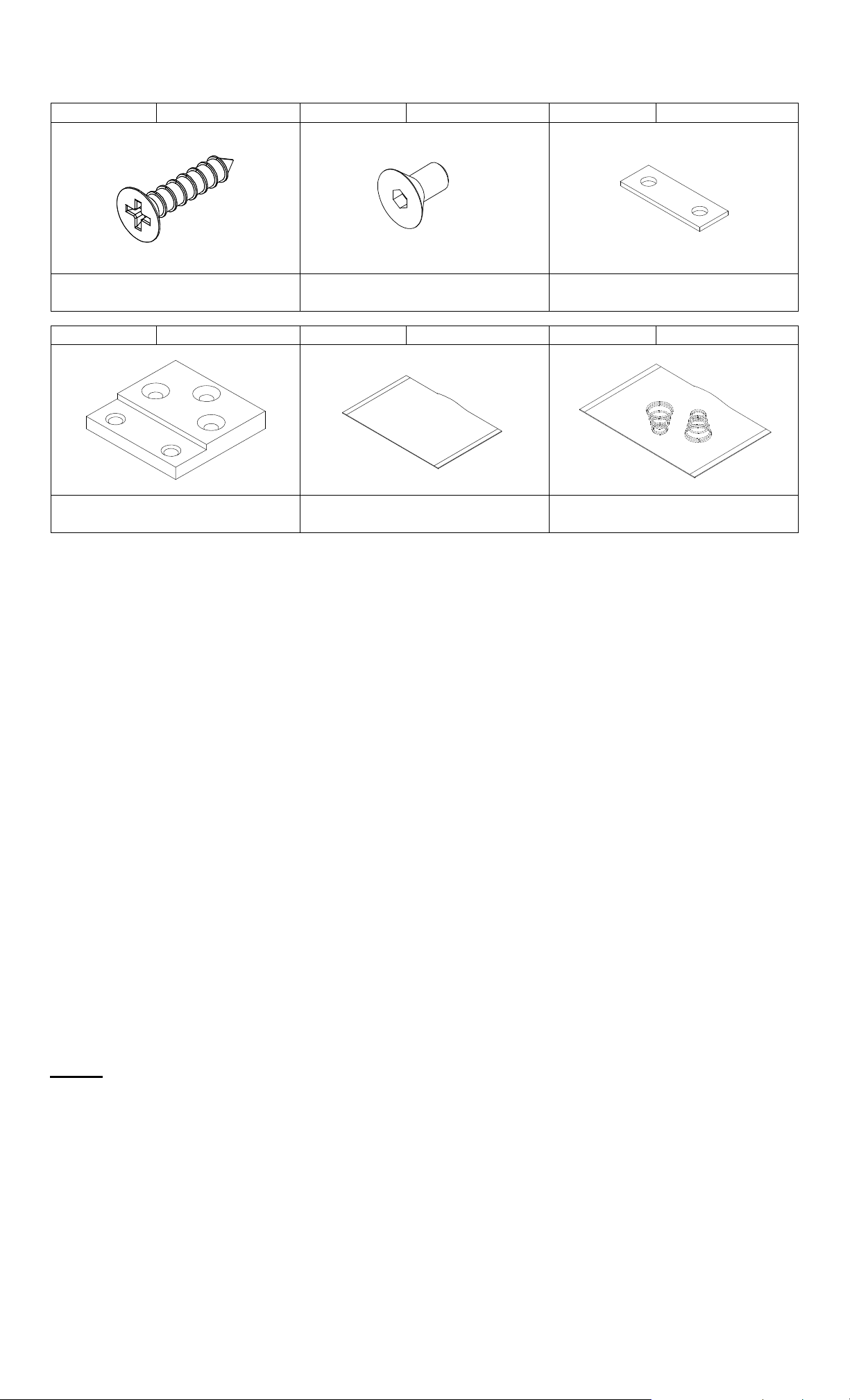

3.1 HARDWARE

10X 20X 8X

Phillips Flat Head

#8 X 3/4” Type “A”

