Page 1

ASSA ABLOY, the global leader

In door opening solutions

MORTISE UNLATCH

®

ELECTRONIC STRIKE

INSTALLATION AND OPERATING INSTRUCTIONS

MODELS MUNL-12 and MUNL-24

Securitron Magnalock Corp. www.securitron.com

Tel 800.624.5625 techsupport@securitron.com

© Copyright, 2011, all rights reserved PN# 500-18800

Rev. E, 11/11

Page 2

Securitron Magnalock Corp. www.securitron.com ASSA ABLOY, the global leader

Tel 800.624.5625 techsupport@securitron.com

in door opening solutions

SECURITRON MODEL MUNL-12, MUNL-24 MORTISE UNLATCH

INSTALLATION AND OPERATING INSTRUCTIONS

1. DESCRIPTION

Securitron’s Mortise UnLatch is a revolutionary new type of electric strike which eliminates the

necessity to perform a routing operation on the door frame for installation. The motor

driven Mortise UnLatch also presents a fully concealed appearance on the door which not

only enhances architectural appeal but improves security over a conventional electric strike as

an intruder is less able to determine the type of security device present on the door. The

Mortise UnLatch functions with all North American mortise locks and includes a latch

status output which reports when the door is in latched (secure) condition or is open.

Product Specifications are: Input Voltages: 12 VDC (MUNL-12), +20%, -10%. 24 VDC

(MUNL-24), +20%, -10%. Current: At rest: 40 mA (either voltage). When operating- 4 Amp

input surge @ 12 VDC; 2 Amp input surge @24 VDC for 1 00 millise conds and 60 0 mA @ 12 V DC

or 300 mA @ 24 VDC during motor movement. Operating Temperature: -10 to 125 F.

