Securitron M380BDX, M380BDX-612, M380BDX-606, M380BDX-605, M380BDX-335 Installation Instructions

...Page 1

MAGNALOCK®

M380BDC/M380BDC2/M380BDX/

M380BDCX/M380BDC2X

Installation Instructions

1 500-23310, Rev C

Page 2

Table of Contents

Warranty ............................................................................................................... 3

Package Contents ................................................................................................ 4

Mounting Hardware .............................................................................................. 4

Recommended Tools ........................................................................................... 5

Specifications ....................................................................................................... 5

Magnalock Preparation and Installation ............................................................... 6

Performing a Pre-Installation Survey................................................................ 6

Positioning the Camera and PIR REX Module Locations in the Magnalock..... 6

Preparing the Magnalock ................................................................................. 9

Locating and Setting the Components ........................................................... 10

Documenting the Configuration Settings ........................................................ 15

Installing the Magnalock................................................................................. 17

Installing the Strike ......................................................................................... 21

Assembling the Lock to the Bracket and Adjusting, as Necessary ................. 25

Performing Final Installation ........................................................................... 27

Performing the Final Wiring ............................................................................ 28

Magnalock Operation With Access Control System ........................................... 32

Magnalock Operation With Local Control ........................................................... 33

Magnalock Maintenance..................................................................................... 33

Proper Cleaning Methods ................................................................................... 33

Troubleshooting Guide ....................................................................................... 34

LED Error Codes ................................................................................................ 35

YouTube Channel: SecuritronAccess

Watch the overall installation

http://tinyurl.com/M380video

2 500-23310, Rev C

Page 3

Warranty

The MAGNALOCK® series of locks are covered by the MagnaCare®

lifetime replacement no fault warranty. No registration is required.

Product will be replaced forever, for any reason, including but not limited

to installation error, vandalism, or act of God. Replacement product is

shipped at Securitron’s expense next day air if needed.

For more information, visit www.securitron.com

3 500-23310, Rev C

Page 4

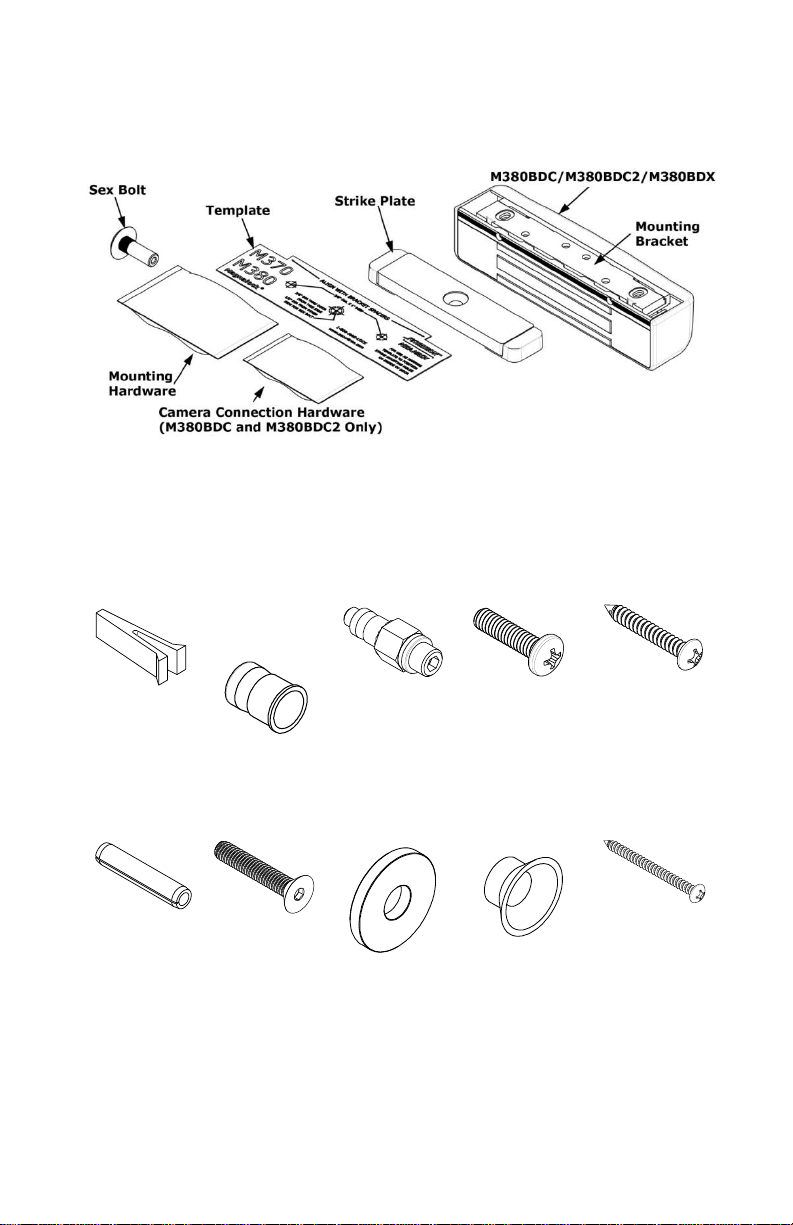

Package Contents

(2) x Bracket

Spacer

(2) x 1/4-20

Blind Nut

(1) x – Blind Nut

Installation Tool

(2) x 1/4-20 x 1”

Phillips Pan Head

(4) x #12 x 1-1/2”

Type A Phillips Pan

Head

(2) x 1/4” x 1-1/4”

Roll Pin

(1) x 5/16-18 x 1-

3/4” Flat Head

Socket

(3) x – Neoprene

Washer

(1) x Plastic Strike

Bushing

(4) x #14 x 3”

Type A Phillips

Pan Head

Mounting Hardware

4 500-23310, Rev C

Page 5

Recommended Tools

Specifications

Mechanical

Electrical

Environmental

(Recommended)

Physical Size:

Height: 2.20” [56mm]

Depth: 2.45” [62mm]

Length: 10.00” [254mm]

Input Voltage:

12/24 VDC. Power

must be at least

Rectified and Filtered

to meet minimum

electrical

specifications. AC,

Half Wave, and Full

Wave power is

unacceptable.