Socket Flat Head

8-32 X 1/2”

Shim Plate

4X 1X 1X

Flush Mount Bracket

Thread Locking Compound

Pack

Floor Install Replacement

Spring Pack (2 Springs)

4 RECOMMENDED TOOLS

Router or Saber Saw Measuring Instrument (Ruler/Tape Measure)

Hammer Masking Tape

Chisel Fish Tape or Lead Wire

Center Punch Wire Strippers/Cutter

Power Drill Crimp Wire Connectors

7/64”, 9,64”, 3/16” & 5/16” Drill Bits Crimp Tool

3/8” Diameter X 82° Countersink Bit Multimeter

Phillips and Standard Screwdrivers

5 INSTALLATION INSTRUCTIONS

5.1 Pre-Installation Survey

It is recommended that an initial on sight survey be performed. A method of mounting should

be determined and an installation plan should be reviewed as follows:

Physical strength of mounting areas should be strong enough to meet or exceed the holding

force of the required Magnalock.

Placement of the Magnalock wiring and protection from potential damage due to intruders or

vandals external attack should be considered during the survey.

Accessibility should be considered for prevention of any potential safety hazard.

The door and frame areas additionally need to be examined for mortising capabilities, sufficie nt

size and should be free of any internal obstructions. The top-of-door installation is

recommended as the most suitable location for protection from impact attacks.

NOTE:

THE SAM2-24 STRIKE ASSEMBLY IS NOT RECOMMENDED FOR USE IN

ALUMINUM OR STEEL FRAMED DOORS THAT HAVE A CHANNEL RECESS AT THE TOP.

FOR PROPER OPERATION IN HOLLOW METAL DOORS THE STRIKE ASSEMBLY SHOULD

BE MOUNTED IN THE FLUSH MOUNT ARRANGEMENT ONLY!