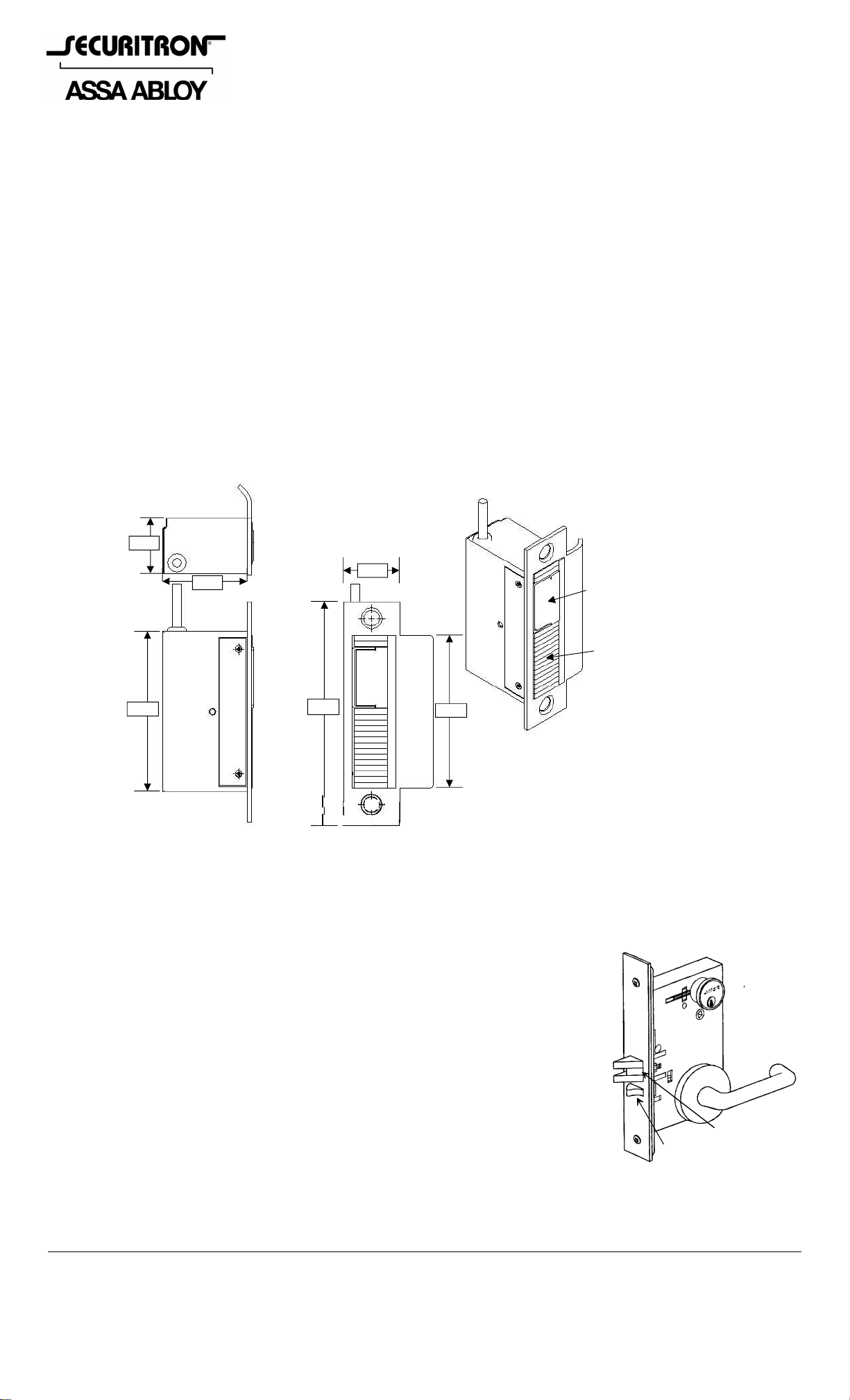

FIG 1: MORTISE UNLATCH DIMENSIONS (INCHES)

1.25

1.25

SPRINGLATCH

PLUNGER

DEADLATCH

FINGERS

3.38

3.50

1.88

4.88

RECOMMENDED TOOLS

MEDIUM + SMALL PHILLIPS DRIVER

MEDIUM SLOTTED DRIVER

CHISEL, 5/64 ALLEN WRENCH

WIRE CUTTER/STRIPPER

VOLT/OHM MET ER

CRIMP CONNECTORS

CRIMP PLIERS

2. PHYSICAL INSTALLATION

2.1 SURVEY

The installer must first be sure that the latch is of the mortise type (see the drawing to the

right.) A mortise lock (or latch) includes a square shaped springlatch

and a “pin” called the deadlatch pin or guard bolt which may be

positioned either above or below the springlatch. Most mortise panic

bar latches are also perfectly compatible with the MUNL. Note,

however, that if the mortise lock assembly includes a dead bolt,

the dead bolt will not be operable The most common alternate type

of latch in use in North America is called cylindrical, tubular or

bored. The standard UnLatch (model numbers UNL-12 and UNL-24)

is designed for this alternate type of latch. Securitron does not offer an

UnLatch solution for a rim latch (rim latches are on the surface of the

door rather than being mortised into the middle of the door).

Deadlatch Pin

Springlatch

© Copyright, 2011, all rights reserved PN# 500-18800

Page 1 Rev. E, 11/11

Page 3

2.2 HOLLOW METAL (STEEL) FRAME MOUNTING

Remove the existing ANSI 4 7/8” strike plate (it will be discarded) and experimentally try to fit

the Mortise UnLatch in the resulting cavity. In some cases the cavity will be large enough to

accommodate the Mortise UnLatch and you will have nothing to do but pull the wires up the

hollow door frame and screw the Mortise UnLatch into place. In other cases you will find a “dust

box” within the frame that will get in the way of the Mortise UnLatch. The dust box must be

cleared away to make room. Generally, a sabre saw, dremel tool or a drill with a fly cutting bit

is the most effective tool to do this. You can also find that the edge of the dry wall panel

interferes with the Mortise UnLatch. Simply chip away some of the dry wall with a screwdriver.

Once you are able to fit the Mortise UnLatch into the frame, vacuum out any concrete dust

and metal shavings (these can work their way into the UnLatch mechanism and cause

problems) and loosely mount it and proceed to Section 2.4, adjusting for latch/deadlatch

location. Note that the face of the Mortise UnLatch is protected by a removable film.

Leave this on during the “pre-mounting” so as to preserve the metal finish against scratching

and to block the possible entry into the mechanism of dust or metal shavings. Remove the film

when you adjust the unit for latch/deadlatch location (Section 2.4).

2.3 WOOD FRAME MOUNTING

For installation in a wood frame use a chisel to create a space for the Mortise UnLatch behind the

existing strike. Remove the strike and place the template (last page of this manual) on the

door (registering it to the strike mounting holes). This will show you the space that must be

chiseled out. As you get close to finishing the chiseling job, experimentally try to fit the body of

the Mortise UnLatch in the cavity. This will avoid chiseling too big a space. A tight fit is

preferred as it helps the solidity of the mounting. Normally, with a wood frame, the wires will

be run inside the wall. Simply drill from the back of the cavity you have created rearward into

the wall space to admit the wires. To mount the Mortise UnLatch to t he wood frame, use the

two #12 x 1” furnished flat head wood screws. Once you are able to fit the Mortise UnLatch in to

the frame, vacuum out any wood dust and metal shavings (these can work their way into

the UnLatch mechanism and cause problems) and loosely mount it and proceed to Section

2.4, adjusting for latch/deadlatch location. Note that the face of the Mortise UnLatch is

protected by a removable film. Leave this on during the “pre-mounting” so as to preserve

the metal finish against scratching and to block the possible entry into the mechan ism of dust or

metal shavings. Remove the film when you adjust the unit for latch/deadlatch location (Section

2.4).