Magnalock Current

12 VDC/550 mA

(±10%)

24 VDC/300 mA

(±10%)

Optional Camera

Current

12 VDC/200 mA

(±10%)

24 VDC/80 mA (±10%)

Optional Passive

Infrared (PIR) Current

12 VDC/25 mA (±10%)

24 VDC/10 mA (±10%)

Operating Temperature

32ºF to 110ºF [0ºC to 43ºC]

Humidity

10% to 90% RH

Camera

Specifications

Color Version:

Horizontal Resolution: 520 TV

Lines

Video Output: 1 V

P-P

, 75Ω

Minimum Illumination: 1.5 LUX

Black and White Version:

Horizontal Resolution: 420 TV

Lines

Video Output: 1 V

P-P

, 75Ω

Minimum Illumination: 0.1 LUX

Shipped Weight:

Weight: 6.5 lb

Holding Force

(Maximum):

600 lbs [272 kg]

UL Tested Ratings:

Static Holding Force:

500 lbs [227 kg]

Dynamic Holding Force:

50 ft-lbs [68 J]

Endurance: 250,000

cycles

Masking Tape

#1 and #2 Phillips

Screwdrivers

Hammer

Measuring Device

1/2” Open End or Crescent

Wrench

Pencil/Pen

Center Punch

Wire Strippers/Cutter

Multimeter

Fish Tape or Lead

Wire

3/16” Hex (Allen) Wrench

Drill bits: 3/16”, 7/32” (wood frames only), 3/8”, 1/2”

5 500-23310, Rev C

Page 6

Magnalock Preparation and Installation

Performing a Pre-Installation Survey

1. Before installing the Magnalock, DETERMINE and ASSESS the

mounting location for the following:

• Physical strength of the frame— it should be strong enough

to meet or exceed the holding force of the Magnalock.

• Frame and vicinity— it should offer protection for the wiring to

prevent vandalism.

• Door inspection—it should be inspected for any obstacles that

may interfere when mounting the strike plate.

• Proper mounting—The Magnalock M380 comes with factory

default mounting for use with an outswing door. Securitron

should be contacted for available brackets for other

installation configurations.