PN# 500-10450

Page 2 Rev. B, 02/12

Page 3

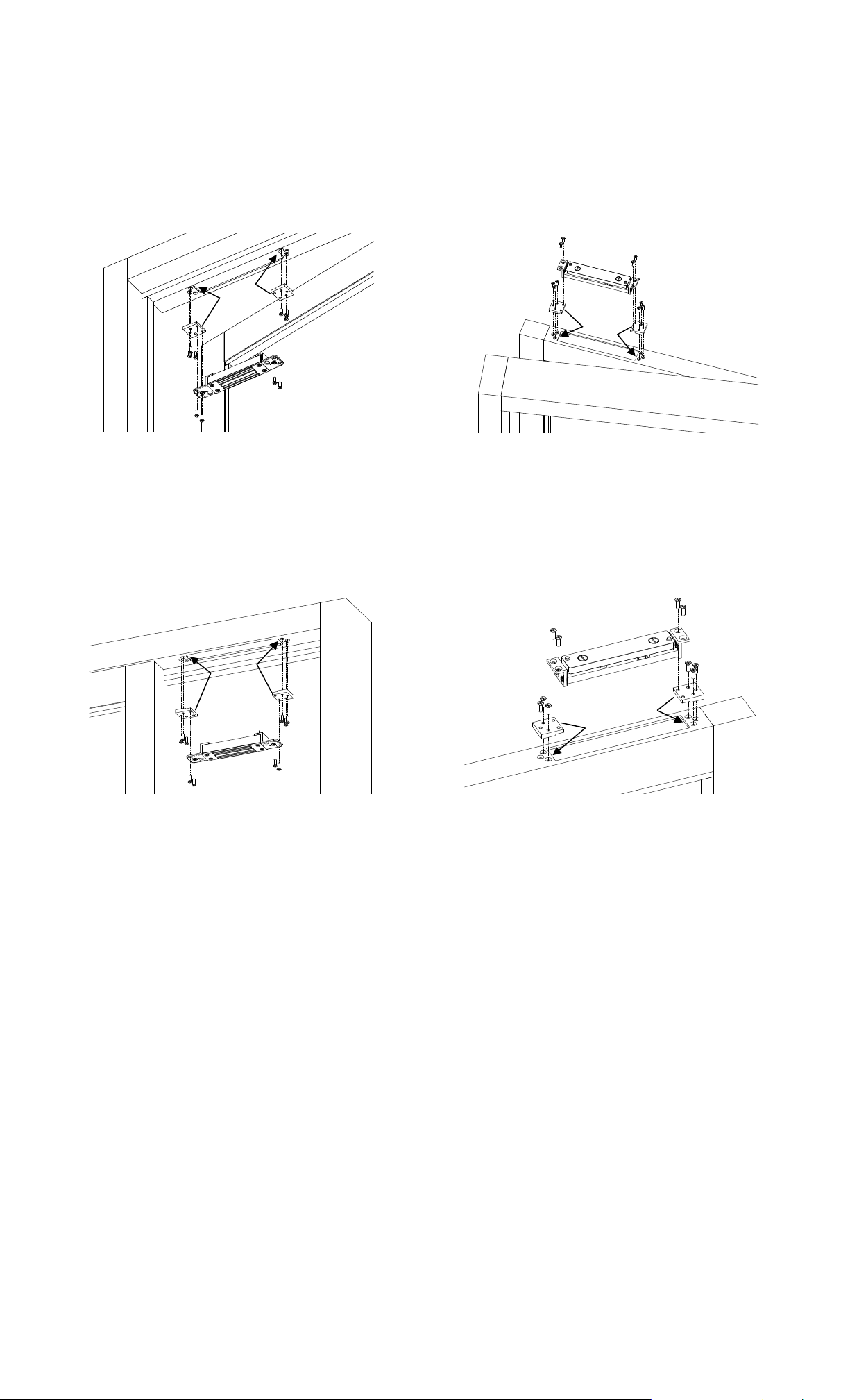

5.2 Swinging Door

The illustrations in Figure 2 demonstrate a SAM2 installed in a swinging door. This is a

common configuration where the Magnalock is recessed into the door frame header near the

corner opposite the hinge side and the strike assembly is flush mounted into the top edge of the

door. The Magnalock may be mounted horizontally or vertically depending on the installation

required. The flush mount brackets shown are inserted into hollow metal door and frame to

provide a recessed installation.

Magnalock mounted in door frame Strike mounted in edge of hollow metal door

Figure 2 - Swinging door configuration

5.3 Sliding Door

The illustrations in Figure 3 demonstrate a SAM2 installed in a sliding door. The Magnalock

mounts recessed into the door frame header and the strike assembly is mounted into the top

edge of the sliding door.

Magnalock mounted in door frame Strike mounted in edge of door

Figure 3 - Sliding door mounting configuration

5.4 Frame and Door Preparation

5.4.1 Frame Preparation

Select a mounting location for the Magnalock and st rike assembly as mentioned in Section 5.1.

The following general guideline should be used for consideration during the installation review:

Read and follow the directions on the template provided which includes drilling and

mounting instructions.

An approximated 2” [51mm] clearance distance should be allowed between the Magnalock

(mounting bracket) and the inside corner of the door frame. This will provide adequate

access for the mounting locations and for drilling and tool access.

ALWAYS CHECK THE STRIKE MOUNTING AREA IN THE EDGE OF THE DOOR FOR

OBSTACLES WHEN DETERMINING WHERE TO LOCATE THE MAGNALOCK. MAKE

CERTAIN THAT THE STRIKE MOUNTING AREA DOES NOT HAVE ANY OBSTRUCTIONS

(I.E. DOOR ADJUSTMENT SCREWS OR DOOR CLOSER OPERATORS) THAT MIGHT

HINDER INSTALLATION - BEFORE CUTTING OR DRILLING ANY HOLES.

Locate and mark the desired lateral centerline position for the Magnalock/strike assembly on

the face of the door. Using this door mark as reference, mark the same lateral center

location of the Magnalock onto the door frame.