2.4 ADJUSTING FOR LATCH/DEADLATCH LOCATION

One of the remarkable features of the Mortise UnLatch is that it adjusts to suit different

models of North American mortise locks. With conventional electric strikes, the strike

model typically needs to be matched to the lock/latch model and this complicates sourcing the

electric strike. There is one known exception: Sargent model 7800 or 8200 in retrofit

(the lock is already present). The Sargent lock can not normally be accommodated because its

springlatch and deadlatch pin are positioned so close to the bottom of the opening. To employ

the Mortise UnLatch with Sargent, purchase the accessory tab kit, model #STK-1. These

new mounting tabs sufficiently reposition the Mortise UnLatch to make it work with the Sargent

Lock. Note that in new construction, when the door and frame have been specifically

prepared for the Mortise UnLatch and Sargent 7800/8200, the accessory tab kit is not

needed.

Adjustment of the Mortise UnLatch is necessary because different lock manufa cturers vertically

position both the springlatch and deadlatch pin in widely differing locations alon g the lock body.

The Mortise UnLatch accommodates this by allowing positional adjustment of its springlatch

plunger (the component which pushes in the springlatch) and then op erating the deadlatch pin

though moving “deadlatch fingers” which fill the rest of the strike opening.

The adjustment procedure is accomplished in two logical steps. First you must determine th e

position of the springlatch plunger and then perform the adjustment to set that

position.

PN# 500-18800

Page 2 Rev. E, 11/11

Page 4

2.4.1 EXCEPTIONS:

When working with Corbin Russwin ML2000 and BEST Series 2 Mortise Locks the dead latch

needs to be removed. With both of these locks the dead latch is not retracted by the lever set

when you are exiting the secure area this means that depending on the door gap the dead latch

may hang up on the stainless steel case of the MUNL.

2.4.2 DETERMINING SPRINGLATCH PLUNGER LOCATION

The goal of this determination is to vertically align the Mortise UnLatch’s springlatch

plunger with the lock’s springlatch. The deadlatch pin will then be “ automatically” operated

by the deadlatch fingers regardless of its position on the lock. It’s important, however, to

determine the position in such a way that maximum tolerance is achieved in the event that the

door shifts against the frame.

To begin, loosely mount the Mortise Unlatch and close the door so that you can see the top and

bottom of the lock’s springlatch. Draw lines on the lip of the Mortise UnLatch’s strike which

correspond to the lock’s springlatch position. Next dismount the Mortise UnLatch. The drawn

lines and knowledge of the gap between the springlatch and deadlatch pin are used to determine

the vertical position of the springlatch plunger. When this gap is greater than ¼”, best

reliability is obtained when the springlatch plunger position is centered on the springlatch.

When the gap is smaller than ¼”, however, simply centering the springlatch plunger risks

positioning the deadlatch pin too close to the springlatch plunger so the procedure is to position

the edge of the springlatch plunger midway between the springlatch and deadlatch pin. Figure 2

illustrates these points.