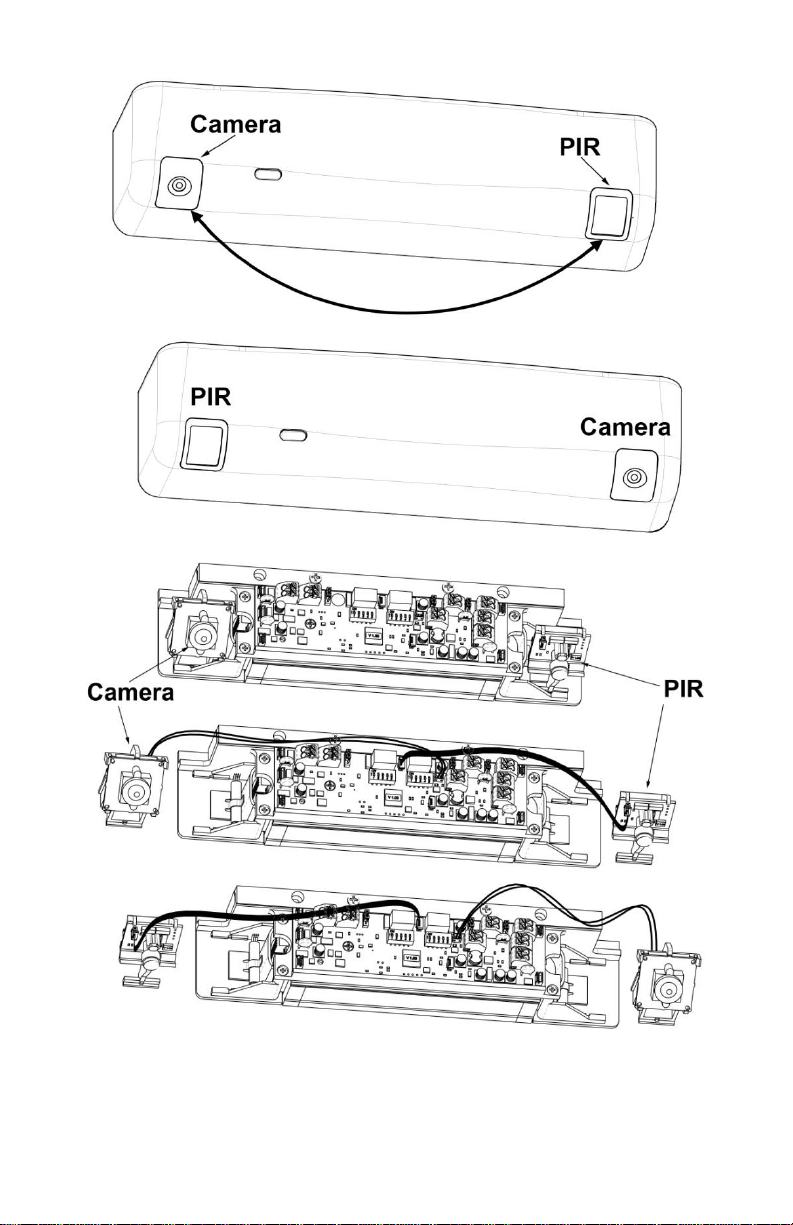

Positioning the Camera and PIR REX Module Locations in the Magnalock

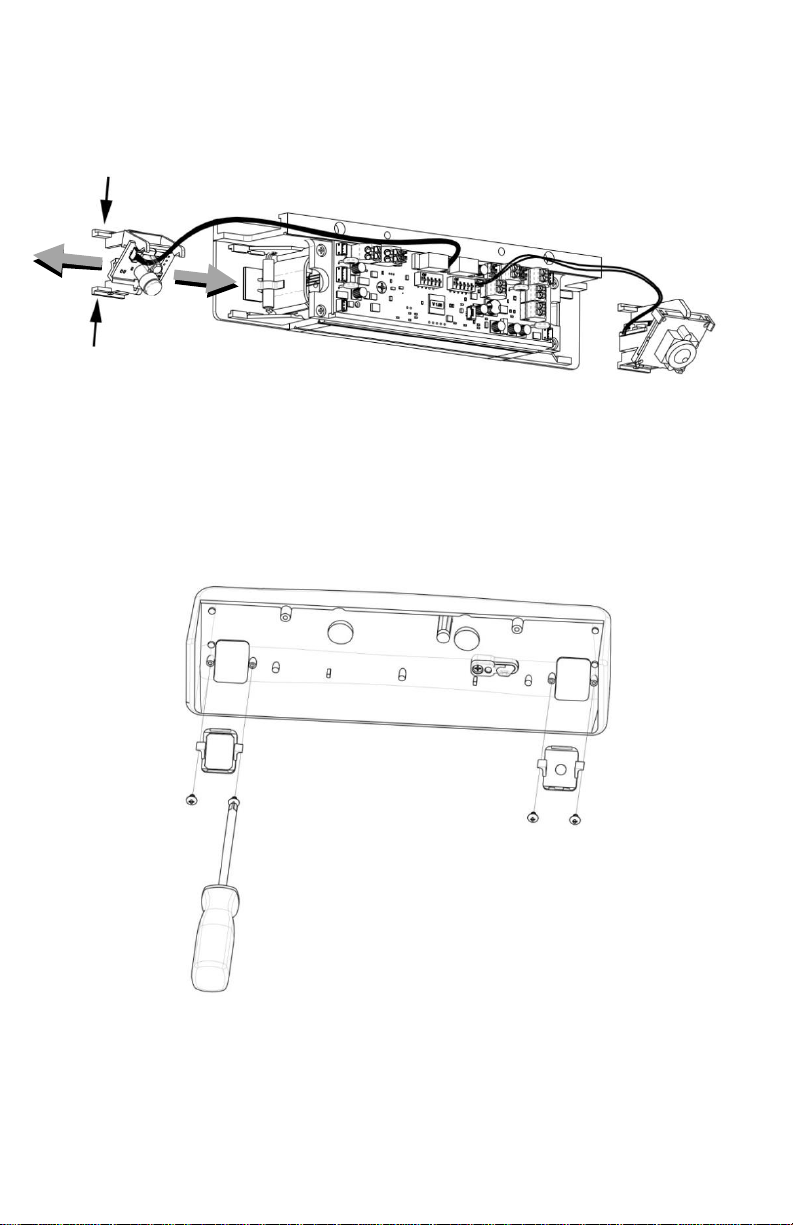

NOTE 1: The physical position of the camera or PIR REX Module may

be reconfigured for either end of the Magnalock, as desired.

NOTE 2: If the Magnalock is equipped with both camera and PIR,

each module position may be reversed from the factory

default positions (see Figure 1, “Camera and PIR

Reversing.”

6 500-23310, Rev C

Page 7

Figure 1. Camera and PIR Reversing

7 500-23310, Rev C

Page 8

1. To remove or install a module, COMPRESS the legs of the support

bracket and SLIDE the module bracket in or out of the retaining rails

(see Figure 2, “Removing and Installing a Module”).

Figure 2. Removing and Installing a Module

2. REMOVE, REPOSITION, and REINSTALL the module inserts in the

cover, as necessary, using a #1 Phillips screwdriver (see Figure 3,

“Removing, Repositioning, and Reinstalling the Module Inserts.”