PN# 500-10450

Page 3 Rev. B, 02/12

Page 4

Setting the depth center position of the Magnalock is more critical because there is not a lot

of free depth in the door frame or door to accommodate any centering error. To locate the

centerline in the door frame:

o For a one-way swing door

: Make sure the door is closed completely and measure the

distance between the face of the door and the frame stop (usually about 1/8”). O pen the

door and measure the thickness of the door. Divide the thickness of th e door in half (this

will be the center of door) and add the distance measured between the door and stop.

Measure the total distance out from the face of the stop and mark the centerline for the

Magnalock.

o For a bi-directional swing door

: Ensure the door is in the centered at-rest position. (A

door closer may require adjustment). Using a pencil, trace the inside and outside edge s

of the door onto the frame. Measure half the distance between these two marked door

silhouette lines and mark the centerline for the Magnalock.

Using the Magnalock mounting information in Section 5.5 and the template provided, align

the appropriate template into position on the frame and mark the mortise cutout area.

Using a router or saber saw, or chisel (for wood) cut out the area for the Magnalock

mounting. Insert the Magnalock into the frame and mark the bracket locations for the

mounting holes.

Using the drill size information on the template and a power drill, bore the holes required.

5.4.2 Door Preparation

NOTE:

THE SAM2-24 STRIKE ASSEMBLY IS NOT RECOMMENDED FOR USE IN

ALUMINUM OR STEEL FRAMED DOORS THAT HAVE A CHANNEL RECESS AT THE TOP.

FOR PROPER OPERATION IN HOLLOW METAL DOORS THE STRIKE ASSEMBLY SHOULD

BE MOUNTED IN THE FLUSH MOUNT ARRANGEMENT ONLY!

Locate the previously marked lateral centerline po sition for the strike assembly on the fa ce of

the door.

Open the door and measure the total depth distance (thickness) of the door. Divide this

distance in half to locate the depth centerline of the strike assembly.

Using the strike assembly mounting information in Section 5.6 and the strike template

provided, center the template into position on the door and mark the mortise cutout area.

Using a router, saber saw or chisel (for wood) cut out the area for the strike assembly

mounting. Insert the strike assembly into the door and mark the bracket locations for the

mounting holes.

Using the drill size information on the template and a power drill, bore the holes required.

IF MOUNTING THE STRIKE AT THE BOTTOM OF THE DOOR (FLOOR MOUNT) IS CHOSEN,

THE TWO (2) IDLE PLATE SPRINGS IN THE STRIKE ASSEMBLY NEED TO BE REPLACED

WITH THE ALTERNATE SET OF IDLE SPRINGS PROVIDED IN THE HARDWARE PACK.

5.5 Mounting the Magnalock

The desired cable exit location should be determined prior to installing the Magnalock. The

Magnalock is symmetrical which allows the cable exit from either end into the doo r frame. There

are many different techniques for mounting the Magnalock depending on the type or style of

doors and frames. The following sections describe installation methods for use on hollow

aluminum, steel and wood type doors and frames.

5.5.1 Hollow Metal Door Frames

Prepare the door frame in accordance with Section 5.4.1.

Place the Magnalock into the cutout area to ensure proper fit. As necessary, perform any filing

or cutting necessary to ensure the mortised fit. Ensure all necessary holes required to moun t

the Magnalock and flush mount brackets into place as indicated on the template have been

provided. Install the Magnalock using a screwdriver, the listed mounting screws and the flush

mount brackets as shown in Figures 4 and 5 below.

The adaptation to variation in frame material thicknesses can be obtained by flipping the

orientation of the flush mount brackets. Shim plates are also provided which may be used in

conjunction with the flush mount brackets to create the desired exposed height of the Magnalock

and/or to compensate for the various material thicknesses of do or frame s.

It is recommended that the Magnalock face protrude approximately 1/16” [1.6mm]

beyond the surface of the frame. Both Figures 4 and 5 show a shim plate between the lock

PN# 500-10450

Page 4 Rev. B, 02/12

Page 5

mounting bracket and the flush mount bracket in order to raise the Magnalock above the frame

surface.