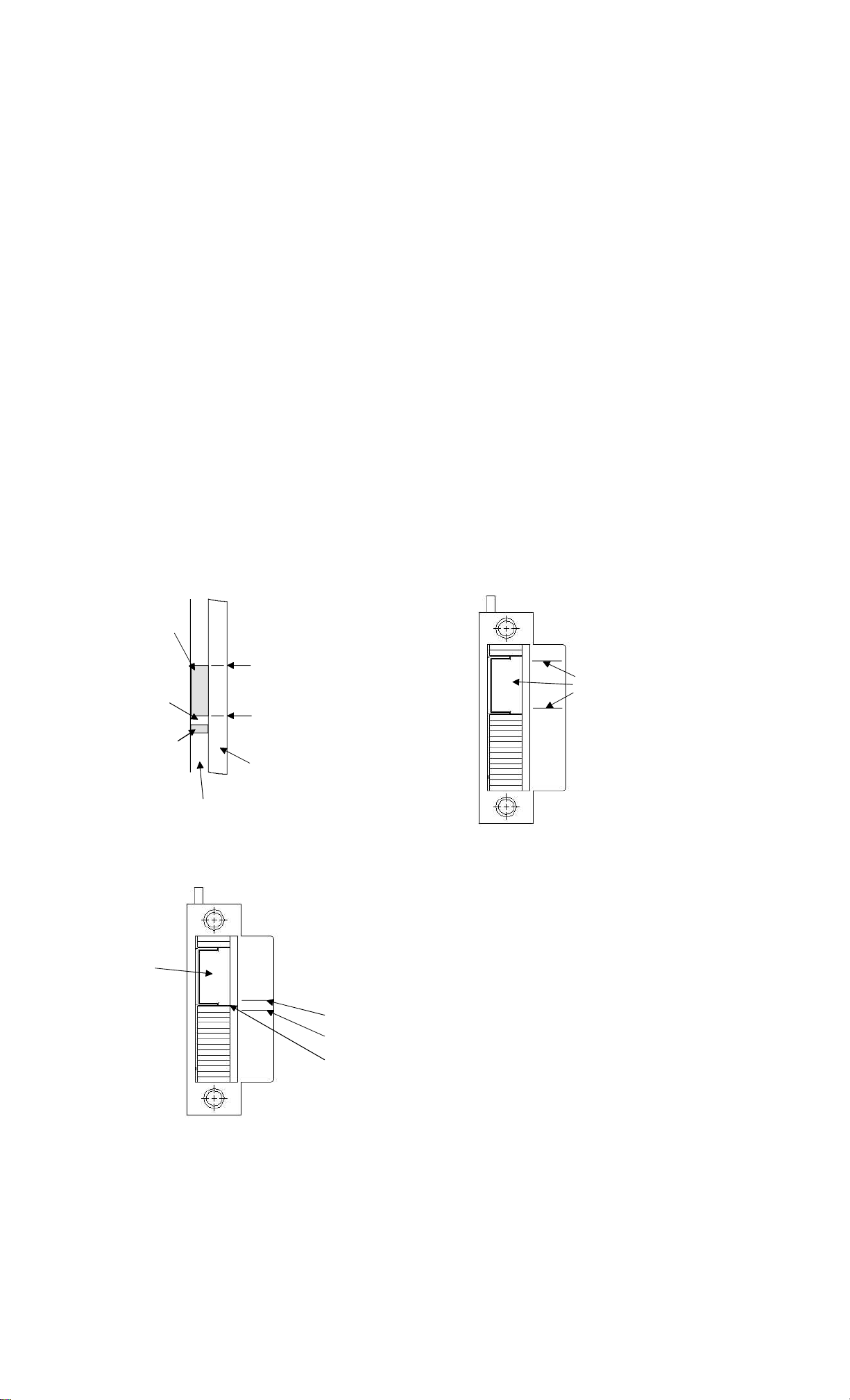

FIG. 2: DETERMINING POSITION OF SPRINGLATCH PLUNGER

SPRINGLATCH

MEASURE GAP

BETWEEN

SPRINGLATCH AND

DEADLATCH PIN

DEADLATCH PIN

(MAY BE ABOVE)

GAP BETWEEN

DOOR AND FRAME

SPRINGLATCH

PLUNGER

GREATER THAN 1/4" GAP

DRAW LINES ON MORTISE

UNLATCH DENOTING TOP

AND BOTTOM OF SPRINGLATCH

CURVED LIP OF

MORTISE UNLATCH

LESS THAN 1/4" GAP

WHEN THE GAP BETWEEN THE SPRINGL ATC H AND DEA DLATCH PI N

IS LESS THAN 1/4", SET THE BO TTOM EDGE OF THE SPRINGLATCH

PLUNGER MIDWAY BETWEEN THE SPRINGLATCH AND DEADLATCH

PIN. (NOTE THAT THE DEADLATCH PIN MAY BE BELOW THE

SPRINGLATCH AS IN THIS EXAMPLE, O R ABOVE IT)

EXAMPLE OF SPRINGLATCH

PLUNGER CENTERED WITH

RESPECT TO SPRINGLATCH

POSITION (SHOWN BY

DRAWN LINES). THE PLUNGER

SHOULD BE CENT ERED WHEN

THE GAP BETWEEN THE

SPRINGLATCH AND DEADLATCH

PIN IS GREATER THAN 1/4"

SPRINGLATCH BOTTOM EDGE (EXAMPLE)

DEADLATCH PIN TOP EDGE (EXAMPLE)

MIDWAY POSITION

2.4.3 ADJUSTING SPRINGLATCH POSITION

Now that you have marked the unit with the correct position for the springlatch plunger, the

actual adjustment must be performed. Figure 3 shows the procedure.

PN# 500-18800

Page 3 Rev. E, 11/11

Page 5

FIG. 3: ADJUSTING SPRINGLATCH POSITION

Perform these adjustments

with the unit on a flat surface

and be careful not to lose

the small screws

Remove Small Cover

A-

SMALL COVER (A)

(Small Phillips Driver)

Remove "U" Sh i el d

B-

(5/64" Allen Wrench)

Be especially careful not to let a screw or any other object fall

inside the housing as it can jam the Mortise UnLatch

"U" SHIELD

Deadlatch

Fingers

SMALL COVER SCREWS (B)

SHIELD SCREWS

(SOCKET HEAD CAP)

D-

Slide Fingers as necessary

C-

Push in Springlatch plunger

and hold it

(You must push them from

their base; you can use a

small screwdriver)

E-

Slide and center springlatch + shield

in the new opening. Then allow it

to spring out.