Figure 3. Removing, Repositioning, and Reinstalling the Module Inserts

8 500-23310, Rev C

Page 9

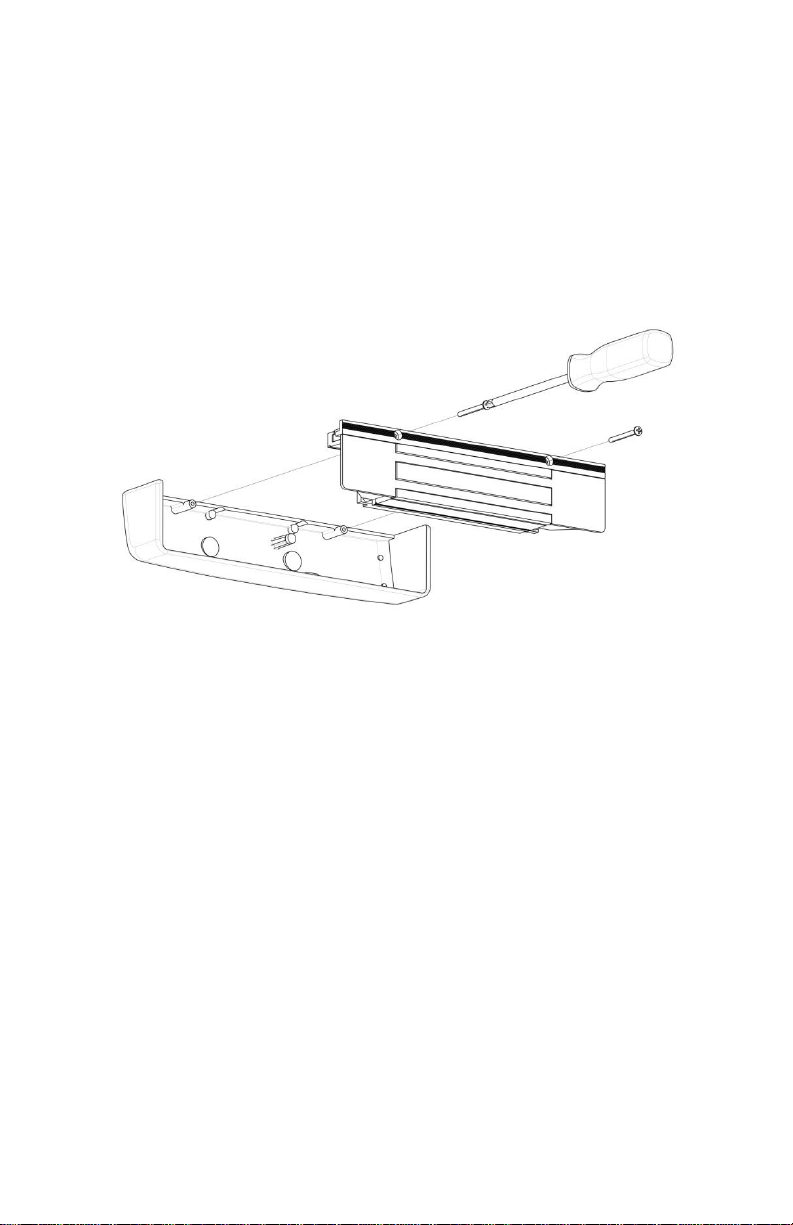

Preparing the Magnalock

NOTE: Removing the cover provides access to the circuit board and

on the back of the magnet.

1. Using a Phillips screwdriver, REMOVE the two (2) screws securing

the cover, as shown in Figure 4, “Removing the Cover Screws.”

2. SET the screws aside to re-attach the cover later.

Figure 4. Removing the Cover Screws

9 500-23310, Rev C

Page 10

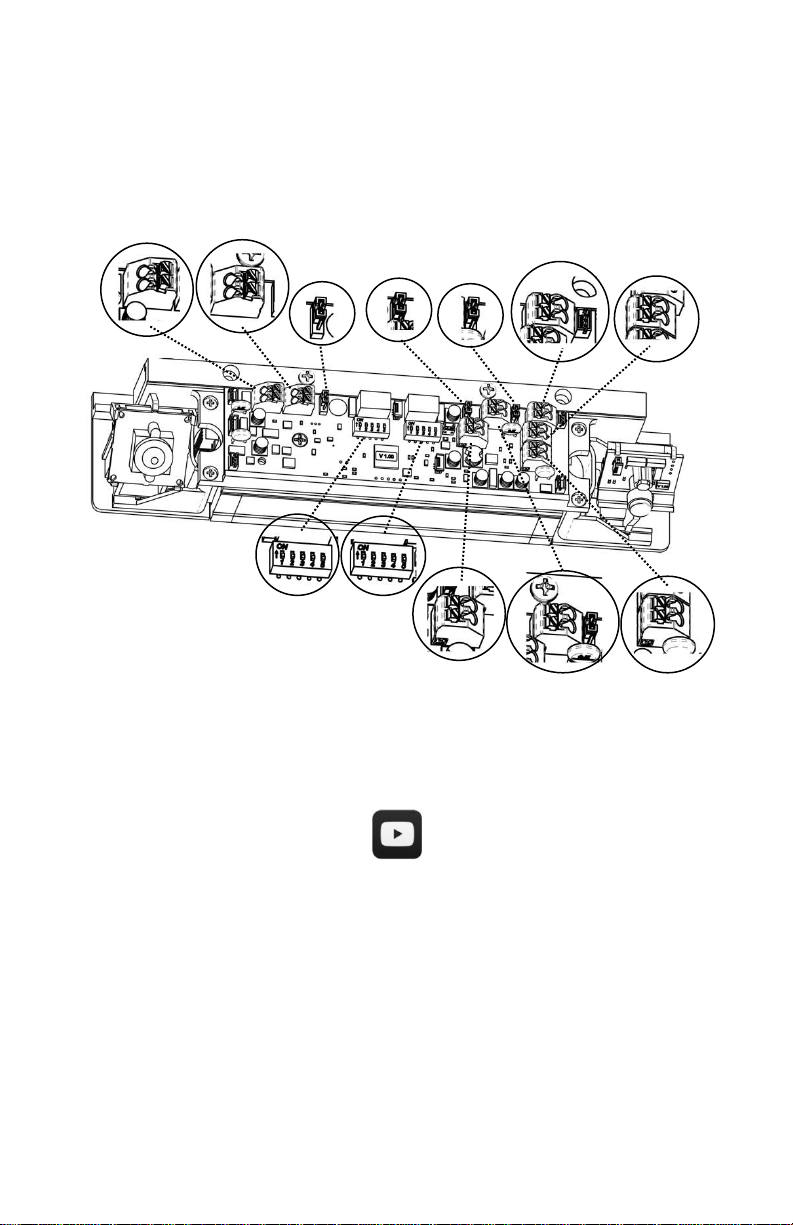

Locating and Setting the Components

J9

J8

JP3

JP4

JP1

J7

J2

SW3

SW1

J6

J12

J3

1. LOCATE and SET the components in the M380 using Figure 5,

“Component Locations,” and Table 1, “Component Label, Name,

Selection, and Position.”