Figure 4 - Flush mount bracket mounting

(thin wall frame)

Figure 5 - Flush mount bracket mounting

(thick wall frame)

APPLY THE PROVIDED THREAD LOCKING COMPOUND TO ALL MOUNTING SCREW

THREADS.

5.5.2 Solid Wood Door Frames

Prepare the door frame in accordance with Section 5.4.1.

Place the Magnalock into the cutout area to ensure proper fit. As necessary, perform any filing

or chiseling necessary to ensure the mortised fit. Ensure all necessary holes required to mou nt

the Magnalock into place as indicated on the template have been provided. The depth of the

mortise cutout is important for proper fit. The minimum depth of the cutout is noted in Figure

6 below and includes enough distance for the required recess depth of 1/16” [1.6mm] of the

mounting brackets. Install the Magnalock using the wood mounting screws as shown in Figure

6.

Figure 6 - Wood frame lock bracket mounting

5.6 Mounting the Strike Assembly

The strike assembly mounting method varies with the type of door being used. The included

template provides preparation and installation information for the various types of doors. The

following sections describe the door type and installation procedures.

The strike bracket assembly has been designed with adjustment features which are intended to

help accurately install and adjust the strike assembly for proper operation. The two L-shaped

end brackets and the idle bracket of the assembly are serrated to provide a secure locking

adjustment of the height of the strike in the door edge. The end brackets have obround slots to

limit the adjustment travel and to support the structure of the assembly. By loosening the

screws at each end, the brackets can be adjusted to the desired mounting height.

The serrations on the brackets are .050” [1.3mm] apart which matches the screw t hread pitch

distance that mounts the strike. This feature will be explained during the final adjustment in

Section 5.7. These end brackets may also be inverted to provide for deeper mounting

configurations. See Figure 7 and Figure 8 for adjustable ranges and mounting methods.

THE POSITION OF THE CENTERLINE OF THE STRIKE ASSEMBLY IS CRITICALLY

RELATED TO THE CENTERLINE OF THE MAGNALOCK LOCATION.

5.6.1 Hollow Metal Door (Flush Top)

PN# 500-10450

Page 5 Rev. B, 02/12

Page 6

NOTE: THE SAM2-24 STRIKE ASSEMBLY IS NOT RECOMMENDED FOR USE IN

ALUMINUM OR STEEL FRAMED DOORS THAT HAVE A CHANNEL RECESS AT THE TOP.

FOR PROPER OPERATION IN HOLLOW METAL DOORS THE STRIKE ASSEMBLY SHOULD

BE MOUNTED IN THE FLUSH MOUNT ARRANGEMENT ONLY!

Prepare the door in accordance with Section 5.4.2.

Mounting the strike assembly into a door with flush outside surfaces u tilizes the same methods

as mounting the Magnalock into a hollow metal type frame. Figure 7 below shows a typical

installation in a flush type aluminum door. In this process the flush mount brackets are u sed to

suspend the strike assembly into the door. Make the necessary adjustme nts to the end bra cket s

of the strike assembly to set the initial strike height in the door installation. The flush mount

brackets may be installed in either direction (see Figures 4 and 5) to set the appropriate flush

mounting condition, and the provided shim plates may also be used to assist in further

adjustment of the installation. Use a screwdriver and the provided mounting screws to complete

the installation.

Figure 7 - Hollow frame strike assembly mounting

APPLY THE PROVIDED THREAD LOCKING COMPOUND TO ALL MOUNTING SCREW

THREADS.

5.6.2 Hard Core Wood Door

Prepare the door in accordance with Section 5.4.2.

For mounting into hard core (solid) wood doors the strike assembly may be mounted with or

without the end brackets attached. The door cutout requires a mortise area for the strike base

assembly with sizes that are dependent on whether the end brackets are used or not (see

template). The depth requirements are illustrated in Figures 8 and 9. If the installation does

not require use of the end brackets (as shown in Figure 8), the installer must be accurate on

the depth of the cutout. (If the mortised cutout is too shallow it will not allow enough room for

the strike to be adjusted down any lower and the door operation may be hindered. If the cutout

is too deep, shimming may be necessary to adjust the idle bracket height in the installation).