F-

Replace Shield and Small Cover

2.5 FINAL ADJUSTMENT WITH SPACERS

For reliable operation, the door needs to close so that the latch ea sily enters and is retained by

the Mortise UnLatch. The door should not have to be pushed to engage as can be the case with

a poorly fitting or poorly closing door. To check this point, when the Mortise UnLatch has been

mounted, after the door is closed and latched, you should be able to “rattle” the latch against

the Mortise UnLatch plunger by pushing the door in and out. The amount of movement in

the door latch should be about 1/16-1/8” (1.5-3MM).

If the amount of slack or rattling is greater than 1/16-1/8”, you need the door to “close

earlier”. In effect, the edge of the stop needs to be closer to the Mortise UnLatch. To adjust

for this, first check to see if the stop has “silencers” on it. These are cylindrical rubber

bumpers which quiet the noise of a closing door but also have the effect of making the door

close earlier. If you have silencers and the door is still rattling too much, contact the factory for

additional door stop spacers (the Mortise UnLatch is shipped with two). If you don’t have

PN# 500-18800

Page 4 Rev. E, 11/11

Page 6

silencers, add one or two door stop spacers as is shown in Figure 4 to cause the door to close

earlier.

If the amount of slack or rattling is less than 1/16-1/8”, you have a “tight” door and the

ability of the door to close and latch reliably is in question. To adjust for this, first check to se e if

the stop has “silencers” on it. These are cylindrical rubber bumpers which quiet the noise of a

closing door but also have the effect of making the door close earlier. Remove the silencers

(they pull out) and this will add slack to the closed position of the door. Be sure to check the

entire length of the door for the silencers. If the door has no silencers and is still tight in

latching, a locksmith should be engaged to readjust the door so that it closes properly or the

installation will not be reliable.

Figure 4 illustrates the points made in this Section.

FIG. 4: FINAL ADJUSTMENT OF DOOR CLOSING TOLERANCE

VIEW OF MO RTISE UNLATCH LOOKING STRAIGHT INTO DOOR FRAME

DEADLATCH

FINGERS

SPRINGLATCH PLUNGER

SILENCER

TWO SPACERS

3. OPERATION

While you can make a successful installation without knowing how the Mortise UnLatch

functions, it’s best if you understand its operation in the event you run into difficulties or

questions. The operation of the Mortise UnLatch is, of course, in timate ly connected with the way

mortise locks work on a door so we’ll cover this first.

Mortise locks are the highest quality and heaviest duty locks for sale in North America. They not

only provide long operating life but deliver the highest leve l of physical security obtainable in a

mechanical latch. To assure this security, all mortise locks in clude deadlatching function. This

means that when the door is closed and latched, a deadlatch pin, present on the lock face, is

pressed in. This mechanically pins the springlatch so that it cannot be moved by an object

(such as a credit card) which is pushed in between the door and frame.

In order to release the mortise latch, the Mortise UnLatch has two moving elements under the

control of a motor. We call these the springlatch plunger and deadlatch fingers . When the

door is in the closed and secure position, the springlatch pushes in the springlatch plunger and

the deadlatch pin rests on the deadlatch fingers which push in the deadlatch pin. This maintains

the latch in the secure position and makes full use of the deadlatching function.

When the Mortise UnLatch operates (the trigger wire connects to the +V wire), the deadlatch

fingers retract into the body of the Mortise UnLatch which allows the deadlatch pin to move out.

Then the springlatch plunger and deadlatch fingers simultaneously push the la tch and deadlatch

pin back into the lock body and the door may be opened from the outside. This operation takes

about 1/3 of a second. When the trigger wire is removed from the +V wire, the Mortise UnLatch

will return to its initial condition: the springlatch plunger will retract into the Mortise UnLatch

body which allows the latch to resecure the door and the deadlatch fingers will push out

depressing the deadlatch pin and freezing the latch for best security.

PN# 500-18800

Page 5 Rev. E, 11/11

Page 7

FIG 5: MORTISE UNLATCH SIDE VIEW IN REST (SECURE) POSITION

DEADLATCH

FINGERS

DEADLATCH PIN

SPRINGLATCH

PLUNGER

SPRINGLATCH

IN THE REST (SECU RE) PO SIT ION , THE SPR IN GLAT C H IS ALL O WE D TO COME O UT BY THE SPR ING L AT CH

PLUNGER THE R EBY SE C UR ING THE DOO R . THE DEADL AT CH FIN GE RS, HO WE VE R, PUSH IN THE

DEADLATCH PIN WHICH "FREEZES" THE SPRINGLATCH F OR BEST SECURITY.