Figure 5. Component Locations

YouTube Channel: SecuritronAccess

Component Configuration

http://tinyurl.com/M380video1

10 500-23310, Rev C

Page 11

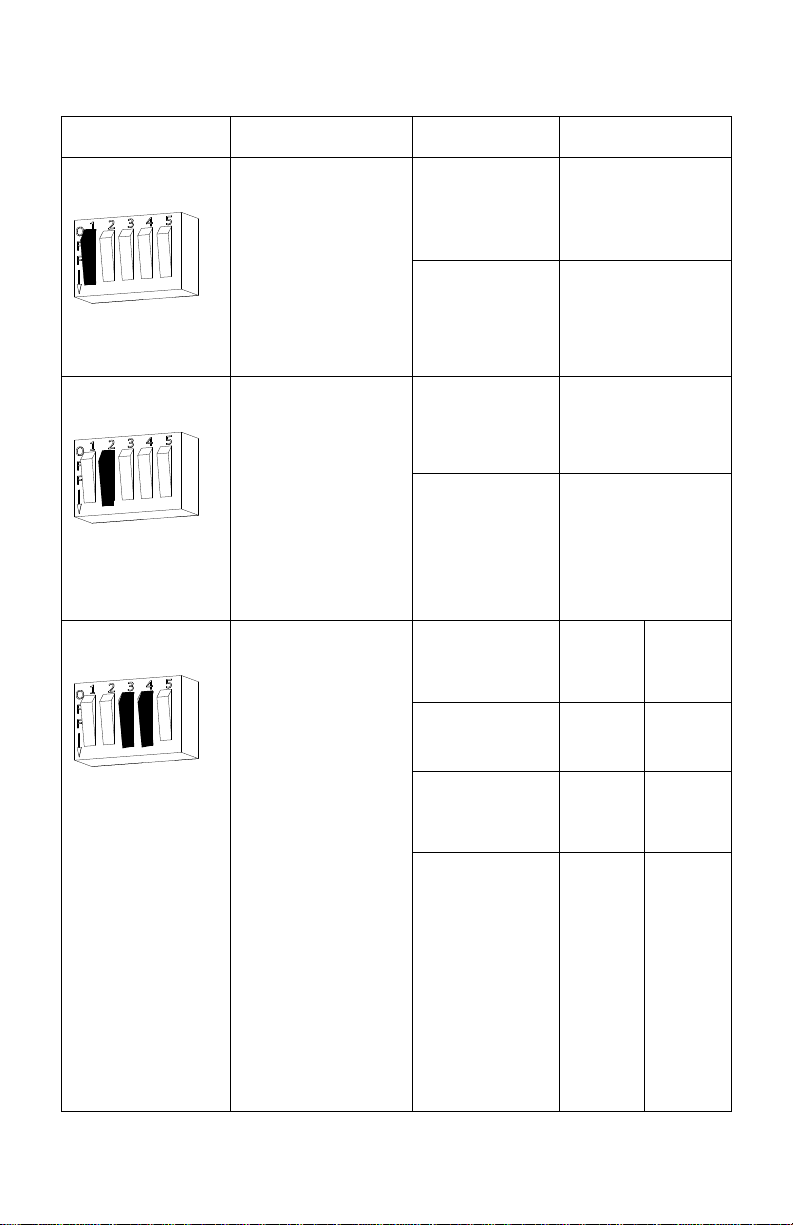

Table 1. Component Label, Name, Selection, and Position

Component Label

Component Name

Selection

Position

SW3

DIP Switch SW3.1:

LED Enable

Position 1 setting of

the DIP switch

enables or disables

the display of the

LED for lock status.

ON = LED

ENABLED

(default setting)

Position 1 ON

(default)

OFF = LED

DISABLED

Position 1 OFF

SW3

DIP Switch SW3.2:

LED Color Select

Position 2 setting of

the DIP switch

controls the color of

the LED output.

Output options are

red or green.

ON = SECURE

= RED

Position 2 ON

OFF =

SECURE =

GREEN

(default setting)

Position 2 OFF

(default)

SW3

DIP Switch SW3.3,

SW3.4:

NOTE: If the

system is using an

access control

system, the relock

timer must be set to

a minimum time.

Relock Delay

Timer:

The Auto Relock

Delay can be

adjusted by

selecting a time

delay with position

3 and position 4 of

SW3.

1/2 second

delay (default)

Position

3 OFF

Position

4 OFF

3 second delay

Position

3 OFF

Position

4 ON

7 second delay

Position

3 ON

Position

4 OFF

15 second

delay

Position

3 ON

Position

4 ON

11 500-23310, Rev C

Page 12

Component Label

Component Name

Selection

Position

SW3

DIP Switch SW3.5:

PIR Model

Position 5 is set by

the factory. This

switch should not

be changed

PIR Model

Position 5 ON

Non-PIR Model

Position 5 OFF

SW1

DIP Switch SW1.1:

PIR Sensitivity

Position 1 setting of

the DIP switch sets

the PIR Sensitivity.

Medium

Sensitivity

(default setting)

Position 1 OFF

(default)

High Sensitivity

Position 1 ON

SW1

DIP Switch SW1.2,

1.3:

PIR Cone

Adjustment

Positions 2 and 3 of

SW1 adjust the PIR

sensing cone.

Wide Beam

(default)

Position

2 OFF

Position

3 OFF

Narrow Beam

Position

2 ON

Position

3 ON

Narrow Plus

Left

Position

2 ON

Position

3 OFF

Narrow Plus

Right

Position

2 OFF

Position

3 ON

SW1

DIP Switch SW1.4:

PIR Ambient Light

Compensation

Can be enabled with

SW1.4

Ambient Light

Compensation

Off (default)

Position

4 OFF

Position

4 OFF

Ambient Light

Compensation

ON

Position

4 ON

Position

4 ON

12 500-23310, Rev C

Page 13

Component Label

Component Name

Selection

Position

SW1

DIP Switch SW1.5:

External PIR Input

External input at J6

can be enabled at

SW1.5

DISABLE

External PIR

Input

Position 5 OFF

(default)

ENABLE

External PIR

Input

Position 5 ON

JP1

Jumper 1: Alternate

(REX) Output

A 3-pin jumper that

controls the output

setting for Alternate

(REX) Output at

Terminal Block J7.

(NO) Normally

Open

Circuit Open,

Circuit closes

when REX

active

(NC) Normally

Closed

Circuit Closed

when Door is

Closed (default

setting)

JP3

Jumper 3:

BondSTAT

Mode Select

A 3-pin jumper that

controls the output

setting for the

BondSTAT in

Terminal Block J8

Position 1 & 2.