When the end brackets are used, the cutout area requires a minimum depth (shown in Figure

9) and because of the adjustability in the end brackets, cutting the recess too deep will not

affect the installation.

Figure 8 - Wood door strike mounting without brackets

PN# 500-10450

Page 6 Rev. B, 02/12

Page 7

5.6.3 Soft Core Wood Door

Use of the end brackets is recommended when installing the strike assembly on soft core wood

style doors because a “pocketed” soft core door is not as strong in supporting the lateral forces

applied to the strike assembly. Use of the end brackets will provide a much more sound and

secure anchoring platform for the installation. Refer to Section 5.6 fo r use and adjustment of

the end brackets. Figure 9 illustrates the dimensional requirements of the cutout necessary for

installation into wood doors using the strike end brackets.

Figure 9 - Wood door strike mounting with brackets

5.7 Strike Assembly Final Adjustments

5.7.1 Strike Level Adjustment (De-energized)

De-energized adjustment of the strike height is important for proper door/lock operations. The

example in Figure 10 illustrates the Magnalock with the proper adjustment. Without power

applied to the Magnalock, both of the (conical) interference buttons should just clear the lock

brackets. Check this by opening and closing the door. To adjust the clearance to be closer, turn

each of the strike adjustment (shoulder) screws (located in the center of the strike) counterclockwise 1/4 turn, one at a time and recheck the clearances. (Both screws do not have to be

adjusted the same amount of turns). The adjustm ents should be made independently so that

the strike level is uniform to the door frame and Magnalock installation. The strike screws are

allowed up to two (2) full turns of adjustment each. If the adjustment required is two (2)

full turns or greater, then tighten the screws clockwise back to the down position, loosen the end

bracket screws and adjust the end brackets the amount of notches necessary to enable the final

adjustments. Repeat adjustments as necessary until a properly functioning gap setting is

achieved.

THE INITIAL SETTING OF THE STRIKE ADJUSTMENT (SHOULDER) SCREWS SHOULD BE

NO MORE THAN TWO (2) TURNS OUT. THIS WILL ALLOW A LARGER ADJUSTMENT

RANGE TO ACCOMMODATE POTENTIAL FUTURE DOOR SAG.

THE CONICAL INTERFERENCE BUTTONS ON THE STRIKE PLATE SHOULD JUST CLEAR

THE LOCK BRACKET SURFACES TO INSURE THE CORRECT GAP.

Figure 10 - Magnalock and strike assembly (side view)

PN# 500-10450

Page 7 Rev. B, 02/12

Page 8

5.7.2 Strike Level Adjustment Testing (Energized)

Energized adjustment testing of the strike height is important for proper door/lock operations.

This adjustment should be performed after the de-energized adjustment, outlined in Section

5.7.1. With the door closed and the Magnalock de-energized, apply power to the Magnalock.

The strike should be pulled up against the Magnalock face. De-energize the Magnalock and the

strike should return to the previously adjusted height. This function should be tested several

times to insure that the strike level adjustment is correct.

If the strike is not pulled up to the face of the Magnalock, the strike is to far away from the

Magnalock. Make small 1/4 turn adjustments to the strike screws until the correct level and

clearances are obtained for proper function.

A second test should be performed with the door starting from the opened position. Apply

power to the Magnalock and then close the door under normal operations. The strike should be

attracted to the Magnalock, but the strike and the interference buttons should pass completely

into the locking position to secure the door. Test this operation several times to ensure

consistent operation of the Magnalock/strike installation.

WHEN THE MAGNALOCK IS ENERGIZED FOR A CONTINUOUS DUTY MODE, THE

ADJUSTMENTS MADE MAKE IT A POSITIVE LOCKING MODE FOR CONTROLLED ACCESS.