FIG 6: MORTISE UNLATCH IN OPERATION

DEADLATCH PIN

DEADLATCH

FINGERS

DEADLATCH PIN

DEADLATCH

FINGERS

SPRINGLATCH

PLUNGER

SPRINGLATCH

IN THE FIRST OPERATIONAL ST EP, THE DEAD LAT CH

FINGERS WITHDRAW WHICH A LLOWS THE DEA DLAT CH

PIN TO COME OUT. THIS "UNFREEZES" THE

SPRINGLATCH

SPRINGLATCH

PLUNGER

SPRINGLATCH

FINALLY, BOTH THE DEADLATCH FING ER S AND

THE SPRINGLATCH PLUNGER MOVE FORWARD

TOGETHER. THIS PUSHES OUT THE SP RINGLATCH AND DEADLATCH PIN AND THEREBY

RELEASES THE DOOR

PN# 500-18800

Page 6 Rev. E, 11/11

Page 8

Note that if the door is heavily pre-loaded (by someone trying to pull it open before the Mortise

UnLatch has released it for example), the Mortise UnLatch may not possess enough power to

release the door. This is termed a stall condition for the motor. When a motor is stalled for a

period of time, it can be damaged by heat build up as motors draw heavy current when they’re

not permitted to move. The Mortise UnLatch automatically detects any stall condition

that persists for more than 1.5 seconds and shuts itself off. To operate, the Mortise UnLatch

must simply be triggered again (which is the normal action for anyone who has failed to enter).

4. WIRING

4.1 GENERAL ELECTRICAL CHARACTERISTICS

The Mortise UnLatch is a six wire device. Power (12 or 24VDC depending on the model) is

applied to the red and black wires observing polarity and power should be continuously

present on these wires. If you connect power in reverse, the Mortise UnLatch will not

operate but it will be damaged if left connected for an extended period of time. To

operate the Mortise UnLatch, the trigger wire (orange) is connected to the red wire (+V) via

an external switch. When this connection is made, the Mortise UnLatch will release the door an d

keep it released so long as the red and orange wires are connected. When connection between

these wires is broken, the door will be resecured (once it recloses). In certain applications the

door is released all day and secured all night. There is no problem operating the Mortise

UnLatch in this manner (continuous duty) but it is more common for the door to be released for

only a few seconds at a time for controlled entr y. This is typically done by relay contacts wh ich

close from an external card reader, digital keypad or keyswitch. The external control device

includes a timing function which will operate the Mortise UnLatch for a few seconds to permit

each entry. Like most conventional electric strikes, the Mortise UnLatch is fail secure which

means that it will maintain the door in a secure position if power is lost. Entry is not possible

(except with a key) but people can, of course, exit by simply turning the door handle or knob

from the inside.

FIG. 7: MORTISE UNLATCH WIRING

DC

POWER SUPPLY

+-

UNLATCH

POWER SHOULD BE CONSTANTLY CONNECTED

BLACK (NEG)

RED (+V)

ORANGE (TRIGGER)

WHITE (STATUS: COM)

GREEN (STATUS: N.C.)

BLUE (STATUS: N.O.)

CLOSURE

BETWEEN +V IN

AND TRIGGER

RELEASES LATCH

In normal operation, the Mortise UnLatch draws about 600 mA @ 12 VDC or 300 mA @ 24VDC

when it operates (the plungers are moving) and a steady 40 mA at all times. Note that

regulated input voltage is not required to operate the Mortise UnLatch. Full wave rectified DC

is acceptable (transformer + bridge rectifier). When using a MUNL-24 with a 24VAC

transformer (TP-24-2) and bridge rectifier (BR-7) two additional components are required.

These are two zener diodes (1N5333B, 5 watt, 3.3 volt or equivalent) that you will find in a

package separate from the hardware pack. Because the peak voltage of a transformer and

bridge rectifier combination can be as high as forty volts the diodes are required to drop the

peak voltage into the operable range for the MUNL-24. The following diagram (Figure 8) notes

installation placement of the zener diodes.