(NO) Normally

Open

Circuit Open

when Door is

Closed

(NC) Normally

Closed

Circuit Closed

when Door is

Closed (default

setting)

13 500-23310, Rev C

Page 14

Component Label

Component Name

Selection

Position

JP4

Jumper 4:

Door Position

Mode Select

A 3-pin jumper that

controls the output

setting for the Door

Position Switch

(DPS) in Terminal

Block J12 Position

1 & 2.

(NO) Normally

Open

Circuit Open

when Door is

Closed

(NC) Normally

Closed

Circuit Closed

when Door is

Closed (default

setting)

J9

Terminal Block 9

Tamper Switch

A 2-wire terminal block providing a

signal which changes state as

determined when the cover is sensed

to be removed. (Circuit is Normally

Closed with cover in place).

J3

Terminal Block 3

Magnalock Input

Power

A 2-wire terminal block providing

connection to a 12 or 24 VDC power

supply for the main Magnalock

operation. Position 1 = (+) Positive.

Position 2 = (-) Negative.

J2

Terminal Block 2

Auxiliary Input

Power

A 2-wire terminal block providing

connection to the power supply for

the auxiliary components (PIR and/or

Camera). Position 1 = (+) Positive.

Position 2 = (-) Negative.

J8

Terminal Block 8

BondSTAT

A 2-wire terminal block providing a

contact in which (NO/NC) state

change is determined by Jumper 3

when the BondSTAT (magnetic

bond) is interrupted.

J12

Terminal Block 12

Door Position

Switch

A 2-wire terminal block providing a

contact in which (NO/NC) state

change is determined by Jumper 4

based on the magnet’s contact with

the strike plate.

14 500-23310, Rev C

Page 15

Component Label

Component Name

Selection

Position

J6

Terminal Block 6

Alternate Input

A 2-wire terminal block providing a

dry contact connection for external

control input.

J7

Terminal Block 7

Alternate (REX)

Output

A 2-wire terminal block provides a

connection for an alternate output.

Video Connection

(Camera Interface

PCB)

Terminal Block

Connection for

Camera Signal

The included Balun and BNC cable

adapter can be used to route wiring

through either side of the Magnalock

housing for connection to a

surveillance system.

Documenting the Configuration Settings

NOTE: The Board Settings are now complete.

1. COPY the settings onto the adhesive-backed circuit board settings label

enclosed with the mounting hardware packet (see Figure 6, “M380 Settings”).

Figure 6. M380 Settings

15 500-23310, Rev C

Page 16

NOTE 1: The figure above shows the Default settings. Settings may vary

based on checklist.

NOTE 2: The settings information is required if the Magnalock needs to be

inspected, serviced, or replaced.

2. COMPLETE the label and AFFIX to the inside cover of the Magnalock (see

Figure 7, “Magnalock Settings Label.”

Figure 7. Magnalock Settings Labels

16 500-23310, Rev C

Page 17

Installing the Magnalock

1. REMOVE the two (2) screws securing lock to mounting bracket and SLIDE

the bracket from the top of the lock chassis (see Figure 8, “Removing the

Securing Screws”).

Figure 8. Removing the Securing Screws

2. PINCH and INSERT spacers flush into the dovetail slots of the lock-mounting

bracket (see Figure 9, “Inserting the Spacers”).

Figure 9. Inserting the Spacers

17 500-23310, Rev C

Page 18

3. PERFORM the following to mark the mounting holes.

a. PROTECT the door and frame surfaces from any possible damage

during marking and drilling by using masking tape.

b. PLACE the lock bracket on the secure side of the door against the

frame stop, towards the side of the door that does not have hinges, and

has a minimum of 7/8” clearance from the frame.

c. CLOSE the door and ADJUST the bracket so that the spacers rest

against the door.

d. MARK the frame through the two (2) oblong bracket mounting holes

(see Figure 10, “Marking the Frame”).

Figure 10. Marking the Frame

4. MARK the frame for wire feed-through hole at the end closest to

where the wire run will be accessed.

5. ENSURE these holes are toward the rear edge of the mounting

bracket and adjacent to the end of the bracket (see Figure 11,

“Position of Wire Feed-Through Holes”).

Figure 11. Position of Wire Feed-Through Holes

YouTube Channel: SecuritronAccess

Marking the Mounting Holes

www.tinyurl.com/M380video2

18 500-23310, Rev C

Page 19

6. REMOVE mounting bracket from frame when drilling holes.

NOTE 1: Steps 7–9c are performed if installing on metal door frame.

NOTE 2: Steps 10–11 are performed if installing on a wood door frame.

7. DRILL two (2) 3/8” diameter holes at bracket-mounting hole marks (see

Figure 12, “Drilling the Bracket Mounting Holes”); DO NOT oversize.

8. USE a step bit or pilot hole first to ensure a snug fit for the blind nuts.

NOTE: Blind nuts provide a highly secure and tamper resistant system for

mounting and are the mounting hardware provided for this unit.

9. INSTALL blind nuts into each 3/8” diameter hole using the provided tool (see

Figure 13, “Installing the Blind Nuts”).

a. HOLD the collapsing nut with a ½” box end wrench.

b. MAINTAIN pressure on the mounting surface, TIGHTEN the cap screw

using a 3/16” hex wrench, and COLLAPSE the blind nut.

c. GO TO Step 12.

Figure 13. Installing the Blind Nuts

3/8” diameter (Metal)

Figure 12. Drilling the Bracket Mounting Holes

YouTube Channel: SecuritronAccess

Blind Nut Installation

www.tinyurl.com/M380video3

19 500-23310, Rev C

Page 20

10. DRILL two (2) 3/16” diameter mounting holes by 1-1/4” deep at bracket-

mounting hole marks (see Figure 14, “Drilling the Mounting Holes”).

Figure 14. Drilling the Mounting Holes

11. DRILL wire access holes (1/2” recommended), as needed, on one or both

sides of the bracket (see Figure 15, “Drilling the Wire Access Holes”).