IF THE MAGNALOCK IS SET FOR CONTINUOUS DUTY, THE EXIT REQUEST ALLOWS THE

STRIKE TO DROP AWAY AND CLEAR FOR SMOOTH EGRESS. WHEN THE MAGNALOCK

BECOMES ENERGIZED, WHILE THE DOOR IS STILL IN THE OPENED POSITION, THE

DOOR CLOSING AND LOCKING FEATURES WILL STILL FUNCTION, WHEN THE DOOR

CLOSES, THE STRIKE REALIGNS BACK TO THE LOCKING POSITION TO SECURE. THERE

SHOULD BE NO INTERFERENCES THAT PREVENT THE DOOR FROM CLOSING OR

BECOMING SECURE.

6 ELECTRICAL INSTALLATION

6.1 General Characteristics

The Magnalock is a low current load device using specialized internal circuitry. The normal

characteristic of an inductive load, such as inductive kick-back, is not present. See Section 2

for more information.

6.2 Electrical Standards

DC voltage, full-wave rectified, must be provided for proper operation of the Magnalock. The red

wire receives +24VDC, and the black wire, 0 Volts (negative). If the Magnalock is connected

with reverse polarity, it will not operate. The SAM2-24 Magnalock is a single voltage (24VDC

only) device.

6.3 Poor Release Characteristics

The SAM2 Magnalock is designed with quick release operation. Wiring errors may cause a

Magnalock to release slowly. Figure 11 illustrates a parallel installation of a resistive load

(correct). Figure 12 illustrates a parallel reverse diode (incorrect).

Figure 11 Figure 12

PN# 500-10450

Page 8 Rev. B, 02/12

Page 9

6.4 Electrical Wiring

The following diagram, Figure 13, represents the proper electrical wiring connections required

for the SAM2-24 Magnalock.

DC

POWER

SUPPLY

120

VAC

INPUT

24

VDC

OUTPUT

+

_

ACCES S

CONTROL

DEVICE

NC

C

NO

SA M2-24

2-WIRE

MAGNALOCK

RED

+

BLK

_

Figure 13

6.5 Emergency Release

Magnalocks are often wired into a system for quick release in case of emergency. Manual

switching or automatic triggering from a fire alarm system is practical. It is the user's

responsibility to correctly hookup the Magnalock according to the instructions. It is

recommended to use a switch or relay to perform break of power. Securitron power supplies

have terminals for the interconnection of such emergency release switches.

THE END USER AND INSTALLER ARE LIABLE FOR ALL FIRE AND BUILDING CODE

COMPLIANCE.

7 MAGNALOCK MAINTENANCE

7.1 Visual Inspection

Check the strike assembly for proper gap, suspension and free movement. Tighten strike

adjustment screws as required.

Check for build-up of debris on the Magnalock and strike armature. Clean as required.

Check for rust on the Magnalock and strike assembly. Clean as required.

7.2 Cleaning Methods

Cleaning once a year is recommended.

Clean every six months where minor rusting occurs.

Clean every three months if rust conditions are severe.

Use a plastic dishwashing scrub pad to aid in the removal of rust.

DO NOT USE PETROLEUM BASED PRODUCTS FOR CLEANING

DO NOT USE STEEL WOOL BASED SCRUB PAD OR SANDPAPER

7.2.1 Indoor Applications

Apply rubbing alcohol onto a clean cloth and thoroughly wipe down the Magnalock and

strike plate armature.

7.2.2 Outdoor Applications

Apply a silicone based cleaner/lubricant onto a clean cloth and thoroughly wipe down

Magnalock and strike plate armature.

Example: Super Lube® Aerosol with SYNCOLON® (PTFE)

Part No.: 31040 ~ 6oz. / 31110 ~ 11 oz. / 32015 ~ 14 oz.