PN# 500-18800

Page 7 Rev. E, 11/11

Page 9

FIG. 8: ZENER DIODE PLACEMENT ( MUNL-24 , TRANSFORMER, BRIDGE RECTIFIER)

TP-24-2

PLUG IN

TRANSFORMER

120

~

VAC

IN

VAC

~

OUT

1N5333B Zener diodes

Note diode orientation:

CROSS BAR

DENOTES CATHODE

BANDED SIDE

DENOTES CATHODE

BR-7

~

~

PB2E

+

-

NC

C

NO

MUNL-24

NC

C

NO

ORG

TRIG

RED

+

-

BLK

Note: The addition of the zener diodes is only required whe n using the MUNL-24 with 24VAC

transformer and bridge rectifier. When using the MUNL-12 with 12VAC transforme r and bridge

rectifier the zener diodes are not necessary.

Power supply surge capacity, however, is ideally 4 Amps @ 12 VDC or 2 Amps @ 24 VDC for

best operation. This is because the Mortise UnLatch’s motor (like all motors) wi ll momentarily

draw a lot more current if it has to “work harder”. This occurs for a very short time at motor

start. If power supply surge capacity is limited, the Mortise UnLatch will still opera te, but more

slowly. The same condition of high current draw will occur for a longer period of time if the latch

is binding which could be a permanent condition of the latch or could be because the person

trying to enter is pulling on the door. Again, the Mortise UnLatch will function but more slowly

and weakly. If a full capacity power supply is not practical, a 1 Amp power supply which

includes battery backup such as Securitron’s model BPS-12-1 or BPS-24-1 (with battery) is an

equally effective device to power the Mortise UnLatch as the battery will provide extra surge

current as it is needed. Another point to note is that when on e relatively large power supply

is serving a number of Mortise UnLatches, the extra current capabilit y will always be there as

each unit will operate at different times so each can draw extra current from the power supply

when needed.

If you are using a smaller capacity power source, you may be satisfied with the operation

of the Mortise UnLatch since the reduction in torque is only noticeable when the door is preloaded. There is, however, an important electronic effect. During the brief moment while the

motor is starting to move, the Mortise UnLatch will “try” to draw 4 or 2 Amps (depe nding on the

voltage). A power supply of lower capacity will react to this condition by sharply dropping its

voltage for the same period. While this will not harm the power supply, it may “crash”

microprocessor equipped devices like digital keypads (such as Securitron’s model D K-11 or DK-

26) that are being operated from the same power supply. If, therefore, your installation

includes a digital keypad, or other microprocessor equipped device, make sure you have full

power supply capacity (or a smaller supply with battery backu p) or use a separate power su pply

for the keypad or other device.

4.2 WIRE GAUGE SIZING

If the power supply is some distance from the lock, voltage will be lost (dropped) in the

connecting wires so that the Mortise UnLatch will not receive full voltage. The amount of voltage

that is dropped in the wires depends on the resistance of the “round trip” wire run compared to

the resistance of the Mortise UnLatch. The issue is complicated by the fact that the resistance of

the Mortise UnLatch is 20 Ohms @ 12 VDC or 80 Ohms @ 24 VDC when it is operating (the

motor is moving) but the resistance drops as low as 3 Ohms @ 12 VD C or 12 Ohms @ 24 VDC

for 100 milliseconds just as the motor starts. If the unit is denied full voltage during this motor

start period, it will operate but with less torque so it will not release the latch as crisply when the

latch has pre-load on it. Selecting thick wires to power the Mortise UnLatch will

maintain strong torque even during start up. The following table shows distances from the

Mortise UnLatch to the power source and calls out the wire gauge needed to fully maintain

torque. Note that if your installation requires the power source to be more distant or has other

complications, the factory can assist you.

PN# 500-18800

Page 8 Rev. E, 11/11

Page 10

Distance (one way) 50 ft. (15 M) 100 ft. (30 M) 200 ft. (60 M)

Wire Gauge for MUNL-12 14 12 8

Wire Gauge for MUNL-24 20 18 14

4.3 LATCH STATUS SENSING

The Mortise UnLatch includes a latch status sensing feature. When the

door is closed and the door latch has engaged the Mortise UnLatch

(specifically the springlatch plunger has been pushed in by the door

latch), the Mortise UnLatch will report this secure condition by

outputting a closed circuit condition between the white (COM) and green

GREEN

BLUE

WHITE

NC

NO

COM

wires (see the drawing to the right). When the door is not securely

latched, the closure will be between the white and blue wires. This dry SPDT output can carry

1 Amp @ 30 VDC maximum. This signal is normally connected to the building alarm system

and it provides superior information compared to conventional door contacts which show only

that the door is closed, not whether it is latched. Note that the Mortise UnLatch’s ability to

report on the latched status of the door depends on it receiving constant power. Any time

power is cut to the Mortise UnLatch, it will report the door as secure re gardless of whether it is

latched or not.