Figure 15. Drilling the Wire Access Holes

20 500-23310, Rev C

Page 21

12. Temporarily INSTALL the bracket with spacers against the closed door

using a Phillips screwdriver (see Figure 16, “Installing the Bracket”).

NOTE: Step 13a applies to metal frames.

a. USE two (2) 1/4-20 X 1” Phillips Pan Head Screws and APPLY

included thread lock to screw threads.

NOTE: Step 13b applies to wood frames.

b. USE two (2) #12 X 1-1/2” Type A, Phillips Pan Head Screws.

Figure 16. Installing the Bracket

1. CLOSE the door and PLACE the template between the bracket

spacers.

2. MARK the strike plate hole locations (see Figure 17, “Marking the

Strike Plate Hole Locations”).

Installing the Strike

21 500-23310, Rev C

Page 22

Figure 17. Marking the Strike Plate Hole Locations

3. REMOVE the bracket spacers from the bracket.

From INSIDE the door:

4. DRILL one (1) 3/8” diameter hole for the sex bolt through the door

at the strike mounting center mark.

5. DRILL two (2) 3/8” diameter x 1” deep holes at each side mark for

the strike alignment roll pins, but DO NOT DRILL through the door

(see Figure 18, “Drilling the Inside Door Holes”).

Figure 18. Drilling the Inside Door Holes

YouTube Channel: SecuritronAccess

Marking the Strike Plate Hole Locations

www.tinyurl.com/M380video4

YouTube Channel: SecuritronAccess

Drilling the Inside Door Holes

www.tinyurl.com/M380video5

22 500-23310, Rev C

Page 23

From OUTSIDE the door:

6. For a Hollow Metal Door, DRILL out the 3/8” diameter strike

mounting hole to 1/2” diameter in the outer wall only.

7. For a Solid Wood Door, DRILL out 3/8” diameter strike mounting

hole to 1/2” diameter; DRILL completely through door (see Figure

19, “Drilling the Outside Door Holes”).

Figure 19. Drilling the Outside Door Holes

8. PERFORM the following to install roll pins into strike plate.

a. REMOVE the two (2) roll pins from the hardware packet.

b. INSERT a roll pin into each of the holes in back of strike.

c. Gently TAP into place using a hammer (see Figure 20, Inserting

the Roll Pins”).

Figure 20. Inserting the Roll Pins

23 500-23310, Rev C

Page 24

NOTE: Figure 21, “Securing the Strike Plate,” provides illustration

for the following steps.

9. PERFORM the following to secure strike plate to the door.

a. APPLY the included thread lock compound to 5/16-18 X 1-3/4”

flat head socket screw.

b. INSERT the 5/16-18 X 1-3/4” flat head socket screw through

the strike bushing, strike plate, two (2) neoprene washers,

door and into the sex bolt as illustrated.

c. TIGHTEN the screw into sex bolt using a 3/16” hex wrench;

and while tightening, gently TAP the head of sex bolt until the

head sits flush with the door using a hammer.

NOTE: The strike should rock on the neoprene washers for

proper function and optimal holding force.

d. DO NOT OVER-TIGHTEN the assembly; the neoprene

washers should not be compressed.

Figure 21. Installing the Strike Plate

YouTube Channel: SecuritronAccess

Installing the Strike Plate

www.tinyurl.com/M380video6

24 500-23310, Rev C

Page 25

Assembling the Lock to the Bracket and Adjusting, as

NOTE: Figure 22, “Assembling the Lock to the Bracket and

Adjusting,” provides illustration for the following steps.

1. LOOSEN the two screws securing the mounting bracket to the

door frame so that the bracket can move.

2. SLIDE the lock onto the mounting bracket and TEST FIT against

the strike plate with the door closed; SLIDE the lock so that the

entire face makes contact with the strike plate.

the lock from the bracket.

Figure 22. Assembling the Lock to the Bracket and Adjusting

5. ENSURE that the mounting bracket aligns with the marks, and

TIGHTEN the mounting screws (see Figure 23, “Tightening the

Mounting Screws”).

Figure 23. Tightening the Mounting Screws

YouTube Channel: SecuritronAccess

Assembling the Lock to the Bracket

www.tinyurl.com/M380video7

Necessary

25 500-23310, Rev C

Page 26

6. Using the mounting bracket as a template, DRILL the four

remaining holes in the frame for the anchor screws as follows (see

Figure 24. Drilling the Anchor Screw Holes”):

• Metal Frames have 3/16” diameter holes.

• Wood Frames have 7/32” diameter holes.

7. INSTALL the four (4) anchor screws using a Phillips screwdriver

(see Figure 25, “Installing the Anchor Screws”):

• Metal Frames use #12 X 1-1/2” Type A, Phillips Pan

Head Screws

• Wood Frames use #14 X 3” Type A, Pan Head Screws

Figure 24. Drilling the Anchor Screw Holes

Figure 25. Installing the Anchor Screws

26 500-23310, Rev C

Page 27

Performing Final Installation

NOTE: The edge of the lock chassis must be flush with the end of

the mounting bracket when centered (see inset).

1. INSERT the top of the Magnalock chassis at the end of the

mounting bracket, and SLIDE the lock chassis to the center of the

bracket (see Figure 26, “Performing Final Installation”).

Figure 26. Performing Final Installation

2. INSTALL the two (2) 6-32 X 3/4” Phillips pan head screws to

secure the lock chassis to the mounting bracket using a Phillips

screwdriver (see Figure 27, “Securing the Lock Chassis to the

Mounting Bracket”).

Figure 27. Installing the Lock Chassis to the Mounting Bracket

YouTube Channel: SecuritronAccess

Final Installation

www.tinyurl.com/M380video8

27 500-23310, Rev C

Page 28

Performing the Final Wiring

NOTE 1: End user and installer are liable for Fire and Building code

compliance.