Phone: (631) 567-5300 / Website: www.super-lube.com

PN# 500-10450

Page 9 Rev. B, 02/12

Page 10

APPENDIX A

Troubleshooting

Problem Lock Does Not Generate a Magnetic Field Points of Reference

Check for specified voltage at Magnalock

Section 2

Solution

Check for specified current draw at Magnalock Section 2

Problem Reduced Holding Force Points of Reference

Check DC power source is Full-Wave Rectified

(Half-wave Rectifier or AC Power unacceptable)

Check for specified voltage at Magnalock

Section 2

Section 6.2

Solution

Check for specified current draw at Magnalock Section 2

Check strike mounting for proper installation Sections 5.6-5.7

Check the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned

Section 7

Problem The Magnalock Does Not Release Points of Reference

Make sure no voltage is present at Magnalock Section 2

Solution

Make sure the Magnalock is not drawing current Section 2

Check if the strike is sticky and hard to release

Check the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned

Section 7

Section 7

Problem The Magnalock is Dirty or Rusty Points of Reference

Solution

Problem

Solution

Improper cleaning – Maintenance Equipment Section 7

Electronic Noise Interference with

Access Control System

Check for voltage from Magnalock to door frame.

There should be no voltage present.

Points of Reference

Section 2

IF PROBLEMS PERSIST CALL SECURITRON TOLL FREE

(800) MAG-LOCK

(800) 624-5625

Appendix B

Wire Gauge Factoring

1.1 Remote Power Supply

The Magnalock requires adequate voltage and current for proper operation.

Resistance is created by the length and gauge (size) of the wire being used.

An accurate estimated distance from the power supply to the opening is crucial.

For superior operation the correct size gauge wire must be used.

The devices used operate the best with the least amount of resistance on the source.

Using the correct gauge wires protects against large voltage and current (load) losses.

The gauge is determined by the wire distance, voltage and current of all devices.

1.2 Determining Wire Gauge

Follow Example A (24VDC system) below.

Use Table 1 to choose the correct wire gauge for the application.

PN# 500-10450

Page 10 Rev. B, 02/12

Page 11

1.2.1 Example A:

Total Current (0.182A) Rounded Up =

Devices Used 24VDC Amps

SAM2-24 Magnalock 0.062

DK-11 Access 0.070

XDT-24 Delay 0.050

0.200A

Using Table 1 (24VDC) Find: - Current Draw .200 Amps

- Wire Distance 1000 Feet [305m] (One-Way)

Solution: 18 Gauge is indicated for proper installation

TO SOLVE: INTERSECT ROW (Total Current Draw) and INTERSECTING COLUMN (OneWay Wire Distance).

1.00A

.800A

C

U

.600A

R

R

E

.400A

N

T

.300A

.200A

24VDC

22

Gauge

22

Gauge

24

Gauge

24

Gauge

24

Gauge

24

Gauge

50’

[15m]

20

Gauge

22

Gauge

22

Gauge

22

Gauge

24

Gauge

24

Gauge

100’

[30m]

20

Gauge

20

Gauge

22

Gauge

22

Gauge

22

Gauge

24

Gauge

150’

[46m]

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

22

Gauge

200’

[61m]

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

300’

[91m]

WIRE DISTANCE

14

Gauge

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

400’

[122m]

14

Gauge

14

Gauge

16

Gauge

18

Gauge

20

Gauge

20

Gauge

500’

[152m]

12

Gauge

14

Gauge

14

Gauge

16

Gauge

18

Gauge

20

Gauge

750’

[229m]

10

Gauge

12

Gauge

14

Gauge

14

Gauge

16

Gauge

18

Gauge

1000’

[305m]

Table 1

The Wire Distance indicated on the table above represents a 2-wire “One-Way” length from

the power supply source to entryway installation area.

The Gauge values specified on the table above represent a 2-wire “Round Trip” length from

the power supply source to entryway installation and returning back to the power supply

source.

IMPORTANT

THE 1000’ [305m] WIRE RUN IN THE TABLE FACTORS A 2000’ [610m] ROUND TRIP

MAGNACARE

For warranty information visit www.securitron.com/en/site/securitron/About/MagnaCare-Warranty/

LIFETIME REPLACEMENT WARRANTY

PATENTS

The Securitron Shear Aligning Magnalock is listed under U.S. patent #4,516,114 and

6,007,119.

Additional patents pending

PN# 500-10450

Page 11 Rev. B, 02/12

Loading...

Loading...