The Mortise UnLatch uses the information as to whether the door is latched or not for a se cond

purpose. The Mortise UnLatch will not operate unless the latch is in the secure position

(the springlatch plunger is pushed in). Operationally, the door can be opened anyway (it is not

latched) so there is no benefit to the end user from the Mortise UnLatch operating unless the

door is latched. Inhibiting operation when the door is not properly closed and latched also helps

protect the Mortise UnLatch against operating it s motor into some jam condition in the event of

severe misalignment of the door.

5. MAGNACARE LIFETIME REPLACEMENT WARRANTY

For warranty information visit: www.securitron.com/en/site/securitron/About/MagnaCare-Warranty/

PATENTS

The Mortise UnLatch is covered under U.S. patents #5,474,342, #6,022,056 and #6,581,991

with other US and international patents pending.

PN# 500-18800

Page 9 Rev. E, 11/11

Page 11

APPENDIX A: TROUBLESHOOTING

PROBLEM-- Unit will not operate when trigger wire is connected to +V.

On a new installation, make sure that DC power (12 or 24 volts depending on the model) is

connected to the red and black wires with correct polarity. When this is confirmed, note that the

Mortise UnLatch will never operate unless the springlatch plunger is pushed in by the springlatch

(see Section 3.3). You can be “fooled” by this feature if you’re trying to test operate the Mortise

UnLatch with the door open. To do this, use a pencil or other similar object to lightly push in the

springlatch plunger and then close the trigger wire to +V and you will see the Mortise UnLatch

plungers move.

On a service call for a unit with successful opera ting history, in addition to the checks mention ed

above, check to see if the door and latch have gotten into a warped situation where there is

heavy pre-loading on the door. The Mortise UnLatch’s motor may not be able to release the

latch under this condition but you should be able to hear it trying to release the latch. The

Mortise UnLatch will automatically shut down its motor if it can’t release the latch within 1.5

seconds. It will operate normally when it is r e-triggered. You should be a ble to try operation by

removing the pre-loading by pushing the door closed with enough force to counteract the preloading. Note that this situation is more likely if power supply capacity is less than 2 or 4 Amps

(see Section 3.1). Corrections for this type of warped door situation is to have th e d oor ser viced

and possibly increase the capacity of the power supply.

If the unit still will not function, note that it does have an internal microprocessor th at may have

gone into a crash condition which may leave the unit’s gears and plungers in an unusual

position. This can happen sometimes if the unit is under-powered (see Section 3.1) and has

consequently stalled (the motor is not receiving enough power to o perate the latch). While the

motor is in the process of stalling, voltage to the processor will sharply drop and this can crash

the microprocessor. A crash can also occur as a random e vent but this is unusual. There are

two recovery methods that may be used to recover the unit’s operation. The first technique is a

simple reset achieved by cycling power to the unit. Remove power (+V) from the unit’s red wire

momentarily. After power is reapplied, the unit may reset and begin normal operation. If this

recovery method did not work perform the second recovery method (POWER ON RESET).

Remove power (+V) from the unit’s red wire. Connect the unit’s red a nd orange wires toge ther.

Now reapply power (+V) to both the orange and red wires simultaneously. This re-initializes the

firmware and may cycle the unit to the unlocked position. Once this operation has been

performed, return the unit to standard wiring (orange only connects to +V to trigger the unit.)

Finally, the unit could have experienced motor failure or other internal electronic failure. It is

repairable by the factory.

PROBLEM -- Unit will occasionally not operate.

Generally, this comes from too much door pre-loading possibly coupled with a low capacity

power source. When the Mortise UnLatch can’t generate enough torque to relea se the latch, it

automatically shuts down but then operates the next time it is triggered. See the previous

paragraph.

PROBLEM -- Latch does not re-secure when the door re-closes.

This is not a problem with the Mortise UnLatch but is rather a problem with the installation. The

latch is simply not moving into position. Make sure the door closer is properly operating to reclose the door with reasonable force. Next, re-read Section 2.5 to make sure the Mortise

UnLatch is in the correct position with respect to the door stop.

PROBLEM -- Latch status sensing does not function.

The latch status output contacts (see Section 3.3) will change state when the springlatch plunger

is pushed in. To check this, therefore, push the springlatch plunger lightly in with a pencil or

other similar object. Make sure the unit is receiving power when you make this check or the

output contacts will not switch. If they still do not switch, the unit will need to be returned to

the factory for repair.

PN# 500-18800

Page 10 Rev. E, 11/11

Page 12

TEMPLATE FOR CHISELING OUT A WOOD FRAME

1 1/4"

INSTALLATION IN WOOD FRAME

DOTTED LINE SHOWS AREA TO

CHISEL OUT 1 7/8" DEEP FOR

4 7/8"

4 1/8"

CENTER LINE

PN# 500-18800

Page 11 Rev. E, 11/11

Loading...

Loading...