NOTE 2: A small screwdriver has been included to help make

connections to the terminal blocks, as required.

1. PULL wires/cables through the wire feed-through hole(s) that are

drilled in the frame, and CONNECT wiring using the Figure 29,

“Wiring for M380 BDC/BDC2,” and Figure 30, “Wiring for M380

BDCX/BDC2X/BDX,” as guides.

Figure 29. Wiring for M380 BDC/BDC2

28 500-23310, Rev C

Page 29

29 500-23310, Rev C

Figure 30. Wiring for M380 BDCX/BDC2X/BDX

NOTE 1: Steps 2–6 are performed for M380 models with the PIR feature.

NOTE 2: PIR control features are accessed by the DIP Switches SW3 and

SW1 settings.

2. SET the relock delay timer using DIP Switch SW3, Positions 3 and 4, as

required.

Page 30

30 500-23310, Rev C

NOTE: Figure 31, “PIR Sensitivity and Cone Adjustment,” provides illustration

to Steps 3 and 4.

Figure 31. PIR Sensitivity and Cone Adjustment

3. SET the PIR sensitivity using DIP Switch SW1, Position 1, as required.

4. SET the PIR Cone Adjustment width using DIP Switch SW1, Positions 2

and 3, as required.

5. ENABLE or DISABLE the PIR ambient light compensation feature using DIP

Switch SW1, Position 4, as required.

6. REPOSITION the PIR sensor PC board in the modular bracket, as

necessary, for increased range (see Figure 32, “Repositioning the PIR”).

Page 31

Figure 32. Positioning the PIR

NOTE 1: Step 7 is performed for M380 models with the camera feature.

NOTE 2: The camera module features an interface PC board which includes a

two-position terminal block.

NOTE 3: A BNC straight adapter is also included for connections to a male

BNC connector (see Figure 30, “Connecting the Camera”).

7. CONNECT the camera to the security system with a two-wire (twisted pair)

from the two-position interface board terminal block to the included video

transceiver balun (see Figure 33).

Figure 33. Connecting the Camera

8. After installation and wiring have been completed, RE-INSTALL the lock

cover through the lock chassis using the two (2) phillips screws (see Figure

34, “Installing the Lock Cover”).

31 500-23310, Rev C

Page 32

Figure 34. Installing the Lock Cover

Magnalock Operation With Access Control System

Front View

NOTE: The Magnalock relock timer is required to be set to minimum.

32 500-23310, Rev C

Page 33

Magnalock Operation With Local Control

NOTE: The Magnalock relock timer is required to be set to minimum.

Magnalock Maintenance

1. PERFORM the following to complete a visual inspection.

a. INSPECT the rubber washers for elasticity and proper pivoting;

and TIGHTEN, as required.

b. INSPECT for build-up of debris on the Magnalock and strike

armature.

c. INSPECT for rust on the Magnalock and strike plate armature;

CLEAN, as required.

Proper Cleaning Methods

2. APPLY rubbing alcohol onto a clean cloth and thoroughly WIPE

DOWN the Magnalock and strike plate armature.

NOTE 1: Cleaning once a year is recommended.

NOTE 2: Petroleum-based products should never be used for cleaning.

NOTE 3: Steel wool-based scrub pads or sandpaper should never be

used for cleaning.

3. CLEAN every three to six months where rusting occurs.

4. USE a plastic dishwashing scrub pad to aid in the removal of rust.

33 500-23310, Rev C

Page 34

Troubleshooting Guide

POSSIBLE ISSUES

TROUBLESHOOTING TIPS

NOTE: When Vaux of a M380 (all M380BDC/C2/X variants) reaches 7.5V,

the lock releases and LV flash commences until the system

recovers or Vaux has fallen to a point causing the system to be in a

brown-out condition.

No power or low power

CONFIRM voltage and current at Magnalock

to specification.

NOTE: Power must be at least Rectified and

Filtered to meet minimum electrical

specifications. AC, Half Wave, and

Full Wave power is unacceptable.

CHECK that the DC power source is Full

Wave Rectified.

Reduced Holding Force

CHECK strike plate position and orientation.

CLEAN surfaces and CHECK for obstructions.

CONFIRM voltage and current at Magnalock

to specification.

NOTE: Power must be at least Rectified and

Filtered to meet minimum electrical

specifications. AC, Half Wave, and

Full Wave power is unacceptable.

CHECK that the DC power source is Full

Wave Rectified.

34 500-23310, Rev C

Page 35

LED Error Codes

CODE

STATE

SOLUTION

SECURE selected

color, on

continuously

Normal Operation

with Door Closed

System working normally,

SECURE selected color can be

selected with position 2 switch

of SW3. See page 4.

NON-SECURE

selected color, on

continuously

Normal Operation

with Door Open

System working normally.

RED/GREEN

continuous flash

Processor Error

CHECK all connections, if error

persists replace unit.

AMBER Continuous

flash

Low Voltage

Condition (Occurs

below 8.2V).

MagnaLock is

disabled.

CHECK voltage and current at

Magnalock connections.

CHECK DC Power Source is

Full Wave Rectified.

Solid AMBER

Any situation, DPS

or Bond.

CHECK strike plate position

and orientation. CLEAN

surfaces and check for

obstructions.

Off

LED disabled

CHECK voltage and current at

Magnalock connections.

CHECK that LED is enabled

with position 1 switch of SW3

is in the OFF position.

NOTE: The position 1 switch of DIP switch SW3 must be set to the ON

position (LED ENABLED) for error codes to be visible.

35 500-23310, Rev C

Page 36

© 2015, Hanchett Entry Systems, Inc., an ASSA ABLOY Group Company.

Securitron

Phoenix, AZ

Tel: 1.800.624.5625

Mon-Fri: 6:00am - 4:00pm PDT

Fax: 1.800.232.7329

www.securitron.com

techsupport@securitron.com

36 500-23310, Rev C

Loading...

Loading...